The Standard 5 Mar06

-

Upload

cgrachanen -

Category

Documents

-

view

225 -

download

0

Transcript of The Standard 5 Mar06

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 1/29

Vol. 20, No. 1 The Newsletter of the Measurement Quality Division, American Society for Quality March 2006

Your Name Here

XXX

How much is the CCT certification really worth? According to the 2005 Salary Survey pub-lished in the December 2005 edition of Quality Progress , the average salary for technicianswithout ASQ certification is $39,625. The average salary for technicians that have receivedtheir CCT is $55,715. A difference of +$16,090!! Each job/circumstance is unique...However,these numbers speak volumes for the possible advantage of obtaining your CCT certification.

CCT

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 2/29

The Standard is published quarterly by the Measurement Quality Division of ASQ; deadlines are February 15, May 15, August 15 and November 15. Text infor-mation intended for publication can be sent via electronic mail as an attachment inMS Word format (Times New Roman, 11 pt). Use single spacing between sen-tences. Graphics/illustrations must be sent as a separate attachment, in jpg format.Photographs of MQD activities are always welcome. Publication of articles, prod-uct releases, advertisements or technical information does not imply endorsementby MQD or ASQ. While The Standard makes every effort to ensure the accuracyof articles, the publication disclaims responsibility for statements of fact or opinionmade by the authors or other contributors. Material from The Standard may not bereproduced without permission of ASQ. Copyrights in the United States and allother countries are reserved. Website information: MQD’s homepage can be foundat http://www.asq.org/measure . © 2005 ASQ, MQD. All rights reserved.

The StandardVol 20, No. 1, March 2006

Editor and PublisherJay L. Bucher6700 Royal View Dr.De Forest, WI 53532-2775

Voice: 608-277-2522Fax: 608-846-4269Email: [email protected] or [email protected]

Advertising Submit your draft copy to Jay Bucher , with arequest for a quotation. Indicate size desired.Since The Standard is published ‘in-house’the requester must submit a photo or graphicof their logo, if applicable. The followingrates apply:

Business card size............................ $1001/8 page .......................................... $1501/4 page ........................................... $2001/3 page ........................................... $250½ page ............................................. $300Full page ......................................... $550

Advertisements will be accepted on a ‘perissue’ basis only; no long-term contracts willbe available at present. Advertising must beclearly distinguished as an ad. Ads must berelated to measurement quality, quality of measurement, or a related quality field. Adsmust not imply endorsement by the Measure-ment Quality Division or ASQ .

Letters to the EditorThe Standard welcomes letters from mem-bers and subscribers. Letters should clearlystate whether the author is expressing opin-ion or presenting facts with supporting infor-mation. Commendation, encouragement,constructive critique, suggestions, and alter-native approaches are accepted. If the con-tent is more than 200 words, we may deleteportions to hold that limit. We reserve theright to edit letters and papers.

Information for Authors The Standard publishes papers on the qual-ity of measurements and the measurement of quality at all levels ranging from relativelysimple tutorial material to state-of-the-art.Papers published in The Standard are notreferred in the usual sense, except to ascer-tain that facts are correctly stated and to as-sure that opinion and fact are clearly distin-guished one from another. The Editor re-serves the right to edit any paper.

TABLE OF CONTENTS CHAIR’S COLUMN ......................................................................3CCT UPDATE................................................................................6THE FUTURE OF QUALITY .......................................................8THE LEARNING CURVE...........................................................11MQD MEETING MINUTES ..............................................14 & 15

MQD MEETING & TELECONFERENCE SCHEDULE ...........16MQD 2005 ~ 2006 LEADERSHIP...............................................17MQD OFFICERS AND COMMITTEE CHAIRS .......................19MQD REGIONAL COUNCILORS .............................................20NCSLI WORKSHOP & SYMPOSIUM.......................................22METROLOGY JOB DESCRIPTION INITIATIVE....................23MJD SURVEY RESULTS ...........................................................24

FROM THE DESK OF THE EDITOR /PUBLISHER

Welcome to the first newsletter for 2006. Looks likewe made it through 2005 with four quarterly editionspublished on time. Of course, every coin has its flipside...now we are expected to maintain the quality andtimeliness of all future newsletters. We will try ourbest to fulfill those expectations. Speaking of coins, allCCT alumni should be getting their new CCT chal-lenge coins very soon. My sincere congratulations toeach and every one of you. A rendition of the coin ispictured on the front cover of this edition. The MQDofficers sincerely hope you enjoy this unique, one-of-a-kind coin. The pic-tures on pages 5, 7 & 18 are used to test the level of stress a person can

handle. The slower the pictures move, the better your ability of handlingstress. Alleged criminals that were tested see them spinning around madly;however, senior citizens and kids see them standing still. None of theseimages are animated - they are perfectly still. Enjoy! The article, The Fu-ture of Quality, is different than the one Graeme refers to in his column.Also, at the very end, we have included the Metrology Job Descriptionsurvey results. So, without further ado...Happy Valentine’s, President’s,and St. Patrick’s Day to all.

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 3/29

MQD Page 3

Vol. 20, No. 1 The Newsletter of the Measurement Quality Division, American Society for Quality March 2006

CHAIR ’S COLUMN By Graeme C. Payne

We are entering a year of celebration, and facing afuture where the inevitability of change is the onlything that is certain. 2006 marks the 60 th anniver-sary of the founding of ASQ, and also the 15 th an-niversary of the formation of the MeasurementQuality Division. Neither organization is the samenow as it was when it started, and the nature of quality and metrology have both changed over thetime periods.

Celebration

The Measurement Quality Divisionwas chartered as a Division on May19, 1991. That means the upcoming2006-2007 year is our 15 th Anniver-sary year! Of course, in a sense theorganization is older than that. It grewfrom the Metrology Technical Com-mittee that was created by the Inspec-tion Division in 1972.

I think it would be great if, in the next several is-sues of this newsletter, we feature some historicalinformation. This will help refresh and documentit, and will (I hope) be of interest to those whohave become MQD members more recently In mycase, I joined ASQ only a couple of months beforethe Division was chartered, so I have no directknowledge of anything that happened before. Wealso have newer members—our Historian, KeelaSniadach, for example—who only know about thepast couple of years and are trying to find outmore. If you share some history, it will help all of us.

We need your help to do this, especially if you areone of our Charter Members. Please send informa-tion to me, Keela or Jay Bucher, the newsletter edi-tor. We can use written recollections, copies of original brochures, posters, newsletters or otheritems, photographs or whatever else you can share.Electronic files are preferable but anything elsewill work as well. If you need the originals back we can scan them or make copies in other ways.All of this will help document the history of ourDivision.

Recognition of Change

This can also be a time for“recalibrating” our vision for thefuture. The historical informa-tion will show us where we havebeen. We also need to look for-ward, to see where we want to bein the next five years, ten years or more. What doyou want from the division? What changes will we

have to make as our professionchanges? What can we do to preparefor the unforeseeable future? We needto discuss this together to reach ashared vision and achievable goals.

There has been a change in the Divi-sion leadership since the last issue of this newsletter. Karl Wigdal asked tostep down as Treasurer, and JayBucher offered to move into that posi-tion. The nominating committee se-lected Rick Roberson to be the new

Chair-Elect. Rick, who is from Norman, Okla-homa, will take over the Chairperson position inJuly 2007 (see Rick’s bio on page 13).

It is important to plan how to deal with both per-sonal and professional change. For example, lastweek (as I write this) I was notified that my posi-tion will be eliminated at the end of March. As I'ma contractor, I can't move to anything else in thecompany. In the area of change in the profession,the nature of metrology is changing with increasedelectronics and automation, smaller dimensions,higher frequencies, more visibility and control of measurement uncertainty and so on. The amountand type of calibration is also changing as the mixof industries changes in each country. If you havenot already read it, I suggest looking at the article“The Future of Quality” by Scott M. Paton, in theFebruary 2006 issue of Quality Digest . If you don'thave a free subscription to the print copy, them a g a z i n e i s a v a i l a b l e o n l i n e a twww.qualitydigest.com . (The article starting onpage 8 is different)

Graeme C. PayneDivision Chairperson

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 4/29

MQD Page 4

Vol. 20, No. 1 The Newsletter of the Measurement Quality Division, American Society for Quality March 2006

We Need to Hear From YOU

The Division leadership team – the elected officers,the committee chairs, the representatives and liai-sons to other organizations, and the regional coun-

cilors – are here for several reasons. We managethe affairs of the Division, represent the member-ship (you!) to ASQ Headquarters and other organi-zations, provide information when needed, and tryto implement the Division's mission, vision andgoals.

In order to be effective in serving you, we need tohave some feedback. We cannot work well in avacuum. We need to hear from you, not only whenwe mess up but also when we are doing well, andespecially if you want to share a point of view that

may not have been considered.

We recognize that you are busy – we all are. How-ever, we do appreciate occasional feedback. Wemay not always be able to do everything you want.On the other hand, if you don't let us know whatyour desires or point of view are, we may not think to consider it at all.

Contact information for the leadership team mem-bers is in every issue of this newsletter, and is onthe Division web site ( www.asq.org/measure/ ).

Please, let's talk.

How the Division Represents You

Some members have asked about how the Divisionrepresents them at various conferences put on byother organizations, and the expenses associatedwith that representation.

The Measurement Quality Division regularly par-ticipates in several activities. Within ASQ, there is

the annual World Congress. In addition, we repre-sent you by co-sponsoring and exhibiting at theannual Measurement Science Conference (MSC)and the annual NCSL International (NCSLI) work-shops and symposium. In all three cases, there is atleast one officer, and usually several other mem-bers, at the event. We feel that it is important tocontinue this. MSC is a consistently high-quality

metrology technical conference;many people believe it is one of the best of its kind. NCSLI alsohas high quality conferences thatattract top managers, engineersand scientists from all levels of metrology; it is likely that thecompany you work for is a mem-ber of NCSLI, and some of ourmembers are also individual members of NCSLI.The ASQ World Congress is, of course, ASQ's an-nual conference, and the Division's attendance asan exhibitor is expected.

Whenever someone from the leadership team isgoing to one of these events in order to representthe Division, we do reimburse the actual expensesconnected with that representation. If the person isdoing other things as well, those other expenses aretheir own responsibility.

For example, let's look at the Measurement ScienceConference, which will be over by the time youread this. I was there representing the Division.That means much of my time was spent on the ex-hibit floor, talking with people who come by ourexhibit booth. The MSC itself is two days, Thurs-day and Friday. Exhibits have to be set up onWednesday and cannot be torn down until after theend of the conference on Friday afternoon. Thatmeans I had to be there from Wednesday to Satur-day (because of flight schedules.) The Divisiondoes pay for those hotel days and the airfare(discounted, advance-purchase non-refundabletickets.) Since I also wanted to attend a few of thetechnical sessions, I had to pay for the conferenceregistration but the Division does not reimburse mefor that – it is a personal expense. One of the fea-tures of MSC is that they always have very goodquality short courses and tutorials on Mondaythrough Wednesday. Many are put on by NIST;others are courses given by people such as our ownDilip Shah. Those are all extra cost. I attended atwo day course put on by NIST, and I have to payfor that myself. The added days at the hotel are alsoa personal expense, because they were not requiredto represent the Division. Also, if I was being paidto put on one of those courses, none of the ex-

(Continued on page 5)

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 5/29

MQD Page 5

Vol. 20, No. 1 The Newsletter of the Measurement Quality Division, American Society for Quality March 2006

penses for the week would be covered because thatwould come out of the fees paid to me for present-ing the course.

Again, the only expenses that are reimbursed arethose directly associated with representing the Di-vision. This means that, in the case of the MSC,considerably less than half of what I actually spentwill be paid for by the Division. That is typical forany of us. Add to that the fact that I have to pay myown ASQ membership fees – I have never workedfor a company that pays for any of that – and youcan see that volunteering for a member leadershipposition is definitely a “non-profit” proposition.

I don't mean to scare anyone away from volunteer-ing for a leadership position. We need more hands

to help with the work! But, I alsowant to be open about what theDivision pays for and what itdoes not pay for. This is typicalat all levels of ASQ, from Sec-tions all the way up to the Presi-dent and Board of Directors. Therelevant policies can be found onthe ASQ web site at http:// w w w . a s q . o r g / a b o u t - a s q / h o w - w e - d o / documents.html .

I appreciate being asked questions like this. It givesan opportunity to explain how things are done, so-licit feedback on how we can improve, and docu-ment the policy for future leaders if it has not al-ready been done. Please let me know how we cando better

(Continued from page 4)

Other Division Activity

February 14 Graeme Payne (Chair) was speaker at Section 1102 meeting, Columbia, SC.March 1 Dilip Shah (Immediate Past Chair) presented a tutorial course on Measurement Uncer-

tainty. This was a pre-conference tutorial associated with MSC.March 2 Division meeting teleconference, Anaheim, CA.March 2 – 3 Graeme Payne (Chair) represented division as an exhibitor at the MSC 2006.

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 6/29

MQD Page 6

Vol. 20, No. 1 The Newsletter of the Measurement Quality Division, American Society for Quality March 2006

CCT U PDATE By Chris Grachanen

MQD Certification Chair

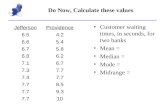

There were 159 candidates that sat for the 05 Dec

2005 offering of the CCT exam. Of those that took the exam 88 passed. As of 01 Jan 2006 there are

now a total of 552CCT alumni. Heartycongratulations goout to all new CCTalumni.

Sat for Passed % Date of Exam Exam Exam Passed

7-Jun-2003 97 69 71% 6-Dec-2003 107 69 64%

23-May-2004 4 4 100% 5-Jun-2004 133 102 77% 4-Dec-2004 139 104 75% 4-Jun-2005 152 116 76% 4-Dec-2005 159 88 55%

Total CCT Alumni: 552

The following is a list of companies that have thelargest concentrations of newly certified CCTprofessionals. The companies are listed from"highest concentration" down through "lowerconcentrations".

SIMCO ElectronicsBoeing

St. Jude MedicalPCIWyle LaboratoriesWestern States CalibrationMedtronic Inc.TRW AutomotivePharmEng Technology Inc.

CALL FOR SPANISH SPEAKINGCCT ALUMNI

ASQ Certification is looking for 12 professionalsacross North America to assist with the CCT Span-ish Cut Score workshop. The workshop is sched-uled for June 23 & 24 at ASQ headquarters in Mil-waukee, WI. The workshop participants must becurrent ASQ members and hold a current CCT cer-

tification. They must be fluent in reading and un-derstanding Spanish. ASQ will reimburse travel upto a maximum of $400 and pay for hotel accom-modations (arrival Thursday June 22 and departureSunday June 25). Breakfast and lunch will be pro-vided during the workshop.

Participants are required to sign a nondisclo-sure agreement . This limits your performingexam preparation training, authoring, or otherwisesharing specific knowledge about the examinationfor a period of two (2) years. This is to ensure that

the knowledge you gain about the exam is not usedin a manner that would give an unfair advantage toanyone sitting for a future exam. Volunteers willreceive 2 RU credits to apply towards recertifica-tion.

If interested please forward a resume to Mary Mar-tin, [email protected] for consideration.

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 7/29

MQD Page 7

Vol. 20, No. 1 The Newsletter of the Measurement Quality Division, American Society for Quality March 2006

The following are recipients of ASQ certifications during the last testing cycle:

Hubert McLeod, United Space Alliance CQMMark Markovich, CQAMiguel A. Decos, Wyle Laboratories CQA (Tested through Section 1405) Fritz Cardona , Wyle Laboratories CCT Brandon L. Capetillo, Wyle Laboratories CCT Larry F. Graham, Wyle Laboratories CCT Erich A. Kelley, Anadarko Industries CCT Bryan A. Kanne, Anadarko Industries CCT John P. Brown, Anadarko Industries CCT Christopher E. Bailey, Anadarko Industries CCT * NOTE: Members in blue belong to the same organization (Anadarko/Wyle)

A special recognition is in order for Anadarko Industries and Wyle Laboratories and especially for Mr.Greg Boyd. Both organizations are the current contractors for the Calibrations and Metrology Service(CAMS) contract at NASA Johnson Space Center (JSC). Mr. Greg Boyd exhibited great leadership byencouraging the CAMS technical and management personnel to consider pursuing ASQ certificationand membership as a means of demonstrating competency in general metrology disciplines and qualityassurance. Through Mr. Boyd's leadership, the laboratory now has eighteen (18) out of twenty-four (24)of the laboratory's technical and management workforce, or 75% of the total workforce, whom nowhave obtained ASQ certifications.

The JSC calibration laboratory is seeking accreditation to ISO/IEC 17025, General requirements for thecompetence of testing and calibration laboratories , through the American Association for Laboratory

Accreditation (A2LA) and reaching this milestone in the pursuit of accreditation will serve to improveour customers confidence in the services provided by the laboratory. Great Job!

Miguel A. Decos, ASQ Member: CQA, CCT Information Technology Manager Education Chairman, ASQ Bay Area Texas Section 1422 Wyle Laboratories, Inc.Measurement Standards and Calibration LaboratoryNASA/Johnson Space Center

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 8/29

MQD Page 8

Vol. 20, No. 1 The Newsletter of the Measurement Quality Division, American Society for Quality March 2006

The Future of QualityIn fifteen years, will you recognize

your organization?By H. James Harrington and Frank Voehl

Changes in practices, technologies and methodsthat show promise today most likely will be ex-tended and widely used tomorrow. One future-looking trend in today's leading organizations is therenewed interest in customer focus. As more com-panies improve information technologies and im-plement just-in-time and lean production systems,an increasing number of made-to-order productsand services will become available. Managingquality in the year 2020 will demand new types of quality management functionalities, more intensivesupplier-qualification systems, and shared designand production information.

Buzzwords are emerging already for the new qual-ity world, as predicted by quality researchers andfuturists such as A. Blanton Godfrey and Patrick Dixon. These buzzwords point to "sense-and-respond" systems replacing the former "make-and-sell" systems. The advantages of low-inventory orno-inventory systems, coupled with no unsold ordiscounted merchandise and truly satisfied custom-ers, are so promising that future-focused organiza-tions are encouraged to move quickly and endorsethese concepts. Given all the buzz, it's interestingto stand back for a moment and see what the worldof quality might look like in the year 2020.

The FUTURE of quality defined

The organization of 2020 will be dominated by sixfactors represented by the acronym FUTURE,which stands for fast, urban, tribal, universal, revo-lutionary and ethics. The acronym is based on theresearch and work of Patrick Dixon(www.globalchange.com ), a well-known interna-tional futurist. In the business world of 2020, mas-tering the quality-related aspects of these six fac-tors will be essential to survival and prosperity.

FastThe world is changing faster than management re-alizes. Survival will require organizations to usequality-based scenario planning before events oc-cur. Quality improvement rapid-response plans willhelp to make every dollar count. The binocular lensof market research can't predict the future in a rap-idly changing world--it just shows what consumersthink. In 2020, we'll need bifocal leadership: clear,short-range thinking and sharp action to steer

through the downturns, as well as accurate visionand steady nerves to see well into the future. Qual-ity managers in the year 2020 will need to be fa-miliar with the next wave of techno-change.

• Implications for the quality practitioner: Speedwill be foremost, and value-information and early-warning systems will provide managers with com-prehensive solutions to their day-to-day problems."Management historians" will provide value infor-mation to analyze organizational successes andfailures. In 2020, who will be watching your radarscreen? Where will you get fresh insights? Whatquality tools will you use to harness external per-spectives to protect you from institutional blind-ness?

(Continued on page 9)

Ten Conclusions for Managing the Future

Thirty years ago, visionary Xerox executive PeterMcColough asked, “Is it inevitable that organiza-tions such as Xerox should have their periods of emergence, full flower of growth and prestige andthen later stagnation and death?” McColougheven identified the causes of the fate awaiting hiscompany as it moved from an enterprise “loose onprocedure, unclear on organizational lines, vari-able in policies” to an institution “governed byrules written and unwritten and the heavy hand of custom.” To avoid the stagnation and death thatMcColough foretold more than 30 years ago, thefollowing factors need to be seriously considered:

1. Prepare for the unexpected.2. Get ready for faster reaction times.

3. Develop flatter organizational structures.4. Build teams and alliance partners.5. Grow with the “global village.”6. Practice cultural sensitivity.7. Invest heavily in technology.8. Create a family work atmosphere.9. Provide a vision with purpose and meaning.10. Enhance your leadership and quality manage-ment competencies.

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 9/29

MQD Page 9

Vol. 20, No. 1 The Newsletter of the Measurement Quality Division, American Society for Quality March 2006

UrbanBig demographic and social "lifestyle" shifts willaffect your business: fickle fashions, aging butwealthy populations, retired people inheriting tril-lions of dollars, aggressive competition for top tal-

ent, female consumer influence, human cloning,medical breakthroughs, virtual relationships and ahost of other factors, including the huge untappedchallenge of megacity markets in emerging econo-mies. These societal changes are fundamental tothe future shape of your business because they'llalter how people think and feel. Soft factors mightcreate your best business opportunities. But areyour teams gearing up to exploit them?

• Implications for the quality practitioner: Popula-tion growth, water shortages, and crime and drugaddiction will be major threats to the quality of lifein our communities and our homes. What early-warning indicators will you have in place to lessenthe effects upon your organization?

TribalPoor project management is one of the majorcauses of quality program failure. Although theworld of 2020 will be increasingly globalized, tri-balism will become the most powerful force onEarth. Groups of people will identify only witheach other, often through projects. Brands will actas relationship partners and create product tribal-ism, where consumers will "belong" to their prod-ucts (and vice-versa). Relationship marketing willfoster special alliances with customers by gatheringand employing massive amounts of informationabout individual vs. tribal behaviors and buyinghabits.

Tribalism today makes people proud of who theyare and provides a national identity. It also affectsus all through niche branding and product loyalty.The key to all successful mergers and leadershipwill be harnessing the quality elements of tribalculture. Although future team leaders will continueto manage up to 20 others, successful tribal leaderswill create dynamic people movements of morethan 100,000.

• Implications for the quality practitioner: Tribal-ism will continue to be the basis of all family, teamand workplace belonging, with a renewed and in-creased respect for culture. How will you maketribalism work for your organization and its qualityof worklife, while rebuilding group confidence anda sense of belonging in a future world of constantworkforce reductions?

UniversalThe opposite of tribalism is universality. Globaliza-tion will hasten the emergence of the global super-brand and create huge pressures to manage globaloperations more effectively. New technologies aswell as virtual teams and companies will be key to

this new paradigm. In today's business environ-ment, we're still playing games with globalization.Many business leaders are already spending morethan six weeks a year flying to and fro at 35,000feet, and it's no fun anymore. Successful multina-tionals will need new management models to growbeyond the constraints of constant air travel. Qual-ity leadership will dominate the shape of all largecorporations, as competitors realign through rapidmergers, acquisitions, disposals or new partner-ships. However, reactions to universal quality stan-dards will grow and require careful handling. Pow-erful global structures will emerge and affect manyorganizations' international interests.

• Implications for the quality practitioner: Globalmanagement will most certainly lead to job insecu-rity, erosion of nonwage benefits and further weak-ening of trade unions. How will you globalize yourorganization's management style and structures?

RevolutionaryFew people in your workforce will likely be activemembers of political parties, although vast num-bers will have signed petitions or campaigned forcauses. With the death of left/right politics and theweakening of "big" government power, corpora-tions will increasingly be held responsible for theiractions by single-issue groups. Examples includethe war against terrorism, animal welfare and childlabor in the textiles industry. Quality-related issuesstrike hard, and their effect can be difficult to pre-dict. Clear quality policies, strong values and rapidmedia response teams will be vital to success in2020. Will you have quality measures in place formonitoring these areas sufficiently? Just-in-timewill continue to grow as a major quality program,even though its effect to date has been on inventorycost. In 2020, we'll need to look at total inventorycosts because a high percentage of our products'components will be manufactured in Asia.

• Implications for the quality practitioner: The in-ventory cost of one month's shipping will be a ma-

jor consideration when outsourcing decisions aremade. Add to that the additional cost of fuel, andmany of the decisions we make today to outsourcelabor-intensive activities won't be justified. Taxstructures will be negatively directed toward thecompany that puts an individual out of work. If

(Continued from page 8)

(Continued on page 10)

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 10/29

MQD Page 10

Vol. 20, No. 1 The Newsletter of the Measurement Quality Division, American Society for Quality March 2006

your organization outsources from the UnitedStates, be prepared to pay higher taxes to offset theadditional costs that unemployed workers bring tohumanity.

EthicsThe United States will stop focusing its quality ef-fort on manufacturing and technology because inthe future it will have no engineering capabilities.At the present time less than 5 percent of U.S. stu-dents are taking engineering classes, compared toChina's 40 percent, according to a National ScienceFoundation study. By 2020, more than 90 percentof all engineering students who graduate from col-lege could be Asian. With that kind of skill shift,there's no way that the United States will be able tocompete in the manufacturing and technologyfields. Instead, the areas of culture change andquality philosophy will become increasingly im-portant in shaping the vision and values of the or-ganization. Whenever CEOs talk about the future,they end up focusing on the personal concerns theyhave, their vision and values, priorities, ethics, mo-tivation, culture and spirituality. All these will bekey issues for large corporations in the year 2020.

• Implications for the quality practitioner: Whatkind of world do you want to live in? Because eth-ics and values will carry us through periods of tre-mendous change and continue to provide increasedcontext and meaning to visions and missions, whatwill your role be in shaping these changes?

The FUTURE at workFinancial rewards are not motivating factors in andof themselves. The genesis of this thinking goesback to the work of Abraham Maslow and Freder-ick Hertzberg. Retaining and motivating top execu-tives in the future will involve various core job di-mensions, such as autonomy, feedback, task iden-tity, skill variety and supervisory satisfaction. Per-sonal work motivation has already changed dra-matically during the last five years and will con-tinue to do so because it's much deeper than work-life balance. The key to capturing people's passionwill be to show how the quality of your products

and services builds a better world, not only for in-dividuals and their families, but also for the com-munity and humanity as a whole.

A second force, the explosion of information tech-nology, will continue to drive change in ways we're

just now beginning to grasp. The Internet, with itspromise of new distribution channels, customerinformation on unimagined scales and instant com-munication across continents, will continue to

change the way people think about business. We'llselect hotel rooms, buy plane tickets, listen to anddownload music, browse newspapers from thou-sands of cities, and shop for almost every conceiv-able product without leaving our own portals. Man-aging the quality of these transactions, services and

products will demand new ideas, new methods,critical thinking and new tools.

A third force, virtual companies, will also stretchour ability to manage quality in the year 2020 andbeyond. As companies follow the lead of Nike,Williams-Sonoma or Sara Lee and establish busi-ness-partner networks rather than vertical or hori-zontal organizations, we'll find a vastly increasedneed for clear specifications, procedures and com-munication. Companies such as Volkswagen inBrazil now have suppliers install and test parts onthe assembly line, which changes Volkswagen'srole to that of coordinator and planner rather thanmanufacturer.

Imagining current trends taken to extreme limitswill offer another way to safely extrapolate the fu-ture. Customer focus will continue to be essential.Nypro Clinton, for example, has reduced its cus-tomer base by more than 90 percent to becomemore customer-focused. By concentrating on asmall number of good customers, the company canco-design and co-locate production facilities anddevelop true business partnerships.

Riskier predictions include speculations about tech-nological breakthroughs or other societal or mana-gerial changes. What happens when informationand communication become virtually free? Orwhen products and services become available any-where in the world? The year 2020 will require thatwe manage development teams comprising thou-sands of far-flung independent programmers whocreate new operating systems and make them avail-able for almost nothing. Information quality willbecome a critical issue, while new methods andtools for managing across company boundaries willbe essential. Old practices of price negotiations andcontracts will have radically changed and trans-formed into new cooperative partnerships with

rapid sharing of information, plans and practices.Quality-driven business-process management willradically extend across company and value-chainboundaries and into customer operations. Timecycles will continue to shrink, and informationflows, decisions and changes will occur with light-ning speed.

(Continued from page 9)

(Continued on page 21)

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 11/29

MQD Page 11

Vol. 20, No. 1 The Newsletter of the Measurement Quality Division, American Society for Quality March 2006

THE LEARNING CURVE By Phil Painchaud

This is the forty-fourth in a series of essays pur-ported to be written concerning the general subject

of Metrology Education but which often wandersomewhat as befits both the available material andthe current whim of the author. Over the span of the past fourteen years the one unchanging elementof its composition is that it is always in the formatof an open letter to our Boss, the re-nowned Editor of this hopefully periodic

journal.

Dear Boss:

I believe that we both had expected this

column to be an analysis and commentaryon the testimony that was given at outMetrology Education Session at lastyear’s Measurement Science Conference. In thelast issue (Column 43), I did quote some of yourtestimony and comment on it. I sent copies of Ms.French’s transcripts to everyone involved — all of the identifiable individuals who gave testimonyasking them to edit their portions. We surely didnot want to be placed in the embarrassing situationof promulgating something that was transcribed inerror or misspoken by the individual. But Boss,

you are the only one among all those who weresent drafts that bothered to return their edited cop-ies. True, Dr. Watson did phone me and tell methat he felt that his was “ok as is” – use it. Butwhile the testimony from both of you was excel-lent, it is scarcely a consensus of the overall opin-ions expressed by both our panel of experts andthose of members of the audience as presented atour session.

Now before you or one of our readers jump me onit, I did use some of your testimony in the last issue

of THE LEARNING CURVE, but that use wasbased on its individual merits as befitted the themeof that column, not a part of a consensus. So onesource of material for this issue was shot to youknow where. My other pertinent source at this timeof year is usually the Annual Measurement ScienceConference, however this year the Conference ismuch later than usual (due, I am told, to schedulingproblems with the hotel). Boss, it will not be held

until after the publication dead-line you have set for this issue.So went my other data source!Now I am left to my own de-vices, please bear with me.

I have been rereading several of my previous columns. COL-UMN 34 in particular drew myattention. In it I had explained that I had beenasked to review a Master’s Thesis for a Master’s

Candidate of Dr. Watson’s Masters inQuality Program at California State Uni-versity—Dominguez Hills. That candidatehad experienced a lifetime in Calibrationin both the Military and in industry, andwas now in the process of acquiring agood handle on Metrology through hisMaster’s level studies in Quality Assur-ance. He was currently in the process of utilizing his new found knowledge and

Calibration experience in the analysis and correc-tion of costly problems in the manufacturing opera-tions of his current employer. He was concentrat-ing on those problems arising due to the lack of proper Metrological control. His thesis was actu-ally a record of his findings and solutions. I pointedout that while I could not agree with all of his solu-tions, many of the statements he made in his thesiswere outstanding in profundity. I shall repeat a fewhere and comment.

“--------Metrology is a system. It must belooked at on a worldwide scale. It cannot belocalized. It cannot exist in a vacuum.”------

How true that is! My own expression was for manyyears, “Metrology cannot be contained in an ‘IvoryTower”, it must be open, visible, and completelyintegrated with our daily life”. We must alwaysremember that Metrology is not just a technologynor is it an engineering discipline. it is a fundamen-tal science—a broad horizontal science encompass-ing all physical sciences without exception. It cov-ers not only all sciences, but also every facet of ourdaily lives. In one way or another it influences ourhome life, our professional and workaday lives, ourtransportation, our health care, our education, and

(Continued on page 12)

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 12/29

MQD Page 12

Vol. 20, No. 1 The Newsletter of the Measurement Quality Division, American Society for Quality March 2006

so on. It cannot be held in a vacuum or an ‘IvoryTower’; it is omnipresent.

In light of the foregoing, my Master’s Candidatemade another wise observation;

“Effective Metrology requires a highly visible top down commitment by management. It can- not be left to the individual whims of the tech- nician, the engineer, or the product line man- ager .”

I countered ( in Column 34) with, “In previouscolumns you have heard me preach (or “soap box”if you prefer) that an effective efficant Metrologyorganization can only be managed by competent

Administrative Metrologist reporting directly and solely to top management. It must not be hiddeneither organizationally or physically. It must stand out such that every member of the parent organiza-tion, from top to bottom, can observe it’s everymove as it sets an example of efficiently, effica-ciousness, ethics, and integrity. It must become theconscious of the entire organization .”— What Idid not add, but should have, is that the Adminis-trative Metrologist must accomplish all of this withhumility. Metrology is no place for the ego trips wesee so often today. I am reminded of a quotation of one of the ancient sages (I cannot remember who),“ Humility is more than scriptural wisdom—it’s a

survival skill”. All who contribute must be recog-nized and credited.

My next gem from my Master’s Candidate is dia-chronic to our usual concepts of justice in a democ-racy, i.e . “ innocent until proven guilty”.

“Metrology------makes the usual assumption that the data collected is questionable and un- certain-----”

In Metrology, all measurements at all times mustbe considered suspect until irrefutably proven to beidiomorphic (proper for the application), andwithin the specifications for accuracy, precision,and resolution, all within the environmental factorsspecified. Neither you nor anyone else within yourchain of command (unless you are NIST) can issuean order that a measurement complies with all of

the specified criteria withoutfully documented empirical evi-dence backing that claim. By Actof Congress, the National Insti-tute of Standards and Technol-ogy (formerly the National Bu-reau of Standards) is always cor-rect and is the only agency inthis nation that can issue suchedicts. If that agency were not in that solo top posi-tion, we would have technological anarchy. In eve-ryday language, if your boss orders you to certifyor to otherwise promulgate a measurement youknow to be incorrect, that order does not make itcorrect. Or, to counter phrase the usual democratictradition, “ It must be considered guilty until

proven innocent”.

My next excerpt from my subject thesis is on amatter that is constantly in argument nearly every-where. I have been able to close that argumentmany times by using the reference I cite below.The statement goes:

“-------Metrology cannot exist unless it is uni- formly applied to everyone in the process.------“

How many times have we heard the baseless argu-ment, “My measurements don’t need to be checkedbecause I am only doing R&D, not production.”?Or, “I don’t want my instruments calibrated as I amonly making comparative measurements?” Thebest irrefutable argument negating these argumentsthat I have ever encountered was written forty-fouryears ago in 1962. You will find it in NBS Miscel-laneous Publication 248, Page 203, in a paper enti-tled “Instrument Recall Concepts and Policies”,and authored by none other than Jerry L. Hayes thelong time head of the U.S Navy Metrology Engi-neering Laboratory. I can only recommend that youacquire a copy of that paper and sell the philosophywithin your own sphere of influence.

My final extraction from the thesis is probably thebest description that I have ever encountered con-cerning what the Calibration element of the overallMetrology function is all about:

(Continued from page 11)

(Continued on page 13)

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 13/29

MQD Page 13

Vol. 20, No. 1 The Newsletter of the Measurement Quality Division, American Society for Quality March 2006

“----Calibration is actually the act of historical story telling. It is the act of creating an NIST traceable uncertainty statement. It relates aunit’s performance with respect to an SI unit of

measurement at a specific time, using a specific set of standards, by a specific individual, at a specific place, in a specific environment. Even a unit operating well outside of its stated manu- facturer’s range of operation, can be calibrated using this philosophy. Physical adjustments of indication to closely represent the value tar-

geted is strictly an act for ease of use and inter- pretation. Without a qualifying uncertainty statement it has little meaning.---”

I might suggest that you print out the above state-ment, frame it, and hang it over your work station.

During years gone by, from time to time I havepublished a few technological brain twisters. I havebeen asked to try a few more. I’ll do one here, if you want more, tell me so. This one goes:

“HOW MANY WATTS DOES IT TAKE TOCOOK A HOT DOG?”

This is a real question; it was used in a final examby a university. I will give you these clues: Theanswer is independent of the mass of the sausageused and is also independent of the means used toapply the energy: i.e., thermal conduction, thermalradiation, thermal convection, electrical resistively,or microwave induction. Send me an e-mail withthe correct answer and I shall credit you.

We will call it quits for this issue, however I wouldlike to ask one favor of any of you who happen torouse out of your lethargy and decide to contactme. Please, when you are contacting concerningmaterial in a specific column, tell me which col-umn you are referring to by number. For examplethis column is Number 44. The column number isalways contained in the preamble to that column. Iget many calls and e-mails that just open up andstart; “I read your column”, and then go on, “thusand so, etc”. I never know which column they arereferring to. A while back an individual called andit took quite many minutes of AT&T Long Dis-tance time to figure out that they were referring to a

column published nearly fiveyears before. When I write a col-umn I have only a vague ideawhen it will be finally publishedand even less of an idea whenyou may receive and read it. Butwith a number I can identify itinstantly. Thank you.

I hope will have seen many of you at the upcomingMeasurement Science Conference. In the mean-while, I am still at the same old stand.

PHIL PAINCHAUD1110 WEST DOROTHY DRIVEBREA. CA 92821-2017TELEPHONE: 714-529-6604FAX: 714-529-1109e-mail: [email protected] [email protected]

Richard D. (Rick) RobersonChair-Elect

Rick has been appointed as the Chair-Elect for theMeasurement Quality Division of ASQ. He will fillthe position for the rest of the 2005~06 term, andfill the position during the 2006~07 term. Follow-ing is a short bio on Rick.

Rick has worked in many different places aroundthe world with the US Air Force on active duty,civil service, and contractor. He currently is thelead technician of the electronics section of theTinker AFB calibration laboratory. He graduatedfrom Embry-Riddle Aeronautical University in2002 with a degree in Management of TechnologyOperations ( cum laude ). He has been a member of ASQ for three years and is a Certified CalibrationTechnician (CCT). Rick has volunteered his timeas a Subject Matter Expert for several Item Writingand Item Review workshops for the CCT program.He also is the current Certification Chair for ASQSection 1408 (Oklahoma City).

On behalf of the officers and committee chairs of the Measurement Quality Division...Welcomeaboard, Rick. Your dedication and support of MQDis much appreciated.

(Continued from page 12)

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 14/29

MQD Page 14

Vol. 20, No. 1 The Newsletter of the Measurement Quality Division, American Society for Quality March 2006

Attendees:Chris Grachanen Graeme PayneJay Bucher Bill McCulloughKarl Wigdal Dan HarperDuane Allen Dilip ShahPhil Painchaud

MinutesGraemeGraeme welcomed everybody to the meeting. His position with Delta Airlines has been eliminated andwill cease the end of March. The Division Management Agreement (DMA) will be going before theASQ board. The DMA could be in place by July 1, 2006.

JayJay and/or Karl will contact Bruce Brown at ASQ to see if he will do an audit of our books. If he is un-

able, they will look at having a CPA performing an audit before Jay takes over as the new Treasurer.Any expense for the audit will come out of the division funds.

ASQ donated four (4) copies of The Metrology Handbook for door prizes at MSC 2006. A big thanks tothem for their generosity. Lots of interest at the booth to see copies, which unfortunately were not avail-able.

PhilPhil’s column in The Standard is approaching its 50th installment. Though sometimes controversial,The Leaning Curve always makes for interesting reading and is The Standard ’s longest running inde-pendent column.

BillZ540.3 has passed the full committee. A draft is available and can be viewed on NCSLI’s web site.

DilipMQD had a session on Friday, March 3, at MSC 2006. The presenters were Dilip and Bob Graham fromSandia Labs. Dilip stated that Craig Gulka says space is available at NCSLI Workshop & Symposium2006 to hold a CCT exam. Dilip will followup.

ChrisSummary of the MJD survey sent to NCSLInewsletter (also included at the end of thisedition).

Professional Examination Services (PES) iscurrently working on draft job descriptionsfor Calibration Technician, Calibration Engi-neer and Metrologist. It is anticipated thatthese drafts will be provided to the core teamfor review by mid-March.

Minutes compiled by Graeme, Jay and Chris.

MQD Teleconference Minutes March 2, 2006

Our illustrious Chairmanning our booth.

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 15/29

MQD Page 15

Vol. 20, No. 1 The Newsletter of the Measurement Quality Division, American Society for Quality March 2006

Attendees:Chris Grachanen Graeme PayneJay Bucher Bill McCulloughKarl Wigdal Norm BeleckiDon Ermer Eduardo M. Heidelberg

MinutesGraeme

Welcomed everybody to meeting and started it by giving an update of ASQ’s Division Affairs Councilactivities and information about the upcoming ASQ World Conference on Quality and Improvement(WCQ&I) conference being held 01-03 May 2006 in Milwaukee, WI.

The new ASQ Management Agreement once ratified (voted scheduled for 01 Jun 2006) will be replac-ing ASQ Division by-laws in order to provide better flexibility and alignment with existing divisionstructure and activities.

The will be volunteer leadership training classes prior to WCQ&I conference. Those that attend the lead-ership training will be attend the conference at the reduce rate of $250. MQD supports officers planningon attending the WCQ&I conference.

Karl

Provide an update on MQD financial status. As of Nov 2006, there is $9k in checking and $73.5k inmarket fund. Professional Examination Services (PES) has been paid for administration of MetrologyJob Description as well as Quality Challenge Coins for minting of CCT commemorative coins (1000minted).

Jay

No activities to report regarding NIST’s US Measurement System Roadmap. Deadline for article sub-mittals to The Standard is 15 Feb 2006.

Norm

The Joe Simmons Scholarship was not awarded in 2005. There were only two candidate submittals for2005 both of which were deemed not meeting criteria for awarding of the scholarship.

The Joe Simmons Scholarship still has not been given non-profit status by the IRS. Work is in progressin creating a Joe Simmons Scholarship website.

Chris

There were 159 candidates that sat for the 05 Dec 2005 offering of the CCT exam of which 88 passedgiving a total CCT alumnus of 552 as of 01 Jan 2006. Congratulation letters sent out to all new CCTalumnus.

(Continued on page 16)

MQD Teleconference Minutes January 10, 2006

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 16/29

MQD Page 16

Vol. 20, No. 1 The Newsletter of the Measurement Quality Division, American Society for Quality March 2006

One thousand CCT commemorative coins have be minted and delivered to Graeme.Currently Chris is investigating using ASQ’s third party fulfillment supplier andASQ’s distribution group as to which can provide shipping and handling services atthe best rate for distribution of the coins to CCT alumni. A letter to accompany eachcoin still needs to be drafted.

Bill

Z-540.3 revision will be voted on at upcoming Measurement Science Conference (MSC). It is expectedto be approved. The next volunteer opportunity will be to form a committee to develop a Z-540.3 hand-book to provide guidance for the standard’s use.

Don

Don’s informative paper on R&R measurements will be appearing in the next two installments of Qual-ity Progress’s Measure for Measure .

Graeme

Next MQD meeting will be on 02 Mar 2006 at MSC at 6:00pm Pacific Time. On behalf of MQD, GregGay, chair of ASQ’s Inspection Division was recommended for an ASQ national directorship. Graememotioned to close meeting, Jay seconded, meeting closed.

Respectfully Submitted,

Christopher L. GrachanenASQ MQD Secretary

Division Meeting & Teleconference Schedule

Here are the planned dates and places for Division meetings and Leadership Team teleconferences forthe rest of 2006. Every meeting is by teleconference. Where a location is specified, any members in thearea are welcome to attend in person. This information is also posted on the Division's web site.

Tuesday, May 2, 2006 6:00 pm CDT ASQ World Congress, Milwaukee, WIWednesday, August 9, 2006 6:00 pm CDT NCSLI Symposium, Nashville, TNTuesday, October 10, 2006 2:00 pm EDT TeleconferenceTuesday, November 14, 2006 2:00 pm EST Teleconference

(Continued from page 15)

Position Name Chair Graeme Payne Chair Elect Rick Roberson Secretary Chris Grachanen Treasurer Jay Bucher

2006 ~ 2007 Officers

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 18/29

MQD Page 18

Vol. 20, No. 1 The Newsletter of the Measurement Quality Division, American Society for Quality March 2006

2005 ~ 2006 MQD Meeting Attendance 8/10/05 10/11/05 1/10/06 3/2/06 5/1/06

Officers Chair Graeme Payne P P P P Chair-Elect Jay Bucher P P P P N/A Chair-Elect Rick Roberson N/A N/A N/A N/A Secretary Chris Grachanen P A P P Treasurer Karl Wigdal P P P P N/A

Treasurer Jay Bucher N/A N/A N/A N/A Committees

Program Dilip Shah P P A P

Liaisons & Representatives Simmons Scholarship Norm Belecki A A P A Standards Comm. Bill McCullough P P P P

ASQ Staff Community Care Karen Prosser A P N/A N/A

Jeannette Cooke N/A N/A A A

Regional Councilors

Region 03 Eduardo Heidelberg A A P A Region 07 Randy Farmer P P A A Region 12 Don Ermer A P P A Region 14 Keith Bennett P A A A

Members & Guests Don Ruth P Georgia Harris P Howard Zion P

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 19/29

MQD Page 19

Vol. 20, No. 1 The Newsletter of the Measurement Quality Division, American Society for Quality March 2006

Chair, Examining ChairGraeme C. PayneGK Systems, Inc.4440 Weston Drive SW, Suite BLilburn, GA 30047 USAVoice: (770) 931-4004 / Fax (866) 887-9344E-mail: [email protected]

Chair-ElectRichard D. Roberson10301 Clinkenbeard Rd NENorman, OK 73026Voice (405) 321-8580E-mail: [email protected]

Secretary, Certification Chair, WebsiteManager, NCSL International Representative

Christopher L. GrachanenManager, Houston Metrology Group Hewlett-PackardP. O. Box 692000 MS070110Houston, TX 77269-2000Voice (281) 518-8486 / Fax (281) 518-7275E-mail: [email protected]

Treasurer, Publication Chair, NewsletterEditor/Publisher, Share Point Administrator

Jay L. BucherBucherview Metrology Services6700 Royal View Dr.De Forest, WI 53532-2775Voice (608) 277-2522 / Fax (608) 846-4269E-mail: [email protected]

Standards Committee RepresentativeBill McCulloughMcCullough Consulting1936 June CrCarson City, NV 89706Voice: (775) 883-3042 Fax: (775) 883-3042Cell: (775) 220-6424E-mail: [email protected]

Immediate Past Chair, Nominating ChairProgram Chair

Dilip A. ShahE = mc3 Solutions197 Great Oaks Trail #130Wadsworth, Ohio 44281-8215Voice (330) 328-4400 / Fax (330) 336-3974E-mail: [email protected], [email protected]

Joe Simmons ScholarshipNorm Belecki7413 Mill Run DrDerwood, MD 20855-1156Voice (301) 869-4520E-mail: [email protected]

HistorianKeela SniadachPromega Corp.5445 East Cheryl ParkwayMadison, WI 53711Voice (608) 298-4681 / Fax (608) 277-2516E-mail: [email protected]

ASQ Division AdministratorMs. Jeannette CookeVoice (800) 248-1946E-mail: [email protected]

MEASUREMENT QUALITY DIVISION OFFICERS AND COMMITTEE CHAIRS

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 20/29

MQD Page 20

Vol. 20, No. 1 The Newsletter of the Measurement Quality Division, American Society for Quality March 2006

ASQ M EASUREMENT QUALITY DIVISION REGIONAL COUNCILORS

Regional Councilors represent the Division to members and Sections in their geographicareas. Regional Councilors are appointed for renewable two-year terms, and are advisory

members of the Division leadership team.Region 1 (CT, MA, ME, NH, RI, VT)

Volunteer Opportunity!

Region 2 (NJ, NY, PA)

Volunteer Opportunity!

Region 3 (CT, NJ, NY)

Mr. Eduardo M. HeidelbergPfizerParlin, NJ 08859

E-mail: [email protected]

Region 4 (Canada)

Mr. Alexander T. C. LauExxonMobilWhitby, ON L1R 1R1E-mail: [email protected]

Region 5 (DC, DE, MD, PA, VA)

Mr. Richard A. LittsLitts Quality Technologies

Downington, PA 19335E-mail: [email protected]

Region 6 (AK, CA, HI, ID, MT, OR, UT, WA,WY)

Volunteer Opportunity!

Region 7 (AZ, CA, NV, part of Mexico)

Mr. Randy D. FarmerMetrology SolutionsChula Vista, CA 91913E-mail: [email protected]

Region 8 (OH, PA)

Volunteer Opportunity!

Region 9 (IN, KY, OH)

Ryan Fischer, ASQ CCTLaboratory Accreditation BureauNew Haven, IN 46774E-mail: [email protected]

Region 10 (OH, MI)

Volunteer Opportunity!

Region 11 (NC, SC, TN, VA)

Volunteer Opportunity!

Region 12 (IL, MN, ND, SD, WI)

Dr. Donald S. Ermer ASQ Fellow; Eugene L. Grant Medal (2001)University of Wisconsin—MadisonMadison, WI 53706E-mail: [email protected]

Region 13 (CO, IA, KS, MO, NE, SD, WY)

Volunteer Opportunity!

Region 14 (AR, LA, NM, OK, TX, part of Mexico)

Mr. R. Keith BennettTRANSCATKingwood, TX 77339E-mail: [email protected]

Region 15 (AL, FL, GA, LA, MS, Puerto Rico)

Mr. E. Bryan Miller ASQ Fellow

Bryan Miller ConsultingFlorence, AL 35633E-mail: [email protected]

Region 25 (all other countries)

Volunteer Opportunity!

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 21/29

MQD Page 21

Vol. 20, No. 1 The Newsletter of the Measurement Quality Division, American Society for Quality March 2006

ConclusionToday's focus is on Six Sigma; tomorrow's focuswill be on error-free performance. There will be aradical focus on reducing the time interval betweenwhen errors occur and when they're measured atthe individual level. Knowledge management willplay a big part in quality in the service industry.Historically, prevention is one art to which we'venever found the key. We talk prevention but prac-tice correction.

By 2020, we'll stop teaching problem solving andfocus on developing new methodologies in preven-tion--ones that really work so we don't need tosolve the same problems over and over again.Quality in U.S. manufacturing organizations is im-proving at a rate of about 10 percent a year. Quality

in service is improving at less than 5 percent ayear, and in some sectors, such as the airline indus-try, it's going in a negative direction. Meanwhile,customer expectations are increasing at a rate of 15percent to 20 percent per year.

The bottom line is this: The FUTURE of qualitylies in reversing the existing negative trends whilethere's still time.

About the authors H. James Harrington is CEO of the Harrington Institute Inc. and chairman of the board of Har-rington Group. He has more than 55 years of ex-

perience as a quality professional and is the author of 22 books. Visit his Web site at www.harrington-institute.com .

Frank Voehl has more than 30 years of experienceas a systems engineer and quality professional and is the author/co-author of 16 books and hundredsof articles and papers on quality management, con-tinuous improvement and teamwork. He is thechairman and CEO of Strategy Associates Inc.

Editor’s note: This article firstappeared in the December 2005issue of Quality Digest . Here’s al i n k t o t h e i r w e bsite...www.qualitydigest.com . Abig THANK YOU goes out toQuality Digest for allowing us toreprint this article.

(Continued from page 10)

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 22/29

MQD Page 22

Vol. 20, No. 1 The Newsletter of the Measurement Quality Division, American Society for Quality March 2006

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 23/29

MQD Page 23

Vol. 20, No. 1 The Newsletter of the Measurement Quality Division, American Society for Quality March 2006

METROLOGY J OB DESCRIPTION INITIATIVE

By Chris Grachanen

The MQD / NCSLI Metrology Job Description(MJD) survey results have been compiled / summa-rized and is currently being used as the basis fordeveloping job descriptions for sub-mittal to the U.S. Department of Labor's Standard Occupational Clas-sification (SOC) system. Readersmay remember that the SOC systemis used by all Federal statisticalagencies to classify workers intooccupational categories for the pur-pose of collecting, calculating, anddisseminating data. The SOC is used as the guidefor developing the Bureau of Labor Statistics' Oc-cupational Outlook Handbook. The OccupationalOutlook Handbook is a nationally recognizedsource of career information, providing valuableassistance to individuals making decisions abouttheir future work lives. The Handbook describeswhat workers do on the job, working conditions,the training and education required, average earn-ings as well as expected job prospects in a widerange of occupations.

It was in the development of the Certified Calibra-tion Technician (CCT) program that I learned thatthe SOC's current job descriptions for calibrationpractitioners were fragmented among many differ-ent job titles, and inaccurate in communicating jobexpectations. Without faithful job descriptions, it isunlikely that prospective candidates will be steeredinto the Metrology field by educators. In addition,demographic information, such as how many folksare in the Metrology profession, how many folksare leaving the profession, etc., can not be accu-rately determined. In early 2006, the Bureau of La-bor Statistics will begin soliciting input for updatesand additions to the SOC listing for the next formalrelease. The SOC is updated once every ten years.The last SOC update was completed in 2000. Bu-

reau of Labor Statistics adminis-trators agreed that updating theSOC would be the first logicalstep in assuring the OccupationalOutlook Handbook accuratelydepicts calibration practitioneroccupational information andassociated demographics.

THE FOLLOWING SIX (6) PAGES ARE THE METROLOGY J OB DESCRIPTION INITIATIVE

SURVEY RESULTS :

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 24/29

American Society for QualityMetrology Job Description Study

Survey Results

February 2006

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 25/29

MQD Metrology Job Descriptions 1 February 2006

JOB DESCRIPTIONS FOR CALIBRATION PROFESSIONALS

I. Education and Experience Requirements 1

Calibration Technician

Education: Technical school or military (PMEL) trainingExperience: 0 to 2 years

Required skills and abilities:• Determine the kind of measurement tools and equipment needed to do a job.• Perform routine maintenance and calibration on equipment and determine when and what kind

of calibration and maintenance is needed.• Use mathematics to solve measurement related problems.• Conduct tests and inspections of products, services, or processes to evaluate quality or

performance.• Determine causes of measurement errors and decide what to do about it.• Choose the right mathematical methods or formulas to solve a problem.• Apply measurement science principles to specific problems to produce answers that make

sense.• Recognize when a measurement is wrong or is likely to go wrong.

Calibration EngineerEducation: Associate’s or Bachelor’s degreeExperience: 3 or more years

Metrologist

Education: Bachelor’s degree or military (PMEL) trainingExperience: 5 or more years

1 For all positions, years of experience can be substituted for education.

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 26/29

MQD Metrology Job Descriptions 2 February 2006

II. Essential Knowledge and Desired Knowledge 2

Calibration Technician

Essential Knowledge Desirable Knowledge Algebra TrigonometryBasic computer skills Electronics – advanced (circuit analysis)Electronics – basic Measurement sciences

Calibration Engineer

Essential Knowledge Desirable Knowledge Algebra TrigonometryBasic computer skills CalculusElectronics – basic Computer programmingMeasurement sciences PhysicsStatistics – basic Electronics – advanced (circuit analysis)Technical writing Engineering – electrical

Quality Management Systems (ISO 9000 Series) Engineering – mechanicalStatistics – advanced (ANOVA, DOE, gage R & R)

Metrologist

Essential Knowledge Desirable Knowledge Algebra Analytic geometryTrigonometry PhysicsBasic computer skills Electronics – advanced (circuit analysis)Electronics – basic Geometric dimensioning and tolerancingMeasurement sciencesStatistics – basicsTechnical writingQuality Management Systems (ISO 9000 Series)

2 Essential knowledge was selected by >65% of survey respondents, desirable knowledge was selected by 51 – 65% of survey respondents.

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 27/29

MQD Metrology Job Descriptions 3 February 2006

III. Essential Responsibilities for Calibration Technicians, Calibration Engineers,and Metrologists

ResponsibilityCalibrationTechnician

CalibrationEngineer Metrologist

1. Calibrate inspection, measurement, and testequipment (IM&TE) in one of the followingdisciplines - electrical, dimensional, optical,

physical/mechanical, chemical - in order toensure compliance with publishedspecifications.

● ● ●

2. Maintain primary and/or intrinsic calibrationstandards.

● ● ●

3. Maintain secondary and/or working calibrationstandards.

● ● ●

4. Develop calibration procedures and methods,according to detailed specifications, blueprints,drawings, and other technical requirements.

● ●

5. Collect, compile, measure, summarize, andrecord data gathered during calibration.

● ● ●

6. Analyze measurement data for identifyingabnormalities, trends and/or predicting futurevalues.

● ● ●

7. Identify IM&TE out-of-tolerance conditions and perform corrective action via adjustments,component replacement, correction factors, etc.

● ● ●

8. Identify and correct measurement errors, asapplicable.

● ● ●

9. Prepare calibration reports and certificates. ● ● ●

10. Inspect and evaluate new calibration standardsfor proper operation before releasing tocalibration laboratory.

● ●

11. Recommend IM&TE for use in measurementapplications.

● ● ●

12. Recommend standards for use in calibrationapplications.

● ●

13. Adapt existing calibration equipment, standards,and techniques to accomplish uniquemeasurements tasks for which they are not

principally used.

● ● ●

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 28/29

MQD Metrology Job Descriptions 4 February 2006

ResponsibilityCalibrationTechnician

CalibrationEngineer Metrologist

14. Apply engineering knowledge to the design anddevelopment of calibration methods, fixtures,and IM&TE not commercially available.

● ●

15. Develop, document, and maintain calibrationsystems and procedures, based on principles of measurement science, technical analysis of measurement problems and accuracy and

precision requirements.

● ●

16. Perform uncertainty evaluation and analysis for measurement standards and associatedmeasurement processes.

● ●

17. Design and document measurement referencematerial for laboratory use.

● ●

18. Conduct technical audits of the calibrationlaboratory to verify traceability of standards andcompliance with published standards andguidelines.

● ●

19. Develop software for calibrating IM&TE.∗

● ●

20. Develop software for the maintenance of calibration standards. ∗

● ●

21. Develop, implement, and maintain thecalibration laboratory's quality systems per

published standards and guidelines.

● ●

22. Train subordinates in calibration concepts and procedures.

● ● ●

23. Perform technical assessments for personnel performance reviews.

● ●

24. Perform laboratory housekeeping. ● ● ●

25. Maintain laboratory recognition/accreditation. ● ● ●

26. Provide technical advice to other departments of the organization.

● ● ●

∗

May be performed, but not in all positions.

8/8/2019 The Standard 5 Mar06

http://slidepdf.com/reader/full/the-standard-5-mar06 29/29

IV. Extent to Which Knowledge is Required 3 for Entry-Level CalibrationTechnicians, Calibration Engineers, and Metrologists

3 Grey indicates 35% to 55%, 51% to 65% for light blue, and greater than 65% for red of respondents indicating

Knowledge

CalibrationTechnician

CalibrationEngineer Metrologist

Algebra ● ● ●

Trigonometry ● ● ●

Analytic geometry ● ● ●

Calculus ● ●

Basic computer skills (word processing,spreadsheets)

● ● ●

Computer programming ● ●

Physics ● ● ●

Electronics – basic ● ● ●

Electronics – advanced (circuit analysis) ● ● ●

Engineering – electrical ●

Engineering – mechanical ● ●

Engineering – systems

Measurement sciences ● ● ●

Geometric dimensioning and tolerancing ● ● ●

Statistics – basic ● ● ●

Statistics – advanced (ANOVA, DOE, gage R & R) ● ●

Technical writing ● ● ●

Quality Management Systems (ISO 9000 Series) ● ● ●