Teoria Variadores de Frecuencuia

-

Upload

asotozuazua -

Category

Documents

-

view

9 -

download

4

Transcript of Teoria Variadores de Frecuencuia

-

FREQUENCY CONTROLLED ACMOTOR DRIVE1.0 Features of Standard AC MotorsThe squirrel cage induction motor is the electrical motormotor type most widely used in industry. This leadingposition results mainly from certain excellent features ofthe squirrel cage motor such as: Uncomplicated, rugged construction. For the user

this means low initial cost and high reliability. Good efficiency coupled with low maintenance costs

resulting in low overall operating costs.

Squirrel cage motors are asynchronous inductionmachines whose speed depends upon applied fre-quency, pole pair number, and load torque. At a constantsupply voltage and frequency, if the effect of temperaturevariations is disregarded, the motor torque will dependupon slip - Shown in Figure as An.

At a positive slip, the squirrel cage machine will act as amotor - at a negative slip, as a generator. To reverse themachine's direction of rotation, the phase sequence tothe motor must be changed.

Assuming similar conditions, the phase current drawn bya squirrel cage motor will depend only on the slip. Amotor running at synchronous speed will only drawminimum current. As shown in Figure 1, as the slip isincreased in either direction from zero, the current beginsto increase rapidly.

The peak torque of standard squirrel cage motors is twoto three times the permissible continuous torque, I e. themotor's rated torque. As shown in Figure 1, the positiveand negative peak torques are respectively produced atslips of nh, determined by the electrical characteristicsof the motor.

For efficient operation, the slip of a squirrel cage motormust be kept small, i.e. within a narrow range of -h+nh. Because of this, speed control of squirrel cage motorscan best be implemented by means of infinitely variable(stepless) frequency control. The nominal slip in mostcases is 3% of the synchronous speed, and dependsmainly on the motor size.

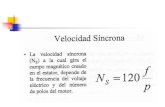

1.1 Motor Speed - In order to use the polyphase ACmotor as an adjustable speed device, it is necessary tocontrol and adjust the frequency of the 3 power appliedto its terminals. The operating speed of the AC motor isdetermined by the following relationship:

where Frequency is described in cycles per second (Hz),and Speed and Slip are expressed in RPM.

Figure 1 -Typical Squirrel Cage Motor Torque T andCurrent I at Constant Supply Voltage and Frequency

When a synchronous or synchronous reluctance motor isused, slip in the above equation is zero, while the motor'sshaft speed is said to be synchronous, and completelycontrolled by applied power frequency.

Operation of an induction (NEMA Type B) machine,however, will result in a slip whose degree is a functionof motor design, and a lower than synchronous operationshaft speed.

1.2 Frequency Controlled Squirrel Cage MotorsIn frequency converter drives, squirrel cage motors areusually run within the range between the peak torques.The single-phase equivalent circuit of the motor, shownin Figure 2, can be used to obtain equations for thetorque T, the peak torque Th and the slip nn corres-ponding to the peak torque. The equations are based onthe assumption that the magnitude of the phase currentI1, does not affect the voltage Ui

-

1.3 Motor Torque - AC motor torque capability isproportional to magnetic flux density in the motor's airgap. In order to maintain constant torque capability atthe output shaft of an AC motor used as an adjustablespeed device, the flux density in the air gap must bemaintained constant over the operating frequencyrange. Since the motor presents a highly inductiveload to the power supply, its impedance increasesdirectly with applied frequency. It is necessary,therefore, to increase the applied voltage in directproportion to the increase in frequency or increase inspeed. Therefore the ratio of volts to frequency mustbe kept constant, as shown in the relationship below:

This ratio is often referred to as Volts-Per-Hertz(V/Hz) and is controlled by the converter.At low supply frequencies the stator resistance R1shown in Figure 2 "consumes" a significant percen-tage of the supply voltage, and the air gap voltage Ujeasily becomes lower than desired. As shown inFigure 3, the effect of the R1 resistance can be com-pensated by raising the supply voltage above thelinear U1f1 curve at low frequencies. The compensa-tion required, known as IR compensation, will besmaller the larger the motor is.Within the constant flux range each torque value al-ways corresponds to the same phase current, regard-less of the frequency. In the equivalent circuit the

reactive current Im and the rotor current I2 remainconstant. In addition, the rotor current has, regardlessof the supply frequency, always the same phase dis-placement in regard to the air gap voltage, (Figure 2).

FIGURE 3 - Supply Voltage Control with an Example of IRCompensation.

1.4 Field Weakening Range - As shown in Figure 3,above the rated speed the supply voltage is main-tained at the rated value. The air gap flux accordinglydecreases in inverse proportion to the frequency. Thepeak torque decreases in inverse proportion to thesquare of the frequency, while the corresponding slipremains nearly constant.

Due to the lowered torque current, the slip corres-ponding to a given load is larger in the fieldweakening range than in the constant flux range.Within the field weakening range the excitation cur-rent Im decreases in inverse proportion to the fre-quency. Because of this, the phase current of anunloaded motor clearly decreases with the fre

Volts / Frequency = CONSTANT

-

quency. On a loaded motor the power factor of therotor current (Figure-2), tends to increase the rotorcurrent 12. The reduction of the excitation current andthe increase in the rotor current roughly cancel eachother out. Within the field weakening range, therefore,a motor supplied at a constant current will produceapproximately constant horsepower.At a frequency characteristic to each individual motor(approximately 1.4fN1.6fN), the peak torque hasdecreased so low that the available slip has to belimited. The limit will be determined by the danger ofpull-out, not by the magnitude of the current. Themotor cannot continue to produce a constant output.

1.5 Output Torque -A squirrel cage motor can bestbe started by increasing the frequency while con-stantly maintaining the slip below the peak slip. Thispermits a starting torque equal to the rated torquewithout using an oversized drive. This type of startingrequires a minimum output frequency of 0.5 to 2 Hz,depending on the size of the motor, and full IRcompensation.Where IR compensation is not used and the machinecan only be fed with a current no higher than the ratedcurrent, the starting torque produced by a standardmotor will usually be 45 to 55% of the rated torque. Inthis case, the motor size or the temperature have nosignificant effect on the starting torque achieved.

Figure 4 - Motor Torque T and HP at Constant Current

As shown in Figure 4, within the constant flux rangethe maximum torque is usually limited by the ACdrive. An oversized AC drive will permit the motor-todeliver a maximum torque above the rated torque.

When the rated current of the adjustable frequencydrive is slightly higher than the rated current of themotor, the torque produced will be approximately asindicated below:

T = (IT/ INM) xTNwhere IT = current produced by the

frequency converterINM = rated current of the motorTN= rated torque of the motor

If the torque is considerably higher than the ratedmotor torque- available, consult the Allen-BradleySales Office to determine the required current anddrive size.

If a large overcurrent is fed into the motor, the motorinductances will be reduced due to the saturation ofthe magnetic circuits. The decreased inductancesoften limits the capacity of the converter to supplyfundamental current. On the other hand, the induc-tances in a smaller motor are larger than those in amotor of the same size as the converter.

In all cases the peak torque of the motor is the toplimit for the torque produced. Due to the danger ofpullout, a certain margin has to be reversed. As a ruleof thumb,2/3 x Th can be taken as the top operatinglimit for the torque depending on the motor.The magnitude of the peak torque Th is indexed inmotor catalogs. NOTE: The long-term load on a motoris restricted by the thermal load capacity of the motor.

-

for f fN

where nN is the difference between the synchronous andrated speeds of a motor supplied at the rated frequencyfN, and f is the input frequency.

As shown previously in Figure2, the motor's rotorresistance R2 at the rated operating temperature is

1.7 Speed Accuracy - In most cases the speed of asquirrel cage motor is controlled without a tachometer,i.e. the motor is run open loop. The speed accuracy isadequate since the torque curve of a squirrel cage motoris steep. As shown previously in Figure 1, even largechanges in the torque do not result in large changes inslip.

The actual speed is lower than the synchronous speedfi/p of the frequency converter control. The differencebetween the synchronous speed and the actual speed isslip. Slip depends on such factors as motor size, design,load, and operating temperature. The speed error An,corresponding to a given load torque can be obtainedfrom the actual torque curve of the motor.

When the load torque T is relatively small compared tothe peak torque, the rated slip nN and the rated torqueTN can be used to approximate the slip as follows:

1.6 Motor Loading Capacity- Figure 5 shows both thetorque and the power which is delivered by a typicaladjustable frequency controlled motor in continuous use.The torque curve starts at 40% of the motor's ratedtorque and rises to approximately 85% at 55Hz. This isrelated to the fact that the motor is self-ventilated andtherefore does not get fully cooled at low speeds. Toimprove cooling, the motor can be equipped with aseparate cooling fan. Load capacity now follows thebroken line shown in Figure 5. The separate fan greatlyimproves load capacity at low speed. Conversely, theself-ventilated motor is capable of greater load capacityat speeds above 65Hz. From this, it is evident that poweris related to the actual speed and the cooling system ofthe motor.

As shown in Figure 6 a frequency controlled squirrelcage motor drive can, (unless the cooling fan preventsit), operate in all four quadrants above and belowminimum frequency, i.e. 0.5 Hz.

A smooth shift into generator operation is accomplished,as it is not necessary to reverse the direction of theexcitation current or of any other current - The shift isachieved by providing a negative slip. This means thatthe supply frequency is reduced to a value lower thanwould be required by the actual speed. The direction ofrotation is usually reversed by electronic means withinthe drive.

In the continuous state the torque supplied by the motordepends upon the slip. In transition states, e.g. when theapplied input frequency suddenly increases while thespeed remains constant, the torque will, within a timeconstant depending on the motor, assume the valuecorresponding to the new slip. The time constant willincrease for each larger motor output rating.

-

Due to the operation principle of the converter, afrequency converter of this type cannot be used in thefield weakening range.

Furthermore, the power rating of a motor connected tothe converter has to be within a narrow output rangedetermined by the converter as the motor forms anessential part of the commutating circuits of theconverter.

Frequency converters having an LC low-pass filter in theintermediate circuit are said to have a DC voltageintermediate circuit. In frequency converters of this typethe amplitude of the output voltage is adjusted either bycontrolling the intermediate circuit voltage (shown inFigures 8b and c), or by altering the output voltagewaveform (Figure 8d). The latter method is called PulseWidth Modulation - PWM. Frequency convertersequipped with DC voltage intermediate circuits aresuitable for use in both single and multiple motor drives.

The PWM frequency converter is the most generallyapplicable of the alternative designs shown. It differsfrom the types equipped with DC voltage intermediatecircuits in such areas as speed control and effects on thevoltage supply lines to the converter.Another method of control used is VVI - Variable VoltageInput. In VVI frequency converters equipped withintermediate circuit DC voltage control, the voltage iscontrolled by adjusting the intermediate circuit voltage.This results in poor speed control as a large capacitor inthe intermediate circuit has to be charged or dischargedto change the voltage. The PWM frequency converterhas a large speed range, as voltage control isimplemented by means of a converter.Due to the diode bridge, the power drawn for the voltagesupply lines by the PWM frequency converter consistsalmost entirely of active power, i.e. fp is approximately.99. Other frequency converter types' except convertershaving a chopper in the intermediate circuit, consumereactive power because of their controlled rectifiers.

2.2 PWM Converter Principles - In PWM frequencyconverters the intermediate circuit produces a fixedvoltage. The task of the converter is to use this DCvoltage to produce a symmetrical, 3 voltage whosemagnitude and frequency can be controlled. Theoperation of the converter can be illustrated by the switchmodel shown in Figure 9. In practice, semiconductorswitches are used.

The switches R, S, and T are controlled as appropriate toproduce a 3 voltage on the poles of the

approximately one and a half times that of the resistanceof a cold motor. Because of this, the slip of a cold motoris approximately 60% of the slip of a motor at the ratedtemperature.

Where a better speed accuracy (>3% of rated speed) isdesired, a tachometer for speed measurement andclosed loop control has to be used. The speed accuracywill mainly be determined by the feedback transducer ortachometer employed.

2.0 General Principles of Frequency Converters2.1 Frequency Converter Alternatives - Frequencycontrolled squirrel cage motor drives employ convertersequipped with an intermediate circuit. Such a converterconsists of four parts as shown in Figure 7.

Figure 7 - Block Diagram of Frequency Converter

The first part on the supply side is a rectifier. In theintermediate circuit the pulsating DC voltage produced bythe rectifier is filtered in an LC low-pass filter orconverted into a DC current in a choke. The last part isconverter which uses the DC current or voltage from theintermediate circuit to produce an AC current or voltagehaving the desired frequency. The control unit overseesthe operation of the frequency converter.

Frequency converters can be classified into two maintypes on the basis of the construction of the intermediatecircuit. If the intermediate circuit consists of a chokealone, the converter is said to have a DC currentintermediate circuit as shown in Figure 8a. A frequencyconverter of this type functions as a current source thatsupplies the motor with a current such that the desiredvoltage is present on the poles of the motor. Theamplitude of the current is determined by a rectifier.Frequency converters equipped with DC currentintermediate circuits are generally used in single-motordrives.

-

motor. As the converter operates, each switch is in eitherof the positions shown, and switching is assumed to takeplace without delay.

The simplest voltage waveform is obtained by keepingthe switches up in the "+" position for half a cycle, anddown in the "-" position for half a cycle. In addition, theswitch positions must have a phase displacement of1200 from one another. The switch positions and thephase voltage URS are shown in Figure 10.

This pulse pattern is suitable for supplying a constantvoltage to a squirrel cage motor. The waveform yields anRMS value of 0.,78 Uc for the voltage at the basicfrequency. PWM frequency converters have thiswaveform in the field weakening range, i.e. 6-step.

The frequency and the voltage can be controlled by usingmore voltage pulses per half-cycle in the main voltage.The RMS value of the basic frequency voltage isadjusted by varying the widths of individual

pulses in the main voltage. Figure 11 shows thewaveform for (5) pulses per half-cycle.A significant part of the power loss in a PWIVI converterconsists of switching losses proportional to the number ofswitching per second. A suitable number of switching persecond or pulse number (number of pulses per half cycleat the operating motor frequency) to maintain lowharmonic currents and low torque pulsation in the motorvary with the power devices used. Power transistors canhandle switching frequencies greater than 1 kHz whilesilicon controlled rectifiers prefer switching frequencies ofless than 1 kHz. Switching frequencies above 300 Hz arereasonable for pulse width control of AC motors. In-creasing the numbers of pulses at low operating motorfrequencies is one method of reducing current pulsationswhen the motor is operating below 200 rpm. Pulse widthmodulation switching frequencies of 400 to 1200 Hzprovide smooth operation over the full speed range of anAC motor.

-

In sine modulation the pulse widths of each main voltagehalf wave increase sinusoidally from the edges of the halfwave towards the center, with significant reduction of the5th and 7th harmonics in particular. The same alsoapplies to the motor torque pulsation at six times theinput frequency. A smooth speed is thus achieved atlower frequencies.

Concerning additional heating resulting from non-sinusoidal voltages and currents, there is no significantdifference between these two voltage waveforms, i.e.modulation types.

2.3 Converter Implementation - The converter switchesare power semiconductors including power transistors,GTO thyristors, or high-speed thyristors.

The industrial application range of power transistors andGTO thyristors is at present limited to power ratings of upto approximately 1000 kVA. The most generallyapplicable power components are the high speedthyristors. They can be used to construct converters inthe megawatt range of power.

The way in which the switch position control signals areproduced is called modulation. All side effects caused bypulse type voltage on a squirrel cage motor depend onthe shape of the voltage curve, i.e. on the modulation. Agood overall result will be obtained when the modulationmethod is properly chosen.

In the simplest form, each half wave of the main voltageconsists of pulses of equal widths. Such a voltagewaveform is quite adequate at frequencies above 10 Hz.The relatively high 5th and 7th harmonic components,due to the shape of the voltage curve, cause the torquecomponents to fluctuate at a frequency six times themotor's supply frequency.

At frequencies below 10 Hz and with lower overallmoments of inertia of the drive, the motor's speed willalso fluctuate at this frequency. At lower frequencies it isaccordingly advisable to use a modulation method knownas sine modulation (Figure 12).

-

The sequence of events used to change over a switchemploying power semiconductors is called commuta-tion. When thyristors are employed, commutationrequires auxiliary circuits known as commutationcircuits, which supply the current pulse needed to turnoff the thyristors.

A three-phase PWM converter is usually implementedas a bridge circuit such as shown in Figure 13.

The diodes (so called free-wheeling diodes) are re-quired for handling inductive load. The diodes alsopass a part of the commutation pulse supplied fromthe commutation circuit.

A number of commutation circuits have been de-veloped employing thyristors and free-wheelingdiodes. One of the most efficient of these variousmodifications is the McMurray circuit.

A commutation circuit can be constructed with com-ponents common for all phases or with a separatecommutation circuit for each phase. The circuit shownin Figure 13 is of the latter type.

The different commutation circuits also differ in theiroperation in that some converters turn off all mainthyristors for charging over a switch.

In most frequency converters the commutation pulseis only applied to the switch of the next phase to beinverted.

-

3.0 General Characteristics of PWM FrequencyConverters

3.1 Supply Current- In PWM frequency converters theDC voltage supplied from the intermediate circuit remainsconstant. Connection to the power supply is normallymade with a diode bridge. Because of the fixedintermediate voltage, the RMS value of the fundamentalcomponent of the supply current is directly proportional tothe active power drawn by the motor, as shown in Figure14.

With a constant load torque the active power decreasesin direct proportion to the speed as the speed decreases.The current drawn from the supply by the frequencyconverter also decreases, although the phase current ofthe motor remains at a constant value.

A DC drive draws a higher supply current than the PWMfrequency converter because in DC drives:a) The rectifier voltage is lower than the diode

bridge voltage even at rated speed.b) As the speed decreases and the torque remains

constant, the output and rectifier voltagedecreases in direct porportion to the speed, andthe supply current remains constant. In PWMfrequency converters the voltage remainsconstant and the current decreases.

As shown in Figure 15, DC drive curves also apply tofrequency converters with thyristor bridge rectifiers.

At constant load at both rated as well as half load, a DCdrive draws from its power supply lines a constant currentthroughout the entire speed range, whereas the PWMconverter drive has an input current which decreases withdecreasing speed. From the rated speed upwards, thepower supply line current of a PWM converter is constantbut still smaller than that for a DC drive of the same size.

The broken curves in Figure 15 indicate loads with atorque proportional to the speed squared, e.g. pumpsand fans. For comparison, the supply current of a DCdrive capable of equal performance is also shown.

There is a significant difference in the current taken fromthe power supply lines by the type of drive as well. Forexample, at 70% of speed the PWM converter drawsonly 2/3 of the current drawn by the DC drive. There are,of course, several advantages with a low power supplyline current. For example, the total current drawn by anumber of variable speed drives together is considerablylower with PWM converter drives than with DC drives ofthe same size.

3.2 Harmonic Components of Supply Current -Seenfrom the supply side network, the diode bridge is anon-linear device. The non-linearity results in harmonicdistortion of the supply current of the frequencyconverter.

In addition to the current component at the fundamentalfrequency, the supply current contains harmoniccomponents at frequencies fn:

fn = n x fo = (6k 1 ) x fowhere fn = frequency of the nth

harmonic componentn = ordinal number of the

harmonicfo = frequency of the supply

currentk = 1,2,3

In the ideal case the magnitudes In of the harmoniccomponents are:

In = I1/n

where In = nth harmonic componentI1 = magnitude of the basic

current

-

The harmonic currents are thus directly proportional tothe fundamental current. The nomogram shown in Figure16 can be used to obtain (in the ideal case) themagnitudes of the harmonic current components of aPWM frequency converter for different speeds andtorques.

The harmonic components are their highest at the ratedspeed and the maximum torque. At a constant loadtorque, as the speed is reduced, the harmonic currentsdecrease because the fundamental current decreases.

As an example: The torque is 60% of the rated torqueand the speed 55% of the rated speed. For 60 Hz

operation, what is the amplitude of the 7th (i.e. 60 x 7 or420 Hz) harmonic current?It can be seen in the lower right-hand quadrant that theoutput is 33% of the rated current. Draw lines parallel tothe axes up to the straight lines, then draw lines to theupper left-hand quadrant. The intersection point showsthat the magnitude of the 7th harmonic is less than 5% ofthe motor's rated current.

As was mentioned earlier, the supply current of a PWMfrequency converter drops in proportion to the speed.Because the harmonics are proportional to thefundamental current of the supply line, the content, ofharmonics drops with decreasing motor speed.

-

As shown in Figure 18, the PWM converter, which isrepresented by the lower, flat curve, has a dioderectifier connected to the power supply lines, andtherefore draws only active power from the powersupply lines, i.e. the power factor cos is almost equalto (1) and is constant throughout the whole controlrange. The upper curve (with the sinking

characteristic) represents both a DC drive and a cur-rent controlled frequency converter. As is evident, thereactive power is very high at low speeds and sinksgradually with rising speed. But even at rated speedthe reactive power is high, which causes a poor powerfactor.

As an example, as shown in Figure 17, the 7th har-monic at 1/2 speed is only 50% of that caused by a DCdrive at the same speed.

Considering the influence that harmonics in the powersupply lines may have on computers, control devices,capacitor banks, etc., the advantage of the PWMconverter over the DC drive or current controlledconverter is evident.

3.3 Reactive Power - A device connected to thesupply consumes fundamental reactive power if thefundamental current drawn lags the supply voltage.The reactive power causes a voltage drop and a lossin the supply network, resulting in costs to the user inthe form of reactive power payments, increasedlosses, and oversized design made necessary by thereactive power.

The basic power factor of a diode bridge is in generalalmost (1) regardless of the load.In PWM frequency converters the consumption ofreactive power is further reduced by the fact that thesupply current drawn decreases as the speed is re-duced. There is a thyristor bridge in regeneratingPWM frequency converters and in those PWM con-verters which also have intermediate circuit voltagecontrol. However, the consumption of reactive poweris relatively small, thanks to the small active power.

-

3.4 Braking and Reversing - In PWM frequencyinverters, the power can flow in either directionthrough the actual converter. The inverter can thusboth drive and brake a motor. A diode bridge is usedto connect the frequency converter to the supply. Asthe diode bridge can only transfer power from thesupply to the intermediate circuit, the braking powermust be smaller than the power loss - otherwisebraking power will be stored in the intermediate circuitcapacitor, and the DC voltage increases excessively.

If a greater braking power is required, special solu-tions are needed. The braking power can be eitherdissipated in a braking resistance connected to theintermediate circuit, or returned to the supply bymeans of an inverting thyristor bridge. Figure 19 com-pares the difference in braking types.

In order to change the direction of motor rotation,reversing can be accomplished by electronicallychanging the phase order of the motor.

The reversing sequence is carried out in differentways depending on the converter's optional equip-ment. If the converter is equipped with an integrator ora ramp device, the reversing takes place as indicatedin Figure 20 by the solid line. The deceleration time isdetermined either by the drive's set ramp or by themotor's moment of inertia, depending on

whether controlled deceleration is required or themotor is simply to freewheel to a halt. Accelerationtime depends on the set acceleration time or, if themoment of inertia is very big, on the pull-out torque ofthe motor. If the motor must be reversed within a fixedtime, calculations may show that the abovementioned system is not sufficient and regenerativebraking must be applied into the supply to achieve asuitable reversing time. The braking sequence isshown in Figure 20 by the broken line.

3.5 Multiple-Motor Drives - Frequency invertersequipped with DC voltage intermediate circuits, i.e.PWM frequency inverters, can be used to supplyseveral parallel motors instead of a single motor.

All the motors will then have the same input voltageand frequency, and the speeds of the motors differ asdetermined by their pole pair numbers and slips. Theslips of different motors depend on the load torques.

In the normal case, the motor has to be connected tothe frequency inverter before the inverter is started. Inmultiple-motor drives however, it is occasionallynecessary to start and stop motors while the fre-quency inverter is running. This can be achieved bychoosing a suff iciently large frequency inverter - con-sult the Allen-Bradley Sales Office.