SW-2000/2024 - FERGUSON PACKAGING

Transcript of SW-2000/2024 - FERGUSON PACKAGING

Continuous Motion, Belted Infeed, Side-Seal Shrink Wrapper

Page 1 of 2Rev. 08/18/08SW-2000/2024

I n n o v a t i o nDesigned to make setup and operation as

simple as possible to increase productivity

SW-2000/2024

SW-2000 shown with optional pre-spacing conveyor

Part # 31008231

Separate cut and seal process eliminates film build-up. No cleaning required.

Handles infinite product lengths.

Positive cut and seal process is ideal for polyolefin and PVC films.

Handles wide temperature and speed ranges.

One-step temperature set-up. No pressure, dwell, angle adjustments needed.

Lantech Rotary Side-Seal

On-the-fly film adjustments reduces downtime.

Sure-Trac™ electronic film drive eliminates film breaks and allows narrow trim to reduce film waste.

Easy film roll placement and threading.

Sure-Trac™ Film Delivery System

More Lantech field-tested packaging solutions @ www.lantech.com

Page 2 of 2Rev. 08/18/08SW-2000/2024Lantech.com • 11000 Bluegrass Pkwy. • Louisville, KY 40299-2399 USA • 800-866-0322 • www.lantech.com

Specifications subject to change without notice. Lantech systems and sub-systems are protected by U.S. and foreign patents. Additional U.S. and foreign patents pending. © Lantech 2008

SW-2000/2024

Part # 31008231

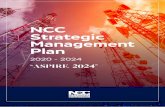

SW-2000 SW-2024Production SPeed- Feet/Minute up to 65 up to 65 - PackageS/Minute up to 60 up to 60Machine tyPe Continuous motion Continuous motioninFeed conveyor 15" W BElT 21" W BElT

*Product SizeS (L x W x h) Min 3" x 1" x 1/8" 3" x 1" x 1/8" (L x W x h) Max Infinite x 15" x 8" Infinite x 21" x 8" croSS SeaL tyPe Hot knife Hot knifecroSS SeaL Width 18" 24"FiLM Width (centerFoLded) 6" to 24" 8" to 32"FiLM tyPeS Most Commercial grade Most Commercial grade Polyolefin, PVC Polyolefin, PVC Some films may require Some films may require change parts. change parts.

triM Winder Mechanical with Electronic Mechanical with Electronic Tension control Tension control

adjuStabLe FiLM inverting head STd STd controLS PlC/Touchscreen PlC/TouchscreeneLectricaL requireMentS 230 V, 1 phase, 20 Amp 230 V, 1 phase, 20 AmpPneuMatic requireMentS 8-12 CFM @ 85 PSI 8-12 CFM @ 85 PSIMachine diMenSionS 96"l x 39"W x 66"H 108"l x 48"W x 68"HoPerating height 34.5" to 39.5" 34.5" to 39.5"

Also available: SW-1000 Intermittent Motion Belted Infeed and SW-3000 Continuous Motion Flighted Infeed Wrappers

S W - 2 0 0 0 / 2 0 2 4 S p e c i f i c a t i o n s

Programmable logic Controller.

Color touch-screen control panel with password protection.

Store and recall set-up parameters.

operator-friendly

Right-to-left flow (standard). Adjustable inverting head. Vertical and horizontal product detection. Electronic package spacing. Random product lengths. Wide variety of standard infeeds; flight bar, flight lug, belt. Perfect match with ST-Series “soft convection” Shrink Tunnels.

Fit to Application

SW-2000 Shrink Wrapper shown with Lantech ST-900 Shrink Tunnel and optional pre-spacing conveyor.

coLor touch Screen hMi Top level access to primary machine functions, changeable without stopping machine Password Protection (3 levels) Easily store and recall up to 16 basic recipes diagnostic and maintenance features Electronic collapse and product spacing (no mechanical variator) On demand operation - automatic product spacing Swivel mounted HMI accessible from both sides of machine Horizontal/Vertical photo-eyeWeight (approx. machine/shipping) 2000 / 2800 lbs. 2400 / 3300 lbs.oPtionS Casters, Pre-spacing conveyor, Print Registration, Exit transition rollers, Film support inverter rods, Film Centerfolder, Adjustable infeed guideService/SuPPort 24 hours - 7 days/weekWarranty 2 Years or 6,000,000 Cycles (except consumable wear items)

All set-up adjustments synchronized to package dimensions

*Maximum height and maximum width cannot run concurrently.