Surface nanoengineering of titanium alloys for …...Surface Nanoengineering of Titanium Alloys for...

Transcript of Surface nanoengineering of titanium alloys for …...Surface Nanoengineering of Titanium Alloys for...

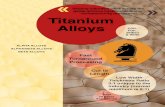

Surface Nanoengineering of

Titanium Alloys for Biomedical

Applications

A thesis submitted in total fulfilment of the requirements for the degree of

Doctor of Philosophy

By

Sepideh Minagar

Faculty of Science, Engineering and Technology

Swinburne University of Technology

Hawthorn, Melbourne

Australia

February 2015

ii

Abstract

Failure of a biomaterial implant occurs when it cannot be accepted by the body. In terms

of orthopaedic implants, this means that there is no bonding between the implant

material and bone cells. In this study, fabricated nanotubular layers on the surface of

Ti50Zr binary alloy was investigated for its bioactivity and osseointegration after

anodisation. This study investigates the effect of nanopatterning of the surface as metal

oxide nanotubes which convert the bio-inert metal surface to be bioactive. This

nanotubular layer was examined for its ability to induce bone-like calcium phosphate

(CaP), e.g. hydroxyapatite or other compositions such as octacalcium phosphate and

tricalcium phosphate through immersion in a modified simulated body fluid (m-SBF).

The biocompatibility of the nanotubular layer was also assessed by cell culture test

using human osteoblast-like cells (SaOS-2). As the bare TiZr metal exhibited potential

for metallic implant applications due to its excellent bioactivity and biocompatibility, it

is expected that the nanotubular layer plays a promising role in forming strong

adhesions with bone cells, allowing it to be used as an implant.

The first part of this study investigates the condition for fabrication of TiO2-ZrO2-

ZrTiO4 nanotubes. This includes the changing of the anodisation parameters such as the

applied potential, the concentration of F- ion in the electrolyte, the type of electrolyte

and the anodisation time. In this research project, a full characterisation of the TiO2-

ZrO2-ZrTiO4 nanotubes including morphological, thermal, topographical, chemical and

mechanical properties has been investigated using scanning electron microscopy

(SEM), thin film X-ray diffraction (XRD), X-ray photoelectron spectroscopy (XPS)

analysis, nanoindentation and water contact angle measurements. Bioactivity and

biocompatibility assessment have been employed in order to demonstrate the

characteristics of the nanotubular layer to improve hydroxyapatite mineralisation and

bone cell integration.

It was found that in the aqueous electrolyte there was a distribution of inner diameter,

outer diameter and wall thickness of nanotubes in comparison to TiO2 nanotubes as well

as in non-aqueous electrolyte, due to the different oxidation rates of Ti and Zr. The

orientation of nanotubes followed the microstructure of the Ti50Zr alloy. This effect

was obvious in the aqueous electrolyte whilst in the non-aqueous electrolyte it was less

affected and the orientation can be observed when the water content of the electrolyte

increased from 5 to 10 wt %. The walls of nanotubes were not separated when they

iii

were fabricated in non-aqueous electrolyte. The roughness parameters of the

nanotubular layer of TiO2-ZrO2-ZrTiO4 were higher than the nanotubular layer of TiO2,

due to the different height of the grown nanotubes. It has been shown that there was a

direct link between roughness parameter and wettability of the nanotubular layer. The

wettability or hydrophilic properties of nanotubes increased with an increase in

roughness. The TiO2-ZrO2-ZrTiO4 nanotubes exhibited higher surface energy than TiO2

nanotubes. Hydroxyapatite mineralised on the TiO2-ZrO2-ZrTiO4 nanotubes with higher

Ca/P ratio and thickness than on the TiO2 nanotubes. When Sa of the as-formed TiO2-

ZrO2-ZrTiO4 nanotubes increased, the Ca/P ratio of HA increased in contrast to

annealed nanotube. Increasing the hydrophilic properties of either as-formed or

annealed nanotubes resulted in an increase of the Ca/P ratio of HA. After annealing, the

Ca/P ratio of HA increased. Results of the MTS assay indicated that the percentage of

cell adhesion on the nanotubes fabricated in aqueous and non-aqueous electrolyte was

critically affected by the nanoscale topographical parameters including the tube inner

diameter (Di), the tube wall thickness (Wt), the amplitude roughness (Sa) and the spacing

roughness (Sm) of the nanotubular surface. The highest percentage of cell attachment

was on the surface of TiO2-ZrO2-ZrTiO4 nanotubes with Di = 18 nm (optimum

nanospacing) and the lowest percentage of cell attachment was on the surface of TiO2-

ZrO2-ZrTiO4 nanotubes with Di = 59 nm (higher amplitude parameter of roughness, Sa)

when the nanotubes were fabricated in an aqueous electrolyte. It was found that a post-

treatment that reduces the contamination of nanotubular surface or mineralising

hydroxyapatite can increase cell attachment significantly from 41.0 % to 74.8 % and

59.7 %, respectively. When the nanotubes were fabricated in non-aqueous electrolyte,

bone cells behaved similarly. The highest percentage of cell attachment was on the

surface of TiO2-ZrO2-ZrTiO4 nanotubes with Di = 25 nm (optimum nanospacing) and

the lowest percentage of cell attachment were on the surface of TiO2-ZrO2-ZrTiO4

nanotubes with Di = 29 nm (higher spacing parameter of roughness, Sm).

iv

Acknowledgments

First and foremost I wish to express my deepest gratitude to my principal supervisor

Professor Cuie Wen for her continuous support, encouragement and unstinting

supervision in conducting research, and her optimistic manner and valuable guidance in

writing the research publications. I also appreciate her trust and friendship which means

a great deal to me. I would also like to express my sincere gratitude to my associate

supervisor Professor Christopher C. Berndt for his invaluable advice and guidance in

writing the research publications. I must thank my other associate supervisor Dr James

Wang for his continuous help and support in the metallographic and spectroscopy

laboratories. I am thankful to Professor Elena P. Ivanova for her supervision on the cell

biology aspect of this research. I also acknowledge the State Government of Victoria of

Australia and Swinburne University of Technology for supporting and funding this

research project through a Victorian International Research Scholarship (VIRS) and

Swinburne University Postgraduate Research Award (SUPRA).

I wish to thank Dr Yuncang Li for his guidance and advice in the cell culture study and

the nanoindentation research at the Institute for Frontier Materials, Deakin University,

Geelong. I also thank Dr Thomas Gengenbach for his help in XPS analysis at

CSIRO Materials Science and Engineering, Clayton.

The help of Dr Mehran Motamed Ektesabi, Dr Igor Sbarski, Dr Akbar Rhamdhani, Dr

Thomas Ameringer, Dr Mostafa Nikzad, Dr Yeannette Lizama and Dr Vi Khanh

Truong for permitting me to use their equipments and/or chemicals is highly

appreciated. My thanks are extended to Dr De Ming Zhu for training me to use the 3D-

Profilometer. The technical assistance of Messieurs Brian Dempster and Andrew Moore

and the technicians of the workshop of the Faculty of Science, Engineering and

Technology are gratefully acknowledged. I thank all my supervisor research group

members (PhD students and Research Fellows) for their scientific discussions and

advice. I wish to thank Ms Madeleine Bruwer, the liaison librarian of the Faculty of

Science, Engineering and Technology because she always answered my questions

patiently. My sincere thanks to Professor Syed H. Masood, Associate Professor Paul

Stoddart and Dr Ryan Cottam for their advice in my annual progress reviews.

v

I wish and must thank especially my close friend Ms Fatemeh Hamedi because of her

sister-like friendship and emotional support. She was, is and will always be willing to

help me no matter how hard the challenge. I would like to thank all my friends here and

in my home country for their friendship and support, which made the course of my PhD

studies an enjoyable experience. I would also like to sincerely thank Dr Gwyneth and

Prof Michael Asten, Ms Rosemarie and Mr John Worboys as they have not only helped

me improve my English but also made me feel right at home.

Last but not least, I should thank my mother Farazandeh and my father Mohammad

Hasan for their endless loves, prays, encouragements and support. I would also like to

express my love and gratitude to my sister Sima, my brother Sepehr and my niece Zahra

who encouraged me all the time.

vi

Declaration

This thesis contains no material which has been accepted for the award to the candidate

of any other degree or diploma, except where due reference is made in the text. I declare

that to the best of my knowledge this study contains no material previously published or

written by another person except where due reference is made in the text.

Sepideh Minagar

February 2015

vii

List of publications

Journal Papers:

Sepideh Minagar, Christopher C. Berndt, James Wang, Elena Ivanova, Cuie Wen. A

review of the application of anodization for the fabrication of nanotubes on metal

implant surfaces. Acta Biomaterialia, (2012), 8, 2875-2888.

Sepideh Minagar, James Wang, Christopher C. Berndt, Elena P. Ivanova, Cuie Wen.

Cell response of anodized nanotubes on titanium and titanium alloys - a review. Journal

of Biomedical Materials Research: Part A, (2013), 101 A (9), 2726-2739.

Sepideh Minagar, Christopher C. Berndt, Thomas Gengenbach, Cuie Wen. Fabrication

and characterization of TiO2-ZrO2-ZrTiO4 nanotubes on TiZr alloy manufactured via

anodization. Journal of Materials Chemistry B, (2014), 2 (1), 71-83.

Sepideh Minagar, Yuncang Li, Christopher C. Berndt, Cuie Wen. The influence of

titania-zirconia-zirconium titanate nanotube characteristics on osteoblast cell adhesion.

Acta Biomaterialia (2015), 12, 281–289.

Presentation at Research Conferences:

Poster presentation entitled “Simultaneous enhancing cell interaction and eliminating

bacterial infection in titania nanotubes”, Proceedings of the 4th International

Conference on Nanostructures (ICNS4), Kish Island, I.R. Iran, March 2012.

Oral presentation entitled “anodised nanotubes on titanium alloy”, 15th International

Conference on Advances in Materials & Processing Technologies Conference (AMPT),

Wollongong, Australia, September 2012.

viii

Table of contents

Abstract ............................................................................................................................. ii

Acknowledgments ............................................................................................................ iv

Declaration ....................................................................................................................... vi

List of publications .......................................................................................................... vii

Table of contents ............................................................................................................ viii

List of figures ................................................................................................................. xiii

List of tables .................................................................................................................. xxii

List of abbreviations ..................................................................................................... xxiv

Chapter 1 Introduction ...................................................................................................... 1

1.1 Overview ................................................................................................................. 1

1.2 Thesis objective .................................................................................................. 4

1.3 Thesis structure ................................................................................................... 5

Chapter 2 Literature review .............................................................................................. 7

2.1 Introduction ............................................................................................................. 7

2.1.1 Bone: structure, composition and properties .................................................... 8

2.1.2 Bone implant materials .................................................................................. 11

2.1.3 Surface treatment for implant materials ......................................................... 15

2.2 Anodic oxidation as a metallic implant surface treatment ............................... 16

2.2.1 The influence of the type and concentration of aqueous electrolyte on TiO2

nanotubes ................................................................................................................ 20

2.2.2 The influence of the non-aqueous electrolyte on TiO2 nanotubes ................. 23

2.2.3 The effect of pH value on the formation of TiO2 nanotubes.......................... 24

2.3 Nanotube oxide layer on titanium alloys and titanium alloying metals ........... 26

2.3.1 Anodisation of biocompatible Ti-Nb-Ta-Zr alloy.......................................... 26

2.3.2 Anodisation of binary titanium alloys for implant applications..................... 28

2.3.3 Anodisation of tantalum as a β stabiliser ....................................................... 33

ix

2.3.4 Anodisation of niobium as a β stabiliser ........................................................ 35

2.3.5 Anodisation of zirconium as a neutral titanium alloying element (or an

effective β stabilizer in multi-elementary Ti alloys) ............................................... 35

2.4 Factors that influence bone cell adhesion ......................................................... 37

2.4.1 The influence of surface physicochemical, mechanical and electrical

properties on bone cell behaviour ........................................................................... 39

2.4.2 Effect of topography on the bone cell behaviour ........................................... 41

2.5 Effect of the characteristics of anodised TiO2 nanotubes on bone cell behaviour

43

2.5.1 Effect of nano-spacing of the surface of TiO2 nanotubes on cell behaviour .. 43

2.5.2 Effect of crystalline phase of TiO2 nanotubes on bone cell behaviour .......... 49

2.5.3 Effect of hydroxyapatite (HA) coating on the surface of TiO2 nanotubes on

bone cell behaviour ................................................................................................. 52

2.6 In vivo effect of micro/nanostructure of the surface of TiO2 nanotubes .......... 54

2.7 Effect of TiO2 nanotubes on bacteria attachment ............................................. 56

2.8 Summary .......................................................................................................... 56

Chapter 3 Materials and methods .................................................................................... 59

3.1 Introduction ........................................................................................................... 59

3.2 Sample preparation ........................................................................................... 59

3.3 Fabrication of nanoporous and nanotubular layers .......................................... 59

3.4 Surface characterisation.................................................................................... 61

3.4.1 Surface morphology and chemical composition characterisation .................. 61

3.4.2 Surface topography and water contact angle and surface energy measurement

................................................................................................................................. 61

3.5 Bioactivity assessment by SBF soaking ........................................................... 62

3.6 Assessing cell responses on nanotubes with different nanoscale dimensions and

surface topographies .................................................................................................... 64

3.7 Nanohardness and elasticity measurements .......................................................... 65

x

Chapter 4 Nanotubes formed in aqueous electrolyte ...................................................... 67

4.1 Introduction ...................................................................................................... 67

4.2 Materials and methods ...................................................................................... 70

4.3 Results and discussion ...................................................................................... 71

4.3.1 Formation of TiO2-ZrO2-ZrTiO4 nanotubes .................................................. 71

4.3.2 Surface roughness of the TiO2-ZrO2-ZrTiO4 nanotubular surface ................ 95

4.3.3 Hydrophilic properties of the nanotubular surfaces ..................................... 100

4.3.4 Mechanical properties of the TiO2-ZrO2-ZrTiO4 nanotubes ........................ 102

4.3.5 Effect of annealing on the TiO2-ZrO2-ZrTiO4 nanotubes ............................ 104

4.4 Conclusions .................................................................................................... 107

Chapter 5 Nanotubes formed in non-aqueous electrolyte ............................................. 110

5.1 Introduction .................................................................................................... 110

5.2 Materials and methods .................................................................................... 112

5.3 Results and discussion .................................................................................... 113

5.3.1 Formation and characterisation of TiO2-ZrO2-ZrTiO4 nanotubes ............... 113

5.3.2 Surface roughness and hydrophilic property of the TiO2-ZrO2-ZrTiO4

nanotubular surface ............................................................................................... 125

5.3.3 Mechanical properties .................................................................................. 131

5.4 Conclusions .................................................................................................... 133

Chapter 6 Bioactivity of nanotubes fabricated in aqueous and non-aqueous electrolytes

....................................................................................................................................... 135

6.1 Introduction .................................................................................................... 135

6.2 Materials and methods .................................................................................... 137

6.3 Results and discussion .................................................................................... 139

6.3.1 Dimensional, physical and chemical properties of TiO2-ZrO2-ZrTiO4

nanotubes fabricated in aqueous electrolyte ......................................................... 139

6.3.2 Bioactivity of TiO2-ZrO2-ZrTiO4 and TiO2 nanotubes fabricated in aqueous

electrolyte .............................................................................................................. 146

xi

6.3.3 Dimensional, physical and chemical properties of TiO2-ZrO2-ZrTiO4

nanotubes fabricated in non-aqueous electrolyte .................................................. 155

6.3.4 Bioactivity of TiO2-ZrO2-ZrTiO4 and TiO2 nanotubes fabricated in non-

aqueous electrolyte ................................................................................................ 158

6.4 Conclusions .................................................................................................... 165

Chapter 7 Cell response of nanotubes formed in both aqueous electrolyte and non-

aqueous electrolyte ........................................................................................................ 167

7.1 Introduction .................................................................................................... 168

7.2 Materials and methods .................................................................................... 170

7.3 Results and discussion .................................................................................... 174

7.3.1 Dimensional, physical and chemical properties of TiO2-ZrO2-ZrTiO4

nanotubes fabricated in aqueous electrolyte ......................................................... 174

7.3.2 Cell adhesion and spreading on TiO2-ZrO2-ZrTiO4 nanotubes fabricated in

aqueous electrolyte ................................................................................................ 180

7.3.3 Dimensional, physical and chemical properties of TiO2-ZrO2-ZrTiO4

nanotubes fabricated in non-aqueous electrolyte .................................................. 201

7.3.4 Cell adhesion and spreading on TiO2-ZrO2-ZrTiO4 nanotubes fabricated in

non-aqueous electrolyte ........................................................................................ 205

7.4 Conclusions .................................................................................................... 210

Chapter 8 Nanoporous and nanotubular metal oxide layers on biocompatible metals of

Ta, Nb and Zr and their potential applications .............................................................. 212

8.1 Introduction .................................................................................................... 213

8.2 Materials and methods .................................................................................... 215

8.3 Results and discussion .................................................................................... 217

8.3.1 Process conditions and formation mechanism of nanoporous/nanotubular

metal oxides .......................................................................................................... 217

8.3.2 The dynamics of the anodisation process for tantala (Ta2O5), niobia (Nb2O5)

and zirconia (ZrO2) ............................................................................................... 218

xii

8.3.3 Physical characteristics of nanoporous Ta2O5 and Nb2O5 and nanotubular

ZrO2 layers ............................................................................................................ 222

8.3.4 Bioactivity of nanoporous and nanotubular metal oxide layers ................... 230

8.4 Conclusions .................................................................................................... 235

Chapter 9 Conclusions .................................................................................................. 237

9.1 Introduction ......................................................................................................... 237

9.2 Major findings ................................................................................................ 237

9.3 Recommendation for future work .................................................................. 244

References ..................................................................................................................... 246

xiii

List of figures

Fig. 2.1 Hierarchical structure of cortical bone (adapted from [32]) ................................ 9

Fig. 2.2 Growth of regular TiO2 nanotubes, a) cathodic reaction, b) anodic reaction, c)

transition state of TiO2 layer, d) starting of nanotube formation and e) titania nanotubes

......................................................................................................................................... 18

Fig. 2.3 Schematic current-time curve (adapted from [58])............................................ 19

Fig. 2.4 SEM and TEM images of TiO2 nanotubes (top view, cross-section and bottom):

a) formed in 1 M H3PO4 + 0.3 wt % HF at 15 V [61], b) in 1 wt % HF at 20 V for 15

and 30 min) [66], c) in 1 M (NH4)2SO4 + 0.5wt % NH4F at 20V [67], d) in ethylene

glycol + 0.3 wt % NH4F + 2 vol % H2O [68] ................................................................. 21

Fig. 2.5 SEM and TEM images (top view, cross-section and bottom) of anodic oxide

nanotube and nanoporous layer formed on a) β phase titanium alloy after anodisation at

20 V for 4000 s [99], d) Zr substrate using 1M (NH4)2SO4 + 0.5 wt % NH4F

electrolyte [102], c) niobium substrate as a function of anodisation temperature at 15 °C

[103], b) tantalum substrate using 1 M H2SO4 + 2 wt % HF electrolyte for 2 h with a

sweep rate 100 mVs-1 [104] ............................................................................................ 28

Fig. 2.6 Representation of the cell proteins involved in cell adhesion on biomaterial: (a)

immediately after implantation; (b) adsorbing proteins from body fluid; and (c) attached

bone cell on an implant material surface in higher magnification (adapted from [15]) . 38

Fig. 2.7 SEM image of filopodia of the SaOs-2 cells on 200 nm deep round concentric

grooves and ridges in quartz [157] .................................................................................. 42

Fig. 2.8 Schematic illustration of a bone cell (osteoblast) attached on titania nanotubes

with a diameter less than 100 nm (adapted from [109] and [35]). .................................. 46

Fig. 2.9 SEM images of extended MC3T3-E1 preosteoblast cell filopodia on nanotube

layers with different diameters: (a) 20 nm, (b) 50 nm, (c) 70 nm, (d) 100 nm, and (e)

120 nm (×70,000), (f) 120 nm (×30,000) [36] ................................................................ 51

Fig. 4.1 SEM images of TiO2-ZrO2-ZrTiO4 nanotubes: (a-1) microstructure of etched

Ti50Zr, (a-2) top view of patterned nanotubes of different phases exhibited in the

microstructure of Ti50Zr alloy, (b) nanoporous patches of different phases, (c) cross

section of the nanotubes showing the nanotube length, (d) view of the nanotubes from

xiv

the bottom, (e) top view and cross section of separated nanotubes of and (f) top view of

damaged nanotubes ......................................................................................................... 72

Fig. 4.2 SEM images of TiO2-ZrO2-ZrTiO4 nanotubes: (a) top view of as-formed

nanotubes anodised in 0.4 wt % NH4F at 20 V, (b) the nanotubes annealed at 500 ºC for

3 h, (c) nanotubes as-formed in 0.5 wt % NH4F anodised at 20 V, (d) the nanotubes

annealed at 500 ºC for 3 h, (e) nanotubes as-formed in 0.5 wt % NH4F anodised at 15 V,

and (f) the nanotubes annealed at 500 ºC for 3 h ............................................................ 74

Fig. 4.3 (a) Illustration of an electrochemical cell that indicates the electrolyte ions

species, (b) SEM image of top view of nanoporous TiO2-ZrO2-ZrTiO4 fabricated on a

Ti50Zr alloy after anodisation for 15 min in 0.1 wt % NH4F, 5V, and c) SEM image of

top view of TiO2-ZrO2-ZrTiO4 nanotubes fabricated on Ti50Zr alloy after anodisation

for 2.75 h in 0.3 wt % NH4F, 5V .................................................................................... 76

Fig. 4.4 Histograms of as-formed and annealed TiO2-ZrO2-ZrTiO4 nanotube parameters

anodised at 20 V for 2 h for different concentrations of fluorine anion (F-): (a,d) inner

diameter (Di), (b,e) outer diameter (Do), and (c,f) wall thickness (Wt), Note: The

nanotube size distribution graphs were generated from100 nanotubes on different

positions for each of three samples (300 measurements)................................................ 79

Fig. 4.5 Histograms of TiO2-ZrO2-ZrTiO4 nanotube parameters anodised in 0.5 wt %

NH4F electrolyte for 2 h at different applied potentials: (a, b) inner diameter (Di) as-

formed and after annealing, (c, d) outer diameter (Do) as-formed and after annealing, (e,

f) wall thickness (Wt) as-formed and after annealing, respectively ................................ 83

Fig. 4.6 Mean nanotube size of Ti50Zr and CP-Ti as a function of CF-: (a) Di for As-

formed, (b) Di for Annealed (c) Do for as-formed, (d) Do for Annealed, (e) Wt for as-

formed and (f) Wt for Annealed ...................................................................................... 84

Fig. 4.7 Mean nanotube size of Ti50Zr and CP-Ti as a function of applied potential: (a)

Di for as-formed, (b) Di for Annealed (c) Do for as-formed, (d) Do for Annealed, (e) Wt

for as-formed and (f) Wt for Annealed ............................................................................ 85

Fig. 4.8 The effect on nanotube length by: a) anodisation time and b) applied potential

......................................................................................................................................... 86

Fig. 4.9 SEM images of nanotubular layer fabricated at a) 20V - as-formed, b) 20V -

annealed, c) 25V - as-formed, d) 25 V - annealed, e) 30 V - as-formed, f) 30V -

annealed, g) 35 V - as-formed and h) 35 V - annealed ................................................... 87

xv

Fig. 4.10 Histogram and distribution of Di, Do and Wt of as-formed and annealed TiO2-

ZrO2-ZrTiO4 nanotubes fabricated at a,b) 20 V, c,d) 25 V, e,f) 30 V and g,h) 35 V ..... 90

Fig. 4.11 Histogram and fitted normal and Weibull distribution of Di of as-formed

nanotubular TiO2-ZrO2-ZrTiO4 fabricated at: a) 20 V, b) 25 V, c) 30 V, d) 35 V and e)

normal distribution of all four conditions ....................................................................... 93

Fig. 4.12 Histogram and fitted normal and Weibull distribution of Di, Do and Wt of

annealed nanotubular TiO2-ZrO2-ZrTiO4 fabricated at a) 10 V, b) 15 V, c) 20 V .......... 94

Fig. 4.13 EDS analysis for the (a) top and (b) bottom of TiO2-ZrO2-ZrTiO4 nanotubes

formed in 0.5 wt % NH4F at 20 V after 2 h .................................................................... 95

Fig. 4.14 The mean roughness (Sa) and the mean water contact angle (W.C.A.) of the

nanotubular surfaces of Ti50Zr alloy as a function of: (a), (b) F- concentration and (c),

(d) applied potential, respectively ................................................................................... 96

Fig. 4.15 The mean roughness (Sa) and the mean water contact angle (W.C.A.) of the

nanotubular surfaces of CP-Ti as a function of: (a), (b) F- concentration and (c), (d)

applied potential, respectively ......................................................................................... 96

Fig. 4.16 Loading-unloading forces versus the nanoindentation depths of a) as-formed

TiO2-ZrO2-ZrTiO4 and b) annealed TiO2-ZrO2-ZrTiO4 fabricated at the applied potential

20 to 35 V ...................................................................................................................... 102

Fig. 4.17 The nano mechanical properties of: a) hardness, b) reduced elastic Modulus

and c) elastic Modulus of TiO2-ZrO2-ZrTiO4 nanotubes fabricated at different applied

potential ......................................................................................................................... 103

Fig. 4.18 XRD patterns of the nanotube samples fabricated on Ti50Zr (α and β phases)

via anodisation. (a) as-formed amorphous TiO2 and ZrTiO4 and orthorhombic ZrO2; (b)

annealed at 500 °C for 3 h tetragonal anatase, srilankite (a mixture of orthorhombic

TiO2 and ZrO2) and orthorhombic ZrTiO4 .................................................................... 105

Fig. 4.19 XPS spectra for the as-formed and the annealed TiO2-ZrO2-ZrTiO4 nanotubes.

(a) O1s, (b) Ti 2p, and (c) Zr 3d .................................................................................... 106

Fig. 5.1 SEM images of top view of nanotubes fabricated at: a) 5 wt % H2O at 20 V, b)

10 wt % H2O at 20V, c) 5 wt % H2O at 30 V and d) 10 wt % H2O at 30V in ethylene

glycol ............................................................................................................................. 114

Fig. 5.2 Histograms of TiO2-ZrO2-ZrTiO4 nanotube parameters anodised in 0.5 wt %

NH4F and ethylene glycol consisting of 5 and 10 wt % H2O for 90 min at 20 and 30V:

xvi

(a, d) inner diameter (Di) of as-formed and annealed nanotubes, (b, e) outer diameter

(Do) of as-formed and annealed nanotubes, (c, f) wall thickness (Wt) of as-formed and

annealed, respectively ................................................................................................... 116

Fig. 5.3 Histogram and fitted normal and Weibull distribution of Di, Do and Wt of as-

formed and annealed nanotubular TiO2-ZrO2-ZrTiO4 fabricated at a,e) 5 wt % H2O, 20

V, b, f) 10 wt % H2O, 20 V c, g) 5 wt % H2O, 30 V, d,h) 10 wt % H2O, 30 V ............ 120

Fig. 5.4 Mean nanotube sizes of Di, Do and Wt: a,c) as-formed and b,d) annealed TiO2-

ZrO2-ZrTiO4 and TiO2 nanotubes fabricated in two different water contents and two

different applied potentials in ethylene glycol .............................................................. 122

Fig. 5.5 EDS analysis for: (a) top and (b) bottom of TiO2-ZrO2-ZrTiO4 nanotubes

formed in 0.5 wt % NH4F, 5 wt % H2O in ethylene glycol at 20 V after 90 min ......... 123

Fig. 5. 6 The effect on TiO2-ZrO2-ZrTiO4 nanotubes length formed in organic

electrolyte by: a) anodisation time and b) applied potential ......................................... 124

Fig. 5.7 XRD patterns of the nanotube samples fabricated on Ti50Zr (α and β phases)

via anodisation in non-aqueous electrolyte. (a) as-formed amorphous TiO2 and ZrTiO4

and orthorhombic ZrO2; (b) annealed at 500 °C for 2 h tetragonal anatase, rutile,

srilankite (a mixture of orthorhombic TiO2 and ZrO2) and orthorhombic ZrTiO4 ....... 125

Fig. 5.8 a), c) The mean roughness (Sa), (Sq) and b), d) the mean water contact angle

(W.C.A.) of the nanotubular surfaces of TiO2-ZrO2-ZrTiO4 and TiO2 respectively, Note:

Each data point is an average of five measurements..................................................... 126

Fig. 5.9 Loading-unloading forces versus the nanoindentation depths of a) as-formed

TiO2-ZrO2-ZrTiO4 and b) annealed TiO2-ZrO2-ZrTiO4 fabricated at 5 and 10 wt % H2O

and the applied potential 20 and 30 V ........................................................................... 131

Fig. 5.10 The nano mechanical properties of of TiO2-ZrO2-ZrTiO4 nanotubes fabricated

at different water content and applied potential: a) hardness, b) reduced elastic Modulus

and c) elastic Modulus .................................................................................................. 132

Fig. 6.1 Mean nanotube size as a function of applied potential: (a) Ti50Zr - as-formed,

(b) Ti50Zr - annealed (c) CP-Ti - as-formed, (d) CP-Ti - annealed ............................. 140

Fig. 6.2 The mean roughness (Sa) of the nanotubular surfaces as a function of the

applied potential: (a) Ti50Zr alloy, (c) CP-Ti; and the mean water contact angle

(W.C.A.) of the nanotubular surfaces as a function of the applied potential: (b) Ti50Zr

alloy and (d) CP-Ti, Note: Each data point is an average of five measurements ......... 141

xvii

Fig. 6.3 Mineralisation of HA on the nanotubular surface of TiO2-ZrO2-ZrTiO4

fabricated at a), b) 20 V (Di = 37 nm)-as-formed, c), d) 20V (Di = 40 nm)- annealed, e),

f) 25 V (Di = 64 nm)-as-formed, g), h) 25V (Di = 59 nm)-annealed, i), j) 30 V (Di = 76

nm)-as-formed, k), l) 30V (Di = 64 nm)-annealed, m), n) 35 V (Di = 81 nm)-as-formed

and o), p) 35V (Di = 82 nm)-annealed .......................................................................... 147

Fig. 6.4 Mineralisation of HA on the nanotubular surface of TiO2 fabricated at a), b) 20

V (Di = 43 nm)-as-formed, c), d) 20V (Di = 51 nm)-annealed, e), f) 25 V (Di = 52 nm)-

as-formed, g), h) 25V (Di = 45 nm)-annealed, i), j) 30 V (Di = 65 nm)-as-formed, k), l)

30V (Di = 53 nm)-annealed, m), n) 35 V (Di = 68 nm)-as-formed and o), p) 35V (Di =

63 nm)-annealed ............................................................................................................ 148

Fig. 6.5 SEM images of cross section of mineralised HA layers on the surface of a)

TiO2-ZrO2-ZrTiO4 nanotubes and b) TiO2 nanotubes fabricated in aqueous electrolyte

....................................................................................................................................... 149

Fig. 6.6 XRD patterns of: a) TiO2-ZrO2-ZrTiO4 nanotubes anodised on Ti50Zr (α and β

phases) and annealed at 500°C for 3 h before and after immersion in m-SBF for 3

weeks, showing tetragonal anatase, srilankite (a mixture of orthorhombic TiO2 and

ZrO2) and orthorhombic ZrTiO4 with mineralised hydroxyapatite, b) TiO2 nanotubes

anodised on CP-Ti (α phase) and annealed at 500 °C for 3 h before and after immersion

in m-SBF for 3 weeks, showing tetragonal anatase with mineralised hydroxyapatite; and

c) hydroxyapatite ........................................................................................................... 150

Fig. 6.7 The percentage of atomic ratio of Ca/P of mineralised HA on four different

nanotubular surfaces of a) Ti50Zr and b) CP-Ti ........................................................... 151

Fig. 6.8 SEM images showing the transition of soluble salt crystal of present ions of m-

SBF into HA on the nanotubular surface of TiO2-ZrO2-ZrTiO4 with increasing

immersion time in m-SBF ............................................................................................. 153

Fig. 6.9 Schematic presentations of the process of bone-like apatite formation on

nanotubular surface in m-SBF ...................................................................................... 153

Fig. 6.10 The pH value of static m-SBF as a function of soaking time for nanotubular

TiO2-ZrO2 -ZrTiO4 fabricated at 20, 25, 30 and 35V .................................................... 154

Fig. 6.11 Loading-unloading forces versus the nanoindentation depths of HA on

nanotubular surface of TiO2-ZrO2-ZrTiO4 fabricated at the applied potential of 35 V 155

xviii

Fig. 6.12 Dimpled surface of TiO2-ZrO2-ZrTiO4 nanotubes after annealing and

removing the upper cracked layer a) 5 wt % H2O - 20 V, b) 10 wt % H2O - 20 V, c) 5 wt

% H2O - 30 V and d) 10 wt % H2O - 30 V ................................................................... 156

Fig. 6.13 a) The mean roughness (Sa), (Sq) and the mean water contact angle (W.C.A.)

of the nanotubular and dimpled surface of TiO2-ZrO2-ZrTiO4, respectively, Note: Each

data point is an average of five measurements.............................................................. 157

Fig. 6.14 SEM images of mineralisation of HA on the as-formed TiO2-ZrO2-ZrTiO4

nanotubes and dimpled surface fabricated in non-aqueous electrolyte: a, b) and c, d)

high and low magnification-5 wt % H2O-20V, e, f) and g, h) high and low

magnification-10 wt % H2O-20V, i, j) and k, l) high and low magnification-5 wt %

H2O-30V and m, n) and o, p) high and low magnification-10 wt % H2O-30V ............ 159

Fig. 6.15 SEM images of mineralisation of HA on the as-formed and annealed TiO2

nanotubes fabricated in non-aqueous electrolyte: a, b) and c, d) high and low

magnification-5 wt % H2O-20V, e, f) and g, h) high and low magnification-10 wt %

H2O-20V, i, j) and k, l) high and low magnification-5 wt % H2O-30V and m, n) and o,

p) high and low magnification-10 wt % H2O-30V ....................................................... 160

Fig. 6.16 SEM images of cross section of mineralised HA layers on the surface of a)

TiO2-ZrO2-ZrTiO4 nanotubes and b) TiO2 nanotubes fabricated in non-aqueous

electrolyte ...................................................................................................................... 161

Fig. 6.17 XRD patterns of the nanotube samples fabricated on Ti50Zr (α and β phases)

via anodisation in non-aqueous electrolyte, annealed dimpled surface (at 500 °C for 2 h)

of tetragonal anatase, rutile, srilankite .......................................................................... 162

Fig. 6.18 The percentage of atomic ratio of Ca/P of mineralised HA on a) as-formed and

annealed dimpled surface of TiO2-ZrO2-ZrTiO4 nanotubes and b) as-formed and

annealed TiO2 nanotubes fabricated in non-aqueous electrolyte .................................. 163

Fig. 6.19 The pH value of static m-SBF as a function of soaking time for nanotubular

TiO2-ZrO2-ZrTiO4 in a non-aqueous electrolyte with 5 and 10 wt % H2O at 20 and 30 V

....................................................................................................................................... 164

Fig. 6.20 Loading-unloading forces versus the nanoindentation depths of HA on

nanotubular surface of TiO2-ZrO2-ZrTiO4 fabricated at 10 wt % H2O and the applied

potential of 30 V............................................................................................................ 165

xix

Fig. 7.1 SEM images of annealed TiO2-ZrO2-ZrTiO4 nanotubes fabricated at a) 10 V, b)

15 V, c) 20 V, and d) 25 V, e) 30 V and f) 35 V........................................................... 174

Fig. 7.2 Mean nanotube size of Di, Do and Wt for annealed TiO2-ZrO2-ZrTiO4 nanotubes

anodised on Ti50Zr as a function of applied potential .................................................. 176

Fig. 7.3 Illustration of changing roughness parameters of Sa and Sq via changing Di of

TiO2-ZrO2-ZrTiO4 nanotubes anodised on Ti50Zr ....................................................... 177

Fig. 7.4 SEM images of SaOS2 cells cultured after 24 h on three different pore sizes of

TiO2-ZrO2-ZrTiO4 nanotubes fabricated at a) 10 V- low magnification, b) 10 V- higher

magnification, c) 15 V- low magnification, d) 15 V- higher magnification, e) 20 V- low

magnification and f) 20 V higher magnification ........................................................... 182

Fig. 7.5 SEM images of SaOS2 cells cultured after 24 h on three different pore sizes of

TiO2-ZrO2-ZrTiO4 nanotubes fabricated at a) 25 V- low magnification, b) 25 V- higher

magnification, c) 30 V- low magnification, d) 30 V- higher magnification, e) 35 V- low

magnification and f) 35 V higher magnification ........................................................... 183

Fig. 7.6 Schematic illustration of exploring tools of an osteoblast cell on nanotubular

surface ........................................................................................................................... 184

Fig. 7.7 Proposed illustration of the position of integrins on a) Di = 18 ± 6 nm best

nanospacing, b) rough surface of Di = 59 ± 17nm and c) Wt = 24 ± 7 nm most existing

of proteins ..................................................................................................................... 186

Fig. 7.8 Illustration of a) the length of filopodia, b) surface area and c) height of SaOS2

cells after 1 day and 7 days grown on different nanotube sizes (ρ < 0.05) ................... 189

Fig. 7.9 SEM images of SaOS2 cells cultured for 7 days on the four different pore sizes

of TiO2-ZrO2-ZrTiO4 nanotubes fabricated at a) 10 V- low magnification, b) 10 V-

higher magnification, c) 15 V- low magnification, d) 15 V- higher magnification, e) 20

V- low magnification and f) 20 V higher magnification ............................................... 191

Fig. 7.10 SEM images of SaOS2 cells cultured for 7 days on the four different pore

sizes of TiO2-ZrO2-ZrTiO4 nanotubes fabricated at a) 25 V- low magnification, b) 25 V-

higher magnification, c) 30 V- low magnification, d) 30 V- higher magnification, e) 35

V- low magnification and f) 35 V higher magnification ............................................... 192

Fig. 7.11 The percentage of cells attached to the surface of different pore sizes of TiO2-

ZrO2-ZrTiO4 nanotubes after 7 days of cell seeding using MTS assay (ρ < 0.05) ....... 194

xx

Fig. 7.12 Confocal images of stained SaOS2 cells presenting nuclei (blue) and actin

stress fibres (red) after 7 days on TiO2-ZrO2-ZrTiO4 nanotubes with a) Di = 18 nm, b)

Di =30 nm, c) Di =40 nm, d) Di = 59 nm, e) Di = 64 nm and f) Di = 82 nm ................. 195

Fig. 7.13 SEM images of SaOS2 cells cultured for 24 h on the TiO2-ZrO2-ZrTiO4

nanotubes (Di = 40 nm) a) with reduced contamination - low magnification, b) with

reduced contamination - higher magnification, c) with post-treated by HA - low

magnification and d) with post-treated by HA - higher magnification ......................... 196

Fig. 7.14 Illustration of a) the length of filopodia, b) surface area and c) height of

SaOS2 cells after 1 day and 7 days grown on different post-treated nanotubular surface

with the same Di ............................................................................................................ 198

Fig. 7.15 The percentage of cells attached to the different post-treated nanotubular

surface of TiO2-ZrO2-ZrTiO4 with the same Di after 7 days of cell seeding using MTS

assay .............................................................................................................................. 199

Fig. 7.16 SEM images of SaOS2 cells cultured for 7 days on the TiO2-ZrO2-ZrTiO4

nanotubes (Di = 40 nm) a) with reduced contamination - low magnification, b) with

reduced contamination - higher magnification, c) with post-treated by HA - low

magnification and d) with post-treated by HA - higher magnification ......................... 200

Fig. 7.17 Confocal images of stained SaOS2 cells presenting nuclei (blue) and actin

stress fibres (red) after 7 days on TiO2-ZrO2-ZrTiO4 nanotubes a) with Di = 40 nm

before post-treating b) reduced contamination, c) with post-treated by HA................. 201

Fig. 7.18 Mean nanotube size of Di, Do and Wt of dimpled surface after annealing and

removing the upper cracked layer fabricated in two different water contents and two

different applied potentials in ethylene glycol, Note: The nanotube size distribution

graphs were generated from 100 nanotubes on different positions for each of three

samples (300 measurements) ........................................................................................ 202

Fig. 7.19 SEM images of SaOS2 cells cultured for 7 days on the four different pore

sizes of TiO2-ZrO2-ZrTiO4 nanotubes fabricated at a) 5 wt % H2O - 20 V, b) 10 wt %

H2O - 20 V, c) 5 wt % H2O - 30 V, d) 10 wt % H2O - 30 V ......................................... 205

Fig. 7.20 Confocal images of stained SaOS2 cells presenting nuclei (blue) and actin

stress fibres (red) after 7 days on dimpled surface with a) Di = 25 nm, b) Di =29 nm, c)

Di =45 nm and Di =49 nm ............................................................................................. 207

xxi

Fig. 8.1 SEM images of nanoporous Ta2O5: (a) top view (b) the bottom view and the

cross section of multilayer, (c) shorted life nanotubes (arrow), (d) the top view of

multilayer formed on a Ta after anodisation for 120 min in 1M H2SO4 + 3.3 wt %

NH4F, 20V, SEM image of nanoporous Nb2O5 (e) top view and (f) cross section formed

on niobium after anodisation for 16 min in 1M H2SO4 + 3.3 wt % NH4F, 20V and SEM

image of ZrO2 nanotubes (g) top view, (h) cross section and (i) bottom view formed on

a zirconium after anodisation for 95 min in 1M (NH4)2SO4 + 0.3 wt % NH4F, pH=5 and

20V ................................................................................................................................ 219

Fig. 8.2 Demonstration of (a,c,e) changes of roughness (Sa) and (b,d,f) water contact

angle of bare tantalum, niobium, zirconium and titanium, after fabrication of

nanotubular and nanoporous layer, and subsequently annealing, respectively, Note:

Each data point is an average of five measurements..................................................... 223

Fig. 8.3 XRD patterns of (a) the nanoporous Ta2O5 and bare tantalum foil, (b) the

nanoporous Nb2O5 and bare niobium foil, (c) the ZrO2 nanotubes and bare zirconium

foil and (d) the TiO2 nanotubes and bare titanium foil ................................................. 229

Fig. 8.4 Illustration of pore size of the nanoporous and nanotubular layers ................. 230

Fig. 8.5 (a) low and (b) high magnifications of HA on as-formed nanoporous Ta2O5; (c)

low and (d) high magnifications of HA on annealed nanoporous Ta2O5 ...................... 231

Fig. 8.6 SEM images of HA on a) as-formed and b) annealed nanoporous Nb2O5 ...... 232

Fig. 8.7 (a) low and (b) high magnifications of HA on as-formed nanotubular ZrO2; (c,)

low and (d) high magnifications of HA on annealed nanotubular ZrO2 ....................... 232

Fig. 8.8 SEM images of cross section of mineralised HA layers on the surface of a)

nanoporous Ta2O5, b) nanoporous Nb2O5, c) nanotubular ZrO2 and d) nanotubular TiO2

....................................................................................................................................... 233

Fig. 8.9 Bioactivity of biocompatible nanoporous and nanotubular oxide metals after 3

weeks in m-SBF at 37 ˚C .............................................................................................. 234

Fig. 8.10 pH value of static m-SBF as a function of soaking time for: a) nanoporous

Ta2O5 and Nb2O5 and b) nanotubular TiO2 and ZrO2 ................................................... 235

xxii

List of tables

Table 2.1 Scale of sizes of the hierarchical bone components, in comparison to the scale

sizes of the implant structures ......................................................................................... 10

Table 2.2 Microstructures, mechanical properties and biological characteristics of

metallic implant materials ............................................................................................... 13

Table 2.3 Anodisation conditions, characteristics and properties of TiO2 nanotubes on

titanium ........................................................................................................................... 30

Table 2.4 Cell responses to different TiO2 nanotubes on titanium and the anodisation

conditions ........................................................................................................................ 47

Table 3.1 Compositions for the aqueous electrolyte used for fabricating nanoporous and

nanotubular layers ........................................................................................................... 60

Table 3.2 The reagents and their amounts for preparing 1000 mL m-SBF .................... 64

Table 4.1 The distribution of Di, Do and Wt according to normal and Weibull

distribution methods ........................................................................................................ 92

Table 4.2 Surface area index SI and roughness amplitude parameters of Sskw and Sku of

the nanotubular surfaces of Ti50Zr and CP-Ti anodised under various conditions, Note:

Each data point is an average of five measurements....................................................... 99

Table 4.3 Calculated surface energy of TiO2-ZrO2-ZrTiO4 nanotubular surfaces

fabricated on Ti50Zr and TiO2 nanotubular surfaces on CP-Ti, Note: Each data point is

an average of five measurements .................................................................................. 101

Table 5.1 The distribution of Di, Do and Wt according to normal and Weibull

distribution methods ...................................................................................................... 118

Table 5.2 Surface area index SI and roughness amplitude parameters of Sskw and Sku of

the nanotubular surfaces of Ti50Zr and CP-Ti anodised under various conditions, Note:

Each data point is an average of five measurements..................................................... 128

xxiii

Table 5.3 Calculated surface energy of as-formed and annealed dimpled surface TiO2-

ZrO2-ZrTiO4 nanotubular surfaces fabricated on Ti50Zr, Note: Each data point is an

average of five measurements ....................................................................................... 130

Table 6.1 Surface area index SI and roughness amplitude parameters of Sq, Sskw and Sku

of the nanotubular surfaces of Ti50Zr and CP-Ti anodised under various conditions,

Note: Each data point is an average of five measurements ........................................... 143

Table 6.2 Calculated surface energies of TiO2-ZrO2-ZrTiO4 nanotubular surfaces

fabricated on Ti50Zr and TiO2 nanotubular surfaces on CP-Ti, Note: Each data point is

an average of five measurements .................................................................................. 145

Table 7.1 Surface index and spacing parameters of TiO2-ZrO2-ZrTiO4 nanotubes

fabricated in different applied potential ........................................................................ 179

Table 7.2 Surface index, spacing parameters and calculated surface energy of TiO2-

ZrO2-ZrTiO4 nanotubes with dimpled surface fabricated in different water contents and

applied potentials, Note: Each data point is an average of five measurements ............ 204

Table 7.3 The percentage of cells attached to the surface of different pore sizes and

roughness parameters of TiO2-ZrO2-ZrTiO4 nanotubes fabricated in organic electrolyte

after 7 days of cell seeding using MTS assay (ρ < 0.05) .............................................. 208

Table 8.1 Surface area and volume index and roughness amplitude parameters of

nanoporous Ta2O5, Nb2O5 and nanotube ZrO2, Note: Each data point is an average of

five measurements ......................................................................................................... 224

Table 8.2 Water contact angle and surface energy of as-formed and annealed

nanoporous Ta2O5, Nb2O5 and nanotube ZrO2 in comparison to its bare metal, Note:

Each data point is an average of five measurements..................................................... 226

xxiv

List of abbreviations

ALP Alkaline phosphatase

ARB Accumulative roll bonding

at % Atomic percentage

BMD Bone mineral density

BSA Bovine serum albumin

Ca/P Atomic percentage of calcium to phosphate ratio

Ca5(PO4, CO3)3(OH) Carbonated apatite

CaP Calcium phosphate

CF- Concentration of fluorine anion

CP-Ti Commercial pure titanium

Di Inner diameter

Do Outer diameter

EB-PVD Electron-beam physical vapour deposition

ECM Extracellular matrix

EDM Electrical discharging machining

EDS Electron dispersive X-ray spectroscopy

FN Fibronectin

HA Hydroxyapatite

HEPES 2-(4-(2-hydroxyethyl)-1-piperazinyl) ethane sulfonic acid

HMDS Hexamethyldisilazane

ISQ Implant stability quotient values

xxv

L/W Length to width ratio

MC3T3-E1 Mouse osteoblast cells

MG63 Human osteosarcoma cells

mMSC Mouse bone marrow MSCs

m-SBF Modified simulated body fluid

MTS assay (3-(4,5-dimethylthiazol-2-yl)-5-(3-carboxymethoxyphenyl)-2-(4-

sulfophenyl)-2H-tetrazolium) assay

N2 Nitrogen gas

Nb Niobium

Nb2O5 Niobium pentoxide (niobia)

OCP Octacalcium phosphate

PBS Phosphate-buffered saline

PTES 1H, 1H, 2H, 2H-perfluorooctyl-triethoxysilane

RBA Rapid breakdown anodisation

RBF Rotating bending fatigue

real-time PCR Real-time polymerase chain reaction technique

Sa Mean roughness

SaOS-2 Human osteoblast-like cells

SAS.F Surface area of the actin stress fibre

SBF Simulated body fluid

Sc Core void volume (space roughness parameter)

SEM Scanning electron microscope

xxvi

SI Surface index

Sku Kurtosis (amplitude roughness parameter)

Sm Surface material volume(space roughness parameter)

Sp Largest peak height value from the reference surface within the

defined sampling area (amplitude roughness parameter)

Sq Root mean square (RMS) Roughness

Sskw Skewness (amplitude roughness parameter)

Sv Surface void volume (space roughness parameter)

Ta Tantalum

Ta2O5 Tantalum pentoxide (tantala)

TCP Tricalcium phosphate

TEM Transmission electron microscope

Ti Titanium

Ti50Zr Titanium zirconium alloy with 35 atomic percentage or 50 weight

percentage of zirconium

TiO2 Titanium dioxide (titania)

TiO2-ZrO2-ZrTiO4 Titanium-zirconium-zirconium titanate

TLM Ti-5Zr-3Sn-5Mo-15Nb

TNTZ Ti-Nb-Ta-Zr alloy

VI Volume index

Vol % Volume percentage

W.C.A or θW Water contact angle

Wt Wall thickness

xxvii

Wt % Weight percentage

XPS X-ray photoelectron spectroscope

XRD X-ray diffraction

Zr Zirconium

ZrO2 Zirconium dioxide (zirconia)

1

Chapter 1 Introduction

1.1 Overview

The fabrication, characterisation and application of biomaterials is an interesting field

which has been the focus of many studies in recent years. Although there are debates on

the exact kind of substance that can be classified as a biomaterial, in simple terms they

can be defined as implantable medical devices such as metals, ceramics and synthetic

polymers, biopolymers, self-assembled systems, nanoparticles, carbon nanotubes and

quantum dot, drug and gene delivery systems, tissue engineering and cell therapies,

organ printing and cell patterning, nanotechnology based imaging and diagnostic

systems and microelectronic devices, engineered tissues, cells, organs and even viruses

[1]. One of the applications of biomaterials is the repair of bone tissue, known as

orthopaedic biomaterials or implants [2]. These kind of biomaterials need to have

suitable mechanical and biological properties. Among different biomaterials used for

implants, such as ceramics, polymers, composites and natural products; metal implants

are preferred for load-bearing applications. Metal implants also exhibit excellent

mechanical properties such as Young’s modulus, tensile strength, ductility, fatigue life,

and wear resistance [3]. In addition, they have excellent chemical properties such as

corrosion resistance, biocompatibility and the ability to fuse and harmonise with other

implant materials [4]. These properties make them more suitable for long-term use in

hard tissue applications such as hip and knee joints [4, 5]. Stainless steels and cobalt-

chromium-molybdenum alloys are some examples alongside the more biocompatible

titanium and titanium alloys [2]. However, as bone is alive, an implant has to be

accepted by the bone cells in order to bond with it and to prevent loosening and

inflammation when it is inserted close to the bone. Surface modifications or treatments

can change the surface of the metal implant making it more stable and agreeable for

bone cells.

Surface modifications of metal implants play a major role in biomedical research. One

of the operations of surface modification techniques, either mechanical, physical or

chemical is the addition of substance to the surface such as plasma spray, physical

vapour deposition (PVD) and surface immobilisation of functional molecules. The

interface of the implant and body fluid can also be converted using ion implantation and

electrochemical oxidation. Another way to modify a surface is by removing undesirable

2

substances from the surface by surface machining, grit blasting and acid etching [6].

Based on the functionality and application of the metal implant, one or more surface

modification can be used. Considering the ability of titanium and titanium alloys to

form a protective oxide layer on their surfaces, electrochemical surface treatment is

utilised as a preferable technique.

Titanium, one of the best known transition metals, is of great interest in biomedical

research. It has an incompletely filled d shell in its electronic structure, which allows the

forming of solid solutions with other alloying elements. One of these elements is

zirconium which produces non-toxic β alloys with titanium. This β type alloy offers the

unique characteristic of mechanical biocompatibility such as low elastic modulus,

superior corrosion resistance, and good osseointegration [7, 8]. Titanium shape memory

alloys and porous titanium alloy are also of great interest because of their shape memory

function, or super-elastic function and bone tissue ingrowth into the porous network,

respectively[4, 9]. These metal implants are applied as plates, nails, screws and endo-

prostheses [8]. The protective oxide layer which forms naturally on the surface of

titanium and titanium alloy makes them bioinert. Therefore, electrochemical surface

modification such as anodisation is one of the suitable techniques available to make

them bioactive.

The significance of a surface treatment such as anodic oxidation, [10] which provides

the possibility of controlled nano-scale fabrication with suitable physico-chemical

properties on the metal surface, has been reported [11]. Highly ordered nanoporous

arrays of titanium dioxide that form on the titanium surface by anodic oxidation are

receiving increasing research interest due to their effectiveness in promoting

osseointegration. Uniform and controllable nano-patterned surfaces of titanium can be

fabricated using electrochemical anodic oxidation, which is an economical , simple and

versatile technique [12]. By applying a constant potential to titanium as a working

electrode in an electrochemical cell with a platinum counter electrode and a standard

reference electrode, the titania nanotubes can be obtained. Different TiO2 nanotube

diameters, wall thicknesses and lengths can be achieved by controlling the condition of

the anodising process, such as the applied potential, current density, anodisation time,

concentration of fluorine anion and type (aqueous and non-aqueous), pH value and the

3

viscosity of the electrolyte [13]. Such nano-scale surfaces exhibit similar properties to

those of physiological bone.

The important factors for cell response can be better controlled by understanding the

mechanism of cell attachment to the biomaterial surface. Various populations of cells,

cytokines, growth factors and the extracellular matrix affect the process of tissue

healing around implants. For example, chemotactic factors are essential for cell

recruitment and cell adhesion, and growth factors and cytokines are effective for the

proliferation and differentiation of cells. Protein adsorption at the implant surface

initiates interactions between cells and implants through a complex series of adsorption

and displacement steps. The interaction of cell and implant is followed by the

attachment phase, which is governed mainly by van der Waals forces. The next step,

termed the adhesion phase, is surface anchoring through fibronectin and vitronectin for

the formation of focal points at cell-membrane integrins. Filopodia and finger-like

protrusions are then produced to enable sensing of the optimum anchorage and

spreading toward the surface [14, 15].

In the specific instance of biomaterial applications, the highly ordered nanostructured

TiO2 promotes osseointegration because the size of integrins and focal contacts of cell-

implant interactions is also in the nano scale (~ 10 nm) [11, 16]. The effects of different

inner and outer diameters of nanotubes and the spaces between them on bone cells

during cell culture have been studied extensively [17-20]. The crystalline form of TiO2

nanotubes exhibited an encouraging effect on cell behaviour due to their enhanced

hydrophilic properties [21]. Furthermore, growing hydroxyapatite on the surface of

these so-formed nanotubes would improve cell behavior such as adhesion, proliferation,

morphology, migration, survival and differentiation due to beneficial changes in the

topographical and chemistry properties [22-25]. Cell biological responses of osteoblasts

on anodised titania zirconia nanotubes [26], the effect of surface energy for its

functionality [27], as well as the antibacterial properties of different sizes of titania

zirconia nanotubes [28] have also been investigated.

Several in vitro studies have examined the optimum nanotopography for cell response

and suggested that the optimum diameter of TiO2 nanotubes is less than 100 nm. The

15 nm diameter nanotubes revealed the best cell response; although there is controversy

[19, 20] regarding the optimum diameter required. The behaviour of the bone cells on

4

the nanotubular of oxide layer on the surface of Ti50Zr needs to be clarified.

Specifically, further studies are required to determine the optimum size, morphology,

physical and chemical properties of nanotubes on the biocompatible titanium-zirconium

(Ti50Zr) binary alloy for the adhesion of bone cell sensing elements. The current work

aims to improve the physicochemical and other properties of the nanotubular layer by

fabricating it on the surface of β alloy of Ti50Zr.

1.2 Thesis objective

This thesis was aimed at imparting new functionalities to the biocompatible Ti50Zr

alloy through surface modification. A nanotubular layer was anodised on the alloy with

enhanced bioactivity and biocompatibility because the nanoscale characteristics of the

nanotubes is able to interlock with bone cells, therefore improving cell adhesion,

proliferation and growth on the nanotubular surface. Extensive research has been

undertaken to fabricate and characterise the nanotubular layer on the surface of CP-Ti

and assess its bioactivity and biocompatibility. Although some research has been

undertaken to fabricate the nanotubular layer on the surface of Ti50Zr, few attempt have

been made to characterise the physical, chemical and mechanical properties of

nanotubular layer of TiO2-ZrO2-ZrTiO4 in respect of their influences on their bioactivity

and bone cell integration.

To accomplish the aforementioned objectives the following tasks were completed:

- Two different types of electrolytes were used to fabricate nanotubes with

different morphologies and physicochemical and mechanical properties.

- The effects of the applied potential and the concentration of fluoride ions in the

electrolyte on the morphology and other characteristics of the nanotubes were

systematically studied.

- The ability to induce hydroxyapatite formation was evaluated by immersing the

substrates with a nanotubular surface in the modified simulated body fluid.

- The cell adhesion was assessed by seeding osteoblast cells on the nanotubular

surfaces of Ti50Zr and CP-Ti.

Major contributions of the thesis include:

5

The TiO2-ZrO2-ZrTiO4 nanotubes fabricated on the surface of Ti50Zr alloy not only

revealed a distribution of nanotube sizes following the needle-like microstructure of the

alloy, but also exhibited a variety of nanotube height. These difference in the height of

nanotubes resulted in an interesting surface topography with a range of amplitude and

spacing roughness parameter. The link between roughness parameter and hydrophilic

properties of the nanotubular layer were evaluated. Hereby the surface of Ti50Zr alloy

was nanoengineered by fabricating the TiO2-ZrO2-ZrTiO4 nanotubes while the factors

which influence cell attachment were taken into consideration. This demonstrates that

the nanotubular layer not only patterned the surface in nano-scale but also created a

special topography in micro-scale. The surface chemistry and mechanical properties of

the substrate are also changed by the nanotubular layer. The TiO2-ZrO2-ZrTiO4

nanotubes were more bioactive than TiO2 nanotubes. The bone cell attachment

significantly increased on two different nanotubular layer of TiO2-ZrO2-ZrTiO4

fabricated in aqueous and non-aqueous electrolyte.

1.3 Thesis structure

Chapter 2 reviews the literature on anodisation of titanium, titanium alloy and transition

metal alloying elements to fabricate nanoporous and nanotubular layer after an

introduction of bone structure, metal implants and their surface modification. It presents

parameters which affect the morphology, topography, physical and chemical properties

of nanotubes. Then it describes in simple terms the mechanism of cell adhesion and the

factors that influence the adhesion of the bone cells on implant surface. Finally, it

highlights the characters of these nanotubular layers which influence bone cell

behaviour. Chapter 3 provides a methodological description of the materials and

methods for fabrication, characterisation and performance of the nanotubular layer. The

materials and methods of individual chapters are described as required in the relevant

chapter to avoid over-complication.

Chapter 4 presents the effect of anodisation parameters on the characteristics of the

TiO2-ZrO2-ZrTiO4 nanotubes fabricated in aqueous electrolyte such as inner, outer

diameter, wall thickness, roughness parameters, mechanical and hydrophilic properties

and surface energy. Chapter 5 presents the effect of anodisation parameters on the

characteristics of the TiO2-ZrO2-ZrTiO4 nanotubes fabricated in non-aqueous electrolyte

such as inner, outer diameter, wall thickness, roughness parameters, mechanical and

6

hydrophilic properties and surface energy. These characteristics are compared with TiO2

nanotubes fabricated on CP-Ti in the same condition to outline the significance of TiO2-

ZrO2-ZrTiO4 nanotubes.

Chapter 6 studies the effect of the characteristics of the nanotubular layer fabricated in

aqueous and non-aqueous electrolyte on their ability to induce hydroxyapatite. These

characteristics are compared with TiO2 nanotubes fabricated on CP-Ti in the same

condition. Chapter 7 investigates the cell adhesion on the surface of these nanotubular

layers and the influence of the morphology of the layer as well as the roughness

parameter, hydrophilic properties and the role of post-treatment on the percentage of

cell attachments is studied.

Chapter 8 presents the nanoporous and nanotubular layer fabricated on the surface of

some biocompatible transition metal such as tantalum, niobium and zirconium in

comparison to titanium. The characteristics of these nanoporous and nanotubular layer

such as roughness parameter, hydrophilic properties and surface energy is studied. The

ability of such a layer to induce hydroxyapatite is also assessed.

7

Chapter 2 Literature review

2.1 Introduction

Metal implants are the best choice for the long-term replacement of hard tissue, such as

hip and knee joints, because of their excellent mechanical properties. Titanium and its

alloys, due to their self-organised oxide layer that protects the surface from corrosion

and prevents ion release, are widely accepted as biocompatible metal implants. They

must also be accepted by bone cells, bonding with and growing on them to prevent

loosening. Surface modification is essential for the promotion of the osseointegration of

these biomaterials. Nanotubes fabricated on the surface of metal implants by

anodisation are currently receiving increasing attention for surface modification. The

response of bone cells to implant materials depends on the topography,

physicochemistry, mechanics and electronics of the implant surface and this influences

cell behavior, such as adhesion, proliferation, shape, migration, survival and

differentiation; for example the existing anions on the surface of a titanium implant

make it negative and this affects the interaction with negative fibronectin (FN).

Although optimal nanosize of reproducible titania nanotubes have not been found

significantly according to different protocols in the studies cell response has been

shown that were more sensitive on titania nanotubes with nanometer diameter and inter

space. By annealing amorphous TiO2 nanotubes change to a crystalline form and

become more hydrophilic, resulting in an encouraging effect on cell behaviour. The

crystalline size and thickness of the bone-like apatite that forms on the titania nanotubes

after implantation are also affected by the diameter and shape. This chapter provides an

overview of the employment of the anodisation for nanotubes fabricated on the surface

of titanium, titanium alloys and titanium alloying metals such as niobium, tantalum and

zirconium metal implants. It explains anodic oxidation and the manner by which

nanotubes form on the surface of the metals. It then assesses this topical research to

indicate how changes in anodising conditions influence nanotube characteristics such as

tube diameters and nanotube-layer thickness. Finally it describes how changes in

nanotube morphologies, such as the tube diameter, the thickness of the nanotube layer,

and the crystalline structure, influence the response of cells.

8

2.1.1 Bone: structure, composition and properties

Bone, as with other parts of our body, becomes damaged or weakened because of age,

accidents or disease. This damage, which includes bone fractures, low back pain,

osteoporosis, scoliosis and other musculoskeletal problems, usually occurs in elderly

people but not exclusively. Biomaterials such as implants are used for repairing injured

bones, cartilage or ligaments and tendons [2].

Weiner et al. [29] have described the basic bone composition that consists mostly of

fibrous protein collagen, carbonated apatite (Ca5(PO4, CO3)3(OH)) and water. The

crystal size and the proportion of these components change over time. As a result,

younger bones replace older bones. Uddin et al. [30] have emphasised that bones are

tissues that are alive and growing. Bone forming cells such as osteoblasts are

responsible for generating the synthesis and deposition of calcium phosphate crystals

that are required to confer hardness and strength in biomineralisation. A schematic

illustration of the hierarchical structure of cortical bone is shown in Fig. 2.1. It can be

seen that cortical bone contains many different structures that exist on several levels of

scale starting from sub-nanostructures. Mour et al. [31] described bone as a solid

material that is highly porous on a micrometre scale. Bone is a viscoelastic material due

to these pores, which are filled with fluid and cells; osteoblasts, osteoclasts, osteocytes

and bone lining cells that are regenerative. Bone, moreover, has values of compression

strength several times higher than, for example, concrete, but its low density is in the

range of aluminium. Table 2.1 lists the size scales of the hierarchical bone components,

in comparison to the size scales of the implant structures.

9

Fig. 2.1 Hierarchical structure of cortical bone (adapted from [32])

10

Table 2.1 Scale of sizes of the hierarchical bone components, in comparison to the scale

sizes of the implant structures

Structures Size

Ref. Micrometer Nanometer

Tissue

component

Osteon 10-500 - [32]

Osteoclast (lacunae) 100 or more - [33]

Osteoblast 20-30 - [33]

Lamella 3-7 - [32]

Collagen fibril 0.5 - [32]

Cell membrane - 10-100 [34]

Plate-like apatite crystals - 50×25×3 [32]

Integrins - 8-12 [35]

Proteins - 1-10 [34]

Collagen molecule - 1 [32]

Amino acids - 0.1-1 [34]

Water molecule - 0.1 [34]

Metal

Implant

Roughness of the surface >100 - [34]

titanium grain sizes 10-20 - [36]

Metal oxide - 5-15 [34]

Atom - 0.1 [34]

11

2.1.2 Bone implant materials