Testing of 110kV Cables

-

Upload

rejnald-zyfi -

Category

Documents

-

view

278 -

download

4

Transcript of Testing of 110kV Cables

-

8/13/2019 Testing of 110kV Cables

1/39

O r d e r

N o :

7 0 8 7 0 1 9 5

09-1026

TYPE TEST CERTIFICATE OF COMPLETE TYPE TEST

OBJECT single-core power cable

TYPE 76 / 132 (145) kV 1x1200 mm 2 CU/XLPE/CWS/AL/HDPE

Rated vo ltage, U o /U (U m ) 76/132 (145) kV Conductor material CuConductor cross-section 1x1200 mm Insulation material XLPE

MANUFACTURER Elsewedy CablesCairo, Egypt

CLIENT Elsewedy CablesCairo, Egypt

TESTED BY KEMA HIGH-VOLTAGE LABORATORY Arnhem, the Netherlands

DATE OF TESTS 23 March 2009 until 12 June 2009

The object, constructed in accordance with the description, drawings and photographs incorporated inthis Certificate, has been subjected to the series of proving tests in accordance with

IEC 60840

This Type Test Certificate has been issued by KEMA following exclusively the STL Guides.

The results are shown in the record of Proving Tests and the osci llograms attached hereto. Thevalues obtained and the general performance are considered to comply with the above Standardand to just ify th e ratings assigned by the manufacturer as listed on page 4.

The Certificate applies only to the object tested. The responsibility for conformity of any object

having the same designations with that tested rests with the Manufacturer.

This Certificate consists of 39 pages in total.

Copyright: Only integral reproduction of this Certificate is permitted without writtenpermission fr om KEMA. Electronic copi es in e.g. PDF-format or scanned version ofthis Certificate may be available and have the status for inform ation only .The sealed and bound version of the Certificate is the only valid version.

KEMA Nederland B.V.

P.G.A. BusKEMA T&D Testing ServicesManaging Director

Arnhem, 6 August 2009

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

2/39

-2- 09-1026

TABLE OF CONTENTS

TABLE OF CONTENTS .......................................................................................................................... 2

1 Identification of the test object......................................................................................................4 1.1 Description of the test object........................................................................................................4 1.2 List of documents .........................................................................................................................6

2 General information......................................................................................................................7 2.1 The tests were witnessed by........................................................................................................7 2.2 The tests were carried out by.......................................................................................................7 2.3 Subcontracting .............................................................................................................................7 2.4 Purpose of the test .......................................................................................................................7 2.5 Measurement uncertainty.............................................................................................................8 2.6 Applicable standards....................................................................................................................8

3 Electrical type tests ......................................................................................................................9 3.1 General.........................................................................................................................................9 3.1.1 Tests at elevated conductor temperature ....................................................................................9 3.2 Test voltage values ....................................................................................................................10 3.3 Bending test followed by a partial discharge test.......................................................................11 3.3.1 Bending test ...............................................................................................................................11 3.3.2 Partial discharge test..................................................................................................................12 3.4 Tan measurement ...................................................................................................................13 3.5 Heating cycle voltage test ..........................................................................................................14 3.6 Partial discharge test..................................................................................................................15 3.7 Lightning impulse test followed by a power-frequency voltage test...........................................16 3.7.1 Impulse test ................................................................................................................................16 3.7.2 Power frequency voltage test.....................................................................................................19

3.8

Examination................................................................................................................................20

3.8.1 Examination of cable..................................................................................................................20 3.8.2 Tests of components of cables with a longitudinally applied metal foil......................................20 3.9 Resistivity of semi-conducting screens ......................................................................................21

4 Non-electrical type tests.............................................................................................................22 4.1 Check of cable construction .......................................................................................................22 4.2 Tests for determining the mechanical properties of the insulation before and after ageing ......24 4.3 Tests for determining the mechanical properties of oversheaths before and after ageing........25 4.4 Ageing tests on pieces of complete cable to check compatibility of materials ..........................26

4.5

Pressure test at high temperature on oversheath type ST 7 .......................................................27

4.6 Hot set test for insulation............................................................................................................28 4.7 Measurement of carbon black content of black PE oversheaths...............................................29 4.8 Shrinkage test for XLPE insulation.............................................................................................30

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

3/39

-3- 09-1026

4.9

Shrinkage test for PE oversheaths.............................................................................................31

4.10 Water penetration test................................................................................................................32 4.11 Tests on components of cable with a longitudinally applied metal foil.......................................33

5 Additional test according to AEIC CS9-06 .................................................................................34 5.1 Conductor shield, voids, protrusions and irregularity limits........................................................34 5.2 Extruded insulation shield, voids, protrusions and irregularity limits..........................................34

APPENDIX A MEASUREMENT UNCERTAINTIES......................................................................... 35

APPENDIX B MANUFACTURERS DRAWING/DATA SHEET ....................................................... 36

-

8/13/2019 Testing of 110kV Cables

4/39

-4- 09-1026

1 IDENTIFICATION OF THE TEST OBJECT

1.1 Descrip tion of the test object

Single-core power cable

Manufacturer Elsewedy CablesType 76 / 132 (145) kV 1x1200 mm 2

CU/XLPE/CWS/AL/HDPEYear of manufacture 2008Sampling procedure by the manufacturerQuantity submitted 54 mRated voltage, U 0/U (U m) 76/132 kVNo. of cores 1Nominal electrical stress at the conductorscreen at U 0 (E i)

4,96 kV/mm

Nominal electrical stress at the insulationscreen at U 0 (E o)

2,59 kV/mm

Marking on the cable EL SEWEDY CABLES 1x1200 MM2 CU 132 KVELECTRIC CABLE XLPE 21.6 MM PROPERTY OFSAUDI ELECTRICITY COMPANY MANUFACTURINGYEAR

Conductor- material plain annealed copper- nominal cross-sectional area 1200 mm 2 - nominal diameter 43,7 approx.- type segmental Milliken- maximum conductor temperature

in normal operation90 C

Conductor screen

- material extruded semi-conducting material- nominal thickness 0,76 mm- material designation LE 595- manufacturer Borealis

Insulation- material XLPE- nominal thickness (t n) 21,6 mm- nominal inner diameter of insulation (d ii) 47,2 mm- nominal outer diameter of insulation (D io) 90,4 mm

- material designation LE 4021 S- manufacturer Borealis

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

5/39

-5- 09-1026

Insulation screen- material extruded semi-conducting material- nominal thickness 1,75 mm- material designation LE 595- manufacturer Borealis

Metallic screen

- material copper wire banded with open helix copper tape- number and nominal diameter of wires 75 wires of 2,18 mm

- nominal thickness and width of tape 0,1 x 20 mm (open helix)- cross-sectional area > 281,9 mm 2 - d.c. resistance < 0,0673 /km- nominal capacitance between conductor

and metallic screen 0,214 F/km

Metal foil longitudinally applied- material laminated aluminium- nominal thickness 0,05 / 0,2 / 0,05 mm

Oversheath- material HDPE, type ST 7 - nominal thickness 5,0 mm- nominal overall diameter of the cable 112,2 approx.- material designation HE 6062- manufacturer Borouge- colour black- graphite coating applied yes

Longitudinally watertightness

- along insulation screen yes- number of swelling tapes 1- nominal thickness and width (overlap) 0,25 x 70 mm (overlap: 10%)- material designation ZSD 20- manufacturer Tianrong

- along the conductor yes- swelling material swelling powder- material designation TUKAPOL PG 105- manufacturer CHT Germany

Fire retardant (IEC 60332-1) no

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

6/39

-6- 09-1026

Manufacturing details- type of extrusion triple extrusion- manufacturer of the extrusion line Maillefer- curing means Dry cure- cooling means Nitrogen

1.2 List of documents

The manufacturer has guaranteed that the cable submitted for tests has been manufactured inaccordance with the following drawings and documents.KEMA has verified that these drawings adequately represent the object tested.

The following drawings/documents are included in this Certificate:

drawing no./document no. revision date title

GB7-TX01-K81-00-00 1 1 February 2009 data sheet 76 / 132 kVpower cable 1x1200 mm 2

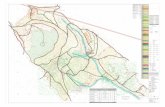

DB7-TX01-K81-00-00 0 1 July 2008 cable cross sectional drawing

-

8/13/2019 Testing of 110kV Cables

7/39

-7- 09-1026

2 GENERAL INFORMATION

2.1 The tests were witnessed by

Name Company

Mr Ahmed Abbas Elsewedy CablesMr Tamer Elwa Cairo, Egypt

Name Company

Mr Aldehamil, Ali Saleh A. Saudi Electric Company

Mr Alamri, Hazam Saleh A. Saudi ArabiaMr Algassar, Abdullah Ahmed H.

2.2 The tests were carried out by

Name Company

Mr H.E. Keizer KEMA Nederland B.V.,Mr E. Pultrum Arnhem, the NetherlandsMr J.J.M. Mooren

Mr B.G.A. JansenMr H.J. Arnoldus

2.3 Subcontracting

The following tests were subcontracted to KEMA Quality B.V.:- measurement of resistivity of semi-conducting screens in accordance with clause 12.3.9- non-electrical type tests in accordance with clause 12.4, with exception of the water penetration test

2.4 Purpose of the test

Purpose of the test was to verify whether the material complies with the specified requirements.

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

8/39

-8- 09-1026

2.5 Measurement uncertainty

A table with measurement uncertainties is enclosed in appendix A. unless otherwise indicated in thereport, the measurement uncertainties of the results presented are as indicated in this table.

2.6 Applicable standards

When reference is made to a standard and the date of issue is not stated, this applies to the latestissue, including amendments, which have been officially published prior to the date of the tests.

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

9/39

-9- 09-1026

3 ELECTRICAL TYPE TESTS

3.1 General

3.1.1 Tests at elevated conducto r temperature

For the tests with the cable system at elevated temperature, a reference loop for temperature controlof the conductor was installed. The reference cable was cut from the total cable length submitted bythe client intended for the type test. This reference loop was installed close to the main loop in order tocreate the same environmental conditions as for the test loop.The heating currents in both the reference loop and the test loop were kept equal at all times, thus theconductor temperature of the reference loop is representative for the conductor temperature of the testloop. Annex A, method 1 of IEC 60840 was used as a guide.The tests at elevated temperature are carried out two hours after thermal equilibrium has beenestablished.

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

10/39

-10- 09-1026

3.2 Test vol tage values

Standard and dateStandard IEC 60840, clause 12.3.1Test date 25 March 2009

nominal thickness(mm)

maximum allowed thickness(mm)

measured average thickness(mm)

21,6 21,6 + 5% = 22,68 22,04

ResultThe average thickness of the insulation did not exceed the nominal value by more than 5%. The testvoltages shall be the normal values specified for the rated voltage of the cable .

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

11/39

-11- 09-1026

3.3 Bending test follow ed by a partial discharge test

3.3.1 Bending test

Standard and dateStandard IEC 60840, clause 12.3.3Test date 23 March 2009

Environmental conditions Ambient temperature 10 CTemperature of test object 10 C

Characteristic test dataBending diameter:Cable with lead, corrugated metallicsheath or metal foil

25(d + D) + 5%

measured outerdiameter of cableD(mm)

measured diameter ofcable conductord(mm)

maximum requiredbending diameterDr(mm)

diameter oftest cylinderDt(mm)

117,6 44,1 D r 4245 3500

ProcedureThe test sample shall be bent around a test cylinder at ambient temperature for at least one completeturn. It shall then be unwound and repeated, except that the bending of the sample shall be in thereverse direction without axial rotation. This cycle of operation shall be carried out three times.

ObservationThe test was carried out successfully.

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

12/39

-12- 09-1026

3.3.2 Partial disc harge test

Standard and dateStandard IEC 60840, clause 12.3.4Test date 27 March 2009

Environmental conditions Ambient temperature 20 CTemperature of test object 20 C

Characteristic test dataCircuit balancedCalibration 5 pCNoise 2 pCSensitivity 4 pCRequired sensitivity 5 pC

Bandwidth 40-400 kHzTest frequency 50 HzCoupling capacitor 2600 pF

core voltage applied, 50 Hz duration partial discharge level

xU0 (kV) (s) (pC)

1 1,75 133 10

1,5 114 - not detectable

Requirement There shall be no detectable discharge exceeding the declared sensitivity from the test object at1,5xU 0.

Result

The test was passed.

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

13/39

-13- 09-1026

3.4 Tan measurement

Standard and dateStandard IEC 60840, clause 12.3.5Test date 31 March 2009

Environmental conditions Ambient temperature 20 CTemperature of test object 97 C

Characteristic test dataLength of test object 17,3 mStandard capacitor 100 pF

core voltage applied, 50 Hz core capacitance 1) tan

xU0 (kV) (F/km)

1 1 76 0,186 3,1x10 -4 1) for information only

Requirement

The measured value shall not be higher than 10x10 -4 at U 0.

ResultThe test was passed.

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

14/39

-14- 09-1026

3.5 Heating cyc le vol tage test

Standard and dateStandard IEC 60840, clause 12.3.6Test period 1 26 April 2009

Environmental conditions Ambient temperature 20 C

Characteristic test dataHeating method conductor currentStabilized temperature 97 C

no. ofheating-cycles

required steadyconductortemperature

heatingcurrentat stablecondition

heating per cycle coolingper cycle

voltage per cycle

(C) (A)

totalduration (hours)

duration ofconductor at steadytemperature(hours)

totalduration

(hours)

totalduration

(hours)

appliedvoltage2U 0 (kV)

20 95-100 2050 8 2 16 24 152

RequirementsNo breakdown shall occur.

ResultThe test was passed.

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

15/39

-

8/13/2019 Testing of 110kV Cables

16/39

-16- 09-1026

3.7 Lightn ing impulse test followed by a power-frequency voltage test

3.7.1 Impulse test

Standard and dateStandard IEC 60840, clause 12.3.7Test date 13 May 2009

Environmental conditions Ambient temperature 20 CTemperature of test object 97 C

Characteristic test dataSpecified test voltage 650 kV

The waveshape of the impulse voltage was determined at approximately 50 percent of the specifiedtest value (see figure 1 and 5).

testing arrangement polarity voltage applied(% of test voltage)

no. of impulses see figure

voltageapplied to

earthed

conductor metallic positive 50 1 1 (waveshape)

screen 65 1 2

80 1 2

100 10 3 and 4

conductor metallic negative 50 1 5 (waveshape)

screen 65 1 6

80 1 6

100 10 7 and 8

Requirement No breakdown of the insulation shall occur.

ResultThe test was passed.

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

17/39

-17- 09-1026

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

18/39

-18- 09-1026

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

19/39

-19- 09-1026

3.7.2 Power frequency volt age test

Standard and dateStandard IEC 60840, clause 12.3.7Test date 14 May 2009

Environmental conditions Ambient temperature 20 CTemperature of test object 20 C

testing arrangement voltage applied,50 Hz

duration

voltage applied to earth connected to xU 0 (kV) (min)

conductor metallic screen 2,5 190 15

RequirementNo breakdown of the insulation shall occur.

ResultThe test was passed.

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

20/39

-20- 09-1026

3.8 Examination

Standard and dateStandard IEC 60840, clause 12.3.8Test date 15 May 2009

3.8.1 Examination of cable

No sign of deterioration, e.g. electrical degradation, was found.

ResultThe cable passed the examination.

3.8.2 Tests of components of cables with a longitudinally applied metal foil

item unit requirement measured/determinedvisual examination- inspection - no cracks or

separationsno cracks or separations

adhesion strength- strength N/mm 0,5 0,7 0,9 0,6 0,9 0,7peel strength- strength N/mm 0,5 0,7 0,6 0,8 0,8 0,7

ResultThe test was passed.

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

21/39

-21- 09-1026

3.9 Resist ivity of semi-conducti ng screens

Standard and dateStandard IEC 60840, clause 12.3.9Test period 25 March 2009 until 7 April 2009

Characteristic test dataTemperature during ageing 100 CDuration 7 daysResistivity measured at 90 2 C

item unit requirement measured/determined

conductor s creen

- without ageing m 1000 6,2

- after ageing m 1000 4,3

insulation s creen

- without ageing m 500 2,3

- after ageing m 500 1,8

ResultThe test was passed.

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

22/39

-22- 09-1026

4 NON-ELECTRICAL TYPE TESTS

4.1 Check of cable const ruct ion

Standard and dateStandard IEC 60840, clause 12.4.1Test date 25 March 2009 and 14 May 2009

item unit requirement specified measured/determined

conductor- diameter of conductor mm - 43,7 approx. 44,1

- number of wires - 61 per segment 61 per segment

- diameter of wires mm - - 2,3 approx.

- resistance at 20C /km 0,0151 - 0,0148

thickness of insulation

- nominal mm - 21,6

- average mm - - 22,0

- minimum, t min mm 19,44 19,44 21,67

- maximum, t max mm - - 22,63

- (tmax t min) / t max - 0,15 - 0,04

thick ness of oversheath

- nominal mm - 5,0 -

- average mm - - 8,0

- minimum, t min mm 4,15 4,5 6,77

ResultThe cable construction complies with the requirements.

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

23/39

-23- 09-1026

4.1 Check of cable const ruct ion (continued)

observed/determined

marking - ELSEWEDY CABLES 1X1200MM2 CU 132KV ELECTRICCABLE XLPE SAUDI ELECTRICITY COMPANY 2008

construction - conductor of copper wires, 5 segments Milliken with swellingpowder in each segment, 61 wires per segment

- semi conducting water-blocking tape

- semi conducting conductor screen

- XLPE insulation

- semi conducting insulation screen- semi conducting water-blocking tape 69 x 0,1mm approx.

- screen of copper wires 75 x 2,2mm approx.

- copper tape with open helix 0,1 x 20mm approx.

- oversheath of HDPE with laminated aluminium tape

- graphite coating

outer diameter of the cableaverage (mm) 117,6

outer diameter of the coreaverage (mm) 94,3

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

24/39

-24- 09-1026

4.2 Tests for determining the mechanical properties of the insulation before andafter ageing

Standard and dateStandard IEC 60840, clause 12.4.2Test period 27 March 2009 until 6 April 2009

Characteristic test dataTemperature during aging 135 3 C

Ageing duration 7 days

item unit requirement measured/determined

without ageing

- tensile strength N/mm 12,5 30,7

- elongation % 200 590

after ageing

- tensile strength N/mm - 26,7

- variation with samples without ageing % 25 max. -13

- elongation % - 537

- variation with samples without ageing % 25 max. -9

ResultThe test was passed.

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

25/39

-25- 09-1026

4.3 Tests for determining the mechanical properties of oversheaths before and afterageing

Standard and dateStandard IEC 60840, clause 12.4.3Test period 27 March 2009 until 7 April 2009

Characteristic test dataTemperature during aging 110 2 C

Ageing duration 10 days

item unit requirement measured/determined

without ageing

- tensile strength N/mm 12,5 31,4

- elongation % 300 750

after ageing

- tensile strength N/mm - 31,2

- variation with samples without ageing % - -1

- elongation % 300 781

- variation with samples without ageing % - 4

ResultThe test was passed.

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

26/39

-26- 09-1026

4.4 Ageing tests on pieces of complete cable to check compatibi lity of materials

Standard and dateStandard IEC 60840, clause 12.4.4Test period 30 March 2009 until 7 April 2009

Characteristic test dataTemperature during aging 100 2 C

Ageing duration 7 days

Insulation

item unit requirement measured/determined

- tensile strength N/mm - 24,3

- variation with samples without ageing % 25 max. -21

- elongation % - 492

- variation with samples without ageing % 25 max. -17

Oversheath

item unit requirement measured/determined

- tensile strength N/mm - 30,7

- variation with samples without ageing % - -2

- elongation % - 773

- variation with samples without ageing % - 3

ResultThe test was passed.

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

27/39

-27- 09-1026

4.5 Pressure test at high temperature on oversheath type ST 7

Standard and dateStandard IEC 60840, clause 12.4.6Test date 14 April 2009

Characteristic test dataTemperature 110 2 CLoad 29,9 NDuration 6 h

item unit requirement measured/determined

- depth of indentation % 50 2

ResultThe test was passed.

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

28/39

-28- 09-1026

4.6 Hot set test for insulation

Standard and dateStandard IEC 60840, clause 12.4.10Test date 14 April 2009

Characteristic test data Air temperature 200 3 CTime under load 15 min

Mechanical stress 20 N/cm2

item unit requirement measured/determined

- elongation under load % 175 90

- permanent elongation % 15 1

ResultThe test was passed.

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

29/39

-29- 09-1026

4.7 Measurement of carbon black content of black PE oversheaths

Standard and dateStandard IEC 60840, clause 12.4.12Test date 31 March 2009

item unit requirement measured/determined

- carbon black content % 2,5 0,5 2,5

ResultThe test was passed.

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

30/39

-30- 09-1026

4.8 Shrinkage test for XLPE insulation

Standard and dateStandard IEC 60840, clause 12.4.13Test date 1 April 2009

Characteristic test dataTemperature 130 3 CDuration 6 h

item unit requirement measured/determined- shrinkage % 4 3

ResultThe test was passed.

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

31/39

-31- 09-1026

4.9 Shrinkage test for PE oversheaths

Standard and dateStandard IEC 60840, clause 12.4.14Test period 26 March 2009 until 1 April 2009

Characteristic test dataTemperature 80 2 CDuration 5 hHeating cycles 5

item unit requirement measured/determined

- shrinkage % 3 1

ResultThe test was passed.

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

32/39

-32- 09-1026

4.10 Water penetration test

Standard and dateStandard IEC 60840, clause 12.4.18 and Annex FTest period 6 17 April 2009

Environmental conditions Ambient temperature 20 C

Characteristic test dataLength of cable sample 6 mWater height above cable centre 1 mHeating method conductor currentStabilized conductor temperature 97 C

no. ofheating cycles

required steadyconductor temperature

heating currentat stablecondition

heating per cycle coolingper cycle

(C) (A)

totalduration (hours)

duration ofconductor atsteady temperature(hours)

totalduration

(hours)

10 95-100 2090 8 2 16

NoteThe manufacturer has claimed that barriers have been included, which prevents longitudinal waterpenetration in the region of the metallic layers and along the conductor.

RequirementNo water shall emerge from the ends of the cable sample.

ResultThe test was passed.

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

33/39

-33- 09-1026

4.11 Tests on components of cable with a longit udinally applied metal foil

Standard and dateStandard IEC 60840, clause 12.4.19Test date 27 March 2009

item unit requirement measured/determined

visual examination- inspection - no cracks or

separationsno cracks or separations

adhesion strength- strength N/mm 0,5 0,7 1,0 0,8 0,9 0,7

peel strength- strength N/mm 0,5 0,6 0,9 0,7 0,8 0,8

ResultThe test was passed.

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

34/39

-34- 09-1026

5 ADDITIONAL TEST ACCORDING TO AEIC CS9-06

5.1 Conductor shield, voids, protrusions and irregularity limit s

Standard and dateStandard AEIC CS9-06, clause 2.2.4Test date 12 June 2009

item unit requirement measured/determined

- voids mm 0,05 not detected- protrusions mm 0,075 not detected

- irregularity mm 0,075 not detected

ResultThe test was passed.

5.2 Extruded insulation shield, voids , protrusions and irregularity limit s

Standard and dateStandard AEIC CS9-06, clause 2.4.4Test date 12 June 2009

item unit requirement measured/determined

- voids mm 0,05 not detected

- protrusions mm 0,125 not detected

- irregularity mm 0,125 not detected

Result

The test was passed.

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

35/39

-35- 09-1026

APPENDIX A MEASUREMENT UNCERTAINTIES

The measurement uncertainties in the results presented are as specified below unless otherwiseindicated.

measurement measurement uncertainty

dielectric testsand impulse current tests

peak value: 3%time parameters: 10%

capacitance measurement

tan measurement

0,3%

0,5% 5x10-5

partial discharge measurement < 10 pC : 2 pC

10 - 100 pC : 5 pC> 100 pC : 20 %

measurement of impedanceac-resistance measurement

1%

measurement of losses 1%

measurement of insulation resistance 10%

measurement of dc resistance 1 - 5 : 1%5 - 10 : 0,5%

10 - 200 : 0,2%

radio interference test 2 dB

calibration of current transformers 2,2 x 10 -4 Ii/Iu and 290 rad

calibration of voltage transformers 1,6 x 10 -4 Ui/Uu en 510 rad

measurement of conductivity 5%

measurement of temperature -50 C - -40 C : 3 K-40 C - 125 C : 2 K125 C - 150 C : 3 K

tensile test 1%

sound level measurement type 1 meter as per IEC 651 and ANSI S1.4.1971

measurement of voltage ratio 0,1%

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

36/39

-36- 09-1026

APPENDIX B MANUFACTURERS DRAWING/DATA SHEET

4 pages (including this page)

drawing no. title date rev.

GB7-TX01-K81-00-00 data sheet 76 / 132 kV power cable1x1200 mm 2

1 February 2009 1

DB7-TX01-K81-00-00 cable cross sectional drawing 1 July 2008 0

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

37/39

-37- 09-1026

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

38/39

-38- 09-1026

V e r s i o n : 1

-

8/13/2019 Testing of 110kV Cables

39/39