Table of Contents : For Cv < 1.7, refer to Specification Data CH 4500 (Varipak) Various flange...

Transcript of Table of Contents : For Cv < 1.7, refer to Specification Data CH 4500 (Varipak) Various flange...

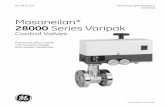

2SD CH1080 E - 11/97

21000 Series

Trade names noted throughout are for reference only. Masoneilanreserves the right to supply trade named material or its equivalent.

21000 Series single ported heavy top guided controlvalves are designed with built in versatility makingthem well-suited to handle a wide variety of processapplications. Standard features include:

Top GuidedRugged, heavy top plug guiding provides maximumsupport to ensure plug stability.

Single and Double Stage LO-DB®/Anti-cavitation

TrimReplacing the conventional plug with the LO-DB

® designprovides excellent noise attenuation or cavitationcontrol.

Reduced CapacityA series of reduced area trim is available to providewide flow range capabilities in all valve sizes.

Environmental PackingLow emission LE Packing is available to assure

compliance with the Clean Air Act.

Pressure Drop Capability

A variety of actuator sizes to handle low to high

pressure drop requirements.

Allowable pressure drop shown on all tables reflect

actuator capability for the leakage class.

Proper application requires consideration with regards

to cavitation, noise, velocity, etc. Refer to Masoneilan

sizing and noise manuals.

Tight Shutoff

Class IV leakage is standard. Optional constructions

meet IEC 534-4 and ANSI/FCI 70.2 Class V and VI.

Hardened Trim

Provided as standard to handle the high pressure drop

capabilities of the 21000 Series.

Trim Type

Standard construction offers a quick change seat ring.

Table of Contents

Foreword ........................................................................ 2Numbering System ......................................................... 3General Data .................................................................. 3Temperature Range/Seat Leakage ................................ 4Ratings/Connections ...................................................... 4CV and FL versus Travel ........................................... 5 - 7Materials ..................................................................... 8, 9Allowable Pressure Drops .................................... 10 - 18Dimensions............................................................. 19, 20Weights ........................................................................ 21Accessories and Options.............................................. 22Sales Offices and Distribution Centers......................... 24

Foreword

3SD CH1080 E - 11/97

21000 Series

• Flow Direction

contoured : flow-to-open

LO-DB® : flow-to-open

anti-cavitation : flow-to-close

• Body

type : high capacity globe

• Bonnet

type : bolted

standard

extension

• Body and Bonnet

materials : carbon steel

316 stainless steel

chrome-molybdenum steel

• Trim

plug type : contoured

soft seat

LO-DB® (1 or 2 stages)

anti-cavitation (1 or 2 stages)

seat ring : threaded

quick change

guide : heavy top guided

capacity : full area

reduced capacity in all sizes

Cv ratio : 50:1

flowcharacteristic : linear

equal percentage

• Actuator

type : spring diaphragm

handwheel : optional

2nd

ControlCharacteristic

0. Undefined1. Linear2. Equal Percentage

Body Series

21

2nd1

5th4th3rd

87 Spring DiaphragmAir to Close

88 Spring DiaphragmAir to Open

1st2

1st8

Plug Type

0. Undefined1. Contoured6. Soft Seat7. Single Stage

LO-DB®/Anti-cavitation

8. Double StageAnti-cavitation

9. Double StageLO-DB®

Actuator Type Seat Type

0. Undefined4. Quick change5. Threaded

General Data

Numbering System

4SD CH1080 E - 11/97

21000 Series

ValveSize

mm inch

20 to 50 3/4 to 2 ■■ • •• ∆80 to 150 3 to 6 ■■ ∆ ■

20 3/4 PN 10 to 100 Threaded-29˚C +232˚C -29˚C +343˚C

to to ANSI ClassMetal

IV VQuick Change-29˚C +232˚C -29˚C +427˚C150 6 150 to 600 Metal

min. max.

Valve

Size

mm inch

Body RatingSeat

Type

PN 10 to 100

ANSI Class

150 to 600

Seat Leakage,IEC 534-4 and ANSI/FCI 70.2

Classmin. max.

Temperature Range

StandardBonnet

ExtensionBonnet

Valve

Size

mm inch

Body RatingSeat

Type

Seat Leakage,IEC 534-4 and ANSI/FCI 70.2

Class

Temperature Range

StandardBonnet

ExtensionBonnet

min. max. min. max.

■■ RF Flanged • Socket Weld •• Threaded ∆ RT Joint ■ Butt Weld

PN 10 to 100

ANSI Class 150 to 600

Contoured Trim

*Quick Change seat ring only for double stage control valves. DN 150 (6'') not available for double stage anticavitation valves.

Note : Other ratings and sizes are available, consult Masoneilan.

*Temperature limitations are valid for PTFE based packings and LE packing. For graphite packing, there is no temperature limitation inherent withthe packing itself.

LO-DB®/Anti-cavitation Trim (1 or 2 stages)*

Ratings/Connections

Temperature Range/Seat Leakage*

Threaded-29˚C +232˚C -29˚C +343˚C

Metal20 3/4 Quick Change

- 29°C +232°C -29°C +427°CIV V

to to Metal

150 6Threaded

-29°C +232°C -29°C +232°CSoft Seat

Quick Change-29˚C +232˚C -29˚C +232˚C

VI

Soft Seat

5SD CH1080 E - 11/97

21000 Series

Contoured TrimBody Rating : PN 10 to 100 - ANSI Class 150 to 600Sizes : DN 20 to DN 150 (3/4" to 6") Flow Characteristic : LINEAR

Percent of Travel

Travel(mm) Rated Cv

FL

ValveSize

mm inch

OrificeDiameter

(mm)

Note : For Cv < 1.7, refer to Specification Data CH 4500 (Varipak)Various flange facings and surface finish available on request. Consult Masoneilan.

* Quick change trim only

Cv and FL versus Travelfor 21100 and 21600 Series

10 20 30 40 50 60 70 80 90 100

0.93 0.93 0.92 0.92 0.91 0.91 0.91 0.90 0.90 0.90

6.4 20.3 0.15 0.31 0.44 0.59 0.76 0.95 1.12 1.31 1.50 1.720 3/4 9.5 20.3 0.34 0.68 0.99 1.33 1.71 2.13 2.51 2.93 3.34 3.8

& 25 & 1 12.7 20.3 0.54 1.08 1.56 2.10 2.7 3.36 4.0 4.6 5.3 620.6 20.3 1.08 2.16 3.12 4.2 5.4 6.7 7.9 9.2 10.6 126.4 20.3 0.15 0.31 0.44 0.59 0.76 0.95 1.12 1.31 1.50 1.79.5 20.3 0.34 0.68 0.99 1.33 1.71 2.13 2.51 2.93 3.34 3.8

40 1 1/212.7 20.3 0.54 1.08 1.56 2.1 2.7 3.4 4.0 4.6 5.3 620.6 20.3 1.17 2.34 3.4 4.55 5.8 7.3 8.6 10 11.5 1331.8 20.3 2.25 4.5 6.5 8.7 11.2 14 16.5 19.2 22 2541.3 20.3 3.15 6.3 9.1 12.2 15.7 19.6 23.1 26.9 31 35*6.4 20.3 0.15 0.31 0.44 0.59 0.76 0.95 1.12 1.31 1.50 1.79.5 20.3 0.34 0.68 0.99 1.33 1.71 2.13 2.51 2.93 3.34 3.8

50 212.7 20.3 0.54 1.08 1.56 2.1 2.7 3.4 4.0 4.6 5.3 620.6 20.3 1.35 2.7 3.9 5.2 6.75 8.4 9.9 11.5 13.2 1531.8 20.3 2.34 4.7 6.8 9.1 11.7 14.5 17.1 20 23 2641.3 20.3 4.14 8.3 12 16 21 26 30.3 35 40 4631.8 38.1 2.79 5.6 8 10.8 14 175 20.5 24 27 31

80 3 41.3 38.1 4.23 8.5 12.2 16.4 21 26 31 39 41 4766.7 38.1 9.9 19.8 28.5 39 50 62 72 84 96 11041.3 38.1 4.4 8.8 12.8 17 22 27 32 37 43 49

100 4 66.7 38.1 10 20.5 29 40 50 63 74 87 99 11388.9 38.1 17.5 35 51 68 87 109 128 150 171 19566.7 50.8 11.5 22.5 33 44 56 70 83 97 110 126

150 6 88.9 50.8 18.5 36.5 53 71 91 113 133 156 178 208127 50.8 36 72 104 140 178 224 263 308 351 400

6SD CH1080 E - 11/97

21000 Series

Flow Characteristic : EQUAL PERCENTAGE

10 20 30 40 50 60 70 80 90 1000.93 0.93 0.93 0.93 0.93 0.93 0.93 0.93 0.93 0.93

0.30 0.64 0.95 1.3 1.7 2.1 2.6 2.9 3.4 40.60 1.28 1.92 2.64 3.36 4.2 5.1 5.8 6.8 8*0.60 1.28 1.92 2.64 3.36 4.2 5.1 5.8 6.8 81.13 2.4 3.6 5.0 6.3 8.0 9.6 11.0 12.7 150.60 1.28 1.92 2.64 3.36 4.2 5.1 5.8 6.8 81.13 2.4 3.6 5.0 6.3 8.0 9.6 11.0 12.7 151.9 4.0 6.0 8.2 10.5 13.2 16 18 21 253.6 7.5 11.5 16 21 26 31 35 41 485.6 12 18 24.5 31.5 40 48 55 64 755.0 10.1 15 21 26 33 40 46 54 637.5 16 24 33 42 53 64 73 85 100

11 24 36 49 63 80 96 110 127 15015 32 48 66 84 106 128 146 170 200

10 20 30 40 50 60 70 80 90 100

0.93 0.93 0.93 0.93 0.93 0.92 0.92 0.91 0.91 0.90

6.4 20.3 0.06 0.09 0.12 0.19 0.32 0.61 0.96 1.28 1.53 1.720 3/4 9.5 20.3 0.13 0.19 0.27 0.42 0.72 1.37 2.14 2.86 3.42 3.8

& 25 & 1 12.7 20.3 0.21 0.30 0.42 0.66 1.13 2.16 3.38 4.52 5.4 620.6 20.3 0.42 0.60 0.84 1.32 2.27 4.32 6.77 9.04 10.8 126.4 20.3 0.06 0.09 0.12 0.19 0.32 0.61 0.96 1.28 1.53 1.7

9.5 20.3 0.13 0.19 0.27 0.42 0.72 1.37 2.14 2.86 3.42 3.8

40 11/212.7 20.3 0.21 0.30 0.42 0.66 1.13 2.16 3.38 4.52 5.4 620.6 20.3 0.46 0.65 0.91 1.43 2.46 4.68 7.3 9.8 11.7 1331.8 20.3 0.88 1.25 1.75 2.75 4.73 9.00 14.1 18.8 22.5 2541.3 20.3 1.23 1.75 2.45 3.85 6.62 12.6 19.7 26 31.5 35*6.4 20.3 0.06 0.09 0.12 0.19 0.32 0.61 0.96 1.28 1.53 1.79.5 20.3 0.13 0.19 0.27 0.42 0.72 1.37 2.14 2.86 3.42 3.8

12.7 20.3 0.21 0.30 0.42 0.66 1.13 2.16 3.38 4.52 5.4 650 220.6 20.3 0.53 0.75 1.05 1.65 2.84 5.40 8.5 11.3 13.5 1531.8 20.3 0.91 1.30 1.82 2.86 4.91 9.4 14.7 19.6 23.4 2641.3 20.3 1.61 2.30 3.22 5.1 8.7 16.6 26 35 41 4631.8 38.1 1.09 1.55 2.17 3.41 5.9 11.2 17.5 23.3 28 31

80 341.3 38.1 1.65 2.35 3.29 5.2 8.9 16.9 26.5 35 42 4766.7 38.1 3.85 5.5 7.7 12.1 21 40 62 83 99 11041.3 38.1 1.72 2.49 3.43 5.4 9.3 17.6 27.6 36.9 44 49

100 4 66.7 38.1 3.96 5.65 7.9 12.4 21 41 64 85 102 11388.9 38.1 6.8 9.8 13.7 21 37 70 110 147 176 19566.7 50.8 4.4 6.3 8.8 13.9 24 45 71 95 113 126

150 6 88.9 50.8 7.3 10.4 14.6 23 39 75 117 157 187 208127 50.8 14 20 28 44 76 144 226 301 360 400

Percent of Travel

Travel(mm)

Contoured TrimBody Rating : PN 10 to 100 - ANSI Class 150 to 600Sizes : DN 20 to DN 150 (3/4" to 6")

Rated Cv

Rated C v

Percent of Travel

ValveSize

mm inch

Travel(mm)

Flow Characteristic : LINEAR

Single Stage LO-DB ®/Anti-cavitation TrimBody Rating : PN 10 to 100 - ANSI Class 150 to 600Sizes : DN 20 to DN 150 (3/4" to 6")

FL

20.6 20.3

31.8 20.311/2

3/4& 1

OrificeDiameter

(mm)

ValveSize

mm inch

OrificeDiameter

(mm)

FL

2

66.73 38.1

66.7 38.14

50.8 20.3

100

80

50

40

20& 25

6 15050.850.8

88.9127

88.9 38.1

25.2 20.3

* Quick change only

*Quick change only

Various flange facings and surface finish available on request. Consult Masoneilan.

Various flange facings and surface finish available on request. Consult Masoneilan.

Cv and FL versus Travelfor 21100, 21600 and 21700 Series

7SD CH1080 E - 11/97

21000 Series

10 20 30 40 50 60 70 80 90 1000.975 0.975 0.975 0.975 0.975 0.975 0.975 0.975 0.975 0.975

0.45 0.90 1.35 1.80 2.3 2.7 3.2 3.6 4.0 4.50.23 0.46 0.69 0.92 1.15 1.4 1.6 1.8 2.1 2.30.85 1.70 2.55 3.40 4.30 5.1 6.0 6.8 7.7 8.50.45 0.90 1.35 1.80 2.3 2.7 3.2 3.6 4.0 4.50.23 0.46 0.69 0.92 1.15 1.4 1.6 1.8 2.1 2.31.4 2.8 4.2 5.6 7.0 8.4 9.8 11.2 12.6 140.85 1.7 2.55 3.4 4.3 5.1 6.0 6.8 7.7 8.50.45 0.90 1.35 1.80 2.3 2.7 3.2 3.6 4.0 4.54.2 8.5 12.5 17 21 25 29 34 38 422.7 5.4 8.1 10.8 13.5 16 19 21.5 24.5 276.2 12.4 18.6 24.8 31 37.2 33.4 39.6 45.8 624.0 8.0 12 16 20 24 28 32 36 40

Rated Cv

Percent of Travel

ValveSize

mm inch

Travel(mm)

Flow Characteristic : LINEAR

Double Stage Anti-cavitation TrimBody Rating : PN 10 to 100 - ANSI Class 150 to 600Sizes : DN 20 to DN 100 (3/4" to 4")

FL

31.8 20.3

31.8 20.311/2

3/4

& 1

OrificeDiameter

(mm)

2 31.8

3

20.3

66.7 38.1

41.3 20.3

80

50

40

20& 25

4 10038.138.1

88.966.7

31.8 20.3

20.6 20.3

31.8 20.3

10 20 30 40 50 60 70 80 90 1000.975 0.975 0.975 0.975 0.975 0.975 0.975 0.975 0.975 0.975

0.57 1.14 1.71 2.28 2.85 3.4 4.0 4.55 5.1 5.70.35 0.7 1.05 1.4 1.75 2.1 2.45 2.8 3.2 3.51.3 2.6 3.9 5.2 6.5 7.8 9.1 10.4 11.7 130.7 1.4 2.1 2.8 3.5 4.2 4.9 5.6 6. 3 72.1 4.2 6.3 8.4 10.5 12.6 14.7 17 19 211.3 2.6 3.9 5.2 6.5 7.8 9.1 10.4 11.7 136.3 12.5 19 25 32.5 38 44 50 57 634 8 12 16 20 24 28 32 36 408.3 16.5 25 33 42 50 58 66 75 835.3 10.5 16 21 27 32 37 42 48 53

13 25 38 50 63 75 87 100 112 125

Rated Cv

Percent of Travel

ValveSize

mm inch

Travel(mm)

Flow Characteristic : LINEAR

Double Stage LO-DB ® TrimBody Rating : PN 10 to 100 - ANSI Class 150 to 600Sizes : DN 20 to DN 150 (3/4" to 6")

FL

31.8 20.3

31.8 20.311/2

3/4& 1

OrificeDiameter

(mm)

231.8

4

20.3

38.1

41.3 20.3

100

50

40

20& 25

6 150 50.888.9

88.9 38.1

20.6 20.3

66.7 20.3

66.7

380

Various flange facings and surface finish available on request. Consult Masoneilan.

Various flange facings and surface finish available on request. Consult Masoneilan.

Cv and FL versus Travelfor 21800 and 21900 Series

8SD CH1080 E - 11/97

21000 Series

Materials of Construction

LE® Packing System (Optional)

Low Emission Stem Packing

*Kalrez and Zymax are registered Dupont Corporation Trademarksfor Perfluoroelastomer and long carbon fiber filled PTFE, respectively.

Standard Construction

Single Stage LO-DB ®/Anti-cavitation Trim

Soft Seat Trim

Kalrez / Zymax *Packing Set5 pieces

SpringLoadedFollower S/A

Flexible Graphite(Fire Tested Version)

Spacer

9SD CH1080 E - 11/97

21000 Series

Temperature Range -29 °C 232°C 343°C 427˚C

Description Standard Materials (Optional Materials)

1 Plug Stem 316 St. St. ASTM 479 TY 316

17-4 PH St. St. ASTM A564 Gr 630

2 Packing Flange Stud 304 St. St. ASTM A193 Gr B8

3 Packing Flange Nut 304 St. St. ASTM A194 Gr 8

4 Packing Flange Carbon Steel ASTM A668 CL B

5 Packing Follower 300 Series Stainless Steel

6 Packing Kevlar PTFE or Braided PTFE w/ std. bonnet

Kevlar PTFE or Braided PTFE with extension bonnet

Flexible Graphite

LE Packing (See Page 4 for Temperature Limits)

7 Lantern ring 300 Series Stainless Steel (Packing Spacer Optional)

8 Bonnet Carbon Steel ASTM A216 Gr WCC

18 Body Chrome-Moly Steel ASTM A217 Gr WC9

316 St. St. ASTM A351 Gr CF8M

9 Valve Body Studs Alloy Steel ASTM

A193 Gr B7

10 Valve Body Stud Nut Alloy Steel ASTM

A194 Gr 2H

11 Valve Body Gasket 316L St. St. w/Flexible Graphite Filler (Spiral Wound)

12 Guide Bushing 440C St. St. ASTM A276 TY 440C ➀

Nitronic 60

13 Cage 304 St. St.

ASTM A487 Gr CA6NM CLB

416 St. St. ASTM A582 TY 416 or ASTM A479 TY 316 ➀

14 Seat Ring ➁ ➂ 316 St. St. ASTM A479 TY 316; Standard w/St. St. Body

316 St. St. ASTM A479 TY 316 with Hardfacing

15 Seat Ring Gasket316 L St. St. w/Flexible Graphite Filler (Spiral Wound)

416 St. St. ASTM A582 TY 416

316 St. St. ASTM A479 TY 316; Standard w/St. St. Body

16 Plug ➂ 316 St. St. ASTM A479 TY 316 with Hardfacing

316 St. St. ASTM A479 TY 316 w/Hardfacing Seat & Post or Solid Stellite

316 St. St. ASTM A479 TY 316

with Teflon Soft Seat

17 Plug Pin ASTM A582 TY 303

19 Drive Nut SAE 1117

Temperature Range -29 °C 232°C 343°C 427˚C

∇∇∇∇Ref.

No.

Ref.

No.

∆ ∆∆ ∆

Note :

- EN materials available on request,

- For temperature below -29°C and above 427° C, consult Masoneilan for recommended materials combination.

➀ Not supplied with st. st. body

➁ For threaded seat ring version, temperature should not exceed limits specified page 4, irrespective of materials

➂ Seat ring material must be identical to plug material

Not applicable

Consult Masoneilan

Materials of Construction

10SD CH1080 E - 11/97

21000 Series

12 6 23 --- 103 103 103 103 103 103 103 * 103 *

6 6 71 4.2 103 103 103 103 103 103 103 * 103 *

3.8 6 103 44 103 103 103 103 103 103 103 * 103 *

1.7 6 103 103 103 103 103 103 103 103 103 * 103 *

35 6 3.2 --- 23 2.7 43 23 63 43 83 * 63 *

35 10 9.9 --- 43 23 76 56 103 * 89 * 103 * 103 *

25 6 7.4 --- 41 15 75 48 103 82 103 * 103 *

25 10 19 --- 75 48 103 103 103 * 103 * 103 * 103 *

13 6 23 --- 103 62 103 103 103 103 103 * 103 *

6 6 71 4.2 103 103 103 103 103 103 103 * 103 *

3.8 6 103 44 103 103 103 103 103 103 103 * 103 *

1.7 6 103 103 103 103 103 103 103 103 103 * 103 *

46 6 3.2 --- 23 2.7 43 23 63 43 83 * 63 *

46 10 9.9 --- 43 23 76 56 103 * 89 * 103 * 103 *

26 6 7.4 --- 41 15 75 48 103 82 103 * 103 *

26 10 19 --- 75 48 103 103 103 * 103 * 103 * 103 *

15 6 23 --- 103 62 103 103 103 103 103 * 103 *

6 6 71 4.2 103 103 103 103 103 103 103 * 103 *

3.8 6 103 44 103 103 103 103 103 103 103 * 103 *

1.7 6 103 103 103 103 103 103 103 103 103 * 103 *

110 10 2.6 --- 15 2.7 28 15 41 * 28 * 54 * 41 *

110 16 6.4 --- 27 14 47 * 35 * --- --- --- ---

47 10 9.9 --- 43 23 76 56 103 * 89 * 103 * 103 *

47 16 20 --- 73 53 103 * 103 * --- --- --- ---

31 10 19 --- 75 48 103 103 103 * 103 * 103 * 103 *

195 10 0.8 --- 8.0 --- 15 5.7 22 * 13 * 30 * 20 *

195 16 3.0 --- 15 5.0 26 * 17 * --- --- --- ---

113 10 2.6 --- 15 2.7 28 15 41 * 28 * 54 * 41 *

113 16 6.4 --- 27 14 47 * 35 * --- --- --- ---

49 10 9.9 --- 43 23 76 56 103 * 89 * 103 * 103 *

49 16 20 --- 73 53 103 * 103 * --- --- --- ---

400 16 0.8 --- 6.5 --- 12 5.4 18 11 23 * 17 *

400 23 2.0 --- 10 3.5 18 12 26 * 20 * 34 28 *

208 16 2.7 --- 14 4.7 26 16 37 28 49 * 39 *

208 23 5.2 --- 22 12 38 29 55 * 45 * 71 * 62 *

126 16 5.8 --- 26 14 47 34 67 54 88 * 75 *

126 23 10 --- 40 27 69 56 98 * 86 * 103 * 103 *

Contoured TrimBody Rating : PN 10 to 100 - ANSI Class 150 to 600Leakage : Per IEC 534-4 and ANSI/FCI 70.2, Class IV and Class VKevlar PTFE Packing and Standard Bonnet

Cl IV Cl V

1.4 2.1 2.8 3.4 4.1Travel

(mm)

Rated

Cv

Actuator

SizeCl VCl IV Cl VCl IV Cl IV Cl V Cl IV Cl V

20 3/4

& &

25 1

20.3

40 11/2 20.3

ValveSize

mm inch

Supply Pressure (bar)

20.350 2

38.180 3

38.1100 4

*17-4PH or A 638 Gr 660 Stem Standard

Bench Range : 3 - 15

50.8150 6

Allowable Pressure Drops for 21100 Series (bar)Air to Close, Flow to Open

Note : Inlet pressure must not exceed the ANSI rating for the selected pressure class,Various flange facings and surface finish available on request. Consult Masoneilan.

11SD CH1080 E - 11/97

21000 Series

Contoured TrimBody Rating : PN 10 to 100 - ANSI Class 150 to 600Leakage : Per IEC 534-4 and ANSI/FCI 70.2, Class IV and Class VKevlar PTFE Packing and Standard Bonnet

12 6 6.9 --- 31 --- 71 30 103 10312 10 23 --- 63 22 103 89 103 103

6 6 29 --- 92 25 103 103 103 1036 10 71 4.2 103 103 103 103 103 1033.8 6 58 --- 103 82 103 103 103 1031.7 6 103 14 103 103 103 103 103 103

35 6 --- --- 5.2 --- 15 --- 35 1535 10 3.2 --- 13 --- 30 9.4 63 4325 6 0.6 --- 11 --- 28 1.0 61 3525 10 7.4 --- 24 --- 52 26 103 8213 6 6.9 --- 31 --- 71 30 103 10313 10 23 --- 63 22 103 89 103 103

6 6 29 --- 92 25 103 103 103 1036 10 71 4.2 103 103 103 103 103 1033.8 6 58 --- 103 82 103 103 103 1031.7 6 103 14 103 103 103 103 103 103

46 6 --- --- 5.2 --- 15 --- 35 1546 10 3.2 --- 13 --- 30 9.4 63 4326 6 0.6 --- 11 --- 28 1.0 61 3526 10 7.4 --- 24 --- 52 26 103 8215 6 6.9 --- 31 --- 71 30 103 10315 10 23 --- 63 22 103 89 103 103

6 6 29 --- 92 25 103 103 103 1036 10 71 4.2 103 103 103 103 103 1033.8 6 58 --- 103 82 103 103 103 1031.7 6 103 14 103 103 103 103 103 103

110 10 --- --- 3.9 --- 10 --- 23 10110 16 2.3 --- 8.5 --- 19 6.0 39 * 26 *110 23 5.0 --- 14 1.1 29 * 16 58 * 45*

47 10 3.2 --- 13 --- 30 9.4 63 4347 16 9.2 --- 25 4.7 52 31 103 * 85 *31 10 7.4 --- 24 --- 52 26 103 8231 16 18 --- 45 18 90 63 103 * 103 *

195 10 --- --- 1.6 --- 5.2 --- 12 2.8195 16 0.7 --- 4.2 --- 9.9 0.4 21 * 12 *195 23 2.2 --- 7.2 --- 15 * 5.9 32 * 22 *113 10 --- --- 3.9 --- 10 --- 23 10113 16 2.3 --- 8.5 --- 19 6.0 39 * 26 *113 23 5.0 --- 14 1.1 29 * 16 58 * 45

49 10 3.2 --- 13 --- 30 9.4 63 4349 16 9.2 --- 25 4.7 52 31 103 * 85 *

400 23 0.4 --- 2.9 --- 6.9 0.3 15 8.3208 16 0.4 --- 3.9 --- 9.6 --- 21 12208 23 1.9 --- 6.9 --- 15 5.6 32 22126 16 1.8 --- 7.9 --- 18 5.4 39 26126 23 4.5 --- 13 0.6 28 15 57 45

Cl IV Cl V

Rated

Cv

Actuator

SizeCl VCl IV Cl VCl IV Cl IV Cl V

Valve

Size

mm inch

Travel

(mm)

Supply pressure is 0.4 bar over bench range

20 & 25 3/4 & 1 20.3

40 11/2 20.3

21 - 456 - 30 11 - 233 - 15

50 2 20.3

38.180 3

38.1100 4

*17-4PH or A 638 Gr 660 Stem Standard

*

*

Bench Range

150 6 50.8

*

Allowable Pressure Drops for 21100 Series (bar)Air to Close, Flow to Open

Note : Inlet pressure must not exceed the ANSI rating for the selected pressure class,Various flange facings and surface finish available on request. Consult Masoneilan.

12SD CH1080 E - 11/97

21000 Series

12 6 16 69 69 69 69 *

35 6 - 20 40 60 69 *

35 10 6.5 40 69 69 * 69 *

25 6 3.0 37 69 69 69 *

13 6 16 69 69 69 69 *

46 6 - 20 40 60 69 *

46 10 6.5 40 69 69 * 69 *

26 6 3.0 37 69 69 69 *

15 6 16 69 69 69 69 *

110 10 0.5 13 26 39 * 52 *

110 16 4.3 25 45 * - -

47 10 6.7 40 69 69 * 69 *

31 10 8.1 64 69 69 * 69 *

195 10 - 6.5 14 21 * 28 *

195 16 1.4 13 24 * - -

113 10 0.5 13 26 39 * 52 *

113 16 4.3 25 45 * - -

49 10 6.7 40 69 69 * 69 *

400 16 - 5.4 11 17 22 *

400 23 1.0 9.0 17 25 * 33 *

208 16 1.1 13 24 36 47 *

208 23 3.6 20 37 53 * 70 *

126 16 3.7 24 45 65 69 *

126 23 8.2 38 70 69 * 69 *

Contoured Soft Seat TrimBody Rating : PN 10 to 100 - ANSI Class 150 to 600Leakage : Per IEC 534-4 and ANSI/FCI 70.2, Class VIKevlar PTFE Packing and Standard Bonnet

Cl VI Cl VI

1.4 2.1 2.8 3.4 4.1Travel

(mm)

Rated

Cv

Actuator

SizeCl VICl VI Cl VI

20 & 25 3/4 & 1 20.3

40 11/2 20.3

ValveSize

mm inch

Supply Pressure (bar)

20.350 2

38.180 3

38.1100 4

*17-4PH or A 638 Gr 660 Stem Standard

Bench Range : 3 - 15

50.8150 6

Note : Inlet pressure must not exceed the ANSI rating for the selected pressure class,Various flange facings and surface finish available on request. Consult Masoneilan.

Allowable Pressure Drops for 21600 Series (bar)Air to Close, Flow to Open

13SD CH1080 E - 11/97

21000 Series

12 6 0.1 24 64 6912 10 16 56 69 6935 6 ---- 1.8 12 3235 10 ---- 9.8 27 6025 6 ---- 6.3 23 5725 10 3.0 20 48 6913 6 0.1 24 64 6913 10 16 56 69 6946 6 ---- 1.8 12 3246 10 ---- 9.8 27 6026 6 ---- 6.3 23 5726 10 3.0 20 48 6915 6 0.1 24 64 6915 10 16 56 69 69

110 10 ---- 1.8 8.1 21110 16 0.2 6.4 17 37 *110 23 2.9 12 26 * 56 *47 10 ---- 9.8 26 6047 16 5.8 22 48 69 *31 10 3.0 20 48 69

195 10 ---- ---- 3.6 11195 16 ---- 2.6 8.3 20 *195 23 0.7 5.6 14 * 30 *113 10 ---- 1.8 8.1 21113 16 0.2 6.4 17 37 *113 23 2.9 12 26 * 56 *49 10 ---- 9.8 26 6049 16 5.8 22 48 69 *

400 23 ---- 1.8 5.8 14208 16 ---- 2.3 8.0 20208 23 0.3 5.3 14 30126 16 ---- 5.8 16 36126 23 2.4 11 26 55

Rated

Cv

Actuator

Size

Valve

Size

mm inch

Travel

(mm)

20 & 25 3/4 & 1 20.3

40 11/2 20.3

21 - 456 - 30 11 - 233 - 15

50 2 20.3

38.180 3

38.1100 4

*17-4PH or A 638 Gr 660 Stem Standard

Bench Range

150 6 50.8

Contoured Soft Seat TrimBody Rating : PN 10 to 100 - ANSI Class 150 to 600Leakage : Per IEC 534-4 and ANSI/FCI 70.2, Class VIKevlar PTFE Packing and Standard Bonnet Supply pressure is 0.4 bar over bench range

Allowable Pressure Drops for 21600 Series (bar)Air to Open, Flow to Open

Note : Inlet pressure must not exceed the ANSI rating for the selected pressure class,Various flange facings and surface finish available on request. Consult Masoneilan.

14SD CH1080 E - 11/97

21000 Series

8 / 4 6 23 --- 103 62 103 103 103 103 103 * 103 *

8 / 4 10 49 8.0 103 103 103 103 103 * 103 * 103 * 103 *

15 / 8 6 7.4 --- 41 15 75 48 103 82 103 * 103 *

15 / 8 10 19 --- 75 48 103 103 103 * 103 * 103 * 103 *

15 / 8 6 7.4 --- 41 15 75 48 103 81 103 * 103 *

15 / 8 10 19 --- 75 48 103 103 103 * 103 * 103 * 103 *

25 6 3.2 --- 23 2.7 43 23 63 43 83 * 63 *

25 10 9.9 --- 43 23 76 56 103 * 89 * 103 * 103 *

75 / 48 10 2.6 --- 15 2.7 28 15 41 * 28 * 54 * 41 *

75 / 48 16 6.4 --- 27 14 47 * 35 * -- -- -- --

100 10 0.8 --- 8.0 --- 15 5.7 22 * 13 * 30 * 20 *

100 16 3.0 --- 15 5.0 26 * 17 * -- -- -- --

63 10 2.6 --- 15 2.7 28 15 41 * 28 * 54 * 41 *

63 16 6.4 --- 27 14 47 * 35 * -- -- --- --

200 / 150 16 0.8 --- 6.5 --- 12 5.4 18 11 23 * 17 *

200 / 150 23 2.0 --- 10 3.5 18 12 26 * 20 * 34 * 28 *

Single Stage LO-DB ® TrimBody Rating : PN 10 to 100 - ANSI Class 150 to 600Leakage : Per IEC 534-4 and ANSI/FCI 70.2, Class IV and Class VKevlar PTFE Packing and Standard Bonnet

Cl IV Cl V

1.4 2.1 2.8 3.4 4.1Travel

(mm)

Rated

Cv

Actuator

SizeCl VCl IV Cl VCl IV Cl IV Cl V Cl IV Cl V

20 3/4& &25 1

20.3

40 11/2 20.3

ValveSize

mm inch

Supply Pressure (bar)

20.350 2

38.180 3

38.1100 4

*17-4PH or A 638 Gr 660 Stem Standard

Bench Range : 3 - 15

50.8150 6

Allowable Pressure Drops for 21700 Series (bar)Air to Close, Flow to Open

Note : Inlet pressure must not exceed the ANSI rating for the selected pressure class,Various flange facings and surface finish available on request. Consult Masoneilan.

15SD CH1080 E - 11/97

21000 Series

Single Stage LO-DB ® TrimBody Rating : PN 10 to 100 - ANSI Class 150 to 600Leakage : Per IEC 534-4 and ANSI/FCI 70.2, Class IV and Class VKevlar PTFE Packing and Standard Bonnet

8 /4 6 6.9 --- 31 --- 71 30 103 1038 / 4 10 23 --- 63 22 103 89 103 10315 / 8 6 0.6 --- 11 --- 28 1.0 61 3515 / 8 10 7.4 --- 24 --- 52 26 103 8215 / 8 6 0.6 --- 11 --- 28 1.0 61 3515 / 8 10 7.4 --- 24 --- 52 26 103 82

25 10 3.2 --- 13 --- 30 9.4 63 4325 16 9.2 --- 25 4.7 52 31 103 85

75 / 48 16 2.3 --- 8.5 --- 19 6.0 39 * 26 *75 / 48 23 5.0 --- 14 1.1 29 * 16 58 * 45 *

100 10 --- --- 1.6 --- 5.2 --- 12 2.8100 16 0.7 --- 4.2 --- 9.9 0.4 21 * 12 *100 23 2.2 --- 7.2 --- 15 * 5.9 32 * 22 *63 10 --- --- 3.9 --- 10 --- 23 1063 16 2.3 --- 8.5 --- 19 6.0 39 * 26 *63 23 5.0 --- 14 1.1 29 * 16 58 * 45 *

200 / 150 16 --- --- 1.4 --- 4.2 --- 9.8 3.2200 / 150 23 0.4 --- 2.9 --- 6.9 0.3 15 8.3

Cl IV Cl V

Rated

Cv

Actuator

SizeCl VCl IV Cl VCl IV Cl IV Cl V

Valve

Size

mm inch

Travel

(mm)

Supply pressure is 0.4 bar over bench range

20 & 25 3/4 & 1 20.3

40 11/2 20.3

21 - 456 - 30 11 - 233 - 15

50 2 20.3

38.180 3

38.1100 4

*17-4PH or A 638 Gr 660 Stem Standard

*

*

Bench Range

150 6 50.8

*

Allowable Pressure Drops for 21700 Series (bar)Air to Open, Flow to Open

Note : Inlet pressure must not exceed the ANSI rating for the selected pressure class,Various flange facings and surface finish available on request. Consult Masoneilan.

16SD CH1080 E - 11/97

21000 Series

Single Stage LO-DB ®/Anti-cavitation TrimBody Rating : PN 10 to 100 - ANSI Class 150 to 600Leakage : Per IEC 534-4 and ANSI/FCI 70.2, Class IV and VKevlar PTFE Packing and Standard Bonnet

6 21 - 45 3.8 41 6 - 30 2.8 41

8 / 4 6 6 - 30 2.8 41 *10 6 - 30 2.8 69 6 - 30 2.8 6916 6 - 30 2.8 103 6 - 30 2.8 1036 21 - 45 3.8 26 21 - 45 3.8 26

10 6 - 30 2.8 44 6 - 30 2.8 40

15 / 810 21 - 45 3.8 4416 6 - 30 2.8 70 6 - 30 2.8 6416 21 - 45 3.8 7023 6 - 30 2.8 101 21 - 45 3.8 1016 21 - 45 3.8 26 21 - 45 3.8 26

10 6 - 30 2.8 44 6 - 30 2.8 40

15 / 810 21 - 45 3.8 4416 6 - 30 2.8 70 6 - 30 2.8 6416 21 - 45 3.8 7023 6 - 30 2.8 101 21 - 45 3.8 1016 21 - 45 3.8 22 - --- ---

10 21 - 45 3.8 37 6 - 30 2.8 22

2510 21 - 45 3.8 4416 6 - 30 2.8 59 6 - 30 2.8 3516 21 - 45 3.8 7023 6 - 30 2.8 85 21 - 45 3.8 10110 21 - 45 3.8 13 21 - 45 4.1 1316 6 - 30 2.8 21 ** 21 - 45 3.8 21

75 / 48 16 21 - 45 3.8 21 *23 6 - 30 2.8 30 6 - 30 2.8 1823 21 - 45 3.8 3110 6 - 30 2.8 7.3 ** 21 - 45 3.8 7.6**10 21 - 45 3.8 7.316 6 - 30 2.8 12 ** 21 - 45 3.8 12

10016 21 - 45 3.8 12 *23 6 - 30 2.8 17 ** 6 - 30 2.8 1023 21 - 45 3.8 17 * 21 - 45 3.8 1810 21 - 45 3.8 13 21 - 45 4.1 1316 6 - 30 2.8 21 ** 21 - 45 3.8 21

63 16 21 - 45 3.8 21 *23 6 - 30 2.8 30 6 - 30 2.8 1823 21 - 45 3.8 3116 6 - 30 2.8 5.8 ** 21 - 45 4.1 5.9

150 / 20016 21 - 45 3.8 5.823 6 - 30 2.8 8.3 ** 6 - 30 2.8 5.023 21 - 45 3.8 8.3 21 - 45 3.8 8.5

Rated

Cv

Actuator

Size

Valve

Size

mm inch

Travel

(mm)

20 & 25 3/4 & 1 20.3

40 11/2 20.3

Supply pressure(bar) ∆P (bar)Bench

range

20.3

38.1

80 3

100 4

Air to Open

150 6 50.8

Air to Close

Supply pressure(bar) ∆P (bar)

Benchrange

*17-4PH or A 638 Gr 660 Stem Standard** ANSI CLASS IV ONLY

50 2 20.3

Allowable Pressure Drops for 21700 Series (bar)Air to Close or Air to Open, Flow to Close

Note : Inlet pressure must not exceed the ANSI rating for the selected pressure class,Various flange facings and surface finish available on request. Consult Masoneilan.

17SD CH1080 E - 11/97

21000 Series

Double Stage Anti-cavitation TrimBody Rating : PN 10 to 100 - ANSI Class 150 to 600Leakage : Per IEC 534-4 and ANSI/FCI 70.2, Class IV and VKevlar PTFE Packing and Standard Bonnet

Rated

Cv

Actuator

Size

Valve

Size

mm inch

Travel

(mm)

20 3/4

& 25 & 120.3

40 11/2 20.3

Supply pressure(bar) ∆P (bar)Bench

range

20.3

38.1

50 2

80 3

Air to Open Air to Close

Supply pressure(bar) ∆P (bar)

Benchrange

* 17-4PH or A 638 Gr 660Stem Standard

** ANSI CLASS IV ONLY

38.1100 4

Allowable Pressure Drops for 21800 Series (bar)Air to Close or Air to Open, Flow to Close

6 3 - 15 2.1 31 ** 6 - 30 2.8 176 6 - 30 4.1 63 ** 11 - 23 2.2 296 21 - 45 4.1 41 21 - 45 3.8 58

4.5 10 3 - 15 2.1 52 ** 11 - 23 2.2 4810 6 - 30 3.8 103 21 - 45 3.8 9716 11 - 23 2.6 84 11 - 23 2.2 7716 21 - 45 3.8 1036 3 - 15 2.1 62 ** 3 - 15 1.7 196 6 - 30 3.5 103 ** 6 - 30 2.8 38

2.3 6 11 - 23 2.6 62 11 - 23 2.2 626 21 - 45 3.8 10310 6 - 30 3.1 103 - --- ---6 3 - 15 2.1 31 ** 6 - 30 2.8 176 6 - 30 4.1 63 ** 11 - 23 2.2 296 21 - 45 4.1 41 21 - 45 3.8 58

8.5 / 4.5 10 11 - 23 2.2 46 11 - 23 2.2 4810 6 - 30 4.1 103 21 - 45 3.8 9716 11 - 23 2.6 84 11 - 23 2.2 7716 21 - 45 3.8 1036 11 - 23 2.6 62 3 - 15 1.7 196 21 - 45 4.1 95 6 - 30 2.8 38

2.3 6 11 - 23 2.2 626 21 - 45 3.8 10310 11 - 23 2.6 103 - - ---6 3 - 15 2.8 20 ** 11 - 23 2.6 186 21 - 45 4.1 25 21 - 45 4.1 3510 11 - 23 2.6 34 11 - 23 2.2 29

1410 21 - 45 4.1 42 21 - 45 3.8 5916 6 - 30 3.8 103 11 - 23 2.2 4716 11 - 23 2.6 54 21 - 45 3.8 9423 - --- -- 11 - 23 2.2 6823 21 - 45 3.8 1036 6 - 30 4.1 63 ** 6 - 30 2.8 176 11 - 23 2.6 31 11 - 23 2.2 296 21 - 45 4.1 41 21 - 45 3.8 58

8.5 /4.5 10 11 - 23 2.6 52 11 - 23 2.2 4810 6 - 30 3.8 103 21 - 45 3.8 9716 11 - 23 2.6 84 11 - 23 2.2 7716 21 - 45 3.8 10310 6 - 30 4.1 28 * 11 - 23 2.6 1210 21 - 45 4.1 23

27 / 4216 3 - 15 2.8 23 ** 11 - 23 2.2 1916 6 - 30 4.1 45 ** 21 - 45 3.8 3823 6 - 30 4.1 65 11 - 23 2.2 2723 11 - 23 2.6 32 * 21 - 45 3.8 5410 21 - 45 4.1 13 21 - 45 4.1 1916 11 - 23 2.6 19 11 - 23 2.6 15

40 16 21 - 45 4.1 3023 6 - 30 4.1 55 11 - 23 2.6 21 *23 11 - 23 2.6 27 * 21 - 45 4.1 43 *10 21 - 45 4.1 8.5 21 - 45 4.1 1216 11 - 23 2.6 12 11 - 23 2.6 9.5

62 16 21 - 45 4.1 1923 11 - 23 2.6 17 * 11 - 23 2.6 14 *23 21 - 45 4.1 19 * 21 - 45 4.1 27 *

Note : Inlet pressure must not exceed the ANSI rating for the selected pressure class,Various flange facings and surface finish available on request. Consult Masoneilan.

18SD CH1080 E - 11/97

21000 Series

Double Stage LO-DB ® TrimBody Rating : PN 10 to 100 - ANSI Class 150 to 600Leakage : Per IEC 534-4 and ANSI/FCI 70.2, Class IV and VKevlar PTFE Packing and Standard Bonnet

6 11-23 1.9 47 26 3 - 15 2.1 69 62

5.7 / 3.56 21 - 45 3.4 98 98 3 - 15 2.8 102 10210 11-23 1.9 81 81 - - - -10 21 - 45 3.4 103 1036 11-23 1.9 23 - 3 - 15 2.8 59 486 21 - 45 3.4 49 35 3 - 15 3.4 83 826 3 - 15 4.1 103 * 103 *

13 / 7 10 11-23 1.9 41 23 3 - 15 2.8 100 10010 21 - 45 3.4 83 8216 11-23 1.9 66 58 - - - -16 21 - 45 3.4 103 * 103 *6 11-23 1.9 23 - 3 - 15 2.8 59 486 21 - 45 3.4 49 35 3 - 15 3.4 83 826 3 - 15 4.1 103 * 103 *

13 10 11-23 1.9 41 23 3 - 15 2.8 100 10010 21 - 45 3.4 83 8216 11-23 1.9 66 58 - - - -16 21 - 45 3.4 103 * 103 *6 11-23 1.9 14 - 3 - 15 3.4 53 436 21 - 45 3.4 31 15 3 - 15 4.1 69 * 63 *10 11-23 1.9 26 7.7 3 - 15 2.8 64 56

2110 21 - 45 3.4 53 43 3 - 15 4.1 103 * 103 *16 11-23 1.9 42 29 3 - 15 2.8 103 * 103 *16 21 - 45 3.4 86 * 85 * - - - -23 11-23 1.9 61 * 53 * - - - -23 21 - 45 3.4 103 * 103 *10 11-23 1.9 9.5 - 3 - 15 2.8 27 1510 21 - 45 3.4 22 10 3 - 15 4.1 48 * 41 *

40 / 6316 11-23 1.9 18 5.0 3 - 15 2.8 43 35 *16 21 - 45 3.4 36 * 26 * - - - -23 11-23 1.9 26 * 14 * - - - -23 21 - 45 3.4 52 * 45 *10 - - - - 3 - 15 2.8 14 5.716 11-23 1.9 9.0 - 3 - 15 4.1 25 * 20 *

83 16 21 - 45 3.4 18 * 12 * 3 - 15 2.8 22 * 17 *23 11-23 1.9 13 * 5.1 * - - - -23 21 - 45 3.4 27 * 22 *10 11-23 1.9 8.6 - 3 - 15 2.8 21 1510 21 - 45 3.4 18 10 3 - 15 3.4 30 * 28 *10 3 - 15 4.1 38 * 38 *

53 16 11-23 1.9 14 5.0 3 - 15 2.8 34 * 34 *16 21 - 45 3.4 29 * 26 * - - - -23 11-23 1.9 20 * 14 * - - - -23 21 - 45 3.4 41 * 41 *16 11-23 1.9 3.9 - 3 - 15 4.1 23 * 17 *

12516 21 - 45 3.4 9.8 3.223 11-23 1.9 6.5 - 3 - 15 2.8 18 * 12 *23 21 - 45 3.4 15 8.3 3 - 15 4.1 32 * 28 *

Rated

Cv

Actuator

Size

Valve

Size

mm inch

Travel

(mm)

20 3/4

& 25 & 120.3

40 11/2 20.3

Supply pressure(bar)

∆P (bar)Cl IV Cl V

Benchrange

20.3

38.1

50 2

80 3

Air to Open Air to Close

Supply pressure(bar)

∆P (bar)Cl IV Cl V

Benchrange

*17-4PH or A 638 Gr 660 Stem Standard

38.1100 4

50.8150 6

Allowable Pressure Drops for 21900 Series (bar)Air to Close or Air to Open, Flow to Close

Note : Inlet pressure must not exceed the ANSI rating for the selected pressure class,Various flange facings and surface finish available on request. Consult Masoneilan.

19SD CH1080 E - 11/97

21000 Series

20 & 25 3/4 & 1 51 51 140 353

40 11/2 64 64 140 353

50 2 76 76 140 353

80 3 94 94 203 390

100 4 117 140 205 404

150 6 150 187 284 520

Extension BonnetsC

ValveSize

mm inch

PN < 63ANSI Class

150-300

PN 63, 100ANSI Class

600PN 10 to 100

ANSI Class 150 to 600

Standard Bonnet

B

PN 10 to 100ANSI Class 150 to 600

20 3/4 206 184 - 194 206 206 206 184 - 194 206 206 206

25 1 206 184 197 197 210 210 210 184 197 197 210 210 210

40 11/2 251 222 235 235 248 251 251 222 235 235 248 251 251

50 2 286 254 267 267 282 286 289 254 267 267 282 286 289

80 3 337 298 311 318 333 337 340 298 311 318 333 337 340

100 4 394 352 365 368 369 394 397 352 365 368 369 394 397

150 6 508 451 - 473 489 508 511 451 - 473 489 508 511

ANSI Class 150 through 600 and equivalent PN

Valve

Size

mm inch

ANSI Class 150and equivalent PN

RTJ RTJ

A

RF

C

B

A A

C

StandardButt, Socket Weldor Threaded Ends

RF

ANSI Class150 - 600

and equivalent PN

BW, SW& THD

RF

ExtensionBonnet

ANSI Class 300and equivalent PN

ANSI Class 600and equivalent PN

PN 10 PN 16, 25and 40

PN 63and 100

RTJ RTJRF RF RF RTJRTJ

Dimensions (mm)

Note : Inlet pressure must not exceed the ANSI rating for the selected pressure class,Various flange facings and surface finish available on request. Consult Masoneilan.

20SD CH1080 E - 11/97

21000 Series

Shown with optional handwheel

Model 87/88 Actuator

Actuator removal clearance = 150 mm

Actuator Size D E F G

6 292 395 254 229

10 368 497 277 305

16 476 717 330 457

23 549 780 381 457

D

G

F

E

Dimensions (mm)

21SD CH1080 E - 11/97

21000 Series

Valve Up to PN 40 Up to PN 40 Up to PN 100 Up to PN 100Size ANSI Class 150, 300 ANSI Class 150, 300 ANSI Class 600 ANSI Class 600

FLG BW, SW FLG BW, SWmm inch & THD & THD

20 3/4 16 12 17 12

25 1 16 12 17 12

40 11/2 22 16 24 16

50 2 26 20 29 20

80 3 57 33 58 45

100 4 89 55 98 61

150 6 161 108 204 123

Actuator Weights (kg) Body/Actuator Cubage (dm 3)

Valve PN 10 to 100mm inch ANSI Class 150 to 600

20 3/4 28325 1 28340 11/2 28350 2 28380 3 623100 4 623150 6 623

ActuarorSize

6 20 27

10 38 48

16 95 111

23 120 154

with HandwheelStandard

Body S/A Weights (kg)

22SD CH1080 E - 11/97

21000 Series

Side Mounted HandwheelsFor 87/88 Actuators (See Specification Data CR8788 E)

Solenoid Valves

Other Limit Switches

4700 P Series Pneumatic PositionerInstrument signals 0.2-1 and 0.4-2 bar

3-15 and 6-30 psig

7000 Electropneumatic (I/P) TransducerInput range 4-20 mA

Split rangeOutput 0.2-1 bar, adjustable

0.4-2 bar, adjustable3-15 psi, adjustable6-30 psi, adjustable

(See TS-Model 7000)

Smart Valve Interface (SVI®)Smart Positioner and Smart Valve ProcessControllerInput range 4-20 mA

Split rangeHART Communication (See Brochure BW1000 E)

ValVue SoftwareCalibration, Configuration, Diagnostic, and Opera-tor Interface Tool (See Brochure BW1000 E)

2700 Controllers (See Bulletin 213 E)

4700 E Series Electropneumatic Positioners8012 and 8013 Series Electropneumatic PositionersInput range 4-20 mA

Split range

77-4 or 77-40 Airset(See Bulletin 78 E)

80-4 or 80-40 Airset77-6 or 77-60 Lockup Valve2'' Gauge 0-2 bar

496 Rotary Electric Switches496-1 (1-Switch SPDT)496-2 (2-Switches SPDT)496-3 (Potentiometer Position Transmitter)496-6 (1-Switch DPDT)496)-7 (2-Switches DPDT)496-8 Opto-Electronic Position Transmitter

(See Specification Data CS7050 E)

Accessories

For additional Accessories and Options,consult Masoneilan

Extension BonnetsEnvironmental Capabilities (LE Packing)Lubricator & Isolation ValveOther Flange FacingsLimit StopsBody Drain PlugReducer and Nipple ConnectionsNACE ComplianceCustom Trim MaterialsU.O.P. Trim MaterialsOther MaterialsNon-Destructive ExaminationOxygen CleaningElectric Actuators

Options