Synthetic Bone Substitute Materials

14

85 Synthetic Bone Substitute Materials Jonathan Du Toit / Howard Gluckman Summary It is undeniable that in terms of ideal bone healing for implant osseointegration, an au- tograft offers the best clinical outcomes and is widely considered “the gold standard.” Nevertheless, replacement options are necessary, and a wide variety of synthetically fab- ricated alloplasts are available to fulfill this task. The literature is abundant with numerous clinical studies reporting on the use of animal-derived bone grafts, yet the quality of bone that is regenerated with xenografts is still considered suboptimal. Often understated are the relevance and interest of synthetic bone substitute materials. They offer the major advantage of being manufactured in unlimited supply without the variability that exists with allografts. Considering the advantages and disadvantages of each of the four classes of bone grafts, synthetic materials have been shown to offer regenerative potential that may be preferred under certain clinical indications. This chapter provides a background on the numerous types of synthetically fabricated biomaterials and compares their biologic properties and resorption patterns. Furthermore, clinical case examples are presented with synthetic bone grafts, and their clinical indications are discussed.

Transcript of Synthetic Bone Substitute Materials

Summary

It is undeniable that in terms of ideal bone healing for implant osseointegration, an au-

tograft offers the best clinical outcomes and is widely considered “the gold standard.”

Nevertheless, replacement options are necessary, and a wide variety of synthetically fab-

ricated alloplasts are available to fulll this task. The literature is abundant with numerous

clinical studies reporting on the use of animal-derived bone grafts, yet the quality of bone

that is regenerated with xenografts is still considered suboptimal. Often understated are

the relevance and interest of synthetic bone substitute materials. They offer the major

advantage of being manufactured in unlimited supply without the variability that exists with

allografts. Considering the advantages and disadvantages of each of the four classes of

bone grafts, synthetic materials have been shown to offer regenerative potential that may

be preferred under certain clinical indications. This chapter provides a background on

the numerous types of synthetically fabricated biomaterials and compares their biologic

properties and resorption patterns. Furthermore, clinical case examples are presented

with synthetic bone grafts, and their clinical indications are discussed.

Miron_CH06.indd 85 11/7/18 8:58 AM

Synthetic Bone Substitute Materials

86

06

It can be daunting to treatment plan with the ideal biomaterials for each individual patient, especially considering the impact of patient preferences due to their cultural and/or religious beliefs. Interestingly, a patient survey was carried out in Turkey, a pre- dominantly Islamic country, and porcine-derived biomaterials were reported as least desired.1 Alloplastic grafts, however, were preferred by more than 60% of the respondents. Synthetic materials are free of any organic origin, and while exceedingly rare, prion infection from medical bovine-derived products has been addressed in the literature.2 Furthermore, many patients would prefer a synthetically fabricated material as opposed to animal-derived products simply based on their own personal, cultural, or religious preferences. This chapter aims to detail the various synthetic materials that are currently available and discusses their material chemistry, composition, classication, and research reporting on their use.

Nomenclature of Synthetic Biomaterials

Synthetic bone substitute materials are manufactured free of any biologic source (human or animal). Nevertheless, their nomencla-

ture is not always consistent. In dentistry, they are often termed alloplasts or alloplastic, yet in other elds of medicine (such as orthopedics) these terms are rarely used.3–5 This class of bone substitutes encompasses many types of synthetically fabricated materials including bioglasses, bioceramics, ceramics, glasses, calcium sulfates, hydroxyapatites, and so forth. The naming of these may be even further complicated when commercial trade- mark names are included in the mix (Table 6-1). The Glossary of Oral and Maxillofacial Implants denes alloplasts as “inorganic, synthetic, or inert foreign material implanted into tissue.”6 Another organization, the International Congress of Oral Implantologists (ICOI), denes an alloplast as “synthetic, inorganic material used as a bone substitute or as an implant, synonymous with al- loplastic graft.”7 Synthetic materials are all derived from calcium phosphate (CaPO4) apatites, the major component of human mineralized tissues (bone, teeth, tendons).4 These tissues are “biologic apatites” that provide structure and function. They can be found elsewhere in the body as well, including as pathologic soft tissue calcications, urinary stones, salivary stones, athero- sclerotic plaques, and arthritic cartilage. They are also present in toothpaste, various foods, fertilizers, antacids, and detergents, among other products. Chemically pure calcium phosphates are clear crystals, yet in powder form they become white. Their chemical compositions vary depending on the phosphate ion, giving the material various names including orthophosphates,

TABLE 6-1 Synthetic bone material examples identied from the reviewed literature

Product Manufacturer Description/constituents

Cerasorb Curasan Pure β-TCP

NovaBone Dental Putty

NovaBone 70% calcium phosphosilicate, with added polyethylene glycol, embedded in glycerin

Ostim paste Osartis 35% nanohydroxyapatite in water

NanoBone Artoss Nanohydroxyapatite (as particulate or as paste with silica gel)

nanoXIM Fluidinova Nanohydroxyapatite water-based paste

DentoGen Orthogen Calcium sulfate

87

metaphosphates, pyrophosphates, or polyphosphates. For rele- vance and simplicity, nearly all human calcied tissues comprise calcium orthophosphates, and only these subtypes are detailed throughout this chapter.

Calcium phosphates consist of three major elements, namely calcium, phosphorus, and oxygen. Many also contain hydrogen, especially if water is incorporated, and are differentiated by the number of hydrogen ions (mono-, di-, tri, tetra-). Bioglasses and bioceramics are inert, fragile, translucent materials derived from silica that is heated into glass, such as window panes. In actuality, glass is not a composition but a state of matter.5 Glass in fact does not have an ordered crystalline structure; rather, it is randomly arranged, and it is dened as any material that has cooled from the melt without crystallizing. True glasses are amorphous, and bioactive glasses, unlike window pane glass, are reactive in biologic tissues. Conversely, ceramics are mainly comprised of crystals. For example, zirconia crystals in restorative and implant materials produce highly resilient ceramic materials. The term glass-ceramics denotes a combination to improve their added properties. Lithium disilicate of dental restorations is a glass-ceramic.

Bioglass is technically a misnomer in the literature. The original Bioglass is in fact a registered trademark name of the commercial product invented at the University of Florida in the 1960s.8 The alternative and correct term for these materials is bioactive glass. One of the earliest uses of bioactive glass was the insertion of original Bioglass cones into fresh extraction sockets in 1987 as ridge-preservation devices/implants be- neath removable dentures.9 Today, Bioglass is incorporated into the toothpaste widely known as Sensodyne Repair & Protect (GlaxoSmithKline).10

Curiously, window pane glass and bioactive glass are both comprised of soda, lime, and silicate. However, bioactive glass contains much less silicate and a lot more calcium and phos- phate, which aids its dissolution in biologic tissues.5 When in- serted in a bone defect site, the glass resorbs slowly, resulting in ion exchange. The importance of calcium and phosphate ions during bone regeneration has been shown in many studies. Phosphate ions are known to regulate osteoblast apoptosis,11

osteopontin production,12 and the mineralization rate,13 and calcium ions have been reported to have a profound effect on osteoblast proliferation and regulation.14,15 The released bioac- tive glass ions cause a rise in the pH of the local environment. Calcium phosphate forms on the outer layer of the glass par- ticles in the form of hydroxycarbonate apatite (HCA), which is very similar to bone hydroxyapatite, thereby allowing the parti- cles to bond to bone. After the formation of HCA, phagocytic macrophages are activated, stem cells attach and differentiate, and a matrix is generated that continues to mature.

The terms bioglass and bioceramic continue to be used inter- changeably, albeit slightly incorrectly. Ultimately, these materials

for use in regeneration of alveolar bone are under the umbrella of calcium orthophosphates, which include hydroxyapatite, β-tricalcium phosphate (β-TCP), and biphasic calcium phos- phates (BCPs), all of which may generally be referred to as bioactive glass or bioceramic, depending on their chemistry and structure.4,5

Biologic Background: Selecting Synthetic Materials

The absolute prerequisites for guided bone regeneration (GBR) are graft stability and space maintenance. In the absence of a bone material and/or barrier membrane, these functions are provided (usually inadequately) by the blood clot. This is then the rationale for using a bone substitute material. Scaffolds are required to chemically and structurally aid the regeneration of connective tissues, directing cell activity toward desired phenotypes.16 Such a 3D construct must be able to exchange signals—be it osteogenic, osteoinductive, or osteoconduc- tive—and gradually be replaced by and/or incorporated into native bone. Today a wide array of synthetically fabricated alloplasts exists on the market, each featuring differences in material composition and surface topography (Fig 6-1). For the regeneration of bone, the orthopedic literature states that hydroxyapatite is the ideal scaffold for bone repair, but this might not be true for all applications of alveolar bone augmentation. For oral regeneration, the clinician needs to consider the following:

• What is the planned current or future procedure? For example, is the site to receive a dental implant, a xed prosthesis pontic, a removable prosthesis, or no prosthesis?

• What is the timing of these procedures? Is a dental implant to be inserted simultaneously with the GBR procedure? Is the implant to be inserted later? If a socket is being grafted, when is re-entry planned? What is the age of the patient? If craniofacial growth is not yet complete, is delay for several years expected?

• To what degree will the implant be inserted into the bone substitute material? What tissue will provide (the majority of) the implant’s bony support? Native bone or augmented bone?

• What site is to be grafted? Maxillary sinus? Extraction socket? Buccal defect? Crestal ridge defect? In the bone envelope or outside? Will it be supported by adjacent teeth?

Miron_CH06.indd 87 11/7/18 8:58 AM

Synthetic Bone Substitute Materials

88

06

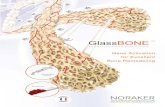

FIG 6-1 Scanning electron microscope (SEM) images of several synthetic bone substitutes, depicting their sur- face characteristics. In general, Cerasorb (Curasan) has a more roughened surface topography than the other bone grafts. Both maxresorb (botiss) and Straumann BoneCeramic are extremely smooth in their surface to- pographies.

Cerasorb (Curasan)

Hydroxyapatite

89

While there may never be a gold standard set of protocols to address all of these raised questions, several factors highlighted below should be addressed.

Resorption

The resorption of bone grafting materials is one feature that cli- nicians consider very important, and there is signicant variability among synthetic materials. It is widely reported that synthetic hydroxyapatites take a long time to be replaced by native bone, while tricalcium phosphates resorb rapidly.17 When resorbed, as with the osteoclastic activity of natural bone, constituent ions are released that stimulate bone formation. Konermann et al18 performed experimental analysis of osteoclast activity on both xenograft hydroxyapatite (cerabone, botiss) and synthetic calcium phosphate materials (maxresorb, botiss; NanoBone, Artoss). Interestingly, cultured osteoclasts mixed with the bone substitute materials all resorbed over time and released primar- ily calcium phosphates to the surrounding microenvironment. NanoBone is a material fabricated from hydroxyapatite em- bedded in silica and thus releases silica when resorbed. After 5 days of culture with osteoclasts, it was found that cerabone released two times more calcium and phosphate into the lo- cal environment than NanoBone did. It was further found that maxresorb released signicantly more than the other materials, at approximately ve to six times the concentrations.

Structurally, the micropores have also been described as be- ing a prominent feature of bone substitute materials. Scanning electron microscope (SEM) analysis of these materials showed that cerabone has the fewest pores, while maxresorb has the most abundant micropores. However, SEM analysis showed sparse osteoclast adhesion to maxresorb versus abundant cellular adhesion to NanoBone and cerabone. Despite the sparse cellular adhesion to maxresorb, the concentrations of released ions were high. Moreover, Horvath et al19 showed that calcium phosphate bone substitute material (Ostim, Osartis) was still present in some human histology samples 7 months after healing of periodontal defects. Future research is ongo- ing to determine the various factors responsible for calcium phosphate resorption, but variability certainly exists within the literature.

Hydroxyapatite Pure hydroxyapatite (Ca10[PO4]6[OH]2) is among the least soluble of the calcium phosphates and is not found in biologic systems.4

This is somewhat different from bone hydroxyapatite, and here the reader is strongly advised not to confuse sintered xenograft bone hydroxyapatite (such as cerabone) with commercially, articially prepared hydroxyapatite (such as Osbone [Curasan]). Synthetic hydroxyapatite is prepared by numerous techniques, broadly divided into (1) solid-state chemical reactions or (2) wet reactions (precipitation, hydrothermal, or hydrolysis of other calcium phosphates). These preparations have different sin- tering temperatures (heated to very high temperatures) and have numerous uses, including as additives to toothpastes and coatings of medical implant devices.

Hydroxyapatite has been studied extensively in the literature in human and animal models. In a histologic study, rabbit sinus- es were augmented with hydroxyapatite derived from animal origin, which produced more bone when compared to sinuses augmented with synthetic hydroxyapatite.20 At 3 months, the amount of new bone was rather minimal for all three materials studied, but the two bovine-derived hydroxyapatites (Endo- bon, Zimmer Biomet; Bio-Oss, Geistlich) produced more bone than the pure synthetic hydroxyapatite (Osbone). The histologic slides demonstrated intimate new bone contact with the residual graft particles and large interconnecting bridges in the Bio-Oss samples. Bio-Oss demonstrated microporosities or cavitations that the other materials did not, which the authors relate to the improved performance of the material, possibly enhancing os- teoblast cellular attachment. Therefore, at present, synthetically pure hydroxyapatite bone grafting materials have been shown to integrate less efciently into host tissues when compared to animal-derived hydroxyapatite.

In general, synthetic hydroxyapatites persist at augmentation sites due to their low substitution rate.21 If grafting of the socket and early re-entry for implant placement is planned, there may not be adequate time for bone formation to take place. The implant is therefore at greater risk for being inserted into nonliv- ing material. Conversely, if the objective is to correct a contour defect (for example, a buccal defect at a missing tooth site) and the majority of the implant is inserted into native bone for osseointegration, then a slowly replaced material would provide the space maintenance over the long term. If a young patient lost a tooth and has not yet completed craniofacial growth, then grafting the socket as an attempt to preserve the ridge is more suitable with a slowly resorbing biomaterial.

Miron_CH06.indd 89 11/7/18 8:58 AM

Synthetic Bone Substitute Materials

90

06

Calcium Phosphosilicate As discussed, bioactive glass materials typically contain calcium, phosphate, and silicate. Probably the best-known example is NovaBone Dental Putty (NovaBone), a 70% calcium phospho- silicate with added polyethylene glycol embedded in glycerin. The paste is designed to improve the handling properties for the clinician. Its use as a putty has therefore been favored in many clinical situations. For example, Huwais and Meyer re- ported its combination with implant osseodensication.22 In a protocol termed the Versah lift, a transcrestal sinus membrane elevation procedure propels bone into the sinus beneath the sinus membrane (see Fig 6-6). As a grafting material, NovaBone is recommended with a lower risk of perforation.

Similarly, Mahesh et al23 grafted human sockets with Nova- Bone Dental Putty and compared bone formation to that achieved with Bio-Oss (all socket grafts were sealed with a collagen plug). The authors published some insightful human histology of the trephined bone cores at 5 to 6 months of healing (Fig 6-2). Signicantly more new bone formed from the bioactive glass putty, as much as 36% to 57%, between 4 and 6 months. Also, it was noted that NovaBone resorbed at approximately 20% per month.23

β-Tricalcium Phosphate β-tricalcium phosphate (β-Ca3[PO4]2), abbreviated as β-TCP, is one of the two polymorphs of tricalcium phosphate. This mate- rial is notably different and cannot be prepared from aqueous solutions. There are four ways in which β-TCP is prepared, yet most bone substitute manufacturers do not adequately report their processing techniques. Typically, β-TCP is prepared by sintering calcium-decient hydroxyapatite to high temperatures.4

It can also be prepared at lower temperatures in water-free me- diums or by solid-state acid-base chemical interactions. Note that ion-substituted β-TCP does occur in nature; as with pure hydroxyapatite, pure β-TCP is not found in biologic systems. Commercially available examples of β-TCP bone grafts include maxresorb and Cerasorb (Curasan).

β-TCP is probably best known for its rapid resorption. One question that intrigued many investigators was whether the timing of bone graft resorption correlates with the rate of new bone formation. Lambert et al24 compared the healing of rabbit sinuses augmented with bovine hydroxyapatite (Bio-Oss), a BCP (Straumann BoneCeramic), and pure β-TCP (Cerasorb).24 New bone formed from each material, but the architecture differed. At 2 months, the xenograft formed intimate bridges of bone

FIG 6-2 Histology of trephined cores harvested from grafted human sockets at 6 months. (a to c) From bone grafted with synthetic NovaBone. (d to f) From bone grafted with a xenograft (Bio-Oss). The red tissue represents regenerated bone. (Reprinted with permission from Mahesh et al.23)

a

d

b

e

c

f

Biphasic Calcium Phosphates

91

between the particles, but bone formation was sparse in the BCP grafts and nonexistent in the β-TCP grafts. By 6 months, no material remained within the β-TCP grafts. This study alludes to the more rapid resorption of pure-phase TCP, demonstrating that synthetic hydroxyapatite slows this process and that nat- ural bovine-sintered hydroxyapatite resorbs even more slowly. Therefore, in certain clinical situations, a slow-resorbing xeno- graft that forms comparable bone is best suited. In another study, Jensen et al25 created defects in minipig mandibles and grafted them with either an autograft, xenograft (Bio-Oss), or β-TCP (Ceros, Thommen Medical) and later harvested bone sections at 1, 2, 4, and 8 weeks. Consistent with other studies, the autografts and β-TCP produced slightly more new bone during initial healing (at 4 weeks).

Biphasic Calcium Phosphates

It is widely perceived that synthetic materials resorb completely and do so rapidly, and xenogeneic bone substitutes are gen- erally considered nonresorbable. The literature is abundant with research reporting on materials termed biphasic calcium phosphates, one of the earliest reports in dentistry being that by Ellinger et al26 in 1986 treating periodontal intrabony defects. Biphasic refers to a combination of two materials, generally β-TCP and hydroxyapatite, whose ratios are adjusted to poten- tially manipulate their biomedical properties. BoneCeramic, for example, is biphasic, consisting of 60% synthetic hydroxyapatite and 40% β-TCP. Another method to control the resorption of calcium phosphates, other than by creating a biphasic material, is by adding a doping agent such as silicon, magnesium, or potassium.27 These also may have a therapeutic effect when they are released into the local environment (see chapter 21).

Grafting a socket with a substitute for re-entry and implant placement may typically take place at 3 to 6 months postex-

traction. For sinuses, this may take even longer. Cordaro et al17 carried out a randomized controlled trial comparing bone healing at grafted human sinuses at 6 to 8 months. Two mate- rials were compared: a biphasic calcium phosphate (BoneCe- ramic) and a bovine xenograft (Bio-Oss). Histologically, 23 synthetic bone samples compared to 25 xenograft samples demonstrated the same amount of new bone formation (syn- thetic 21.6% ± 10.0% versus xenograft 19.8% ± 7.9%). This amount of bone may be considered low, or lower than the desired quantity to accommodate a dental implant, and yet all 109 planned implants achieved appropriate primary sta- bility. The materials differed at later healing, with less residual synthetic material remaining than xenograft (26.6% ± 5.2% versus 37.7% ± 8.5%, P < .001). Thus, for sinus augmenta- tion procedures, BCP bone grafts produced comparable new bone as xenografts.

Dahlin et al28 also compared synthetic bone substitutes—an experimental ratio of 10% hydroxyapatite and 90% β-TCP (Fig 6-3), BoneCeramic (60% hydroxyapatite, 40% β-TCP), and Bio-Oss—and found that the xenograft produced more new bone at 8 weeks.28

A new novel BCP biomaterial of the same ratio (10% hydroxy- apatite and 90% β-TCP) was extensively tested by Miron et al.29

This synthetic (formerly VivOss by Straumann, currently Osopia by Regedent) was compared to Bio-Oss as well as to autografts and allografts, and all were investigated for their ability to form ectopic bone in rat muscle. They concluded the following29:

• The xenograft material (Bio-Oss) did not form bone ectopically. • The allograft (demineralized freeze-dried bone allograft

[DFDBA], LifeNet) formed bone ectopically. • The autograft formed some bone ectopically, but it was rapidly

resorbed. • The synthetic BCP (formerly VivOss, currently Osopia) formed

more bone ectopically.

FIG 6-3 Histology of an experimental β-TCP. Note the active resorption of the β-TCP and the hydroxyapatite (HA) lined with new bone (NB). (Reprinted with permis- sion from Dahlin et al.28)

β-TCP

NB

HA

Synthetic Bone Substitute Materials

92

06

Contrasted to an experiment in the dog model, the same working group found the following30:

• The xenograft (Bio-Oss) showed no ectopic bone formation and little resorption.

• The allograft (DFDBA, Straumann) formed ectopic bone, but it was rapidly resorbed by 8 weeks.

• The autograft also rapidly resorbed, and there was no ectopic bone formation at slightly longer time points.

• The synthetic BCP (formerly VivOss, currently Osopia) con- sistently formed ectopic bone by 8 weeks.

This new class of osteoinductive BCP is highlighted in chapter 7.

Synthetic Polymers

A variety of synthetic materials and admixtures of these have been described in the literature and continue to be widely inves- tigated. Tevlin et al31 reported on a composite material scaffold of a hydroxyapatite and polylactic-co-glycolic acid (PLGA) core that may be enriched with other materials such as bioactive growth factors.31 However, experimental socket grafting with PLGA/hydroxyapatite has demonstrated biocompatibility issues, with numerous reported failures (though in a limited number of test sites).32 Konopnicki et al33 evaluated 3D-printed β-TCP/ polycaprolactone scaffolds inserted into pig mandible defects.33

The results were promising, showing greater cell penetration and bone formation than in empty defects; however, comparative studies with standard replacement materials such as allografts and xenografts are still lacking. Notably, these biomaterials that incorporate polymers are not widely commercially available yet and are mostly limited to preclinical testing thus far. Future research is ongoing.

Titanium Granules

The use of titanium granules as a synthetic bone graft material has also been reported in the literature. They were rst utilized in orthopedics in the mid-2000s.34 A study carried out by Arruda et al35 histologically examined new bone formation in sockets grafted with titanium granules at 1 month. The control (non- grafted) sockets presented more new bone. In human subjects, Verket et al36 grafted maxillary sinuses and biopsied the grafts at 6 months; they found histologic new bone of 16.1% (standard deviation of 9.4%). This is notably low, and the titanium particles remained (25% of the total defect volume). Furthermore, the

effect of drilling an osteotomy into titanium particles was not discussed. Wohlfahrt et al37 debrided peri-implant defects with chemical decontamination and grafted half of the defects with porous titanium granules. While the improvement in radiographic defect ll was reported as signicant, no other notable differenc- es were observed. Apart from these studies, few studies have further investigated the use of titanium particles as synthetic materials, and their use is not clinically recommended at present.

Material Surface and Structure

The porosity of biomaterials has been cited as important for the ingrowth of capillaries and the ability to form bone. Various research groups have reported that submicron topography facilitates osteoblast differentiation and mineralization potential. For example, Hallman and Thor38 stated that material pore size needs to be larger than 300 microns. Bohner et al27 stated that macropores typically are bigger than 50 microns and allow cel- lular and capillary passage that facilitates bone formation. Yet early research of Haversian canal diameters in human mandible bone reported their diameter as 60 to 80 microns.39

To date, no ideal architecture or porosity has been provided, possibly due to each material’s different surface energy, chem- istry, and hydrophilicity. Some commercially available products identify their porosity, such as BoneCeramic, which states that the material comes in a 90% porosity. SEM images may provide more accurate depictions of these materials’ surfaces. Figure 6-4 provides high-resolution images of various commercially available materials as highlighted below:

• Cerasorb: Very smooth surface, lobular, highly interconnected material network, with pores or cavitations about 10 to 30 microns in size

• maxresorb and BoneCeramic: Mostly at and smooth, slightly rippled; highly fragmented; almost no interconnections, pores, or cavitations

• NovaBone Dental Putty: Embedded in a putty, its surface appears smooth and undulated, with microrough areas

• Perioglas (NovaBone): Microarchitecture highly similar to Cerasorb, yet much smaller; highly interconnected, intricate network of cavitations, about 1 to 5 microns in size; individual particles are highly fragmented, with numerous larger pores 10 to 100 microns in size (not seen in Cerasorb)

• Osbone: Highly fragmented particles, with larger pores lost in fragments; very rough surface; highly interconnected network of cavitations at the 2-micron level

• Ostim: Embedded in a putty, the particles appear smooth, with no pores; microrough at the <1-micron level

Miron_CH06.indd 92 11/7/18 8:58 AM

Clinical Indications and Case Presentations of Bone Regeneration

93

How each of these surface characteristics truly relates to clin- ical outcomes and bone regeneration remains relatively under- studied. Lambert et al20 reported on the surface topography of xenograft hydroxyapatite compared to synthetic hydroxyapatite and the effect on bone formation in animal sinus augmentations. At the 2-micron level, Bio-Oss appeared microrough compared to the other xenograft (Endobon) and the synthetic material (Osbone). None had large pores; all had micropores less than 1 micron in size, and Bio-Oss appeared to have abundant pores. The newly formed bone from Bio-Oss was nearly double that of the synthetic option (19.28% vs 11.93%).

A more informative study by Hinze et al40 compared allografts to a synthetic nanohydroxyapatite (Ostim). Harvested human alveolar bone samples were collected during routine dental surgeries. The osteoblasts were cultured, added to the two bone grafting materials, and compared for osteoblast activity. The authors reported that osteoblasts did not proliferate well or spread on the synthetic material (Ostim). Few vital cells were noted after 3 weeks of culture on the material. Proliferation

of osteoblasts on the allograft was far greater. Thus, this in vitro study demonstrated a poor performance for the synthetic nanohydroxyapatite.

Clinical Indications and Case Presentations of Bone Regeneration

Figure 6-5 shows a case of ridge preservation prior to implant placement. The mandibular right rst molar was extracted, and the socket was grafted with maxresorb, a synthetic BCP (60% hydroxyapatite, 40% β-TCP) particulate material, and sealed with a collagen membrane (Jason, botiss). At 3 months, the site appears well preserved (see Figs 6-5e and 6-5f). A tissue-level implant (Straumann) was placed, osseointegrated, and restored (see Figs 6-5g to 6-5i).

FIG 6-4 (a) NovaBone Putty is an injectable biomaterial that forms a relatively smooth surface but also features some topographic differences, like- ly as a result of the putty-based composition. (b) Cerasorb displays an extremely smooth surface. These surfaces typically are not as conductive toward osteoblast differentiation as roughened surfaces, presenting more micro- and nanotopographies. (c) SEM image of Perioglas (NovaBone). Notice the roughened surface morphology. (d) SEM image of Ostim paste. Notice the roughened surface. (e) SEM image comparing two synthetic materials: maxresorb and BoneCeramic. Notice the relatively smooth surfaces and lack of porosity. (All images original magnication ×6,000.)

a b

d e

Cerasorb (Curasan) Perioglas (NovaBone)

Synthetic Bone Substitute Materials

94

06

FIG 6-5 Socket grafting of a mandibular left rst molar site followed by implant placement. (a) Minimally traumatic tooth extraction due to an apical lesion. (b and c) A maxresorb synthetic bone graft and a Jason membrane (botiss) are utilized within the extraction socket. (d) Radiograph immediately postoperative. (e and f) Clinical photograph and radiograph after 3 months of healing. Notice the excellent maintenance of the site dimensions postextraction. (g) Implant placement. (h) Radiograph showing the implant and provisional crown. (i) Clinical photograph of the nal crown. (Case performed by Dr Massimo Frosecchi.)

a b

Clinical Indications and Case Presentations of Bone Regeneration

95

Figure 6-6 shows a case of transcrestal sinus elevation and augmentation. Using osseodensication burs, a Versah lift was carried out at the site of a missing maxillary right premolar that had a vertical deciency. The unique nonextractive drilling sys- tem propelled autogenous bone into the sinus, simultaneously

lifting the sinus membrane. The sinus was additionally augment- ed by lling the osteotomy with 70% calcium phosphosilicate putty (NovaBone), and the Versah burs were repeatedly applied into the osteotomy, further propelling the graft material. A sig- nicant vertical augmentation was achieved.

FIG 6-6 Versah lift at the site of a missing maxillary right second premolar. A transcrestal sinus elevation was performed with osseodensication burs, and the sinus was augmented with a synthetic bone material (NovaBone) prior to implant placement. (a) Maxillary right second premolar site with observed dimensional loss of bone width. (b) Cone beam computed tomography (CBCT) of the implant planning. (c) Osteotomy prepared with Versah burs. (d and e) Injection of NovaBone (radiopaque). (f and g) Clinical images of implant placement. (h) Final radiograph. Notice the radiopaque NovaBone found within the sinus. (Case performed by Dr Jonathan Du Toit.)

a b

Synthetic Bone Substitute Materials

96

06

Figure 6-7 shows a case of grafting the buccal gap during immediate implant placement. A maxillary premolar was de- coronated and a socket shield prepared. An immediate implant was placed, and the buccal gap was grafted with NovaBone Putty. At the 1-year follow-up, there appeared to be little or no collapse of the buccal ridge (see Fig 6-7f).

Conclusion It is fair to state that the ideal synthetic bone graft replacement has not yet been developed or conclusively proposed. However, premanufactured synthetic scaffolds for the rehabilitation of alve- olar bone defects continue to improve. There remains no single graft material that is ideally suited for all clinical situations in all patients. In the future, it is expected that synthetic bone grafts will be the class of bone grafts with the greatest improvements regarding their use in daily clinical practice.

FIG 6-7 Socket-shield technique and immediate implant placement at the site of a maxillary right rst premolar. The buccal gap was augmented with a synthetic bone material (NovaBone Putty). (a and b) The maxillary right rst premolar was partially extracted due to decay; a portion of the tooth root was left in place to maintain the buccal bone. (c) Injection of NovaBone synthetic bone putty. (d) Implant placement. Notice the NovaBone on the buccal aspect of the implant. (e and f) Radiograph and CBCT images 1 year after surgery. (g) Clinical image demonstrating the excellent esthetic result. (Case performed by Dr Howard Gluckman.)

a

c

References

97

References 1. Güngörmüs Z, Güngörmüs M. Eect of religious belief on selecting of

graft materials used in oral and maxillofacial surgery. J Oral Maxillofac Surg 2017;75:2347–2353.

2. Kim Y, Rodriguez AE, Nowzari H. The risk of prion infection through bo- vine grafting materials. Clin Implant Dent Relat Res 2016;18:1095–1102.

3. Laurencin CT, Jiang T. Bone Graft Substitutes and Bone Regenerative Engineering. West Conshohocken: ASTM International, 2014.

4. Dorozhkin SV. Calcium Orthophosphate-Based Bioceramics and Bio- composites Dorozhkin/Calcium Orthophosphate-Based Bioceramics and Biocomposites. Weinheim, Germany: Wiley-VCH Verlag GmbH & Co. KGaA, 2016.

5. Jones JR, Clare A. Bio-glasses: An Introduction. Chichester, England: Wiley, 2012.

6. Laney WR. Glossary of Oral and Maxillofacial Implants. Berlin: Quin- tessence, 2007.

7. ICOI. ICOI Glossary of Implant Dentistry.www.icoi.org/wp-content/ uploads/2016/12/Glossary-of-Implant-Dentistry-3.pdf. Accessed 12 January 2018.

8. Hench LL. The story of Bioglass. J Mater Sci Mater Med 2006;17:967–978. 9. Stanley HR, Hall MB, Clark AE, King CJ 3rd, Hench LL, Berte JJ. Using

45S5 bioglass cones as endosseous ridge maintenance implants to prevent alveolar ridge resorption: A 5-year evaluation. Int J Oral Maxil- lofac Implants 1997;12:95–105.

10. Maçon Anthony LB, Valliant Esther M, Earl Jonathan S, Jones Julian R. Bioactivity of toothpaste containing bioactive glass in remineraliz- ing media: Eect of uoride release from the enzymatic cleavage of monouorophosphate. Biomed Glasses 2015;1.

11. Meleti Z, Shapiro IM, Adams CS. Inorganic phosphate induces apop- tosis of osteoblast-like cells in culture. Bone 2000;27:359–366.

12. Wu X, Itoh N, Taniguchi T, Nakanishi T, Tanaka K. Requirement of calci- um and phosphate ions in expression of sodium-dependent vitamin C transporter 2 and osteopontin in MC3T3-E1 osteoblastic cells. Bio- chim Biophys Acta 2003;1641:65–70.

13. Wang D, Christensen K, Chawla K, Xiao G, Krebsbach PH, Franceschi RT. Isolation and characterization of MC3T3-E1 preosteoblast sub- clones with distinct in vitro and in vivo dierentiation/mineralization potential. J Bone Miner Res 1999;14:893–903.

14. Zaidi M, Datta HK, Patchell A, Moonga B, MacIntyre I. ‘Calcium-activated’ intracellular calcium elevation: A novel mechanism of osteoclast regulation. Biochem Biophys Res Commun 1989;163:1461–1465.

15. Kanatani M, Sugimoto T, Fukase M, Fujita T. Eect of elevated extra- cellular calcium on the proliferation of osteoblastic MC3T3-E1 cells: Its direct and indirect eects via monocytes. Biochem Biophys Res Commun 1991;181:1425–1430.

16. Antoniac IV. Handbook of bioceramics and biocomposites. Cham, Switzerland: Springer, 2016.

17. Cordaro L, Bosshardt DD, Palattella P, Rao W, Serino G, Chiapasco M. Maxillary sinus grafting with Bio-Oss or Straumann Bone Ceramic: Histomorphometric results from a randomized controlled multi- center clinical trial. Clin Oral Implants Res 2008;19:796–803.

18. Konermann A, Staubwasser M, Dirk C, et al. Bone substitute material composition and morphology dierentially modulate calcium and phosphate release through osteoclast-like cells. Int J Oral Maxillofac Surg 2014;43:514–521.

19. Horvath A, Stavropoulos A, Windisch P, Lukacs L, Gera I, Sculean A. Histological evaluation of human intrabony periodontal defects treat- ed with an unsintered nanocrystalline hydroxyapatite paste. Clin Oral Investig 2013;17:423–430.

20. Lambert F, Bacevic M, Layrolle P, Schupbach P, Drion P, Rompen E. Im- pact of biomaterial microtopography on bone regeneration: Compari- son of three hydroxyapatites. Clin Oral Implants Res 2017;28:e201–e207.

21. Bosshardt DD, Bornstein MM, Carrel JP, Buser D, Bernard JP. Maxillary sinus grafting with a synthetic, nanocrystalline hydroxyapatite-silica gel in humans: Histologic and histomorphometric results. Int J Peri- odontics Restorative Dent 2014;34:259–267.

22. Huwais S, Meyer EG. A novel osseous densication approach in im- plant osteotomy preparation to increase biomechanical primary sta- bility, bone mineral density, and bone-to-implant contact. Int J Oral Maxillofac Implants 2017;32:27–36.

23. Mahesh L, Venkataraman N, Shukla S, Prasad H, Kotsakis GA. Alveolar ridge preservation with the socket-plug technique utilizing an al- loplastic putty bone substitute or a particulate xenograft: A histologi- cal pilot study. J Oral Implantol 2015;41:178–183.

24. Lambert F, Leonard A, Lecloux G, Sourice S, Pilet P, Rompen E. A compar- ison of three calcium phosphate-based space llers in sinus elevation: A study in rabbits. Int J Oral Maxillofac Implants 2013;28:393–402.

25. Jensen SS, Broggini N, Hjorting-Hansen E, Schenk R, Buser D. Bone healing and graft resorption of autograft, anorganic bovine bone and beta-tricalcium phosphate. A histologic and histomorpho- metric study in the mandibles of minipigs. Clin Oral Implants Res 2006;17:237–243.

26. Ellinger RF, Nery EB, Lynch KL. Histological assessment of periodontal osseous defects following implantation of hydroxyapatite and bipha- sic calcium phosphate ceramics: A case report. Int J Periodontics Re- storative Dent 1986;6:22–33.

27. Bohner M, Galea L, Doebelin N. Calcium phosphate bone graft substi- tutes: Failures and hopes. J Eur Ceram Soc 2012;32:2663–2671.

28. Dahlin C, Obrecht M, Dard M, Donos N. Bone tissue modelling and re- modelling following guided bone regeneration in combination with biphasic calcium phosphate materials presenting dierent micropo- rosity. Clin Oral Implants Res 2015;26:814–822.

29. Miron RJ, Zhang Q, Sculean A, et al. Osteoinductive potential of 4 com- monly employed bone grafts. Clin Oral Investig 2016;20:2259–2265.

30. Miron RJ, Sculean A, Shuang Y, et al. Osteoinductive potential of a novel biphasic calcium phosphate bone graft in comparison with autographs, xenografts, and DFDBA. Clin Oral Implants Res 2016;27:668–675.

31. Tevlin R, McArdle A, Atashroo D, et al. Biomaterials for craniofacial bone engineering. J Dent Res 2014;93:1187–1195.

32. Noronha Oliveira M, Rau LH, Marodin A, et al. Ridge preservation after maxillary third molar extraction using 30% porosity PLGA/HA/ beta-TCP scaolds with and without simvastatin: A pilot randomized controlled clinical trial. Implant Dent 2017;26:832–840.

33. Konopnicki S, Sharaf B, Resnick C, et al. Tissue-engineered bone with 3-dimensionally printed beta-tricalcium phosphate and polycapro- lactone scaolds and early implantation: An in vivo pilot study in a porcine mandible model. J Oral Maxillofac Surg 2015;73:1016.e1– 1016.e11.

34. Alram PA, Bruce L, Bjursten LM, Urban RM, Andersson GB. Implan- tation of the femoral stem into a bed of titanium granules using vi- bration: A pilot study of a new method for prosthetic xation in 5 patients followed for up to 15 years. Ups J Med Sci 2007;112:183–189.

35. Arruda T, Sukekava F, de Souza AB, Rasmusson L, Araujo MG. Early heal- ing in alveolar sockets grafted with titanium granules. An experimen- tal study in a dog model. J Biomed Mater Res A 2013;101:1971–1976.

36. Verket A, Lyngstadaas SP, Rasmusson L, et al. Maxillary sinus augmen- tation with porous titanium granules: A microcomputed tomography and histologic evaluation of human biopsy specimens. Int J Oral Max- illofac Implants 2013;28:721–728.

Miron_CH06.indd 97 11/7/18 8:58 AM

Synthetic Bone Substitute Materials

98

06

37. Wohlfahrt JC, Lyngstadaas SP, Ronold HJ, et al. Porous titanium gran- ules in the surgical treatment of peri-implant osseous defects: A ran- domized clinical trial. Int J Oral Maxillofac Implants 2012;27:401–410.

38. Hallman M, Thor A. Bone substitutes and growth factors as an alterna- tive/complement to autogenous bone for grafting in implant dentist- ry. Periodontol 2000 2008;47:172–192.

39. Bazantová I. The blood and lymph bed in Haversian bone. Folia Mor- phol (Praha) 1989;37:213–215.

40. Hinze MC, Wiedmann-Al-Ahmad M, Glaum R, Gutwald R, Schmel- zeisen R, Sauerbier S. Bone engineering-vitalisation of alloplastic and allogenic bone grafts by human osteoblast-like cells. Br J Oral Maxillo- fac Surg 2010;48:369–373.

Miron_CH06.indd 98 11/7/18 8:58 AM View publication statsView publication stats

It is undeniable that in terms of ideal bone healing for implant osseointegration, an au-

tograft offers the best clinical outcomes and is widely considered “the gold standard.”

Nevertheless, replacement options are necessary, and a wide variety of synthetically fab-

ricated alloplasts are available to fulll this task. The literature is abundant with numerous

clinical studies reporting on the use of animal-derived bone grafts, yet the quality of bone

that is regenerated with xenografts is still considered suboptimal. Often understated are

the relevance and interest of synthetic bone substitute materials. They offer the major

advantage of being manufactured in unlimited supply without the variability that exists with

allografts. Considering the advantages and disadvantages of each of the four classes of

bone grafts, synthetic materials have been shown to offer regenerative potential that may

be preferred under certain clinical indications. This chapter provides a background on

the numerous types of synthetically fabricated biomaterials and compares their biologic

properties and resorption patterns. Furthermore, clinical case examples are presented

with synthetic bone grafts, and their clinical indications are discussed.

Miron_CH06.indd 85 11/7/18 8:58 AM

Synthetic Bone Substitute Materials

86

06

It can be daunting to treatment plan with the ideal biomaterials for each individual patient, especially considering the impact of patient preferences due to their cultural and/or religious beliefs. Interestingly, a patient survey was carried out in Turkey, a pre- dominantly Islamic country, and porcine-derived biomaterials were reported as least desired.1 Alloplastic grafts, however, were preferred by more than 60% of the respondents. Synthetic materials are free of any organic origin, and while exceedingly rare, prion infection from medical bovine-derived products has been addressed in the literature.2 Furthermore, many patients would prefer a synthetically fabricated material as opposed to animal-derived products simply based on their own personal, cultural, or religious preferences. This chapter aims to detail the various synthetic materials that are currently available and discusses their material chemistry, composition, classication, and research reporting on their use.

Nomenclature of Synthetic Biomaterials

Synthetic bone substitute materials are manufactured free of any biologic source (human or animal). Nevertheless, their nomencla-

ture is not always consistent. In dentistry, they are often termed alloplasts or alloplastic, yet in other elds of medicine (such as orthopedics) these terms are rarely used.3–5 This class of bone substitutes encompasses many types of synthetically fabricated materials including bioglasses, bioceramics, ceramics, glasses, calcium sulfates, hydroxyapatites, and so forth. The naming of these may be even further complicated when commercial trade- mark names are included in the mix (Table 6-1). The Glossary of Oral and Maxillofacial Implants denes alloplasts as “inorganic, synthetic, or inert foreign material implanted into tissue.”6 Another organization, the International Congress of Oral Implantologists (ICOI), denes an alloplast as “synthetic, inorganic material used as a bone substitute or as an implant, synonymous with al- loplastic graft.”7 Synthetic materials are all derived from calcium phosphate (CaPO4) apatites, the major component of human mineralized tissues (bone, teeth, tendons).4 These tissues are “biologic apatites” that provide structure and function. They can be found elsewhere in the body as well, including as pathologic soft tissue calcications, urinary stones, salivary stones, athero- sclerotic plaques, and arthritic cartilage. They are also present in toothpaste, various foods, fertilizers, antacids, and detergents, among other products. Chemically pure calcium phosphates are clear crystals, yet in powder form they become white. Their chemical compositions vary depending on the phosphate ion, giving the material various names including orthophosphates,

TABLE 6-1 Synthetic bone material examples identied from the reviewed literature

Product Manufacturer Description/constituents

Cerasorb Curasan Pure β-TCP

NovaBone Dental Putty

NovaBone 70% calcium phosphosilicate, with added polyethylene glycol, embedded in glycerin

Ostim paste Osartis 35% nanohydroxyapatite in water

NanoBone Artoss Nanohydroxyapatite (as particulate or as paste with silica gel)

nanoXIM Fluidinova Nanohydroxyapatite water-based paste

DentoGen Orthogen Calcium sulfate

87

metaphosphates, pyrophosphates, or polyphosphates. For rele- vance and simplicity, nearly all human calcied tissues comprise calcium orthophosphates, and only these subtypes are detailed throughout this chapter.

Calcium phosphates consist of three major elements, namely calcium, phosphorus, and oxygen. Many also contain hydrogen, especially if water is incorporated, and are differentiated by the number of hydrogen ions (mono-, di-, tri, tetra-). Bioglasses and bioceramics are inert, fragile, translucent materials derived from silica that is heated into glass, such as window panes. In actuality, glass is not a composition but a state of matter.5 Glass in fact does not have an ordered crystalline structure; rather, it is randomly arranged, and it is dened as any material that has cooled from the melt without crystallizing. True glasses are amorphous, and bioactive glasses, unlike window pane glass, are reactive in biologic tissues. Conversely, ceramics are mainly comprised of crystals. For example, zirconia crystals in restorative and implant materials produce highly resilient ceramic materials. The term glass-ceramics denotes a combination to improve their added properties. Lithium disilicate of dental restorations is a glass-ceramic.

Bioglass is technically a misnomer in the literature. The original Bioglass is in fact a registered trademark name of the commercial product invented at the University of Florida in the 1960s.8 The alternative and correct term for these materials is bioactive glass. One of the earliest uses of bioactive glass was the insertion of original Bioglass cones into fresh extraction sockets in 1987 as ridge-preservation devices/implants be- neath removable dentures.9 Today, Bioglass is incorporated into the toothpaste widely known as Sensodyne Repair & Protect (GlaxoSmithKline).10

Curiously, window pane glass and bioactive glass are both comprised of soda, lime, and silicate. However, bioactive glass contains much less silicate and a lot more calcium and phos- phate, which aids its dissolution in biologic tissues.5 When in- serted in a bone defect site, the glass resorbs slowly, resulting in ion exchange. The importance of calcium and phosphate ions during bone regeneration has been shown in many studies. Phosphate ions are known to regulate osteoblast apoptosis,11

osteopontin production,12 and the mineralization rate,13 and calcium ions have been reported to have a profound effect on osteoblast proliferation and regulation.14,15 The released bioac- tive glass ions cause a rise in the pH of the local environment. Calcium phosphate forms on the outer layer of the glass par- ticles in the form of hydroxycarbonate apatite (HCA), which is very similar to bone hydroxyapatite, thereby allowing the parti- cles to bond to bone. After the formation of HCA, phagocytic macrophages are activated, stem cells attach and differentiate, and a matrix is generated that continues to mature.

The terms bioglass and bioceramic continue to be used inter- changeably, albeit slightly incorrectly. Ultimately, these materials

for use in regeneration of alveolar bone are under the umbrella of calcium orthophosphates, which include hydroxyapatite, β-tricalcium phosphate (β-TCP), and biphasic calcium phos- phates (BCPs), all of which may generally be referred to as bioactive glass or bioceramic, depending on their chemistry and structure.4,5

Biologic Background: Selecting Synthetic Materials

The absolute prerequisites for guided bone regeneration (GBR) are graft stability and space maintenance. In the absence of a bone material and/or barrier membrane, these functions are provided (usually inadequately) by the blood clot. This is then the rationale for using a bone substitute material. Scaffolds are required to chemically and structurally aid the regeneration of connective tissues, directing cell activity toward desired phenotypes.16 Such a 3D construct must be able to exchange signals—be it osteogenic, osteoinductive, or osteoconduc- tive—and gradually be replaced by and/or incorporated into native bone. Today a wide array of synthetically fabricated alloplasts exists on the market, each featuring differences in material composition and surface topography (Fig 6-1). For the regeneration of bone, the orthopedic literature states that hydroxyapatite is the ideal scaffold for bone repair, but this might not be true for all applications of alveolar bone augmentation. For oral regeneration, the clinician needs to consider the following:

• What is the planned current or future procedure? For example, is the site to receive a dental implant, a xed prosthesis pontic, a removable prosthesis, or no prosthesis?

• What is the timing of these procedures? Is a dental implant to be inserted simultaneously with the GBR procedure? Is the implant to be inserted later? If a socket is being grafted, when is re-entry planned? What is the age of the patient? If craniofacial growth is not yet complete, is delay for several years expected?

• To what degree will the implant be inserted into the bone substitute material? What tissue will provide (the majority of) the implant’s bony support? Native bone or augmented bone?

• What site is to be grafted? Maxillary sinus? Extraction socket? Buccal defect? Crestal ridge defect? In the bone envelope or outside? Will it be supported by adjacent teeth?

Miron_CH06.indd 87 11/7/18 8:58 AM

Synthetic Bone Substitute Materials

88

06

FIG 6-1 Scanning electron microscope (SEM) images of several synthetic bone substitutes, depicting their sur- face characteristics. In general, Cerasorb (Curasan) has a more roughened surface topography than the other bone grafts. Both maxresorb (botiss) and Straumann BoneCeramic are extremely smooth in their surface to- pographies.

Cerasorb (Curasan)

Hydroxyapatite

89

While there may never be a gold standard set of protocols to address all of these raised questions, several factors highlighted below should be addressed.

Resorption

The resorption of bone grafting materials is one feature that cli- nicians consider very important, and there is signicant variability among synthetic materials. It is widely reported that synthetic hydroxyapatites take a long time to be replaced by native bone, while tricalcium phosphates resorb rapidly.17 When resorbed, as with the osteoclastic activity of natural bone, constituent ions are released that stimulate bone formation. Konermann et al18 performed experimental analysis of osteoclast activity on both xenograft hydroxyapatite (cerabone, botiss) and synthetic calcium phosphate materials (maxresorb, botiss; NanoBone, Artoss). Interestingly, cultured osteoclasts mixed with the bone substitute materials all resorbed over time and released primar- ily calcium phosphates to the surrounding microenvironment. NanoBone is a material fabricated from hydroxyapatite em- bedded in silica and thus releases silica when resorbed. After 5 days of culture with osteoclasts, it was found that cerabone released two times more calcium and phosphate into the lo- cal environment than NanoBone did. It was further found that maxresorb released signicantly more than the other materials, at approximately ve to six times the concentrations.

Structurally, the micropores have also been described as be- ing a prominent feature of bone substitute materials. Scanning electron microscope (SEM) analysis of these materials showed that cerabone has the fewest pores, while maxresorb has the most abundant micropores. However, SEM analysis showed sparse osteoclast adhesion to maxresorb versus abundant cellular adhesion to NanoBone and cerabone. Despite the sparse cellular adhesion to maxresorb, the concentrations of released ions were high. Moreover, Horvath et al19 showed that calcium phosphate bone substitute material (Ostim, Osartis) was still present in some human histology samples 7 months after healing of periodontal defects. Future research is ongo- ing to determine the various factors responsible for calcium phosphate resorption, but variability certainly exists within the literature.

Hydroxyapatite Pure hydroxyapatite (Ca10[PO4]6[OH]2) is among the least soluble of the calcium phosphates and is not found in biologic systems.4

This is somewhat different from bone hydroxyapatite, and here the reader is strongly advised not to confuse sintered xenograft bone hydroxyapatite (such as cerabone) with commercially, articially prepared hydroxyapatite (such as Osbone [Curasan]). Synthetic hydroxyapatite is prepared by numerous techniques, broadly divided into (1) solid-state chemical reactions or (2) wet reactions (precipitation, hydrothermal, or hydrolysis of other calcium phosphates). These preparations have different sin- tering temperatures (heated to very high temperatures) and have numerous uses, including as additives to toothpastes and coatings of medical implant devices.

Hydroxyapatite has been studied extensively in the literature in human and animal models. In a histologic study, rabbit sinus- es were augmented with hydroxyapatite derived from animal origin, which produced more bone when compared to sinuses augmented with synthetic hydroxyapatite.20 At 3 months, the amount of new bone was rather minimal for all three materials studied, but the two bovine-derived hydroxyapatites (Endo- bon, Zimmer Biomet; Bio-Oss, Geistlich) produced more bone than the pure synthetic hydroxyapatite (Osbone). The histologic slides demonstrated intimate new bone contact with the residual graft particles and large interconnecting bridges in the Bio-Oss samples. Bio-Oss demonstrated microporosities or cavitations that the other materials did not, which the authors relate to the improved performance of the material, possibly enhancing os- teoblast cellular attachment. Therefore, at present, synthetically pure hydroxyapatite bone grafting materials have been shown to integrate less efciently into host tissues when compared to animal-derived hydroxyapatite.

In general, synthetic hydroxyapatites persist at augmentation sites due to their low substitution rate.21 If grafting of the socket and early re-entry for implant placement is planned, there may not be adequate time for bone formation to take place. The implant is therefore at greater risk for being inserted into nonliv- ing material. Conversely, if the objective is to correct a contour defect (for example, a buccal defect at a missing tooth site) and the majority of the implant is inserted into native bone for osseointegration, then a slowly replaced material would provide the space maintenance over the long term. If a young patient lost a tooth and has not yet completed craniofacial growth, then grafting the socket as an attempt to preserve the ridge is more suitable with a slowly resorbing biomaterial.

Miron_CH06.indd 89 11/7/18 8:58 AM

Synthetic Bone Substitute Materials

90

06

Calcium Phosphosilicate As discussed, bioactive glass materials typically contain calcium, phosphate, and silicate. Probably the best-known example is NovaBone Dental Putty (NovaBone), a 70% calcium phospho- silicate with added polyethylene glycol embedded in glycerin. The paste is designed to improve the handling properties for the clinician. Its use as a putty has therefore been favored in many clinical situations. For example, Huwais and Meyer re- ported its combination with implant osseodensication.22 In a protocol termed the Versah lift, a transcrestal sinus membrane elevation procedure propels bone into the sinus beneath the sinus membrane (see Fig 6-6). As a grafting material, NovaBone is recommended with a lower risk of perforation.

Similarly, Mahesh et al23 grafted human sockets with Nova- Bone Dental Putty and compared bone formation to that achieved with Bio-Oss (all socket grafts were sealed with a collagen plug). The authors published some insightful human histology of the trephined bone cores at 5 to 6 months of healing (Fig 6-2). Signicantly more new bone formed from the bioactive glass putty, as much as 36% to 57%, between 4 and 6 months. Also, it was noted that NovaBone resorbed at approximately 20% per month.23

β-Tricalcium Phosphate β-tricalcium phosphate (β-Ca3[PO4]2), abbreviated as β-TCP, is one of the two polymorphs of tricalcium phosphate. This mate- rial is notably different and cannot be prepared from aqueous solutions. There are four ways in which β-TCP is prepared, yet most bone substitute manufacturers do not adequately report their processing techniques. Typically, β-TCP is prepared by sintering calcium-decient hydroxyapatite to high temperatures.4

It can also be prepared at lower temperatures in water-free me- diums or by solid-state acid-base chemical interactions. Note that ion-substituted β-TCP does occur in nature; as with pure hydroxyapatite, pure β-TCP is not found in biologic systems. Commercially available examples of β-TCP bone grafts include maxresorb and Cerasorb (Curasan).

β-TCP is probably best known for its rapid resorption. One question that intrigued many investigators was whether the timing of bone graft resorption correlates with the rate of new bone formation. Lambert et al24 compared the healing of rabbit sinuses augmented with bovine hydroxyapatite (Bio-Oss), a BCP (Straumann BoneCeramic), and pure β-TCP (Cerasorb).24 New bone formed from each material, but the architecture differed. At 2 months, the xenograft formed intimate bridges of bone

FIG 6-2 Histology of trephined cores harvested from grafted human sockets at 6 months. (a to c) From bone grafted with synthetic NovaBone. (d to f) From bone grafted with a xenograft (Bio-Oss). The red tissue represents regenerated bone. (Reprinted with permission from Mahesh et al.23)

a

d

b

e

c

f

Biphasic Calcium Phosphates

91

between the particles, but bone formation was sparse in the BCP grafts and nonexistent in the β-TCP grafts. By 6 months, no material remained within the β-TCP grafts. This study alludes to the more rapid resorption of pure-phase TCP, demonstrating that synthetic hydroxyapatite slows this process and that nat- ural bovine-sintered hydroxyapatite resorbs even more slowly. Therefore, in certain clinical situations, a slow-resorbing xeno- graft that forms comparable bone is best suited. In another study, Jensen et al25 created defects in minipig mandibles and grafted them with either an autograft, xenograft (Bio-Oss), or β-TCP (Ceros, Thommen Medical) and later harvested bone sections at 1, 2, 4, and 8 weeks. Consistent with other studies, the autografts and β-TCP produced slightly more new bone during initial healing (at 4 weeks).

Biphasic Calcium Phosphates

It is widely perceived that synthetic materials resorb completely and do so rapidly, and xenogeneic bone substitutes are gen- erally considered nonresorbable. The literature is abundant with research reporting on materials termed biphasic calcium phosphates, one of the earliest reports in dentistry being that by Ellinger et al26 in 1986 treating periodontal intrabony defects. Biphasic refers to a combination of two materials, generally β-TCP and hydroxyapatite, whose ratios are adjusted to poten- tially manipulate their biomedical properties. BoneCeramic, for example, is biphasic, consisting of 60% synthetic hydroxyapatite and 40% β-TCP. Another method to control the resorption of calcium phosphates, other than by creating a biphasic material, is by adding a doping agent such as silicon, magnesium, or potassium.27 These also may have a therapeutic effect when they are released into the local environment (see chapter 21).

Grafting a socket with a substitute for re-entry and implant placement may typically take place at 3 to 6 months postex-

traction. For sinuses, this may take even longer. Cordaro et al17 carried out a randomized controlled trial comparing bone healing at grafted human sinuses at 6 to 8 months. Two mate- rials were compared: a biphasic calcium phosphate (BoneCe- ramic) and a bovine xenograft (Bio-Oss). Histologically, 23 synthetic bone samples compared to 25 xenograft samples demonstrated the same amount of new bone formation (syn- thetic 21.6% ± 10.0% versus xenograft 19.8% ± 7.9%). This amount of bone may be considered low, or lower than the desired quantity to accommodate a dental implant, and yet all 109 planned implants achieved appropriate primary sta- bility. The materials differed at later healing, with less residual synthetic material remaining than xenograft (26.6% ± 5.2% versus 37.7% ± 8.5%, P < .001). Thus, for sinus augmenta- tion procedures, BCP bone grafts produced comparable new bone as xenografts.

Dahlin et al28 also compared synthetic bone substitutes—an experimental ratio of 10% hydroxyapatite and 90% β-TCP (Fig 6-3), BoneCeramic (60% hydroxyapatite, 40% β-TCP), and Bio-Oss—and found that the xenograft produced more new bone at 8 weeks.28

A new novel BCP biomaterial of the same ratio (10% hydroxy- apatite and 90% β-TCP) was extensively tested by Miron et al.29

This synthetic (formerly VivOss by Straumann, currently Osopia by Regedent) was compared to Bio-Oss as well as to autografts and allografts, and all were investigated for their ability to form ectopic bone in rat muscle. They concluded the following29:

• The xenograft material (Bio-Oss) did not form bone ectopically. • The allograft (demineralized freeze-dried bone allograft

[DFDBA], LifeNet) formed bone ectopically. • The autograft formed some bone ectopically, but it was rapidly

resorbed. • The synthetic BCP (formerly VivOss, currently Osopia) formed

more bone ectopically.

FIG 6-3 Histology of an experimental β-TCP. Note the active resorption of the β-TCP and the hydroxyapatite (HA) lined with new bone (NB). (Reprinted with permis- sion from Dahlin et al.28)

β-TCP

NB

HA

Synthetic Bone Substitute Materials

92

06

Contrasted to an experiment in the dog model, the same working group found the following30:

• The xenograft (Bio-Oss) showed no ectopic bone formation and little resorption.

• The allograft (DFDBA, Straumann) formed ectopic bone, but it was rapidly resorbed by 8 weeks.

• The autograft also rapidly resorbed, and there was no ectopic bone formation at slightly longer time points.

• The synthetic BCP (formerly VivOss, currently Osopia) con- sistently formed ectopic bone by 8 weeks.

This new class of osteoinductive BCP is highlighted in chapter 7.

Synthetic Polymers

A variety of synthetic materials and admixtures of these have been described in the literature and continue to be widely inves- tigated. Tevlin et al31 reported on a composite material scaffold of a hydroxyapatite and polylactic-co-glycolic acid (PLGA) core that may be enriched with other materials such as bioactive growth factors.31 However, experimental socket grafting with PLGA/hydroxyapatite has demonstrated biocompatibility issues, with numerous reported failures (though in a limited number of test sites).32 Konopnicki et al33 evaluated 3D-printed β-TCP/ polycaprolactone scaffolds inserted into pig mandible defects.33

The results were promising, showing greater cell penetration and bone formation than in empty defects; however, comparative studies with standard replacement materials such as allografts and xenografts are still lacking. Notably, these biomaterials that incorporate polymers are not widely commercially available yet and are mostly limited to preclinical testing thus far. Future research is ongoing.

Titanium Granules

The use of titanium granules as a synthetic bone graft material has also been reported in the literature. They were rst utilized in orthopedics in the mid-2000s.34 A study carried out by Arruda et al35 histologically examined new bone formation in sockets grafted with titanium granules at 1 month. The control (non- grafted) sockets presented more new bone. In human subjects, Verket et al36 grafted maxillary sinuses and biopsied the grafts at 6 months; they found histologic new bone of 16.1% (standard deviation of 9.4%). This is notably low, and the titanium particles remained (25% of the total defect volume). Furthermore, the

effect of drilling an osteotomy into titanium particles was not discussed. Wohlfahrt et al37 debrided peri-implant defects with chemical decontamination and grafted half of the defects with porous titanium granules. While the improvement in radiographic defect ll was reported as signicant, no other notable differenc- es were observed. Apart from these studies, few studies have further investigated the use of titanium particles as synthetic materials, and their use is not clinically recommended at present.

Material Surface and Structure

The porosity of biomaterials has been cited as important for the ingrowth of capillaries and the ability to form bone. Various research groups have reported that submicron topography facilitates osteoblast differentiation and mineralization potential. For example, Hallman and Thor38 stated that material pore size needs to be larger than 300 microns. Bohner et al27 stated that macropores typically are bigger than 50 microns and allow cel- lular and capillary passage that facilitates bone formation. Yet early research of Haversian canal diameters in human mandible bone reported their diameter as 60 to 80 microns.39

To date, no ideal architecture or porosity has been provided, possibly due to each material’s different surface energy, chem- istry, and hydrophilicity. Some commercially available products identify their porosity, such as BoneCeramic, which states that the material comes in a 90% porosity. SEM images may provide more accurate depictions of these materials’ surfaces. Figure 6-4 provides high-resolution images of various commercially available materials as highlighted below:

• Cerasorb: Very smooth surface, lobular, highly interconnected material network, with pores or cavitations about 10 to 30 microns in size

• maxresorb and BoneCeramic: Mostly at and smooth, slightly rippled; highly fragmented; almost no interconnections, pores, or cavitations

• NovaBone Dental Putty: Embedded in a putty, its surface appears smooth and undulated, with microrough areas

• Perioglas (NovaBone): Microarchitecture highly similar to Cerasorb, yet much smaller; highly interconnected, intricate network of cavitations, about 1 to 5 microns in size; individual particles are highly fragmented, with numerous larger pores 10 to 100 microns in size (not seen in Cerasorb)

• Osbone: Highly fragmented particles, with larger pores lost in fragments; very rough surface; highly interconnected network of cavitations at the 2-micron level

• Ostim: Embedded in a putty, the particles appear smooth, with no pores; microrough at the <1-micron level

Miron_CH06.indd 92 11/7/18 8:58 AM

Clinical Indications and Case Presentations of Bone Regeneration

93

How each of these surface characteristics truly relates to clin- ical outcomes and bone regeneration remains relatively under- studied. Lambert et al20 reported on the surface topography of xenograft hydroxyapatite compared to synthetic hydroxyapatite and the effect on bone formation in animal sinus augmentations. At the 2-micron level, Bio-Oss appeared microrough compared to the other xenograft (Endobon) and the synthetic material (Osbone). None had large pores; all had micropores less than 1 micron in size, and Bio-Oss appeared to have abundant pores. The newly formed bone from Bio-Oss was nearly double that of the synthetic option (19.28% vs 11.93%).

A more informative study by Hinze et al40 compared allografts to a synthetic nanohydroxyapatite (Ostim). Harvested human alveolar bone samples were collected during routine dental surgeries. The osteoblasts were cultured, added to the two bone grafting materials, and compared for osteoblast activity. The authors reported that osteoblasts did not proliferate well or spread on the synthetic material (Ostim). Few vital cells were noted after 3 weeks of culture on the material. Proliferation

of osteoblasts on the allograft was far greater. Thus, this in vitro study demonstrated a poor performance for the synthetic nanohydroxyapatite.

Clinical Indications and Case Presentations of Bone Regeneration

Figure 6-5 shows a case of ridge preservation prior to implant placement. The mandibular right rst molar was extracted, and the socket was grafted with maxresorb, a synthetic BCP (60% hydroxyapatite, 40% β-TCP) particulate material, and sealed with a collagen membrane (Jason, botiss). At 3 months, the site appears well preserved (see Figs 6-5e and 6-5f). A tissue-level implant (Straumann) was placed, osseointegrated, and restored (see Figs 6-5g to 6-5i).

FIG 6-4 (a) NovaBone Putty is an injectable biomaterial that forms a relatively smooth surface but also features some topographic differences, like- ly as a result of the putty-based composition. (b) Cerasorb displays an extremely smooth surface. These surfaces typically are not as conductive toward osteoblast differentiation as roughened surfaces, presenting more micro- and nanotopographies. (c) SEM image of Perioglas (NovaBone). Notice the roughened surface morphology. (d) SEM image of Ostim paste. Notice the roughened surface. (e) SEM image comparing two synthetic materials: maxresorb and BoneCeramic. Notice the relatively smooth surfaces and lack of porosity. (All images original magnication ×6,000.)

a b

d e

Cerasorb (Curasan) Perioglas (NovaBone)

Synthetic Bone Substitute Materials

94

06

FIG 6-5 Socket grafting of a mandibular left rst molar site followed by implant placement. (a) Minimally traumatic tooth extraction due to an apical lesion. (b and c) A maxresorb synthetic bone graft and a Jason membrane (botiss) are utilized within the extraction socket. (d) Radiograph immediately postoperative. (e and f) Clinical photograph and radiograph after 3 months of healing. Notice the excellent maintenance of the site dimensions postextraction. (g) Implant placement. (h) Radiograph showing the implant and provisional crown. (i) Clinical photograph of the nal crown. (Case performed by Dr Massimo Frosecchi.)

a b

Clinical Indications and Case Presentations of Bone Regeneration

95

Figure 6-6 shows a case of transcrestal sinus elevation and augmentation. Using osseodensication burs, a Versah lift was carried out at the site of a missing maxillary right premolar that had a vertical deciency. The unique nonextractive drilling sys- tem propelled autogenous bone into the sinus, simultaneously

lifting the sinus membrane. The sinus was additionally augment- ed by lling the osteotomy with 70% calcium phosphosilicate putty (NovaBone), and the Versah burs were repeatedly applied into the osteotomy, further propelling the graft material. A sig- nicant vertical augmentation was achieved.

FIG 6-6 Versah lift at the site of a missing maxillary right second premolar. A transcrestal sinus elevation was performed with osseodensication burs, and the sinus was augmented with a synthetic bone material (NovaBone) prior to implant placement. (a) Maxillary right second premolar site with observed dimensional loss of bone width. (b) Cone beam computed tomography (CBCT) of the implant planning. (c) Osteotomy prepared with Versah burs. (d and e) Injection of NovaBone (radiopaque). (f and g) Clinical images of implant placement. (h) Final radiograph. Notice the radiopaque NovaBone found within the sinus. (Case performed by Dr Jonathan Du Toit.)

a b

Synthetic Bone Substitute Materials

96

06

Figure 6-7 shows a case of grafting the buccal gap during immediate implant placement. A maxillary premolar was de- coronated and a socket shield prepared. An immediate implant was placed, and the buccal gap was grafted with NovaBone Putty. At the 1-year follow-up, there appeared to be little or no collapse of the buccal ridge (see Fig 6-7f).

Conclusion It is fair to state that the ideal synthetic bone graft replacement has not yet been developed or conclusively proposed. However, premanufactured synthetic scaffolds for the rehabilitation of alve- olar bone defects continue to improve. There remains no single graft material that is ideally suited for all clinical situations in all patients. In the future, it is expected that synthetic bone grafts will be the class of bone grafts with the greatest improvements regarding their use in daily clinical practice.

FIG 6-7 Socket-shield technique and immediate implant placement at the site of a maxillary right rst premolar. The buccal gap was augmented with a synthetic bone material (NovaBone Putty). (a and b) The maxillary right rst premolar was partially extracted due to decay; a portion of the tooth root was left in place to maintain the buccal bone. (c) Injection of NovaBone synthetic bone putty. (d) Implant placement. Notice the NovaBone on the buccal aspect of the implant. (e and f) Radiograph and CBCT images 1 year after surgery. (g) Clinical image demonstrating the excellent esthetic result. (Case performed by Dr Howard Gluckman.)

a

c

References

97

References 1. Güngörmüs Z, Güngörmüs M. Eect of religious belief on selecting of

graft materials used in oral and maxillofacial surgery. J Oral Maxillofac Surg 2017;75:2347–2353.

2. Kim Y, Rodriguez AE, Nowzari H. The risk of prion infection through bo- vine grafting materials. Clin Implant Dent Relat Res 2016;18:1095–1102.

3. Laurencin CT, Jiang T. Bone Graft Substitutes and Bone Regenerative Engineering. West Conshohocken: ASTM International, 2014.

4. Dorozhkin SV. Calcium Orthophosphate-Based Bioceramics and Bio- composites Dorozhkin/Calcium Orthophosphate-Based Bioceramics and Biocomposites. Weinheim, Germany: Wiley-VCH Verlag GmbH & Co. KGaA, 2016.

5. Jones JR, Clare A. Bio-glasses: An Introduction. Chichester, England: Wiley, 2012.

6. Laney WR. Glossary of Oral and Maxillofacial Implants. Berlin: Quin- tessence, 2007.

7. ICOI. ICOI Glossary of Implant Dentistry.www.icoi.org/wp-content/ uploads/2016/12/Glossary-of-Implant-Dentistry-3.pdf. Accessed 12 January 2018.

8. Hench LL. The story of Bioglass. J Mater Sci Mater Med 2006;17:967–978. 9. Stanley HR, Hall MB, Clark AE, King CJ 3rd, Hench LL, Berte JJ. Using

45S5 bioglass cones as endosseous ridge maintenance implants to prevent alveolar ridge resorption: A 5-year evaluation. Int J Oral Maxil- lofac Implants 1997;12:95–105.