Technical Specification · Tree guards Guards: Rigid UV-stabilised cortflute plastic guards, welded...

Transcript of Technical Specification · Tree guards Guards: Rigid UV-stabilised cortflute plastic guards, welded...

Technical Specification 4481-19-S2 Lake Ewlyamartup

Living Lakes: Lake Ewlyamartup Foreshore Katanning, WA PROJECT LEAD LANDSCAPE ARCHTECTURE ECOSCAPE

Revision Schedule

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 2

REVISION SCHEDULE

Revision Description Date Approved by

0 Issue for Tender 09.03.2020 P.Jordan

Table of Contents

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 3

TABLE OF CONTENTS

Revision Schedule 2 Table of Contents 3 Schedule of Prices 4 0100 Materials and Finishes Schedule 6 0160 Quality 8 0171 General requirements 10 0221 Site preparation 17 0241 Landscape – edging 20 0250 Landscape – combined 21 0261 Landscape – furniture and fixtures 26 0271 Pavement base and subbase 28 0272 Asphalt 31 1424 Maintenance 36

Schedule of Prices

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 4

SCHEDULE OF PRICES

Name of principal Wheatbelt NRM

Name of project Living Lakes – Lake Ewlyamartup Foreshore

Tender I/We tender to perform the work for the above project as described in, and in accordance with, the tender documents referenced in the Conditions of tendering and in accordance with the attached Schedule of rates/Contract sum analysis/priced Bills of quantities and for the lump sum (which includes specified provisional sums) of ………………………….………………………….………………………….………………………….………………………….……………………………….

……………………………………………………………………………………………………….. including GST (sum in words and figures)

ITEM No DESCRIPTION UNIT QTY RATE AMOUNT

1.0 PRELIMINARIES

1.1 Charges relating to all levies and insurance requirements (including BCITF levy). item

1.2 Mobilisation. item

1.3 Setting out of the Works. item

1.4 Provision and maintenance of Contractor’s site facilities. item

1.5

Charges for preparing and updating the Works Program, for progress reporting and attendance at progress meetings, all as detailed in the Specification.

item

1.6

Removal of all spoil, debris, rubbish excess material, etc., and tidying up and making good of the site during the works and on completion.

item

1.7

Charges for complying with the Conditions of Contract, Specification and Drawings not included elsewhere in this Schedule including managing the site during the 13 week Defects Period.

item

2.0 SITE WORKS

2.1 Relocate existing bins on site item

2.2 Protection of existing trees item

2.3 Undertake earthworks to accommodate path alignment item

3.0 PLANTS, PLANTING & MULCHING

3.1 Supply & install unirrigated tubestock including fertiliser and soil preparation ea

3.2 Supply & install tree guards to tubestock tree specimens including stakes ea

3.2 Supply & install 50mm depth organic mulch to tubestock as detailed sq m

4.0 SURFACES & EDGES

4.1 Supply & install red asphalt paving sq m

Schedule of Prices

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 5

4.2 Supply & install concrete edge beam lin m

5.0 FURNITURE & FIXTURES

5.1 Supply & install ‘Brolga’ bevelled edge recycled plastic bollard Item

5.2 Supply & install removable bollard sleeve suitable for ‘Brolga’ bollards item

5.3 Supply & install custom angled interpretive signage Item

5.4 Supply & install totem destination signage Item

6.0 DEFECTS & MAINTENANCE

6.1 Allowance for a 13 week establishment period per week 13

7.0 ADDITIONAL ITEMS NOT LISTED ABOVE

7.1

7.2

7.3

TENDER TOTAL (EXCL. GST)

GST

TENDER TOTAL (INCL. GST)

The contract duration will be .....................weeks from the date of site possession.

This tender remains open for consideration for .....................weeks from the date and time of closing of the tender period.

I/We acknowledge the receipt of addenda numbered .......................................during the tender period.

I/We acknowledge that the above tender includes all liaison and communication with nominated sub-contractors and other contractors on site.

I/We acknowledge that the above tender quote includes maintaining the site during the 13 week period.

Name of tenderer

ABN/ACN

Telephone

Tenderer’s address or registered business office address

Address for service of notices

Tenderer’s bank and branch address

Execution if tenderer is an individual or unincorporated body

Tenderer’s signature

Witness’ signature

Execution of tenderer is a company The common seal of the tenderer was affixed in accordance with the Articles of Association

Authorised officer’s signature

Witness’ signature

Date of tender

0100 Materials and Finishes Schedule

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 6

0100 MATERIALS AND FINISHES SCHEDULE

General The following schedule is to be read in conjunction with the project drawings:

DWG # SHEET NAME L0-1 COVER SHEET

L1-1 GENERAL ARRANGEMENT PLAN 1

L1-2 GENERAL ARRANGEMENT PLAN 2

L1-3 GENERAL ARRANGEMENT PLAN 3

L1-4 GENERAL ARRANGEMENT PLAN 4

L2-1 SECTIONS

L3-1 CONSTRUCTION DETAILS

L3-2 SIGNAGE DETAILS

The following schedule is to be read in conjunction with the drawings and specification. Where conflict between materials listed below and the specification; the specification will take precedence. Materials and finishes schedule

ITEM Description Finish / Colour Other details

PLANTING & MULCHING Mass planting Tubestock Species nominated on

Softworks & Planting plan Fertiliser: Baileys Native Plant Food - fertiliser granules Soil Conditioner: Richgro ‘Metro’ soil conditioner or approved equivalent

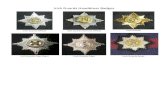

Tree guards Guards: Rigid UV-stabilised cortflute plastic guards, welded shut. Stakes: Bamboo

Guards: Triangular, 450(H) x 140mm sides Stakes: 10mm diameter x 750mm length

Imported organic mulch

Richgro ‘Sandgroper Mulch’ or approved equivalent

50mm depth

SURFACES & EDGES Concrete edge beam

Formed concrete beam to asphalt paving

Colour: Grey Float finish

Width: 200mm Depth: 150mm

Asphalt paving Red asphalt Red (2 x 25mm layers): Top layer with 10mm aggregate and bottom layer with 14mm aggregate

Subbase: 98% compacted limestone subbase

FURNITURE & FIXTURES Bollard ‘Brolga’ bevelled edge

recycled plastic bollard Code: BO2010 / 1200 black

Finish: Black Height: 1200mm above ground surface

Supplier: Replas (1800 737 527) Fixing: Cast in-ground

0100 Materials and Finishes Schedule

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 7

ITEM Description Finish / Colour Other details

Removable bollard sleeve

Sleeve suitable for ‘Brolga’ bollards Code: Bol-Sleeve-Brolga

Finish: HDG Supplier: Replas (1800 737 527) Fixing: Cast in-ground lockable sleeve. Padlock to Shire requirements.

Angled interpretive signage

Custom interpretive signage

All sign posts and frames are to be powdercoated Dulux ‘Intensity Storm’ (90N5365S0) Artwork: Supplied by Principal.

Fixing: Refer drawings. Shop drawings required

Totem destination signage

Custom destination signage

All sign posts and frames are to be powdercoated Dulux ‘Intensity Storm’ (90N5365S0) Artwork: Supplied by Principal.

Fixing: Refer drawings. Shop drawings required

0160 Quality

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 8

0160 QUALITY

1 GENERAL

1.1 RESPONSIBILITIES General Requirement: - Provide a project Quality Management System. - Quality Management System is to apply to all works including the following:

o Site works o Landscape works o All works that form part of the tender package including specifications and drawings.

1.2 STANDARDS General Standard: To AS/NZS ISO 9001.

1.3 INTERPRETATION Definitions General: For the purposes of this worksection the definitions given in AS/NZS ISO 9000 and the following apply: - Quality package: A designated part of the works, which may include the whole works, for which an

individual quality system is required. - Service: After sales' service, repairs, maintenance.

1.4 SUBMISSIONS Execution details Requirement: Provide the procedure for sign-off and audit.

2 PROJECT QUALITY MANAGEMENT SYSTEM REQUIREMENTS

2.1 DOCUMENTATION REQUIREMENTS Quality plan Standard: Conform to the recommendations of AS/NZS ISO 10005. Include inspection and test plans.

2.2 INSPECTION AND TEST PLANS Content Plan: Include the following: - Detail all inspections and tests required including Hold points. - Identify acceptance criteria, sampling and testing and frequency of sampling/testing. - Identify responsibilities for inspection and testing and product/service approval. Control of non-conforming product Acceptance of concession: Before the provision or repair of a non-conforming product, obtain permission to use the product. Hold points Stages: Hold points during the construction/manufacturing process require release by the contract administrator. Release: Requirements for release of a Hold point may include the following: - Provision of information required by the technical specifications. - Certification of design/construction or installation. - Submission of any checklists or non-conformance forms as required. - Inspection/demonstration of works.

0160 Quality

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 9

2.3 CORRECTIVE ACTION General Review: Provide procedure to review the various control methods to minimise non-conformance. Record amendments to the project Quality Management System resulting from corrective action. Non-conforming works: Include in the Quality Plan the procedure for reporting any non-conforming works to the contract administrator and any corrective action requests.

3 SELECTIONS

3.1 SCHEDULES Project Quality Management System schedule Quality package Activities included Standard The whole of the works All AS/NZS ISO 9001

0171 General requirements

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 10

0171 GENERAL REQUIREMENTS

1 GENERAL

1.1 RESPONSIBILITIES General Requirement: - Provide a project Quality Management System. - Quality Management System is to apply to all works including the following:

o Site works o Landscape works o All works that form part of the tender package including specifications and drawings.

Performance Noise levels: Install systems within the limits of the contract design and documented equipment performance and as documented.

1.2 DESIGN Design development Conflict with the documents: If it is believed that a conflict exists between statutory requirements and the documents, notify the contract administrator immediately and provide a recommendation to resolve the conflict.

1.3 PRECEDENCE General Order of precedence: - The requirements of other worksections of the specification override conflicting requirements of this

worksection. - The requirements of worksections override conflicting requirements of their referenced documents.

The requirements of the referenced documents are minimum requirements.

1.4 REFERENCED DOCUMENTS General Contractual relationships: Responsibilities and duties of the principal, contractor and contract administrator are not altered by requirements in the documents referenced in this specification. Current editions: Use referenced documents which are the editions, with amendments, current 3 months before the closing date for tenders, except where other editions or amendments are required by statutory authorities. Site copies: A full set of the latest drawings and specifications for the whole project must be on site in HARD copy.

1.5 INTERPRETATION Documentation conventions Imperative mood and streamlined language: The words shall or shall be are implied where a colon is used following a keyword or within a sentence or sentence fragment. Subject of sentences and phrases: Specification requirements are to be performed by the contractor, unless stated otherwise. Abbreviations General: For the purposes of this specification the following abbreviations apply: - AS: Australian Standard. - BCA: National Construction Code Series Volume One: Building Code of Australia Class 2 to 9

Buildings and Volume Two: Building Code of Australia Class 1 and Class 10 Buildings. - NATA: National Association of Testing Authorities. - NCC: National Construction Code.

0171 General requirements

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 11

- NZS: New Zealand Standard. - PCA: National Construction Code Series Volume 3: Plumbing Code of Australia. - PVC: Polyvinyl Chloride. - PVC-U: Unplasticised Polyvinyl Chloride. Also known as UPVC. - SDS: Safety data sheets. - VOC: Volatile Organic Compound. - WHS: Work Health and Safety. Definitions General: For the purposes of this specification, the following definitions apply: - Attendance: Attendance, provide attendance and similar expressions mean give assistance for

examination and testing. - Contract administrator: Has the same meaning as superintendent and is the person appointed by

the owner or principal under the contract. - Contractor: Has the same meaning as builder and is the person or organisation bound to carry out

and complete the work under the contract. - Default: Specified value, product or installation method which is to be provided unless otherwise

documented. - Documented: Documented, as documented and similar terms mean contained in the contract

documents. - Give notice: Give notice, submit, advise, inform and similar expressions mean give notice (submit,

advise, inform) in writing to the contract administrator. - Hot-dip galvanized: Zinc coated to AS/NZS 4680 after fabrication with coating thickness and mass

to AS/NZS 4680 Table 1. - Local (government) authority: A body established for the purposes of local government by or under

a law applying in a state or territory. - Manufacturer’s recommendations: Recommendations, instructions, requirements, specifications

(and similar expressions) provided in written or other form by the manufacturer and/or supplier relating to the suitability, use, installation, storage and/or handling of a product.

- Obtain: Obtain, seek and similar expressions mean obtain (seek) in writing from the contract administrator.

- Practical completion or defects free completion: The requirements for these stages of completion are defined in the relevant building contract for the project.

- Principal: Principal has the same meaning as owner, client and proprietor and is the party to whom the contractor is legally bound to construct the works.

- Proprietary: Identifiable by naming the manufacturer, supplier, installer, trade name, brand name, catalogue or reference number.

- Prototype: A full size mock-up of components, systems or elements to demonstrate or test construction methods, junctions and finishes, and to define the level of quality.

- Provide: Provide and similar expressions mean supply and install and include development of the design beyond that documented.

- Referenced documents: Standards and other documents whose requirements are included in this specification by reference.

- Required: Required by the contract documents, the local council or statutory authorities. - If required: A conditional specification term for work which may be shown in the documents or is a

legislative requirement. - Sample: A physical example that illustrates workmanship, materials or equipment, and establishes

standards by which the work will be judged. It includes samples, prototypes and sample panels. - Statutory authority: A public sector entity created by legislation, that is, a specific law of the

Commonwealth, State or Territory. - Supply: Supply, furnish and similar expressions mean supply only. - Tests – completion: Tests carried out on completed installations or systems and fully resolved

before the date for practical completion, to demonstrate that the installation or system, including components, controls and equipment, operates correctly, safely and efficiently, and meets

0171 General requirements

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 12

performance and other requirements. The superintendent may direct that completion tests be carried out after the date for practical completion.

- Tolerance: The permitted difference between the upper limit and the lower limit of dimension, value or quantity.

- Verification: Provision of evidence or proof that a performance requirement has been met or a default exists.

1.6 CONTRACT DOCUMENTS Services diagrammatic layouts General: Layouts of service lines, plant and equipment shown on the drawings are diagrammatic only. Before commencing work: - Obtain measurements and other necessary information. - Coordinate the design and installation in conjunction with all trades. Levels General: Spot levels take precedence over contour lines and ground profile lines. Drawings and manuals for existing services Warranty: No warranty is given as to the completeness or accuracy of drawings and/or manuals of existing services.

1.7 SUBMISSIONS Requirement General: Submit the following: - Construction Environmental management plan including

o Site Control and Protection Measures o Other Environmental Controls.

- Authority approvals: Notes of meetings with authorities whose requirements apply to the work and evidence that notices, fees and permits have been sought and paid, that authority connections are complete and that statutory approvals by the authorities whose requirements apply to the work have been received.

- Certification: Certification of conformance to documented requirements, including certification that the plant and equipment submitted meets all requirements of the contract documents and that each installation is operating correctly.

- Operation and maintenance manuals: For the whole of the work to EXECUTION, OPERATION AND MAINTENANCE MANUALS.

- Prototypes: Prototypes of components, systems or elements. - Records: As-built documents, photographs, system diagrams, schedules and logbooks to

EXECUTION. - Samples: Representative of proposed products and materials and including proposals to incorporate

samples into the works, if any to EXECUTION, SAMPLES. - Substitutions: To PRODUCTS, GENERAL, Substitutions. - Tests:

. Inspection and testing plan consistent with the construction program including details of test stages and procedures.

. Test reports for testing performed under the contract. - Warranties: To EXECUTION, WARRANTIES. Contractor review: Before submissions, review each submission item and check for coordination with other work of the contract and conformance to contract documents. Submit to: Project Superintendent Submission times Default timing: Make submissions at least 5 working days before ordering products or starting installation of the respective portion of the works. Submission program: Submit a program of proposed submission dates for the following critical items and major components:

0171 General requirements

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 13

- Plant Procurement: Submit order details within 2 weeks of award of the contract of plant species / number and stock size to confirm stock required for the project will be installed.

Submission response times: Allow in the construction program for at least the following times: - Management Plans / Other Plans: 3 weeks of award of the contract - Shop drawings: 5 working days - Samples and prototypes: 5 working days - Manufacturers’ or suppliers’ recommendations: 5 working days - Product data: 5 working days - Product/design substitution or modification: 5 working days Proposed products schedules: If major products are not specified as proprietary items, submit a schedule of those proposed for use within 3 weeks of site possession. Errors Requirement: If a submission contains errors, make a new or amended submission as appropriate, indicating changes made since the previous submission. Electronic submissions Electronic copies file format: PDF Transmission medium: Email Final Submissions Quantity and format General: Conform to the following: - Require 1 hard copy of documents, drawings, O&Ms etc. - Require 2 USB with a soft copy of all hand over documents (signed where applicable). Drawings to

be provided in AutoCad (DWG) and PDF formats.

1.8 INSPECTION Notice Concealment: If notice of inspection is required for parts of the works that are to be concealed, advise when the inspection can be made before concealment. Tests: Give notice of the time and place of documented tests. Minimum notice: As documented in the Notices schedule. Light levels Requirements: To AS/NZS 1680.2.4. Attendance General: Provide attendance for documented inspections and tests.

2 PRODUCTS

2.1 GENERAL Manufacturers’ or suppliers’ recommendations General: Provide and select, if no selection is given, transport, deliver, store, handle, protect, finish, adjust and prepare for use the manufactured items in conformance with the recommendations of the manufacturer or supplier. Project modifications: Advise of activities that supplement, or are contrary to the recommendations of the manufacturers or supplier. Product identification Sealed containers: If materials or products are supplied by the manufacturer in closed or sealed containers or packages, bring the materials or products to point of use in the original containers or packages. Sources policy General: Preference for goods sourced from the Wheatbelt. Prohibited materials General: Do not provide the following: - Materials, exceeding the limits of those listed, in the Safe Work Australia

Hazardous Chemical Information System (HCIS).

0171 General requirements

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 14

- Materials that use chlorofluorocarbon (CFC) or hydrochlorofluorocarbon (HCFC) in the manufacturing process.

Substitutions Identified proprietary items: Identification of a proprietary item does not necessarily imply exclusive preference for the identified item, but indicates the necessary properties of the item. Alternatives: If alternatives to the documented products, methods or systems are proposed, submit sufficient information to permit evaluation of the proposed alternatives. Criteria: If the substitution is for any reason other than unavailability, submit evidence that the substitution: - Is of net enhanced value to the principal. - Is consistent with the contract documents and is as effective as the identified item, detail or method.

3 EXECUTION

3.1 SAMPLES General Incorporation of samples: Only incorporate samples in the works which have been endorsed for inclusion. Do not incorporate other samples. Retention of samples: Keep endorsed samples in good condition on site, until the date of practical completion. Unincorporated samples: Remove on completion.

3.2 OFF-SITE DISPOSAL Removal of material General: Dispose of building waste material off site to the requirements of the relevant authorities.

3.3 WARRANTIES General: Warranty to commence at date of practical completion, not the date of installation. General Requirement: If a warranty is documented, name the principal and project name as warrantee. Register with manufacturers as necessary. Retain copies delivered with components and equipment. Warranty period: Start warranty periods at acceptance of installation. All works (including sub consultant scope packages) shall have a minimum of 12 months warranty.

3.4 ‘AS CONSTRUCTED’ DRAWINGS General General: Submit ‘As Constructed’ drawings. Show the ‘as installed’ locations of all elements. Include ‘as installed’ amendments to shop drawings. Date for submission: Within 2 weeks following to practical completion. Drawings: Include all documented shop drawings. Accuracy Documents: Incorporate all modifications made during the progress of the work. Endorsement: Sign and date all record drawings. Keep one set of drawings on site at all times expressly for the purpose of marking changes made during the progress of the works. Quantity and format General: Conform to the following: - Require 1 hard copy of documents, drawings, O&Ms etc. - Require 2 USB with a soft copy of all hand over documents (signed where applicable). Drawings to

be provided in AutoCad (DWG) and PDF formats.

3.5 OPERATION AND MAINTENANCE MANUALS General Authors and compilers: Personnel experienced in the maintenance and operation of equipment and systems installed, and with editorial ability.

0171 General requirements

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 15

Referenced documents: If referenced documents or technical worksections require that manuals be submitted, include corresponding material in the operation and maintenance manuals. Contents Requirement: Include the following: - Table of contents: For each volume. Title to match cover. - Directory: Names, addresses, email addresses and telephone numbers of principal consultant,

subconsultants, contractor, subcontractors and names of responsible parties. - Record drawings: Complete set of record drawings, full size. - Installation description: General description of the installation. - Certificates:

. Copies of manufacturers’ warranties. - Maintenance records. Format – electronic copies Scope: Provide the same material as documented for hardcopy in electronic format. Quantity and format: Conform to SUBMISSIONS , Electronic submissions. Printing: Provide material that can be legibly printed on A4 size paper. Date for submission Draft submission: The earlier of the following: - 2 weeks before the date for practical completion. - Commencement of training on services equipment. Final submission: Within 2 weeks after practical completion.

3.6 CLEANING Final cleaning General: Before the date for practical completion, clean throughout, including all exterior surfaces except those totally and permanently concealed from view. Labels: Remove all labels not required for maintenance.

4 SELECTIONS

4.1 GENERAL The Contractor shall give notice to the Superintendent and comply with the following notices schedules.

4.2 NOTICES Notices Schedule Item Minimum notice 0241 Landscape – edging • Submissions as nominated. • Set out before starting construction.

5 working days

0251 Landscape – combined • Submissions as nominated. • All plant stock secured. • Garden beds prepared for integration of soil amendments.

5 working days

0261 Landscape – furniture and fixtures • Site locations or substrates prepared to receive furniture or fixtures before

installation.

5 working days

0271b Pavement base and subbase • Submissions as nominated. • Prepared subgrade. • Proof rolling of subbase before spreading of base. • Proof rolling of base before sealing.

5 working days

0171 General requirements

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 16

Item Minimum notice 0272 Asphalt • Submissions as nominated. • Surface prepared for asphalt surfacing. • Commencement of asphalt surfacing.

5 working days

0221 Site preparation

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 17

0221 SITE PREPARATION

1 GENERAL

1.1 RESPONSIBILITIES General Requirement: Provide site preparation, as documented. Designated areas for protection: Existing mature trees. Incidental works Generally: Undertake the following: - Reinstatement: Reinstate undeveloped ground surfaces to the condition existing at the

commencement of the contract. - Minor trimming: As required to complete the works, as documented.

1.2 CROSS REFERENCES General Requirement: Conform to the following: - 0100 Materials and Finishes Schedule - 0160 Quality - 0171 General requirements Specific requirements Requirement: Conform to the following: - 0201b Demolition - 0222 Earthwork

1.3 INTERPRETATION Definitions General: For the purposes of this worksection the following definitions apply: - Authorities: Any authority or agency covering statutory requirements relating to the project, including

clearances for work in that particular area. - Clearances: A formal certificate, approval or condition issued by an authority to allow work to be

carried out in a particular area. - Network utility operator: The entity undertaking the piped distribution of drinking water or natural gas

for supply or is the operator of a sewerage system or external stormwater drainage system.

2 EXECUTION

2.1 EXISTING SERVICES General Requirement: Before commencing earthworks, locate and mark existing underground services in the areas which will be affected by the earthworks operations including excavating. Utility services: Contact DIAL BEFORE YOU DIG to identify location of underground utility services pipes and cables. Excavation: Do not machine excavate within 1 m of existing underground services.

2.2 TREE PROTECTION General Warning signs: Display in a prominent position at each entrance to the site, warning that trees and plantings are to be protected during the contract. Remove on completion. Lettering: Road sign type sans serif letters, 100 mm high to AS 4970 Appendix C. Protection measures: Provide before commencement of earthworks. Tree protection zone (TPZ):

0221 Site preparation

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 18

To AS 4970 Section 3. As per the Australian Standards AS 4970-2009 Protection of trees on development sites the tree protection zone (TPZ) is the principal means of protecting trees on sites where development is to occur. The TPZ is a combination of the root area and crown area requiring protection. It is an area isolated from construction disturbance, so that the tree remains viable. The radius of the TPZ is calculated for each tree by multiplying its DBH x 12. E.g. DBH is 0.5m x 12 = 6m radius (TPZ = 6m measured from the centre of the trunk at ground level.) If the proposed encroachment is greater than 10% into the TPZ or SRZ an Arborist must demonstrate that the tree(s) would remain viable. Once proposed changes or designs of the site are completed the project Arborist may need to re-inspect selected trees to ensure the trees are adequately protected. The purpose of this is to determine the potential impact on trees proposed to be retained. Structural Root Zone (SRZ): A structural root zone area of a tree is required for tree stability. Using Australian Standards AS 4970-2009 Protection of trees on development sites the structural root zone area can be calculated when major encroachment into a TPZ is proposed. This zone considers a tree’s structural stability only and not the root zone required for a tree’s health and long-term viability, which is usually a much larger area. (As cited by AS 4970-2009) An indicative SRZ radius can be determined from the trunk diameter measured immediately above the buttress using the following formula. SRZ radius = (D x 50)0.42 x 0.64 or using the following guide from AS 4970-2009. Eg. Diameter at root flare is 0.8m (red circle) and using the graph below a 3m SRZ radius is required. This is measured from the centre of the trunk at ground level. Key considerations to be noted by the Contractor when constructing near trees: - More than 90% of trees’ roots are located in the upper 1.0m of soil depth and tree roots generally

extend well beyond the canopy spread of the tree. - Machinery and vehicle movements in proximity to trees and the stock piling of building materials

beneath trees can damage both tree roots and the lower sections of the canopy. - Stock piling of building materials beneath trees can damage both tree roots and the lower sections

of the canopy. - Where trees are retained it is crucial that contractors and sub-contractors are informed of the likely

extent of tree roots and the potential damage to roots and lower branches from the construction of infrastructure too close to trees.

Key actions to be undertaken by the Contractor when constructing near trees: General: The Contractor is to ensure all contractors and sub-contractors are informed of the likely extent of tree roots and the potential damage to roots and lower branches from the construction of infrastructure too close to trees. Fencing: - Tree Protection Fencing is erected around each tree or groups of trees to prevent damage to

canopies and the root zone, where practical. Where this is not practical the Contractor is to nominate another method of protection.

Harmful materials: Conform to the following: - Machinery and vehicle movements in TPZs of trees to be retained are to be minimised. - Stock piling of building materials in TPZs of trees to be retained is not permitted. - Keep the area within the dripline free of construction material and debris. - Do not place bulk materials and harmful materials under or near trees. - Do not place spoil from excavations against tree trunks. - Prevent wind-blown materials such as cement from harming trees and plants. Damage: Prevent damage to tree bark. Do not attach stays, guys and the like to trees. - Where damaged, roots are to be cleanly cut using a hand saw or secateurs. An Arborist is to be

advised if more than 3 x 30mm diameter roots are cut on any tree which is being retained to ensure the trees remain low risk and structurally stable.

Work under trees: Do not remove topsoil from, or add topsoil to, the area within the dripline of the trees. Soil levels around trees out to the TPZ radius are not to be raised or lowered unless otherwise documented. Excavation: Minimise period of excavation under tree canopies.

0221 Site preparation

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 19

- When clearing the site and removing overburden, excavators should be fitted with a flat edge bucket and a spotter employed to check for tree roots.

Hand methods: Use hand methods to locate, expose and cleanly remove the roots on the line of excavation. If it is necessary to excavate within the drip line, use hand methods so that root systems are intact and undamaged. Roots: Do not cut tree roots exceeding 50 mm diameter. Where it is necessary to cut tree roots, use cutting methods that do not excessively disturb the remaining root system. Immediately after cutting, water the tree and apply a liquid rooting hormone to stimulate the growth of new roots. Backfilling: Backfill excavations around tree roots. Place the backfill in layers of 300 mm maximum depth and compacted to a dry density similar to that of the original or surrounding soil. Do not backfill around tree trunks to a height greater than 200 mm above the original ground surface. Immediately after backfilling, thoroughly water the root zone surrounding the tree. Backfill material: - Mix proportions (topsoil:well-rotted composts) by volume: 3:1. - Neutral pH value. - Free from weed growth and harmful materials. Compacted ground: Do not compact the ground or use skid-steel vehicles under the tree dripline. If compaction occurs, give notice. Watering: Water trees as necessary, including where roots are exposed at ambient temperature more than 35°C. And to minimise stresses upon the trees to be retained the Contractor is to provide supplementary watering to the retained trees once per week with added wetting agent, approximately 600 – 1,000 litres per tree is required.

2.3 COMPLETION Clean up Progressive cleaning: Keep the work included in the contract clean and tidy as it proceeds and regularly remove from the site waste and surplus material arising from execution of the work, including any work performed during the defects liability period or the plant establishment period.

0241 Landscape – edging

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 20

0241 LANDSCAPE – EDGING

1 GENERAL

1.1 RESPONSIBILITIES General Requirement: Provide landscape walling and edging, as documented.

1.2 CROSS REFERENCES General Requirement: Conform to the following: - 0100 Materials and Finishes Schedule - 0160 Quality - 0171 General requirements Specific requirements Requirement: Conform to the following: - 0271 Pavement base and subbase - 0272 Asphalt

1.3 INSPECTION Notice Inspection: Give notice so inspection may be made of the following: - Set out before starting construction. - Foundation conditions before placing concrete in footings.

2 PRODUCTS

2.1 CONCRETE General Standard: To AS 1379. Exposure classification: To AS 3600 Table 4.3.

3 EXECUTION

3.1 GENERAL Set-out General: Set out the position of edging. Extent: Excavate for extent of edging.

3.2 EDGING Concrete Edge beam: Place in a shallow trench between timber forms. Wood float finish flush with the adjacent finished level. Provide control joints, filled with resilient bituminous material, at 3 m maximum centres.

4 SELECTIONS

Finishes schedule Type Location Size Finish

Concrete edge beam Bordering asphalt paving 200 x 150mm Float finish Colour: Grey

0250 Landscape – combined

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 21

0250 LANDSCAPE – COMBINED

1 GENERAL

1.1 RESPONSIBILITIES General Requirement: Provide landscaped planting, as documented. Performance Plants: Grown to a standard that allows establishment and growth to maturity. Maintenance: Encourage and maintain healthy growth for the duration of the contract.

1.2 CROSS REFERENCES General Requirement: Conform to the following: - 0100 Materials and Finishes Schedule - 0160 Quality - 0171 General requirements.

1.3 INTERPRETATION Definitions General: For the purposes of this worksection the following definitions apply: - Imported topsoil: Similar to local natural soil, suitable for the establishment and ongoing viability of

the selected vegetation, free of weed propagules and of contaminants, and classified by texture to AS 4419 Appendix K Table K1, as follows: . Fine: Clay loam, fine sandy clay loam, sandy clay loam, silty loam, loam. . Medium: Sandy loam, fine sandy loam. . Coarse: Sand, loamy sand.

- Plant establishment period: The period between the date of practical completion and the end of the defects liability period.

- Site topsoil: Natural soil, excavated from the site, that contains organic matter, supports plant life, conforms generally to the fine-to-medium texture classification to AS 4419 and is free from the following: . Stones more than 25 mm diameter. . Clay lumps more than 50 mm diameter. . Weeds and tree roots. . Sticks and rubbish. . Material toxic to plants.

1.4 SUBMISSIONS Certification Plant species: Submit the supplier’s certification as evidence that plants are true to the required species and type and free from diseases, pests and weeds at time of delivery. Samples General: Submit representative samples of each material, packed to prevent contamination and labelled to indicate source and content. Bulk materials: At least 5 working days before bulk deliveries, submit a 1 kg sample of each type documented with required test results. Subcontractors General: Submit names and contact details of proposed suppliers and evidence of the following, if appropriate: - Experience in the required type of work. - Production capacity for material of the required type and quantity.

0250 Landscape – combined

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 22

- Lead times for delivery of materials to the site.

1.5 INSPECTION Notice Inspection: Give notice so that inspection may be made of the following: - All plant stock secured. - Garden beds prepared for integration of soil amendments. - Plant material set out before planting.

2 PRODUCTS

2.1 TOPSOIL Standard Site and imported topsoil: To AS 4419. Potting mixes: To AS 3743. Composts, soil conditioners and mulches: To AS 4454. Source General: If the topsoil of documented quality cannot be provided from material recovered from site, provide imported topsoil. Site topsoil General: Provide site topsoil, as documented. Soil blend: If required, stripped natural soil with sand and/or organic matter and recommended ameliorants.

2.2 FERTILISER General Type: Proprietary fertilisers, delivered to the site in sealed bags marked to show manufacturer or supplier, weight, fertiliser type, N:P:K ratio, recommended uses and application rates. Application rate: Vary the application rate to allow for the plant-available immediate fertilizer equivalence value of the soil conditioning compost. Fertiliser schedule Fertiliser key Location N:P:K ratio Application rate Baileys Native Plant Food - fertiliser granules

All tubestock planting

(N) 21.0% : (P) 0.89% : (K) 9.1%

In accordance with manufacturer

2.3 PLANTS - GENERAL Supply Supply trees to AS 2303 and with the following properties: - Stress: Free from stress resulting from inadequate watering, excessive shade or excessive sunlight

experienced at any time during their development. - Site environment: Grown and hardened off to suit anticipated site conditions at the time of delivery. - Pests and disease: Free from attack by pests, pathogens or disease including Phytophthora sp. - Native species with a history of attack by native pests: Restrict plant supply to those with evidence

of previous attack to less than 15% of the foliage and make sure actively feeding insects are absent. Labelling General: To AS 2303 clause 4.2.1. Label type: To withstand transit without erasure or misplacement. Root system Requirement: Supply plant material with a root system that is: - Well-proportioned in relation to the size of the plant material. - Conducive to successful transplantation.

0250 Landscape – combined

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 23

- Free of any indication of having been restricted or damaged. Root inspection: If inspection is by the removal of soil test, such as investigative inspection, sample as follows: - For > 100 samples: Inspect 1%. - For < 100 samples: Inspect 1 sample. Sample plants: Replace plants used in investigative inspection. Defective samples: Reject entire line. Rejection: Do not provide root bound stock.

2.4 TREE GUARDS Guards Product: Rigid UV-stabilised cortflute plastic guards, welded shut. Size: Triangular, 450(H) x 140mm sides Stakes Product: Bamboo stake Size: 10mm diameter x 750mm length

3 EXECUTION

3.1 PREPARATION Weed eradication Herbicide: Eradicate weeds using environmentally acceptable methods, such as a non-residual glyphosate herbicide in any of its registered formulae, at the maximum application rate. Manual weeding: Regularly remove weed growth by hand throughout planted and mulched areas. Vegetative spoil Disposal: Remove vegetative spoil from site. Do not burn.

3.2 SUBSOIL Planting beds Unexcavated: Remove weeds, roots, rubbish and other debris. Reduce the planting bed level to 75 mm below finished design levels. Cultivation Cultivation depths (mm): Refer drawings. Services and roots: Do not disturb services or tree roots. If required, cultivate these areas by hand. Cultivation: Cultivate manually within 300 mm of paths or structures. Remove stones exceeding 25 mm, clods of earth exceeding 50 mm, and weeds, rubbish or other deleterious material brought to the surface during cultivation. Trim the surface to design levels after cultivation. Subsoil additives schedule Location Additive type Additive rate All garden beds Richgro ‘Metro’ soil conditioner or approved

equivalent (AS4454 certified) Refer drawings

3.3 PLANTING General Plant location and spacing: If necessary to vary plant locations and spacings to avoid service lines, or to cover the area uniformly, or for other reasons, give notice. Timing Tubestock is unirrigated. Timing of planting is to coincide with onset of winter rains, typically June. Planting conditions Weather: Do not plant in unsuitable weather conditions, including extreme heat, cold, wind or rain. In other than sandy soils, suspend excavation when the soil is wet, or during frost periods.

0250 Landscape – combined

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 24

Watering Timing: Thoroughly water the plants before planting and immediately after planting. Placing General: Place plants as follows: - Remove the plant from the container with minimum disturbance to the root ball. Make sure that the

root ball is moist. - Place the plant in its final position, in the centre of the hole and plumb, and with the topsoil level of

the plant root ball level with the finished surface of the surrounding soil. Fertilising Pellets: In planting beds and individual plantings, place fertiliser pellets around the plants at the time of planting. Backfilling General: Backfill with topsoil mixture. Tamp lightly and water to eliminate air pockets. Make sure that topsoil is not placed over the top of the root ball, so the plant stem remains the same height above ground as it was in the container. Avoid mixing mulch with topsoil.

3.4 CONTINGENCY PLANT MATERIAL Replacement Provision: Anticipate replacement of failures on site. Amount: 15% above any normal allowances made in the nursery trade for anticipated losses in the course of propagation and the growing on of plant materials. Delivery: Supply to the site upon 7 days’ notice to the supplier. Surplus plant material: To remain the property of the supplier.

3.5 WARRANTIES True-to-species Parties: Supplier(s) to the principal. Form: All the plants supplied under these works are true-to-species and type, and free of disease, fungal infection, pathogens, Phytophthora sp. and/or any other impediment to their future growth and that they have been fully acclimatised for the conditions of the site. Submission of warranty: At the time of each delivery.

3.6 MULCHING Placing mulch General: Place mulch to the required depth and clear of plant stems, so that after settling it conforms to the following: - Smooth and evenly graded between design surface levels. - Flush with the surrounding finished levels. - Sloped towards the base of plant stems in plantation bed. - For gravel mulches: Not closer to the stem than 50 mm. Depths: - Organic mulch: 75 mm. Installation: - In mass planted areas: Place after the preparation of the planting bed but before planting and other

work. Mulching schedule Mulch key Location Mulch type Depth (mm) Imported organic mulch All garden beds Richgro ‘Sandgroper Mulch’

or approved equivalent (AS4454 certified)

75mm

0250 Landscape – combined

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 25

3.7 TREE GUARDS Installation Location: To tree species only – refer drawings. Installation: Install upright. Secure each guard with a single bamboo stake, at least 250mm in ground.

0261 Landscape – furniture and fixtures

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 26

0261 LANDSCAPE – FURNITURE AND FIXTURES

1 GENERAL

1.1 RESPONSIBILITIES General Requirement: Provide landscape furniture and fixtures, as documented.

1.2 CROSS REFERENCES General Requirement: Conform to the following: - 0100 Materials and Finishes Schedule - 0160 Quality - 0171 General requirements Specific requirements Requirement: Conform to the following: - 0274 Concrete pavement - 1424 Maintenance -

1.3 INSPECTION Notice Inspection: Give notice so that inspection may be made of the following: - Shop drawings as required.

2 PRODUCTS

2.1 GENERAL Storage and handling General: Deliver, unload and store products and accessories in sealed manufacturer's packaging.

3 EXECUTION

3.1 INSTALLATION Erection Line and level: Erect posts or poles vertically. Erect furniture items level.

3.2 COMPLETION Cleaning General: On completion, remove protective coatings, clean all surfaces and remove all labels not required for maintenance, or by AS 4685 series.

4 SELECTIONS

4.1 FURNITURE Bollard Description: ‘Brolga’ bevelled edge recycled plastic bollard Manufacturer: Replas (1800 737 527) Code: BO2010 / 1200 black Finish: Black Fixing: Cast in-ground

0261 Landscape – furniture and fixtures

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 27

Removable bollard sleeve Description: Sleeve suitable for ‘Brolga’ bollards Manufacturer: Replas (1800 737 527) Code: Bol-Sleeve-Brolga Finish: HDG Fixing: Cast in-ground lockable sleeve. Padlock to Shire requirements.

4.2 SIGNAGE General: All custom-built signage is to be supplied, delivered to site and installed by the Contractor. All signage to be AA compliant. All external and internal signage should be positioned to be clearly visible to people with a disability, in accordance with the Building Code of Australia (BCA), Australian Standards, AS 1428.1 and AS1428.2. The Australian Standard, AS 2899.1, Public Information, Symbols and Signs is also relevant. The signage artwork/graphics will be supplied by the Principal in electronic format for printing, prior to installation. Signage – Interpretive Description: Angled interpretive signage Artwork: Supplied by Principal. Finishing: All sign posts and frames are to be powdercoated Dulux ‘Intensity Storm’ (90N5365S0) Fixing: Refer drawings. Signage – Destination Description: Totem desitination signage Artwork: Supplied by Principal. Finishing: All sign posts and frames are to be powdercoated Dulux ‘Intensity Storm’ (90N5365S0) Fixing: Refer drawings.

0271 Pavement base and subbase

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 28

0271 PAVEMENT BASE AND SUBBASE

1 GENERAL

1.1 RESPONSIBILITIES General Requirement: Provide base and subbase courses as documented.

1.2 CROSS REFERENCES General Requirement: Conform to the following: - 0100 Materials and Finishes Schedule - 0160 Quality - 0171 General requirements Specific requirements Requirement: Conform to the following: - 0272 Asphalt

1.3 INTERPRETATION Definitions General: For the purposes of this worksection, the following definitions apply: - Base: One or more layers of material, forming the uppermost structural element of a pavement and

on which the surfacing may be placed. - Subbase: Material laid on the subgrade below the base either for the purpose of making up

additional pavement thickness required, to prevent intrusion of the subgrade into the base, or to provide a working platform.

1.4 INSPECTION Notice Inspection: Give notice so that inspection may be made of the following: - Prepared subgrade. - Proof rolling of subbase before spreading of base. - Proof rolling of base before sealing.

2 PRODUCTS

2.1 BASE AND SUBBASE MATERIAL Granular material Requirement: Provide unbound granular materials, including blends of two or more different materials, which when compacted develop structural stability and are uniform in grading and physical characteristics. Natural gravel Requirement: Provide unbound natural gravel materials as follows: - Base: 10 mm nominal. - Subbase: 20 mm nominal.

3 EXECUTION

3.1 SUBGRADE PREPARATION General Requirement: Prepare the subgrade in conformance with 0222 Earthwork.

0271 Pavement base and subbase

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 29

3.2 PLACING BASE AND SUBBASE General Weak surfaces: Do not place material on a surface that is weakened by moisture and is unable to support, without damage, the construction plant required to perform the works. Spreading: Spread material in uniform layers without segregation. Moisture content: Maintain wet mixed materials at the required moisture content before and during spreading. Add water to dry mixed materials through fine sprays to the entire surface of the layer after spreading, to bring the material to the required moisture content. Compacted layer thickness: 200 mm maximum and 100 mm minimum. Provide layers of equal thickness in multilayer courses. Joints General: Plan spreading and delivery to minimise the number of joints. Offset joints in successive layers by a minimum of 300 mm. Start of shift: Remix last 2 m of previous days' work for continuity of compaction. Final trimming General: Trim and grade the base course to produce a tight even surface with no loose stones or slurry of fines.

3.3 TOLERANCES Surface level General: Provide a finished surface level which is free draining and evenly graded between level points. Subbase: + 10 mm, - 25 mm. Base: + 10 mm, - 5 mm. Base abutting gutters: ± 5 mm from the level of the lip of the gutter, minus the design thickness of the wearing course. Surface deviation Base: ≤ 5 mm from a 3 m straightedge laid on the surface.

3.4 BASE AND SUBBASE COMPACTION General Construction operation: Compact each layer of fill to the required depth and density, as a systematic construction operation. Unstable areas: If unstable areas develop during rolling or are identified by proof rolling, open up, dry back and recompact, to the requirements of this worksection. If dry back is not possible, remove for the full depth of layer, dispose of and replace with fresh material. Minimum relative compaction table Item description Minimum dry density ratio (modified

compaction) to AS 1289.5.2.1 Subbase 95% Base 98% Compaction requirements General: Apply uniform compactive effort over the whole area to be compacted, until the required density is achieved or until failure is acknowledged. If failure is acknowledged, conform to Rectification. Equipment: Use rollers appropriate to the materials and compaction requirements documented. Moisture content General: During spreading and compaction, maintain material moisture content within the range of -2% to +1% from the optimum moisture content (modified compaction). Spraying: Use water spraying equipment to distribute water uniformly, in controlled quantities, over uniform lane widths. Dry back: Allow materials to dry to 60 to 80% of the optimum moisture content before applying the seal or wearing course.

0271 Pavement base and subbase

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 30

Rectification General: If a section of the pavement material fails to meet the required density or moisture content after compaction, remove the non-conforming material, dispose of off-site or rectify for re-use, replace with fresh material, and re-compact. Level corrections General: Rectify incorrect levels as follows: - High areas: If the area can be rectified by further trimming to produce a uniform, hard surface by

cutting without filling, trim so that the rectified area conforms to TOLERANCES. - Low areas and high areas not rectifiable by further trimming: Remove layers to a minimum depth of

75 mm, lightly tyne and replace with new material and re-compact.

3.5 TESTING Site tests Compaction control tests: To AS 1289.5.4.1 and AS 1289.5.4.2.

0272 Asphalt

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 31

0272 ASPHALT

1 GENERAL

1.1 RESPONSIBILITIES General Requirement: Provide asphalt surfacing as documented. Performance Requirements: Provide asphalt surfacing conforming to the following: - Free draining and evenly graded between level points. - Even and smooth riding.

1.2 CROSS REFERENCES General Requirement: Conform to the following: - 0100 Materials and Finishes Schedule - 0160 Quality - 0171 General requirements Specific requirements Requirement: Conform to the following: - 0221 Site preparation - 0271 Pavement base and subbase - 0277 Pavement ancillaries Common requirements Requirement: Conform to the following:

1.3 STANDARDS General Hot mix asphalt: To the recommendations of AS 2150.

1.4 INTERPRETATION Definitions General: For the purposes of this worksection the definitions given below apply: - Absolute level tolerance: Maximum deviation from design levels. - Lot: A lot consists of any part of the works which has been constructed/manufactured under a

continuous operation of uniform conditions and is essentially homogeneous with respect to material and general appearance. The whole of the work included in a lot is of a uniform quality without obvious changes in attribute values.

- Relative level tolerance: Maximum deviation from a 3 m straightedge laid on the surface. - Relative compaction: The ratio between the field bulk density and the bulk density of the job mix

when compacted in the laboratory.

1.5 TOLERANCES Surface level General: Provide a finished surface which is free draining and evenly graded between level points. Tolerances table Item Level tolerance Level (Longitudinal) ± 10 mm Absolute 5 mm

Relative Level (Transverse) ± 10 mm Absolute 10 mm

Relative Compacted layer thickness (Any one sample) + 10 mm, - 5 mm.

0272 Asphalt

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 32

Item Level tolerance Edges abutting gutters ± 5 mm from the level of the lip of the gutter. Shape Conform to AS 2150 Table 15. Roughness Conform to AS 2150 Table 16. The tolerances apply to the finished level of each layer, unless overridden by the requirements (including tolerances) for the finished level and thickness of the surface course.

1.6 SUBMISSIONS Products and materials Certificate of compliance: Submit the manufacturer’s certificate together with the results of recent tests undertaken by the manufacturer, showing conformance with test criteria.

1.7 INSPECTION Notice Inspection: Give notice so that inspection may be made of the following: - Surface prepared for asphalt surfacing. - Commencement of asphalt surfacing.

2 PRODUCTS

2.1 AGGREGATE Properties General: Clean, sound, hard, angular, of uniform quality, free from deleterious matter. Type: Graded laterite. Standard: To AS 2758.5. Mineral filler: To AS 2150 clause 4.2. Combined aggregate grading: To AS 2150 clause 5.2. Crushed slag: Air-cooled blast furnace slag of uniform quality, free from vesicular, glassy or other brittle pieces. Fine aggregate: Clean, sound, hard, durable particles of natural sand or particles derived from crushed stone, gravel or slag, free from injurious coating or particles of clay, silt, loam or other deleterious matter. Aggregate properties table Property Test method Value Particle shape AS 1141.14 ≤ 25 for wearing course

≤ 30 for binder course and corrective course Wet strength AS 1141.22 ≥ 100 kN Wet/dry strength variation AS 1141.22 ≤ 35%

2.2 TACK COATING Properties Bitumen emulsion: Rapid setting to AS 1160. Tack coat mix: 3:2 bitumen emulsion:water.

2.3 ASPHALT General Hot mix asphalt: To AS 2150. Medium cut back bitumen: To AS 2157. Bitumen emulsion: To AS 1160. Bitumen binder: Class 170.

0272 Asphalt

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 33

Mix design Design: To AS/NZS 2891.5, AS 2150 clause 6 and the Marshall method: - Marshall stability: Greater than 4.5 kN. - Marshall flow: 2 mm to 4 mm. - Voids in total mix (maximum theoretical density based on apparent specific gravity of aggregates):

. Wearing courses: 3% to 5%.

. Binder courses and 7 mm mixes: 4% to 6%. - Voids in aggregate filled with bitumen:

. Wearing courses: 75% to 85%.

. Binder courses and 7 mm mixes: 70% to 80%. Reclaimed asphalt pavement (RAP): To AS 2150 clause 4.6. Warm mix asphalt additive General: If required, include warm mix asphalt additive to asphalt to reduce the asphalt manufacturing temperature and/or to improve workability during the paving and compaction operations. Product tests General: Take samples from trucks at the mixing plant and test for mix properties using one of the following methods as appropriate: Standard: To AS 2150 Table 9 and AS/NZS 2891.5. - Marshall stability of compacted mix: Compactive effort:

. 35 blows for light traffic,

. 50 blows for general conditions

. 75 blows for heavy traffic or deep lifts. Variations in mix properties General: Make sure the maximum variation between the mix property of each sample and the job mix value conforms to the Mix property table. Mix property table Mix property Maximum variation from job mix value Aggregate passing 4.75 mm sieve or larger ± 7% by mass Aggregate passing 2.36 mm to 300 µm sieves ± 5% by mass Aggregate passing 150 µm sieve ± 2.5% by mass Aggregate passing 75 µm sieve ± 1.5% by mass Bitumen content ± 0.3% by mass Added filler content ± 0.3% by mass Mixing temperature ± 10°C

2.4 OTHER MATERIALS Concrete Edge Refer 0241 Landscape – edging worksection for products.

3 EXECUTION

3.1 PREPARATION Cleaning Requirement: Immediately before priming or tack coating remove loose stones, dust and foreign material from the base surface using a power broom or blower. Keep traffic off the cleaned surface. Priming Requirement: Prime the base surface as soon as possible after compaction and finishing. Tack coating Application rate: Apply tack coat 30 to 120 minutes before asphalt surfacing is placed. Cover the surface uniformly at an application rate of 0.10 to 0.30 L/m2 of residual binder.

0272 Asphalt

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 34

3.2 SURFACING Spreading Conditions: Place asphalt surfacing in dry weather on dry pavement surface, at minimum pavement temperature of 10˚C. Operations: Spread the mix in layers covering the full width of the pavement, or in the case of carriageways and wide pavements, in lanes of 3 m wide minimum. Place layers in adjoining lanes to the same compacted thickness. Self-propelled paving machine spreading: To AS 2150 clause 12.2. Hand spreading: To AS 2150 clause 12.3. Average thickness tolerance: - Thickness > 50 mm: ± 10% of total thickness to a maximum of ± 15 mm. Frequently check thickness: Measure uncompacted and compacted layer in conformance with AS 2150. Direction of placement: To ensure finished levels are achieved and the path is free draining. Protection Adjacent surfaces: Protect adjacent surfaces during spraying. Freshly spray surfaces: Protect from contamination. Joints Standard: To AS 2150 clause 12.6. Requirement: Provide joints that are well bonded and sealed, with a smooth riding surface across the joint. Minimise the number of joints. Transverse joints: Provide if the operation is stopped for more than 20 minutes or if pavement temperature falls below 90°C. Provide a straight vertical face for the full layer depth and offset in adjoining spreader runs and layer to layer by 1 m minimum. Longitudinal joints: Offset joints from layer to layer by 150 mm minimum. Longitudinal joint locations in the wearing course to coincide with the lane line. Edges: Form exposed edges of each spreader run while hot to a straight line with a dense face inclined between vertical and 45°. Cold joints: Tack coat the surface of cold longitudinal and transverse joint before placing the adjoining asphalt. Abutting structures Level: Place asphalt surfacing to match the level of abutting surfaces such as kerbs or adjoining pavement as for longitudinal and transverse joints. Fill: Fill spaces left unfilled between the spreader run, abutting edges with sufficient surfacing material to the required height. Matched junctions Requirement: Where asphalt is to match an existing pavement, or other fixture, place the surfacing material to provide a smooth riding surface across the junction as follows: - Remove existing pavement or taper the thickness of layers. - Terminate layers at a 20 mm deep and 400 mm wide chase cut into the existing pavement. - Coarse particles: Remove from a layer of tapering thickness using hand raking. Tack coat: Where the thickness of the layer tapers to less than twice the nominal size of the mix, tack coat the surfacing area at a uniform application rate. Existing sealed pavement: Trim the seal to a neat edge. Compaction Trimming: Before compaction, correct any irregularities in line or level. Trim lane edges to a straight line. Rolling: Compact asphalt surfacing uniformly as soon as it will support rollers without undue displacement, and complete rolling while the mix temperature is above 90°C. Density tests: Perform a field bulk density test for each test site from one of the following: - On a core sample taken from the asphalt surfacing layer. - If the nominal layer thickness is 50 mm or greater, measured in situ using a nuclear gauge.

0272 Asphalt

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 35

Sample preparation: To AS/NZS 2891.2.1 and AS/NZS 2891.2.2, as appropriate. Number of test per lot: To AS 2150, 6 tests per lot for simple/small works. Nuclear gauge tests: To AS/NZS 2891.14.2. Density criteria: Mean density: Generally 92 to 95 %

3.3 TESTING General Tests: Perform tests of the type and frequency necessary to control the materials and processes used in the construction of the works and as documented. Process control tests Records: Show the results of process control tests using control charts or graphs displayed on site in a readily accessible location and updated daily. Methods: Use wet preparation methods where applicable. Sampling: Timing and location to AS/NZS 2891.1.1. Compliance assessment tests Timing: Obtain material samples at the time of delivery to the site. Location: Obtain sample from selected sites within designated test lots, consisting of surfacing areas placed, and/or compacted in one day. Test lots to be uniform in material properties and density.

3.4 COMPLETION Non-conforming asphalt Requirement: Remove asphalt surfacing, including defective joints and finish, to the full depth of the layer, and replace with conforming pavement. Joints: Treat edges of remedial work as documented for cold joints. Reinstating adjacent surfaces Requirement: Reinstate surfaces next to new pavements and associated elements. Where an existing flexible road pavement has been disturbed, trim it back to a straight edge 250 to 300 mm from and parallel to the new concrete for the full depth of the slab. Backfill with asphalt rammed solid, using suitable rammers. Removal: Dispose of any residual or non-conforming material to a location off site. Finished pavement properties Tolerances: Make sure finished pavement levels, thickness and shape conforms to TOLERANCES. Non-conforming surfaces: Where tolerances are exceeded, remove and replace surface. Cleaning Spraying equipment: Flushing, if required, is to be contained. Return waste in a container to the depot for disposal. Excess material: Sweep any excess material away from traffic lanes and remove. Excavated material: Remove from site.

4 SELECTIONS

4.1 SCHEDULES Properties schedule Property Asphalt Paving Asphalt colour Red

Edge treatment 200mm width concrete edge as nominated on drawings

Subbase 200mm depth 98% compacted subbase

Typical Details Refer drawings

1424 Maintenance

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 36

1424 MAINTENANCE

1 GENERAL

1.1 RESPONSIBILITIES General Requirement: Provide landscape maintenance of the contract area during the 13 week post Practical Completion maintenance period. Performance Extent of maintenance: - All works. - Keeping of a log book. - Monthly reports. Maintenance period: 13 weeks post award of practical completion. Maintenance procedures: To the SELECTIONS Maintenance schedule. Procedure for additional works: A contract variation if not covered in the selected contract.

1.2 THE SITE Protection of persons and property Temporary works: Provide and maintain required guards, fencing, footpaths, signs and lighting. Accessways, services: Do not obstruct or damage footpaths, drains and watercourses or other existing services in use on or adjacent to the site. Property: Do not interfere with or damage property which is to remain on or adjacent to the site, including adjoining property encroaching onto the site, and trees. Rectification Accessways, services: Rectify immediately any obstruction or damage to footpaths, drains or other existing services in use on or adjacent to the site. Provide temporary services whilst repairs are carried out. Property: Rectify immediately any interference or damage to property which is to remain on or adjacent to the site, including adjoining property encroaching onto the site, and trees.

1.3 GENERAL CONDITIONS Contractor and staff Affiliation: Suitable professional qualifications acceptable to the principal e.g. Member of the Landscape Contractors Association. Representative: Nominate a personal experienced in maintenance nursery practices and horticulture, to be responsible for taking and carrying out instruction, and reporting to the principal. Special instructions Priority: If instructed by the principal attend to certain areas and procedures as a priority. Obtain approval for additional costs prior to commencement of works. Reporting Monthly report: Submit regular reports by the last Friday of each month, to the SELECTIONS Monthly reports schedule and as follows: - General status of the works. - Any plant replacement requirements. Incident reports: Report immediately verbally and confirmed in writing any disturbance or incidence affecting or likely to affect the scheduling of the works. Notice Inspection: Provide notice of the following operations: - Application of herbicide. - Work affecting public access or amenity on the Thursday of the week before the work is planned.

1424 Maintenance

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 37

Log book Records: Log the following on a weekly basis: - Description, time and method of application of toxic material. - Maintenance work details. Availability: Upon request. Replacement plants Species: Provide written plant material true-to-species and type, and free of disease and fungal infection. Replace all plants at contractor’s expense. Disruption of works by others Other contractors: Make arrangements to work around the disturbance.

2 EXECUTION

2.1 GENERAL Weeding Requirement: Remove unwanted broadleaf plants and grasses considered invasive to the locality. Program: - Trees and shrubs: As required for planted, paved and mulched areas to be weed free when

observed at fortnightly intervals. Vigorous ground covers: Keep 200 mm clear from the base of any shrub or tree. Remove as follows: - Small areas: By hand. Herbicide application: Apply as follows: - To the manufacturer’s recommendations and the material data and safety data sheets. - When the weather is humid with moderate temperatures and maximum sunlight. - When the ground has adequate soil moisture. - Avoid windy days or if rain is likely to follow within 12 hours. Insect and disease control Requirement: Control any insects or diseases affecting the garden bed areas as follows: - Identify the problem. - Execute the correct treatment until the problem has been eliminated. - Apply hazardous material during normal working hours, i.e. when foreshore is less likely to be

visited. - Protect staff and public.

2.2 PLANTING Plant replacements General: Replace all evergreen plants that have died or lost 50% of their normal foliage cover. Provide replacement plants as follows: - Of the same species and variety and of the closest commercially available size. - With a balanced root system in relation to the size of the plant. - Without signs of having been stressed at any stage during their development due to inadequate

watering, excessive shade/sunlight, suffered physical damage or have restricted habit due to growth in nursery rows.

- Grown in final containers for not less than twelve (12) weeks. Responsibility: The contractor shall be responsible for replacement of plants at no cost to the Principal.

2.3 MULCHING General Clean up: Remove all mulching materials off paved areas and maintain a clean and tidy appearance when viewed on a weekly basis. Requirement: Maintain a minimum depth as follows:

1424 Maintenance

© ECOSCAPE (LAKE EWLYAMARTUP FORESHORE | MARCH 2020) 38

- As per Landscape – combined worksection. Top up: Areas of excessive wear.

2.4 CONTROL MEASURES Rabbit control Generally: Implement rabbit control until the completion of the plant establishment period. Tree guards: Maintain rabbit guards in a working upright and taut order with singe bamboo stake. Install additional stakes if necessary to secure guards in place. Replacement: Replace missing or damaged guards with the same as previously specified. Removal: At the completion of the plant establishment period or as directed by the Superintendent.

2.5 INCIDENTAL WORKS Supplementary works General: Execute the following: - Removal of waste from maintenance work. - Removal of leaf litter fortnightly during leaf fall. - Wash paving on completion of herbicide application.

3 SELECTIONS

3.1 MAINTENANCE REPORT Monthly reports schedule Item Action Plant material Replace failed plants

Additional planting – if required prepare a submission for the proposed works and seek approval Treat for disease or insect attack Monitor transplanted trees surgery Fertilising generally and for specific nutrient deficiencies Thin out planting Pruning/trimming Weeding

Mulch Top up mulch to mass planting and mulch only areas Rubbish removal Daily removal of broken glass, particularly from the skate park, multi-

court and other areas of hardstand. Generally remove bottles, paper, cigarette butts etc. Remove leaf, litter from rain gardens, drainage swale, path and paved areas

Furniture and signage Remove stains and graffiti Ensure in working order and footing / fixings secure

![[Site name] e.g. Biscay Street...Tree Guards – plastic Tree guards can be reused, ask around if there are any available from last year Tree Guards- cardboard Require 2 bamboo stakes](https://static.fdocuments.net/doc/165x107/5f0b1ffc7e708231d42ef89c/site-name-eg-biscay-tree-guards-a-plastic-tree-guards-can-be-reused-ask.jpg)