Testing of electrochemical capacitors: Capacitance, resistance, energy density, and power capability

-

Upload

andrew-burke -

Category

Documents

-

view

245 -

download

13

Transcript of Testing of electrochemical capacitors: Capacitance, resistance, energy density, and power capability

Ta

AU

a

ARRAA

KETERP

1

esdMitcatTatpetdbb

2

t

0d

Electrochimica Acta 55 (2010) 7538–7548

Contents lists available at ScienceDirect

Electrochimica Acta

journa l homepage: www.e lsev ier .com/ locate /e lec tac ta

esting of electrochemical capacitors: Capacitance, resistance, energy density,nd power capability�

ndrew Burke ∗, Marshall Millerniversity of California-Davis, United States

r t i c l e i n f o

rticle history:eceived 16 November 2009eceived in revised form 23 March 2010ccepted 21 April 2010

a b s t r a c t

DC testing of electrochemical capacitors has been reviewed with emphasis on the test procedures used bythe USABC, IEC, and the University of California-Davis (USA). Differences in the test procedures are iden-tified and the effect of the differences on the inferred characteristics of various carbon/carbon and hybrid(pseudo-capacitive) electrochemical devices evaluated from test data. The effect of the test procedures

vailable online 29 April 2010

eywords:lectrochemical capacitorsest proceduresnergy density

is greater for hybrid devices than carbon/carbon capacitors.It was found that the differences in the test procedures have a minor effect on capacitance, but larger

effects on resistance and energy density. The pulse power capability of devices is calculated from therated voltage of the device and its measured resistance. The inferred power capability of a device basedon the matched impedance value (V2/4R) is nearly a factor of ten higher than that corresponding to an

red in

esistanceower capabilityefficiency of 95% as requi

. Introduction

There have been many studies in recent years of materials forlectrochemical capacitors (also referred to as ultracapacitors orupercapacitors) and testing of small laboratory and proto-typeevices as well as a wide range of larger commercial products.uch of the testing of materials and small laboratory devices has

nvolved the application of cyclic voltammetry and AC impedanceest approaches. These approaches in most cases utilize smallurrents and limited voltage ranges and/or AC frequencies andre intended primarily to determine the electrochemical charac-eristics of the materials and electrodes used in the capacitors.esting of the larger proto-type and commercial devices is usu-lly done using DC test procedures similar to those used toest batteries. This paper is concerned with discussing DC testrocedures and how they can be used to characterize/evaluatelectrochemical capacitors. There is a need to standardize theest procedures for determining the capacitance and resistance of

evices and for assessing their energy density and power capa-ility especially in relationship to comparisons with high poweratteries.� Paper presented at the ISEE’Cap09 Conference, Nantes, 30th June–02nd July009.∗ Corresponding author at: University of California-Davis, Institute of Transporta-

ion Studies, Davis, CA 95616, United States.E-mail address: [email protected] (A. Burke).

013-4686/$ – see front matter © 2010 Published by Elsevier Ltd.oi:10.1016/j.electacta.2010.04.074

the USABC and IEC test procedures.© 2010 Published by Elsevier Ltd.

2. Summaries of DC test procedures

As indicated in Section 1, this paper is concerned with DCtesting proto-type and commercial devices with the objective ofdetermining their performance and cycle life characteristics for var-ious transportation (vehicle) and stationary applications. As wouldbe expected, the various groups (laboratories) world-wide thathaving been testing electrochemical capacitors for a number ofyears have developed their own test procedures and approachesfor interpreting their data. In this paper, the DC testing of elec-trochemical capacitors has been reviewed with emphasis on thetest procedures used by the USABC, IEC, and the University ofCalifornia-Davis (USA). There has been testing of electrochemi-cal capacitors in Europe [1–3] using the EUCAR test procedures[4], but unfortunately it has been difficult to obtain detailed infor-mation on those test procedures so they are not reviewed in thispaper.

This paper is intended as a first step in the standardizationprocess in that it attempts to identify the differences in the testprocedures and how that has/can lead to differences in datainterpretation and claimed device performance. Tables 1 and 2summarize the performance characteristics to be determined inthe testing and the type of tests to be performed for which testprocedures are required.

2.1. USABC test procedures

The USABC is a consortium of the Big Three US auto companies– Ford, Chrysler, and General Motors – that work in conjunction

A. Burke, M. Miller / Electrochimica Acta 55 (2010) 7538–7548 7539

Table 1Performance characteristics of electrochemical capacitors.

Energy density (Wh/kg vs. W/kg)Cell voltage (V) and capacitance (F)Series and parallel resistance (� and � cm2)Power density (W/kg) for a charge/discharge at 95% efficiencyTemperature dependence of resistance and capacitance especially at low

temperatures (−20 ◦C)

wtT1Rcgcmpspcic

fccfcAsdpttutt

trwt1ptc

TT

Cycle life for full dischargeSelf-discharge at various voltages and temperaturesCalendar life (h) at fixed voltage and high temperature (40–60 ◦C)

ith the United States Department of Energy (DOE) to develop andest advanced batteries and ultracapacitors for vehicle applications.he DOE test procedures for ultracapacitors were first presented in994 in Ref. [5] and later issued as USABC/DOE test procedures inef. [6]. The initial test procedures were developed as a means ofharacterizing evolving ultracapacitor devices with little attentioniven to specific automotive applications. The later USABC test pro-edures were written with hybrid-electric vehicle applications inind and thus were intended to show whether a particular ultraca-

acitor technology could meet the USABC design requirements fortart-stop and power-assist hybrid vehicles. For this reason, the testrocedures are not specified in terms easily interpreted for generalharacterization testing of devices, but nevertheless, they do resultn a body of data from which the complete characteristics of devicesan be determined.

The USABC test manual [6] is a complete set of test proceduresor all the tests listed in Table 2. The manual specifies a series ofonstant current and constant power tests to characterize the ultra-apacitors, but the tests are specified in terms more appropriateor batteries than ultracapacitors. By that is meant that the dis-harge rates are given as nC based on an effective Ah rating, whereh = Cdev (Vmax − Vmin)/3600. The rated capacitance Cdev is mea-ured at the 5C rate, which for a capacitor is a very low rate (12 minischarge). In general, the USABC constant current and constantower testing is concentrated at relatively low rates for capaci-ors and does not extend to the limits of device performance inerms of discharge times. However, capacitance and resistance val-es for devices are calculated from the USABC test data. The USABCest procedures also specify in detail self-discharge and cycle lifeests.

As noted previously, the USABC test procedures are intendedo evaluate ultracapacitors for hybrid vehicle applications. For thiseason, the test procedures specify a series of pulse test cycleshich are quite demanding. The energy efficiency and life cycle

ests are performed at 100C currents with depths-of-discharge of

0% (UC10) and 50% (UC50) in the discharge pulses (4 and 8 sulses). The USABC also has a high rate pulse characterization testhat systematically discharges the capacitor by a sequence of dis-harge/charge pulses. The intent of these tests is to determine theable 2esting of electrochemical capacitors.

Constant current charge/dischargeCapacitance and resistance for discharge times of 5 to 60 s

Pulse tests to determine resistanceConstant power charge/discharge

Determine the Ragone Curve for power densities between 100 and at least1000 W/kg for the voltage between Vrated and 1/2Vrated. Test at increasingW/kg until discharge time is less than 5 s. The charging is often done atconstant current with a charge time of at least 30 s

Sequential charge/discharge step cyclingTesting done using the PSFUDS (Pulsed Simple FUDS) test cycle with themax. power step being 500 W/kg. From the data, the round-trip efficiencyfor charge/discharge is determined

Tests modules with at least 15–20 cells in series

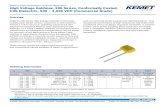

Fig. 1. Pulse test data for a 1500F ultracapacitor using the USABC UC10 and pulsecharacterization test procedures.

resistance of a device as a function of state-of-charge and the round-trip efficiency for the charge/discharge cycles. Data taken at UCDavis using the USABC UC10 and pulse characterization test proce-dures are shown in Fig. 1.

2.2. IEC test procedures

The IEC (International Electrotechnical Commission) hasrecently developed a test procedure [7] for determining thecapacitance C and resistance R of electrochemical capacitors. Thecommittee tasked with developing the procedure had represen-tatives from Europe, Asia, and the United States. The objective ofthe IEC activity was quite limited in that it specified a single testintended to determine the performance of the capacitor at a sin-gle current—that at which the efficiency in charge and dischargewas 95%. It was assumed that the capacitors to be tested behave asideal double-layer capacitors with constant C and R. The resultantrelationships for the test current are the following:

Icharge = V0

38R, Idischarge = V0

40R, V0 = rated voltage of the device

The energy and power are to be calculated from the followingidealized equations:

Energy E = 12

CV20 , power P = V2

04R

The capacitance is calculated from the measured energybetween specified voltage limits as follows:

C = 2E

(.9V0)2 − (.7V0)2

The resistance R is calculated from the voltage drop at the ini-tiation of the discharge at Idischarge assuming that the voltage vs.time trace is linear with time. The IEC procedure specifies the restperiods at the end of charge and discharge as 300 s. The chargeand discharge are performed between V0 and V0/2. The energy effi-ciency for the charge/discharge cycle is calculated from the voltageand current data and compared with the requirement of 90% (95%for each of the charge/discharge steps).

The IEC test procedure is quite limited in scope, but as shown inTable 3, it appears to be a useful approach for characterizing devicesif an accurate estimate of their resistance is known. Otherwise, aninitial test is needed to measure the resistance.

2.3. UC Davis test procedures

Most of the data presented in this paper have been obtainedusing test procedures utilized in the laboratory at the Univer-

7540 A. Burke, M. Miller / Electrochimica Acta 55 (2010) 7538–7548

Table 3Application of the IEC test procedure to various ultracapacitor devices.

Cap (F)

IEC Full V Eff (1) Eff (2) R (m�) R (m�) meas Av. cur. (A)

LS CableRound-trip eff. 3045 3071 83.5 85 0.37 0.44 194

Ch/disch eff 0.91 0.92

MaxwellRound-trip eff. 3202 3168 88.4 89.2 0.44 0.45 157Ch/disch eff 0.94 0.94

NessRound-trip eff. 3254 3285 86.9 88.6 0.47 0.45 147Ch/disch eff 0.93 0.94

Ness-term connRound-trip eff. 3253 3266 85 87 0.28 0.275 245Ch/disch eff 0.92 0.93

JSRRound-trip eff. 2070 1900 89.1 89.5 2.6 2.7 37Ch/disch eff 0.94 0.95

Charge or discharge efficiency = sqroot (round-trip efficiency).Capacitance from 0.9Vmax to 0.7Vmax (2.43–1.89).FF

spssaosT

ctgowT

TS

or JSR from 3.48 to 2.84.ull V means the discharge from Vrated to 1.35 V.

ity of California-Davis (UC Davis). These procedures are basedrimarily on those presented in Ref. [5] and thus are welluited for the evaluation of the performance of devices of allizes and states-of-development including commercial devicesnd those intended for use in hybrid-electric vehicles. The intentf the testing at UC Davis is summarized in Table 1 and theeries of tests performed on the devices are summarized inable 2.

The test conditions for a particular device are set based on itsapacitance, resistance, and weight. These values are provided ini-

ially by the developer/manufacturer of the devices to be tested. Theeneral philosophy of the testing is to test the devices to their limitf performance in terms of currents (A) and power (W) consistentith the voltage and temperature limits set by the manufacturer.he testing includes constant current and constant power charge

able 4ummary of the performance characteristics of ultracapacitor devices.

Device Vrated C (F) R (m�) RC

Maxwell* 2.7 2885 .375 1.08Maxwell 2.7 605 .90 .55ApowerCap** 2.7 55 4 .22ApowerCap** 2.7 450 1.4 .58Ness 2.7 1800 .55 1.00Ness 2.7 3640 .30 1.10Ness (cyl.) 2.7 3160 .4 1.26Carbon Tech non-acetonitrile 2.85 1600 1.0 1.6Asahi Glass (propylene carbonate) 2.7 1375 2.5 3.4Panasonic (propylene carbonate) 2.5 1200 1.0 1.2EPCOS 2.7 3400 .45 1.5LS Cable 2.8 3200 .25 .80BatScap 2.7 2680 .20 .54Power Sys. (activated carbon, propylene carbonate)** 2.7 1350 1.5 2.0Power Sys. (graphitic carbon, propylene carbonate)** 3.3 1800 3.0 5.4

3.3 1500 1.7 2.5Fuji Heavy Industry-hybrid (AC/graphitic carbon)** 3.8 1800 1.5 2.6JSR Micro (AC/graphitic carbon)** 3.8 1000 4 4

2000 1.9 3.8

a Energy density at 400 W/kg constant power, Vrated − 1/2 Vrated.b Power based on P = 9/16(1 − EF)V2/R, EF: efficiency of discharge.* Except where noted, all the devices use acetonitrile as the electrolyte.

** All device except those with ** are packaged in metal containers, these devices are in

and discharge tests as well as pulse current and pulse cycle test-ing. A summary of test results [8,9] for various devices tested at UCDavis are given in Table 4.

3. Application of the test procedures to carbon/carbondevices

In this section, the various test procedures discussed in the pre-vious section are applied to carbon/carbon capacitors to determine

their capacitance, resistance, energy density, and power capabil-ity. These devices use activated carbon in both electrodes and innearly all cases, an organic electrolyte. The dominate energy stor-age mechanism in these devices is charge separation (double-layercapacitance).(s) Wh/kga W/kg (95%)b W/kg match. imped. Wgt. (kg) Vol. lit.

4.2 994 8836 .55 .4142.35 1139 9597 .20 .2115.5 5695 50625 .009 –5.89 2574 24,595 .057 .0453.6 975 8674 .38 .2774.2 928 8010 .65 .5144.4 982 8728 .522 .385.8 1026 9106 .2234.9 390 3471 .210 (estimated) .1512.3 514 4596 .34 .2454.3 760 6750 .60 .483.7 1400 12,400 .63 .474.2 2050 18,225 .50 .5724.9 650 5785 .21 .1518.0 486 4320 .21 .156.0 776 6903 .23 .159.2 1025 10,375 .232 .143

11.2 900 7987 .113 .07312.1 1038 9223 .206 .132

laminated pouches.

A. Burke, M. Miller / Electrochimica Acta 55 (2010) 7538–7548 7541

r a ca

3

cb

C

cAVVtilir

3

o

•••

•

TE

Fig. 2. Voltage–time trace fo

.1. Capacitance

The capacitance of a device can be determined directly fromonstant current discharge data. A typical V vs. time trace for a car-on/carbon double-layer capacitor is shown in Fig. 2. By definition,

= I

dV /dtor C = I(t2 − t1)

V1 − V2, V = V(t)

Since the voltage trace is not exactly linear, the value of C cal-ulated depends to some extent on the values of V1 and V2 used.s noted previously, the IEC procedure specifies that V1 = .9V0 and2 = .7V0. Other choices for voltage range that have been used are0 to V0/2 and V0 to 0. When V0 is used, it is important to includehe IR drop in the determination of the effective V1 value. As shownn Table 5, the differences in the calculated capacitance C are notarge for the various selected voltage ranges. The results in Table 5ndicate that the determination of the capacitance of devices iselatively insensitive to the test procedure.

.2. Resistance

The resistance of a capacitor or battery can be determined usingne of several methods.

IR drop at the initiation of a constant current dischargeCurrent pulses (5–30 s) at specified states-of-chargeVoltage recovery at the interruption of a discharge or charge cur-rentMeasurement of the AC impedance at 1 kHz

able 5ffect of voltage range and test current on the measured capacitance.

V0 to 0 V

I C I

Device/developer3000F/Maxwell 100A 2880F 200A3000F/Nesscap 50A 3190F 200A450F/ApowerCap 20A 450F 40A

3.8–2.2 V2000F/JSR Micro 80A 1897F 200A

Device IEC .9V0 to .7V0 V0 to

Capacitance (F)LS Cable 3045 3071Maxwell 3202 3166Ness 3254 3285JSR 2070 1900

rbon/carbon ultracapacitor.

The method specified by both the IEC and the USABC test pro-cedures as well as that used routinely at UC Davis involves analysisof the IR drop and voltage variation at the initiation of a constantcurrent discharge. Determination of the resistance of the capaci-tor is complicated by the fact that the voltage decreases due bothto the resistance and capacitance of the device. In addition, due tothe porous character of the electrode, the resistance of the capaci-tor varies with time until the current distribution in the electrodesis fully established. This problem has been analyzed mathemati-cally [10,11]. The results of the analysis are shown in Fig. 3, whichindicates that the steady-state resistance R is not approached untilseveral time constants RC into the discharge. The initial value of theresistance R0 can be as low as 1/2 the steady-state value.

As shown in Fig. 4, the voltage–time trace does not become lin-ear immediately at the initiation of the discharge meaning that theuse of the initial IR drop to calculate the cell resistance results in avalue of R significantly less than the steady-state value which is thedesired quantity. A good estimate of the steady-state resistance canbe obtained by extrapolating the linear portion of the voltage-timetrace back to t = 0 and utilizing that IR drop value to calculate R.

For many applications of ultracapacitors, it is the steady-stateresistance that is the resistance most relevant for the calculationof power capability/electrical losses/heating and not the R0 valuewhich is smaller. It is important to define what resistance value isbeing reported. The dependence of resistance on discharge time at

the initiation of a discharge is shown in Fig. 5.Another reliable method of determining the DC resistance ofa capacitor is the current pulse method in which a short pulse(5–10 s) is applied to the device. In fact for batteries, this is proba-bly the only reliable method to determine its resistance using most

V0 to 1.35 V

C I C I C

2893F 100A 3160F 200A 3223F3149F 50A 3214F 200A 3238F453F 20A 466F 40A 469F

3.8–2.6 V1817F 80A 1941F 200A 1938F

0

(3.8–2.2 V)

7542 A. Burke, M. Miller / Electrochimica Acta 55 (2010) 7538–7548

sistan

bTpnftp

tcr

Fv

redistribution in the device with time at I = 0 and the effect on thevoltage is both significant and not well understood. As a result, thereis an uncertainty as to the time after the setting of I = 0 at which thevoltage should be read and R calculated from �V/I. This effect is

Fig. 3. Transient solution for the re

attery testers. The pulse can be either a discharge or charge pulse.he effective resistance (R = �V/I) can vary with time through theulse depending on the response time of the tester and/or mecha-isms occurring in the device. It is, of course, greatly preferred if the

ormer is negligible and only the latter is important. Unfortunatelyhis is often not the case. As shown in Fig. 6 for 1600F device, theulse tests shows clearly the change in resistance from R to R

0 ss.The resistance of a capacitor or battery can also be inferred fromhe recovery of the voltage at the end of a current pulse when theurrent is removed (I = 0). Some researchers prefer this methodather than that involving the initiation of the pulse because the

ig. 4. Method for determining the steady-state resistance by extrapolating theoltage trace to t = 0 (ApowerCap 450F cell).

ce of an ultracapacitor cell [10,11].

current is zero and the effect of the capacitance of the device onthe voltage is not present. However, there is the effect of the charge

Fig. 5. Change of resistance with time at the initiation of a discharge of an electro-chemical capacitor [10].

A. Burke, M. Miller / Electrochimica Acta 55 (2010) 7538–7548 7543

F

irvtc

rvost

3

cce

F(

Table 6Test data for the 3000F Nesscap cylindrical device.

Current (A) Time (s) Capacitance Resistance (m�)

Constant current discharge data 2.7 to 050 171 3190 –

100 84.3 3181 .44 (1)200 41.3 3157 .42300 27 3140 .37400 20 3150 .40

Power (W) W/kga Time (s) Wh Wh/kg Ceff

Constant power discharge data 2.7–1.35 V100 192 84.8 2.36 4.52 3107200 383 41.8 2.32 4.44 3055300 575 27.1 2.26 4.33 2976400 766 19.7 2.19 4.20 2884

ig. 6. Voltage and resistance during a current pulse (Skeleton Tech 1600 F device).

llustrated in Fig. 7. Comparing Figs. 6 and 7 indicates that the cur-ent initiation and interruption methods result can yield the samealue of resistance both for the R0 and Rss. The voltage recoveryime seems to be relatively short-being about equal to the RC timeonstant of the device tested.

For ultracapacitors, it is common for manufacturers to list theesistance measured with an AC impedance meter at 1 kHz. Thisalue of resistance is always significantly lower than the DC valueften by about a factor of two. The power capability of deviceshould not be calculated using the AC impedance value of the resis-ance.

.3. Energy density

The total energy stored in a carbon/carbon capacitor can bealculated from the relationship E = 1/2 CV2

0 . If the voltage of the

apacitor is restricted to the range V0 to V0/2, only 75% of the storednergy can be used. Hence the useable energy density is given byWhkg

= 3/8CV20

device weight

ig. 7. Resistance determination using voltage recovery after current interruptionSkeleton Tech 1600F).

500 958 15.4 2.14 4.1 2818700 1341 10.9 2.12 4.06 2792

a Weight of device .522 kg, dimensions of the device 6 cm D, 13.4 cm lengthCeff = 2(W s)/.75(2.7)2.

This simple relationship is often used to calculate the energydensity of ultracapacitors. The most reliable approach to determin-ing the energy stored in a device, however, is to measure the Whstored for a range of constant power densities W/kg. In general, testsshould be made for power densities between 100 and 1000 W/kg oreven higher for high power devices. The plot of Wh/kg vs. W/kg iscalled the Ragone Curve for the device. Typical data for a commer-cially available 3000F capacitor are shown in Table 6. Note that theenergy density gradually decreases with W/kg. This is the case forall ultracapacitors. The value of energy density quoted by the devicemanufacturer is often calculated from the energy correspondingto 1/2 CV2

0 using the rated voltage and specified capacitance. Thisvalue is too high as it is not the useable energy density and also itcorresponds to a low power density of 100 W/kg or lower. As shownin Table 6, the effective capacitance Ceff of a device decreases sig-nificantly with W/kg and often agrees with the value claimed bythe manufacturer only for relatively low power densities. Hencecombining the useable energy factor (.75) and the effective capac-itance reduction factor (.9 from Table 6), the simple calculation ofenergy density from 1/2 CV2

0 can overestimate the energy densityof a device by at least 1/3.

3.4. Power capability

There is much confusion and unreliable information in the lit-erature concerning the power capability of ultracapacitors andbatteries. This confusion stems to a large extent from the persis-tent use of the simple formula P = V2

0 /4R to calculate the maximumpower capability of electrochemical devices. This formula grosslyoverestimates the maximum power as it corresponds to operationof the device at the matched impedance point at which one-halfof the discharge energy is electricity and one-half is in heat. Thecorresponding efficiency is 50%, which makes that operating con-dition unuseable for nearly all applications. It is more reasonable toexpress the power capability of devices in terms of the pulse effi-ciency (EF). This can be done using the following relationships forultracaps and batteries:

Ultracapacitors : P = 9/16(1 − EF)V20

R

Batteries : P = EF(1 − EF)V2oc

R

These relationships are for pulse power and not constant power.In the case of the ultracapacitor, the power pulse is occurring at avoltage of 3/4V0 and is intended to remove only a relatively smallfraction of the energy stored in the device. The battery relationship

7544 A. Burke, M. Miller / Electrochimica Acta 55 (2010) 7538–7548

Table 7Ratios of the power calculated using the efficiency and the matched impedancemethods.

Efficiency EF Peff/Pmat. imp.

Ultracapacitor Batteries

.5 1.0 1.0

.6 .9 .96

cSeeptdpmp

mctsmpmfTa

ostApfaoEoFitaabt

i

F

Table 8Time-power steps for the PSFUDS test cycle.

Step no. Time stepduration (s)

Charge C/discharge D

P/Pmax

Pmax = 500 W/kg

1 8 D .202 12 D .403 12 D .104 50 C .105 12 D .206 12 D 1.07 8 D .408 50 C .309 12 D .20

10 12 D .4011 18 D .1012 50 C .2013 8 D .2014 12 D 1.015 12 D .1016 50 C .3017 8 D .2018 12 D 1.019 38 C .25

hybrid-electric vehicle applications. Another pulse test cycle, thePSFUDS, which was first defined in Ref. [5], has been used exten-sively at UC Davis to test ultracapacitors and high power batteries.The test cycle, specified in terms of W/kg-time steps, is given inTable 8. It can be utilized to test devices of all sizes and perfor-

.7 .68 .84

.8 .45 .64

.9 .22 .36

.95 .11 .19

an be applied at any state-of-charge by using the Voc and R for thatOC. Note that the power from both the matched impedance andfficiency EF relationships is proportional to V2/R. The key param-ters in determining the power capability are thus R and V0. Highower devices necessarily must have low resistance. Hence oncehe resistance of a device is known its power capability followsirectly. It is unfortunate that device manufacturers often do notrovide information concerning the resistance of their devices. Thisakes careful measurement of the resistance as discussed in the

revious section very important.For simple power pulses using capacitors, the ratio of the

atched impedance to the efficiency power is 4/9/(1 − EF). In thease of batteries, the ratio is 1/4/[EF(1 − EF)]. The ratios as func-ions of EF are given in Table 7. For ultracapacitors, the efficiencypecified by the USABC and IEC is 95% which results in the useableaximum power being only about 1/10 the matched impedance

ower (V2/4R). Hence for capacitors using the V2/4R formula to esti-ate the useable maximum power does not yield a realistic value

or most applications, especially vehicle applications. Note that inable 4 both the matched impedance and EF = 95% power densitiesre presented for the various devices.

The USABC has a procedure for calculating the power capabilityf ultracapacitors based on the resistance and rest voltage mea-ured as a function of state-of-charge in their pulse characterizationest (see Fig. 1). The details of this calculation are shown in Fig. 8.s indicated in the figure, the procedure calculates the maximumulse current for charge and discharge (I = �V/R) based on the dif-erence in voltage between the rest voltage (Voc) and the minimumnd maximum voltages for discharge and charge, respectively. Inrder to compare the USABC power capability with that for theF method, the USABC calculation was done for a state-of-chargef 50% (Voc = 3/4 V0). The ratios of powers (PEF/PABC) are shown inig. 8 as a function of the efficiency of the pulse. For efficiencies EFn the range of 90–95% as specified in the USABC test procedures,he power ratios are .1–.4 indicating that the USABC power valuesre a large factor greater than those given by the EF method. This islso the case for high power batteries so the relative power capa-

ilities for capacitors and batteries should be the same using thewo methods.All methods for projecting the pulse capabilities of ultracapac-tors and batteries yield maximum power values proportional to

ig. 8. Calculation of the power capability of ultracapacitors by the USABC method.

20 12 D .4021 12 D .2022 ≥50 Charge to V0 .30

V20 /4R which means that careful measurement of the resistance R

is essential and specification of the rest voltage at the specified SOCmust be accurate.

3.5. Pulse cycle testing

Since in many applications ultracapacitors experience highlytransient operation, pulse cycle testing should be included in eval-uating their performance capabilities. The pulse cycles are simply asequence of discharge and charge pulses of specified currents (A) orpowers (W) of specified time duration (s). As discussed previously(see Fig. 1), the USABC has defined pulse cycle test procedures for

Fig. 9. PSFUDS test results for a 45 V Ness ultracapacitor module.

himica

mm

rF

4

fiIliriaft

A. Burke, M. Miller / Electroc

ance capabilities by adjusting the W/kg and time duration of theaximum power steps (6, 14, 18).The test data of most interest in using the PSFUDS cycle is the

ound-trip efficiency. Typical data using the cycle are shown inig. 9.

. Testing of hybrid, pseudo-capacitive devices

Most of the electrochemical capacitors that have been availableor testing are of the carbon/carbon type that use activated carbonn both electrodes and double-layer capacitance for energy storage.n this section of the paper, the testing of devices that use interca-ation carbon or other battery-like (pseudo-capacitive) materialsn at least one electrode is considered. These devices are often

eferred to as hybrid ultracapacitors. Some testing of hybrid capac-tors has been done and differences between testing carbon/carbonnd hybrid capacitor devices are becoming apparent. These dif-erences will be discussed in this section with emphasis on howhey affect test procedures and data interpretation. This will beFig. 10. Voltage vs. time traces for the constant

Acta 55 (2010) 7538–7548 7545

done in a format similar to that followed for the carbon/carbondevices.

4.1. Capacitance

As is the case for carbon/carbon devices, the capacitance is deter-mined from constant current discharge data. However, as shownin Fig. 10, the character of voltage vs. time traces for the hybridcapacitors is quite different than the carbon/carbon devices.

As seen in Fig. 10, the key differences in the traces are the non-linearity of the hybrid device traces, especially in charging, and thewell defined voltage below which the capacitance of the device isvery small. Hybrid capacitors can also be assembled using variousmetal oxides in one or both electrodes. The character of the voltage

vs. time trace of those devices would be similar to those in Fig. 10.As would be expected, the character of the V vs. t trace must be con-sidered in testing a particular hybrid capacitor device. In the caseof the hybrid carbon device (9a), the voltage should be restrictedto be between the rated voltage (3.8 V) and that of the shouldercurrent discharges of hybrid capacitors.

7 himica Acta 55 (2010) 7538–7548

(defptantth

4

rcclbatpJmTdd

FM

Table 9Characteristics of the JSR Micro 2000F cell.

Current (A) Time (s) C (F) Resistance (m�)a

Constant current discharge 3.8–2.2 V30 102.2 2004 –50 58.1 1950 –80 34.1 1908 –

130 19.1 1835 2.0200 11.1 1850 1.9250 8.2 1694 1.84

Power (W) W/kg Time (s) Wh Wh/kgb Ceff Wh/Lb

Constant power discharges 3.8–2.2 V102 495 88.3 2.5 12.1 1698 18.9151 733 56 2.35 11.4 1596 17.8200 971 40 2.22 10.8 1508 16.9300 1456 24.6 2.05 10.0 1392 15.7400 1942 17 1.89 9.2 1283 14.4500 2427 12.5 1.74 8.5 1181 13.3

Current (A) Resistance (m�)

Pulse test (5 s) RC (s)

Pulse resistance tests results100 2 3.8200 1.9 3.5

546 A. Burke, M. Miller / Electroc

2.2 V). It is evident from Table 5 (note the data for the JSR Microevice) that the selection of voltage limits makes a greater differ-nce in the calculation of the capacitance for hybrid capacitors thanor carbon/carbon devices. The best approach is to use the com-lete range between the rated and shoulder voltages to calculatehe capacitance, but correct the initial voltage (V1) for the IR drops is done for the carbon/carbon devices. For hybrid capacitors, it isecessary to look closely at the V vs. t trace before adapting a par-icular method for the calculation of capacitance. It seems unlikelyhat the simple IEC test procedure will be applicable to all types ofybrid capacitor device without modification.

.2. Resistance

The same method can be used for calculating the steady-stateesistance Rss of the hybrid carbon capacitors as was used for thearbon/carbon devices. As shown in Fig. 11, the V vs. time traces foronstant current discharges of the hybrid carbon devices becomeinear within a couple of seconds and the IR drop can be determinedy extrapolating back to t = 0. Hence Rss = (�V)t=0/I. When testingny new hybrid device, one should check the linearity of V vs. timerace near the initiation of discharge to determine whether the sim-le method of linear extrapolation is applicable. Pulse tests with the

SR Micro devices yield resistance values that are in good agree-ent with those obtained using the linear extrapolation method.

he pulse method is the most universally applicable approach toetermining the resistance of ultracapacitors and batteries. Testata for the JSR Micro 2000F device are given in Table 9.

ig. 11. Determination of the steady-state resistance of a hybrid ultracapacitor (JSRicro 2000F cell).

Peak pulse power at 95% efficiency R = 1.9 m�. P = 9/16*.05*(3.8)2/.0019 = 214 W,

1038 W/kg.a Resistance is steady-state value from linear V vs. time discharge curve.b Based on the weight and volume of the active cell materials. Cell weight 206 g,

132 cm3. Ceff = 2(W s)/(3.82 − 2.22).

4.3. Energy density

In simplest form, the energy stored in a hybrid capacitor can beexpressed as

Estored = 12

Ceff(V2rated − V2

min)

assuming that capacitance Ceff is a constant. In the case of thecarbon/carbon devices, Vmin = 1/2 Vrated. In the case of the hybridcapacitor Vmin is the minimum voltage at which the device storessignificant charge. Ceff has been calculated from the test data fora carbon/carbon device in Table 6 and for a hybrid capacitor inTable 9. It is clear from comparing the tables that the Ceff approx-imation and the simple 1/2CV2 relationship is valid to obtainthe energy stored at low power densities for the carbon/carbondevices, but not for the hybrid devices. Hence the energy densityof hybrid capacitors should be obtained from testing them over arange of power densities. The simple 1/2CV2 relationship overes-timates the energy stored in the hybrid capacitors. As is the casefor carbon/carbon devices, energy density decreases with increas-ing power density due to the effect of resistance on the operatingvoltage range of the device.

4.4. Power capability and pulse cycle tests

Pulse testing of hybrid capacitors to obtain the resistance andthe round-trip efficiency on the PSFUDS is essentially the same asfor carbon/carbon devices. The power capability of hybrid capac-itors can be calculated using the same relationships used forcarbon/carbon devices when Vrated and the pulse resistance R areknown.

5. Uncertainties in ultracapacitor data interpretation

Various aspects of testing carbon/carbon and hybrid ultracapac-itors were discussed in the previous sections. The intent of thetesting is to determine the performance of the devices to a high

himica

lopaotifs

123456

5

ascVUittrc

5

adstlttcdVtiidHbgc

5

tdlcttetbt

A. Burke, M. Miller / Electroc

evel of confidence and to provide data for a wide range of deviceperating conditions. Based on the present considerations of testingrocedures, there are, however, a number of uncertainties that canrise in the interpretation of data available in the literature and/orn manufacturer’s specification sheets for devices. These uncer-ainties are due to differences in test procedures and incompletenformation on how the data were used to calculate device per-ormance. The uncertainties in the following areas are discussedeparately.

. Charging algorithm

. Capacitance

. Resistance

. Energy density

. Power capability

. Round-trip efficiency

.1. Charging algorithm

Little has been discussed in the previous sections on the charginglgorithm used in the testing. That is primarily because the energytored in the capacitor is essentially independent of the chargingurrent and the charging is terminated when the device reachesrated (no current taper as for batteries). It is common practice atC Davis to hold the voltage about 60 s before the discharge test is

nitiated. This permits the charge in the capacitor to equalize andhe current prior to initiation of discharge to be a small fraction ofhe discharge current. It would be advantageous if all capacitor testeports stated how the charge was terminated as the hold periodan have a significant effect on the test data if it is too short.

.2. Capacitance

The uncertainty in the capacitance is relatively small. It is onlyfew percent for carbon/carbon devices and up to 10% for hybridevices. In nearly all cases, the capacitance is determined from con-tant current discharge data. The largest source of uncertainty ishe voltage range over which the capacitance (C = �Q/�V) is calcu-ated. However, examination of the data (Tables 3 and 5) indicatehat selecting different voltage ranges only has a minor effect onhe capacitance calculated. The best approach is to calculate theapacitance based on the useable voltage operating range of theevice. For carbon/carbon devices, the operating range is usuallyrated to Vrated/2. For hybrid devices, it seems appropriate to basehe capacitance on the difference between the Vrated and the min-mum operating voltage set by the shoulder of the voltage curven charge or discharge. The capacitance depends only slightly onischarge current except for very low rates and very high rates.owever, the IR voltage drop at the initiation of discharge shoulde included in the determination of �V when C is calculated. It isood practice to state the discharge current or time for which theapacitance value corresponds.

.3. Resistance

Knowledge of the resistance of a device is important and unfor-unately the uncertainty in the resistance is relatively large. This isue both to the inherent difficulty is measuring the resistance of a

ow resistance (<1 m�) device and the variety of approaches thatan be used to measure the resistance. Part of the difficulty is thathe resistance at the initiation of a discharge or pulse varies during

he period in which the current distribution is established in thelectrodes. The resistance values reported by UC Davis correspondo the steady-state resistance after the current distribution haseen established. This resistance value can be a factor of two higherhan that measured at very short times after the discharge/pulseActa 55 (2010) 7538–7548 7547

has been initiated. Hence the uncertainty in the resistance valuecan be as great as a factor of two. It is important that when resis-tance values are given that the method and time for measuring theresistance be stated clearly. It is not uncommon for device manu-facturers to give the resistance of their device measured by an ACimpedance meter at 1 kHz. This value of resistance is about a factortwo lower than the steady-state value.

5.4. Energy density

The only reliable way to determine the energy stored and theenergy density of an electrochemical capacitor is to test it over arange of power densities. This is especially true of hybrid capacitors.These measurements should be done over the useable operatingvoltage range of the device. The energy stored and dischargedand the resultant energy density will decrease as the dischargerate (W/kg) increases. When energy and energy density values arereported, they should be useable values and indicate the dischargerate (W/kg) at which they were measured. Utilizing the 1/2 CV2

relationship to calculate the energy density can overestimate theuseable energy density by at least 1/3 for carbon/carbon devicesand even greater for hybrid devices.

5.5. Power capability

The power capability is a calculated value based on therated voltage and resistance of the capacitor. As discussed pre-viously, there are at least three approaches to calculating thepower capability: (1) matched impedance P = Vrated

2/4R, (2) USABCP = 1/8 Vrated

2/R, (3) pulse efficiency P = 9/16(1 − EF)Vrated2/R. For

the same device, the maximum power values vary by the ratios1, 0.5, 0.11 (95%), 0.22 (90%) for the three cases. The large differ-ences in the projected power capability have lead to large confusionconcerning the power capability of capacitors and the relationshipto that of high power batteries. In the case of the power capability,the uncertainty is due to differences in data interpretation and notin the test data itself.

6. Summary and conclusions

DC testing of electrochemical capacitors has been reviewed withemphasis on the test procedures used by the USABC, IEC, and theUniversity of California-Davis. Differences in the test proceduresare identified and the effect of the differences on the inferred char-acteristics of various carbon/carbon and hybrid (pseudo-capacitive)electrochemical devices evaluated from test data. The effect of thetest procedures is greater for hybrid devices than carbon/carboncapacitors.

It was found that the differences in the test procedures havea minor effect on capacitance (less than 10%), but larger effects onresistance and energy density. The uncertainty in the resistance canbe as high as a factor two depending on the pulse duration and themethod used to infer it. The pulse power capability of devices iscalculated from the rated voltage of the device and its measuredsteady-state resistance. The calculated power values are highlydependent on the assumptions made concerning the efficiencyEF of the pulse (fraction of energy into electricity). The inferredpower capability of a device based on the matched impedance value(V2/4R) is nearly a factor of ten higher than that corresponding to anefficiency of 95% as required in the USABC and IEC test procedures.

References

[1] E.V. Conte, F. Pirker, Electrical Performances of High Power Electric DoubleLayer Capacitors under Thermal and Mechanical Stress, 2010, available on theweb.

7 himica

548 A. Burke, M. Miller / Electroc[2] F. Rafik, H. Gualous, R. Callay, A. Crausaz, A. Berthon, Supercapacitors Character-ization for Hybrid Vehicle Applications, Paper Presented at ESSCAP, Lausanne,Switzerland, 2006, available on web.

[3] T. Andersson, J. Groot, H. Berg, J. Lindstrom, T. Thiringer, AlternativeEnergy Storage System for Hybrid Electric Vehicles, 2010, available on theweb.

[4] Specification of test procedures for supercapacitors in electric vehicle

applications, EUCAR, Traction battery working group, ECE contract ENK 6-CT20000-00088, draft 2003.[5] Electric Vehicle Capacitor Test Procedures Manual, Idaho National EngineeringLaboratory Report DOE/ID-10491, October 1994.

[6] FreedomCar Ultracapacitor Test Manual, Idaho National Engineering Labora-tory Report DOE/NE-ID-11173, September 21, 2004.

[

[

Acta 55 (2010) 7538–7548

[7] IEC, Electric Double-layer Capacitors for Use in Hybrid Electric Vehicles-TestMethods for Electrical Characteristics, finalized April 2008.

[8] A.F. Burke, M. Miller, Electrochemical Capacitors as Energy Storage in Hybrid-Electric Vehicles: Present Status and Future Prospects, 2009, EVS-24, Stavanger,Norway, May 2009 (paper on the CD of the meeting).

[9] A.F. Burke, M. Miller, Supercapacitors for hybrid-electric vehicles: recent testdata and future projections, in: Proceedings (CD) of the Advanced Capacitor

World Summit 2008, San Diego, CA, July, 2008.10] C.J. Farahmandi, Analytical solution to an impedance model for electrochemicalcapacitors, in: Advanced Capacitor World Summit 2007, San Diego, CA, June,2007.

11] V. Srinivasan, J.W. Weidner, Mathematical modeling of electrochemical capac-itors, Journal of the Electrochemical Society 146 (1999) 1650.