Tekla reference: Capital Gate Tower Abu Dhabi

description

Transcript of Tekla reference: Capital Gate Tower Abu Dhabi

capital gate towerunited arab emirates

tekla software in practice:

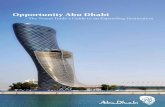

a capital gate is adnec’s (abu dhabi national exhibition company) gravity-defying new tower in the uae capital. its engineers created an 18-degree westward lean – four times the inclination of the leaning tower of pisa – using complex diagrid structures that were aligned geometrically using tekla structures bim (building information modeling) software.

world’s most

inclined tower

A tekla structures has been used to detail some of the world’s most iconic buildings. its three-dimensional modeling functions allow for making gravity-defying architectural designs a reality. the 3d coordinates for each diagrid component of the capital gate tower were calculated using tekla structures, which ensured seamless integration and assembly of the frame and its supporting beams. “tekla solutions help craft even the most complicated designs, and capital gate is yet another example of tekla’s ability to help eversendai design and model iconic marvels,” said Tahir Sharif, managing director of tekla middle east.

capital gate is a 35-storey illustrious iconic tower of 525 feet, part of the capital centre development around the abu dhabi national exhibition centre. it features a presidential-style luxury hotel and office spaces. leaning towards one direction to an angle of about 18 degrees, the tower has been nominated for the consideration of guinness book of world records as ‘the world’s most inclined building’. the structure features a cantilevered internal atrium at 17th and 18th floors to accommodate the facilities of the projecting swimming pool and tea lounge. diagrid technology has been adopted in the construction of the structure. each diamond of the external cladding is supported by the steel diagrid panel. to maintain the required curved surface profile, every panel surface is slightly deviating with respect to the adjacent panel surfaces. external diagrid members are of rectangular hollow tubes whereas the internal diagrid members are of circular hollow pipes. external diagrid members provide secondary supports for the wave-shaped ‘splash’ structure from

19th level down to the bottom, providing an attractive sun shade to the tower. main structural steel work consumed more than 13,000 tonnes of material in addition to the metal decking. steel skeleton consists of 702 nodes of external diagrids with an addition of 5 nodes of external dummy diagrids at level 18-18m-19 and 120 internal diagrid nodes at the intersection of the members. at the intersecting nodal points, the hollow members have met with offsets in two axes and floor beam met at the third axes along their surfaces. as none of the panels is co-planar to another, each node is unique and formed with heavy thick cruciform punch through the plates. in order to minimise the member offsets at the nodal points, diagrid members have been oriented by the ‘bisection of bisecting planes’ method.

bim control of the structure in every stage of the projects modeling the complex diagrid members of the capital gate tower was managed well with the features of tekla structures. the attributes in the software helped to smoothen the construction of the structure. for the design part, the members were oriented with minimal offset by adopting the method of ‘bisection of bisecting planes’. these offset values were taken from the tekla 3d model and used in the design of cruciform nodes. the lengths of the welds included in the model were used to do the weld design of the cruciform nodes. beams connected to the nodes were moved in the model to avoid member clashing, which could result in eccentric connections. the eccentricity was measured from the model and used in the connection design.

the actual cut-to-length measures of the members were taken from the preliminary model developed at the initial stage of the project to procure the material. this helped in reducing material wastage. the quantities for bolts, shear studs and paint were obtained from tekla structures reports. the assembly lists derived from the tekla model were converted into worksheets, and other departmental activities, such as fabrication, painting and erection, were planned and monitored using these worksheets.

nc files exported from tekla structures facilitated faster and more accurate fabrication. for the fabrication of diagrid members, temporary jigs were made with the help of coordinates of individual assemblies that were taken from the model. fit up of the individual parts of the nodes was done with the 3d coordinates taken from the model. location of centre of gravity and weight of individual assembly were taken from the reports. these were used to work out the lifting method statement and in the design of erection engineering. a bolt report based on the assembly marks helped the rigging team to have control over bolt usage. the global 3d coordinates taken from the tekla model were utilised for erecting the diagrid assemblies at their exact position. after this, the tekla model was passed on to the cladding team to work out the design of the cladding system. the model was used to coordinate with the architectural profile model to nullify interface issues. thus the model generated in tekla structures played a vital role also in completing the works in a safe and faster way.

“compared to detailing with e.g. 2-dimensional autocad, the use of tekla structures 3d and 4d modeling in any project generates 4 to 5-fold time savings.”

“a 3d model prototype structure can provide all the needed database files, such as material lists, and there is no chance for mistakes in the output of drawings.”

fast-track, precise and cost-efficient steel modelingC instead of subcontracting structural design and engineering, eversendai has been using tekla structures modeling software since 1997. the most important decisive factor in their decision to purchase the solution was that a 3d model prototype structure can provide all the needed database files, such as material lists, and that there is no chance for mistakes in the output of drawings, which saves time for efficient project delivery.

the complicated structures that the company works with cannot be done in a 2d environment, so the change to efficient building information modeling has been a welcome progress. mr. N.S. Rao, regional director at eversendai engineering describes their recent projects a success in terms of project delivery. they confirm that the use of tekla structures has had a definite role in this. in addition to the capital gate tower, the company currently handles high-rise buildings, airports, roof features, bridges, and any structure in steel. they have produced many famous landmarks, such as kingdom trade center in saudi arabia, Qstp, new doha international airport, tornado tower in Qatar, klss, perdana tower, putrajaya convention centre, new bintulu airport in malaysia, changi airport terminal 3 in singapore, salalah amphitheater in oman, burj dubai, dubai mall, dragon mart, dfc in dubai, as shams sky tower, saadiyat cultural park in abu dhabi, and chathrapathi shivaji international airport in india.

compared to detailing with e.g. 2-dimensional autocad, eversendai estimates that the use of tekla structures 3d and 4d modeling in any project generates 4 to 5-fold time savings. in addition, the quality of drawings is superb. eversendai describes work with tekla structures 100% accurate and 5 times more productive than without the software, which eventually translates into notable cost savings.

T eversendai corporation is a world-class steel contractor that offers services in structural design, engineering, fabrication and erection of high-rise buildings, industrial plants, roof structures, bridges, stadiums, power plants, and petrochemical plants. they have a reputation for impeccable quality and reliability in the fast growing structural steel engineering sector of the middle east region. since its modest beginnings in the early 1980s, eversendai has been steadily growing from a small engineering concern with only a handful of dedicated staff to a reputable, highly sought-after international organisation with a workforce of over 3000 around the world.

more information at www.eversendaiuae.com

W with an ambition to multiply customers’ potential to think and achieve big, tekla provides a bim (building information modeling) software environment that can be shared by contractors, structural engineers, steel detailers and fabricators, as well as concrete detailers and manufacturers.

the highly detailed as-built 3d models created, combined and distributed with tekla software enable the highest level of constructability and production control.

centralizing building information into the model allows for more collaborative and integrated project management and delivery. this translates into increased productivity and elimination of waste, thus making construction and buildings more sustainable.

our ambition is to multiply your potential to think and achieve big

Tekla is a registered trademark of Tekla Corporation in the European Union, the United States and in several other countries.

T with its software, tekla corporation drives the evolution of digital information models and provides more and more competitive advantage to the construction and infrastructure industries. tekla was established in 1966, and today it has customers in 100 countries, offices in 15 countries, and a global partner network.

tekla software is used worldwide to model all types of buildings. visit our website to learn more about tekla solutions and references for building and construction.

www.tekla.com