T Pearce CV PIPNG MANAGER ENGINEER 2015

-

Upload

terry-pearce -

Category

Documents

-

view

199 -

download

5

Transcript of T Pearce CV PIPNG MANAGER ENGINEER 2015

Terence A Pearce

Piping Manager / Engineer

317/4 M.Nongdon

Saraburi

18190

Resume 2015

Off Shore - Super Complex Layout Topsides Layout & Design MOC _ Management Of Change OFFSHORE Installations Construction Management Commissioning Mangement FPSO - Layout / Design Hook –Up Methodology Turnover Management CMT (Completions Management

Tool) Fabrication / Welding Client Specifications- BP-Total –

Shell-ADMA

Design Optimization Group Management Group Training & Development Man power Recruitment EDMS Management HSE Awareness & Promotion QA/QC Management PDS/PDMS 3D Management Performance Appraisals Cost Reduction Techniques VE – Value Engineering

002-000-CPF-016 (007848) HRF-0033 Corporate Base Page 1

Rev 5 (18-Feb-08)

Nationality : British Passport No : 761 282 142

Birth date: : 08/05/1955 Salary Current: : £ 180 k ( pa net) – (280k USD)

22k p/month

Salary Required: : Same OR more

Email: [email protected] [email protected]

Language : English / French Tel No. +971 50 661 4731 mobile

+ 971 2 677 9310

Availability : Immediate Education: HND – Mechanical Engineering

Terence A Pearce

Piping Manager / Engineer

317/4 M.Nongdon

Saraburi

18190

Resume 2015

SUMMARY40 Years experienced Piping/Pipelines Engineer/Manager with excellent communication and manage-ment skills, Delivers results through personal contribution and team, uses personal power to motivate, guide and influence others. Demonstrates willingness and ability to focus on the delivery of results and respond accordingly to needs in order to provide the best quality service to our customers. Develops others to achieve individual and organizational potential, managing self and immediate team to deliver results.

Plan, Schedule, Resource, Cost & manage project Engineering deliverables. Direct effort to acquire and retain resources thru out, Working for either the client on the PMT Team or the EPCM Contractor Han-dling Multi Nationality Task forces and Work share Procedures. Provide key managerial and adminis-trative support for Piping Department and assist in activities related to manpower resources, organiza-tion development

Ensure compliance with all laws, Safety, international regulations and client requirements applicable to the assigned location, and contract Set standards goals, and formulates, produce and implement com-pany policies and procedures. Demonstrates willingness and ability to focus on the delivery of results and respond according to needs in order to provide the best quality service to our customers

Management of Piping department, From Concept, FEED, to Detail design, Layout, and construction to final Turnover activities. Provide leadership and boost morale in the Piping Team members (direct re-ports). Identify strengths and weaknesses of Piping members, Take measures for maintaining quality of engineering, completion of projects within the budgeted man-hours and cost, adhering to project schedule Liaison and interface with EPCM contractors. Attend all Risk Assessment Reviews & Analysis Including HAZOP, HAZID, and ALARP.

Predominantly engaged in the Oil & Gas/Petrochemical-Power Generation, and Off Shore Industry, 10 yrs. Experience in Top Sides Layout & design, 25 years in construction, Engaged in multi-Billion dol-lar green and brown field works thru out, Africa, Namibia, Zimbabwe, South East Asia Uzbekistan, Yemen, Egypt, Korea, Japan, The Middle East, India, China, Singapore, Malaysia, Norway, Germany, France, Belgium, Czech Republic, Thailand & Australia.

Projects Include: Umm Lulu Supa Complex, FPSO, LNG, CTL, SRU, Petrochemical, Hydro - Cracker, Marine, Offshore, Phosphate Plants, Gas Injection, De-Gassing Stations, Gas-Pipelines, Oil & Gas Gath-ering Systems.Offshore Installations in compliance with DNV-OS-B101 Materials,DNV-OS-C401 Fabrication & Testing Requirements,NV-OS-D101 Marine Systems. DNV-OSS-101 Rules for Classification of Offshore Drilling and Support Units

DNV OSS-102 Rules for Classification of Floating Production, Storage and Loading Units

DNV-OSS-103 Rules for Classification of LNG/LPG Floating Production and Storage Units or Installa-tions,DNV-OSS-202 Verification for Compliance with UK Shelf Regulations (North Sea) DNV-OS-A101 Safety Principles and Arrangements,DNV-OS-F101 Submarine Pipeline Systems.

002-000-CPF-016 (007848) HRF-0033 Corporate Base Page 2

Rev 5 (18-Feb-08)

Terence A Pearce

Piping Manager / Engineer

317/4 M.Nongdon

Saraburi

18190

Resume 2015

DNV-RP-D101 Structural Analysis of Piping SystemsDNV-RP-D102 Failure Mode and Effect Analysis (FMEA) of Redundant Systems

WORK HISTORY:

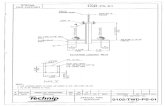

2013-2015 – Lead Piping Engineer ADMA/NPCC – CLIENT - Amec International – Abu Dhabi (6 +bill)

IPMT Team Umm Lulu Project - Off Shore - Supa Complex.

• Off Shore Complex - Comprising of: Accommodation Platform (ULAP).

• Utilities Platform (ULUTP).

• Separation Platform (ULSP).

• Riser Platform (ULRP Topside only).

• Gas Treatment Platform (ULGTP).

• Water Disposal Platform (ULWDP).

• Bridge Support S 1.to 4

• Flare Platforms 1 (ULFL 1).& 2

Responsibilities:

EPCM – Technip / NPCC Teams – Supervision , Guidence, Mentor, Control.

Full Field development of offshore facilities. All platforms

Ensure ALL EPC deliverables are in compliance to client specs

Ensure constructability/install ability of designs and procedures.

Initiating Concept ideas, Into FEED and Detailed design.

002-000-CPF-016 (007848) HRF-0033 Corporate Base Page 3

Rev 5 (18-Feb-08)

Terence A Pearce

Piping Manager / Engineer

317/4 M.Nongdon

Saraburi

18190

Resume 2015

Lay out Optimization implementation and checking

Verify Wall Thickness Calcs

Approve Project Piping Specifications

Launcher / Receiver Layout

Check CTR,s Man hours

Review MTO and long lead items

Flare System Layout - Knock out drum

Close out engineering technical documentation

Review and approve all contractors documentation

Close out all Feed docs to proceed with detail design

Perform 3D PDS client model reviews

2013 - Piping Design Manager SBM Offshore , KL Malaysia

Design and construct FPSO,s From concept to completion

Responsibilities:

Managing The Piping Design Team approx. 95 personnel, Establish performance criteria, agree performance objectives with Piping Team and de-

velop competency of Team members. Set performance benchmarks, KPIs and conduct regular performance appraisals, mentor and guide piping team.

Conduct regular technical interviews for potential new hires.

Establish goals and objectives for engineering operations and make operational decisions

Identify strengths and weaknesses of Piping Team members and recommend training and development intervention, planning and career opportunities

Understand clients' needs; independently evaluate, organize and prioritize work for self

002-000-CPF-016 (007848) HRF-0033 Corporate Base Page 4

Rev 5 (18-Feb-08)

Terence A Pearce

Piping Manager / Engineer

317/4 M.Nongdon

Saraburi

18190

Resume 2015

and others

Facilitate and co-ordinate manpower recruitment process in collaboration with HR. Organize internal quality audits/peer reviews for monitoring quality and ensure timely

close-out of actions. Provide advice and guidance to engineers and designers on important technical issues as

well as on managerial matters. Provides necessary guidance on manpower planning and takes responsibility for recruit-

ment and performance management of his/her team.

2012 Lead Piping Engineer - PMT Client - Q8 - Refinery Project Holland – (1Bill USD)

Green & Brownfield’s Works RE-investment into existing facilities,

New Hydrocracker and facilities.

Responsibilities:

Team of 50 personel

Ensure ALL deliverables are in compliance to Shell DEP,s

Ensure constructability/install ability of designs and procedures.

Initiating Concept ideas, Into FEED and Detailed design.

Verify Wall Thickness Calcs

Approve Project Piping Specifications

Launcher / Receiver Layout

Check CTR,s Man hours

002-000-CPF-016 (007848) HRF-0033 Corporate Base Page 5

Rev 5 (18-Feb-08)

Terence A Pearce

Piping Manager / Engineer

317/4 M.Nongdon

Saraburi

18190

Resume 2015

Review MTO and long lead items

Flare System Layout - Knock out drum

Close out engineering technical documentation

Review and approve all contractors documentation

Close out all Feed docs to proceed with detail design

Perform 3D PDS client model reviews

2011-12 Department Technical Authority - WorleyParsons, London Office

Rumaila Project – Iraq. – (8 Bill USD)

Green & Brownfield’s Works RE-investment into existing facilities, ie: flow /trunk lines, gathering systems, Cluster pump stations, Degassing stations, design and build New De-Gassing facilities, and pumping stations.

Responsibilities:

Ensure BP ETP,s & Standards are adhered to.

Act as Focal point for client , EPCM for all project interfaces, delegating where appropriate

Ensure all QA/QC BP practices are followed

Oversee and direct key areas of discipline engineering, including design codes, legislative re-quirements and current good engineering practice.

Optimise Oil Gathering System Layouts

Sign and issue technical documentation as approver, accepting personal responsibility for its adequacy

Water injection field layout

WT calculations

Interface with discipline leads and / or group leads to ensure deliverable schedule is being met and budget is on track.

002-000-CPF-016 (007848) HRF-0033 Corporate Base Page 6

Rev 5 (18-Feb-08)

Terence A Pearce

Piping Manager / Engineer

317/4 M.Nongdon

Saraburi

18190

Resume 2015

Ensure constructability/install ability of designs and procedures.

Initiating Concept ideas, Into FEED and Detailed design.

Ensuring all QA/QC procedures are applied and worked to.

De Gassing Station facilities design

Cluster pumping station design - layout

Well pad - Trunk & Flow line design

Verify Wall Thickness Calcs

Approve Project Piping Specifications

Launcher / Receiver Layout

Check CTR,s Man hours

Review MTO and long lead items

Flare System Layout - Knock out drum

Monitoring the Technical Assurance of the Engineering and Design services and deliverables incl Stress Group Management (Caesar II)

Design of Onshore production facilities (well sites, flow lines, gathering lines, metering sta-tions, central field manifolds etc.)

Reviewed and approved as necessary Site prepared Contractor’s engineering requisitions, doc-uments and drawings.

Participated in overall Project design, risk and construction reviews.

Attend Site Surveys, Field trips. Check construction As Built to EPC design documents

Contribute to CLIENT's continuous improvement in HSE performance by ensuring safety and environmental standards are followed within the workplace by providing ongoing training to all staff and ensuring the appropriate control mechanisms, procedures and processes are followed in accordance with the Operational Excellence System.

002-000-CPF-016 (007848) HRF-0033 Corporate Base Page 7

Rev 5 (18-Feb-08)

Terence A Pearce

Piping Manager / Engineer

317/4 M.Nongdon

Saraburi

18190

Resume 2015

2010 –2011 Lead Mech-Piping Engineer, TG Engineering - OMV, Sana’a Yemen,

Block S_2 Well Development. Field Gathering Systems. Approx. – 56 wells – ( 1 Bill USD)

Responsibilities:

Team of 20 engineers

Optimise Gathering System Layouts

Control, supervise Mech-Piping group

Responsible for all Mech/Piping Discipline.

Development of discipline engineering specifications.

Responsible for all Project QA Implementation

Review MTO and long lead items

Monitoring the Technical Assurance of the Engineering and Design services and deliverables incl Stress Group Management (Caesar II)

Design of Onshore production facilities (well sites, flowlines, gathering lines, metering stations, central field manifolds etc.)

Provided engineering support at Site including review / approval of Material Approval Requests Provided Piping engineering support as team member of the Project Management Consultant (PMC) during the detailed design and construction phases of the project.

2009- 200 Lead Piping Engineer, PMC Team ILF CONSULTING ENGI-NEERS, ( 1.5 Bill )

UZBEKISTAN ASIA TRANS GAS.-- China Petroleum Engineering Construction Com-

002-000-CPF-016 (007848) HRF-0033 Corporate Base Page 8

Rev 5 (18-Feb-08)

Terence A Pearce

Piping Manager / Engineer

317/4 M.Nongdon

Saraburi

18190

Resume 2015

pany.

ASIA TRANS GAS PIPE LINE PROJECT & GAS COMPRESSION STATIONS:

Responsibilities:

Working to GOST 17380-2001,SNIP,ROK, ISO 3419-81, Russian Industry standards.BNAR.Building Norms and Regulations,II-45-75

Liaise and coordination with Chinese Design Institute, CPECC, CPPE, for FEED and Detail design documents.

Audit Caesar 2 Stress Analysis’s Review. Project requirements.Provided piping engineering support as team member of the Project Management Consultant (PMC) during the detailed design and con-struction phases of the Asia Trans Gas Pip Line project.

Reviewed Piping deliverables and methods for compliance with safety, environmental and engineer-ing requirements.

Provided engineering support at Site including review / approval of Material Approval Requests Provided Piping engineering support as team member of the Project Management Consultant (PMC) during the detailed design and construction phases of the project.

Reviewed and approved as necessary Site prepared Contractor’s engineering requisitions, docu-ments and drawings.

Participated in overall Project design, risk and construction reviews.

Audit of “As-Built” Piping documents to ensure all comments made during the construction have been incorporated.

Attend Site Surveys, Field trips. Check construction As Built to EPC design documents

Close out engineering technical documentation

Provide discipline engineering services as part of a team providing engineering, design services to support Existing Field Facilities Program. This includes responsibility for work on a wide variety of facilities including:

• Coordination and review of off-site discipline engineering work performed by engineering service contractors.

• Specification and supervision of site survey work.002-000-CPF-016 (007848) HRF-0033 Corporate Base Page 9

Rev 5 (18-Feb-08)

Terence A Pearce

Piping Manager / Engineer

317/4 M.Nongdon

Saraburi

18190

Resume 2015

• Production of discipline engineering of new (and modifications to existing) Oil & Gas produc-tion facilities, and production of “Approved for Construction” work packages under the guidance of Lead Discipline Engineers and Discipline Designers.

• Specification and order documentation for purchasing materials and equipment. Can include coordination activities with vendors/suppliers. For Mechanical Discipline this will include piping bulks, static / rotating equipment and packaged units.

2008-2009 Department Manager Piping / Pipelines , WorleyParsons, Egypt Cairo Office

Multi Projects-Ramadan-6 –(4 Offshore Platforms)/ North Shadwan / Akik Eng / ELNG – WHRU / Petro Alam / ( 2 Bill USD)

Responsibilities:

Department of 70 personnel

PDS Training of locals

PDS Project Set Up

Prepare CTR,s

Prepare SOW

Prepare all training material

Prepare and issue design office proced-ures

Man hr estimates

Interview candidates

Chair weekly meeting

Peer appraisals review

Perform Design office audits

Oversee development, communication, implementation and maintenance of En-gineering group

Top Sides Layout & Design

Act as Focal point for client on project interfaces, delegating where appropri-ate

Establish goals and objectives for engi-neering operations and make opera-tional decisions

Understand clients' needs; indepen-dently evaluate, organise and prioritise work for self and others

002-000-CPF-016 (007848) HRF-0033 Corporate Base Page 10

Rev 5 (18-Feb-08)

Terence A Pearce

Piping Manager / Engineer

317/4 M.Nongdon

Saraburi

18190

Resume 2015

Responsible for all Mech/Piping Disci-pline.

Development of discipline engineering specifications.

FPSO Top Sides Focal Point for Piping engineering with other companies and industry bodies

Responsible for all Project QA Imple-mentation

Review MTO and long lead items

Identify any deviation from the Project Basis of Requirements and reporting these to the

Engineering-Project Manager.

PDS 3D Model layout supervision and review of all modules on FPSO includ-ing interfaces.

Review Lay out

Model review set up

Responsible for development of Engin-eering Management Systems and Pro-cesses for the office in line with corpor-ate requirements

Co-ordinate and implement all PDS 3D Works

Monitoring the Technical Assurance of the Engineering and Design services and deliverables incl Stress Group Man-agement (Caesar II)

Assist with identification and prepara-tion of training and career development requirements of staff

2007- 2008

Lead Piping Engineer, PMT WorleyParsons, Saudi Arabia. ( 5 Bill USD)

Maaden Phosphate Project Al-Khobar-Grass Roots Chemical production facilities;

Sulphuric, Phosphoric Acid Plant, Ammonia Plant. DAP (di–ammonium phosphate) Plant.

Responsibilities:

Co-ordinate and control all piping activities.

Assess scope of work, priorities, and man hours,

Review piping specifications

Review, approve Sub Contractor plot plans, lay outs.002-000-CPF-016 (007848) HRF-0033 Corporate Base Page 11

Rev 5 (18-Feb-08)

Terence A Pearce

Piping Manager / Engineer

317/4 M.Nongdon

Saraburi

18190

Resume 2015

Prepare hydro test procedure

Close out engineering technical documentation

Review and approve all contractors documentation

Close out all Feed docs to proceed with detail design

Perform 3D PDS client model reviews

Piping specifications review

FRP Vendor expediting

Instruct contractor of project responsibilities

Represent the discipline on the project for client resolve technical questions as required to coordi-nate work.

Answer all incoming TQ, s, RFI, s, NCR, s, on be half of client.

Control and monitor progress of piping installation, through construction phase to completion.

Answer all technical memorandums from contractor

2007-2006

Lead Piping Engineer , EPCM Fluor Daniel, Holland ( 3 Bill USD)

Multi Projects Group.- Hurcules & Miro site trips

Responsibilities:

Co-ordinate and control piping activities. For multi projects

Prepare and Update Man Hr estimates

Write up Scope of works

Write up Scope of facilities

Prepare PA M.

Prepare Isometric schedule

Prepare Piping design job book002-000-CPF-016 (007848) HRF-0033 Corporate Base Page 12

Rev 5 (18-Feb-08)

Terence A Pearce

Piping Manager / Engineer

317/4 M.Nongdon

Saraburi

18190

Resume 2015

Ensure the efficient usage of resource’s

Site visits to prepare FEED Documents

Control materials group

Control Stress group

Set up Work share procedures

Chair and present client model review meetings

Attend internal meetings. Liaise with client/lead engineers daily, control of personnel and duties.

Work Share Co-ordination.

Supervise and provide technical knowledge to checkers, designers ,drafters. and area leads

Provide technical direction and assign work to subordinate engineers, designers, drafters, and oth-ers who assist in performing specific assignments.

Ensure all work is performed and checked effectively, records kept before issue.

Control, monitor and progress the piping design group.

Prepare isometric control sheet. isometric flow procedure

Monitor and control Checker daily progress and performance.

Plan and produce all piping deliverables according to schedule

Ensure sufficient recourses available utilizing local labour

Piping group Approx 70 personnel under my control

2005 –-2006

Lead Piping Engineer, ( EPCM ) Foster Wheeler Energy Limited, Saudi Ara - bia & India

SHARQ 3RD Expansion Ethylene Plant Site based- ( 6 Bill USD)

Responsibilities:

Co-ordinate and control all piping activities.

Prepare and Update MPP schedule

002-000-CPF-016 (007848) HRF-0033 Corporate Base Page 13

Rev 5 (18-Feb-08)

Terence A Pearce

Piping Manager / Engineer

317/4 M.Nongdon

Saraburi

18190

Resume 2015

Prioritise deliverables according to schedule

Prepare Isometric schedule

Assess scope of work, priorities, and man hours,

Ensure the efficient usage of resource’s

Maintain isometric control, and issue AFC Documents

Attend internal meetings. Liaise with client/lead engineers daily, control of personnel and duties.

Control and reply to all incoming transmittals

up date iso register, monitor checking activities,

Supervise and provide technical knowledge to checkers, designers and drafters. and area leads

Provide technical direction and assign work to subordinate engineers, designers, drafters, and oth-ers who assist in performing specific assignments.

Ensure all work is performed and checked effectively, records kept before issue.

Control, monitor and progress the piping design group.

Prepare isometric control sheet. isometric flow procedure

Monitor and control Checker daily progress and performance.

Plan and produce all piping deliverables according to schedule

Ensure sufficient recourses available utilizing local labor

Piping group Approx 70 personnel under my control

Control and monitor progress of piping installation, through construction phase to completion.

Answer all technical memorandums from contractor

Co-ordinate /Oversee all piping construction work to meet objectives of the project,

Represent the discipline on the project and with the client resolve technical questions as required to coordinate work.

Review and approve all contractors documentation

Prepare AS BUILT isometrics

002-000-CPF-016 (007848) HRF-0033 Corporate Base Page 14

Rev 5 (18-Feb-08)

Terence A Pearce

Piping Manager / Engineer

317/4 M.Nongdon

Saraburi

18190

Resume 2015

Prepare compile All Test Packs, and work packs

2004-2005

Lead Piping Engineer - Commissioning ( PMT ) Qatar Petroleum, Qatar – Site & Office.

Ethylene Expansion Project - LNG Plant Site ( 5 Bill USD)

Responsibilities:

Co-ordinate /Oversee all piping technical and construction obligations are met by contractor. and work meets with objectives and schedules of the project,

Oversea All Commissioning activities

Instruct contractor of project responsibilities

Close out engineering technical documentation

Represent the discipline on the project for client resolve technical questions as required to coordi-nate work.

Answer all incoming TQ, s, RFI, s, NCR, s, on be half of client.

Control and monitor progress of piping installation, through construction phase to completion.

Answer all technical memorandums from contractor

Review and approve all contractors documentation

Close out all Feed docs to proceed with detail design

2002-2004

Lead Piping Engineer – Commissioning , ( EPCM ) United KG Aus - tralia – Site & Office.

Caltex Clean Fuels Expansion Project - Site ( 4 Bill USD)

002-000-CPF-016 (007848) HRF-0033 Corporate Base Page 15

Rev 5 (18-Feb-08)

Terence A Pearce

Piping Manager / Engineer

317/4 M.Nongdon

Saraburi

18190

Resume 2015

RESPONSIBILITIES:

Team of 60+ personnel

Co-ordinate /Oversee all piping construction work to meet objectives of the project,

Represent the discipline on the project and with the client resolve technical questions as required to coordinate work.

Responsible for All Pre – Commissioning activities

Answer all incoming TQ, s, RFI, s, NCR, s, on be half of PC contractor UKG.

Over see, and manage all welding QA/QC.NDE

Set up All welding documentation, and weld maps.

Control and monitor all FW data .

Control and monitor progress of piping installation, through construction phase to completion.

Prepare AS BUILT isometrics

Monitor and control daily progress and performance of punching activities.

Comply with all the requirements of OSHA act. Ensure steps are taken to meet applicable codes, standards. and specifications.

Check all hand over docs to client.

Prepare compile All Test Packs, and work packs ,

Ensure all data is correct and entered in to test packs,

Prepare All relevant procedures

Prepare and control all Hydro test activities

Ensure all documentation sign off by UKG/client.

Provide Technical direction and guidance to supervisors and engineers assign work to subordinate en-gineers,

Control and supervise All Punch List activities, By field engineers.

002-000-CPF-016 (007848) HRF-0033 Corporate Base Page 16

Rev 5 (18-Feb-08)

Terence A Pearce

Piping Manager / Engineer

317/4 M.Nongdon

Saraburi

18190

Resume 2015

2001-2002

Lead Piping Engineer, ( EPCM) Worley International, Thailand Bangkok Office.

Multi- Projects FPSO - OFF SHORE PLAT FORMS,Brown fields mods,hook ups.

Responsibilities:

Co-ordinate all checker activities.

Access scope of work, priorities, man hours,

Maintain isometric control,

Attend internal meetings. Liaise with client/lead area eng daily, control of personnel and duties.

up date iso register, monitor checking activities,

Supervise and provide technical knowledge to checkers, designers and drafters.

Provide technical direction and assign work to subordinate engineers, designers, drafters, and oth-ers who assist in performing specific assignments.

Ensure all work is checked effectively and records kept before issue.

Control, monitor and progress the piping design checking group.

Prepare isometric control sheet. isometric flow procedure

Monitor and control Checker daily progress and performance.

Report to senior management on checking group performance and progress.

Ensure effective operation, communication and co-operation between leads, Designers and group.

Worley International, Kuala Lumpar Office

Supervise and provide technical knowledge to checkers, designers and drafters.

Optimize piping layout

Review all area studies

Issue optimized pipe routing to stress

002-000-CPF-016 (007848) HRF-0033 Corporate Base Page 17

Rev 5 (18-Feb-08)

Terence A Pearce

Piping Manager / Engineer

317/4 M.Nongdon

Saraburi

18190

Resume 2015

Prepare isometric control sheet. isometric flow procedure

Monitor and control Checker daily progress and performance.

Ensure all work is checked effectively and records kept before issue.

Provide technical direction and assign work to subordinate engineers, designers, drafters, and oth-ers who assist in performing specific assignments.

2000-2001

Lead Piping Engineer (PMT) Bechtel, China . ( 7 Bill USD)

Nanhai Petrochemical Project - Site

Responsibilities:

Co-ordinate /Oversee all PDS, and piping design work to meet objectives of the project,

Represent the discipline on the project and with the client to resolve technical questions and as re-quired to coordinate work.

Answer all incoming TQ, s, RFI, s, NCR, s, on be half of PMC (Shell) refer all Shell DEP, s SP, s etc,

Training of locals, attend Contractor, client meetings.

Organise and manage the technical workload of the piping department.

Supervise and provide technical direction to engineers, designers and drafters. And others who as-sist in performing specific assignments.

Control, monitor and progress the piping design deliverables including Equipment layouts, piping general arrangements, piping isometrics’, and supports.

Review documents against contract scope; advise on resources required for workload.

Apply good interpersonal skills between EPC and PMC interfaces.

Prepare technical scope of MR, data sheets, drgs, and standards.

Perform work using Bechtel Standard Application Programs (BSAPs) EDMS, CMT, and appropriate 2-D and 3-D computer aided design and PDS (CAD) tools.

Demonstrate due diligence in managing hazards associated with design. 002-000-CPF-016 (007848) HRF-0033 Corporate Base Page 18

Rev 5 (18-Feb-08)

Terence A Pearce

Piping Manager / Engineer

317/4 M.Nongdon

Saraburi

18190

Resume 2015

Comply with all the requirements of OSHA act. Ensure steps are taken to meet applicable codes, standards. and specifications.

Preparation of checking, fabrication, and testing procedures.

Ensure all work is checked effectively and records kept before issue.

1999-2000

Field Piping Engineer, ( EPCM) KJV Australia – Site

Wood side Project- LNG Train ( 5 Bill USD)

Responsibilities:

Co-ordinate all site work activities,

site measure,

Compile site sketches

Mark up isometrics, and P&ID.

PDS design- review (Smart plant) training of locals,

Punch line activities.

Compile test packs

Supervise and provide technical direction to engineers, designers and drafters.

Review documents against contract scope; advise on resources required for workload

Comply with all the requirements of OSHA act. Ensure steps are taken to meet applicable codes, standards. and specifications.

Comply with all safety rules on site

The natural gas fed into the LNG plant will be treated to remove water, hydrogen sulfide, dioxide, ethane, propane, butane and some heavier alkanes.

002-000-CPF-016 (007848) HRF-0033 Corporate Base Page 19

Rev 5 (18-Feb-08)

Terence A Pearce

Piping Manager / Engineer

317/4 M.Nongdon

Saraburi

18190

Resume 2015

1997-99 Lead Piping Engineer, ( EPCM) Technip Paris/ Abu Dhabi

Saroosh - Naroosh Project 7 Offshore Platforms, brown fields, hook ups.

Responsibilities:

Co-ordinate /Oversee all PDS, and piping design work to meet objectives of the project,SPP-1

Organize and manage the technical workload of the piping department for topsides

Control, monitor and progress the piping design deliverables including Equipment layouts, piping general arrangements, piping isometrics, and supports.

Equipment vendor co-coordinator.

Topsides equipment lay out and detailed piping design.

Control, monitor Back draughting squad (20 off )

Supervise and provide technical direction to checkers, , designers and drafters.

Attends internal meetings. Liaise with client/lead area eng daily, control of personnel and duties.

Monitor and control all vendor documentation

Distribute all vendor docs to leads

Ensure all work is checked effectively and records kept before issue.

Layout of CPP and well heads with all cluster assemblies.

Preparation of plot plans.

Plant Layout and detailed piping.

Piping studies, general arrangements

Preparation of stress sketches.

Extraction of isometrics.

Checking of layouts.

002-000-CPF-016 (007848) HRF-0033 Corporate Base Page 20

Rev 5 (18-Feb-08)

Terence A Pearce

Piping Manager / Engineer

317/4 M.Nongdon

Saraburi

18190

Resume 2015

96-97 Lead Piping Checker, ( EPCM) MGJV Australia – Office

MGJV Magnesium Project

Responsibilities:

Co-ordinate all P.D.S. Checker activities.15 off

Access scope of work, priorities, man hours,

Maintain isometric checking control,

Attend internal meetings. Liaise with client/lead area eng daily, control of personnel and duties.

up date iso register, monitor checking activities,

Supervise and provide technical knowledge to checkers, designers and drafters.

Provide technical direction and assign work to subordinate engineers, designers, drafters, and oth-ers who assist in performing specific assignments.

Ensure all work is checked effectively and records kept before issue.

Control, monitor and progress the piping design checking group.

Prepare isometric control sheet. isometric flow procedure

Monitor and control Checker daily progress and performance.

Report to senior management on checking group performance and progress.

Ensure effective operation, communication and co-operation between leads, Designers and group.

DATE 999POSITION COMPANY

002-000-CPF-016 (007848) HRF-0033 Corporate Base Page 21

Rev 5 (18-Feb-08)

Terence A Pearce

Piping Manager / Engineer

317/4 M.Nongdon

Saraburi

18190

Resume 2015

94-95 Senior Piping Engineer ( PDS) Aker Off-shore, Norway

93-94 Senior Piping Engineer ( PDS) MWKellogs, UK

93-92 Senior Piping Engineer ( PDS) Stone & Webster, UK

91-92 Senior Piping Engineer ( PDS) Foster Wheeler , UK

88-90 Design Office Manager Promatech Engineering SA

86-87 Senior Piping Designer Foster Wheeler , SA

83-85 Senior Piping Designer Uhde , South Africa

79-82 Senior Piping Designer/ Checker Sasol-Secunda , South Africa

77-79 Piping Design & Fabrication National Chemicals SA

71-76 Piping Design & Welding Apprentice Weldtite Engineering UK

Reference Details:

002-000-CPF-016 (007848) HRF-0033 Corporate Base Page 22

Rev 5 (18-Feb-08)

Terence A Pearce

Piping Manager / Engineer

317/4 M.Nongdon

Saraburi

18190

Resume 2015

Yellow highlight are contactable now.

Name Company Tele Position

[email protected] Chiyoda Engineering Manager

FW 966-554-010-014 Construction Manager

[email protected] WP Systems Manager

[email protected] FW 966-503-308-379 QA/QC Manager

[email protected] WP 07769640243 QA Manager

[email protected] JGCV QA

[email protected] Bechtel Lead Engineer

Passport:

002-000-CPF-016 (007848) HRF-0033 Corporate Base Page 23

Rev 5 (18-Feb-08)