Surface Finish

description

Transcript of Surface Finish

The Journeyman’s Guide to CNC Machines

Guidelines 169

5

10

20

40

80160200300400500

1

10

100

1000

10000

1 10 100 1000

Diameter (D) mm

RP

M

0.05

0.1

0.2

0.4

0.8

1.63.26.412.825.6

1

10

100

1000

10000

1 10 100 1000 10000

RPM

Fee

d R

ate

mm

/min

16.5 Surface Finish

It is impossible to achieve a close tolerance unless the finish produced is suitably fine. The economical range of

surface finishes for turning and milling is 64-250 CLA (1.6-6.3µm); the extended range is 24-500 CLA (0.6-

12.6µm). Many factors affect the ability to produce a specific surface finish, feed, state of the cutter, lubrication

and the physical properties of the material; accordingly, consider the values as a practical starting point.

Insert Radius Surface Finish

Tolerance Below 0.4 0.8 1.2 1.6 2.4 3.2

Ra µm CLA mm Feed in mm / rev

0.6 24 ± 0.025 0.07 0.10 0.12 0.14 0.17 -

0.8 32 ± 0.050 0.08 0.12 0.14 0.17 0.20 0.23

1.6 64 ± 0.100 0.11 0.15 0.19 0.22 0.26 0.30

3.2 128 ± 0.150 0.17 0.24 0.29 0.34 0.42 0.50

6.3 250 ± 0.250 0.22 0.30 0.37 0.43 0.53 0.63

8.0 320 0.27 0.38 0.47 0.54 0.66 0.78

32 1280 1.08 1.32 1.56

Insert Radius Code Feed mm / rev

0.4 0.8 1.2 1.6 2.4 3.2

F1 0.25 - 3.7 2.7 2.0 1.4 0.9

F2 0.20 4.75 2.40 1.6 1.4 0.8 -

F3 0.15 3.10 1.50 1.1 0.8 - -

F4 0.10 1.30 0.60 0.4 - - -

Surface Finish Ra µm

In addition to feeds, use the values for the depth of cut for each pass for profile milling using ball end cutters.

Cutter Diameter Surface Finish

Tolerance

Below 10 12 16 20 25 32

Ra µm CLA mm Feed in mm / rev

0.6 24 ± 0.025 0.25 0.28 0.32 0.36 0.40 0.45

0.8 32 ± 0.050 0.30 0.33 0.38 0.43 0.48 0.54

1.6 64 ± 0.100 0.40 0.44 0.51 0.57 0.63 0.71

3.2 128 ± 0.150 0.63 0.69 0.80 0.89 1.00 1.13

6.3 256 ± 0.250 0.80 0.88 1.01 1.13 1.26 1.43

8.0 320 1.00 1.10 1.26 1.32 1.41 1.79

32.0 1280 2.00 2.20 2.54 2.94 3.33 3.59

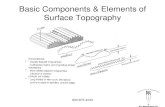

16.6 Feed and Speed Conversion Charts

16161616----3333 Feedrate Conversion ChartFeedrate Conversion ChartFeedrate Conversion ChartFeedrate Conversion Chart 16161616----4444 Speed Conversion ChartSpeed Conversion ChartSpeed Conversion ChartSpeed Conversion Chart

M/min

rpm = Speed / Circumference

= (M/Min) / (πD/1000) M/min = Revs × Circumference

= RPM × (πD/1000)

mm/rev

mm/min = mm/rev×rpm

mm/rev = mm/min÷rpm