The Challenge of Welding Jumbo Shapes -...

Transcript of The Challenge of Welding Jumbo Shapes -...

The Challenge of WeldingJumbo ShapesReprinted Articles from Welding Innovation Magazine

The James F. Lincoln Arc Welding Foundation

by Omer W. Blodgett, Sc.D., P.E. and Duane K. Miller, Sc.D., P.E.

2Welding Innovation Vol. X, No. 1, 1993

Australia and New ZealandRaymond K. RyanPhone: 61-29-772-7222Fax: 61-29-792-1387

CroatiaProf. Dr. Slobodan KraljPhone: 385-1-6168306Fax: 385-1-6157124

HungaryDr. Géza Gremsperger Phone: 361-156-3306

IndiaDr. V.R. KrishnanPhone: 91-11-247-5139Fax: 91-124-321985

JapanDr. Motoomi OgataPhone: 81-565-48-8121Fax: 81-565-48-0030

People’s Republic of ChinaDai Shu HuaPhone: 022-831-4170Fax: 022-831-4179

RussiaDr. Vladimir P. YatsenkoPhone: 07-095-238-5543Fax: 07-095-238-6934

United KingdomDr. Ralph B.G. YeoPhone & Fax:44-1709-379905

3 Part I: The AISC Specifications

6 Part II: Increasing Ductility of Connections

10 Part III: Case Study

12 Consider Welded Vs. Bolted Connections for Jumbo Sections

The serviceability of a prod-uct or structure utilizing thetype of information presentedherein is, and must be, thesole responsibility of thebuilder/user. Many variablesbeyond the control of TheJames F. Lincoln Arc WeldingFoundation or The LincolnElectric Company affect theresults obtained in applyingthis type of information.These variables include, butare not limited to, weldingprocedure, plate chemistryand temperature, weldmentdesign, fabrication methods,and service requirements.

INTERNATIONAL ASSISTANT SECRETARIES

Volume XNumber 1, 1993

EditorDuane K. Miller, Sc.D., P.E.

Assistant EditorR. Scott Funderburk

The James F. Lincoln Arc Welding Foundation

Omer W. Blodgett, Sc.D., P.E.Design Consultant

The Challenge of Welding Jumbo Shapes

Visit Welding Innovation online at http://www.lincolnelectric.com/innovate.htm

3 Welding Innovation Vol. X, No. 1, 1993

The Challenge of Welding Jumbo Shapes

Part I: The AISC SpecificationsBy Duane K. Miller, P.E.

Welding Design EngineerThe Lincoln Electric Company, Cleveland Ohio

IntroductionIn 1989, the American Institute of SteelConstruction developed specifications forwelding jumbo shapes. The next three arti-cles will review the AISC specifications, dis-cuss additional welding engineering principlesand structural details that will contribute to thesuccess of similar projects, and present acase study of a recent successful projectwhich utilized these principles extensively.

Special Problems ofWelding Jumbo ShapesDuring fabrication and erection of weldedassemblies that utilized Group 4 and 5shapes, commonly called “jumbo” sections,cracking problems were experienced on anumber of projects. Particularly alarmingwere complete, through-section cracks thatoccurred in the tension cords of large truss-es. The failures were classic brittle-type frac-tures that occurred in the complete absenceof service loads. The typical crack wouldbegin in the region of the weld access holeand propagate through the web, or theflange, or both. The fracture was usually inthe base metal, with the weld unaffected.Fortunately, since these incidents occurredduring construction, their impact was mini-mized. Nevertheless, these experiencescaused many engineers to look to alternatematerials or revert to bolted connectionswhen jumbo shapes were used.

Group 4 and 5 shapes are very heavy rolledsections that weigh up to 848 pounds per lin-ear foot (see Figure 1). During the initialsolidification of the ingot used to make theseshapes, it is possible for carbon and otheralloys to segregate, causing an enriched con-centration of elements in the center of theingot. Upon rolling, the outer surfaces of theshape being formed will be cooled by the millrolls and other external cooling methods. In

addition, the surfaces of the shape receivesignificant mechanical working, improving thetoughness of these surfaces, but the centerregion receives minimum mechanical work-ing. As shown in Figure 2, a “cast” structureis formed in the middle of the section whichmay exhibit poor notch toughness. Wherefailures have been experienced in the past,poor toughness in this region has been char-acteristic.

The greatest problems with welding on jumboshapes occurred when these materials, origi-nally contemplated for compression (or col-umn) applications, were used in tensionapplications. Since the failures occurredbefore the structures were subject to serviceloads, the difference was not inherent to theapplication, but rather to the type of welddetails used in the two types of applications.In primary tensile applications, CompleteJoint Penetration (CJP) groove welds typical-ly are required. For compression applica-tions, Partial Joint Penetration (PJP) groovewelds generally are sufficient. When CJPgroove welds are used, weld access holes(colloquially known as “rat holes”) arerequired. For PJP groove welds, they arenot. The presence or absence of weldaccess holes, and the difference in residualstresses experienced by CJP welds (whichhave greater weld metal volume than PJPgroove welds) explain the difference inbehavior between tension and compression

applications. The PJP groove weld may notintersect the as-cast core structure in thecenter of the section, while the weld accesshole used with CJPs automatically intrudesinto this region.

A common method of preparing the variousrolled sections for welding is to use the oxyfuel thermal cutting process, which generatesa change in microstructure. The surface maybe enriched in carbon content, and the hotsteel on the surface of the cut is rapidlycooled by the conduction of heat into the sur-rounding steel. As a result, a small, thinlayer of relatively hard, brittle microstructuremay form. Under some conditions, micro-cracks have resulted in this zone. Goodworkmanship is also required in this area. Insome cases, ragged edges resulted in crack-like notches in the weld access hole region.Further complicating the cutting process isthe semicircular nature of the weld accesshole, where good manual dexterity isrequired in order to create a uniform surface.Finally, as the cut approaches the region ofthe web-to-flange interface, the natural radiusthat occurs in rolled shapes makes precisecutting difficult. In many examples involvingfracture, poor workmanship resulted in inade-quate preparation of the weld access holes.

When welds cool from elevated tempera-tures, they must shrink in size due to thethermal contraction that takes place.

Figure 1. Group 4 and 5 shapes can weighup to 848 pounds per linear foot.

Figure 2. A “cast” structure is found in themiddle of the section.

Welding Innovation Vol. X, No. 1, 1993 4

As the hot, but already solidified, weld metalshrinks in size, it induces shrinkage strainson the surrounding materials. These strainsinduce stresses that cause localized yielding.As the weld metal cools to near-room tem-perature, the remaining strain may be insuffi-cient to cause yielding, but will result inresidual stresses that are present after weld-ing is complete. For example, a weld that isused to join flanges will establish a residualstress pattern that is transverse and longitu-dinal to the direction of welding. The webweld will similarly set up a longitudinal andtransverse shrinkage stress. Surrounding theregions of high residual tensile stress, therewill be a region of residual compressivestress. When weld access holes are small insize, the residual stresses from these twowelds can combine and develop into a triaxi-al state of stress. Under these conditions,the steel may be unable to exhibit its normalductility, although the same material underuniaxial conditions may behave in a veryductile fashion. The formation of this high tri-axial stress in the region of the web-to-flangeinterface is the driving force behind the initia-tion of these brittle cracks.

Figure 3 illustrates the interaction of weldtype (CJP vs. PJP), weld access holes, andthe cast core region. In the top figures, theCJP preparation automatically intersects theregion of the shape with questionablemicrostructure. For the PJP, the absence ofaccess holes, plus the reduced depth ofbevel, minimizes or eliminates the amount ofcore region that is intersected by the cuttingprocess. As a result, weld metal, and theshrinkage stress it will induce, does notdirectly act on the core region.

Fracture mechanics methods may be used todetermine the required notch toughness toprevent brittle fracture. In the case of thejumbo section failures, the cracks located inthe weld access holes were of sufficient size,and the residual stresses from welding of asufficient level, that they exceeded the resist-ing force, or the fracture toughness, of thebase material, particularly in the cast coreregion. To ensure reliable fabrication, theAISC Task Group addressed all three issues:notch toughness of the base material, qualityof the weld access holes, and a reduction inthe residual stresses developed by examin-ing the geometry of the weld access hole.

The AISC ResponseThe AISC task group set up to study thismatter established, and the SpecificationCommittee adopted, a series of controls topermit problem-free welding of jumbo sec-tions. These were initially published in 1989as Supplements 1 and 2 to the AISC SteelConstruction Manual. They have now beenincorporated into the ninth edition of the ASDManual. The first was a requirement that thebase metal exhibit a minimum notch tough-

ness of 20 foot-pounds at +70°F. It isrequired that the Charpy specimens be takenfrom the web-to-flange interface, the regionexpected to have the poorest toughness. Avariety of methods may be employed toimprove the notch toughness in this area,including the use of semi-killed steel, fine-grain practice, and special cooling tech-niques.

To provide additional resistance to crackingduring the thermal cutting of weld accessholes, the specification now requires a pre-heat of 150°F before the thermal cutting is tobe performed. This slows the cooling rateexperienced by the cut surface, providingincreased resistance to cracking. After ther-mal cutting, the surfaces must be ground tobright metal and inspected with either mag-netic particle testing (MT) or liquid penetranttesting (PT), further assuring smooth transi-tions that are free of notches and cracks.

In order to reduce the level of residual stress-es in the area of concern, specific minimumdimensional requirements were imposed onthe size and shape of the weld access holes.The minimum size for the width of the weldaccess hole is required to be 1.5 times thethickness of the web on either side of thejoint. The root opening and overall width ofthe weld joint further add to the width of theaccess hole, as shown in Figure 4. If a B-U2-S type prequalified welding joint is usedon a W 14 x 730 rolled section, the resultingtotal weld access hole dimension is requiredto be a minimum of 11.4 inches. These mini-mum dimensions are required for severalreasons. First, generously sized weldaccess holes prohibit the residual stress pat-terns from the flange welds and the webweld from interacting with each other. Whenthe radius which forms the end of the weldaccess hole is placed away; from the flangeweld, the radius is located in a region ofresidual compressive stress, or a region ofnearly no stress. In either case, ductility ofthe steel is enhanced. Finally, the separationof the web from the flange for this distancepermits the unrestricted yielding of the webregion. When small access holes are used,the web, rigidly attached to the flanges, isforced to absorb all the shrinkage stresses ina very small area, concentrating stressesright in the region of concern: the weldaccess hole. The requirement of minimumdimensions for the weld access hole reduces

Figure 3. The interaction of weld type, weldaccess holes, and the cast core region isshown here.

Figure 4. The root opening and overall widthof the weld joint further add to the width ofthe access hole.

5 Welding Innovation Vol. X, No. 1, 1993

residual stress levels. This is discussed inthe following article entitled “IncreasingDuctility of Connections.”

The preheat requirement for welding onjumbo sections has been increased to 350°F.The preheat temperature level should beextended to a minimum interpass tempera-ture as well, although this is not detailed inthe AISC specification.

FurtherRecommendationsThe new AISC guidelines apply only to appli-cations where the members are subject toprimary tensile stresses and spliced with fullpenetration groove welds. These require-ments do not apply to situations where mem-bers are not subject to primary tensilestresses. However, as noted, these failureswere not associated with service loading. Ifthe types of details that are typically used fortension applications are applied to compres-sion components, e.g., CJP groove welds,the same types of cracking problems mayoccur.

Additional techniques that minimize the accu-mulation of residual stresses should beemployed when welding on jumbo shapes,even though they are not enumerated in theAISC specification. Selection of the specificwelding joint detail is important. Double-sided joints reduce the amount of weld metalrequired by a factor of two. Reducing theamount of weld metal proportionatelyreduces the residual stresses. Double-sidedjoints require access from both sides, whichin the case of field welding would dictateoverhead welding. While out-of-position

welding is generally discouraged, it may beadvisable in this case to minimize theamount of residual stresses.

Furthermore, welding sequence can beimportant. On jumbo sections that involvedcracking, when the flanges were welded first,the crack would form in the web; when theweb was welded first, the cracking typicallyoccurred in the flanges. Finally, cracking wasmore likely when the final weld passes wereapplied on the inside surfaces of the flanges(closest to the weld access hole). The follow-ing should be observed with regard to weld-ing sequence:

1. As much as is practical, do not weld anyspecific joint to completion. Weld nomore than 1/3 of the depth of any jointbefore moving on to a separate joint.

2. Utilize joint details that permit the appli-cation of the final weld passes on theouter surfaces of the weld flanges wherepossible. For shop fabrication where sin-gle vee groove welds may be used, asshown in Figure 5a, the last welds willautomatically be made on the outer sur-faces. If double vee groove welds arepreferred (because of the reduced weldvolume and reduced shrinkage stresses),the last passes should be on the outerflanges, as shown in Figure 5b. For fieldwork where flanges are horizontal, acombination of these joints may be desir-able. The top flange can be preparedwith a single vee groove, while the bot-tom flange is prepared as a double vee,as illustrated in 5c. This necessitatessome overhead welding, but the finalpasses occur on the other flanges, reduc-ing cracking tendencies.

The AISC specifications do not impose anynew requirements on welding processes orthe consumables used to join these jumboshapes. The failures that had been experi-enced were not weld metal failures, butrather were located in the base materials.True, the driving force for cracking was dueto the residual stresses from welding, but theprimary problem was one of inadequate basemetal toughness.

Some confusion has resulted regarding therequirements for filler metals on jumboshapes. The new specifications do notimpose notch toughness requirements on thewelding materials. This was confusingbecause the supplements were printed withan additional comment regarding the use of“mixed weld metal.” This provision is applica-ble under circumstances where notch tough-ness has been specified for the weld metal,and the composite weld metal consisting ofdifferent compositions must have a compos-ite notch-tough weld metal. However, therequirement applies only to situations wherenotch toughness has been specified for theweld metal – typically, in dynamic structures,since static structures rarely require the useof weld metal with increased notch tough-ness properties.

ConclusionThe New AISC specification requirementssuccessfully addressed the variables thathave been associated with the fracture ofwelded jumbo sections in the past. In addi-tion, proper selection of the welding jointdetail and careful consideration of weldingsequence will contribute to the successfuluse of welded jumbo sections in tensionapplications.

Referenced DocumentsAmerican Institute of Steel Construction:

Supplement No. 2 to the Specification for theDesign, Fabrication, and Erection ofStructural Steel for Buildings (8th Edition ASDManual) January 1, 1989.

American Institute of Steel Construction:Supplement No. 1 to the Load andResistance Factor Design Specification forStructural Steel Buildings (1st Edition LRFDManual), January 1, 1989.

American Institute of Steel Construction:Specification for Structural Steel Building,Allowable Stress Design and Plastic Design(9th Edition ASD Manual), Paragraph A3.1.c,June 1, 1989.

Figure 5. Final weld passes should be made on the outer surfaces of the weldflanges wherever possible.

Welding Innovation Vol. X, No. 1, 1993 6

IntroductionMaterials used in steel structures are becom-ing increasingly thicker and heavier. Agreater chance of cracking during welding ofbeams in columns, for example, has resulteddue to increased thickness of material. Withweld shrinkage restrained in the thickness,width, and length, triaxial stresses developthat may inhibit the ability of steel to exhibitductility. This article attempts to explain whythese cracks may occur, and what can bedone to prevent them, by expanding on infor-mation presented in the AISC SupplementNo. 2 entitled “To the Specification for theDesign, Fabrication & Erection of StructuralSteel for Buildings.”

Field ResultsEngineers have been taught that the yieldpoint property of the material is the primefactor relating to ductility. This, however,offers a limited view. Figure 1 shows astress-strain curve applied to a steel speci-men which is loaded in tension parallel to itslength (a). In this type of test, the specimenis free to neck-down once the yield strengthis reached (b). As it plastically yields, itstrain-hardens to a higher strength (b to c).This stress continues to increase to (d), butbecause of a reduction in the cross-section,its apparent strength drops from (c) to (d).

If the load is removed, the specimen will notreturn to its original dimensions. Within thelimit of elastic behavior occurring from (a) to(b), however, movement is small and wouldnot be noticed unless measured. If the spec-imen’s load is removed, it will return to itsoriginal dimensions with a springlike move-ment. For example, if a steel flange platehas a yield strength of 40 ksi, elastic move-ment would be:

Laboratory ResultsIn the laboratory, it is typical to think of apply-ing a force to a tensile specimen so that itsresulting strain or movement may beobserved. But this is not what really hap-pens with a tensile laboratory testingmachine. When the machine is turned on, amotor gradually turns a screw feed whichslowly strains or stretches the specimen inthe longitudinal direction. The resisting forceof the specimen against this straining move-ment is indicated on a gauge. Yield strengthis reached when the applied stress exceeds

the critical point, and the specimen is free toplastically neck-down. If the specimen isrestrained, as it usually is in the field, thestress-strain curve indicated in Figure 1 maycontinue to the point of ultimate tensilestrength in an almost straight path, until itultimately fails without exhibiting much appar-ent ductility.

When an axial force (F) is applied to a testspecimen, it will cause a normal stress (σ) ona plane 90 degrees to the direction of theforce. It also causes a shear stress (τ),which reaches its maximum on a plane 45degrees to this force, and is equal to one-halfthe value of normal or tensile stress. If thisshear exceeds a critical value, a slidingaction takes place, allowing the specimen tobecome longer in the direction of the forceand narrow across its width. If the resultingshear value is low, based on design, and thecritical shear stress point cannot be exceed-ed, then an increased load will mean failurewhen the critical tensile point is exceeded.

Sliding action can also take place on the 45degree plane in the other direction. If theaction continues, a necked-down elongationresults in a tensile-tested specimen as Figure2 indicates. The slip plane lies at 45degrees, forming a reduced section, initiallyhaving a square outline. If the unrestrainedlength (L) of this section is at least equal toor greater than the width (W), the specimen

Figure 1.

Figure 2.

The Challenge of Welding Jumbo Shapes

Part II: Increasing Ductility of ConnectionsBy Omer W. Blodgett, P.E.

Senior Design EngineerThe Lincoln Electric Company, Cleveland Ohio

7 Welding Innovation Vol. X, No. 1, 1993

will be free to neck-down and show full ductil-ity. If the unrestrained length (L) is less thanthe width (W), the shear component (τ) willdecrease. A greater applied force will benecessary for the critical shear value to beexceeded, reducing its ductility. This is onereason AISC Supplement 2 requires theweld-access hole to extend a distance oneach side of the weld, equal to three timesthe web thickness. Doing so provides anunrestrained length of web, giving the speci-men sufficient ductility.

Field ApplicationIn the field, specimens do not usually existindependently. Steel plates are oftenrestrained and not free to neck-down. Theweld solidifies and shrinks as it cools, similarto a steel casting. When this shrinkage orstrain is restricted, a high residual tensilestress results, sometimes sufficient to causesome part of the joint to pull apart and crack.

Instead of looking for stresses which mightcause such a crack in the welded joint, it isbetter to consider strains and how they canbe reduced to avoid cracking. Application ofdistortion and residual stress factors will helpreduce these strains when a restrained mem-ber is welded.

Mohr’s Circle Explains StressA biaxial stress condition in a steel plate canbe explained using Mohr’s circle of stress asFigure 3 indicates. The tensile specimen willbe stressed in one direction only. Stressesσ2 and σ1 equal zero. Their circle has zeroradius and zero shear stress (τ1-2) along thevertical access.

The two cubes on the right part of Figure 3show that the resulting shear stresses (τ1-3)and (τ2-3) from the normal stress (σ) cause asliding action which produces movements ε3(1-3) and ε3(2-3) in the direction of (σ3).

The lower figure plots shear stress (τ) versusnormal stress (σ3). In this particular loadcondition – a simple tensile test – the shearstress is always equal to one-half the appliednormal stress (σ). Notice that this load linewill increase upward and to the right until itreaches the critical shear value of 20 ksi, atwhich time the yield strength is reached

(σy = 40 ksi). Ductility or plastic strain takesplace until the critical normal stress (70 ksi)is reached. Failure then occurs immediately.During this time, plastic straining ε3(1-3) andε3(2-3) from two different shear stresses (τ1-3)and (τ2-3) results in a very ductile condition.

The other two resulting shear stresses (τ1-3)and (τ2-3) are each equal to one-half appliednormal stress. Shear stress, if incorporatedinto a structure’s original design, accommo-dates yield, if needed. For example, if theyield point is 40 ksi, the critical shear stressvalue would be 20 ksi. Below 20 ksi, onlyelastic strain exists; above 20 ksi, there isplastic strain.

At the critical shear stress point of 20 ksi,plastic straining begins; the steel specimenstarts to neck-down. With two sheer planesinvolved (two similar circles), ductility dou-bles. Applied tensile stress at this point iscalled the yield point (40 ksi). When the sec-tion necks-down to the extent that the resul-tant normal tensile stress exceeds the criticalvalue of 70 ksi, tensile failure occurs.Between these two points, ductility occurs.

Two Residual Stresses IsolatedFigure 4 illustrates that two important resid-ual stresses exist in the weld’s terminationzone. The butt weld in the flange has aresidual stress longitudinal to the length ofthe flange (σ3) as well as a stress transverseto the flange (σ1). Longitudinal stress is ten-sile along the center line of the flange wherethe weld-access hole terminates. It can becompared to tightening a cable lengthwise inthe center in tension, with compressionspread on both sides. The transverse stressis tensile in the weld zone, with a portion ofthe adjacent plate, going through zero, andthen compression, beyond the adjacentplate. A transverse stress is also similar totightening a cable.

In addition, because some restraint existsthrough the thickness of the flange in theregion where the flange connects to the webat the termination of the weld access hole, atriaxial stress may be introduced.Terminating near the side of the flange weld(A), the access hole is subjected to residualtensile stress (σ1) transverse to the flange,as well as to residual tensile stress (σ3) longi-

Figure 3.

Figure 4.

Welding Innovation Vol. X, No. 1, 1993 8

tudinal to the flange, with full ductility restrict-ed. If the weld access hole is made wider(B), terminating at a point where the residualstress (σ1) transverse to the flange is com-pressive, a more ductile condition results.The result is similar to one person pulling ona tube of toothpaste, while another squeezesit. It can stretch more easily. Otherwise, thecombination of transverse and longitudinalstresses results in two tensile stresses at 90degrees.

Residual StressesAppliedThese residual stresses may be applied to aweld detail having a narrow weld-access hole,Figure 5. The hole terminates at point (A),resulting in (σ1) and (σ3) being in tension.Although (τ1-2) may be high, the right portion ofFigure 5 indicates that this strain, ε1 (1-2), doesnot act in the direction of (σ3). It offers littlehelp in producing ductility in this direction.

Normal stresses, (σ1) and (σ3), produceshear stresses which act in opposite direc-tions, so the final value will be small and nothelpful in the prevention of cracking. Thisleaves only shear stress (τ2-3) which will beeffective in providing ductility.

As Figure 6 suggests, it is possible that thisdoes not fully represent the problem. Sincethe web at the edge of the weld-access holeoffers some restraint against movement inthe through-thickness direction of the flangeplate, stress in the σ2 direction may have anappreciable tensile value. For example, bymoving stress σ2 from zero up to a tensilevalue, resulting circles and their correspond-ing shear stresses become similar. For thesame value of (σ3), both (τ2-3) and (τ1-3) willprobably never intersect with the criticalshear stress value, and plastic strain or duc-tility will not occur as the lower portion ofFigure 6 illustrates.

If the weld access hole can be made wider – asrecommended by AISC Supplement 2 – so thatit terminates in a zone where the transverseresidual stress (σ1) is compressive (see Figure7), then a more favorable stress condition willresult in greater ductility in the (σ3) direction. Inthis case, shear stress (τ1-3) will be high asshown by Mohr’s Circle of Stress.

Figure 5.

Figure 6.

The diagram on the right of Figure 7 showsthat (σ1) and (σ3) produce shear stress (τ1-3)which, in turn, produces two strains or move-ments ε3 (1-3), acting in the same direction.Not only is the plastic movement larger, butas the lower diagram shows, the criticalshear value is reached at a much lower nor-mal stress or load value. This producesmore ductility in the (σ3) direction, greatlyreducing the chance of a transverse crack inthe flange at the termination of the weldaccess hole.

If there is some restraint in the through-thick-ness of the flange plate enabling σ2 to havean appreciable residual tensile stress, thiswould simply move the point on Mohr’s Circleof Stress from its initial value of zero, to theright, to some tensile value. Circle (2-3)would become smaller, reducing shear stress(τ2-3) and lowering load line (2-3) shown inthe lower diagram. This would not, however,change circle (1-3) or its shear stress (τ2-3). Italso should not affect the position of the loadline (1-3) in the lower figure, and should stillresult in good ductility.

9 Welding Innovation Vol. X, No. 1, 1993

Using a method proposed by F. R. Shanley, itis possible to take a representative stress-strain curve for mild steel (Figure 8a), sepa-rate the plastic strain portion from it, (Figure8b), and convert this into a shear stress-plas-tic strain for any given shear stress (τ) once itexceeds the critical shear value. The shearstresses (τ1-3) and (τ2-3) can now be convert-ed into plastic strain plus elastic strain as thevalue of the applied normal stress (σ3) isincreased. A stress-strain curve for anycombination of triaxial stresses may be con-structed. Figure 9 contains curves for theconditions already discussed. This makes itpossible to “see” the ductile behavior of thesedetails. Notice the beneficial effects of thewide access hole as recommended by AISCSupplement 2.

ConclusionThe way in which a designer selects structur-al details under particular load conditionsgreatly influences whether the condition pro-vides enough shear stress component sothat the critical shear value may be exceededfirst, producing sufficient plastic movementbefore the critical normal stress value isexceeded. This will result in a ductile detailand minimize the chances of cracking.

ReferencesAmerican Institute of Steel Construction:

Supplement No. 2 to the Specification for theDesign, Fabrication, and Erection ofStructural Steel for Buildings (8th Edition ASDManual), January 1, 1989.

Blodgett, Omer W. Weight of Weld Metal, TheJames F. Lincoln Arc Welding Foundation,Bulletin D417, April 1978.

Gensamer, Maxwell, “Strength of Metals UnderCombined Stresses,” American Society ofMetals, 1941, pg. 10.

Bjorhovde, Brozzetti, Alpsten and Tall. “ResidualStresses in Thick Welded Plates,” AWSWelding Journal, August 1972, pg. 397.

Estuar and Tall. “Experimental Investigation ofWelded Built-Up Columns,” AWS WeldingJournal, April 1963, pg. 170.

Parker, Earl R., Brittle Behavior of EngineeringStructures, John Wiley and Sons, Inc., 1957,pg. 19.

Gayles and Willis. “Factors Affecting ResidualStresses in Welds,” AWS Welding Journal,August 1940, pg. 303.

Shanley, F.R., “Plastic Strain – CombinedLoading,” Strength of Materials, McGraw-HillBook Co., 1957; Chapter 11, pgs. 178 – 200.

Figure 7.

Figure 8.

Figure 9.

Welding Innovation Vol. X, No. 1, 1993 10

Figure 1. Good workmanship is exhibited inthis access hole. Extension tabs havealready been removed.

Figure 2. The non-planar orientation of the catenary would have made bolted connectionsdifficult or impossible to achieve.

IntroductionWhen EDS, Inc. (Plano, Texas) wanted toexpand their world headquarters, they chosea design that involved suspending a four-story building between two six-story struc-tures. Two, two-lane roads would run belowthe elevated four-story section. W&W Steel(Oklahoma City, Oklahoma) was awarded thecontract to fabricate the 8,000 tons of steel;because of the size of the project, they subletabout 50% of the work to AFCO Steel (LittleRock, Arkansas). Initially, both fabricatorswere concerned about a number of articlesthat had documented problems associatedwith the welding of jumbo sections. In addi-tion to their determination to create a struc-turally sound building, they adopted a furthergoal: to successfully fabricate by welding astructure that would utilize jumbo members intension applications.

Design DetailsThe design called for four catenary trusses,with two double catenaries located on oppo-site sides of vertical columns. The endcolumns were W14x500, while the catenarysection ranged from W14x370 to W14x398.Interior columns were typically W14x145, andfloor beams were W27x146. The upper cordof the truss was W14x283. On the exteriortrusses, the catenary was to be the continu-ous member, with the columns cut to fitaround the diagonal catenary member.Stiffeners were required for continuity andthe columns were then to be welded to thecatenary.

Knowing they were facing a real challenge,the fabricators sought and obtained consulta-tion advice from The Lincoln ElectricCompany. Reviews of past failures werestudied. The AISC specifications, their impli-cations, and the background justifications for

them were carefully reviewed. Particularattention was focused on the weld accesshole geometries and steel toughness require-ments. Welding procedures and increasedpreheat requirements were discussed. Therewere a dozen different geometric configura-tions because of the ever-changing orienta-tion of the catenary to the trusses and/orfloor beams. This dictated that each specificgeometry be carefully evaluated. Because of

The Challenge of Welding Jumbo Shapes

Part III: Case StudyBy Duane K. Miller, P.E.

Welding Design EngineerThe Lincoln Electric Company, Cleveland Ohio

the unusual geometries involved, direct appli-cation of the specifications did not alwaysgenerate an acceptable configuration thatwould assure freedom from intersection ofthe various residual stress patterns in thevicinity of the weld access hole. Under theseconditions, engineering judgment was usedto extend the minimum requirements to amore liberally sized access hole.

The specification requirements dictate theremoval of weld extension tabs and weldbacking. While all the extension tabs wereremoved, it was impossible to remove theweld backing in every case due to accessproblems. In these situations, engineeringapproval was sought and gained to leave thebacking in place.

The assembly sequence of the more complexgeometries had to be carefully planned inorder to assure access for the deposition ofquality welds and subsequent inspection.After a feasible plan was developed, a fullsized mock-up was fabricated. Although someof the configurations were extremely difficult toexecute, none proved to be impossible.

11 Welding Innovation Vol. X, No. 1, 1993

The weld access hole geometries weredetailed on the shop drawings to ensurecomplete communication. Instead of burningor thermally cutting the access holes, bothfabricators elected to drill a hole to serve asthe radius. Thermal cutting was then used toextend the hole to the weld joint. This elimi-nated grinding of the access hole, as well assubsequent nondestructive testing of the sur-face. An example of the excellent workman-ship is shown in Figure 1.

Fabrication DetailsBoth fabricators utilized conventional weldingprocesses with standard welding procedures.One fabricator chose gas-shielded flux-core(E70T-1), while the other used self-shieldedflux-core (E71T-8Ni1). Excellent results wereachieved in each case. Shop welding wasemployed as much as possible, although thesize of the parts dictated that extensive fieldassembly would be required.

On many projects of this type, there is con-siderable debate regarding the relativeadvantages of field bolting vs. field welding.On the EDS project, however, there was littlequestion. The non-planar orientation of somany of the catenary members would havemade the use of field bolted splices difficult ifnot impossible. The lap splices would haverequired bending, and it would have beennearly impossible to assure adequate contactbetween the surfaces. Field welding wasperformed using self-shielded flux-coredelectrodes, as well as manual shielded metalarc welding.

During construction, the field erector utilizedLincoln Electric LN22 and LN25 portable wirefeeders because of their versatility and porta-bility. DC600 multi-process power sourceswere advantageous since they permitted theuse of both constant current (e.g., SMAW)and constant voltage (e.g., FCAW) weldingfrom one power supply. To simplify electricalinstallation and handling of the power sup-plies, Lincpacks were used. With thisarrangement, a common frame accommodat-ed six electrically connected power supplies.

ConclusionToday, the EDS structure in Plano, Texasstands as a dramatic illustration of engineer-ing progress. The fabricators are to be com-mended for having employed current industryrequirements to overcome problems experi-enced by others I the past. To the steelindustry, the EDS project offers welcomeproof that designers can use jumbo sectionsin welded construction with confidence.

Figure 3. Access holes can become large. The location of field splices allows for shop fabri-cation of the most difficult assemblies. Note the EDS campus in the background.

Figure 4. The catenaries can be clearly seen as two of the four trusses near completion.

12Welding Innovation Vol. X, No. 1, 1993

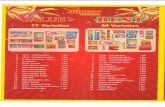

BackgroundOther articles in this issue of The Welding Innovation Quarterly cover thenew American Institute of Steel Construction (AISC) specifications forwelding on jumbo shapes, as well as the associated development ofsound fabrication principles. This Design File column will demonstratethat welding jumbo sections can provide a safe and very economicalalternate to bolted construction.

The fabrication of any quality welded connection requires specificpreparatory activities which are labor-intensive, and therefore expensive.Furthermore, when the connections involve joining jumbo sections, AISCspecifications impose additional requirements, again increasing costs. Itmust be noted, however, that the time required to prepare the work is notdirectly proportional to the thickness of the materials involved. Therefore,for thin members (such as Group 1 or 2 shapes), preparation andassembly time may take more time than the actual welding, while in thecase of jumbo shapes, the welding time will constitute a higher percent-age of the total fabrication time.

When connections are bolted, the amount of time required for cutting,drilling, bolt installation and torquing dramatically increases as the mater-ial involved becomes thicker. Welded connections use material moreefficiently, since they do not require splice plates. Therefore, the relativeeconomics of bolting vs. welding change as the beam weights change.Welded connections gain an economic advantage as the membersbecome thicker.

Case StudyTaking a W14x730 jumbo section made of A572 Grade 50 as an exam-ple, two full-strength butt splice connections will be compared: a bolteddesign and the welded alternative.

The bolted design required a total of 256, 1 1/8” diameter A325 bolts indouble shear, with a bolt length of 1’2”. The outer plate measured 18” x4” x 8’5”, and the inner plates were 7” x 3 ½” x 8’5”. Only the flangeswere bolted since the web had inadequate space to develop the requiredconnection.

The welded alternative utilized prequalified CJP groove welds: B-U3a-Sfor the flanges, and B-U2-S for the web. Hand held semi-automatic sub-merged arc welding at a rate of 16 lbs/hr, at a 25% operating factor,yielded a net deposit rate of 4 lbs/hr.

Although the requirements for welding jumbo sections are more compli-cated than those for other materials, the necessary controls will assureproduct integrity. In this case, a cost savings of $4600 per splice morethan justifies the extra effort.

Consider Welded Vs. BoltedConnections for Jumbo Sections

Practical Ideas for the Design Professional by Duane K. Miller, Sc.D., P.E.

Design File