Test Report issued under the responsibility of - - APC USA · Test Report issued under the...

Transcript of Test Report issued under the responsibility of - - APC USA · Test Report issued under the...

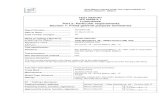

Test Report issued under the responsibility of:

TEST REPORT

IEC 62040-1 Uninterruptible power systems (UPS) –

Part 1: General and safety requirements for UPS Report Reference No ...................... : 17022083 002

Date of issue .................................... : August. 06, 2012

Total number of pages ...................... 22

CB Testing Laboratory ..................... : TÜV Rheinland (Shenzhen) Co., Ltd.

Address ............................................ : 3&4 F, Cybio Technology Building No. 1, Langshan No. 2 Road South, 5th Industrial Area, High-Tech Industry Park North, Nanshan District, 518057 Shenzhen, P.R. China

Applicant’s name ............................ : Schneider Electric IT France

Address ............................................ : 140, Avenue Jean Kuntzmann, Zirst-Montbonnot, 38330 Saint Ismier Cedex, France

Test specification:

Standard........................................... : IEC 62040-1 : 2008 (1st Edition)

Test procedure ................................. : CB

Non-standard test method…………..: N/A

Test Report Form No ...................... : IEC62040_1A

Test Report Form(s) Originator ........ : TÜV Rheinland Japan Ltd.

Master TRF ...................................... : Dated 2009-11

Copyright © 2009 IEC System for Conformity Testing and Certification of Electrical Equipment (IECEE), Geneva, Switzerland. All rights reserved. This publication may be reproduced in whole or in part for non-commercial purposes as long as the IECEE is acknowledged as copyright owner and source of the material. IECEE takes no responsibility for and will not assume liability for damages resulting from the reader's interpretation of the reproduced material due to its placement and context.

If this Test Report Form is used by non-IECEE members, the IECEE/IEC logo and the reference to the CB Scheme procedure shall be removed.

This report is not valid as a CB Test Report unless signed by an approved CB Testing Laboratory and appended to a CB Test Certificate issued by an NCB in accordance with IECEE 02.

Test item description ..................... : Uninterruptible Power Supply

Trade Mark ....................................... :

Manufacturer .................................... : Same as Applicant

Model/Type reference ...................... : G3HT**** series, G3HT****-IN series, G3HTI**** series (see page 9-11for details information of variable)

Ratings ............................................. : See information in page 9-11

Page 3 of 22 Report No. 17022083 002

TRF No. IEC62040_1A

Summary of testing:

Tests performed (name of test and test clause):

• Tests performed on the bench (details see table 7.7)

• Maximum ambient temperature: +35 °C • Tested for moderate conditions • Overvoltage category II considered • EUT is designed for altitudes not exceeding

2000m. • Unless otherwise stated. Model 3 phases

(20kV model) and 3 phases (40kVA model) are selected to represent the other models.

Testing location:

See page 2 for detail.

Summary of compliance with National Differences:

For national difference, see original report 1702083 001 for detail.

Copy of marking plate:

Page 4 of 22 Report No. 17022083 002

TRF No. IEC62040_1A

Page 5 of 22 Report No. 17022083 002

TRF No. IEC62040_1A

Page 6 of 22 Report No. 17022083 002

TRF No. IEC62040_1A

Others see original reports 1702083 001 for details.

Page 7 of 22 Report No. 17022083 002

TRF No. IEC62040_1A

Test item particulars .................................................. :

Equipment mobility .................................................... : [] movable [x] stationary [ ] for building-in

Connection to the mains............................................ : [ ] pluggable equipment [x] permanent connection [] detachable power supply cord [ ] non-detachable power supply cord

Operating condition ................................................... : [x] continuous [ ] rated operating / resting time:

Access location ........................................................ : [x] operator accessible [ ] restricted access location

Over voltage category (OVC) ................................... : [ ] OVC I [x] OVC II [ ] OVC III [ ] OVC IV [ ] other:

Mains supply tolerance (%) or absolute mains supply values ....................................................................... :

+15%, -10% (As manufacturer declared depending on the normal input 380/400/415V phase-phase voltage)

Tested for IT power systems .................................... : [x] Yes [] No

IT testing, phase-phase voltage (V) ......................... : 400V for Norway only

Class of equipment ................................................... : [x] Class I [ ] Class II [ ] Not classified

Considered current rating (A) ................................... : 136A max.

Pollution degree (PD) ............................................... : [ ] PD 1 [x] PD 2 [ ] PD 3

IP protection class .................................................... : IP21 for G3HT****-IN and G3HTI**** series IP20 for G3HT**** series

Altitude during operation (m) .................................... : 2000m

Altitude of test laboratory (m) ................................... : Below 2000m

Mass of equipment (kg) ............................................ : See page 6 for details

Possible test case verdicts:

- test case does not apply to the test object.................: N/A

- test object does meet the requirement.......................: P (Pass)

- test object does not meet the requirement.................: F (Fail)

Testing ......................................................................... :

Date of receipt of test item ............................................: March. 29, 2012

Date(s) of performance of tests ....................................: March-July, 2012

Page 8 of 22 Report No. 17022083 002

TRF No. IEC62040_1A

General remarks:

The test results presented in this report relate only to the object tested. This report shall not be reproduced, except in full, without the written approval of the Issuing testing laboratory. "(see Enclosure #)" refers to additional information appended to the report. "(see appended table)" refers to a table appended to the report. Throughout this report a comma (point) is used as the decimal separator. Standard IEC 62040-1:2008 is to be used in conjunction with IEC 60950-1:2005, which is referred to in this TRF as "RD".

Comments: Contents of the report:

22 pages of IEC 62040-1:2008 report and 5 pages photo documentation.

Factory(ies): APC (Xiamen) Power Infrastructure Co Ltd

No.1678 Jixian Road, Tongan District, Xiamen, Fujian 361100, P.R. China History of amendments and modifications: Ref. No. 17022083 001, dated Sept. 19, 2011 (original test report) Ref. No. 17022083 002, dated Aug. 06, 2012 (1st modification)

General product information:

Description of change(s): 1. Adding new series model G3HT****-IN series. Comparing with the original certified models, the new

adding models are different with the old one in terms of the filter function which integrated at the front panel for specified market and the configuration for the type of charger board and internal batteries. See below bold font in the table of rating information for the detailed description.

2. Add new series model G3HTI**** series, the new models are identical to the above mentioned structure except for adding the evaluation of the IP protection and new integrated transformer.

3. Slight change of the information for the address of applicant and factory, see page 1 and page 8 for details

For the above described change(s) the following was considered to be necessary:

Change Testing Comments

1. N/A Due to internal separated cooling channel provided and the dust filter function

2 Heating Test See appended table 4.5 and 7.7 for details

3. N/A See page 1 and page 8

Page 9 of 22 Report No. 17022083 002

TRF No. IEC62040_1A

Rating Information:

Model Name Mains Input Mains input 2 Output External battery Internal battery

G3HT10KHB1 None 10 minutes battery integrated

G3HT10KHB2 None 30 minutes battery integrated

G3HT10KH

G3HT10KH-IN

None None

G3HT10KHL

G3HTI10KHL

G3HT10KHL-IN

342-475Vac, 14-10A, 45-65Hz, 3Φ+N+PE

380/400/415Vac, 15/14/14A, 50/60Hz, 3Φ+N+PE

380/400/415Vac, 15/14/14A, 50/60Hz, 3Φ+N+PE, 8kW/10kVA

External battery cabinet

None

G3HT15KHB1 None 10 minutes battery integrated

G3HT15KHB2 None 30 minutes battery integrated

G3HT15KH

G3HT15KH-IN

None None

G3HT15KHL

G3HTI15KHL

G3HT15KHL-IN

342-475Vac, 22-16A, 45-65Hz, 3Φ+N+PE

380/400/415Vac, 23/22/21A, 50/60Hz, 3Φ+N+PE

380/400/415Vac, 23/22/21A, 50/60Hz, 3Φ+N+PE, 12kW/15kVA

External battery cabinet

None

Page 10 of 22 Report No. 17022083 002

TRF No. IEC62040_1A

Continued:

G3HT20KHB1 None 10 minutes battery integrated

G3HT20KHB2 None 25 minutes battery integrated

G3HT20KH

G3HT20KH-IN

None None

G3HT20KHL

G3HTI20KHL

G3HT20KHL-IN

342-475Vac, 29-21A, 45-65Hz, 3Φ+N+PE

380/400/415Vac, 30/29/27A, 50/60Hz, 3Φ+N+PE

380/400/415Vac, 30/29/27A, 50/60Hz, 3Φ+N+PE, 16kW/20kVA

External battery cabinet

None

G3HT30KHB1 None 10 minutes battery integrated

G3HT30KHB2 None 25 minutes battery integrated

G3HT30KH

G3HT30KH-IN

None None

G3HT30KHL

G3HTI30KHL

G3HT30KHL-IN

342-475Vac, 44-32A, 45-65Hz, 3Φ+N+PE

380/400/415Vac, 45/43/41A, 50/60Hz, 3Φ+N+PE

380/400/415Vac, 45/43/41A, 50/60Hz, 3Φ+N+PE, 24kW/30kVA

External battery cabinet

None

G3HT40KHB1 None 10 minutes battery integrated

G3HT40KHB2 None 20 minutes battery integrated

G3HT40KH

G3HT40KH-IN

None None

G3HT40KHL

G3HTI40KHL

G3HT40KHL-IN

342-475Vac, 58-42A, 45-65Hz, 3Φ+N+PE

380/400/415Vac, 60/58/55A, 50/60Hz, 3Φ+N+PE

380/400/415Vac, 60/58/55A, 50/60Hz, 3Φ+N+PE, 32kW/40kVA

External battery cabinet

None

G3HT10K3IB1 None 10 minutes battery integrated

G3HT10K3IB2 None 30 minutes battery integrated

G3HT10K3I

G3HT10K3I-IN

None None

G3HT10K3IL

G3HTI10K3IL

G3HT10K3IL -IN

342-475Vac, 14-10A, 45-65Hz, 3Φ+N+PE

220/230/240Vac, 50/60Hz, 45/43/42A, 1Φ+N+PE

220/230/240Vac, 50/60Hz, 45/43/42A, 1Φ+N+PE, 8kW/10kVA

External battery cabinet

None

Page 11 of 22 Report No. 17022083 002

TRF No. IEC62040_1A

Continued:

G3HT15K3IB1 None 10 minutes battery integrated

G3HT15K3IB2 None 30 minutes battery integrated

G3HT15K3I

G3HT15K3I-IN

None None

G3HT15K3IL

G3HTI15K3IL

G3HT15K3IL-IN

342-475Vac, 22-16A, 45-65Hz, 3Φ+N+PE

220/230/240Vac, 50/60Hz, 68/65/62A, 1Φ+N+PE

220/230/240Vac, 50/60Hz, 68/65/62A, 1Φ+N+PE, 12kW/15kVA

External battery cabinet integrated

None

G3HT20K3IB1 None 10 minutes battery integrated

G3HT20K3IB2 None 25 minutes battery integrated

G3HT20K3I

G3HT20K3I-IN

None None

G3HT20K3IL

G3HTI20K3IL

G3HT20K3IL-IN

342-475Vac, 29-21A, 45-65Hz, 3Φ+N+PE

220/230/240Vac, 50/60Hz, 98/87/83A, 1Φ+N+PE

220/230/240Vac, 50/60Hz, 98/87/83A, 1Φ+N+PE, 16kW/20kVA

External battery cabinet

None

G3HT30K3IB1 None 10 minutes battery integrated

G3HT30K3IB2 None 25 minutes battery integrated

G3HT30K3I

G3HT30K3I-IN

None None

G3HT30K3IL

G3HTI30K3IL

G3HT30K3IL-IN

342-475Vac, 44-32A, 45-65Hz, 3Φ+N+PE

220/230/240Vac, 50/60Hz, 136/130/125A, 1Φ+N+PE

220/230/240Vac, 50/60Hz, 136/130/125A, 1Φ+N+PE, 24kW/30kVA

External battery cabinet

None

Remark: All G3HTI**** series will be provided with integrated transformer. Accessory:

Model Name Description

G3HTEFBAT Empty battery cabinet

G3HTBAT1 G3HTBAT1 External battery cabinet with capacity: ±206Vdc or ±218Vdc

G3HTBAT2 G3HTBAT2(G3HTBAT2A, G3HTBAT2B) External battery cabinet with capacity: ±206Vdc or ±218Vdc

G3HTBAT3 G3HTBAT3(G3HTBAT3A, G3HTBAT3B) External battery cabinet with capacity: ±206Vdc or ±218Vdc

G3HTPARKIT Accessory for parallel configuration kit for 2 UPS (Redundancy 1+1)

G3HTOPT001 Dust Filter - Narrow Tower (400mm) for G3HT****-IN series

G3HTOPT002 Dust Filter - Wide Tower (500mm) for G3HT****-IN series

G3HTOPT005 Dust Filter - Narrow Tower (400mm) for G3HTI**** series

G3HTOPT006 Dust Filter - Wide Tower (500mm) for G3HTI**** series

Page 12 of 22 Report No. 17022083 002

TRF No. IEC62040_1A

4.5 TABLE: List of critical components P

Object/part no. Manufacturer/ trademark

Type/model Technical data

Standard Mark(s) of conformity 1.

Battery YUASA TOPLITE NPW45-12 8.0AH(10Hr) UL1989 UL MH29104

Battery YUASA SWL1100 38AH(10Hr) UL1989 UL MH29616

Battery YUASA SWL1850 65AH(10Hr) UL1989 UL MH29616

Battery CSB GP1272 7.0AH UL924,UL1989 UL MH14533

Battery CSB GP12120 11.3AH UL924,UL1989 UL MH14533

Battery CSB GP12340 31.4AH UL924,UL1989 UL MH14533

Battery BB HRC1234W 7.0AH IEC61056,JIS C8702,UL1989

UL MH19884

Transformer TRAFOMEC 432-0133-XFMR ISO STEEL 50HZ 1-PH 15KVA MSTAR

3:1 15KVA Insulation Class H

-- Test in appliance

Transformer TRAFOMEC 432-0136-XFMR ISO STEEL 50HZ 1-PH 20KVA MSTAR

3:1 20KVA Insulation Class H

-- Test in appliance

Transformer TRAFOMEC 432-0132-XFMR ISO STEEL 50HZ 1-PH 30KVA MSTAR

3:1 30KVA Insulation Class H

-- Test in appliance

Transformer TRAFOMEC 432-0137-XFMR ISO STEEL 50HZ 3-PH 20KVA MSTAR

3:3 20KVA Insulation Class H

-- Test in appliance

Transformer TRAFOMEC 432-0138-XFMR ISO STEEL 50HZ 3-PH 40KVA MSTAR

3:3 40KVA Insulation Class H

-- Test in appliance

Supplementary information:

1. An asterisk indicates a mark that assures the agreed level of surveillance.

7.7a TABLE A: temperature test P

Test Voltage(V) a b c

tamb1 (°C) ...................................... : -- -- --

tamb2 (°C) ...................................... : -- -- --

maximum temperature T of part/at: T (°C) allowed Tmax (°C)

For 20kVA 3 phases output model

PFCM VT10 74.1°C 64.2°C 65.2°C 130. PFCM VT32 57.1°C 51.0°C 51.9°C 130 PFCM VT29 66.2°C 57.1°C 58.1°C 130 PFCM VT12 65.3°C 58.0°C 58.8°C 130

Page 13 of 22 Report No. 17022083 002

TRF No. IEC62040_1A

PFCM VT43 70.8°C 58.3°C 59.3°C 130 PFCM VT9 72.1°C 62.5°C 63.2°C 130. PFCM VD8 63.3°C 57.4°C 58.4°C 130 PFCM VT30 64.2°C 56.0°C 57.0°C 130 PFCM VT11 63.7°C 56.8°C 57.6°C 130 PFCM VT44 64.3°C 54.4°C 55.6°C 130 PFCM VT21 67.0°C 58.8°C 59.2°C 130 PFCM VT22 83.4°C 61.6°C 62.4°C 130 PFCM VT20 65.6°C 57.8°C 58.0°C 130 PFCM VT16 87.0°C 65.9°C 66.7°C 130 PFCM VT6 87.2°C 67.1°C 67.8°C 130. PFCM VT4 91.8°C 78.3°C 79.3°C 130 PFCM VT5 87.7°C 68.3°C 69.4°C 130 PFCM VT13 104.5°C 89.0°C 90.9°C 130 PFCM VT15 92.0°C 69.0°C 70.0°C 130 PFCM VT3 100.2°C 85.4°C 86.9°C 130 PFCM VT14 70.3°C 60.8°C 61.3°C 130 PFCM VT19 69.6°C 61.2°C 61.9°C 130 PFCM VT46 53.4°C 47.8°C 48.6°C 130 PFCM L5 108.7°C 85.3°C 84.2°C 120 PFCM L1 116.2°C 89.9°C 89.4°C 120 PFCM L6 99.5°C 78.4°C 77.4°C 120 PFCM L3 102.1°C 81.9°C 81.3°C 120 PFCM L4 100.1°C 79.5°C 78.0°C 120 PFCM L2 93.3°C 75.6°C 74.6°C 120 CHGM VD3 56.0°C 46.2°C 56.5°C 130 CHGM VD4 66.9°C 48.0°C 67.9°C 130 CHGM VT4 79.8°C 48.6°C 81.5°C 130 CHGM VT3 67.7°C 47.1°C 68.8°C 130 CHGM L1 68.7°C 52.6°C 70.7°C 120 CHGM L2 101.2°C 64.7°C 104.8°C 120 IGBT INV L1 67.7°C 66.0°C 70.0°C 120 IGBT INV L2 62.8°C 61.0°C 64.6°C 120 IGBT INV L3 66.2°C 64.3°C 68.4°C 120 ASPM VT7 66.7°C 65.8°C 67.2°C 130 ASPM C4 50.8°C 50.2°C 51.2°C 105 ASPM VD2 57.2°C 54.5°C 56.5°C 130.

ASPM TV1 Transformer 57.5°C 56.9°C 57.7°C 120. IPTM DC BUS cap 41.4°C 41.1°C 41.1°C 105 IPTM DC BUS cap 41.0°C 39.0°C 40.5°C 105

Ambient Temperature room 37.0°C 34.9°C 36.7°C --

Page 14 of 22 Report No. 17022083 002

TRF No. IEC62040_1A

temperature T of winding: R1 (Ω)

R2 (Ω)

T (°C)

allowed Tmax (°C)

insulation class

Supplementary information: Test voltage: a) Input: 342V AC, 60Hz, output voltage set 400V AC, loaded with 20kVA / 16kW b) Input: 380V AC, 50Hz, output voltage set 400V AC, loaded with 20kVA / 16kW c) Input: 475V AC, 50Hz, output voltage set 400V AC, loaded with 20kVA / 16kW Having a specified maximum ambient temperature of +35 °C, the maximum temperatures are calculated as follows based upon a (minimum) test temperature of 35 °C: Winding components (providing safety isolation): - Class B → Tmax = 120 °C - 10 °C °C = 110 °C Other components:

→ Tmax=Tmax

7.7b TABLE A: temperature test P

Test Voltage(V) a b c

tamb1 (°C) ...................................... : -- -- --

tamb2 (°C) ...................................... : -- -- --

maximum temperature T of part/at: T (°C) allowed Tmax (°C)

For 40kVA 3 phases output model

PFCM Left PFCM VD08 67.3 63.6 62.6 130 PFCM Left PFCM VT12 59.8 55.5 54.2 130 PFCM Left PFCM VT11 59.3 55.4 53.8 130 PFCM Left PFCM VD07 64.4 63.9 67.7 130 PFCM Left PFCM VT10 66.2 62.2 58.7 130 PFCM Left PFCM VT09 64.7 60.2 57.6 130 PFCM Left PFCM VD26 53.9 50.7 51.0 130 PFCM Left PFCM VD36 54.3 50.5 51.4 130 PFCM Right PFCM VD8 63.2 59.9 58.2 130 PFCM Right PFCM VT9 62.7 60.7 55.8 130 PFCM Right PFCM VD9 49.8 48.1 48.0 130 PFCM Right PFCM VD36 46.0 79.4 45.2 130 Choke Left PFC choke L1 82.6 78.2 66.5 120 Choke Left PFC choke L2 88.2 83.3 69.4 120 Choke Left PFC choke L6 88.5 83.9 70.3 120 Choke Right PFC choke L2 79.6 76.7 64.9 120 Choke Right PFC choke L5 83.8 80.1 67.6 120 Choke Left Rectifier choke L1 115 80.9 68.9 120 Choke Output INV choke L1 52.8 53.2 53.5 120 Choke Output INV choke L3 67.5 68.3 68.9 120 IGBT INV PH3 65.3 66.2 69.0 130 IGBT INV PH2 66.0 67.1 69.7 130

Page 15 of 22 Report No. 17022083 002

TRF No. IEC62040_1A

IGBT INV PH1 70.2 71.3 73.5 130 SCR Output INV SCR PH3 59.5 60.1 61.3 130 SCR Output INV SCR PH2 63.1 63.8 64.9 130 SCR Output INV SCR PH1 61.7 62.3 63.7 130 INSM Left INSM VT6 62.6 60.8 55.1 130 INSM Left INSM VT5 64.2 62.4 56.7 130 INSM Left INSM VT4 75.9 74.0 66.9 130 INSM Left INSM VT3 77.4 75.5 67.9 130 APSM VT7 47.4 48.1 47.7 130 APSM VT1 50.7 50.8 50.3 130 APSM VD2 52.4 55.8 53.8 130 CHGM VT3 81.5 80.7 81.7 130 CHGM VD3 55.4 55.3 55.5 130 CHGM L1 93.3 93.2 91.6 120 AC cap Output OND AC cap PH2 43.1 42.9 42.3 105 IPYM DC Bus cap 40.4 40.3 40.3 105 Ambient Ambient 35.0° 35.1 34.9 --

temperature T of winding: R1 (Ω)

R2 (Ω)

T (°C)

allowed Tmax (°C)

insulation class

Supplementary information: Test voltage: d) Input: 342V AC, 60Hz, output voltage set 400V AC, loaded with 40kVA / 32kW e) Input: 380V AC, 50Hz, output voltage set 400V AC, loaded with 40kVA / 32kW f) Input: 475V AC, 50Hz, output voltage set 400V AC, loaded with 40kVA / 32kW Having a specified maximum ambient temperature of +35 °C, the maximum temperatures are calculated as follows based upon a (minimum) test temperature of 35 °C: Winding components (providing safety isolation): - Class B → Tmax = 120 °C - 10 °C °C = 110 °C Other components:

→ Tmax=Tmax

Attachment 1

Page 16 of 22

TRF No. IEC 60529

TEST REPORT

IEC 60529:2001

Degree of Protection By Enclosures

Report reference No . ....................... : 17022083 002

Compiled by (+ signature) ................ : See main report

Approved by (+ signature)................ : See main report

Date of issue ................................... : See main report

Testing laboratory ............................ : TÜV Rheinland (Shenzhen) Co., Ltd.

Address ........................................... : 3&4 F, Cybio Technology Building No. 1, Langshan No. 2 Road South, 5th Industrial Area, High-Tech Industry Park North, Nanshan District, 518057 Shenzhen, P.R. China

Testing location ............................... : CBTL CCATL SMT TMP

Address ............................................ : Same as above

Applicant .......................................... : Schneider Electric IT France

Address ........................................... : 140, Avenue Jean Kuntzmann, Zirst-Montbonnot St Martin, 38334 St Ismier Cedex, France

Test specification

Standard ........................................... : IEC 60529:2001

Test Report Form No........................ : CB scheme

TRF originator . ................................ : TUV Rheinland of North America, Inc.

Procedure deviation ........................ : N.A

Test item........................................... : Uninterruptible Power Supply

Trademark ....................................... :

Model and/or type reference ........... : G3HT**** series, G3HTI**** series (see page 9-11for details information of variable)

Manufacturer .................................... : Same as applicant

Page 17 of 22 Report No. 17022083 002

IEC 60529

Clause Requirement − Test Result – Remark Verdict

TRF No. IEC 60529

5 Degrees of protection against access to hazardous parts and against solid foreign objects indicated by the first characteristic numeral

P

5.1 Protection against access to hazardous parts P

First characteristic numeral: 2 P

Test conditions according to sub-clause 12.2 P

Compliance checked The test probe can not touch any hazardous parts

P

5.2 Protection against solid foreign objects P

First characteristic numeral: 1 P

Test conditions according to sub-clause 13.2 or 13.4 or 13.5

P

Compliance checked The dust does not impair safety; the dust can not enter into the inner side of the equipment.

P

6 Degrees of protection against ingress of water indicated by the second characteristic numeral

P

Second characteristic numeral : 1 P

Test conditions according to sub-clause 14.2.1 to 14.2.8 as applicable

P

Compliance checked P

7 Degrees of protection against access to hazardous parts indicated by the

additional letter N

Additional letter : No Additional Protection Letter N/A

Test conditions according to sub-clause 15.2 No Additional Protection Letter N/A

Compliance checked No Additional Protection Letter N/A

8 Supplementary letters N/A

Additional supplementary letter : No Additional Protection Letter N/A

Test conditions according to sub-clause 15.2 No Additional Protection Letter N/A

Compliance checked No Additional Protection Letter N/A

9 IP code designations IP 21 P

10 Marking N/A

Specified in relevant product standards No Marking N/A

Page 18 of 22 Report No. 17022083 002

IEC 60529

Clause Requirement − Test Result – Remark Verdict

TRF No. IEC 60529

Such standard also specify the method of marking which is to be used when

N/A

-one part of an enclosure has a different degree of protection to that of another part of the same enclosure

N/A

-the mounting position has an influence on the degree of protection

N/A

-the maximum immersion depth and time are indicated

N/A

11 General requirements for tests P

11.1 Atmospheric conditions for water or dust tests P

-temperature

-relative humidity

15°C to 35°C

25% to 75% P

-air pressure 860mbar to 1060mbar P

11.2 Test samples

-number of samples tested 1 sample P

-conditions for mounting, assembling and positioning of the samples

The sample was mounted as normal use

P

-pre-conditioning, if any None N/A

-tested energized or not Not energized P

-tested in motion or not None N/A

The manufacturer’s instructions shall apply in the absence of such specifications

Enclosure will meet the requirements of IP21 with the door closed.

P

11.3 Application of test requirements and interpretation of test results

Drain Holes and Ventilation Openings provided

P

-responsibility of the relevant technical committee The ventilation openings and drain holes are insulated from the inner chamber, the water can not get into the chamber, see attachement 1 for details

P

-in the absence of such specification the requirement of this standard shall apply

N/A

11.4 Combination of test conditions for the first characteristic numeral

1.0mm Test Wire P

First characteristic numeral 5 P

11.5 Empty enclosures N/A

Page 19 of 22 Report No. 17022083 002

IEC 60529

Clause Requirement − Test Result – Remark Verdict

TRF No. IEC 60529

Detailed requirements shall be indicated by the enclosure manufacturer in his instructions for the arrangement and spacing of hazardous parts or parts which might be affected by the penetration of foreign objects or water

N/A

The manufacturer of the final assembly shall ensure that after the electrical equipment is enclosed the enclosure meets the declared degree of protection of the final product

N/A

12 Tests for protection against access to hazardous parts indicated by the first characteristic numeral

P

12.1 Access probes according to Table VI are used No hazardous Parts can be accessed through the ventilation openings

P

12.2 Test conditions as specified P

12.3 Acceptance conditions The protection is satisfactory. P

Adequate clearance is kept between access probe and hazardous parts

Adequate clearance provided between Hazardous parts and access probe

P

12.3.1 For low-voltage equipment P

The access probe shall not touch hazardous live parts

The probe can not touch hazardous live parts.

P

12.3.2 For high-voltage equipment No such equipment N/A

The equipment shall be capable of withstanding the dielectric tests as specified in the relevant product standard applicable to the equipment

None N/A

Where an enclosure includes sections at different voltage levels the appropriate acceptance conditions for adequate clearance shall be applied for section

None N/A

12.3.3 For equipment with hazardous mechanical parts None N/A

The access probe shall not touch hazardous mechanical parts

None N/A

13 Tests for protection against solid foreign objects indicated by the first

characteristic numeral P

13.1 Test means and the main test conditions according to table VII are used

Dust chamber P

13.2 Test conditions for first characteristic numerals 1,2,3,4

None N/A

Object probe is pushed against any openings of the enclosure with the force specified in table VII

None N/A

Page 20 of 22 Report No. 17022083 002

IEC 60529

Clause Requirement − Test Result – Remark Verdict

TRF No. IEC 60529

13.3 Acceptance conditions for first characteristic numerals 1,2,3,4

None N/A

The protection is satisfactory if the full diameter of the probe does not pass through any opening

None N/A

13.4 Dust test for first characteristic numerals 5& 6 2 P

Tests are conducted as specified and classified according to its category 1 or 2

Category 1 P

If it is impractical to test the complete enclosure in the test chamber, one of the following procedures shall be applied:

Entire enclosure was tested to category 1

N/A

-testing of individually enclosed sections of the enclosure

Entire enclosure was tested to category 1

N/A

-testing of representative parts of the enclosure , comprising components such as doors, ventilation openings, joints, shaft seals, etc., in position during test

N/A

-testing of a smaller enclosure having the same full-scale design details

N/A

13.5 Special conditions for first characteristic numeral 5

P

13.5.1 Test conditions as specified P

13.5.2 Acceptance conditions P

The protection is satisfactory if talcum powder has not accumulated in a quantity or location such that, as with any other kind of dust, it could interfere with the correct operation of the equipment or impair safety

Minimal dust entered the enclosure, but did not effect the operation or the safety of the equipment

P

No dust shall deposit where it could lead to tracking along the creepage distances

No dust was near any electrical terminals or connections

P

13.6 Special conditions for first characteristic numeral 6

None N/A

13.6.1 Test conditions as specified None N/A

13.6.2 Acceptance conditions None N/A

The protection is satisfactory if no deposit of dust is observable inside the enclosure at the end of the test

none N/A

14 Tests for protection against water indicated by the second characteristic numeral P

14.1, 14.2

Test means and test conditions are performed according to table VIII

IPX1, protected against vertically falling water drops

P

Page 21 of 22 Report No. 17022083 002

IEC 60529

Clause Requirement − Test Result – Remark Verdict

TRF No. IEC 60529

14.2.1 Test for second characteristic numeral 1 with drip box

None P

14.2.2 Test for second characteristic numeral 1 with drip box

None P

14.2.3 Test for second characteristic numeral 3 with oscillating tube or spray nozzle

None N/A

14.2.4 Test for second characteristic numeral 4 with oscillating tube or spray nozzle

None N/A

14.2.5 Test for second characteristic numeral 5 with the 6.3mm nozzle

N/A

14.2.6 Test for second characteristic numeral 6 with the 12.5mm nozzle

None N/A

14.2.7 Test for second characteristic numeral 7:

Temporary immersion between 0.15m and 1m

None N/A

14.2.8 Test for second characteristic numeral 8:

Continuous immersion subject to agreement

None N/A

14.3 Acceptance conditions P

It is the responsibility of the relevant technical committee to specify the amount of water which may be allowed to enter the enclosure and the details of a dielectric strength test, if any

Some water entered the enclosure, but didn’t affect the operation or the safety of the equipment.

P

In general, if any water has entered, it shall not Some water entered the enclosure, but didn’t affect the operation or the safety of the equipment.

P

-be sufficient to interfere with the correct operation of the equipment or impair safety

Some water entered the enclosure, but didn’t affect the operation or the safety of the equipment.

N/A

-deposit on insulation parts where it could lead to tracking along the creepage distances

Same as above. N/A

-reach live parts or wingdings not designed to operate when wet

Same as above. N/A

-accumulate near the cable end or enter the cable if any

No cables N/A

For enclosure with drain-holes, it should be proved by inspection that any water which enters does not accumulate and that it drains away without doing any harm to the equipment

N/A

For enclosures without drain-holes, the relevant product standard shall specify the acceptance conditions if water can accumulate to reach live parts

N/A

Page 22 of 22 Report No. 17022083 002

IEC 60529

Clause Requirement − Test Result – Remark Verdict

TRF No. IEC 60529

15 Test for protection against access to hazardous parts indicated by the additional

letter N/A

15.1 Access probes to hazardous parts according to table VI

No additional letter N/A

15.2 Test conditions as specified No additional letter N/A

15.3 Acceptance conditions No additional letter N/A

The protection is satisfactory if adequate clearance is kept between the access probe and hazardous parts

No additional letter N/A

Page 1 of 5

Type Designation: G3HT**** series, G3HT****-IN series G3HTI**** series Report Number: 17022083 002

Figure 1: 15kVA transformer 3phase in/1phase out

Page 2 of 5

Type Designation: G3HT**** series, G3HT****-IN series G3HTI**** series Report Number: 17022083 002

Figure 2: 20kVA transformer 3phase in/1phase out

Page 3 of 5

Type Designation: G3HT**** series, G3HT****-IN series G3HTI**** series Report Number: 17022083 002

Figure 3: 20kVA transformer 3phase in/3phase out

Page 4 of 5

Type Designation: G3HT**** series, G3HT****-IN series G3HTI**** series Report Number: 17022083 002

Figure 4: 30kVA transformer 3phase in/1phase out

Page 5 of 5

Type Designation: G3HT**** series, G3HT****-IN series G3HTI**** series Report Number: 17022083 002

Figure 5: 40kVA transformer 3phase in/3phase out

End of photo document