The KAGRA Cryogenic Payload R&D Status and Future · PDF fileAleksandr Khalaidovski The KAGRA...

Transcript of The KAGRA Cryogenic Payload R&D Status and Future · PDF fileAleksandr Khalaidovski The KAGRA...

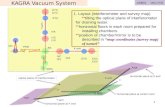

Aleksandr Khalaidovski 1The KAGRA cryogenic payload – R&D status and future plans GWADW – May 25th – 30th 2014 – Takayama, Japan

The KAGRA Cryogenic Payload

-

R&D Status and Future Plans

D. Chen, A. Khalaidovski, G. Bergmann, A. Bertollini, A. Conte, R. Douglas, G. Hammond, M. Hanke,

K. Haughnian, E. Hennes, E. Hirose, G. Hofmann, J. Hough, S. Kawamura, N. Kimura, J. Komma,

R. Kumar, H. Lück, E. Majorana, T. Miyamoto, R. Nawrodt, S. Rowan, Y. Sakakibara, A. Scheie,

C. Schwarz, T. Suzuki, H. Tanaka, C. Tokoku, T. Tomaru, S. v. Leeuwen, M. v. Veggel, K. Yamamoto

and the AEI, Glasgow, Jena, NIKHEF and Roma groups

Aleksandr Khalaidovski 2The KAGRA cryogenic payload – R&D status and future plans

Motivation

Drawing by S. Koike

Aleksandr Khalaidovski 3The KAGRA cryogenic payload – R&D status and future plans

Current approaches

Cradle suspension 垂れ耳 = lop-eared suspension

Credits: E. Hirose

See talks by E. Hirose and R. Kumar

Aleksandr Khalaidovski 4The KAGRA cryogenic payload – R&D status and future plans

Outline

The lop-eared suspension

- Heat conductivity measurements on fibers

- Heat extraction through the weld „nail head – fiber“

- Fiber Q measurements

- Heat conductivity through hydroxide catalysis and indium bonds

Status of the single R&D items

- Indium and HCB Q measurements

Prototype experiments planned

- HCB strength test after thermal cycling

Aleksandr Khalaidovski 5The KAGRA cryogenic payload – R&D status and future plans

Lop-eared suspension

Hydroxide catalysis bond (HCB)

between test mass and ear

Indium brazing between fiber and ear

(connected in compression)

Indium brazing between fiber and blade

(connected in compression)

Aleksandr Khalaidovski 6The KAGRA cryogenic payload – R&D status and future plans

Lop-eared suspension

consists of 11 single components

connected using indium and HC bonds

indium bonds can be disconnected if a

broken fiber/blade needs to be

substituted

only HCB need to be strong (1 MPa)

Requirements

flat cuts to mirror cylinder to connect

ears, polished to λ/10 or better

long ear to place fiber bending point at

the center of mass

(about 40mm from the head)

Aleksandr Khalaidovski 7The KAGRA cryogenic payload – R&D status and future plans

Status of the single R&D items

Aleksandr Khalaidovski 8The KAGRA cryogenic payload – R&D status and future plans

Outline

The lop-eared suspension

- Heat conductivity measurements on fibers

- Heat extraction through the weld „nail head – fiber“

- Fiber Q measurements

- Heat conductivity through hydroxide catalysis and indium bonds

Status of the single R&D items

- Indium and HCB Q measurements

Prototype experiments planned

- HCB strength test after thermal cycling

Aleksandr Khalaidovski 9The KAGRA cryogenic payload – R&D status and future plans

Measuring the heat conductivity of fibers

Aleksandr Khalaidovski 10The KAGRA cryogenic payload – R&D status and future plans

Measuring the heat conductivity of fibers

heater

T sensors

Aleksandr Khalaidovski 11The KAGRA cryogenic payload – R&D status and future plans

Measuring the heat conductivity of fibers

Analyzed fibers:

Cylindrical nail heads. One head monolithic, other welded. Head

diameter 10mm, height 5mm. Fiber diameter 1.6mm, total length

100mm. Rough surface.

Aleksandr Khalaidovski 12The KAGRA cryogenic payload – R&D status and future plans

Measuring the heat conductivity of fibers

Analyzed fibers:

Cylindrical nail heads. One head monolithic, other welded. Head

diameter 10mm, height 5mm. Fiber diameter 1.6mm, total length

100mm. Rough surface.

Same dimensions, but monolithic, grinded from 10mm sapphire

rod. Better surface polishing, no treatment.

Aleksandr Khalaidovski 13The KAGRA cryogenic payload – R&D status and future plans

Measuring the heat conductivity of fibers

Analyzed fibers:

Cylindrical nail heads. One head monolithic, other welded. Head

diameter 10mm, height 5mm. Fiber diameter 1.6mm, total length

100mm. Rough surface.

Same dimensions, but monolithic, grinded from 10mm sapphire

rod. Better surface polishing, no treatment.

Same dimensions. 1.6mm rod welded into two pre-fabricated

nail heads. HEM sapphire, thermo-polished fiber rod.

Aleksandr Khalaidovski 14The KAGRA cryogenic payload – R&D status and future plans

Measuring the heat conductivity of fibers

Fibers satisfy the KAGRA requirements in terms of Tc

KAGRA prototype

Aleksandr Khalaidovski 16The KAGRA cryogenic payload – R&D status and future plans

Heat extraction through fiber nail heads

Aleksandr Khalaidovski 17The KAGRA cryogenic payload – R&D status and future plans

Measuring the heat conductivity of fibers

Aleksandr Khalaidovski 18The KAGRA cryogenic payload – R&D status and future plans

Final KAGRA fiber design

• Total length 300mm

• Nailhead: 20mm cube

• All head surfaces with

flatness better λ/4

6 surfaces per head that can

be used for optical bonding

Aleksandr Khalaidovski 19The KAGRA cryogenic payload – R&D status and future plans

Advertising posters

Aleksandr Khalaidovski 20The KAGRA cryogenic payload – R&D status and future plans

Outline

The lop-eared suspension

- Heat conductivity measurements on fibers

- Heat extraction through the weld „nail head – fiber“

- Fiber Q measurements

- Heat conductivity through hydroxide catalysis and indium bonds

Status of the single R&D items

- Indium and HCB Q measurements

Prototype experiments planned

- HCB strength test after thermal cycling