Table Saw Safety Training Table Saw Safety Training: MACHINE GUARDING OSHA and Kitchen Cabinet...

-

Upload

jocelin-austin -

Category

Documents

-

view

224 -

download

0

Transcript of Table Saw Safety Training Table Saw Safety Training: MACHINE GUARDING OSHA and Kitchen Cabinet...

Table Saw Safety TrainingTable Saw Safety Training

Table Saw Safety Training:Table Saw Safety Training:MACHINE GUARDINGMACHINE GUARDING

OSHA and Kitchen Cabinet Manufacturers Association (KCMA) Alliance, KCMA developed this OSHA and Kitchen Cabinet Manufacturers Association (KCMA) Alliance, KCMA developed this power point presentation for informational purposes only. It does not necessarily reflect the power point presentation for informational purposes only. It does not necessarily reflect the

official views of OSHA or the U.S. Department of Labor. Jan 2009official views of OSHA or the U.S. Department of Labor. Jan 2009

Why guard equipment?Why guard equipment?

As you know, there are risks involved in As you know, there are risks involved in everything you do. When operating machines, everything you do. When operating machines, one way to reduce your risk of injury is to one way to reduce your risk of injury is to ensure all safety guards are in place.ensure all safety guards are in place.

Some of the injuries associated with Some of the injuries associated with unguarded equipment may include (but are not unguarded equipment may include (but are not limited too):limited too): Crushed body partsCrushed body parts Amputated body partsAmputated body parts BlindnessBlindness

What am I looking for?What am I looking for?

Chains and sprocketsChains and sprockets RollersRollers FlywheelsFlywheels Blade exposureBlade exposure Any moving part that could cause bodily Any moving part that could cause bodily

injuryinjury

What if a guard was not provided What if a guard was not provided with the equipment?with the equipment?

Anticipate all possibilities, sometimes you have Anticipate all possibilities, sometimes you have to design, build, and install additional guardsto design, build, and install additional guards

Table SawsTable Saws

Table saws are used for straight sawing. Table saws are used for straight sawing. Depending on the blade, they cut either across Depending on the blade, they cut either across (crosscut) or with (ripsaw) the grain of the (crosscut) or with (ripsaw) the grain of the wood. wood.

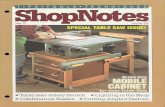

Table Saw SafetyTable Saw Safety

Blade guard should rest Blade guard should rest

on the wood.on the wood.

The blade should stick up The blade should stick up

no more than ¼” above no more than ¼” above

the wood.the wood.

Make sure the rip fence is Make sure the rip fence is

locked into place.locked into place.

Lockout the saw before Lockout the saw before

changing the blade.changing the blade.

Don’t cut with a dull Don’t cut with a dull

blade.blade.

On/Off

Rip Fence

Height/Angle Blade Adjustment

Blade Guard

Power Tool Injury StatisticsPower Tool Injury Statistics

According to estimates made by the Consumer According to estimates made by the Consumer Product Safety Commission, more than 52,000 Product Safety Commission, more than 52,000 injuries involving table saws, band saws, miter injuries involving table saws, band saws, miter saws, or radial arm saws, required medical saws, or radial arm saws, required medical attention in the United States in 2001. 83% of attention in the United States in 2001. 83% of the injuries involved fingers. Almost all of the the injuries involved fingers. Almost all of the injuries were lacerations, amputations, injuries were lacerations, amputations, fractures, or avulsions.fractures, or avulsions.

Operator InvolvementOperator Involvement

Adjust the height and angle of the bladeAdjust the height and angle of the blade Push the stock into the bladePush the stock into the blade Use the guide to maintain a straight cutUse the guide to maintain a straight cut Self-feed or power table saws are equipped Self-feed or power table saws are equipped

with rollers or a conveyor system to hold the with rollers or a conveyor system to hold the lumber and force-feed it into the saw blade. lumber and force-feed it into the saw blade.

Injury CausesInjury Causes

Inexperienced operatorInexperienced operator Improper trainingImproper training Inadequate or missing guardsInadequate or missing guards Employee taking shortcuts / rushingEmployee taking shortcuts / rushing Distracted operatorDistracted operator Substance abuseSubstance abuse

Point of OperationPoint of Operation

Potential Hazard:Potential Hazard: Injuries can occur if an operator’s hands slip Injuries can occur if an operator’s hands slip

while feeding the stock into the saw, or if the while feeding the stock into the saw, or if the operator holds his or her hands too close to the operator holds his or her hands too close to the blades while cutting. The operator can also be blades while cutting. The operator can also be injured when removing scrap or finished pieces injured when removing scrap or finished pieces of stock from the table.of stock from the table.

Point of OperationPoint of OperationSolutions:Solutions: Enclose the portion of the ripsaw and crosscut saw above the table Enclose the portion of the ripsaw and crosscut saw above the table

with a self-adjusting guard as shown. The guard must adjust to the with a self-adjusting guard as shown. The guard must adjust to the thickness of the material being cut and remain in contact with it thickness of the material being cut and remain in contact with it [1910.213 (c)(1) and and (d)(1)]. Hinge the guard so that the blades can . Hinge the guard so that the blades can be changed easily.be changed easily.

Use a push stick for small pieces of wood and for pushing stock Use a push stick for small pieces of wood and for pushing stock past the blade. past the blade. [1910.213(s)(9)]

Point of OperationPoint of Operation

Additional Safety MeasuresAdditional Safety Measures

Keep hands out of the line of the cut. Keep hands out of the line of the cut. Attach a brake to the motor’s arbor to stop the Attach a brake to the motor’s arbor to stop the

saw from coasting after the power has been saw from coasting after the power has been cut off, or have the operator remain at the saw cut off, or have the operator remain at the saw station after the motor is shut off, until the station after the motor is shut off, until the blade stops turning. blade stops turning.

Other Moving PartsOther Moving Parts

Potential Hazard:Potential Hazard: Injuries can occur if the operator makes contact with Injuries can occur if the operator makes contact with

the blade under the table or with the power the blade under the table or with the power transmission apparatus (if not enclosed). transmission apparatus (if not enclosed).

Solution:Solution: Always guard the portion of the blade below the table. Always guard the portion of the blade below the table.

Protect operators from possible contact when reaching Protect operators from possible contact when reaching under the table. under the table. [1910.213(a)(12)]

Always guard the power transmission apparatus (belts, Always guard the power transmission apparatus (belts, pulleys, chains, sprockets, etc.). pulleys, chains, sprockets, etc.). [1910.213(a)(9)]

KickbacksKickbacks Potential Hazard:Potential Hazard: Kickbacks occur when the blade catches the stock and throws it back toward the Kickbacks occur when the blade catches the stock and throws it back toward the

operator. Kickbacks can result if the blade height is not correct or if the blade operator. Kickbacks can result if the blade height is not correct or if the blade

is not maintained properly. Kickbacks are more likely to occur when ripping, is not maintained properly. Kickbacks are more likely to occur when ripping,

rather than crosscutting. Kickbacks also can occur if safeguards are not used rather than crosscutting. Kickbacks also can occur if safeguards are not used

or if poor-quality lumber is cut. or if poor-quality lumber is cut.

For ripsaws, use a spreader to prevent material from squeezing the saw or For ripsaws, use a spreader to prevent material from squeezing the saw or

kicking back during ripping. [1910.213(c)(2)] kicking back during ripping. [1910.213(c)(2)]

Use anti-kickback fingers to hold the stock down in the event that the saw Use anti-kickback fingers to hold the stock down in the event that the saw

kicks back the material. kicks back the material. [1910.213(c)(3)][1910.213(c)(3)]

Maintain and sharpen blade. [1910.213(s)(2)] Maintain and sharpen blade. [1910.213(s)(2)]

Wear kickback apronWear kickback apron..

Additional Safety MeasuresAdditional Safety Measures Use the proper blade for the cutting action. For example, do not use a crosscut Use the proper blade for the cutting action. For example, do not use a crosscut

blade for ripping. blade for ripping. Operate the saw at the speed specified by the manufacturer. Operate the saw at the speed specified by the manufacturer. Leave sufficient clearance for stock. Leave sufficient clearance for stock. Stand to the side of the saw blade to avoid injury due to kick back. Stand to the side of the saw blade to avoid injury due to kick back. Guide the wood to be cut parallel to the rip fence to minimize the potential for Guide the wood to be cut parallel to the rip fence to minimize the potential for

kick back.kick back. Avoid crosscutting long boards on table saws. Considerable hand pressure is Avoid crosscutting long boards on table saws. Considerable hand pressure is

required close to the saw blade, and the boards create a safety hazard to other required close to the saw blade, and the boards create a safety hazard to other people. people.

Table saw with rip fenceTable saw with rip fence

Use a filler piece between the fence and the saw blade when necessary such as Use a filler piece between the fence and the saw blade when necessary such as when there is little clearance on the fence side. when there is little clearance on the fence side.

Properly support all pieces of stock, including the cut and uncut ends, scrap, and Properly support all pieces of stock, including the cut and uncut ends, scrap, and finished product. finished product.

Flying ParticlesFlying Particles

Potential Hazard:Potential Hazard: The cutting action of the blade may throw wood chips, The cutting action of the blade may throw wood chips,

splinters, and broken saw teeth. splinters, and broken saw teeth.

Solution:Solution: Remove cracked saw blades from service. [1910.213(s)Remove cracked saw blades from service. [1910.213(s)

(7)] (7)]

AAdditional Safety Measuresdditional Safety Measures

Maintain sharp blades.Maintain sharp blades. Safety Glasses and Faceshield are requiredSafety Glasses and Faceshield are required

Easiest Injury Prevention from Easiest Injury Prevention from SawsSaws

Avoid loose-fitting clothes Avoid loose-fitting clothes Tie back long hair that might become Tie back long hair that might become

entangled in a power tool entangled in a power tool Remove rings, watches, neck chains and other Remove rings, watches, neck chains and other

jewelry jewelry

Amputation -UnguardedAmputation -Unguarded

A worker was assembling parts of a cabinet when he A worker was assembling parts of a cabinet when he noticed one of the parts needed another cut to fit. noticed one of the parts needed another cut to fit. When he walked over to the operating side of the table When he walked over to the operating side of the table saw, he noticed that the blade guard was lying on the saw, he noticed that the blade guard was lying on the floor under the saw. Without installing the guard, the floor under the saw. Without installing the guard, the worker proceeded to make the cut and then reached worker proceeded to make the cut and then reached across behind the blade to remove the scrap piece. across behind the blade to remove the scrap piece. While dragging the scrap piece towards himself, the While dragging the scrap piece towards himself, the scrap caught on the blade and pulled his hand right scrap caught on the blade and pulled his hand right into the unguarded rotating blade. This resulted in into the unguarded rotating blade. This resulted in multiple finger amputations on his left hand. multiple finger amputations on his left hand.

Rip Saw finger amputationRip Saw finger amputation

A worker was ripping a wooden work piece with a dado on a manual-A worker was ripping a wooden work piece with a dado on a manual-

feed table rip saw. When the work piece began to bind, the worker feed table rip saw. When the work piece began to bind, the worker

attempted to move the work piece through by pushing hard on it in attempted to move the work piece through by pushing hard on it in

the normal direction of operation. The work piece subsequently the normal direction of operation. The work piece subsequently

broke free, exposing the circular saw blade underneath which broke free, exposing the circular saw blade underneath which

caught the worker's fingers on his right hand. The worker suffered caught the worker's fingers on his right hand. The worker suffered

amputations of his index and little finger at the first knuckle, and amputations of his index and little finger at the first knuckle, and

middle and ring fingers at the second knuckle. The worker should middle and ring fingers at the second knuckle. The worker should

have used a push stick to free the binding work piece instead of have used a push stick to free the binding work piece instead of

his right hand. his right hand.

Lockout / TagoutLockout / Tagout

Remove the energy source to the Remove the energy source to the equipment so the equipment will not equipment so the equipment will not start-up accidentally. start-up accidentally.

The table saw must be locked out:The table saw must be locked out: during lunch and at the end of each shiftduring lunch and at the end of each shift if the table-saw is not used consistently if the table-saw is not used consistently

throughout the daythroughout the day when changing the blade when changing the blade when maintenance is conducted on the sawwhen maintenance is conducted on the saw

What is next?What is next?

Watch and discuss DVDWatch and discuss DVD Go over Table Saw Commandments – Go over Table Saw Commandments –

each Team Mate must sign and turn in.each Team Mate must sign and turn in. Take written test – must make a Take written test – must make a

minimum score of 75% to be eligible for minimum score of 75% to be eligible for certification.certification.

Take hands-on testTake hands-on test

Program Developed by: Kelly F. Moore