The Effects of Minor Elements on the Welding ...files.aws.org/wj/supplement/WJ_1988_09_s202.pdf ·...

Transcript of The Effects of Minor Elements on the Welding ...files.aws.org/wj/supplement/WJ_1988_09_s202.pdf ·...

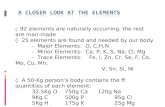

The Effects of Minor Elements on the Welding Characteristics of Stainless Steel

Sulfur, oxygen and deoxidant contents determine penetration, while the silicon-to-aluminum ratio controls

slagging characteristics

BY B. POLLARD

ABSTRACT. The effects of systematic variations in the aluminum, sulfur, silicon, manganese, phosphorus, molybdenum and copper contents on the penetration and slagging characteristics of laboratory heats of Type 304 stainless steel have been investigated. The effects of aluminum and sulfur on penetration in tungsten inert gas welding can be satisfactorily explained in terms of their effects on the temperature coefficient of surface tension and the theory of surface tension driven fluid flow. However, the results for silicon and manganese are more complex and, while not inconsistent with the surface tension driven fluid f low model, indicate that other factors besides the temperature coefficient of surface tension must be taken into account. In the case of silicon, its influence on the viscosity of the molten metal appears to have a significant effect on penetration. As expected, phosphorus, molybdenum and copper had no effect on penetration since they are not surface active elements, or likely to interact with surface active elements and, therefore, have no effect on the temperature coefficient of surface tension.

Penetration values for production heats of Types 304 and 316 stainless steels showed a strong dependence on sulfur content, but were lower for the laboratory heats, which was attributed to their lower oxygen contents.

Slag formation during the GTA welding of stainless steels was found to be caused primarily by the oxide inclusions in the steel. However, EDS analyses indicated that the composition of the slag was not always equivalent to a mixture of all the

B. POLLARD is with the Research Center, Armco, Inc., Middletown, Ohio. The paper was prepared while the author was with I TV Steel Co., Independence, Ohio.

Paper presented at a conference on "Progress in Resolving Undesirable Trace Element Effects on the Weldability of Steels," held November 21, 1985, in Charlotte, N.C.

inclusions in the steel because it tended to approach an equilibrium corresponding to temperatures near the surface of the weld pool, which were much higher than those encountered in steelmaking. Provided that sufficient amounts of the appropriate deoxidant was present, these high temperatures favored the formation of slags that were richer in the high-stability oxides, such as those of calcium, aluminum, titanium and silicon, and poorer in the low-stability oxides, such as those of manganese and chromium, than the inclusions. In general, the slagging characteristics of stainless steel were found to be determined primarily by the silicon-to-aluminum ratio of the steel. Patch type slags, which caused an uneven weld bead and irregular penetration, were formed when the silicon-to-aluminum ratio was less than 50 and the less troublesome globular slags formed when it was greater than 50.

Compositional limits for stainless steel with welding characteristics suitable for the production of welded tubing are given.

Part I—Penetration Characteristics

Introduction

The effects of minor elements on the welding characteristics of stainless steel are of particular interest to steelmakers

KEY W O R D S

GTA Welding Stainless Steels Minor Element Effect Weld Characteristics Weld Penetration Weld Slagging Welded Tubing Si-to-AI Ratio Sulfur-02 Deoxidants Weld Bead Geometry

who supply stainless steel strip to welded tubing manufacturers. Welded stainless steel tubing is made by continuously roll-forming a strip of steel into a tube and welding the butt joint of the strip together. For wall thicknesses up to 0.125 in. (3.18 mm), the welding process most commonly used is gas tungsten arc (GTA). Since no filler wire is used, welding characteristics of the steel are determined completely by its composition. The two welding characteristics of particular concern to tubemakers are penetration and slagging. Poor penetration characteristics limit welding speed and, therefore, have an adverse effect on the economics of the tubemaking operation. In extreme cases, they can result in material that is unweldable because there is essentially no difference between the current required for full penetration and that which causes excessive melt through. The second problem, slag formation, is covered in Part II.

The problem of heat-to-heat variations in the penetration characteristics of stainless steel was first reported in the literature by Oyler, et al. (Ref. 1), in 1967. However, it was not until 1975 that it became a major problem for steelmakers. At that time, steelmakers noticed a significant increase in the number of complaints from tube-making customers regarding the poor penetration characteristics of 300 Series stainless steels. There were two reasons for these complaints: first, many tube mills had installed new high-speed welding lines, which required steel with improved penetration characteristics in order to exploit the higher welding speeds which the equipment was capable of; and second, the argon-oxygen decarburization (AOD) process was rapidly replacing the electric furnace (EF) for refining stainless steel. The most obvious difference between AOD and EF steel is the oxygen content, which typically averages about 60 ppm for AOD steel versus 120 ppm for EF steel. Therefore, poor penetration was originally attributed to the low oxygen

202-s | SEPTEMBER 1988

content of AOD steel (Ref. 2). Evidence for the beneficial effect of oxygen was provided by the results of other investigators who showed that oxygen present as an oxide film improved penetration (Refs. 3, 4). However, laboratory welding tests and customer experience revealed that, although on average EF steel exhibited slightly better penetration than AOD steel, there were wide variations in penetration for steel produced by either process. Low penetration was found to be associated with the presence of strong deoxidants, specifically aluminum, magnesium, cerium and calcium (Refs. 5, 6). If oxygen increases penetration, then it is to be expected that strong deoxidants will reduce penetration. Of the foremen-tioned deoxidants, only aluminum has been widely used in stainless steel. It is sometimes added to the desulfurization mix to facilitate the removal of sulfur by the reaction

3 (CaO)s 4- 2 [AI]M + 3 [5]*,— 3 (CaS)s + (Al203)s (1)

Low penetration was found to be associated with high-aluminum residuals, i.e., aluminum contents up to 0.030%. To prevent high-aluminum levels in steel for tubing applications, aluminum additions were prohibited and penetration was generally found to be satisfactory when the aluminum content did not exceed

low-sulfur heats, which were solved by increasing the sulfur content to 0.015%. The adverse effect of aluminum and the beneficial effect of sulfur on weld penetration have been confirmed by more recent studies (Refs. 7-9). Unfortunately, although high-sulfur contents result in good penetration characteristics, they have an adverse effect on the hot workability, cold formability and pitting corrosion resistance of stainless steel. Therefore, the present practice at LTV Steel Specialty Products Co.1 for common grades of stainless steels, such as Types 304 and 316 and their low-carbon equivalents, is to produce both a regular quality grade, which may be low-sulfur if desired, and a tubing quality grade in which maximum aluminum and minimum sulfur contents are specified so as to ensure good welding characteristics.

Recently, questions about the effect of composition on the welding characteristics of stainless steel have again been raised. The reasons for this resurgence in interest are primarily economic. First, a significant reduction in inventory cost could be achieved by combining regular and tubing grades; and second, an improvement in the hot workability of difficult-to-roll grades such as Type 316, which would reduce surface defects and increase yields, could be obtained by

going to lower sulfur contents if this could be done without sacrificing weldability.

In order to determine if it were possible to produce low-sulfur steel with good penetration characteristics, a better understanding of the interaction between the surface active elements oxygen and sulfur, and the deoxidants aluminum, silicon and manganese was required. Optimum manganese and silicon contents were suggested by Oyler, et al. (Ref. 1), but no data were provided to support their recommendations. A systematic study was, therefore, made of the effects of aluminum, sulfur, silicon and manganese on the welding characteristics of Type 304 stainless steel using laboratory heats in which one element at a time was varied. The effects of phosphorus, molybdenum and copper additions in amounts typical of those found in production heats were also investigated. The results of this study were then compared with penetration data for production heats of Types 304 and 316 stainless steel.

Experimental Procedure

Material

tion problems were still e

Table 1 -

Heat . No.

V154 1329 1330 1331 1332 1333 V155 1334 V156 1335 1336 1337 1338 1339 1340 1341 1342 1343 1344 1345 1346 1347 1348 1349 1350 1509 1510 1511 1512 1513

xper ienced w i t h 7. Now l&L Specialty

-Compositions and Penetration Ratios for Laboratory

C

0.040 0.034 0.044 0.038 0.037 0.033 0.038 0.015 0.035 0.026 0.046 0.042 0.035 0.045 0.044 0.040 0.043 0.037 0.034 0.040 0.041 0.037 0.035 0.035 0.045 0.072 0.065 0.060 0.065 0.060

Mn

0.050 0.12 0.50 0.96 1.38 2.02 1.41 1.46 1.47 1.45 1.48 1.42 1.54 1.43 1.44 1.46 1.46 1.49 1.44 1.48 1.53 1.47 1.55 1.56 1.52 1.42 1.41 1.45 1.47 1.44

Si

0.50 0.47 0.49 0.49 0.47 0.50 0.01 0.05 0.22 0.26 0.73 0.92 0.49 0.51 0.50 0.49 0.49 0.50 0.50 0.48 0.50 0.49 0.53 0.52 0.52 0.46 0.44 0.46 0.47 0.45

S

0.014 0.009 0.013 0.013 0.014 0.013 0.014 0.012 0.015 0.014 0.014 0.012 0.004 0.007 0.010 0.017 0.026 0.014 0.014 0.014 0.014 0.014 0.013 0.016 0.015 0.005 0.007 0.014 0.028 0.052

P

0.016 0.012 0.014 0.014 0.013 0.014 0.015 0.013 0.017 0.014 0.015 0.013 0.014 0.013 0.014 0.014 0.014 0.005 0.005 0.019 0.014 0.014 0.014 0.016 0.013 0.023 0.023 0.024 0.024 0.022

Heats

'ercent

Cr

18.79 18.92 18.93 19.09 18.95 17.28 18.78 19.09 18.75 19.04 19.19 19.08 17.66 19.10 18.95 18.88 19.00 18.98 18.80 18.85 18.96 18.90 16.95 18.80 19.00 18.52 18.75 18.51 18.56 18.48

Products Co

Ni

8.50 8.39 8.57 8.60 8.51 8.79 8.37 8.59 8.35 8.82 8.74 8.52 9.26 8.55 8.60 8.53 8.55 8.58 8.40 8.65 8.68 8.60 8.75 8.74 8.43 8.44 8.47 8.49 8.46 8.46

Mo

0.01 0.01 0.02 0.03 0.03 0.04 0.01 0.04 0.01 0.04 0.04 0.03 0.03 0.03 0.03 0.03 0.03 0.02 0.03 0.03 0.03 0.03 0.03 0.44 0.03 0.02 0.03 0.03 0.03 0.03

Cu

0.05 0.04 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.45 0.05 0.05 0.05 0.05 0.05

ingots we re

Al

0.001 0.005 0.002 0.001 0.001 0.001 0.001 0.001 0.001 0.005 0.001 0.001 0.002 0.004 0.009 0.002 0.010 0.004 0.001 0.002 0.010 0.015 0.031 0.001 0.002 0.019 0.029 0.040 0.033 0.021

made

N

0.024 0.018 0.018 0.024 0.024 0.015 0.024 0.034 0.025 0.033 0.019 0.018 0.014 0.024 0.023 0.055 0.052 0.029 0.029 0.014 0.049 0.015 0.033 0.029 0.010 0.065 0.072 0.075 0.73 0.076

w i t h the

O, ppm

194 178 159 195 152 158 197 160 206 183 151 149 156 194 132 166 121 160 125 164 174 156 74

174 197 68 88 73 52 75

a luminum,

D / W

0.472 0.493 0.551 0.542 0.549 0.508 0.423 0.418 0.475 0.440 0.525 0.477 0.546 0.528 0.432 0.533 0.491 0.533 0.535 0.537 0.473 0.460 0.455 0.533 0.543 0.383 0.384 0.415 0.528 0.510

WELDING RESEARCH SUPPLEMENT 1203-s

Table 2 -

Heat No

70024 71261 93504 70002 70030 70037 70069 70097 70099 70919 71028 71030 803175 894104 91776

Compositions and Penetration Ratios for Types

Grade

304L 304L 304L 304 304 304 304 304 304 304 304 304 304 304 304

Thickness

in. mm

0.108 0.064 0.061 0.063 0.071 0.032 0.052 0.050 0.108 0.027 0.060 0.060 0.046 0.046 0.058

2.74 1.63 1.55 1.60 1.80 0.81 1.32 1.27 2.74 0.69 1.52 1.52 1.17 1.17 1.47

C

0.023 0.026 0.022 0.051 0.070 0.063 0.055 0.055 0.054 0.044 0.049 0.036 0.050 0.034 0.036

Mn

1.66 1.63 1.72 1.60 1.66 1.67 1.67 1.68 1.75 1.64 1.70 1.67 1.87 1.84 1.61

Si

0.54 0.56 0.69 0.52 0.55 0.57 0.43 0.49 0.52 0.68 0.66 0.61 0.57 0.57 0.61

S

0.023 0.010 0.021 0.017 0.004 0.003 0.018 0.017 0.014 0.002 0.022 0.015 0.025 0.019 0.019

304 and 304L Production Heats

P

0.028 0.029 0.032 0.030 0.025 0.026 0.027 0.030 0.027 0.024 0.026 0.025 0.034 0.034 0.035

Percent

Cr

18.37 18.40 18.19 18.32 18.38 18.35 18.39 18.26 18.31 18.22 18.34 18.32 18.21 18.42 18.13

Ni

8.97 8.88 8.97 8.14 8.92 9.08 8.60 8.18 8.15 8.92 8.17 8.14 8.24 8.28 8.28

Mo

0.35 0.23 0.25 0.18 0.16 0.16 0.16 0.15 0.20 0.20 0.18 0.15 0.35 0.30 0.25

Cu

0.41 0.35 0.38 0.19 0.19 0.25 0.22 0.23 0.21 0.36 0.30 0.19 0.37 0.33 0.32

Al

0.001 0.001 0.001 0.003 0.003 0.001 0.001 0.003 0.004 0.004 0.003 0.003 0.001 0.001 0.003

Ti

ND ND

0.006 ND ND ND ND ND ND ND ND ND

0.007 0.007 ND

N

0.090 0.079 0.091 0.090 0.048 0.039 0.050 0.078 0.084 0.037 0.079 0.078 0.061 0.072 0.080

O, ppm

ND 64 57 ND ND ND ND ND ND ND ND ND 36 37 92

D / W

Measured

0.457 0.367 0.480 0.408 0.401 0.380 0.450 0.530 0.415 0.403 0.456 0.433 0.472 0.473 0.496

Corrected

0.501 0.371 0.481 0.411 0.411 0.354 0.443 0.521 0.459 0.373 0.456 0.433 0.459 0.460 0.494

sulfur, silicon, manganese and phosphorus contents varied within the following ranges: aluminum 0 to 0.03%, sulfur 0 to 0.05%, silicon 0 to 1.0%, manganese 0 to 2.0% and phosphorus 0 to 0.020%. Also, one heat was made with an addition of 0.5% molybdenum and one with an addition of 0.5% copper, which are typical maximum values for these elements in Type 304 stainless steel. The compositions of the laboratory heats are presented in Table 1. All material was made into 0.060-in. (1.52-mm) thick annealed and pickled strip using standard processing procedures for Type 304 stainless steel.

Production material for weldability studies was obtained in the annealed and pickled condition in thicknesses of 0.020 to 0.110 in. (0.51 to 2.79 mm), depending on availability. The compositions of the production heats are presented in Tables 2 and 3.

Penetration Measurements

Welding tests were performed on strips of metal approximately 13 in. long X 1.5 in. wide (33 mm X 3.8 mm), which were washed with mineral spirits, followed by acetone, before testing. The test specimens were held in a Jetline longitudinal positioner with a copper backing bar containing a 0.50-in. wide X 0.25-in. deep (12.7-mm X 6.4-mm) groove, and weld penetration was measured using a variable current technique and the welding conditions listed in Table 4. After striking the arc at a current level well below that required to penetrate the strip, the current was continuously increased at a rate of 6 A/s to a value above that required for full penetration before the arc was extinguished. The bead width was then measured at the point where the weld bead just penetrated the underside of the material

and the penetration ratio, D /W, was defined as the ratio of the strip thickness to the bead width.

The ratio D /W varies with welding conditions as well as steel composition, and the choice of welding conditions under which D / W measurements are made is somewhat arbitrary. D / W increases with welding current to a maximum value when the weld just penetrates the underside of the strip. The D / W measurements were made at this current level, because measurements made under these conditions should relate more closely to the situation in an actual welding operation than those made at lower current levels. As noted previously, the D / W measurements on laboratory process material were made at a fixed strip thickness.

Tests on various thicknesses of strip made from the same heat of Type 304 stainless steel showed that D / W

Table 3 -

Heat No

70008 70143 70411 90587 91711 91716 91804 91958 92131 70248 90291 90448 90532 90591 90690 91712 91715 91717 91992 92132

SS

Compositions and Penetration Ratios for Types 316 and 316L Production Heats

Grade

316L 316L 316L 316L 316L 316L 316L 316L 316L 316 316 316 316 316 316 316 316 316 316 316 316

Thickness

in. mm

0.077 0.075 0.102 0.036 0.062 0.063 0.062 0.060 0.060 0.105 0.036 0.112 0.060 0.103 0.106 0.062 0.062 0.061 0.060 0.060 0.117

1.96 1.91 2.59 0.91 1.57 1.60 1.57 1.52 1.52 2.67 0.91 2.84 1.52 2.62 2.69 1.57 1.57 1.55 1.52 1.52 2.97

C

0.022 0.015 0.018 0.015 0.020 0.018 0.015 0.017 0.022 0.063 0.048 0.058 0.053 0.037 0.042 0.057 0.049 0.049 0.046 0.059 0.065

Mn

1.75 1.78 1.68 1.82 1.72 1.68 1.67 1.70 1.66 1.46 1.54 1.57 1.56 1.60 1.59 1.62 1.68 1.67 1.71 1.72 1.10

Si

0.45 0.62 0.67 0.59 0.50 0.60 0.54 0.46 0.60 0.55 0.61 0.63 0.70 0.62 0.69 0.52 0.69 0.67 0.54 0.68 0.61

S

0.017 0.016 0.016 0.010 0.005 0.007 0.007 0.006 0.007 0.025 0.023 0.017 0.015 0.018 0.004 0.003 0.004 0.010 0.008 0.001 0.002

P

0.021 0.027 0.024 0.026 0.027 0.027 0.034 0.031 0.029 0.028 0.025 0.024 0.024 0.026 0.026 0.025 0.028 0.028 0.042 0.031 0.028

Percent

Cr

17.00 16.74 17.55 16.34 17.33 16.69 16.75 16.67 16.48 16.77 16.99 16.79 16.77 16.28 16.33 16.79 16.98 16.70 16.84 16.78 16.77

Ni

10.37 10.24 12.58 11.02 11.24 11.05 11.07 11.05 11.16 10.22 10.36 10.35 10.90 10.92 10.95 10.79 11.11 11.06 10.90 11.07 10.26

Mo

2.08 2.14 2.66 2.12 2.32 2.14 2.03 2.06 2.10 2.07 2.10 2.10 2.12 2.05 2.11 2.03 2.09 2.10 2.06 2.17 1.99

Cu

0.16 0.37 0.31 0.30 0.30 0.32 0.31 0.27 0.37 0.56 0.24 0.29 0.65 0.33 0.30 0.30 0.31 0.32 0.49 0.24 0.28

Al

0.001 0.005 0.001 0.004 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.001 0.002 0.001 0.001 0.001 0.001 0.001 0.001 0.001

Ti

ND 0.007 ND

0.016 0.009 0.009 0.010 0.008 0.008 0.005 0.006 0.018 0.012 0.008 0.014 0.010 0.010 0.010 0.008 0.012 0.008

N

0.084 0.068 0.061 0.017 0.072 0.025 0.040 0.026 0.037 0.045 0.036 0.037 0.014 0.014 0.020 0.030 0.029 0.035 0.043 0.029 0.017

O, ppm

ND ND ND ND 78 ND ND ND ND ND ND ND ND ND ND 64 ND ND ND ND ND

D / W

Measured

0.396 0.376 0.390 0.447 0.346 0.364 0.362 0.360 0.358 0.442 0.455 0.451 0.422 0.413 0.360 0.437 0.377 0.447 0.434 0.391 0.381

Corrected

0.412 0.390 0.429 0.425 0.348 0.367 0.364 0.360 0.358 0.483 0.433 0.499 0.422 0.453 0.400 0.439 0.379 0.448 0.434 0.391 0.433

204-s I SEPTEMBER 1988

Table 4—Welding Conditions

Process Nozzle diameter Shielding gas Backing gas Electrode

Arc length Current

Welding speed

Gas tungsten arc 0.50 in. (12.7 mm) 25 cfh (11.8 L/min) argon 25 cfh (11.8 L/min) argon Tungsten —2% thoria,

0.125 in. (3.18 mm) diameter, 60-deg point

0.10 in. (2.54 mm) 90 to 140 A for full

penetration 20 ipm (0.85 cm/s)

decreased with increasing strip thickness—Fig. 1. The slope of the curve for the welding conditions used was —0.92 i n . - 1 (—2.34 cm - 1 ) , and this value was used to correct the D / W values for specimens of production material to a common thickness of 0.060 in. (1.52 mm).

Oxygen Content

Although oxygen content was not varied systematically, measurements of oxygen content were required to explain the difference in penetration characteristics between laboratory and production heats.

The oxygen contents of the strip were measured instead of the oxygen contents of the welds because prior experience had indicated little difference between base metal and weld oxygen contents. Moreover, weld oxygen contents are more difficult to measure accurately because of inhomogeneous distribution of slag particles within the welds.

Since some oxygen present in the steel as inclusion is lost as slag that floats to the weld surface, base metal content may, in fact, be a more appropriate value to use than weld metal oxygen content. The latter is characteristic of the weld after it has solidified, while the penetration characteristics of the weld are determined by the oxygen content of the molten metal during weld pool formation.

It seems evident that significant oxidation of the weld pool by the air during the formation of the weld did not occur, because the compositions of the slags were consistent with their formation from inclusions in the steel. For example, a slag with a high-calcium content could not have been formed by air reacting with the weld pool, because essentially all of the very low calcium content of the steel was already present as oxide.

Results

Laboratory Heats

Penetration results for the laboratory heats are presented in Table 1. Penetration ratios for heats containing 1.5% man-

0.70 r—

0.60

0.50

0.40

0.30

* * 1 1 _

HEAT 36I96

-col

- o-

A SLOPE =-0.92

0 .020 .040 .060 .080 .100

THICKNESS, INCHES Fig. 1 —Effect of strip thickness on the penetration ratio, D/W

. 1 2 0

ganese, 0.5% silicon and 0.014% sulfur decreased 14% for an increase in aluminum content from 0.001 to 0.015%, but only an additional 1% for a further increase to 0.031 % — Fig. 2. It is significant that most of the change in the penetration ratio occurred at aluminum contents of less than 0.010%, which had little effect on the measured oxygen content (Fig. 3); and conversely, aluminum contents of 0.010 to 0.031%, which had little effect on penetration, significantly reduced the measured oxygen content. These results indicate that it is the amount of oxygen in solution in the molten steel rather than the total oxygen content that affects penetration.

The effect of sulfur content on penetration for heats containing 1.5% manga-

0.60

nese and 0.5% silicon was found to depend on the aluminum content —Fig. 4. Sulfur content had no effect on penetration for heats containing no more than 0.004% aluminum. In contrast, penetration ratios for heats containing 0.02 to 0.04% aluminum increased with an increase in the sulfur content up to 0.028%, beyond which a further increase to 0.052% had no further effect on penetration. At the 0.005% sulfur level, 0.02% aluminum reduced penetration by 31.5%. Two heats which contained 0.009 and 0.010% aluminum had similar D / W values as the heats containing 0.02 to 0.04% aluminum, which again emphasizes the fact that to obtain maximum penetration the aluminum content must be tightly controlled, preferably to a level

V 0.50 Q

0.40 0 .005 .010 .015 .020 .025 .030

WT % ALUMINUM Fig. 2—Effect of aluminum content on penetration

. 0 3 5

WELDINC RESEARCH SUPPLEMENT I 205-s

*t(JU

300

Z 200 a. c a.

m

5 IOO «> 80

X 60 O

40

30

on

k~ -o-_ 1 3 — — - c 3 — —*

— ' • — « ^ ^

o

1 1

\ v \ ~ ^w c s Q > o

\ "^ > V s

1

.001 (10)

.002 .004.006 .010 .020 .040.060 .100 (100) (1000)

WT% ALUMINUM.(PPM) Fig. 3 - Effect of aluminum content on the oxygen content of the laboratory heats

of not more than 0.005%. The effects of silicon on penetration

for heats containing 1.5% manganese and 0.014% sulfur appear to be more complex than those of aluminum and sulfur, since penetration first increased with silicon additions up to about 0.50% and then decreased with further additions up to 0.92% —Fig. 5. The increase in penetration associated with a 0.50% silicon addition to a silicon-free heat was about 30%.

The effect of manganese on penetration for heats containing 0.50% silicon and 0.014% sulfur was similar to that of silicon. Penetration increased with the addition of manganese to a maximum value at about 0.80% manganese,

0.60

beyond which further manganese additions reduced penetration slightly —Fig 6. The increase in penetration associated with a 0.80% addition to a manganese-free heat was about 20%.

Phosphorus contents in the range 0.005 to 0.019% had no effect on penetration for heats containing 1.5% manganese, 0.5% silicon and 0.014% sulfur - Fig. 7. Likewise, additions of 0.5% molybdenum or 0.5% copper had negligible effect on penetration —Table 1.

Production Heats

Penetration test results for production heats of Types 304 and 304L stainless steel are presented in Table 2, and those

0.55

0.50

0.35

0.30

o o

1

/

o o

i

D

/ •

WT % O 0.004 °>

• 0 .009-

1

&l '.MAX

0.010

1 1

D

1 .010 .020 .030 .040 .050 .060

WT % SULPHUR Fig. 4 —Effect of sulfur content on penetration

for Types 316 and 316L in Table 3. No difference in penetration was found between production heats of Types 304 and 304L stainless steels containing less than 0.004% aluminum, which both had lower penetration ratios than the best laboratory heats —Fig. 8. Penetration increased with increasing sulfur content, but was not quite equal to the laboratory heats even at the 0.020% sulfur level.

The Types 316 and 316L heats had similar penetration ratios to the Types 304 and 304L heats. However, on average the penetration ratio was about 14% higher for the Type 316 than for the Type 316L heats —Fig. 9. The penetration ratios for the Types 316 and 316L production heats also increased with increasing sulfur content, but, like the 304 and 304L heats, none had penetration ratios equal to the best laboratory heats.

Discussion

Penetration Mechanism

Various mechanisms have been proposed to explain the effect of small variations in composition on the penetration characteristics of stainless steels and other metals. In general, these mechanisms can be divided into three groups: those that involve changes in arc characteristics (Refs. 5, 7, 10-12), such as the size of the anode spot (Ref. 10) or the anode drop voltage (Ref. 12); those that involve changes in the liquid-gas or liquid-solid interfacial tensions (Refs. 13-18); and those that depend on changes in the pattern of fluid flow in the weld pool (Refs. 9, 19).

The circulation of molten metal within the weld pool may be a result of magne-tohydrodynamic flow (Refs. 20, 21) or surface tension driven fluid flow (Ref. 9), otherwise known as Marangoni convection, or a combination of both processes. At the current levels typical of most GTA welding, Marangoni convection appears to be the dominant driving force, and the surface tension driven fluid flow model proposed by Heiple, ef al. (Ref. 9), best explains the effects of very small amounts of elements such as sulfur and aluminum on penetration. The basis of the phenomenon of surface tension driven fluid flow is that at the surface of the weld pool molten metal is pulled from a region of low surface tension to one of high surface tension, and molten metal flows upwards from the depths of the pool to maintain continuity —Fig. 10. If the temperature coefficient of surface tension is positive, then the hot metal immediately beneath the arc is drawn down into the depths of the pool, producing deep penetration. Conversely, if the temperature coefficient of surface tension is negative, then the hot metal immediately beneath the arc flows outward to the edges of the

206-s I SEPTEMBER 1988

pool, thereby widening the weld pool and producing shallow penetration. The temperature coefficients of surface tension for pure metals are negative (Ref. 22) and the beneficial effects of surface active elements such as sulfur and oxygen on weld penetration are believed to be due to the fact that they produce positive temperature coefficients of surface tension (Refs. 9, 23). A mathematical model for convection in weld pools developed by Oreper, et al. (Ref. 24), is in good agreement with the Heiple, et al. model, particularly in regard to the effect of the temperature coefficient of surface tension on the direction of fluid flow within the weld pool.

Effects of Sulfur and Aluminum

The results obtained in this investigation for the effects of sulfur and aluminum on weld penetration are in complete agreement with the Heiple, et al. theory that surface tension driven fluid flow is the dominant driving force for metal circulation within the weld pool. As explained previously, the positive effect of sulfur on penetration is due to the fact that it produces a positive temperature coefficient of surface tension, while the negative effect of aluminum is due to it combining with the oxygen, thereby reducing the soluble oxygen content of the molten metal and producing a negative temperature coefficient of surface tension.

Effects of Silicon and Manganese

The results for silicon and manganese additions to Type 304 stainless steel both showed penetration increasing up to a maximum value beyond which further additions of either element caused a reduction in penetration. These results are not inconsistent with the surface tension driven fluid flow model, but they do indicate that other factors besides the temperature coefficient of surface tension must be taken into account. Silicon is a moderately strong deoxidant, and its addition to a steel that does not contain any stronger deoxidants must lower the soluble oxygen content of the weld pool. However, the laboratory heats contained 0.014% sulfur, which was apparently sufficient to produce a positive temperature coefficient of surface tension and a downward movement of the hot metal at the center of the weld pool. The beneficial effect of the initial silicon addition was most likely due to it reducing the viscosity of the molten steel (Ref. 25). If a downward flow pattern already existed because of the 0.014% sulfur content, then a reduction in the viscosity of the molten steel would increase the flow velocity and hence increase penetration. However, with increasing silicon additions, a point was eventually reached

0.60

0.50

0.40

U?f--y 0 . 2 0 . 4 0 . 6 0 .8 I.O

W T % SILICON

Fig. 5 —Effect of silicon content on penetration

0.60

0.50

0.40

p

0.50 I.O 1.5 2 . 0 2 . 5

WT % MANGANESE Fig. 6 — Effect of manganese content on penetration

where the soluble oxygen content became the dominant factor, the temperature coefficient of surface tension was reduced sufficiently to more than offset any further decrease in viscosity by the silicon and penetration subsequently decreased.

The same explanation cannot be used for the initial increase in penetration observed with manganese additions to laboratory heats containing 0.5% silicon and 0.014% sulfur, since manganese additions up to 1.0% have little effect on the viscosity of iron (Ref. 26). A more likely explanation for the beneficial effect of a 0.5% manganese addition on penetration is that it drastically changes the nature of the slag formed on the surface of the

weld pool. The patch-type slag formed on the manganese-free heat produced a puckered surface on the weld bead, which was not observed with any other heat. This puckered surface suggests a high slag-metal interfacial tension, which, although not itself detrimental to penetration, may also be associated with a reduction in the temperature coefficient of surface tension.

Effects of Phosphorus, Molybdenum and Copper

Additions of 0.005 to 0.019% phosphorus, 0.5% molybdenum or 0.5% copper had no effect on penetration. This is not surprising since there is no evidence

WELDING RESEARCH SUPPLEMENT 1207-s

to indicate that these elements are surface active, interact in any way with surface active elements, or have a significant effect on viscosity at the levels added.

Production Heats

The results of tests on the laboratory heats suggested that good penetration characteristics could be obtained with low-sulfur steel by simply limiting the aluminum content. However, tests on production material with aluminum contents in the range of 0.001 to 0.003% showed penetration ratios that were significantly lower than those obtained with

0 .6

the laboratory heats, not only at low-sulfur contents, but also to a lesser extent at high-sulfur levels —Figs. 8 and 9. The most likely reason for the difference in penetration characteristics between the laboratory and production heats was oxygen content, which was only 40 to 80 ppm for the production heats versus 150 to 200 ppm for the laboratory heats.

Increasing penetration by increasing the oxygen content of the steel is not a practical means of compensating for a low-sulfur content because it would result in low chromium recoveries, poor surface quality and increased slagging. Penetration can be increased by adding oxygen (Refs. 2, 27) or sulfur dioxide (Ref.

V . Q

0 .5

0 .4

—

—

<s> o

cT

. 0 0 4 . 0 0 8 .012 .016

WT % PHOSPHORUS

. 020

Fig. 7—Effect of phosphorus content on penetration

.60

.50

.40

.30

.20

LAB HEATS 150 TO 200 PPM OXYGEN

O 304L • 304

4 0 TO 80 PPM OXYGEN 0 . 0 0 4 % MAX Al

.005 .010 .015 .020 .025 .030

WT% SULPHUR Fig. 8 — Effect of sulfur content on penetration for production heats of Types 304 and 304L stainless steels containing 0.004% maximum aluminum

28) to the shielding gas. However, the amount required is 500 to 1000 ppm, which is sufficient to cause accelerated electrode wear in production welding of tubing, where uninterrupted runs of one hour or more are normal practice. Also, sulfur dioxide is toxic and its use would create potential health and environmental problems. Therefore, oxygen or sulfur dioxide additions to the shielding gas are not likely to alleviate the need for adequate sulfur levels in stainless steel for welded tubing applications.

The optimum sulfur content is a tradeoff between weld penetration and other properties such as the hot workability of the steel and the cold formability of the finished tubing. For good penetration, not less than 0.010% and preferably 0.015% sulfur is recommended. A range of 0.005 to 0.010% sulfur will give improved hot workability and cold form-ability at the cost of some decrease in penetration, while less than 0.005% sulfur gives a significant improvement in the hot workability of difficult-to-work grades, such as Type 316, but penetration is generally only poor to fair. At the other end of the sulfur range, sulfur contents of up to 0.025% have been satisfactory for thin-walled tubing (e.g., 0.060 in./1.52 mm thick) not subject to severe forming operations. For heavy-wall tubing, too high a sulfur content can reduce the surface tension to the point where it cannot support the weld pool and excessive melt through occurs. For this type of application, sulfur content is usually limited to a maximum value of 0.015%.

With a sulfur content of 0.014%, the effect of aluminum on weld penetration was found to be greatest at aluminum contents below 0.010%-Fig. 2. With appropriate steelmaking practice, most heats contain less than 0.005% aluminum, but aluminum contents of 0.005 to 0.010% sometimes occur. A maximum aluminum content of 0.010% is, therefore, specified. This limit guarantees only slightly better penetration than would be obtained at higher aluminum contents, but prevents the formation of patch-type slags and uneven penetration, which will be discussed further in Part II of this paper.

Maximum penetration for the laboratory heats occurred with a silicon content of 0.50%, which is the same value that has been found in practice to provide good weldability with production material. With this silicon content, maximum penetration occurred at a manganese content of 0.80%. However, since manganese is an austenite former, it is used as a low-cost substitute for nickel, and the manganese content of production heats of Type 304 stainless steel is usually in the range 1.50 to 2.00%, the maximum value allowed by the AISI specification for this grade. Fortunately, the decrease in the

208-s I SEPTEMBER 1988

penetration ratio, D /W, attributable to the higher manganese content is only 4 to 9%.

Conclusions

1) The results of this investigation confirm that the effects of small amounts of sulfur, oxygen and aluminum on weld penetration in the GTA welding of stainless steels are due to their effects, either directly or indirectly, on the temperature coefficient of surface tension and the resultant pattern of surface tension driven fluid f low within the weld pool.

2) The effects of silicon and manganese on weld penetration are not inconsistent with the surface tension driven fluid flow model for penetration, but in the case of silicon, its effect on viscosity must also be taken into account.

3) Good penetration can be obtained with sulfur contents of less than 0.005% provided that sufficient oxygen is present. However, with oxygen contents typical of AOD steelmaking, there is a steady decrease in penetration with decreasing sulfur content when the latter is less than about 0.025%.

4) The optimum sulfur content is a trade-off between hot workability, weldability and formability requirements. For Type 304 stainless steel tubing, a sulfur content of 0.010 to 0.015% is a good compromise for most applications.

5) The effect of aluminum on penetration is greatest in the range 0 to 0.010%, so the aluminum content should preferably be limited to 0.005%, but steelmaking limitations dictate a more realistic limit of 0.010% maximum.

6) Phosphorus, molybdenum and copper, in amounts typical of those normally found in Type 304 stainless steel, have no effect on penetration.

Part II—Slagging Characteristics

Introduction

By comparison with the penetration problem, slag formation during the GTA welding of stainless steel has received much less attention. Nevertheless, excessive slag formation is particularly troublesome in automatic welding operations, such as making an autogenous weld in tubing, where it has been reported to cause arc instability, an irregular weld bead and reduced penetration (Refs. 6, 7, 29). Also, it can cause weld discontinuities during postweld rolling and drawing operations (Ref. 29).

Welding tests in an inert gas chamber have proved that the source of the slag is the steel and not oxidation due to incomplete shielding (Ref. 6). Slagging has been attributed primarily to high melting-point oxides, particularly the oxides of aluminum, calcium, magnesium, titanium, zirconium and cerium (Refs. 6, 7, 10, 29);

60

.50

.40

.30

.20

LAB HEATS I50 TO 200 PPM OXYGEN

0 3 I 6 L

• 3 I6

4 0 TO 80 PPM OXYGEN 0 . 0 0 4 % MAX Al

.005 .010 .015 .020 .025 .030

WT % SULPHUR Fig. 9 — Effect of sulfur content on penetration for production heats of Types 316 and 316L stainless steels containing 0.004% maximum aluminum

Fig. 10 —Effect of Marangoni convection on penetration

but silicon, chromium, manganese and iron have also been found in welding slags (Refs. 10, 29).

Although it is widely accepted that oxide inclusions in the steel are the source of the slag, a correlation between the compositions of the steel, the inclusions and the welding slag has not been established. The effect of slag characteristics on weldability in tubemaking also has not been adequately explained. Therefore, in order to determine how to minimize the effect of slagging, the

effects of minor elements on the slagging characteristics of both laboratory and production heats of 300 Series stainless steels were investigated.

Experimental Procedure

Specimens for slagging studies were made using the same specimen size, cleaning procedure and welding conditions as used in the penetration studies, except for the current level, which was constant and about 50 A above the

WELDING RESEARCH SUPPLEMENT 1209-s

Fig. 11 — Typical globular slag particle on a weld crater. 10X

current level required to just penetrate the strip. Slag particles formed on the top surface of the weld crater, sometimes on the underside of the weld crater, and on the top and bottom surfaces of the weld bead. These slag particles were examined visually and classified according to their appearance. They were basically two distinct types: more or less hemispherical-ly shaped globules, which were often glassy in appearance (Fig. 11), and thin patches-Fig. 12. In Fig. 12A, the patch-type slag is clearly visible as the comet-shaped gray area covering the weld crater and forming a tail downstream. The weld discontinuity in Fig. 12B is a hump on the underside of the weld bead caused by the slag patch. Specimens with attached slag particles were cut from the welds. Qualitative energy dispersive spectroscopic (EDS) analyses were then performed on the slag particles and on inclusions in polished longitudinal metallographic sections of the base metal.

The effect of slag on weld penetration was examined by measuring penetration, defined in this case as the ratio of the weld root width to the weld face width, at intervals along a weld.

Results

Laboratory Heats

As expected, the types of inclusions present in the laboratory heats and the resultant weld slag compositions were found to depend upon the manganese, silicon and aluminum contents of the steel-Table 5. With a %Mn/%Si ratio of 0.26 (Heat 1329), the inclusions were pure silica, but the slag contained primarily chromium oxide and only a small amount of silica. For heats with %Mn/ %Si ratios of 1.0, 2.0 to 2.9 and 4.0 to 5.6, the inclusions identified were 100% manganese chromium silicates, a mixture of manganese chromium silicates and chrome galaxites (Cr203-MnO), and 100% chrome galaxites, respectively, but all formed manganese chromium silicate slags. However, Heat 1334, which contained only 0.05% silicon, and hence chrome galaxite inclusions, formed a slag of essentially the same composition.

The majority of the inclusions in heats containing 0.010% or more aluminum were alumina, but manganese chromium aluminum oxides and manganese chromium silicates were also present. With these heats, alumina patch-type slags were formed on the top and bottom faces of the weld crater and the weld bead, but several small manganese chromium silicate globules containing varying amounts of aluminum were also observed on the rear half of the weld crater top surf ace — Table 5. The patch-type slag present on the top surface of the weld bead was extremely variable in composition. It contained chromium, aluminum and silicon, varying amounts of manganese and, with some heats, a small amount of calcium. The variable composition of this slag was due to the fact that it consisted of a mixture of the alumina and manganese chromium aluminum silicate slags in various proportions. In addition, the manganese content of the slag decreased with an increase in the aluminum content of the steel. The small amount of calcium present, which was not added intentionally and not identified in the inclusions, was probably from the furnace lining.

Fig. 12 — Typical patch-type slags on: A — the weld crater; B — the underside of the weld bead. 2X

Globular slags were formed when the %Si/%AI ratio was greater than about 50 and patch-type slags when it was less than 50. The only exceptions were heats that were very low in manganese (Heat 1329) or silicon (Heat 1334), which formed chromium-rich, patch-type slags even though they had %Si/%Al ratios of 94 and 50, respectively.

Production Heats

The compositions of the weld slags formed with production heats are in Table 6. They varied more widely than those formed with laboratory heats, even though their range of manganese, silicon and aluminum contents was more restricted. These slags contained as few as two or as many as six different oxides. Their wide range of compositions undoubtedly reflects differences in steelmaking practices since the samples were from many different sources. Another notable difference in regard to slag compositions between laboratory and production heats was the presence of significant amounts of calcium, from the lime used in steelmaking, in the latter.

The slags formed with production heats were classified on the basis of their appearance in the same manner as the slags formed with the laboratory heats. The high-silica slags generally formed distinct globules, whereas the high-alumina slags formed thin patches. However, there were a few exceptions, most noticeably the manganese chromium oxide and calcium titanium oxide slags, which were the patch type, and the calcium titanium aluminum oxide and calcium chromium aluminum oxide slags, which were the globular type —Table 6. As with the laboratory heats, globular slags were formed when the silicon-to-aluminum ratio was greater than 50 and patch-type slags when less than 50.

Effect of Slag on Weld Penetration

Globular slags had no significant effect on weld penetration. Yet, when a patch-type slag was present, although width of the weld face, Wp, was fairly constant, local increases in root width, W R , were observed — Fig. 13. This variation in penetration was more clearly shown by a plot of W R / W F versus distance along the weld. Penetration peaks were found to coincide with the locations of slag patches, which also produced humps on the surface of the weld bead.

Discussion

Slagging Mechanism

The results of this investigation confirm that the source of the slag formed in the GTA welding of stainless steels is primarily the oxide inclusions in the steel. A slag is

210-s I SEPTEMBER 1988

generated by the motion of molten metal in the weld pool transferring inclusions from the interior to the surface of the pool. Not all slag particles, however, remain on the surface of the weld pool. Some are subsequently swept back into the depths of the pool by the same forces that brought them to the surface. Nevertheless, in the process of making a long continuous weld, as in tubemaking, there is a net transfer of inclusions to the surface of the weld pool, and the slag particle formed increases in size until it is caught on the surface of the advancing weld bead. A new slag particle then begins to form, and the whole process is repeated.

The motion of inclusions within the weld pool is a combination of an upward motion resulting from buoyancy forces and the pattern of fluid flow established by Marangoni convection. Alumina slags were formed on both the top and bottom surfaces of the weld pool, which indicates that the effect of buoyancy forces on the alumina inclusions was

small. This result is a consequence of the high melting point of the alumina inclusions (2020°C/3668°F) (Ref. 30), which were solid in all regions of the weld pool except the hot zone immediately beneath the arc and, therefore, did not coalesce and grow to a size where the buoyancy force was significant. In contrast, silicate inclusions were found primarily on the top surface of the weld pool. Since most silicates have melting points in the range 1291° to 1723°C (2350° to 3133°F) (Ref. 30), they were molten in the weld pool and were able to coalesce and grow by collision with other inclusions until they attained a size such that the buoyancy force in combination with Marangoni convection propelled them to the surface of the weld pool.

Slag Composition

A comparison of inclusion and slag compositions for the laboratory heats (Table 5) showed that not all the heats had slag compositions similar enough to

the inclusion compositions for the slags to be considered simply as mixtures of all the inclusions in the steel. There are a number of possible explanations for differences between the slag and inclusion compositions. In most cases, the smallest inclusions analyzed were those visible at 500X magnification in an optical microscope, which was used to locate areas for subsequent EDS analysis in a scanning electron microscope. It is quite possible that smaller inclusions of different compositions could have been present in some specimens. However, although these inclusions might modify the slag composition to some extent, it is unlikely that they would be the major constituents of the slag when many larger inclusions were present.

A possible source of higher chromium contents in some slags, as compared to the inclusions from which they were formed, is the passive film present on the surface of stainless steel. However, this film is usually very thin and would only be significant in cases where the volume

Table 5—Inclusio

Heat No. Mn

1329 0.12

1330 0.50 1331 0.96

1332 1.38

1333 2.02 1334 1.46 1335 1.45 1336 1.48 1337 1.42 1346 1.53

1347 1.47

1348 1.55

Si

0.47

0.49 0.49

0.47

0.50 0.05 0.26 0.73 0.92 0.50

0.49

0.53

n and Slag Analyses for Laboratory Percent

Al Si/AI

0.005

0.002 0.001

0.001

0.001 0.001 0.005 0.001 0.001 0.010

0.015

0.031

94

245 490

470

500 50 52

730 920

50

32.7

17.1

Mn/Si

0.26

1.02 1.96

2.94

4.04 29.20

5.58 2.03 1.54 3.06

3.00

2.92

Elements

Major

Si

Mn, 1)Mn, 2 )Mn, 1)Mn, 2) Mn,

Mn, Mn, Mn, Mn, Mn,

1) Al

2) M a

1) Al

2) Al

3 )Mn,

1) Al

2 )Mn ,

Cr, Si Cr Cr, Si Cr Cr, Si Cr Cr Cr Cr, Si Cr, Si

Cr, Al

Cr, Si

Cr, Si

Heats in Inclusions

Minor

Si

Ti Ti,

Ti,

Ti, Ti, Ti, Ti, Ti,

Ti

Cr

Cr

Trace

Al,

Al,

Al, Al, Al. W Al

Si

Si

Si Si Si

Slag Location

Weld bead top surface

Crater top surface Crater top surface

Crater top surface

Crater top surface Crater top surface Crater top surface Crater top surface Crater top surface Crater top

surface, front Crater top

surface, rear Weld bead top

surface Crater bottom

surface Weld bead

bottom surface Crater top

surface, front Crater top

surface, rear Weld bead

top surface Crater bottom

surface Weld bead

bottom surface Crater top

surface, front Crater top

surface, rear Weld bead

top surface Crater bottom

surface Weld bead

bottom surface

Slag Type

Patch

Globular Globular

Globular

Globular Patch Globular Globular Globular Patch

Globular

Patch

Patch

Patch

Patch

Globular

Patch

Patch

Patch

Patch

Globular

Patch

Patch

Patch

Cr

Mn Mn

Mn

Mn Mn Mn Mn Si Al

Mn

1)Cr, 2 ) M n

Al

Al

Al

Mn

2) Al, 2)Cr,

Al

Al

Al

Mn

Cr,

Al

Al

Major

Cr, Cr,

Cr,

Cr, Cr Cr, Cr,

Cr,

Al Cr,

Cr,

Si Si

Si

Si

Si Si

Al,

Al,

Al,

Al, Si

Cr, Al,

Al, Si

Elements in

Si

Si

Si

Si

Si

Mn

Slag

Minor

Cr Si, Cr

Si Ca

Cr

Mn Cr, Ca

Ca,

Ca

Ca, Ca,

Al

Ti

Cr

Cr

Ca

Cr

Cr

Ca

Cr

Trace

Al

Al Al, Ti, Si

WELDING RESEARCH SUPPLEMENT!211-s

0 . 8

\ 0 . 6

CO UJ 0.4 X u

£ 0.2 f t

tx

o

HEAf 1348 ( 0 . 0 3 1 % A I ) ^ WELDING SPEED 3 0 " / M I N

SLAG PATCHES

4 6 8

DISTANCE, INCHES Fig. 13 — Effect of slag patches on weld penetration

f ract ion of ox ide inclusions was very l o w or w h e r e very f e w of t hem b e c o m e a part of the slag. Heat 1329 is a g o o d example of the latter si tuation.

M o r e f requent ly , the d i f ference in compos i t ion b e t w e e n the slag and inclusions consists o f the slag being richer in the m o r e stable oxides, such as those of calcium, a luminum, t i tanium and silicon, than the inclusions. The most likely reason for this d i f ference is the much higher temperatures that exist near the surface o f a w e l d p o o l , as c o m p a r e d to those encoun te red in steelmaking. H o w d e n and Mi lner est imated the ef fect ive react ion tempera tu re of the hot zone at the surface o f an i ron w e l d p o o l under an argon arc t o be 2100°C (3812°F) (Ref. 31). At this tempera ture , a d i f ferent equi l ibrium exists b e t w e e n metal and slag than that wh i ch existed at steelmaking temperatures o f about 1600°C (2912°F). This h igh- temperature equi l ibr ium favors the fo rmat ion o f the m o r e stable oxides. There fore , it is postulated that, p rov ided they are present in sufficient quantit ies, elements such as calcium, a luminum, t i tan ium and silicon will tend to reduce the less stable oxides, such as those of manganese and ch rom ium, dur ing slag fo rmat ion . The simplest examples o f we ld slags f o r m e d in this manner w e r e the laboratory Heats 1333 and 1335, wh i ch b o t h conta ined approx imate ly 0.5% silicon and f o r m e d manganese ch romium silicate slags a l though they conta ined only ch rome galaxite inclusions — Table 5. In contrast, laboratory Heat 1334, wh ich also conta ined ch rome galaxite inclusions, f o r m e d a manganese ch romium oxide slag of similar compos i t ion because it conta ined only 0.05% sil icon, wh ich was clearly insufficient t o reduce the ch rome galaxites. It is t o be expec ted that m o r e

complex slags f o r med in the same manner wi l l be richer in calcium, a luminum and t i tanium, and poo re r in manganese and ch rom ium than the inclusions in the steel. The results for the a luminum-containing laboratory heats show this t rend . Heats 1347 and 1348, wh i ch conta ined alumina and manganese ch romium silicate inclusions, f o r m e d a mixture o f alumina and manganese ch romium aluminum silicate slags, w i t h a luminum replacing part of the manganese and chromi um. Heat 1346, wh i ch conta ined only 0.010% a luminum, conta ined alumina and manganese ch romium aluminum oxide inclusions, but f o r med a mixture of alumina and manganese ch rom ium aluminum silicate slags. In this case, essentially all the a luminum was probab ly in the f o r m of oxide so that the next strongest deoxidiz

er, silicon, reduced part o f the manganese and ch romium oxides in the manganese ch romium aluminum oxide inclusions to f o r m a manganese ch romium aluminum silicate slag.

Slag Physical Characteristics

The mel t ing point and surface tension o f the mo l ten slag at temperatures just above the melt ing point of steel are clearly the t w o proper t ies wh ich most strongly inf luence the behavior of w e l d ing slags. High-silica slags typically have l o w melt ing points and high surface ten sions at temperatures close to the melt ing point of steel, so that they solidify as hemispherical ly shaped globules o n the we ld surface. In contrast, pure alumina slags have high melt ing points ( 2 0 2 0 ° C / 3668 CF), and on the b o t t o m of the w e l d and the outer regions o f the w e l d poo l surface, they f o r m patch- type slags, wh ich are actually rafts of solid alumina inclusions. Nevertheless, w h e n the slag patch on the surface of the w e l d poo l g rows to a size such that it covers most o f the w e l d poo l surface, the por t i on closest t o the center of the we ld poo l wi l l be mo l ten . H o w e v e r , since alumina slags apparent ly have lower surface tensions than high-silica slags, the solid and l iquid port ions o f the slag f o r m a cont inuous thin layer over the w e l d poo l surface. High-alumina slags contain ing o ther oxides have significantly l ower melt ing points than pure alumina, but f o r m patch-type slags, presumably because they also have l o w surface tension.

Effect of the Slag Type on the Weld Bead Geometry

O t h e r investigators have stated that w e l d slagging results in p o o r penetrat ion (Refs. 7 , 1 2 , 29). In this study, it was f o u n d that patch- type slags p r o d u c e d irregular

Table 6—Summary of Major Elements Found in Weld Slags Formed on Production Heats of Type 304 Stainless Steel

Patch Type Globular Type

Mn Ca, Ca, Ti, Mn

Mn

Ca.

Cr Al Ti M

Cr,

Cr,

Cr,

Al

Al

Al,

Si

Si

Mn, Si

Mn, Cr, Si M

Mn, Cr, Al, Si

Si Al •— Ca, Cr, Al, Si

Si Al

Ca, Mn, Cr, Al, Si -<— Ca, Mn, Cr, AI, Si

Ca, Mn, Cr, Ti, Al, Si Ca, Mn, Cr, Mg, Al, Si

Ca, Si Al, Si

Ca, Ti, Al

Ca, Mn, Si Ca, Al, Si Ca, Cr, Al

Ca, Mn, Cr, Si Ca, Mn, Al, Si

Ca, Cr, Ti, Si

212-s | SEPTEMBER 1 9 8 8

penetration with localized regions of high penetration occurring beneath slag patches. The apparent disagreement with other investigators is due to the fact that elements that cause poor penetration, e.g., aluminum and magnesium, are also major causes of slagging. A possible explanation for the effect of a patch-type slag on weld penetration is that it constricts the arc root so that magnetohydro-dynamic flow within the weld pool increases. When a slag patch is caught on the surface of the advancing weld bead, weld penetration abruptly decreases. However, a new slag patch soon starts to form, penetration increases and the whole cycle is repeated.

Patch-type slags also cause the formation of humps on the weld bead surface. These humps are due to the fact that, at temperatures just above the freezing point of the steel, the metal-slag interfacial tension is higher than the metal-gas interfacial tension.

Practical Significance of the Slag Type in Tubemaking

The results of this investigation have confirmed tubemill experience that patch-type slags are to be avoided because they produce an uneven weld bead and irregular penetration. It was also shown that in most cases globular instead of patch-type slags will be formed if the %Si/%AI ratio is greater than 50, i.e., if for a silicon content of 0.50% the aluminum content is less than 0.010%. Globular slags are generally less harmful than patch-type slags, except for critical applications such as dairy tubing. Some welding lines utilize rollers downstream from the arc to contour the weld while it is still hot. Slag globules are rolled into the weld surface and then etched out during pickling forming pits, which are unacceptable on dairy tubing since they are potential sites for the growth of bacteria. Although weld slagging cannot be completely eliminated, for this critical application it must be minimized by using clean steel and welding under conditions that produce a narrow weld bead, so that the volume of metal melted and hence the slag volume are held to a minimum.

Conclusions

1) Slag is formed in the CTA welding of stainless steel when oxide inclusions are transferred from the interior to the surface of the weld pool by a combination of buoyancy forces and Marangoni convection.

2) The composition of the slag is not always equivalent to a mixture of all the inclusions present in the steel because it tends to approach an equilibrium corresponding to temperatures near the surface of the weld pool, which are much higher than those encountered in steel

making. Provided that they are present in sufficient quantities, elements such as calcium, aluminum, titanium and silicon tend to reduce the less stable oxides, such as those of manganese and chromium, during slag formation.

3) Slags formed with production material contain from two to six oxides of calcium, aluminum, titanium, magnesium, silicon, manganese and chromium. However, in general, the slagging characteristics of stainless steel were found to be determined primarily by the ratio of silicon to aluminum in the steel. Patch-type slags were formed when % silicon/% aluminum was less than 50 and globular slags when it was greater than 50.

4) To prevent the formation of patch-type slags, which cause an uneven weld bead and irregular penetration, the aluminum content must not exceed 0.010% for a silicon content of 0.50%.

A ckno wledgments

The author wishes to thank D. ). Modrak for performing the welding and P. I. Henderson for the EDS analysis.

References

1. Oyler, G. E., Matuszesk, R. A., and Carr, C. R. 1967. Why some heats of stainless steel may not weld. Welding journal 46(12)4006-1011.

2. Willgoss, R. H., and Yeo, R. B. G. 1975. Union Carbide Corp., Linde Division, Research report.

3. Majetic, |. C , and Yeo, R. B. G. lune 8, 1971. Method of Welding Stainless Steel. U.S. Patent 3,584,187.

4. Bukarov, V. A., and Ishchenko, Yu. S. 1974. Melting of metal and seam formation in the welding of a steel of Type 18-8 with an oxidized surface. Welding Production 21(12): 22-25.

5. Bennett, W. S., and Mills, G. S. 1974. GTA weldability studies on high manganese stainless steel. Welding lournal 53(12):548-s to 553-s.

6. Franklin, I. E. June 25, 1975. Effects of Addition Alloys on the Weldability of 304 Stainless Steel. INCO Research report 600.5.

7. Metcalf, ]. C , and Quigley, M. B. C. 1977. Arc and pool instability in GTA welding. Welding lournal 56(5): 133-s to 139-s.

8. Heiple, C. R„ Cluley, R. ]., and Dixon, R. D. 1980. Effect of aluminum on CTA geometries in stainless steel. Physical Metallurgy of Metal joining. Eds. R. Kossowsky and M. E. Glicksman. The Metallurgical Society —AIME, Warrendale, Pa., pp. 160-165.

9. Heiple, C. R., and Roper, ]. R. 1982. Mechanism for minor element effect on GTA fusion zone geometry. Welding Journal 61(4): 97-s to 102-s.

10. Ludwig, H. C. 1968. Current density and anode spot size in the gas tungsten arc. Welding journal 47{5):234-s to 240-s.

11. Glickstein, S. S., and Yeniscavich, W. May 1977. A Review of Minor Element Effects on the Welding Arc and Weld Penetration. Welding Research Council Bulletin 226.

12. Savage, W. F., Nippes, E. F., and Goodwin, G. M. 1977. Effect of minor elements on fusion zone dimensions of Inconel® 600.

Welding lournal 56(4): 126-s to 132-s. 13. Hazlett, T. H., and Parker, E. R. 1956.

Effect of individual coating ingredients on surface tension of iron electrode. Welding journal 35(3):113-S to 114-s.

14. Bradstreet, B. |. 1968. Effect of surface tension and metal f low on weld bead formation. Welding journal 47(7):314-s to 322-s.

15. Ishizaki, K. 1966. Interfacial tension theory of arc welding phenomena — formation of welding bead. Welding Research Abroad 12(3):68-86.

16. Ishizaki, K. 1962. Interfacial tension theory of the phenomena of arc welding — mechanism of penetration. Physics of Welding Arc Symposium, The Welding Institute, Cambridge, U.K., pp. 195-209.

17. Roper, j . R., and Olson, D. L. 1978. Capillarity effects in the GTA weld penetration of 21-6-9 stainless steel. Welding journal 57(47): 104-s to 107-s.

18. Friedman, E. 1978. Analysis of weld puddle distortion and its effect on penetration. Welding lournal 57'(6): 161-s to 166-s.

19. Mills, G. S. 1977. Analysis of high manganese steel weldability problem. Welding lournal 56(6): 186-s to 188-s.

20. Woods, R. A., and Milner, D. R. 1971. Motion in the weld pool in arc welding. Welding lournal 50(4): 163-s to 173-s.

21. Willgoss, R. A. 1980. Electromagnetic control of fluid motion in TIG weld pools. Arc Physics and Weld Pool Behavior, The Welding Institute, Cambridge, U.K., Vol. 1, pp. 361-373.

22. Allen, B. C. 1972. The surface tension of liquid metals. Liquid Metals— Chemistry and Physics. Ed. S. Z. Beer, M. Dekker, Inc., New York, N.Y., pp. 161-212.

23. Keene, B. )., Mills, K. C , Bryant, I. W., and Hondros, E. D. 1982. Effects of interaction between surface active elements on the surface tension of iron. Canadian Metallurgical Quarterly 21(4):393-403.

24. Oreper, G. M., Eagar, T. W., and Szekely, ]. 1983. Convection in arc weld pools. Welding lournal b2(-}-\)-307-s to 312-s.

25. Romanov, A. A., and Kochegarov, V. G. 1964. Viscosity of binary iron-silicon melts in the low concentration range of the second component. Physics of Metals and Metallography 17(2):136-138.

26. Romanov, A. A., and Kochegarov, V. G. 1964. Viscosity of Fe-Mn, Fe-P, Fe-Cr, and Fe-V melts in the initial concentration range of the second component. Physics of Metals and Metallography 18(6):67-73.

27. Heiple, C. R„ Burgardt, P., and Roper, |. R. 1984. The effect of trace elements on GTA weld penetration. Modelling of Casting and Welding Processes II. Eds. |. A. Danzig and |. T. Berry. TMS-AIME, Warrendale, Pa., pp. 193-205.

28. Heiple, C. R., and Burgardt, P. 1985. Effects of SO2 shielding gas additions on GTA weld shape. Welding journal 64(6): 159-s to 162-s.

29. Linnert, G. F. 1967. Weldability of austenitic stainless steels as affected by residual elements. Effects of Residual Elements on Properties of Austenitic Stainless Steels, ASTM Symposium lune 1966. ASTM Pub. No. 418.

30 CRC Press, Inc. CRC Handbook of Chemistry and Physics, 60th Edition. Boca Raton, Fla. 1979-80.

31. Howden. D. G., and Milner, D. R. 1963. Hydrogen absorption in arc melting. British Welding lournal 42(6):304-316.

WELDING RESEARCH SUPPLEMENT I 213-s

WRC Bulletin 328 November 1987

This bulletin contains two reports covering related studies conducted at The University of Kansas Center for Research, Inc., on the CTOD testing of A36 steel.

Specimen Thickness Effects for Elastic-Plastic CTOD Toughness of an A36 Steel By G. W. Wellman, W. A. Sorem, R. H. Dodds, Jr., and S. T. Rolfe

This paper describes the results of an experimental and analytical study of the effect of specimen size on the fracture-toughness behavior of A36 steel.

An Analytical and Experimental Comparison of Rectangular and Square CTOD Fracture Specimens of an A36 Steel By W. A. Sorem, R. H. Dodds, Jr., and S. T. Rolfe

The objective of this study was to compare the CTOD fracture toughness results of square specimens with those of rectangular specimens, using equivalent crack depth ratios.

Publication of these reports was sponsored by the Subcommittee on Failure Modes in Pressure Vessel Materials of the Pressure Vessel Research Committee of the Welding Research Council. The price of WRC Bulletin 328 is $20.00 per copy, plus $5.00 for postage and handling. Orders should be sent with payment to the Welding Research Council, Suite 1301, 345 E. 47th St., New York, NY 10017.

WRC Bulletin 330 January 1988

This Bulletin contains two reports covering the properties of several constructional-steel weldments prepared with different welding procedures.

The Fracture Behavior of A588 Grade A and A572 Grade 50 Weldments By C. V. Robino, R. Varughese, A. W. Pense and R. C. Dias

An experimental study was conducted on ASTM A588 Grade A and ASTM A572 Grade 50 microalloyed steels submerged arc welded with Linde 40B weld metal to determine the fracture properties of base plates, weld metal and heat-affected zones. The effects of plate orientation, heat treatment, heat input, and postweld heat treatments on heat-affected zone toughness were included in the investigation.

Effects of Long-Time Postweld Heat Treatment on the Properties of Constructional-Steel Weldments By P. J. Konkol

To aid steel users in the selection of steel grades and fabrication procedures for structures subject to PWHT, seven representative carbon and high-strength low-alloy plate steels were welded by shielded metal arc welding and by submerged arc welding. The weldments were PWHT for various times up to 100 h at 1100°F (593°C) and 1200°F (649°C). The mechanical properties of the weldments were determined by means of base-metal tension tests, transverse-weld tension tests, HAZ hardness tests, and Charpy V-notch (CVN) impact tests of the base metal, HAZ and weld metal.

Publication of these reports was sponsored by the Subcommittee on Thermal and Mechanical Effects on Materials of the Welding Research Council. The price of WRC Bulletin 330 is $20.00 per copy, plus $5.00 for postage and handling. Orders should be sent with payment to the Welding Research Council, 345 E. 47th St., Suite 1301, New York, NY 10017.

214-s I SEPTEMBER 1988