TECH TIPS Terminal Unit Sizing: Inlet Valves€¦ · TECH TIPS |. rieinstries .com 2010 | Terminal...

Transcript of TECH TIPS Terminal Unit Sizing: Inlet Valves€¦ · TECH TIPS |. rieinstries .com 2010 | Terminal...

TECH TIPS

| www.priceindustries.com 2010 | Terminal Unit Sizing: Inlet Valves | 1

Terminal Unit Sizing: Inlet Valves

By Jerry Sipes, PH.D., P.E.

All variable air volume (VAV) terminal units (single duct, bypass, system powered induction, fan powered, and dual duct) have a common function: the volume regulation of the primary air entering the terminal unit. This control of the primary air volume may be for the purpose of occupied space temperature regulation, discharge air pressure regulation, discharge air temperature regulation, or to mix primary air with return air in an induction terminal. The primary air valve assembly contains an inlet tube, damper, and airflow sensor.

HVAC designers have several goals to meet when sizing a terminal unit inlet. One is to minimize the sound generation of the terminal unit and the other is to accurately resolve the flow signal at both full cooling and minimum cooling.

One of the most important components to a terminal unit is the airflow sensor. The most commonly supplied airflow sensor in terminal units is a velocity pressure sensor (differential pressure sensor). The differential pressure sensor provides the terminal unit controller with a velocity pressure signal (difference between total pressure and static pressure). Regardless of upstream static pressure fluctuations, the velocity pressure airflow sensor will generate a velocity pressure signal dependent on the speed of the air as it passes the sensor. The terminal controller uses this velocity pressure signal to adjust the airflow to match a control scheme and/or operate as a pressure independent device.

There are two basic types of velocity pressure airflow sensors: single point (pitot tube) and multiple point (ring, linear and center averaging). Not all multiple point sensors are equal. The

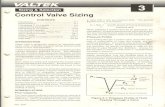

center averaging, multiple point type provides the most stable and consistent velocity pressure signal, even with poor inlet conditions due to the way the measurement points are distributed throughout the inlet duct (see Figure 1). The Price SP-300 flow sensor is an example of a center averaging, multiple point type sensor.

The SP-300 has 12 total pressure ports and four static pressure ports. In general, the higher the number of measurement points (total and static), the higher the expected accuracy of the velocity pressure signal at both minimum turndown and full open airflow volumes.

Precise control at minimum settings is critical to maintaining the air change rates in the occupied zone. Since minimum flows occur at the minimum turndown for cooling, it is necessary to adequately resolve the flow signal at the lowest possible flow volume. The ability to control the flow to the lowest possible minimum will potentially lead to a reduced requirement for reheat due to the lowered cool air volume. Due to the profile shape, a typical center averaging sensor can operate at a minimum air velocity in the primary air inlet of 400 to 450 fpm. The Price SP-300 can provide a consistent velocity pressure signal down to around 200 fpm (see Figure 2). However, this low of a flow signal requires a careful analysis of the pressure transducer on the terminal controller to determine if the pressure transducer can accurately resolve the pressure signal.

The HVAC designer must balance the flow signals and the overall size of the inlet. One common misconception is that a larger diameter inlet will generate less sound. This is not true.

Total Pressure Ports

Center Averaging Chamber

Static Pressure Port

Figure 1: Multiple point, center averaging airflow sensor

1.000.900.800.700.600.50

0.40

0.300.25

0.20

0.15

0.100.090.080.070.060.05

0.04

0.030.025

0.020

0.015

0.01

Air Flow: cfm at Standard Density

4 5 6 7 8 9 10 12 14 16 24 x16

Diffe

rent

ial P

ress

ure

at S

enso

r (Am

plifi

ed V

eloc

ity P

ress

ure

in. w

.g.)

40 50 60 70 80 90 100

150

200

250

300

400

500

600

700

800

900

1000

1500

2000

2500

3000

4000

5000

6000

7000

8000

9000

Figure 2: Price SP-300 velocity pressure vs. cfm

| www.priceindustries.com 2010 | Terminal Unit Sizing: Inlet Valves | 2

Figure 3 shows the radiated and discharge sound for a single duct terminal. As you can see, there is no significant difference in sound generation until the unit size is very large. But at the minimum turndown flow, the flow sensor may not be able to resolve the velocity pressure signal. It is recommended that the terminal unit valve be selected so that the maximum air volume needed is around 75 to 85% of the inlet rated air volume capacity (typically this is the air volume at 2000 fpm through the inlet). The designer should then verify that the minimum turn down air volume is going to provide an adequate air velocity pressure signal – a safe neck velocity for minimum turn down is 400 fpm. For more information on this topic, please see the Price Engineering Handbook.

1 2 3 4 5 6

Dis

char

ge S

ound

Pow

er L

evel

in d

B

Octave Band Center Frequency

2000 cfm Single Duct Terminal

2000 cfm Single Duct Terminal

Size 12, 2500fpm (NC27)Size 14, 1870fpm(NC27)Size 16, 1430fpm(NC25)Size 24x16, 955fpm(NC22)

Size 12, 2500fpm (NC28)Size 14, 1870fpm(NC29)Size 16, 1430fpm(NC26)Size 24x16, 955fpm(NC26)

1 2 3 4 5 6

Rad

iate

d S

ound

Pow

er

Leve

l in

dB

Octave Band Center Frequency

Figures 3: Sound generation for different size inlets

1 2 3 4 5 6

Dis

char

ge S

ound

Pow

er L

evel

in d

B

Octave Band Center Frequency

2000 cfm Single Duct Terminal

2000 cfm Single Duct Terminal

Size 12, 2500fpm (NC27)Size 14, 1870fpm(NC27)Size 16, 1430fpm(NC25)Size 24x16, 955fpm(NC22)

Size 12, 2500fpm (NC28)Size 14, 1870fpm(NC29)Size 16, 1430fpm(NC26)Size 24x16, 955fpm(NC26)

1 2 3 4 5 6

Rad

iate

d S

ound

Pow

er

Leve

l in

dB

Octave Band Center Frequency