SURFHOPE SUGAR ESTERS - PharmaCompass...phase and a dispersed oil phase consisting of very small...

Transcript of SURFHOPE SUGAR ESTERS - PharmaCompass...phase and a dispersed oil phase consisting of very small...

SURFHOPE® SE COSME

Distributor Manufacturer

natUral emUlsifiers for extraordinary textUres…

SURFHOPE® SUGAR ESTERS

Distributor Manufacturer

SURFHOPE® SE COSME

2

Of vegetal origin, sucrose fatty acid esters, commonly called sugar esters, are non ionic, PEG-free emulsifiers. Ultra-mild and highly pure, they present an excellent tolerance with even the most sensitive skins. Strong water binders, sugar esters bring natural moisturization to the skin.

Their amphiphilic character brings them excellent emulsifying capacity, both for water in oil and oil in water emulsions. They can also form concentrated and transparent emulsions.

Used alone or in combination, they allow the formulation of all types of skin care product and also sun care, make-up, hair care and cleansing products.

Formulated using standard method or using the novel D-phase emulsification procedure, the emulsions obtained are fine, fresh and highly stable.

sUrfHope® sUGar esters

Multifunctionalemulsifiersofnaturalorigin…

Innovativespontaneousemulsificationtechnology…

Surprisingandvariedtextures…

MITSUBISHI-KAGAKU FOODS & GATTEFOSSÉ present a range of emulsifiers that meet today’s trend for natural cosmetics:

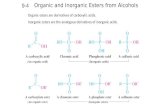

C X Y

Cosmetic grade Fatty acid chain length: from 12 (lauric) to 22 (behenic)

HLB: from 1 to 16

3

Sugar esters are formed by esterification between methyl esters of saturated and mono-unsaturated fatty acids sourced from vegetable oils (palm, palm kernel, rapeseed, coconut oil…), and a molecule of sucrose (saccharose, obtained from sugar cane or sugar beet).

The saccharose can be esterified on one or more of its 8 hydroxyl groups, forming between mono- and octa-esters. The association of a hydrophilic sugar and a hydrophobic hydrocarbon chain brings the sugar ester emulsifying properties and a HLB value that depends on the degree of esterification.

Largely used in the food industry, in particular in cakes and dairy products, their exceptional dispersing and solubilising properties are highly appreciated.

Depending upon the HLB of the sugar ester used, oil in water or water in oil emulsions can be created. it is also possible to create a new kind of transparent gelled concentrated emulsion, called a D-phase gel.

brinGinG toGetHer veGetable oils and sUGar…

a simple nomenclatUre…SURFHOPe® Sugar esters have a very simple nomenclature related to the composition of the product:

example: SURFHOPe® C-1815 is a sucrose stearate (C18) of HLB 15

0

1 0

1

0

1

SURFHOPE® C-1216 / SURFHOPE® C-1616 (50:50)

GLYCERINE 80%WATER 20% LABRAFAC® CC

4

it is possible to formulate stable, transparent D-phase gels using either a unique sugar ester or a combination of two sugar esters. in all cases, only high HLB sugar esters are suitable.

Made up of an isotropic surfactant phase called the D-phase and a high quantity of dispersed oil phase, the D-phase gel has the appearance of a transparent gelled emulsion with a rich and gourmand texture. The gel presents a continuous aqueous phase and a dispersed oil phase consisting of very small particles (< 300 nm) due to low interfacial tension.

Associating stability and originality, these concentrated emulsions can be used on their own in a wide range of applications: skincare (massage gel), cleansing (make-up remover, exfoliant) and in shower and bath products.

The rinseability of the D-phase gel is excellent. indeed, the structure undergoes spontaneous emulsification upon addition of water. The transparent gel is transformed into milk, rinsing perfectly and leaving the skin soft and refreshed.

creation of a d-pHase Gel

How to formulate the D-phase gel?

TYPICAL D-PHASE FORMULA

SUGAR eSTeRS: 5 - 20% POLYOL: 10 - 20%

OiL PHASe: 50 - 80% WATeR: 5 - 10%

Transparent gel

5

The recommended grades and use levels for the formulation of a D-phase gel are given below.

Other combinations are possible and, by varying the overall level and the relative ratios of each sugar ester, the physico-chemical characteristics of the D-phase gel will change.To obtain more viscous formula, it is recommended to increase the length of the fatty acid in the sugar ester, for example by increasing the percentage of C-1616 or C-1816.

Suitable glycols include glycerine, propylene glycol and sorbitol. Many types of different oils can be used including vegetable oils, mineral oils and esters. it is possible to incorporate a low quantity of silicone oil. Both hydrophilic and lipophilic active substances can be added to their respective phases without destroying the structure of the gel and its transparency.

Optimal formulation conditions

The water, glycol and sugar ester are heated to 75°C and mixed together until homoge-neous and transparent. The oil phase is then heated to the same temperature and added very slowly to the water / polyol / sugar ester combination under mixing. The mixing conditions required depend on the viscosity of the D-phase gel. As the oil phase is added, the gel becomes more viscous which requires a higher mixing strength. Once all the oil phase has been added and the mixture is homogeneous, the heat is removed and the gel allowed to cool. it is recommended to work under vacuum during the emulsification process as the sugar esters can create foam during formulation in water.

The sugar esters can be used to formulate particularly cool and aqueous oil in water emulsions. Two manufacturing processes can be chosen: a method which involves an intermediate stage, consisting of a D-phase gel, or a standard method, as used with other emulsifiers.

Recommendedgrades Uselevel

C-1216 alone between 5 and 10%

C-1416 alone between 5 and 10%

C-1416 and C-1816 in combination 50:50 at 10%

C-1216 and C-1616 in combination 50:50 at 5%

C-1216 and C-1816 in combination 60:40 at 5%

6

creation of an oil in water emUlsion UsinG ad-pHase Gel intermediate

The D-phase gel undergoes spontaneous dilution upon addition of water. The emulsion obtained is very fluid, fine and presents excellent stability. The emulsion can then be gelled by the addition of classical gelling agents such as carbomers allowing the viscosity to be adapted as desired. The self-emulsification process requires low energy input (helical stirrer) and no heat, allowing the incorporation of ingredients that are shear or temperature sensitive.

emulsion made by standard method emulsion made via the intermediateD-phase concentrated emulsion

The very fine particle size means that these emulsions are ideal for vectorization of active ingredients. The low starting viscosity allows the development of sprayable emulsions.

How to formulate an O/W emulsion using a D-phase gel intermediate?

in this method, a concentrated D-phase gel is prepared as an intermediate step before dilution. The process for formulation of the D-phase gel is as given before. However, it is necessary to increase the level of sugar ester in the D-phase gel in order to achieve stability of the final emulsion. The recommended level of sugar ester in the final formula is between 3 and 5%.

The dilution can be carried out without any heat input, simply using a stirrer or mixer, depending upon the viscosity of the intermediate gel phase. it is often easier to add the water to the gel rather than the inverse, if the water phase is not pre-gelled. The emulsion obtained is very fluid and consists of very fine particles (<1 µm).Other ingredients may then be added: gelling or consistency agents, waxes, active substances and sun filters allowing the texture and functionality of the product to be adapted as wished.

The emulsions obtained by this method are finer and more stable than those formed using a classical manufacturing process. However use of an aqueous gelling agent is still recommended.

7

creation of an oil in water emUlsion UsinG a classical emUlsification process

Sugar ester emulsions can be obtained using standard methods of emulsification. To obtain maximum stability it is recommended to associate a high HLB and a low HLB sugar ester:

Recommendedgrades Uselevel

C-1803/C-1816 in combination 40:60 C-1803/C-1615 in combination 40:60 C-1805/C-1815 in combination 70:30

The amount of sugar esters to be used depends upon the nature and level of the oil phase. However the usual recommended level is between 3 and 5%. it is essential to add an aqueous gelling agent to improve stability. A wide range of ingredients (gelling and consistency agents, polymers…) can be added to the emulsion in order to create every kind of texture imaginable.

The oil in water emulsions, whatever the manufacturing process, increase slightly in viscosity during the first 24 hours following manufacture.

Optimal formulation conditions

in order to achieve the best dispersion, the high HLB sugar ester should be wetted with a glycol or with a small quantity of water before adding to the remainder of the aqueous phase. The aqueous phase should then be heated to 75°C until complete dissolution of the sugar ester (translucent solution).The low HLB sugar ester is added to the oil phase then heated to 75°C until dissolution of the sugar ester (transparent solution).The oil phase is then added to the aqueous phase, preferably using high shear mixing (rotor-stator), until a fine emulsion is obtained. Use of a vacuum is recommended.

creation of a water in oil emUlsion

To create water in oil emulsions, a cold or hot process can be used. it is necessary to add salts and/or consistency agents to improve stability. The emulsions obtained are smooth and cool with excellent spreading capacity.

Recommendedgrades Uselevel

C-2102 alone at 5% C-1801/Plurol® Diisostearique in combination 30:70 at 5% (polyglyceryl-3 diisostearate)

888

Optimal formulation conditions

The sugar ester is added to the oil phase under stirring. in the case of C-2102, it is not necessary to heat the oil phase; the C-1801 requires heating to solubilize the emulsifier. Using high shear agitation (rotor-stator), the aqueous phase is then added slowly to the oil phase. Salt (MgSO4) is to be used in the aqueous phase.

sensorial properties

The texture and sensorial characteristics of the sugar esters can vary widely, depending on the oil phase and aqueous gelling agent employed. However, all the sugar ester emulsions are fresh, aqueous and very soft to the touch. This cooling, refreshing effect is immediately noticeable whatever the type of emulsion (O/W and W/O). They spread easily upon the skin, leaving a smooth, soft and non-sticky after feel.

applications

The sugar esters are suitable for all types of personal care products, in particular skin-care, sun care and for natural or sensitive skin lines.

conclUsion

The SURFHOPe® Sugar esters, emulsifiers of natural origin, are characterized by their extreme purity, multi-functionality, soft and cool touch and excellent tolerance with even the most sensitive of skins.

The wide range of available grades allows the creation of many oil in water and water in oil emulsions. Their unique structure enables the creation of novel “D-phase” transparent concentrated emulsions.

Presenting excellent compatibility with all personal care ingredients, the SURFHOPe® Sugar esters allow the formulation of a new generation of innovative, light and refreshing cosmetics.

8

999

Productname INCIname CASnumbers EINECSnumbers(usedonlabel) Mainsubstance Mainsubstance

SURFHOPe® C-1201 Sucrose polylaurate 94139-22-7 3030373

SURFHOPe® C-1205 Sucrose dilaurate 25915-57-5 2473455

SURFHOPe® C-1215 L Sucrose laurate 25339-99-5 2468733

SURFHOPe® C-1216 Sucrose laurate 25339-99-5 2468733

SURFHOPe® C-1416 Sucrose myristate 27216-47-3 2483400

SURFHOPe® C-1601 Sucrose hexapalmitate 29130-29-8 2494627

SURFHOPe® C-1615 Sucrose palmitate 26446-38-8 2477067

SURFHOPe® C-1616 Sucrose palmitate 26446-38-8 2477067

SURFHOPe® C-1701 Sucrose polyoleate 77138-73-9 N/A

SURFHOPe® C-1715 Sucrose oleate 25496-92-8 2470412

SURFHOPe® C-1800 Sucrose polystearate 90567-58-1 2922022

SURFHOPe® C-1801 Sucrose polystearate 94139-18-1 3030347

SURFHOPe® C-1802 Sucrose polystearate 94139-18-1 3030347

SURFHOPe® C-1803 Sucrose tristearate 27923-63-3 2487316

SURFHOPe® C-1805 Sucrose distearate 27195-16-0 2483175

SURFHOPe® C-1807 Sucrose distearate 27195-16-0 2483175

SURFHOPe® C-1809 Sucrose distearate 27195-16-0 2483175

SURFHOPe® C-1811 Sucrose stearate 25168-73-4 2467059

SURFHOPe® C-1815 Sucrose stearate 25168-73-4 2467059

SURFHOPe® C-1816 Sucrose stearate 25168-73-4 2467059

SURFHOPe® C-2101 Sucrose hexaerucate 115536-98-6* N/A

SURFHOPe® C-2102 Sucrose pentaerucate 287493-01-0 N/A

SURFHOPe® C-2203 Sucrose tribehenate 84798-44-7 N/A

Grades available and specifications

Organoleptic characteristicsPhysico-chemical characteristicsTransport and storage conditionsPackingRegulatory situationToxicological profile

9

Individual specification sheets available upon request

* blanket number

10

CHILDREN'S SUNSCREEN CREAM SPF 16 (W/O EMULSION) EG 336/F

I SUCROSE POLYSTEARATE SURFHOPE® C-1801 1.50 POLYGLYCERYL-3 DIISOSTEARATE PLUROL® DIISOSTEARIQUE 3.50 GLYCERYL DIBEHENATE (AND) TRIBEHENIN (AND) GLYCERYL BEHENATE COMPRITOL® 888 ATO 0.50 POLYDECENE 15.00 DIMETHYCONE 4.00 OCTYL PALMITATE 6.00 HYDROGENATED CASTOR OIL 1.00

II TITANIUM DIOXIDE 10.00

III WATER 56.90 PRESERVATIVE 0.50 MAGNESIUM SULFATE 0.50 SODIUM CHLORIDE 0.50

IV PERFUME 0.10

100.00

Heat phase i up to 85°C. Add phase ii to phase i and mix until homogeneous. Under rapid stirring (rotor-stator 3000 rpm) add phase iii heated to 80°C to phase i + ii heated to 85°C. Continue rapid stirring for 10 minutes. Cool under moderate stirring (1500 rpm). At 30°C add phase iV.

formUlas

HYDRASOFT GEL (0/W EMULSION) EG 437

I SUCROSE STEARATE SURFHOPE® C-1816 2.40 GLYCERINE 3.00 PRESERVATIVE 0.50

II WATER 77.50 HYDROXYETHYLCELLULOSE 0.20 SODIUM HYALURONATE 1.00

III SUCROSE TRISTEARATE SURFHOPE® C-1803 1.60 AMMONIUM ACRYLOYLMETHYLTAURATE (AND) BEHENETH-25

METHACRYLATE COPOLYMER 0.30 HYDROGENATED PALM KERNEL GLYCERIDES (AND) HYDROGENATED PALM GLYCERIDES LIPOCIRE® A 1.00 TOCOPHERYL ACETATE 0.30 ETHOXYDIGLYCOL OLEATE SOFTCUTOL® O 3.00

IV CYCLOMETHICONE 7.00 CYCLOMETHICONE (AND) DIMETHICONOL 1.00

V GLYCERINE (AND) TRITICUM VULGARE (WHEAT) FLOUR EXTRACT PHYTOCERAMIDES® BLE 1.00 CI 14720 0.10 PERFUME 0.10

100.00

Mix ingredients of phase i and phase ii. Then add phase ii to phase i. Heat phases i and ii to 75°C. Under rapid mixing (rotor-stator) add phase iii to phase i + ii. Quickly add phase iV. Keep mixing during 10 minutes. Cool down to room temperature under moderate stirring. Add phase V ingredients one by one.

Trade name %INCI name

INCI name Trade name %

11

CHOCOLATE BODY MASSAGE GEL (D-PHASE EMULSION) EG 360/C

I SUCROSE LAURATE SURFHOPE® C-1216 3.00 SUCROSE STEARATE SURFHOPE® C-1816 2.00 GLYCERINE 10.00 DEMINERALIZED WATER 3.50

II CAPRYLIC/CAPRIC TRIGLYCERIDE LABRAFAC® CC 30.40 PROPYLENE GLYCOL DIPELARGONATE DPPG 50.00III CI 19140 + CI 16255 + CI 73015 + CI 42090 0.60 PERFUME 0.50

100.00

At room temperature, mix well ingredients of phase i and then heat to 80°C until homogeneous. Heat phase ii up to 80°C. While stirring at 500 rpm (helical stirrer) add slowly phase ii to phase i. increase stirring as the viscosity increases and until homogeneous. Cool down to room temperature. Add phase 3 ingredients one by one.

INCI name Trade name %

STRAWBERRY YOGHURT (0/W EMULSION with D-PHASE intermediate) EG 368/E

I SUCROSE STEARATE SURFHOPE® C-1816 3.00 GLYCERINE 5.00 DEMINERALIZED WATER 1.40

II OCTYLDEDECYL MYRISTATE MOD 6.00 PROPYLENE GLYCOL DIPELARGONATE DPPG 6.00 PRESERVATIVE 0.50 HELIANTHUS ANNUUS (AND) ROSMARINUS OFFICINALIS OXY'LESS® CLEAR 0.10III CYCLOMETHICONE 3.00

IV DEMINERALIZED WATER 72.60

V ACRYLATES/ACRYLAMIDE COPOLYMER (AND) MINERAL OIL

(AND) POLYSORBATE-85 1.80 JOJOBA ESTERS 0.50 PERFUME 0.10

100.00

First prepare the D-phase gel: At room temperature, mix well ingredients of phase i. Heat phase i and phase ii to 80°C. Using helical stirring, add slowly phase ii to phase i. Adjust stirring speed with respect to viscosity. Cool down and at 50°C add phase iii. Cool to room temperature. Then dilute the D-phase gel: At room temperature add water of phase iV to D-phase gel (i + ii + iii). Then add phase V ingredients one by one.

INCI name Trade name %

This information is presented in good faith and we believe it is correct, but no warranty as to accuracy of results, or fitness for a particular use is given, nor is freedom from patent infringement to be inferred. it is offered solely for your consideration, investigation and verification.

G a t t e f o s s é r e G i o n a l a f f i l i a t e s

Gattefossé: 36 chemin de Genas - BP 603 - F-69804 Saint-PrieSt Cedex - FranCetel. +33 4 72 22 98 00 - Fax: +33 4 78 90 45 67 - e-mail: [email protected]

www.gattefosse.com

United KinGdom

Gattefossé (UK) Limited Arc House, Terrace Road South Binfield, Bracknell, BeRKSHiRe RG42 4PZ Tel. +44 1344 861 800 Fax +44 1344 451 400

france

Gattefossé France Parc des Barbanniers 5 Promenade de la Bonnette F-92632 GeNNeViLLieRS Cedex Tel. +33 1 41 47 19 00 Fax +33 1 41 47 19 29

spain

Gattefossé españa, S.A. • Av. Diagonal 460 6° A e-08006 BARCeLONA Tel. +349 3 416 05 20 Fax +349 3 415 35 46

• C/Padilla, 73, 1° B e-28006 MADRiD Tel. +349 1 402 13 11/16 12 Fax +349 1 402 00 82

Germany

Gattefossé (Deutschland) GmbH Rheincenter, Hauptstrasse 435 D-79576 WeiL-AM-RHeiN Tel. +49 7621 720 07 Fax +49 7621 79 22 93

italy

Gattefossé italia s.r.l. Via Derganino 20 i-20158 MiLANOTel. +39 02 39314073 Fax +39 02 66200440

w o r l d w i d e p o s i t i o n

GatteFoSSé is an independent, multinational company headquartered in

France which creates, manufactures and distributes specialty products used as

ingredients by the cosmetic and pharmaceutical industries.

Present in almost 50 countries worldwide, GatteFoSSé enjoys a strong

know-how and position in lipochemistry, biology and extraction from

natural sources.

GatteFoSSé offers the cosmetic industry a variety of high performance

products classified as:

• bases & additives: emulsifiers, coemulsifiers, emollients, dispersers, solubilizers, thickeners…

• �traditional plant extracts

• sUbstantiated active inGredients from vegetable and marine origins.

c o r p o r a t e & H e a d q U a r t e r s

![Your Boutique for [niche] APIs - PharmaCompass](https://static.fdocuments.net/doc/165x107/61d16914bcc5ac39b7116de0/your-boutique-for-niche-apis-pharmacompass.jpg)