Calculation of the Capacity, Power and Specific Energy of a Rotary Drum Scrubber

TELSMITH Rotary Drum Scrubber New

-

Upload

tsakalakis-g-konstantinos -

Category

Documents

-

view

315 -

download

9

description

Transcript of TELSMITH Rotary Drum Scrubber New

-

'

Ne w York - Screw Clossifiers and Dewatering & Classifying Tanks. Wisconsin - Super Scrubber, Screw Rewashers.

TELS IT

-

Canada- Super Scrubber, Classifying Tonk, Screw Classifiers.

Today, most of the better gravel pits have been exhausted. Removal of large amounts of clay, soft stone or both is necessary for profitable marketing of specification aggregates. Most states now require strict adherence to abrasion and soundness tests and demand that all sizes of aggregate be thoroughly scrubbed, washed and rinsed before screening. Years of experience and know-how in the design and manu-facture of aggregate equipment stand behind every Telsmith machine and guarantee that Telsmith equip-

Washington- Dewatering and Classifying Tanks, Sand Classifiers, Screw Rewashers and Sand Tanks.

ment performs to the highest standards. No other type of ore or aggregate washing machine does such a thorough job of cleansing as the Telsmith Super Scrub-ber. Along with Telsmith washing screens, screw re-washers, classifiers and tanks It has solved the most difficult washing problems encountered. When "specs" are hard to meet, aggregate producers the world over depend on Telsmith- efficient equipment for mines, quarries and gravel pits.

PORTABLE WASHING PLANTS-For mobility in washing plants,

successful producers rely on Tel-smith Portables which combine rugged stationary equipment in various arrangements to meet spe-cific applications. Typical combina-tions include (both portable and semi-portable plants): Screening and Classifying Plants (Washing Screen and Classifier); Scrubbing and Classifying Plants (Scrubber, Washing-Sizing Screen and Classi-fier); and Washing, Screening and Classifying Plants (Rotary Screen, Washing-Sizing Screen and Classi-fier). Consult factory for details.

Alabama -Portable Washing & Screening Plant.

Portable Screening & Classifying Plant.

-

I =

TELSMITH The solution to even the most difficult washing

problems is the Telsmith Super-Scrubber. Super-Scrubbers for stone and gravel are covered on this and the opposite page, those for ores on page 6, and those for sand are covered on page 7 with a table of speci-fications covering all types on page 7. This high speed, rotary scrubber has proven to be very effective with a minimum of water, power and upkeep expense. In fact, these units have proven so efficient on such a wide variety of difficult washing problems that they have almost completely replaced the former demand for log-washers. It has been found that the Telsmith Super-Scrubber will, in most cases, do a much better job of dirt and clay removal than the log-washer and at a lower cost per ton. It also far surpasses the wash-ing action of the ordinary rotary washing screen.

All of this is brought about by the intense impact and grinding action which takes place in the high

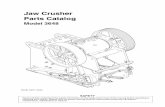

Fig. 410. Cover removed from Super-Scrubber drive to show pulleys and V-be lts. Drive can be fully enclosed as shown in Fig. 411.

4

SUPE SCRUBBERS

speed drum of the Telsmith Super-Scrubber. The drum is rotated so rapidly that the aggregate is car-ried up much higher than in a washing screen. The powerful impact of the falling and cascading rock or gravel disintegrates lumps of clay or soft rock. The grinding action which takes place at the same time and as the entire mass rolls in the drum with all sizes of aggregate particles rubbing and grinding against each other, very effectively disintegrates soft particles and removes any coatings on all sizes of particles. This high-speed, falling-cascading-grinding action cannot be had in a log or any other type washer.

The Telsmith Super-Scrubber is just as effective on rock as on sand and gravel and many are being used very successfully in quarry operations. Their high speed, ball-mill action is proving to be the quick-est and the lowest cost method of removing dirt, clay, soft particles and coatings of this same ex-

Fig. 411. Telsmith Super-Scrubber for stone o r grovel complete on steel frame with steel

motor support and completely enclosed V-rope d rive both of which can be

furnished a t extra charge .

-

............ - :;;~,: -- "': --:--- --~,., ~e e f ,. , 1 ~ -:-~ ~J!." 'fir. , . '. ~~ f 9

- - - . -~ ~-~

traneous matter. This is also true in the case of ores containing dirt and clay which must be removed before shipment or before further treatment.

Elimination of wood chips, roots, coal, vegetation, shale, etc., is very often a problem requiring special additional equipment. Consult the factory.

In the Super-Scrubbers for stone, gravel, mixed sand and gravel and for ores, the wash water enters at the discharge end of the drum and flows to the intake end against the travel of the aggregate or ore, carrying the sand, fine material, dirt and clay through the screen plates at the feed end. These have radial

Fig. 412. Aggregate is subject to high speed cascading and ball-mill action as it travels against the flow of water carry-ing sand and dirt through feed end screen plates.

Fig. 413. The inside of the Super-Scrubber is lined with easily replaceable, special wear-resisting steel liner plates.

blades which push the coarse aggregate away from the screen plates, preventing excessive wear. See Figure 416, page 6. The clean water gives the aggregate or ore a final rinsing just before being discharged from the drum. A further rinsing with clean water takes place as the discharged aggregate or ore travels over the perforated trommel attached to the end of the drum. See Figure 412. An unloading chute, also shown in Figure 412, which will empty the drum for repairs or maintenance, furnished at extra charge.

Drum construction and action of the water in Super-Scrubbers for sand is different than described above; see details on page 7.

Fig. 414. Special guide rollers prevent drum end travel and keep it in cor-rect position on support-ing rollers.

Fig. 41 5. The perforated double trammel used on Super-Scrubbers for Stone or Gravel is of special construction far more effi-cient dewatering and sizing.

5

-

r i -

I

~

6

-

ELS ITH

The Telsmith Standard Super-Scrubber is an exceptionally well constructed machine. The main supporting frame is a very substantial structure, fabri-cated of steel I-beams and channels, welded together with heavy gusset plates. Heavy cross members sup-port the wide, large diameter rollers which have heavy-duty roller bearings on both sides well protected against the entrance of moisture. The roller rings are of high carbon steel and are accurately welded to the thick steel drum. The drum shell is of heavy steel plate protected by renewable liner plates of wear-resisting steel. Gears and pinions are cut steel. All models are equipped with a heavy, renewable steel in-take chute with lining. The countershaft on which the pinion is mounted is journaled in roller bearings. All sizes have special roller bearing guide idlers to prevent end travel and to keep the drum in perfect alignment.

A great deal of care is taken at the factory when assembling these Super-Scrubbers to make sure that all parts are in proper alignment. A large and ex-pensive jig on which the drum is mounted for welding and on which the roller ring guide stops are welded to the drum, prevents misalignment and excessive roller ring wear when the machine is put into operation. The same care is taken when the drum is assembled on the main frame to make sure that the roller ring and rollers are in proper alignment, assuring minimum

SUPER SCRUBBERS

upkeep expense on all operating parts. Care must also be exercised by the customer when the Super-Scrubber is installed to make sure that no distortion takes place in the Super-Scrubber main franie.

The construction of Telsmith Standard Super-Scrubbers for stone, gravel and sand is described in the opposite column. The Heavy-Duty Super-Scrubbers for ore, as illustrated on this page, are avail-able in the 84" and 96" sizes and are much heavier and more expensive machines including the following differences in design. (1) The main supporting frame has heavier members. (2) The drum is thicker and has heavy, manganese steel liners and lifting blades. (3) The roller rings and rollers are wider, larger in diameter and heavier throughout. ( 4) The roller shafts are larger in diameter and have larger roller bearings. (5) The drive pinion and gear are heavier. (6) In some sizes, drive gear is on intake end of drum with a shorter, heavier countershaft.

These Heavy-Duty Super-Scrubbers are in success-ful use in many different kinds of mining all over the world and are particularly outstanding in cleaning dirty taconite ores in Minnesota.

Fig. 416. Telsmith Extra Heavy-Duty Super-Scrubber for han-dling heavy ores has special manganese steel liners and extra heavy manganese steel lifting blades.

Fig. 417. Telsmith Super-Scrubber for ores is of special heavy-duty construction throughout and is complete on extra heavy steel frame.

-

SUPER SCRUBBERS

Telsmith Super-Scrubbers usually give best results when the sand and gravel is treated together as de-scribed on page 5 (see Fig. 412). This is especially true when clay or dirt is present in the fine aggregate as well as in the coarse aggregate. When coarse aggre-gate is dirty and sand is clean, we often recommend that the sand be removed ahead of the Super-Scrubber by means of a vibrating screen equipped with spray bars. In this way only the coarse aggregate goes into the Super-Scrubber, and thus receives the most in-tense and effective action.

When it is desired to scrub and clean sand only, or fine aggregate containing sand and very little large or coarse aggregate, we recommend the special Super-Scrubber for sand as described and shown on this page.

Super-Scrubbers for sand, as shown below, have a blank plate on the feed end with a perforated plate on the discharge end. The latter allows sand and water to flow out onto the blank trornmel but retains a deep bed of gravel or stone in the drum, which helps to clean and scrub the sand and fine aggregate. A vibrating screen with spray bars is often used following the Super-Scrubber to again rinse material and make re-quired separations of aggregate.

If you have a tough washing problem, send us a small sample of the material in an air-tight container together with complete information such as screen analysis, capacity required, amount of water available and sizing desired.

SPECIFICATIONS-TELSMITH STANDARD SUPER-SCRUBBERS .I

Number of Telsmith Super-Scrubber (diom. in inches) . 60 5 72 6 84 7 96 8 Type of Super-Scrubber .... ............ . .. Sand Gravel Sand Grovel Sand Grovel Sand Grovel length of scrubber cylinder, feet ..... ...... . ... 9 , 9 / 10Y2 1 OY2 ' 12' 12 14 , 14 / Weight, complete scrubber empty with countershoft

but no pulley, lbs., about .................... 13500 14000 22000 22500 32000 33000 49000 51500 Weight, full of aggregate and water, lbs., about . 16960 17500 27800 28300 41000 42000 63500 65700 Weight, boxed for export, lbs., about ...... ..... ... 14850 15400 24200 24750 35200 36300 53900 57000 Cubical contents, cubic feet, about ....... . ....... 600 650 985 1050 1480 1600 2275 2450 Thickness of material in cylinders, inches .. . ........ 7'a e rl6 rl6 Y2 Y2 Y2 V2 Thickness of material in liners, inches ........ . ..... e lla V2 Y2 Y2 V2 % % Speed ot drum, R.P.M ...................... 30 30 27 27 25 25 23 23 Speed of standard countershoft, R.P.M ....... . ...... 185 185 175 175 165 165 160 160 Horsepower required, high torque, squirrel cage

electric motor . . .... . ...... . ..... .... 40 40 60 60 100 100 125 125 Horsepower required, slip-ring electric motor ...... 40 40 50 50 75 75 100 100 Capacity per ho~r, tons, about lNo!e I) .. ......... 3,5-70 35-70 60-120 60-120 95-180 95-180 120-240 120-240 Maximum size of feed advisable, inches ............ 3 3 4Vl 4Y2 6 6 8 8 Water required, G.P.M., about. .... , ... .. 200-300 200-300 350-550 350-550 550-850 550-850 700-1100 700-1100 Code-word with standard countershoft but no pulley . Subarid Suave Sud or Sulton Suet Sumoc Suga Sulcate

NOTE 1: Capacity varies with the amount a nd killd of e :dfoneous metter to be washed out.

Fig. 418. T elsmith Super-Scrubbers for Sand hove a blank plate on the feed end as shown in the right-hand view and a special per-forated plate on the discharge end as shown in the left-hand view. 7