The binder of the «Roman Concrete» of the Ponte di Augusto ...

Transcript of The binder of the «Roman Concrete» of the Ponte di Augusto ...

Per. Mineral. (2002), 71, SPECIAL ISSUE: Archaeometry and Cultural Heritage, 113-123 http://go.to/permin

PERIODICO di MINERALOGIAestablished in 1930

An International Journal ofMINERALOGY, CRYSTALLOGRAPHY, GEOCHEMISTRY,ORE DEPOSITS, PETROLOGY, VOLCANOLOGYand applied topics on Environment, Archaeometry and Cultural Heritage

The binder of the «Roman Concrete» of the Ponte di Augusto at Narni (Italy)

EMMA CANTISANI 1, ALBERTO CECCHI2, IVAN CHIAVERINI3, FABIO FRATINI 1,

CARLO MANGANELLI DELFAI,ELENA PECCHIONI4* and SILVIA RESCIC I

I C.N.R.-Centro di Studio suiIe Cause di Deperimento e sui Metodi di Conservazione delle Opere d' Arte,Via degli Alfani, 74, 50121 Firenze, Italy.

2 Ingegneria dei Materiali, Universita di Perugia, Terni, Italy.3 Dipartimento di Ingegneria Civile, Universita di Firenze.

4 Dipartimento di Scienze della Terra, Universita degli Studi di Firenze, Via G. La Pira, 4,50121 Firenze, Italy.

ABSTRACT. - The main aim of this work was tostudy the characteristics of the mortar binder used inthe building of the bridge called «Ponte di Augusto»,erected over the river Nera (Narni, Italy) in 27 B.C ..

Mineralogical, chemical, physical,micropaleontological, granulometric andpetrographical analyses were carried out on wholesamples and on the binder itself, particular carebeing devoted to lumps.

In the past, the Romans were able to create highquality mortars of relatively low porosity, withstrong mechanical characteristics and highhydraulicity. The mortars used in the «Ponte diAugusto» also show the same characteristics and areexcellently conserved.

Preliminary results ascribe these goodcharacteristics to the use of a binder of highhydraulicity, obtained by calcinating local impurelimestone and not by inserting any particularadditives.

RIASSUNTO. - Scopo di questo lavoro e statostudiare il legante della malta usata nella costruzionedel «Ponte di Augusto», eretto sopra il Fiume Nera(Narni-Italy), nel 27 a. c..

Sono state condotte analisi mineralogiche,chimiche, fisiche, micropaleontologiche,granulometriche e petrografiche, sui campioni dellegante e sui grumi presenti in esso.

Nel passato i Romani furono in grado di realizzaremalte di elevata qualita, con una porositarelativamente bassa, forti caratteristiche meccanichee grande idraulicita. Le malte utilizzate nella

* Corresponding author, E-mail: [email protected]

realizzazione del «Ponte di Augusto» mostranoanch'esse queste caratteristiche e si presentano inottimo stato di conservazione.

I risultati preliminari attribuiscono queste buonecaratteristiche all' uso di un legante ad altaidraulicita, ottenuto dalla calcinazione di un calcareimpuro e non dall' aggiunta di particolari additivi.

KEy WORDS: mortar, binder, lumps, hydraulicity.

INTRODUCTION

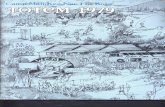

Narni is located in Umbria, not far from theborder with Latium. It was founded by theSabin people and then turned into a Romancolony (Narnia), of high military importancebecause of its strategic position on the «ViaFlaminia». The road crosses the valley of theriver Nera over an imposing bridge known asthe «Ponte di Augusto», built in 27 B.C. duringwidening of the consular road ordered by theemperor Augustus himself.

This bridge is one of the longest ever erectedby the Romans. It was 170 m long and in allprobability originally had four spans. Atpresent, only one arch is left standing, probablynot the largest (fig. 1). Its chord is about 20 mlong and its height at the intrados is about 27m. The arches, piers and abutments are made ofmasonry of well-cut travertine ashlars, filledwith mortar of such strong cohesion and good

114 E. CANTISANI, A. CECCHI, I. CHIAVERINI, F. FRATINI, C. MANGANELLI DEL FA,E. PECCHIONI and S. RESCIC

mechanical characteristics that is similar tomodern concrete.

In December 2000, the territory of Narni wasstruck by an earthquake and the State CulturalHeritage Authority, warned about theendangered condition of the remaining arch ofthe bridge, constituted a commission to checkits degree of safety and study its history andconstruction.

The main aim of the present work was tocharacterise the mixture used by the Romans inpreparing concrete (a mortar made of a binderand a coarse aggregate), particular care beingtaken to determine the kind of limestone usedto prepare the lime and to study possiblemixing with additives capable of increasing thecohesion, hydraulicity and durability of themortar.

ANALYTICAL PROBLEMS OF ANCIENT MORTARS

Study of ancient mortars often presentsdifficulties concerning determination of the socalled «recipe». Over the centuries, several

kinds of mortars have been made according toage, place and function. The preparation of amortar involves several technologicalvariables:

- the kind of limestone used to prepare thelime;

- the kind of kiln and burning conditions(temperature, time of burning, size of limestonefragments);

- slaking conditions (amount of water,seasoning);

- use of additives;- composition and granulometry of

aggregate;- method of setting.Architectural treatises from the Roman age

until nowadays give precious information onthe selection of raw materials and thetechnology of preparing of mixtures, althoughpoor-quality products often result whenattempts are made to exploit such «recipes».There are several reasons for the present-daygood characteristics of some ancient mortars,e.g.:

Fig. 1 - River Nera (province of Terni, Italy), with imposing bridge called Ponte di Augusto, built in 27 B.C.

The binder of the «Roman Concrete» of the Ponte di Augusto at Narni (Italy) 115

- optimal carbonation, favoured by the longperiod of time since setting;

- further cementation due to precipitation ofcalcite from water solutions circulating insidethe masonry;

- mortars were prepared without following«classic recipes». This sometimes depended onthe difficulty of finding the required rawmaterials, so that materials from various nearbyareas were used.

In addition, special additives could bemixed in, at the master mason's discretion.Such manufacturing technologies were oftenkept secret, so that no kind of documentationis left.

As regards analytical methods, greatdifficulties arise when studying bindercomposition - for two principal reasons:

- the difficulty of separating binder fromaggregate. In some cases, partial separationmay be obtained by soft mechanical grinding,followed by exposure to ultrasonic waves. Thesample is then sieved and the < 63 11m fractionis considered to belong to the binder, althoughmore or less significant quantities of finelygrained aggregate may sometimes be found inthis fraction (Bakolas et al., 1995). Thepresence of large lumps, not mixed with theaggregate, can be particularly useful becausethey represent the remains of pure binder,before the addition of any additive and it iseasier to separate it from the mixture;

- the nature of the binder itself, which maysometimes be composed of not negligibleamounts of amorphous or poorly crystallinecompounds, e.g., hydrated calcium aluminiumsilicates or organic compounds. In this case,mineralogical study only provides partialinformation about the nature of the binder,and different types of determinations areneeded.

MATERIALS AND METHODS

The mortar samples studied here come fromthe ruins of collapsed bridge piers and weretaken by coring.

The following analytical methods wereapplied on the total sample (binder +aggregate):

- macroscopic description ofmortar;- optical microscopy: thin sections of mortar

samples were examined under a polarisingZeiss microscope, for mineralogicalpetrographical characterisation;

- granulometry by image analysis: thinsections were examined under a polarisingZeiss microscope linked to a video analysissystem, to determine the granulometry of thefiner aggregate « 1 mm). The granulometry ofthe coarser aggregate was determined frommacrophotographs. Both analyses yielded thebinder/aggregate ratio;

- physical characteristics determined withthe following analytical methods:

total open porosity: a total of 20 test samples1.5 x 1.5 x 3 em were prepared. Samples weredried at 60°C and dry weights weredetermined. Real volume Vr (measured by aQuantachrome helium pycnometer) and bulkvolume Vb (measured on a ChandlerEngineering mercury pycnometer) were alsodetermined. Total open porosity (P) wascomputed as:

water absorption through total immersion:each test lasted 21 days. Water absorptionthrough total immersion yielded the waterabsorption coefficient, which may be expressedas weight (ICw) or as volume (ICy):

where Ww =wet weight; Wd =dry weight

The ICy gives the Saturation Index (SI):ICy =ICw '[« where Ys =bulk densitySI = 100 IC/P

For correct information about the binder,both lumps and binder separated fromaggregate were studied. Powder from lumps

116 E. CANTISANI, A. CECCHI, I. CHIAVERINI, F. FRATINI, C. MANGANELLI DEL FA, E. PECCHIONI and S. RESCIC

(which represent fragments of pure binder)was extracted with a scalpel. As regards thebinder, soft mechanical grinding of mortarsamples was followed by exposure toultrasound. Samples were then sieved and the<63 urn fraction was considered to belong tothe binder.

The following analytical methods wereapplied:

- XRD analysis (Philips PW 1729diffractometer with Cu anticathode) todetermine mineralogical composition;

- calcimetry (Dietrich Fruling instrument) todetermine quantity of calcite, obtained by theCO2 volume method;

- XRF analysis (Philips PW 1480spectrometer) to determine chemicalcomposition of major elements;

- thermal analysis (TG) (ThermoanalyzerNETZSCH STA 409). The weight loss of massof 20-50 mg was monitored through a heatingcycle from 20 to 800°C with a temperaturegradient of 10°C/minute in a static airatmosphere. This process reveals thermaltransformations such as dehydration,dehydroxidation, oxidation and decomposition,giving quantitative information on bindercompounds. TG data were processedaccording to Moropoulou et al. (1995) in therange 200-600°C and weight loss due to waterbound to hydraulic components wasdetermined; for temperatures > 600°C, weightloss due to decomposition of carbonates wasobtained;

- microchemical analysis of both binder andlumps was made by EPM (Jeol SuperprobeJXA-8600 WDS);

- micropaleontological analyses: carried outin order to detect any fossils present (siliceousand/or calcareous); for siliceous fossil contents(radiolarians), analyses were performed with astereoscopic microscope (Leica HZ8) on the<63 urn powder fraction (considered to belongto the binder); for nannofossil and diatomcontents, smear slides (again on the <63 urnfraction) were observed under a light polarisedmicroscope (Orthoplan).

RESULTS

Macroscopic observations

The mortar has high cohesion and shows aquite abundant binder, light brown in colour.The aggregate covers several granulometricclasses (fig. 2). The coarsest is made up oflarge angular clasts (0 5-15 em), disposed inbeds and composed of micritic limestone andtravertine; the finest classes are made up ofvarious limestones (cherty limestone, red«scaglia», etc.). Widespread in the mixture areseveral lumps of variable consistency, sizedbetween 0.1 and 1 em.

Microscopic observations

Binder is quite abundant, with microspariticstructure and a heterogeneous aspect, generallycharacterised by high birefringence (fig. 3a).Many lumps with microsparitic structure and ahomogeneous aspect are present, generallywith a compact aspect but sometimes revealinglarge pores.

Aggregate: mainly made up of roundedfragments of micritic limestone and secondarilyof chert and travertine fragments, quartz,feldspars, and rare pyroxene grains. The chertand limestone fragments show often welldeveloped reaction rims (fig. 3b). Macropores(> 150 urn) are mainly composed of microfossilchambers and cavities inside travertinefragments and lumps; fractures due toshrinkage are not visible.

Granulometry by image analysis

Grain size distribution, expressed as volumeper cent, indicates three main classes, withdimensions of 0.06-0.25 mm, 1.6-4 cm and SIS cm respectively. Calculating thegranulometric cumulative curve expressed asweight per cent, comparisons with the Fullercurve (P = 100 ~d/D, where P = undersize %, d= grain diameter, and D = diameter of coarsergrains) are possible. This curve represents thegranulometric distribution which determinesthe lowest presence of empty spaces among the

The binder of the «Roman Concrete» of the Ponte di Augusto at Narni (Italy) 117

Fig. 2 - Macroscopic image of mortar, showing details of various granulometric classes of aggregate and several lumps(white grains) of variable consistency.

aggregate grains (fig. 4). A quite largedifference between the two curves is evident.In particular, this is due to larger amounts ofthe middle grain classes with respect to the

Fig. 3a - Micrographic image of thin section (6.2x crossednicols): abundant binder characterised by highbirefringence and aggregate, mainly composed of variouskinds of limestone.

finer and coarser ones. Together with otherfactors (like original doses), this contributestowards producing a quite highbinder/aggregate ratio (0.75 ± 0.10).

Fig. 3b - Micrographic image of thin section (6.2x crossednicols). Centre: large chert fragment showing reaction rimwith binder.

118 E. CANTISANI, A. CECCHI, 1.CHIAVERINI, F. FRATINI, C. MANGANELLI DELFA, E. PECCHIONI and S. RESCIC

pOlo undersize

-. mortar aggregate ~

Fuller distribution -----------__-J

100100.1

100

9080 -r---------------------J70 I---------~~t::::::=~-==----J

60 -r--------------J~----'-----.......j

50 I-------------;~---__-----J40 I ---=~!!!L----- .--------1

30 I--------:;~--------,-;-----------J

20 -r----~!:.......----------- --------

10 -j------/-:..------ =---------------..j

O-j---1-...=-----'---~---~,____---__,__----J

0.01 1log d (mm)

Fig. 4 - Fuller distribution and grain size cumulative curve of mortar: note quite large difference between curves.

Physical analyses

Table I lists the physical characteristics ofthe .mortar. Porosity is quite low (31 %)~artIcularly when compared with that of purehme mortars, which is in the range 35-45%(Franchi et al., 1985; Fratini and Giovannini2000; Moropoulou et al., 2000). Nevertheless'it is higher than that of mortars made withPortland cement (values around 15-20%:Fratini et al., 1990, 1992; Moropoulou et al.,2?00) and shows values similar (or slightlyhigher) to magnesian lime mortars (Fratini etal., 1996; Atzeni et al., 1996).

As regards water absorption, the material isa1mo.st completely saturated (SI= 99%),showmg behaviour similar to that of hydraulicmortars (Fratini et al., 1992).

Mineralogical and chemical analyses

Mineralogical analysis on samples obtainedby mechanical separation of binder and lumpsfrom the aggregate reveals the absence of

quartz and feldspars. Nevertheless, slightcontamination due to the carbonaticcomponent of the aggregate cannot beexcluded, as indicated by the higher calcitecontent in the binder than in the lumps (Table2). In addition to calcite, two hydratedcalcium silicates (tobermorite 11Atobermorite 14A) were found. These mineral~are distinctive of hydraulic mortars andrepresent the reaction between calcium oxideand microcrystalline silica. The lumps containthe same minerals.

Chemical analysis by XRF of both binderand lumps revealed a slightly greater amount ofCaO in the binder, which depends on the scarcecontamination due to the carbonatic componentof the aggregate (see above) (Table 3, fig. 5).

On the whole, these data indicate thehydraulic nature of the binder, further confirmedby calculation of the hydraulicity index:

I = Si02 + Al20 3 + Fe20/CaO + MgO ==1.2±0.1

The binder of the «Roman Concrete» of the Ponte di Augusto at Narni (Italy)

TABLE 1

Physical characteristics determined on samples mortar.

119

Mortar

mean*standard deviation

2.53± 0.05

1.74± 0.16

P%

31±5

ICv%

31±5

SI%

99±4

*determined on 15 samples. g density, gs = bulk density; P% = porosity; ICv imbibition coefficient involume; SI = saturation index

TABLE 2

Mineralogical analyses (XRD) ofthe binder and the lumps of the roman mortar.

samples

Lumps *Binder *

Tobermorite llA**(ASTM 19-1364)

xxxxxx

Tobermorite l4A**(ASTM 29-331)

xxxxxx

Calcite (%)***

3238

* determined on 10 samples**XRD***calcimetry

TABLE 3

Chemical analyses (XRF) determined on the samples ofbinder and lumps of the mortar.

samples* L.O.I. Na20 MgO A120 3 Si02 P20S K20 CaO Ti02 MnO Feto t

Binder 26.0 0.06 0.83 2.37 36.47 0.03 0.49 32.60 0.06 0.04 1.05

standarddeviation 2.00 0.02 0.18 0.65 3.50 0.01 0.07 2.92 0.02 0.01 0.11

Lumps 29.60 0.02 0.94 1.95 36.55 0.01 0.41 30.35 bdl 0.02 0.15

standarddeviation 1.00 0.01 0.37 0.53 2.45 0.01 0.05 3.05 0.01 0.06

mean values determined on 5 samples for each typology% valuesbdl =below detection limit

120 E. CANTISANI, A. CECCHI, I. CHIAVERINI, F. FRATINI, C. MANGANELLI DEL FA,E. PECCHIONI and S. RESCIC

binder

e lumps

CaO+MgO

o10

20~--¥-_-*

30~--¥-_-¥--~

40x:----¥--*--'l:-----*

50)f------'t-~--+---J(

60lE-----"t--~-----J(--J(;__-~-_k

)f------'t-~--1(-----Jt__-+-~-'f;_____l<" 20

x:----¥--1E-------;~--7(;--~___7'[--_7';_-T______7\ 10

100 0o 10 20 30 40 50 60 70 80 90 100

Fig. 5 - Chemical composition (CaO+MgO - AI20 3+K20 - Si02 triangle) of binder and lumps, expressed as molar %,determined by XRF analysis. Note slightly higher amount of CaO in binder.

which shows a very high value - particularlywhen compared, for instance, with Portland325 cement (1=0.50-0.65).

As regards TO data, Moropoulou et al,(1995) set the CO2 versus CO2/H20 diagram(where CO 2 is weight loss due todecomposition of carbonates and H20 is weightloss due to water bound to hydrauliccomponents) which classifies the mortars intodifferent groups, as follows (fig. 6):

- typical lime mortars have less than 3% ofstructurally bound water (due to hydrauliccomponents) (weight loss between 200 and600°C) and CO2 values (weight loss >600°C)of 30-40%;

- hydraulic lime mortars have CO2 contents

between 16 and 34% and chemically boundwater higher than 3%;

- crushed lime brick mortars have CO 2

contents from 22 to 32% and chemically boundwater from 3.5 to 6%;

- pozzolanic mortars have more than 5% ofhydraulic water and less than 20% of CO2,

Our binder falls in the field of pozzolanicmortars (although it is not truly pozzolanic, asindicated by the absence of pozzoiana), and thelumps show even higher hydrauliccharacteristics according to the chemical datapreviously reported.

Chemical analysis of lumps and bindercarried out on thin sections by EPM (fig. 7)confirms the XRF data. According to EPM

The binder of the «Roman Concrete» of the Ponte di Augusto at Narni (Italy) 121

30 -,---------------y = O.5903e O.0823x

25 +--------------

o 20 +_----------------~L.......N

~15+-----------------...."....-r--NoUl0+--------------------.-,~~---

5 +------_0---

binder • lumpshydraulic lime mortars

D D lime mortarshigh hydraulic lime mortars

o 5 10 15 20 25 30 35 40 45

C02%

Fig. 6 - Correlation between TG data: CO2 is weight loss due to decomposition of carbonates and H20 is weight loss dueto water bound to hydraulic components.

CaO+MgO

binder• lumps

100 Y------7'--+---r--7----7'-----7'---7'---T------7'----+ 0

o 10 20 30 40 50 60 70 80 90 100

o

Fig. 7 - Chemical composition of binder and lumps, expressed as molar %, determined by WDS analysis.

122 E. CANTISANI, A. CECCHI, 1. CHIAVERINI, F. FRATINI, C. MANGANELLI DEL FA, E. PECCHIONI and S. RESCIC

analysis, the binder has the same compositionas the lumps, demonstrating that, duringmechanical separation between binder andaggregate, no significant contaminationoccurred.

The question of the nature of the stronghydraulicity of this kind of binder arises.

The low amounts of Al and K and the higheramount of Si exclude the use of marlylimestone to produce the lime. One possibleexplanation for such a high degree ofhydraulicity of the binder is the addition of adiatomaceous earth, as indicated by Franzini etal. (2000) for the Medieval mortars of theLeaning Tower of Pisa. At present, preliminarymicropaleontological analyses of the binder donot reveal any traces of siliceous additives suchas radiolarians or diatoms, but only calcareousnannofossils of Upper Oligocene age.

Another source of Si may be chertylimestone. As reported above, chert fragmentsare widespread in the mortar mixture. Hencethis research will continue with experimentalproduction of lime from the cherty limestoneoccurring at various levels of the Umbriansequence outcropping around Narni, in anattempt to find the stone used by the Romans inlime production.

CONCLUSIONS

The analytical data presented here explainthe good conditions of conservation of themortar used to construct the bridge built by theRomans over the river Nera near Narni. It isimportant to note that data on the binder weregathered from the lumps representing the purebinder before the addition of any additive andwithout the influence of the aggregate fraction.In particular, the durability of the mortar ismostly due to the kind of binder used, withvery good hydraulic characteristics(hydraulicity index = 1.2). This hydraulicityappears to be natural, and is not the result ofadditives (like porzolana, diatomaceous earth,kaolin, etc.) because no differences were foundbetween the mineralogical and chemical

compositions of the binder itself and those ofthe lumps. The chemical data give furtheruseful information: the high Si content and theA1203/Si02 and K 201A1203 ratios are notcompatible with the use of marly limestone toproduce the lime. Stone chemically compatiblewith the observed data is cherty limestone,which outcrops extensively around Narni andfragments of which are frequently found in themortar mixture.

ACKNOWLEDGMENTS

The authors are grateful to Prof. SimonettaMonechi, Department of Earth Sciences, Universityof Florence, for micropalaeontological analyses.

REFERENCES

AZTENI C., MASSIDDA L. and SANNA U. (1996) Magnesian limes. Experimental contributionto interpreting historical data. Sci. Technol. Cult.Heritage, 5 (2), 29-36.

BAKOLAS A., BISCONTIN G., CONTARDI V.,FRANCESCHI E, MOROPOULOU A., PALAZZI D. andZENDRI E. (1995) - Thermoanalytical researchon traditional mortars in Venice. ThermochimicaActa, 269/270, 817-828.

FRANCHI R., FRATINI F. and MANGANELLI DEL FA C.(1985) - Caratteri zzazione degli Intonacimediante l'impiego di tecniche mineralogicopetrografiche. Atti del Convegno Scienza e BeniCu1tura1i «L' Intonaco: Sto ria, Cultura eTecnologia», Bressanone, 24-27 Giugno 1985,167-183.

FRANZINI M., LEONI L., LEZZERINI M. and SARTORI F.(2000) - The mortar of the Leaning Tower ofPisa: the product of a Medieval technique forpreparing high strength mortars. Eur. 1. Mineral.,12,1151-1163.

FRATINI F. and GIOVANNINI P. (2000) Caratteristiche composizionali dei mattoni e dellemalte di allettamento della Rocca di Montemassi.In «Archeologia a Montemassi: un castello frastoria e storia dell'Arte», 227-230, All'insegna delGiglio Ed., Firenze.

FRATINI F., MANGANELLI DEL FA c., MAUDUIT S.,PRINCIPI G., ROGGERO F. and TERZANI L. (1992)Influenza degli aggregati sulle caratteristichedegli imp asti cementizi. Arkos Notizie GOR,Giugno 1992, 18, 5-11.

The binder of the «Roman Concrete» of the Ponte di Augusto at Narni (Italy) 123

FRATINI F., MANGANELLI DEL FA C., PARENTI R.,PECCHIONI E. and TIANO P. (1996) - Le malte diallettamento nelle strutture medievali: struttura,composizione, durabilita. Atti del ConvegnoScienza e Beni Culturali «Dal Sito archeologicoall 'Archeologia del costruito», Bressanone, 3-6Luglio 1996, 299-307.

FRATINI F, MANGANELLI DEL FA c., PECCHIONI E.,MATTEINI M., MOLES A. and RIZZI M. (1990) - IlColosso dell 'Appennino: studio delle malte e deilaterizi pertinenti la struttura ed il rivestimento, in

«Le Pitture Murali», 59-72, Centro Di Ed.,Firenze.

MOROPOULOU A., BAKOLAS A. and BISBIKOUA.(1995) - Characterisation ofancient Byzantineand later historic mortars by thermal analysis andX-ray diffraction techniques. ThermochimicaActa, 269/270, 779-795.

MOROPOULOU A., BAKOLAS A. and BISBIKOUA. (2000) - Investigation of the technologyof historic mortars. 1. Cultural Heritage, 1,45-58.