Technical Catalogue

-

Upload

nadeem-ahmed -

Category

Documents

-

view

28 -

download

0

description

Transcript of Technical Catalogue

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 156

APPROVED

General director

JSC laquoAZNTraquo

Tampayev Ya Т

laquo raquo 2012 у

ТЕCHNICAL CATALOGUEo output goods o Joint-Stock Company

laquoAktobe Plant o Nonmetallic pipesraquo

DEVELOPED BY

Engineering director Uteuov АB

Unit manager Kayirov ShSh

Chie technologist Kanatov BК

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 256 ndash 2 ndash

CONTENT

I About company 3

II Introduction 4

III Terms and adjectives 5

IV Production line CFW 300ndash2600 or manuacturingo GRP pipes by continuous winding method 6

41 Technical parameters o GRP pipes 842 Sleeve couplings 1143 Bends segmented 1344 Bends monolithic 14

45 Тees 1546 Reductions 1847 Flanges 19

V Production line DFW 80ndash1000 or manuacturingo GRE pipes by discontinuous method 20

51 Technical parameters o GRE pipes 2252 Bends monolithic 27

53 Tees 2954 Reduction 3255 Couplings 3356 Nipples 3457 Flanges 35

VI Tanks 36

VII Inspection shafs 40

VIII Nonstandard products 41

Appendix 1 43Appendix 2 47Appendix 3 53

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 356 ndash 3 ndash

I ABOUT COMPANY

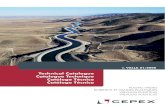

The JSC laquoAZNTraquo was established on 2 June 2004 The first stage

was placed in operation on 30 December 2005 and second stage inAugust 2009 and produce glass fiber pipes on basis o polyester epoxyresins and quartz sand reinorced with glass fiber tanks with capacityup to 75m3 or storage and transportation o hostile environment

The JSC laquoAZNTraquo or the first time mastered in production oglass fiber pipes with diameter 2600 mm on pressure 06 MPa andstiffness 7500 Hm2 or underground sanitation o circulating pipes inNevinnomyssk State District Power Station (Pyatigorsk city Russian

Federation)The glass fiber pipes produced at JSC laquoAZNTraquo are competitive

and supplied not only to inner market o Kazakhstan and also toCIS countries (Uzbekistan to different regions o Russia rom StPetersburg to Krasnoyarsk)

Plant production capacity is 320 km o glass fiber pipes perannum (in standard unit)

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 456 ndash 4 ndash

II INTRODUCTION

The essential efforts and capital investments related with constructionreconstruction and repair o engineering communications ortransportation o various fluid mediums are demands the new

technologies allowing to low material costs to reduce terms o workto increase reliability and communication longevity

The world practice testifies to more and wider application inparticular or systems o water supply the sewerage and oil and gas branch o the fiberglass pipes made o polymeric composite materials

The glass fiber pipe made o composite materials on basis othermosetting resins quartz sand reinorced with glass fiber

The application o pipes made o reinorced glass fiber has

advantages as ollowsHigh mechanical durability provided by presence o glass fiber

materialsCorrosion resistance o external and inner suraces o the pipe

that allows reusing need rom lying o protecting coats coloring andcathode protection Durable and effective exploitation (up to 50 years)The pipes made o reinorced fiber glass are suitable or transportationpractically o all chemical agents even at highest temperatures in

comparison with other plasticsSmoothness surace o inner wall which brings to

minimum loss o velocity pressure The low losses on riction reducetransportation and exploitation costs At total absence o deposits thecosts o cleaning is donrsquot demand

Long-term o pipe exploitationAbsolutely inner and external hermiticity o pipes and jointsLow weight o a pipe 14 o steel pipe weight and 110 o

concrete that allows using stackers small load-lifing and acilitatestheir transportation

Possibility o manuacturing o pipe pieces o bigger length in comparison with pipes rom other materials

The Convenience o installation both underground and overground pipe laying rom reinorced fiber glass differs by its simpleinstallation and can be carry out in short period

Simple processing material allows carrying out works on site

o exploitation o pipe using simple tools

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 556 ndash 5 ndash

III TERMS AND ADJECTIVES

Nominal diameter (DN) mdash conventional inner pipe diameter(mm) [appendix 3 item 1]

Nominal pressure (PN) mdash parameter determining the work

pressure in the pipe at the exploitation (MPa) [appendix 3 item 1]Nominal stiffness (SN) mdash parameter o a pipe causing installation

and laying o pipeline in various conditions or example spaces betweensupports at over ground laying or depth and pipeline burial conditions atunderground laying (Hm2) [appendix 3 item 1]

Specified work temperature (T) mdash maximum constanttemperature at which system unctioning is expected (degС) [appendix3 item 14]

GRР pipes mdash reinorced glass fiber composite on basis opolyester resin [appendix 3 item 3]

GRЕ pipes mdash reinorced glass fiber composite on basis o epoxyresin [appendix 3 item 3]

Fitting mdash hermetic constituent element designed ortransportation o liquid and having a geometric shape differs romstraight pipe [appendix 3 item 3]

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 656 ndash 6 ndash

IV PRODUCTION LINE CFW 3009912512600FOR MANUFACTURING OF GRP PIPESBY CONTINUOUS WINDING METHOD

Technical parameters of pipes

Pipe diameters (DN) rom 300 up to 2600 mm inclusive Standard pipe length 3 6 9 12 m Pressure (PN) up to 4 MPa

Stiffness (SN) 2500 5000 10 000 Нmsup2 and more Used temperature 60degС

Hydrotest machineIn accordance with acting standards the product pass control test onpressure class (double rom work pressure) and on stiffness at theplantrsquos accredited laboratory

Hydrotest Machine or PipeDN 300ndash2600

Hydrotest machine or couplingDN 300ndash2600

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 756 ndash 7 ndash

Kind of joints used for GRP pipe

Sleeve coupling joint with Reka rubbergaskets and centre stopper designed orpipelines DN300ndash2600 mm working on

pressure up to 4 MPa

Flange joint or pipelines DN300ndash2600 mmworking on pressure up to 4 MPa

Band joint or pipelines DN300ndash2600 mmworking on pressure up to 32 MPa

Field of application of GRP pipes Industry and drink water supply Industry and communal sewerage

Hydraulic works or cooling system Outalls o wastewater to sea Underwater pipelines

Production line o industry equipments Fire saety system Transportation system and distribution o petrol Flue pipe or corrosion liquids and ventilation pipes Receiver bushing or downed pumps

Pressure pipelines Neutralization o combustion gas Irrigative systems

Flue pipe or combustion gas

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 856 ndash 8 ndash

41 TECHNICAL PARAMETERS OF GRP PIPES

PN 06 ΜΡа

PN 06 ΜΡа

SN (Нmsup2) 2 500 5 000 10 000

D N ( m m )

D 1 ( m m )

T o l e -

r a n c e

D 2 ( m m )

T s ( m m )

W ( k g m )

D 2 ( m m )

T s ( m m )

W ( k g m )

D 2 ( m m )

T s ( m m )

W ( k g m )

300 3146 plusmn26 3056 45 73 3036 55 92 3009 68 115

350 3666 plusmn26 3566 5 97 3532 67 132 3511 78 154

400 4131 plusmn27 4019 56 123 3986 72 162 3962 84 19

450 4641 plusmn27 4518 62 153 4485 78 196 4453 94 239

500 5151 plusmn28 5018 67 185 4981 85 238 4942 105 297

600 6171 plusmn29 6017 77 258 5972 10 338 5924 123 422

700 7191 plusmn3 7009 91 358 6962 114 455 6909 141 565

800 8211 plusmn31 801 101 455 7953 129 59 7892 16 734

900 9231 plusmn32 9008 111 569 894 145 75 8872 18 932

1000 10251 plusmn33 10002 124 708 9936 158 905 9859 196 1131

1200 12291 plusmn35 1200 145 999 11916 187 1295 11826 232 1614

1400 14331 plusmn37 13993 169 1361 13899 216 1745 13803 264 2142

1600 16371 plusmn39 15989 191 176 15835 268 2485 15761 305 2835

1800 18411 plusmn41 17983 214 2224 17853 279 2913 17723 344 3601

2000 20451 plusmn43 19981 235 272 19844 304 3525 19698 377 4385

2200 22491 plusmn45 21974 258 3292 21832 33 4214 21663 414 5308

2400 24531 plusmn47 23971 28 3898 23806 363 5067 23618 457 63942600 26571 plusmn49 25963 304 4585 25786 392 5942 25593 489 7423

Tolerance [Appendix 3 item 1]

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 956 ndash 9 ndash

PN 1 ΜΡа

PN 1 ΜΡа

SN (Ηmsup2) 2 500 5 000 10 000

D N

( m m )

D 1

( m m )

T

o l e -

r a

n c e

D 2

( m m )

T s

( m m )

W ( k g m )

D 2

( m m )

T s

( m m )

W ( k g m )

D 2

( m m )

T s

( m m )

W ( k g m )

300 3146 plusmn26 306 43 7 3042 52 86 3017 65 109

350 3666 plusmn26 3571 47 9 3548 59 114 3515 75 15

400 4131 plusmn27 4027 52 113 400 66 145 3966 82 185

450 4641 plusmn27 4523 59 145 4491 75 188 4453 94 239

500 5151 plusmn28 5023 64 176 4992 79 221 4949 101 286

600 6171 plusmn29 6025 73 243 598 96 323 5934 119 405

700 7191 plusmn3 7021 85 332 6978 107 422 6918 136 545

800 8211 plusmn31 8023 94 422 7973 119 54 7901 155 711

900 9231 plusmn32 9021 105 534 8966 133 68 8886 173 893

1000 10251 plusmn33 10021 115 65 9958 146 836 9866 193 1111

1200 12291 plusmn35 1202 135 924 11826 232 1614 11838 227 1572

1400 14331 plusmn37 14015 158 1261 13928 201 1621 13805 263 2313

1600 16371 plusmn39 16017 177 1618 15911 23 2123 15773 299 2779

1800 18411 plusmn41 18016 198 2041 17899 256 2663 17742 334 34992000 20451 plusmn43 20014 219 2513 19886 282 3267 19707 372 4332

2200 22491 plusmn45 22014 239 3019 21871 31 3948 21674 409 5235

2400 24531 plusmn47 24008 261 3615 23854 338 4709 23646 442 6188

2600 26571 plusmn49 26007 282 4231 25844 363 548 25591 49 7435

DN 400 mm PN1 MPaSN10000 Nmsup2

Application Transportationo drink water Makhachkalacity Russian Federation

Glass fiber Pipes GRP DN 2600 mmPN 06 MPa SN 7500 Nmsup2

Flow speed 4 ms volume 17 msup3s Application Circulating water pipes orNevinnomyssk State District Power Station

Pyatigorsk city Russian Federation

Glass fiber Pipes GRP

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 1056 ndash 10 ndash

PN 16 ΜΡа

PN 16 ΜΡа

SN (Ηmsup2) 2 500 5 000 10 000

D N

( m m )

D 1

( m m )

T

o l e -

r a

n c e

D 2

( m m )

T s

( m m )

W ( k g m )

D 2

( m m )

T s

( m m )

W ( k g m )

D 2

( m m )

T s

( m m )

W ( k g m )

300 3146 plusmn26 3032 57 96 3032 57 96 3015 66 111

350 3666 plusmn26 3543 62 121 3543 62 121 3516 75 15

400 4131 plusmn27 3993 69 155 3993 69 155 3967 82 185

450 4641 plusmn27 4491 75 189 4491 75 189 4458 92 234

500 5151 plusmn28 4988 81 228 4988 81 228 4951 10 284

600 6171 plusmn29 5981 95 321 5981 95 321 5939 116 397

700 7191 plusmn3 6974 108 43 6974 108 43 6927 132 528

800 8211 plusmn31 7966 122 557 7966 122 557 7911 15 688

900 9231 plusmn32 8963 134 686 8963 134 686 8899 166 858

1000 10251 plusmn33 9955 148 845 9955 148 845 9887 182 1046

1200 12291 plusmn35 11944 173 1192 11944 173 1192 1186 215 149

1400 14331 plusmn37 13933 199 1599 13933 199 1599 13838 247 1995

PN 25 32 4 ΜΡа

PN (ΜΡа) 25 32 4

SN 2 500 mdash 10 000 Ηmsup2

D N ( m m )

D 1 ( m m )

T o l e -

r a n c e

D 2 ( m m )

T s ( m m )

W ( k g m )

D 2 ( m m )

T s ( m m )

W ( k g m )

D 2 ( m m )

T s ( m m )

W ( k g m )

300 3146 plusmn26 2995 75 128 2965 91 156 2931 107 185

350 3666 plusmn26 3498 84 168 3464 101 201 3449 12 242

400 4131 plusmn27 3946 93 209 3907 112 255 3892 133 304

450 4641 plusmn27 4439 101 258 4397 122 313 4377 147 378

500 5151 plusmn28 4931 11 311 4884 133 38 4865 16 458

600 6171 plusmn29 5917 127 433 5858 156 536 5795 188 647

700 7191 plusmn3 6903 144 576 6836 178 712 6758 216 87

800 8211 plusmn31 7888 161 738 781 20 92 7722 245 1126

900 9231 plusmn32 8874 178 92 8785 223 1154 8691 27 140

1000 10251 plusmn33 986 196 1122 9759 246 1415 9654 299 1721

Note The parameters o pipes with intermediate or higher classification are madeaccording to technical requirements o customer

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 1156 ndash 11 ndash

42 SLEEVE COUPLINGS

PN 06 1 16 ΜΡа

PN (ΜΡа) 06 1 16

SN 2 500 mdash 10 000 Ηmsup2

D N ( m m )

D 1 ( m m )

T o l e -

r a n c e

L ( m m )

D 2 ( m m )

T s ( m m )

W ( k g m )

D 2 ( m m )

T s ( m m )

W ( k g m )

D 2 ( m m )

T s ( m m )

W ( k g m )

300 3146 plusmn26 250 3507 171 342 3507 171 342 3537 186 374

350 3666 plusmn26 250 4034 174 401 4034 174 401 4066 19 441

400 4131 plusmn27 250 4506 178 457 4506 178 457 4542 196 507

450 4641 plusmn27 250 5024 182 521 5024 182 521 5064 202 584

500 5151 plusmn28 250 5538 184 581 5538 184 581 5587 208 664

600 6171 plusmn29 300 6653 232 881 6653 232 881 6709 259 995

700 7191 plusmn3 300 769 24 1056 769 24 1056 7753 272 1204

800 8211 plusmn31 300 8722 246 1227 8722 246 1227 8797 284 1426

900 9231 plusmn32 300 9757 254 1415 9757 254 1415 9841 296 1662

1000 10251 plusmn33 300 10793 261 1612 10793 261 1612 10881 306 190

1200 12291 plusmn35 300 12861 276 2026 12861 276 2026 12968 329 24381400 14331 plusmn37 300 14954 302 2583 14954 302 2583 15055 352 3032

1600 16371 plusmn39 300 17079 345 337 17079 345 337 mdash mdash mdash

1800 18411 plusmn41 300 19212 391 4305 19212 391 4305 mdash mdash mdash

2000 20451 plusmn43 300 21342 436 5331 21342 436 5331 mdash mdash mdash

2200 22491 plusmn45 300 23451 471 6328 23451 471 6328 mdash mdash mdash

2400 24531 plusmn47 300 25581 515 756 25581 515 756 mdash mdash mdash

2600 26571 plusmn49 300 27708 559 8889 27708 559 8889 mdash mdash mdash

Tolerance [Appendix 3 item 1]

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 1256 ndash 12 ndash

PN 25 32 4 ΜΡа

PN (ΜΡа) 25 32 4

SN 2 500 mdash 10 000 Ηmsup2

D N ( m m )

D 1 (

m m )

T o

l e -

r a n

c e

L ( m

m )

D 2 (

m m )

T s ( m m )

W ( k

g m )

D 2 (

m m )

T s ( m m )

W ( k

g m )

D 2 (

m m )

T s ( m m )

W ( k

g m )

300 3146 plusmn26 250 358 207 423 3616 225 464 3656 245 511

350 3666 plusmn26 250 4119 217 508 4158 236 56 4207 261 625

400 4131 plusmn27 250 4602 226 592 4645 248 655 4696 273 731

450 4641 plusmn27 250 5126 233 681 5179 26 766 5236 288 858

500 5151 plusmn28 250 5655 243 782 5713 271 883 5776 303 997

600 6171 plusmn29 300 6795 302 1173 686 335 1311 6939 374 1482700 7191 plusmn3 300 7852 321 1439 7927 358 1622 8018 404 1849

800 8211 plusmn31 300 8906 338 172 8995 382 1963 9094 432 2241

900 9231 plusmn32 300 9963 356 2028 10063 406 2334 10172 461 2677

1000 10251 plusmn33 300 11019 375 2357 11125 428 2715 11251 491 315

Note The parameters o couplings with intermediate or higher classification aremade according to technical requirements o customer

Fiber glass couplingcompleted with

REKA gaskets andcentre stopper

Fragment o manuacturing o the fiber glass couplingDN 2600 mm PN 1 MPa SN 7500 Nmsup2

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 1356 ndash 13 ndash

43 BENDS SEGMENTED

F 1degndash30deg F 31degndash60deg F 61degndash90deg

PN 06 1 16 ΜΡа

D N ( m m ) 0degndash15deg 16degndash30deg 31degndash45deg 46degndash60deg 61degndash90deg

L1=Ls(mm)

L1=Ls(mm)

L 1 ( m m )

L 2 ( m m )

L s ( m m )

L 1 ( m m )

L 2 ( m m )

L s ( m m )

L 1 ( m m )

L 2 ( m m )

L s ( m m )

300 350 400 403 179 500 411 241 550 421 241 750

350 400 450 437 209 550 438 281 600 416 281 800

400 450 450 471 239 600 464 322 650 461 322 900

450 450 500 455 269 600 491 362 700 506 362 1000

500 450 500 489 298 650 518 402 750 501 402 1050

600 400 450 406 358 600 422 482 700 441 482 1100

700 400 450 424 418 650 475 563 800 431 563 1200

800 450 500 442 477 700 479 643 850 472 643 1350

900 450 550 509 537 800 532 723 950 512 723 1500

1000 500 550 527 597 850 536 804 1000 552 804 1650

1200 550 600 562 716 950 643 965 1200 632 965 19501400 600 700 648 835 1100 700 1125 1350 713 1125 2250

1600 700 800 733 955 1250 807 1286 1550 793 1286 2550

1800 750 850 769 1074 1350 865 1447 1700 873 1447 2850

2000 750 900 804 1193 1450 872 1608 1800 904 1608 3100

2200 750 900 840 1313 1550 929 1768 1950 934 1768 3350

2400 750 1000 775 1432 1550 986 1929 2100 965 1929 3600

2600 750 1000 793 1492 1600 1040 2010 2200 1005 2012 3750

Note The parameters o standard pipe-bends produced by JSC laquoAZNTraquo are specifiedabove the pipe-bends o other parameters are produce according to projectrequirements o customer

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 1456 ndash 14 ndash

44 BENDS MONOLITHIC

PN 25 32 4 ΜΡа

DN (mm) R (mm)1125deg 225deg 45deg 90deg

Ls (mm) Ls (mm) Ls (mm) Ls (mm)

300 450 200 230 330 590

350 525 215 245 360 665

400 600 220 260 390 740450 675 220 260 390 740

500 750 240 285 450 890

600 900 290 350 545 1070

700 1050 310 380 610 1220

800 1200 330 405 670 1370

900 1350 400 450 710 1410

1000 1500 420 480 750 1450

Segment pipe-bends Monolithic pipe-bends

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 1556 ndash 15 ndash

45 ТEES

PN 06 1 16 ΜΡаDN2

(mm)DN1(mm)

80-100

150 200 250 300 350 400 450 500

LH (mm)

3001000550

1200650

1300650

1300650

1400700

mdash mdash mdash mdash

3501100600

1100600

1400750

1400750

1500800

1600800

mdash mdash mdash

4001100650

1200700

1500800

1500800

1600850

1700850

1700850

mdash mdash

4501200700

1200750

1500850

1500850

1600900

1700900

1700900

1700950

mdash

5001300800

1400800

1400850

1800950

18001000

19001000

19001000

19001050

20001000

DN2(mm)

DN1(mm)

300-350

400 450 500 600 700 800 900 1000

LH (mm)

6001100750

1400750

1400750

1500750

1700850

mdash mdash mdash mdash

7001200750

1500850

1500850

1600850

1700900

1900900

mdash mdash mdash

8001300850

1400850

1400850

1700950

18001000

19001000

21001050

mdash mdash

9001400

950

1500

950

1500

950

1700

1000

1900

1050

2000

1050

2100

1100

2300

1150

mdash

100014001000

15001000

15001000

16001000

19001150

20001150

22001200

23001200

25001250

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 1656 ndash 16 ndash

DN2(mm)

DN1(mm)

300-350

400-450

500 600 700 800 900 1000 1200

LH (mm)

120015001200

16001200

17001200

18001200

22001350

23001350

24001350

25001350

28001400

1400 16001350

17001350

18001350

20001400

21001400

24001500

25001500

26001500

29001550

160017001500

18001500

20001500

21001550

22001550

23001550

27001700

28001700

31001750

180013501400

16001450

17001450

19001550

21001600

23001650

25001700

27001750

31001850

200014001500

17001600

18001600

19001700

21001700

23001800

25001800

27001900

31002000

220014001600

17001600

18001600

19001700

21001800

23001800

25001900

27001900

31002000

240015001700

17001650

18001650

19001750

21001850

23001850

25001950

27001950

31002100

260017001750

18001800

18001800

19001900

22001900

2300200

25002000

27002000

31002100

DN2(mm)

DN1

(mm)

1400 1600 1800 2000 2200 2400 2600

LH (mm)

140032001600

mdash mdash mdash mdash mdash mdash

160034001800

36001800

mdash mdash mdash mdash mdash

180031001850

32501950

32502000

mdash mdash mdash mdash

200031002000

32502100

35002100

35002200

mdash mdash mdash

220033002100

33002200

35002300

37002300

40002400

mdash mdash

240033002200

35002300

37002400

40002500

45002500

48002600

mdash

260033002300

35002400

37002500

40002600

45002600

48002700

51002800

Note 1 Above specified the parameters o standard tees produced by JSC laquoAZNTraquo thesewerage or tees o other parameters are produce according to project requirements

o customer

Note 2 The tees on working pressure more than 16 MPa are produce by monolithic

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 1756 ndash 17 ndash

Fiber glass Tee DN 2600times2000 mm with angle branch 45deg PN 06 MPa SN 7500 Nmsup2 Application Circulating water pipe o Nevinnomyssk State District

Power Station (SDPS) Pyatigorsk city Russian Federation

Fragment o installation o the fiber glass tee DN 2600times900 mmPN 06 MPa SN 7500 Nmsup2

SDPS o Nevinnomyssk Pyatigorsk city Russian Federation

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 1856 ndash 18 ndash

46 REDUCTIONS

PN 06ndash16 ΜΡа

DN1(mm)

DN2(mm)

L(mm)

DN1(mm)

DN2(mm)

L(mm)

DN1(mm)

DN2(mm)

L(mm)

100 80 725 450 350 1050 1200 1000 1500150 80 775 450 400 925 1400 1000 1750

150 100 725 500 400 1050 1400 1200 1500

200 80 900 500 450 925 1600 1200 2200

200 100 850 600 450 1175 1600 1400 1700

200 150 725 600 500 1050 1800 1400 2200

250 100 975 700 500 1300 1800 1600 1700

250 150 850 700 600 1050 2000 1600 2200250 200 725 800 600 1300 2000 1800 1700

300 200 1050 800 700 1050 2200 1800 2200

300 250 925 900 700 1300 2200 2000 1700

350 250 1050 900 800 1050 2400 2000 2200

350 300 925 1000 800 1300 2400 2200 1700

400 300 1050 1000 900 1050 2600 2200 2200

400 350 925 1200 900 1750 2600 2400 1700

Note 1 Above specified the parameters o standard adapters produced by JSC laquoAZNTraquothe adapters o other parameters are made according to project requirements ocustomer

Note 2 The adapters on working pressure more than 16 MPa are made by monolithic

Concentric adapter Eccentric adapter

Fragment o concentricadapter DN 400times300 mm

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 1956 ndash 19 ndash

47 FLANGES

Used or fiber glass pipe element joints with metal pipelines andarmature The conjunctive sizes o fiber glass flanges are carrying out by State Standard 12815-80 where

DN mdash nominal diameterD1 mdash diameter o bolt circle

D mdash outside diameter o a flanged mdash bolt holes diametern mdash bolt numberst mdash flange thickness

Formed PN 06ndash16 MPa Monolithic PN 06ndash16 MPa

Fragment o flange joint with

metal latchDN 600 mm PN 06

MPa SN 10000 Nmsup2Bukhara cityUzbekistan

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 2056 ndash 20 ndash

V PRODUCTION LINE DFW 809912511000FOR MANUFACTURING OF GRE PIPES

BY DISCONTINUOUS METHOD

Hydrotest machine or pipe DN 80ndash1000

Hydrotest machine or pipeDN 80ndash200

Technical parameters of pipes Pipe diameter (DN) rom 80 up to 1000 mm inclusive Pipe standard length 9 m

Pressure (PN) 64 MPa and more

Stiffness (SN) 10000 Nmsup2 and more Used temperature 90ndash130degС

Hydrotest machineIn accordance with acting standards the product pass control test onpressure class (double rom work pressure) and on stiffness at theplantrsquos accredited laboratory

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 2156 ndash 21 ndash

Kind of joints used for GRE pipe

Bell-and-spigot joint with two ring gasketsor pipelines DN 80ndash1000 mm working onpressure up to 32 MPa

Spigot and laquoKey-Lockraquo joint with two ringgaskets and holders or pipelines DN 80ndash1000mm working on pressure 32 MPa and more

Flange joint or pipelines DN 80ndash2600 mmworking on pressure 64 MPa and more

Spigot-nipple and conical glue (adhesivebutt) joint or pipelines DN 80ndash400 mmworking on pressure 64 MPa and more

Spigot-nipple laquoKey-Lockraquo threaded joint

with improved combined tread or pipelineDN 80ndash200 mm working on pressure 272MPa and more

Pipe application Oil and oil products Hot water supply heating system

Transportation o chemical hostile environment Drink and industrial water supply Sewerage and industrial flows

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 2256 ndash 22 ndash

51 TECHNICAL PARAMETERS OF GRE PIPES

DN 80ndash200 PN 06ndash32 ΜΡа

PN (ΜΡа) 06ndash1 16 25 32

SN 2 500 ndash 15 000 Ηmsup2

DN = D1(mm)

D 2 ( m m )

T s ( m m )

W ( k g m )

D 2 ( m m )

T s ( m m )

W ( k g m )

D 2 ( m m )

T s ( m m )

W ( k g m )

D 2 ( m m )

T s ( m m )

W ( k g m )

80 85 25 13 868 34 18 868 34 18 868 34 18100 1072 36 24 110 5 32 110 5 32 110 5 32

150 1568 34 32 1586 43 42 1586 43 42 1606 53 51

200 2066 33 41 2084 42 53 2102 51 65 212 6 76

DN 80ndash200 PN 4ndash75 ΜΡа

PN (ΜΡа) 4 55 64 75

SN 2 500 ndash 15000 Ηmsup2

DN = D1(mm)

D 2 ( m m )

T s ( m m )

W ( k g m )

D 2 ( m m )

T s ( m m )

W ( k g m )

D 2 ( m m )

T s ( m m )

W ( k g m )

D 2 ( m m )

T s ( m m )

W ( k g m )

80 886 43 23 904 52 28 904 52 28 924 62 32

100 1116 58 38 1116 58 38 1152 76 51 1152 76 51

150 1624 62 61 1662 81 8 170 10 10 1738 119 12

200 2156 78 10 219 95 125 2226 113 149 228 14 187

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 2356 ndash 23 ndash

DN 80ndash200 PN 86ndash138 ΜΡа

PN (ΜΡа) 86 103 121 138

SN 15000 Ηmsup2 и более

DN = D1

(mm) D 2

( m m )

T s

( m m )

W ( k g m )

D 2

( m m )

T s

( m m )

W ( k g m )

D 2

( m m )

T s

( m m )

W ( k g m )

D 2

( m m )

T s

( m m )

W ( k g m )

80 924 71 39 96 8 44 978 89 5 998 99 55

100 1152 76 51 117 85 57 1186 93 64 1222 111 77

150 1738 119 12 1776 138 141 1832 166 173 187 185 195

200 2326 163 22 2404 202 278 2464 232 323 2542 271 384

DN 80ndash150 PN 172ndash276 ΜΡа

PN (ΜΡа) 172 207 234 276

SN 15000 Ηmsup2 и более

DN = D1(mm)

D 2 ( m m )

T s ( m m )

W ( k g m )

D 2 ( m m )

T s ( m m )

W ( k g m )

D 2 ( m m )

T s ( m m )

W ( k g m )

D 2 ( m m )

T s ( m m )

W ( k g m )

80 1052 126 78 1108 154 92 1146 173 105 1238 219 139

100 1274 137 97 1344 172 126 1378 189 141 1466 233 179

150 1984 242 263 2096 298 335 219 345 398 mdash mdash mdash

DN 250ndash400 PN 06ndash1 ΜΡа

PN (ΜΡа) 06 06 1 1

SN (Ηmsup2) 2 500 ndash 5 000 5 000 ndash 10 000 2 500 ndash 5 000 5 000 ndash 10 000

DN = D1(mm)

D

2 ( m m )

T

s ( m m )

W

( k g m )

D

2 ( m m )

T

s ( m m )

W

( k g m )

D

2 ( m m )

T

s ( m m )

W

( k g m )

D

2 ( m m )

T

s ( m m )

W

( k g m )

250 2568 34 53 2586 43 68 2568 34 53 2586 43 68

300 307 35 65 3088 44 83 307 35 65 3088 44 83

350 359 45 99 3618 59 13 359 45 99 3618 59 13

400 4106 53 132 4132 66 167 4106 53 132 4132 66

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 2456 ndash 24 ndash

DN 250ndash400 PN 16ndash4 ΜΡа

PN (ΜΡа) 16 25 32 4

SN (Ηmsup2) 2 500 ndash 10 000 2 500 ndash 15 000 2 500 ndash 15 000 2 500 ndash 15 000

DN = D1

(mm) D 2 ( m m )

T s ( m m )

W ( k g m )

D 2 ( m m )

T s ( m m )

W ( k g m )

D 2 ( m m )

T s ( m m )

W ( k g m )

D 2 ( m m )

T s ( m m )

W ( k g m )

250 2586 43 68 2604 52 83 2642 71 113 266 8 128

300 3108 54 102 3128 64 12 3166 83 158 3224 112 215

350 361 55 121 365 75 165 369 95 21 3748 124 278

400 413 65 162 4168 84 212 4228 114 289 4286 143 367

DN 250ndash400 PN 55ndash75 ΜΡа

PN (ΜΡа) 55 64 75

SN (Ηmsup2) 2 500 ndash 15 000 2 500 ndash 15 000 2 500 ndash 15 000

DN = D1D2

(mm)Ts

(mm)W

(kgm)D2

(mm)Ts

(mm)W

(kgm)D2

(mm)Ts

(mm)W

(kgm)

250 2736 118 191 2774 137 222 283 165 271

300 3314 157 305 3374 187 368 3434 2217 431

350 3836 168 38 3892 196 449 397 235 542

400 4404 202 525 4464 232 606 4562 281 743

DN 500ndash1000 PN 06 ΜΡа

PN 06 ΜΡа

SN (Ηmsup2) 2 500 5 000 10 000

DN=D1(mm)

D2(mm)

Ts(mm)

W(kgm)

D2(mm)

Ts(mm)

W(kgm)

D2(mm)

Ts(mm)

W(kgm)

500 5124 62 187 5146 73 223 5186 93 285600 6144 72 263 6172 86 315 622 11 409

700 7164 82 343 7202 101 426 7248 124 528

800 8192 96 464 8234 117 565 8282 141 688

900 9212 106 576 926 13 713 9322 161 884

1000 10226 113 682 10274 137 83 10352 176 1075

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 2556 ndash 25 ndash

DN 500ndash1000 PN 1 ΜΡа

PN 1 ΜΡа

SN (Ηmsup2) 2500 5000 10 000

DN=D1(mm)

D2(mm)

Ts(mm)

W(kgm)

D2(mm)

Ts(mm)

W(kgm)

D2(mm)

Ts(mm)

W(kgm)

500 5124 62 187 5146 73 223 5186 93 285600 6144 72 263 6172 86 315 622 11 409

700 7164 82 343 7202 101 426 7248 124 528

800 8192 96 464 8234 117 565 8282 141 688

900 9212 106 576 926 13 713 9322 161 884

1000 10226 113 682 10274 137 83 10352 176 1075

DN 500ndash1000 PN 16 ΜΡа

PN 16 ΜΡа

SN (Ηmsup2) 2 500 5 000 10 000

DN=D1(mm)

D2(mm)

Ts(mm)

W(kgm)

D2(mm)

Ts(mm)

W(kgm)

D2(mm)

Ts(mm)

W(kgm)

500 5146 73 223 5146 73 223 5186 93 285

600 6172 86 315 6172 86 315 622 11 409

700 7254 127 543 7202 101 426 7248 124 528

800 8234 117 565 8234 117 565 8282 141 688900 9264 132 723 926 13 713 9322 161 884

1000 10274 137 83 10284 142 862 10352 176 1075

DN 500ndash1000 PN 25ndash4 ΜΡа

PN (ΜΡа) 25 32 4

SN (Ηmsup2) 2 500 ndash 10 000 2 500 ndash 10 000 2 500 ndash 10 000

DN=D1

(mm)

D2

(mm)

Ts

(mm)

W

(kgm)

D2

(mm)

Ts

(mm)

W

(kgm)

D2

(mm)

Ts

(mm)

W

(kgm)

500 521 105 323 5282 141 449 534 17 544

600 6266 133 496 6318 159 606 6396 198 757

700 7316 158 678 741 205 899 747 235 1034

800 8354 177 872 8464 232 1159 8588 294 1479

900 9394 197 109 9502 251 1408 9624 312 1755

1000 10432 216 1332 10558 279 1745 10722 361 2269

Note The pipe parameters with intermediate and higher classification are produceaccording to technical requirements o customer

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 2656 ndash 26 ndash

Fiber glass pipes DN 100 mm PN6 MPa with spigot-nipple key-lock thread joint Application injection line Balginbayeva field Atyrau region RK

Fiber glass pipes DN 100 mm PN 25 MPa laquoKey-Lockraquo joint Application exhaust line Zhanatalap field Atyrau

region Republic o Kazakhstan (RK)

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 2756 ndash 27 ndash

52 BENDS MONOLITHIC

PN 06ndash64 ΜΡа

DN (mm) R (mm)1125deg 225deg 45deg 90deg

Ls (mm) Ls (mm) Ls (mm) Ls (mm)80 120 2405 2405 2355 3055

100 150 2405 2405 2462 3362

150 225 318 318 3138 4438

200 350 400 400 4052 5802

250 375 327 327 407 630

300 450 369 369 469 734

350 525 369 369 500 809

400 600 404 404 540 894

500 750 472 472 582 870

600 900 493 493 625 982

700 1050 522 522 672 1088

800 1200 542 542 714 1190

900 1350 567 567 761 1295

1000 1500 610 610 820 1405

Note Above specified the parameters o standard bends or spigot spigot laquoKey-Lockraquoand spigot nipple conical glue joints

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 2856 ndash 28 ndash

PN 64ndash272 ΜΡа

DN (mm)Thread

dimension(inches)

1125deg 225deg 45deg 90deg

Ls (mm) Ls (mm) Ls (mm) Ls (mm)

80 3 frac12 179 179 1683 2254

100 4 frac12 179 179 1683 2254

150 7 2047 200 1969 2921

200 8 ⅝ 2174 2125 2096 3459

Note Above specified the parameters o standard bends or spigot nipple laquoKey-Lockraquothread joint

Fragment o fiberglass bend 90deg DN

100 mm PN7 5 MPawith thread joint

Bend 90deg DN100mm PN25 MPa

with spigot laquoKey-Lockraquo joint

Bend 45degDN100 mm

PN16 MPawith spigot

joint

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 2956 ndash 29 ndash

53 TEES

РN 06ndash64 ΜΡаDN2

(mm)DN1(mm)

80 100 150 200 250 300 350 400 500

LH (mm)

80480240

mdash mdash mdash mdash mdash mdash mdash mdash

100500

250

500

250

mdash mdash mdash mdash mdash mdash mdash

150640320

640320

640320

mdash mdash mdash mdash mdash mdash

200830360

830360

830360

830415

mdash mdash mdash mdash mdash

250860390

860390

860390

860430

850430

mdash mdash mdash mdash

300980420

980420

980460

980460

980490

980490

mdash mdash mdash

350 1060460 1060460 1060460 1060500 1060500 1060530 1060530 mdash mdash

4001160560

1160560

1160560

1160580

1160580

1160580

1160580

1160580

mdash

5001420600

1420600

1420600

1420640

1420640

1420680

1420680

1420710

1420710

For spigot spigot and laquoKey-Lockraquo spigot and nipple conical glue joint

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 3056 ndash 30 ndash

РN 06ndash64 ΜΡа

DN2(mm)

DN1(mm)

80 100 150 200 250 300 350 400 500

LH (mm)

6001560

660

1560

660

1560

660

1560

720

1560

720

1560

760

1560

760

1560

780

1560

780

7001720720

1720720

1720720

1720780

1720780

1720820

1720820

1720840

1720840

8001860720

1860720

1860720

1860780

1860780

1860780

1860820

1860820

1860880

9002000780

2000780

2000780

2000820

2000820

2000880

2000880

2000920

2000920

10002160880

2160880

2160880

2160920

2160920

2160960

2160960

21601040

21601040

РN 06ndash64 ΜΡаDN2

(mm)DN1(mm)

600 700 800 900 1000

LH (mm)

600 1560780 mdash mdash mdash mdash

700 1720860 1720860 mdash mdash mdash

800 1860880 1860930 1860930 mdash mdash

900 2000960 2000960 20001000 20001000 mdash

1000 21601040 21601040 21601080 21601080 21601080

Note Above specified the parameters o standard tees or spigot spigot and laquoKey-Lockraquo and spigot and nipple conical glue joints

PN 64ndash272 ΜΡаDN2

(mm)DN1(mm)

80 100 150 200

LH (mm)

80 45082254 mdash mdash mdash

100 45082254 45082254 mdash mdash

150 58422254 58422254 58422921 mdash

200 69282254 69282254 69282921 69283464

Note Above specified the parameters o standard tees or spigot and nipple key-lock

thread joint

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 3156 ndash 31 ndash

Fragment o tee with equal diameter DN100 mmPN 75 MPa with thread joint

Fragment o tee withequal diameter DN 150mm PN 25 MPa with

spigot laquoKey-Lockraquo joint

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 3256 ndash 32 ndash

54 REDUCTION

РN 06ndash64 ΜΡа

DN1(mm)

DN2(mm)

L (mm) DN1(mm)

DN2(mm)

L (mm) DN1(mm)

DN2(mm)

L (mm)

100 80 725 300 200 1050 600 500 1050

150 80 775 300 250 925 700 500 1300

150 100 725 350 250 1050 700 600 1050

200 80 900 350 300 925 800 600 1300

200 100 850 400 300 1050 800 700 1050

200 150 725 400 350 925 900 700 1300

250 100 975 500 400 1050 900 800 1050

250 150 850 500 450 925 1000 800 1300

250 200 725 600 450 1175 1000 900 1050

Note Above specified the parameters o adapters or spigot spigot and laquoKey-Lockraquoandspigot nipple conical glue joints

PN 64ndash272 ΜΡа

DN1(mm)

Threaddimen-

sion(inches)

DN2(mm)

Threaddimen-

sion(inches)

L(mm)

DN1(mm)

Threaddimen-

sion(inches)

DN2(mm)

Threaddimen-

sion(inches)

L(mm)

100 4 frac12 80 3 frac12 322 200 8 ⅝ 80 3 frac12 354

150 7 80 3 frac12 354 200 8 ⅝ 100 4 frac12 354

150 7 100 4 frac12 354 200 8 ⅝ 150 7 382

Note Above specified the parameters o standard adapters or spigot nipple laquoKey-

Lockraquo thread joint

Concentric adapter Eccentric adapter

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 3356 ndash 33 ndash

55 COUPLINGS

РN 06ndash64 ΜΡа

DN(mm)

L(mm)

DN(mm)

L(mm)

80 280 250 400

100 280 300 400

150 400 350 400

200 400 400 400

Note Above specified the parameters ostandard coupling joints or spigot andnipple conical glue joint

PN 64ndash272 ΜΡа

DN(mm)

Thread dimen-sion (inches)

L (mm)

80 3 frac12 248

100 4 frac12 248

150 7 2795

200 8 ⅝ 305

Note Above specified the parameters ostandard coupling joints or spigot andnipple laquoKey-Lockraquo thread joint

Installation ragmento fiber glass pipeswith coupling and

threading joint

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 3456 ndash 34 ndash

56 NIPPLES

PN 64ndash272 ΜΡа

DN (mm)Thread dimension

(inches)L (mm)

80 3 frac12 2032 и более

100 4 frac12 2032 и более

150 7 3048 и более

200 8 ⅝ 3556 и более

Note The parameters o standard joint nipples or spigot-nipple and laquoKey-Lockraquothreading joint are specified above

Threading nippleapplication Fragment atthe pipe jointing DN100

mm and bend 45deg

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 3556 ndash 35 ndash

57 FLANGES

The conjunctive sizes o fiber glass flanges are carrying out by StateStandard 12815ndash80 or Standard ANSI where

DN mdash nominal diameter

D1 mdash diameter o a bolt circleD mdash outside diameter o a flanged mdash bolt holes diametern mdash bolt numberst mdash flange thickness

Monolithic PN 16ndash64 MPa Adapters PN 64 and more

Fragment o the flangeadapter DN100 mm withthreading inside 4frac12rsquorsquo

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 3656 ndash 36 ndash

VI TANKS

V 1ndash50 мsup3

DN (mm) V (msup3) L (mm) H (mm) W (kg) Ts (mm) Tt (mm)

1000

1 1270 1270 167 158 158

12 1530 1530 190 158 158

15 1920 1920 225 158 158

2 2550 2550 283 158 158

25 3190 3190 341 158 158

3 3830 3830 399 158 158

35 4470 4470 456 158 158

4 5100 5100 513 158 158

5 6380 6380 629 158 158

10 12760 12760 1207 158 158

1400

2 1300 1300 365 216 216

25 1630 1630 422 216 216

3 2000 2000 487 216 21635 2280 2280 536 216 216

4 2600 2600 592 216 216

45 2930 2930 649 216 216

5 3250 3250 705 216 216

10 6500 6500 1274 216 216

15 9750 9750 1839 216 216

20 13000 13000 2406 216 216

With ront plug With elliptical plug

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 3756 ndash 37 ndash

DN (mm) V (msup3) L (mm) H (mm) W (kg) Ts (mm) Tt (mm)

1600

4 2000 2000 701 268 268

5 2490 2490 823 268 268

6 3000 3000 949 268 268

7 3500 3500 1074 268 268

8 4000 4000 1198 268 268

9 4490 4490 1320 268 268

10 4980 4980 1441 268 268

15 7470 7470 2060 268 268

20 9960 9960 2679 268 268

25 12450 12450 3298 268 268

1800

5 2500 1600 754 279 279

6 2900 2000 871 279 2797 3300 2400 988 279 279

8 3700 2800 1104 279 279

9 4100 3200 1220 279 279

10 4480 3580 1331 279 279

15 6450 5550 1905 279 279

20 8400 7500 2473 279 279

25 10360 9460 3044 279 279

30 12350 11450 3623 279 279

2000

8 2550 2550 1291 304 304

9 2870 2870 1404 304 304

10 3200 3200 1502 304 304

12 3830 3830 1742 304 304

15 4800 4800 2084 304 304

18 5740 5740 2417 304 304

20 6400 6400 2648 304 304

25 7980 7980 3205 304 304

30 9570 9570 3765 304 304

35 11150 11150 4322 304 304

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 3856 ndash 38 ndash

DN (mm) V (msup3) L (mm) H (mm) W (kg) Ts (mm) Tt (mm)

2400

10 2220 2220 1799 363 363

12 2660 2660 2022 363 363

15 3320 3320 2356 363 363

20 4430 4430 2919 363 363

25 5530 5530 3476 363 363

30 6650 6650 4044 363 363

35 7750 7750 4601 363 363

40 8850 8850 5158 363 363

45 9960 9960 5722 363 363

50 11060 11060 6278 363 363

2600

10 2670 1370 1668 392 392

12 3050 1750 1894 392 39215 3600 2300 2220 392 392

20 4550 3250 4104 392 392

25 5500 4200 3350 392 392

2600

30 6430 5130 3902 392 392

35 7380 6080 4467 392 392

40 8320 7020 5025 392 392

45 9260 7960 5584 392 392

50 10200 8900 6142 392 392

Note 1 Above specified are parameters o standard tanks V 1ndash50 msup3 producedby JSC laquoAZNTraquo The Tanks rom 50 up to 75m3 are produce according to technicalrequirements o customer

Note 2 Weight (W) wall thickness (Ts) and plug thickness (Tt) are releases taking intoaccount the specificity o order

Note 3 DN mdash there is producing with ront plug at the present stage DN mdash withtwo types o plugs

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 3956 ndash 39 ndash

Fiber glass tank DN 1800 V mdash 15 мsup3 Application storage and transportation o inhibited solution

o hydrochloric acid with 27ndash30 o concentration

Fiber glass tank DN2600 V mdash 75 msup3 Application storage o drink water

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 4056 ndash 40 ndash

VII INSPECTION SHAFTS

Tangential shaf Standard shaf

DN (mm) Н (mm)

300ndash2600 по заказу

Fragment o standard inspection shaf DN 2000 Hndash8000 mm

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 4156 ndash 41 ndash

VIII NONSTANDARD PRODUCTS

The JSC laquoAZNTraquo offers the nonstandard shaped products o variousconfiguration or non-pressure and pressure systems The givenproducts are designing by engineers o JSC laquoAZNTraquo where selects

suitable product parameters according to technical requirementso customer In case o large-dimensioned nonstandard productsexceeding permissible carrying capacity the products can be delivered by parts and assembled directly at site o installation

Fragment o fiber glass channels and lids or pulp ash removal systemEkibastuz State District Power Station 1 Republic o Kazakhstan

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 4256 ndash 42 ndash

Fragment o reduction DN2600times2000 with branchangle 45deg DN 2000times800and 90deg DN 2600times1200

Reconstruction o

Borsuchkovsk hydraulicworks o NevinnomysskState District Power

Station Pyatigorsk cityRussian Federation

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 4356 ndash 43 ndash

Appendix 1

The list of allowed and non-recommended liquid andgaseous substances transported by GRP pipelines

produced at the JSC laquoAZNTraquo on basis of polyester resin

Description of solution substances

Standardresins

or resinson basisof vinyl

ester

Resinson basisof vinyl

esteronly

Non-recom-mended

Acetate lead aqueous +

Acetic acid up to 20 +

Adipinic acid +Alkiline process lye (cellulose) +

Ammonia water solution up to 20 +

Ammonium fluoride +

Barium carbonate +

Barium chloride +

Barium sulate +

Beet sugar alkaline +

Benzenesulonic acid up to 10 +

Benzoic acid +

Bisulpite calcium +

Bluestone aqueous up to 40degС +

Borax +

Borax +

Boric acid +

Bromine 5 aqueous +

Butyric acid up to 25 up to 40degС +

Calcium chloride aqueous +Calcium hydroxide 100 +

Calcium hypochlorite +

Calcium nitrate up to 40degС +

Cane-sugar alkaline +

Carbon dioxide aqueous +

Carbon tetrachloride +

Casein +

Chemical chalk +

Chloric acid +

Chloride acid calcium aqueous up to 40degС +

Chloride aluminium aqueous +

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 4456 ndash 44 ndash

Chloride chlorides +

Chloride lithium aqueous up to 40degС +

Chloride magnesium aqueous up to 25degС +

Chlorine aqueous +

Chlorine dry gas +

Chlorine wet gas +Chloroacetic acid +

Chlorous ammonium aqueous up to 40degС +

Chlorous zink aqueous +

Citric acid aqueous up to 40degС +

Copper Acetous +

Copper Chloride aqueous +

Copper cyanide up to 30degС +

Copper nitrate aqueous up to 40degС +

Corrosive sublimate aqueous +

Crude oil (desulurize) +

Crude oil (sulphury) +

Crude oil salt water up to 25degС +

Cyclohexane +

Cyclohexanol +

Decolorant +

Dibutyl phthalate +

Dibutyl sebacate +Dichloride tin aqueous +

Dichromic acid potassium aqueous +

Dichromic acid sodium +

Diesel oil +

Dioctyl phthalate +

Distilled water +

Ethylene glycol +

Ethyl petrol +

Ferrous sulate (2) aqueous +

Ferrous sulate (3) aqueous +

Formaldehyde +

Glycerin +

Green Alkaline paper +

Gypsum NL AOC +

Hexane +

Hydrobromic acid +

Hydrochloric acid up to 15 +Hydrochloric aniline +

Hydrofluoric acid +

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 4556 ndash 45 ndash

Hydrogen sulfide dry +

Iron Chloride (2) aqueous +

Iron Chloride (3) aqueous +

Iron nitrate (2) aqueous +

Iron nitrate (3) aqueous +

Kerosene +Lactic acid up to 10 +

Lactic acid up to 80 up to 25degС +

Lauric acid +

Lauryl sulate +

Ligroin +

Linseed oil +

Lower bormide Lithium aqueous up to 40degС +

Lower bromide potassium aqueous up to 40degС +

Magnesium bicarbonate aqueous up to 40degС +

Magnesium carbonate up to 40degС +

Magnesium nitrate aqueous up to 40degС +

Magnesium sulphate +

Manganese chloride aqueous up to 40degС +

Marganic acid potassium up to 25 +

Mazut +

Mineral oils +

N-heptan +Naphthalene +

Natural gas methane +

Nickel chloride aqueous up to 25degС +

Nitrate ammonium aqueous up to 40degС +

Nitrate lead aqueous up to 30degС +

Nitrate nickel aqueous up to 40degС +

Nitrate zinc aqueous +

Nitric acid +

Oil refined +

Oleic acid +

Oxalic acid aqueous +

Ozone gas +

Paraffin +

Pentane +

Phosphate ammonium monobasic aqueous +

Phosphoric acid +

Phosphoric acid up to 40degС +Phthalic acid up to 25degС +

Potassium alum +

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 4656 ndash 46 ndash

Potassium bicarbonate +

Potassium chloride aqueous +

Potassium errocyanide aqueous up to 30degС +

Potassium hydroxide +

Potassium nitrate aqueous +

Potassium sulphate up to 40degС +Propylene glycol up to 25degС +

Sea-water +

Sea-water +

Silicone oil +

Silver nitrate aqueous +

Sodium chloride aqueous +

Sodium erricyanic +

Sodium hydroxide up to 10 +

Sodium lower bromide aqueous +

Sodium nitrate aqueous +

Sodium nitrite aqueous +

Sodium Phosphate monosubstituted +

Sodium silencer +

Sodium sulphate aqueous +

Stearic acid +

Sulur +

Suluric lead aqueous +Sulphate ammonium aqueous +

Sulphate nickel aqueous up to 40degС +

Sulphate zink aqueous +

Sulphite zinc aqueous up to 40degС +

Sulphuric acid up to 25 up to 40degС +

Sulphury sodium +

Tannic acid aqueous +

Tartaric acid +

Tetrachloride tin aqueous +

Toluene sulonic acid +

Tributyl phosphate +

Trichloro Stibium +

Triethanolamine +

Triethylamine +

Turpentine +

Urea aqueous +

Vinegar +Wastewater +

Water-pipe drink +

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 4756 ndash 47 ndash

Appendix 2

The list of allowed and non-recommended liquidand gaseous substances transported by GRE pipelinesproduced at the JSC laquoAZNTraquo on basis of epoxy resin

DescriptionAllowed at

temperature 0degСup to

Non-recommended

Acetate sodium 60

Acetone up to 5 60

Acrylic acid 10 25

Adipinic acid solution 100

Air 100

Airplane uel 100Allyl chloride 25

Aluin 100

Aluminium chloride 100

Aluminium fluoride up to 25 60

Aluminum sodium sulphate 60

Ammonia gas (dry) 60

Ammonia gas (wet) 25

Ammonium carbonate 100

Ammonium chloride 100Ammonium fluoride up to 25 60

Ammonium hydroxide 30 25

Ammonium hydroxide up to 20 25

Ammonium nitrate 100

Ammonium phosphate 100

Ammonium sulphate 100

Ammonium thiocyanate 100

Amyl acetate 25

Amyl alcohol 60Amyl chloride 25

Anhydride vinegar acid 25

Aniline 25

Antimony trichloride 60

Barium acetate 100

Barium carbonate 100

Barium chloride 100

Barium hydroxide up to 10 60

Barium sulphate 100

Barium sulphide 100

Beer 25

Beet sugar 100

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 4856 ndash 48 ndash

Benzenesulonic acid 25

Benzine high-sulur 100

Benzine octane level 108 60

Benzoic acid 60

Benzol 5 o solution in kerosene 60

Benzol 25

Benzyl chloride 25Bicarbonate potassium 100

Biphosphate sodium 60

Borax (kernite) 100

Borax (tinkal) 100

Boric acid 60

Bromide potassium 100

Bromide sodium 100

Bromine 4 o solution 25

Butadiene 60Butane 60

Butyl acetate 25

Butyl alcohol 60

Butyric acid 60

Calcium carbonate 60

Calcium chlorates 60

Calcium chloride 60

Calcium nitrate 100

Calcium sulphate 100

Cane-sugar 100

Carbonate magnesium 100

Carbonate potassium 60

Carbon dioxide 100

Carbonic acid 60

Carbon monoxide 100

Casein 60

Castor oil 60

Chloracetic acid 25 25

Chlorbenzene 25

Chloride magnesium 100

Chloride potassium 100

Chlorine aqueous solution timesChlorine dry gas timesChlorine wet gas timesChlorine acid 60

Chlorous manganese aqueous 60

Citric acid 100

Cresol 10 25Crude oil нефть сырая mixture salt water 100

Cupric acetate 60

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 4956 ndash 49 ndash

Cupric chloride 100

Cupric cyanide 60

Cupric fluoride 100

Cupric nitrate 100

Cupric sulphate 100

Cyclohexane 100

Cyclohexanol 60Decahydronaphthalene 60

Diallyphtalate 60

Dibutylphtalat 60

Dibutyl sebacate 60

Dichloride mercury aqueous timesDichlorobenzene 25

Dichromate potassium 100

Diesel oil 100

Dioctylphatalate 60Ethyl acetate 60

Ethyl alcohol 60

Ethylene glycol 60

Fatty acids 60

Ferricyanide potassium 100

Ferrocyanide sodium 40 100

Ferrocyanides potassium 100

Fluoride potassium 30 60

Formaldehyde 25 60

Formic acid 25 25

Gas natural 100

Glucose 100

Glycerin 100

Glycol 60

Heptane 60

Hexane 60

Hexylen glycol 60

High-sulur crude oil 100

Hydraulic fluid 60

Hydrobromic acid timesHydrochloric acid 1 60

Hydrochloric aniline 25

Hydrofluoric acid timesHydrogen 60

Hydrogen sulfide dry 60

Hydrogen sulfide wet 60

Hydrosulfide sodium 60

Hydrosulphate sodium 25Hydrosulphite calcium 25

Hydroxide aluminium 60

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 5056 ndash 50 ndash

Hydroxide calcium 50 60

Hydroxide magnesium 60

Hydroxide potassium 25

Hydroxide sodium 50 60

Hypochlorite calcium 60

Iodine solution 60

Iron (II) chloride 100Iron (II) nitrate 100

Iron (II) sulphtae 100

Iron (III) chloride 100

Iron (III) nitrate 100

Iron (III) sulphtae 100

Isobutyl alcohol 60

Isopropyl alcohol 60

Kerosene 100

Lactic acid 60Lauric acid 100

Laurilchloride 60

Laurilsulphate 100

Lead acetate 100

Lead tetraethyl 25

Levulinic acid 25 100

Linseed oil 100

Lithiumbromide aqueous 100

Lithiumchloride 100

Lithium hydroxide 25

Low-sulur crude oil 100

Magnesium bicarbonate aqueous 100

Maleinic acid 60

Maleinic acid anhydride 60

Manganese sulphate aqueous 100

Mazut 100

Mercury 100

Mercury chloride aqueous timesMethane 40

Methyl ethyl ketone 25

Methyl isobutyl alcohol 60

Methyl isobutyl carbinol 60

Methyl isobutyl ketone 40

Mineral oil 100

Naphtha 100

Naphtha 100

Naphthaline 60

Natural vinegar 100Nickel chloride 100

Nickel nitrate 100

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 5156 ndash 51 ndash

Nickel sulphate 100

Nitrate acetate 100

Nitrate aluminium 100

Nitrate magnesium 100

Nitrate potassium 100

Nitrate sodium 100

Nitric acid 25Oleic acid 60

Olive oil 100

Ozone gas timesParaffin 100

Pentane gas 60

Peroxide sodium 25

Petroleum ather 25

Phenol 1 25

Phosphate potassium 100Phosphate sodium monosubstituted 60

Phosphate sodium 60

Phosphoric acid 25 25

Phthalic acid 60

Picric acid 25

Potassium alum 100

Potassium permanganat 10 60

Propane 60

Propylene glycol 100

Refined oil 100

Rizinus oil 100

Sdium Hydrosulphite 60

Silicate sodium 25

Silicic acid 60

Silicone oil 100

Silver chloride 100

Silver cyanide 100

Silver nitrate 100

Soap (cleanser) 100

Sodium benzoate 60

Sodium bicarbonate 20 100

Sodium carbonate 60

Sodium chlorates 50 60

Sodium chloride 100

Sodium cyanide 100

Sodium dichromate 100

Sodium fluoride 100

Sodium methylate 60Stearic acid 100

Strontium carbonate 100

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 5256 ndash 52 ndash

Strontium chloride 100

Styrene 25

Sulur 100

Sulphate aluminium 100

Sulphate magnesium 100

Sulphate potassium 100

Sulphate sodium 100Sulphate zinc 100

Sulphite sodium 60

Sulphochloride benzol 25

Sulphuric acid 1 60

Tannic acid 60

Tannin acid 100

Tartaric acid 100

Tetrachloroethane 100

Thiocyanate sodium 60Thiosulate sodium 60

Tin (II) chloride 100

Tin (IV) chloride 100

Toluene 40

Toluene sulonic acid 60

Tributyl phosphate 60

Trichloroethylene 25

Triethanolamine 50 60

Triethylamine 10 25

Trinatriphosphate 25 60

Turpentine 25

Turpentine 60

Urea 60

Urea ammonium nitrate 60

Vinegar acid 10 60

Vinyl acetate 60

Water chlorinate 100

Water deionized 100

Water distilled 100

Water drink 100

Water sea 100

Water sweet 100

Whitener 25

Xylene 60

Zinc acetate 100

Zinc chloride 100

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 5356 ndash 53 ndash

Appendix 3

Basic standards used at JSC laquoAZNTraquo for productionof fiber glass pipelines on basis of polyester vinyl

ester epoxy and other thermosetting resins

STANDARDSOF THE REPUBLIC OF KAZAKHSTAN

Number Description of Standards

1 СТ РК 1128-2002Plastic pipes reinorced with glass fiber on basis o

polyester resin General technical conditions

2 СТ РК 1129-2002

Plastic pipes reinorced with glass fiber on basis

o polyester resin Joint details General technicalconditions

3СТ РК 1255-1-2004

(ISO 14692-12002 MOD)Oil and Gas industry Fiberglass pipeline system

(GRP) Part 1 Dictionary symbols used materials

4СТ РК 1255-2-2004

(ISO 14692-22002 MOD)

Oil and Gas industry Fiberglass pipelinesystem (GRP) Part 2 Qualification estimate and

manuacturing

5СТ РК 1255-3-2004

(ISO 14692-32002 MOD)Oil and Gas industry Fiberglass pipeline system

(GRP) Part 3 System engineering

6СТ РК 1255-4-2004

(ISO 14692-42002 MOD)

Oil and Gas industry Fiberglass pipeline system(GRP) Part 4 Assembling installation and

exploitation

TECHNICAL REQUIREMENTSOF RUSSIAN FEDERATION

Number Description of Standards

7ТУ 2296-003-

99675234-2007

Pipes and sleeves shaped and joint details maderom composite material by laquoNTTraquo technology

or transportation o drink water

8ТУ 2296-004-

99675234-2007Sewerage pipes shaped details and fittings maderom composite materials by laquoNTTraquo technology

9Technical

recommendations

Assembling o underground pipelines water supplyand drainage systems made rom glass fiber pipes

by continuous winding method

10 ГОСТ Р 53201-2008 Glass fiber pipes and fittings Technical conditions

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 5456 ndash 54 ndash

FOREIGN STANDARDSHARMONIZED AT JSC 983211AZNT983227

Number Description of Standards

11 AWWA C 950ndash07 Fiberglass pipes with pressure

12 AWWA Manual M 45 Fiberglass pipe design manual

13 BS EN 14364

Plastic piping system or drainage and sewerage withor without pressure Glass reinorced thermosetting

plastics (GRP) based on unsaturated polyester resin (UP)Specifications or pipes fittings and joints

14 BS EN 1796Plastics piping systems or water supply with or withoutpressure Glass-reinorced thermosetting plastics (GRP)

based on unsaturated polyester resin (UP)

15 DIN 16868ndash11994Wound and filled glass fibre reinorced polyester resin

pipes

16 DIN 16945Reactive resins hardening agents and molding mass

based on reactive resin Test methods

17 ASTM 2996ndash01Standard specification or Filament-Wound laquoFiberglassraquo

(Glass-Fiber-Reinorced Thermosetting-Resin) Pipe

18 ASTM D 3418Standard Test Method or Transition Temperatures o

Polymers by Differential Scanning Calorimetry

19 ASTM D 2471ndash99Standard Test Method or Gel Time and Peak Exothermic

Temperature o Reacting Thermosetting Resins

20 ASTM D 2563ndash94Standard practice or classiying visual deects in glass-

reinorced plastic laminate parts ASTM standardD 2563ndash94 (Re-approved 2002)

21 ASTM D 2583ndash06Standard Test Method or Indentation Hardness o Rigid

Plastics by Means o a Barcol Impressor

22 ASTM D 2584ndash02Standard test method or ignition loss o cured

reinorced polymer

23 ASTM D 638ndash03 Standard Test Method or Tensile Properties o Plastics

24 ASTM D 792 Standard Test Methods or Density and Specific Gravity(Relative Density) o Plastics by Displacement

25 D 2563ndash94Standard rules or Classiying Visual Deects rom

Glass-Reinorced Plastic Laminate Parts

26 D 2584ndash02Standard test method or ignition loss o cured

reinorced resins

27 D 2471ndash99Standard Test Method or Gel Time and Peak Exothermic

Temperature o Reacting Thermosetting Resins

28 D 3418ndash03

Standard Test Method or Phase Transition

Temperatures o Polymers by Differential ScanningCalorimetry

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 5556 ndash 55 ndash

Number Description of Standards

29 D 2583ndash06Standard Test Method or Indentation Hardness o Rigid

Plastics by Means o a Barcol Impressor

30 D 638ndash03The Standard Test Method or Mechanical Properties o

Plastics in tension

31 D 792ndash00Standard Test Methods or Density and Specific Gravity

(Relative Density) o Plastics by Displacement

32 EN ISO 2114Plastics (polyester resins) and paints and varnishes(binders) mdash Determination o partial acid value and

total acid value

33 EN ISO 1782003 Plastics Determination o flexural properties

34 ISO 1887Textile glass mdash Determination o combustible-matter

content

35 EN ISO 178Plastics mdash Determination o flexural properties (ISO

1782001) Changed 178199636 ISO 1782001 Plastics mdash Determination o flexural properties

37 ISO 178Plastics mdash Determination o flexural properties

Correction 1 Exact improvement

38 ISO 3344ndash1997Reinorcement products mdash Determination o moisture

content

39 ISO 3374ndash2000Reinorcement products mdash Mats made rom abrics mdash

Determination o mass per unit area

40 ИСО 3344 Reinorcement products mdash Determination o moisturecontent

41 ИСО 3374Reinorcement products mdash Mats and abrics mdash

Determination o mass per unit area

42 ИСО 188ndash1Rubber vulcanized or thermoplastic Accelerated ageing

and heat resistance tests Technical correction 1

43 ИСО 188Rubber vulcanized or thermoplastic Accelerated ageing

and heat resistance tests

44 ИСО 2114

Plastics (polyester resins) and paints and varnishes

(binders) mdash Determination o partial acid value andtotal acid value

45 ИСО 48Rubber vulcanized or thermoplastic mdash Determination

o hardness (hardness between 10 IRHD and 100 IRHD)

46 ИСО 815Rubber vulcanized or thermoplastic mdash Determination

o compression set at ambient elevated or lowtemperatures

47 ИСО 178ndash1 Plastics Determination o flexural properties

48 ИСО 2535Plastics mdash Unsaturated-polyester resins mdash

Measurement o gel time at ambient temperature

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 5656

Notes

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 256 ndash 2 ndash

CONTENT

I About company 3

II Introduction 4

III Terms and adjectives 5

IV Production line CFW 300ndash2600 or manuacturingo GRP pipes by continuous winding method 6

41 Technical parameters o GRP pipes 842 Sleeve couplings 1143 Bends segmented 1344 Bends monolithic 14

45 Тees 1546 Reductions 1847 Flanges 19

V Production line DFW 80ndash1000 or manuacturingo GRE pipes by discontinuous method 20

51 Technical parameters o GRE pipes 2252 Bends monolithic 27

53 Tees 2954 Reduction 3255 Couplings 3356 Nipples 3457 Flanges 35

VI Tanks 36

VII Inspection shafs 40

VIII Nonstandard products 41

Appendix 1 43Appendix 2 47Appendix 3 53

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 356 ndash 3 ndash

I ABOUT COMPANY

The JSC laquoAZNTraquo was established on 2 June 2004 The first stage

was placed in operation on 30 December 2005 and second stage inAugust 2009 and produce glass fiber pipes on basis o polyester epoxyresins and quartz sand reinorced with glass fiber tanks with capacityup to 75m3 or storage and transportation o hostile environment

The JSC laquoAZNTraquo or the first time mastered in production oglass fiber pipes with diameter 2600 mm on pressure 06 MPa andstiffness 7500 Hm2 or underground sanitation o circulating pipes inNevinnomyssk State District Power Station (Pyatigorsk city Russian

Federation)The glass fiber pipes produced at JSC laquoAZNTraquo are competitive

and supplied not only to inner market o Kazakhstan and also toCIS countries (Uzbekistan to different regions o Russia rom StPetersburg to Krasnoyarsk)

Plant production capacity is 320 km o glass fiber pipes perannum (in standard unit)

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 456 ndash 4 ndash

II INTRODUCTION

The essential efforts and capital investments related with constructionreconstruction and repair o engineering communications ortransportation o various fluid mediums are demands the new

technologies allowing to low material costs to reduce terms o workto increase reliability and communication longevity

The world practice testifies to more and wider application inparticular or systems o water supply the sewerage and oil and gas branch o the fiberglass pipes made o polymeric composite materials

The glass fiber pipe made o composite materials on basis othermosetting resins quartz sand reinorced with glass fiber

The application o pipes made o reinorced glass fiber has

advantages as ollowsHigh mechanical durability provided by presence o glass fiber

materialsCorrosion resistance o external and inner suraces o the pipe

that allows reusing need rom lying o protecting coats coloring andcathode protection Durable and effective exploitation (up to 50 years)The pipes made o reinorced fiber glass are suitable or transportationpractically o all chemical agents even at highest temperatures in

comparison with other plasticsSmoothness surace o inner wall which brings to

minimum loss o velocity pressure The low losses on riction reducetransportation and exploitation costs At total absence o deposits thecosts o cleaning is donrsquot demand

Long-term o pipe exploitationAbsolutely inner and external hermiticity o pipes and jointsLow weight o a pipe 14 o steel pipe weight and 110 o

concrete that allows using stackers small load-lifing and acilitatestheir transportation

Possibility o manuacturing o pipe pieces o bigger length in comparison with pipes rom other materials

The Convenience o installation both underground and overground pipe laying rom reinorced fiber glass differs by its simpleinstallation and can be carry out in short period

Simple processing material allows carrying out works on site

o exploitation o pipe using simple tools

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 556 ndash 5 ndash

III TERMS AND ADJECTIVES

Nominal diameter (DN) mdash conventional inner pipe diameter(mm) [appendix 3 item 1]

Nominal pressure (PN) mdash parameter determining the work

pressure in the pipe at the exploitation (MPa) [appendix 3 item 1]Nominal stiffness (SN) mdash parameter o a pipe causing installation

and laying o pipeline in various conditions or example spaces betweensupports at over ground laying or depth and pipeline burial conditions atunderground laying (Hm2) [appendix 3 item 1]

Specified work temperature (T) mdash maximum constanttemperature at which system unctioning is expected (degС) [appendix3 item 14]

GRР pipes mdash reinorced glass fiber composite on basis opolyester resin [appendix 3 item 3]

GRЕ pipes mdash reinorced glass fiber composite on basis o epoxyresin [appendix 3 item 3]

Fitting mdash hermetic constituent element designed ortransportation o liquid and having a geometric shape differs romstraight pipe [appendix 3 item 3]

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 656 ndash 6 ndash

IV PRODUCTION LINE CFW 3009912512600FOR MANUFACTURING OF GRP PIPESBY CONTINUOUS WINDING METHOD

Technical parameters of pipes

Pipe diameters (DN) rom 300 up to 2600 mm inclusive Standard pipe length 3 6 9 12 m Pressure (PN) up to 4 MPa

Stiffness (SN) 2500 5000 10 000 Нmsup2 and more Used temperature 60degС

Hydrotest machineIn accordance with acting standards the product pass control test onpressure class (double rom work pressure) and on stiffness at theplantrsquos accredited laboratory

Hydrotest Machine or PipeDN 300ndash2600

Hydrotest machine or couplingDN 300ndash2600

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 756 ndash 7 ndash

Kind of joints used for GRP pipe

Sleeve coupling joint with Reka rubbergaskets and centre stopper designed orpipelines DN300ndash2600 mm working on

pressure up to 4 MPa

Flange joint or pipelines DN300ndash2600 mmworking on pressure up to 4 MPa

Band joint or pipelines DN300ndash2600 mmworking on pressure up to 32 MPa

Field of application of GRP pipes Industry and drink water supply Industry and communal sewerage

Hydraulic works or cooling system Outalls o wastewater to sea Underwater pipelines

Production line o industry equipments Fire saety system Transportation system and distribution o petrol Flue pipe or corrosion liquids and ventilation pipes Receiver bushing or downed pumps

Pressure pipelines Neutralization o combustion gas Irrigative systems

Flue pipe or combustion gas

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 856 ndash 8 ndash

41 TECHNICAL PARAMETERS OF GRP PIPES

PN 06 ΜΡа

PN 06 ΜΡа

SN (Нmsup2) 2 500 5 000 10 000

D N ( m m )

D 1 ( m m )

T o l e -

r a n c e

D 2 ( m m )

T s ( m m )

W ( k g m )

D 2 ( m m )

T s ( m m )

W ( k g m )

D 2 ( m m )

T s ( m m )

W ( k g m )

300 3146 plusmn26 3056 45 73 3036 55 92 3009 68 115

350 3666 plusmn26 3566 5 97 3532 67 132 3511 78 154

400 4131 plusmn27 4019 56 123 3986 72 162 3962 84 19

450 4641 plusmn27 4518 62 153 4485 78 196 4453 94 239

500 5151 plusmn28 5018 67 185 4981 85 238 4942 105 297

600 6171 plusmn29 6017 77 258 5972 10 338 5924 123 422

700 7191 plusmn3 7009 91 358 6962 114 455 6909 141 565

800 8211 plusmn31 801 101 455 7953 129 59 7892 16 734

900 9231 plusmn32 9008 111 569 894 145 75 8872 18 932

1000 10251 plusmn33 10002 124 708 9936 158 905 9859 196 1131

1200 12291 plusmn35 1200 145 999 11916 187 1295 11826 232 1614

1400 14331 plusmn37 13993 169 1361 13899 216 1745 13803 264 2142

1600 16371 plusmn39 15989 191 176 15835 268 2485 15761 305 2835

1800 18411 plusmn41 17983 214 2224 17853 279 2913 17723 344 3601

2000 20451 plusmn43 19981 235 272 19844 304 3525 19698 377 4385

2200 22491 plusmn45 21974 258 3292 21832 33 4214 21663 414 5308

2400 24531 plusmn47 23971 28 3898 23806 363 5067 23618 457 63942600 26571 plusmn49 25963 304 4585 25786 392 5942 25593 489 7423

Tolerance [Appendix 3 item 1]

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 956 ndash 9 ndash

PN 1 ΜΡа

PN 1 ΜΡа

SN (Ηmsup2) 2 500 5 000 10 000

D N

( m m )

D 1

( m m )

T

o l e -

r a

n c e

D 2

( m m )

T s

( m m )

W ( k g m )

D 2

( m m )

T s

( m m )

W ( k g m )

D 2

( m m )

T s

( m m )

W ( k g m )

300 3146 plusmn26 306 43 7 3042 52 86 3017 65 109

350 3666 plusmn26 3571 47 9 3548 59 114 3515 75 15

400 4131 plusmn27 4027 52 113 400 66 145 3966 82 185

450 4641 plusmn27 4523 59 145 4491 75 188 4453 94 239

500 5151 plusmn28 5023 64 176 4992 79 221 4949 101 286

600 6171 plusmn29 6025 73 243 598 96 323 5934 119 405

700 7191 plusmn3 7021 85 332 6978 107 422 6918 136 545

800 8211 plusmn31 8023 94 422 7973 119 54 7901 155 711

900 9231 plusmn32 9021 105 534 8966 133 68 8886 173 893

1000 10251 plusmn33 10021 115 65 9958 146 836 9866 193 1111

1200 12291 plusmn35 1202 135 924 11826 232 1614 11838 227 1572

1400 14331 plusmn37 14015 158 1261 13928 201 1621 13805 263 2313

1600 16371 plusmn39 16017 177 1618 15911 23 2123 15773 299 2779

1800 18411 plusmn41 18016 198 2041 17899 256 2663 17742 334 34992000 20451 plusmn43 20014 219 2513 19886 282 3267 19707 372 4332

2200 22491 plusmn45 22014 239 3019 21871 31 3948 21674 409 5235

2400 24531 plusmn47 24008 261 3615 23854 338 4709 23646 442 6188

2600 26571 plusmn49 26007 282 4231 25844 363 548 25591 49 7435

DN 400 mm PN1 MPaSN10000 Nmsup2

Application Transportationo drink water Makhachkalacity Russian Federation

Glass fiber Pipes GRP DN 2600 mmPN 06 MPa SN 7500 Nmsup2

Flow speed 4 ms volume 17 msup3s Application Circulating water pipes orNevinnomyssk State District Power Station

Pyatigorsk city Russian Federation

Glass fiber Pipes GRP

7172019 Technical Catalogue

httpslidepdfcomreaderfulltechnical-catalogue-569150d21f94e 1056 ndash 10 ndash

PN 16 ΜΡа

PN 16 ΜΡа

SN (Ηmsup2) 2 500 5 000 10 000

D N

( m m )

D 1

( m m )

T

o l e -

r a

n c e

D 2

( m m )

T s

( m m )

W ( k g m )

D 2

( m m )

T s

( m m )

W ( k g m )

D 2

( m m )

T s

( m m )

W ( k g m )

300 3146 plusmn26 3032 57 96 3032 57 96 3015 66 111

350 3666 plusmn26 3543 62 121 3543 62 121 3516 75 15

400 4131 plusmn27 3993 69 155 3993 69 155 3967 82 185

450 4641 plusmn27 4491 75 189 4491 75 189 4458 92 234

500 5151 plusmn28 4988 81 228 4988 81 228 4951 10 284

600 6171 plusmn29 5981 95 321 5981 95 321 5939 116 397

700 7191 plusmn3 6974 108 43 6974 108 43 6927 132 528

800 8211 plusmn31 7966 122 557 7966 122 557 7911 15 688

900 9231 plusmn32 8963 134 686 8963 134 686 8899 166 858

1000 10251 plusmn33 9955 148 845 9955 148 845 9887 182 1046

1200 12291 plusmn35 11944 173 1192 11944 173 1192 1186 215 149