Supplementary Protectors/Miniature Circuit BreakersAuxiliary/Signal Alarm 1492-ASPHS3 or ......

Transcript of Supplementary Protectors/Miniature Circuit BreakersAuxiliary/Signal Alarm 1492-ASPHS3 or ......

-

Technical Data

Supplementary Protectors/Miniature Circuit BreakersCatalog Numbers 1492-SP Series C

-

Important User InformationSolid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1 available from your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/) describes some important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference, and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous temperatures.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

http://literature.rockwellautomation.com/idc/groups/literature/documents/in/sgi-in001_-en-p.pdfhttp://www.rockwellautomation.com/literature/

-

Introduction Supplementary Protectors & Accessories

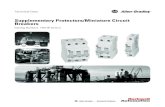

Figure 1 - 1492-SP* Devices & Accessory Overview

Supplementary Protector/Miniature Circuit Breaker Available in single-, two-, three-pole, one-pole neutral, and four-pole

neutral Specifications & Certifications:

Meets UL 1077/CSA 22.2 No. 235 In conformity with IEC/EN 60 898 CE Marked

Trip Characteristics B-Trip for resistive or slightly inductive loads C-Trip for inductive loads D- Trip for highly inductive loads

Switched Pole Protector (not field-mountable) Switched neutral pole closes before the adjacent protected pole (i.e., early

make) Instantaneous/magnetic release provided, but no overload thermal release

Auxiliary/Signal Alarm1492-ASPHS3 or142-ASPHSC3

Dual Auxiliary Contact1492-ASPHH3

Auxilliary Contact 1492-ASPH3

Accessories

Shunt Trip 1492-ASPA1

Undervoltage Release 1492-ASPU115

Two-Pole1492-SP2

Supplementary Protector/Miniature Circuit Breaker

Single-Pole1492-SP1

Three Pole1492-SP3

2

1

3

4

5

6

7

Switched Pole Neutral Protector

Rockwell Automation Publication 1492-TC010D-EN-P April 2011 3

-

Shunt Trip Field installable Mounts to side Module width is equal to that of a single-pole

Undervoltage Release Field installable Mounts to side Module width is equal to that of a single-pole

Auxiliary Contact Field installable Changeover contact Switches when protective device is operated manually or is tripped

electrically 1 Form C

Dual Auxiliary Contact Field installable Two auxiliary contacts Changeover contact Switches when protective device is operated manually or is tripped

electrically 2 Form C Version with convertible contact

Auxiliary/Signal Alarm Field installable Auxiliary contacts Auxiliary contact switches when protective device is operated manually or

is tripped electrically Signal alarm Signal alarm contact switches only when protective device is tripped

electrically Changeover contact 2 Form C Front indicator indicates when device is tripped electrically

4 Rockwell Automation Publication 1492-TD010D-EN-P April 2011

-

Description Bulletin 1492-SP Supplementary Protector/Miniature Circuit Breakers are energy limiting, thermal-magnetic type, overcurrent-protective devices meeting UL 1077/CSA 22.2 No. 235, IEC/EN 60898 and IEC 60947-2. These devices are designed for the protection of a wide variety of products including:

Bulletin 1492-SP Supplementary Protectors/Miniature Circuit Breakers are available in one-, two-, three-, and four-pole units as well as one- and three-pole plus neutral units. One- and two-pole AC units also have limited DC ratings. Two and three-pole units are connected at the handle for simultaneous operation.

Screw termination is standard on all Bulletin1492-SP units. Both line and load side terminals accept #164 AWG (1.525 mm2) copper wire.

Solenoids Test Equipment Controller I/O Points Relay and Contractor Coils Computers

Transformers Automotive Systems Power Supplies Medical Equipment Control Instrumentation

IMPORTANT UL 1077, CSA C22.2 No. 235 In North America, miniature circuit breakers are recognized as supplementary protectors and are intended for use as overcurrent protection within an appliance or other electrical equipment where branch circuit protection is already provided or not required.

Internationally, these products are rated to IEC standards as miniature circuit breakers for equipment.

Rockwell Automation Publication 1492-TD010D-EN-P April 2011 5

-

International Approvals The Bulletin 1492-SP, Supplementary Protectors/Miniature Circuit Breakers, are designed to comply with standards for worldwide customer acceptance. The Bulletin 1492-SPs meet the following standards:.

Table 1 - Bulletin 1492-SP Standards

Certifying Agency Certification Marks Country Standard

Underwriters Laboratory USA UL 1077

Canadian Standards Association Canada CSA 22.2 No. 235

Verband Deutscher Electrotechniker

Germany IEC/EN 60 898

Germanischer Lloyd Germany IEC/EN 60 947-2

per Conformite European European Union IVD Directives

per International ElectrotechnicalCommission

Global IEC 60 898IEC 60 947-2

China Quality Certification Center Global GB 10963

6 Rockwell Automation Publication 1492-TD010D-EN-P April 2011

-

Features The following features provide superior performance.Table 2 - Features of Bulletin 1492-SP

Feature Description

Energy limiting design protects downstream components better than conventional breakers during short circuits

Field mountable options for selective applications

True IP2X finger safe design (front)

International approvals CE Marked and meets UL, CSA, and IEC (VDE, GL) standards for worldwide acceptance

Ratings to 480Y/277V AC @ 240/415V AC 10,000 A Interrupt Rating

AC and DC voltage ratings in one convenient device

A positively trip-free mechanism where the breaker operation cannot be defeated by holding the handle in the ON position

Three trip curves B, C, and D

Time delay (D characteristic) for high inrush currents during inductive startups, such as transformers and power supplies

Superior shock and vibration resistance capabilities

helps to prevent nuisance tripping

Mounts on DIN Rail

Reversible line and load connections

Rockwell Automation Publication 1492-TD010D-EN-P April 2011 7

-

Construction

Figure 2 - Construction

Switched Neutral Module (not field-mountable)

The switched neutral module opens the neutral line of the circuit when the protected poles are tripped. This module should be used as a safety measure (required by some standards) when protecting networks with a grounded neutral system. The switched neutral pole closes before the adjacent protected pole (i.e., early make).

The switched neutral module also provides instantaneous/magnetic trip, manual actuation is through the linked handles, and should always be mounted on the right side of the protected poles. These modules are not field installable.

Side View

Catalog Number Prefix Current & Voltage Ratings

Approval Symbols

Screw Termination accepts #16...#4 (1.5... 25 mm2)

wire as standard

Convenient Terminals for commoning links and bus bars (both line and load side)

Nylon Body provides toughness and durability

required by the environment

Ease of Installation & Replacementeasily snaps on and off of DIN rail

Finger Safe to IEC 947-1 Front

Positively Trip-Free Mechanism

Flag Indicator is clearly marked for position in both international and domestic indication green OFF and red ON

Amperage Rating is clearly marked on the front of the

device for easy identification

Variety of Pole Optionsavailable in one-, two-, or three-pole and one- or three-pole neutral

Front View

8 Rockwell Automation Publication 1492-TD010D-EN-P April 2011

-

Ordering Information To order the proper device, you need to know the: maximum rated current of equipment to be protected, system phase of one, two, or three, maximum startup (inrush) current, and accessories that are required.

Catalog Number

Determine the catalog number by following the steps below and referencing the Selection Tables on page 12.

1. Select a one-, two-, or three-pole device.

2. If needed, select the Switched Neutral Module. The Switched Neutral Module is mounted on the right side of the breaker. This module must be mounted at the factory. It cannot be installed in the field.

3. If applicable, consider the derating factors listed in the Rating Determination on page 9.

4. Order accessory contacts or modules as separate items. Accessory modules are always mounted on the left side of the supplemental protector/miniature circuit breaker. A maximum of two accessory modules can be mounted on a single device. Refer to the Accessories on page 18 for possible combinations.

Rating Determination The standard tripping characteristic for Bulletin 1492-SP is Type C. Type C has a magnetic trip activated at 510 times the rated current of the circuit breaker. The reference temperature for the thermal tripping characteristics is 30 C. The Type C characteristic will suit most applications. Use the following steps to determine the current rating for the breaker.

1. Take the rated current of the equipment. For example, 10 A.

2. Take the ambient temperature of the 1492-SP location (e.g., 50 C (122 F)).

3. Refer to the table below, which rerates the 1492-SP current for the given ambient temperature. Influence of the ambient temperature on the thermal tripping characteristic.

Rockwell Automation Publication 1492-TD010D-EN-P April 2011 9

-

Table 3 - Ambient Temperature Derating Calibration temperature = 30 C; application below 0 C is for non-condensing atmosphere*

*Care should be taken for application below 0 C. These devices are not certified to operate correctly in the presence of ice.

4. All other specifications for standard Bulletin1492-SP products remain unchanged. The ambient temperature derating applies to applications of the device as an IEC Miniature Circuit Breaker (MCB) following 60 947-2 and as a supplementary protector to UL1077/CSA 22.2 No 235. Ambient temperature refers to the free air temperature in contact with the 1492-SP. Contact Rockwell Automation for ambient temperatures beyond those shown above.

5. Select the 1492-SP with the next available rating at the given ambient temperature. In this example, it would be 13 A. With this selection, adequate overload protection is provided and nuisance tripping by thermal influences is avoided.

6. Check that transients of the system do not exceed the must hold value of the trip characteristic. This will eliminate nuisance tripping by magnetic influences. The Type C characteristic will be adequate for most applications. Refer to the Selection Tables on page 12.

Ambient Temperature in C

Prod

uct N

amep

late

Cont

inuo

us C

urre

nt R

atin

g

-25 -20 -10 0 10 20 30 35 40 45 50 55 60

0.5 0.61 0.60 0.58 0.56 0.54 0.52 0.50 0.49 0.48 0.47 0.46 0.45 0.44

1 1.2 1.1 1.0 0.99 0.97 0.95 0.93 0.90 0.89

2 2.4 2.3 2.2 2.1 2.0 1.9 1.8

3 3.7 3.6 3.5 3.4 3.3 3.1 3.0 2.9 2.8 2.7

4 4.9 4.8 4.7 4.5 4.3 4.2 4.0 3.9 3.8 3.7 3.6 3.5

5 6.1 6.0 5.8 5.6 5.4 5.2 5.0 4.9 4.8 4.7 4.6 4.5 4.4

6 7.3 7.2 7.0 6.7 6.5 6.3 6.0 5.9 5.8 5.7 5.6 5.4 5.3

8 9.8 9.6 9.3 9.0 8.7 8.4 8.0 7.9 7.7 7.6 7.4 7.2 7.1

10 12 11 10 9.9 9.7 9.5 9.3 9.0 8.9

13 16 15 14 13 12

15 18 17 16 15 14 13

16 20 19 18 17 16 15 14

20 24 23 22 21 20 19 18

25 31 30 29 28 27 26 25 24 23 22

32 39 38 37 36 35 33 32 31 30 29 28

40 49 48 47 45 43 42 40 39 38 37 36 35

50 61 60 58 56 54 52 50 49 48 47 46 45 44

63 77 76 73 71 68 66 63 62 61 60 58 57 56

10 Rockwell Automation Publication 1492-TD010D-EN-P April 2011

-

7. In rare occurrences when the Type C characteristic does not fully meet the application, the following additional magnetic trip characteristics are available:

8. Type D allows for transients approximately twice as high as the standard Type C. Refer to the Selection Tables on page 12.

9. Type B achieves instantaneous tripping at current levels approximately half as high as Type D. Refer to the Selection Tables on page 12.

10. If multiple supplementary protectors are mounted side-by-side, they must be derated to determine the load carrying capacity. Use the derating equation below.

Adjusted Current Rating = Rated Current multiplied by

The figure below shows the rated diversity factor, where miniature circuit breakers influence one another thermally at rated load.

Figure 3 - Rated Diversity Factor

1 2 3 4 5 6 7 8

0.70

0.80

0.90

1.00

Number of Circuit Breakers

Rate

d Di

vers

ity F

acto

r

Rockwell Automation Publication 1492-TD010D-EN-P April 2011 11

-

Selection Tables B-Trip Characteristics Resistive/Slightly Inductive Loads, 35 InTable 4 - One Pole & One-Pole Neutral

Current rating used only in North America.

One-Pole One-Pole plus Neutral

Continuous Current Rating (In)

Catalog Number

3rd PartyCertification

Continuous Current Rating (In)

Catalog Number

3rd PartyCertification

1 1492-SP1B010 1 1492-SP1B010-N

2 1492-SP1B020 2 1492-SP1B020-N

3 1492-SP1B030 3 1492-SP1B030-N

4 1492-SP1B040 4 1492-SP1B040-N

5 1492-SP1B050

6 1492-SP1B060 6 1492-SP1B060-N

7 1492-SP1B070

8 1492-SP1B080 8 1492-SP1B080-N

10 1492-SP1B100 10 1492-SP1B100-N

13 1492-SP1B130 13 1492-SP1B130-N

15 1492-SP1B150

16 1492-SP1B160 16 1492-SP1B160-N

20 1492-SP1B200 20 1492-SP1B200-N

25 1492-SP1B250 25 1492-SP1B250-N

30 1492-SP1B300

32 1492-SP1B320 32 1492-SP1B320-N

40 1492-SP1B400 40 1492-SP1B400-N

50 1492-SP1B500 50 1492-SP1B500-N

63 1492-SP1B630 63 1492-SP1B630-N

Operational Voltage IEC 240/415V AC/48V DC IEC 240V AC

UL/CSA 277V AC/48V DC UL/CSA 277V AC

Pieces Per Package 2 1

Diagram 1

2

1

N2

N

12 Rockwell Automation Publication 1492-TD010D-EN-P April 2011

-

Table 5 - Two-Pole, Three-Pole, & Three-Pole Neutral

Current rating used only in North America.

Two-Pole Three-Pole Three-Pole plus Neutral

Continuous Current

Rating (In)Catalog Number

3rd PartyCertification

Continuous Current

Rating (In)Catalog Number

3rd PartyCertification

Continuous Current

Rating (In)Catalog Number

3rd PartyCertification

1 1492-SP2B010 1 1492-SP3B010 1 1492-SP3B010-N

2 1492-SP2B020 2 1492-SP3B020 2 1492-SP3B020-N

3 1492-SP2B030 3 1492-SP3B030 3 1492-SP3B030-N

4 1492-SP2B040 4 1492-SP3B040 4 1492-SP3B040-N

5 1492-SP2B050 5 1492-SP3B050

6 1492-SP2B060 6 1492-SP3B060 6 1492-SP3B060-N

7 1492-SP2B070 7 1492-SP3B070

8 1492-SP2B080 8 1492-SP3B080 8 1492-SP3B080-N

10 1492-SP2B100 10 1492-SP3B100 10 1492-SP3B100-N

13 1492-SP2B130 13 1492-SP3B130 13 1492-SP3B130-N

15 1492-SP2B150 15 1492-SP3B150

16 1492-SP2B160 16 1492-SP3B160 16 1492-SP3B160-N

20 1492-SP2B200 20 1492-SP3B200 20 1492-SP3B200-N

25 1492-SP2B250 25 1492-SP3B250 25 1492-SP3B250-N

30 1492-SP2B300 30 1492-SP3B300

32 1492-SP2B320 32 1492-SP3B320 32 1492-SP3B320-N

40 1492-SP2B400 40 1492-SP3B400 40 1492-SP3B400-N

50 1492-SP2B500 50 1492-SP3B500 50 1492-SP3B500-N

63 1492-SP2B630 63 1492-SP3B630 63 1492-SP3B630-N

Operational Voltage

IEC 415V AC IEC 415V AC IEC 415V AC

UL/CSA 480Y/277V AC, 96V DC UL/CSA 480Y/277V AC UL/CSA 480Y/277V AC

Pieces per Package

1 1 1

Diagram + DC1 3

42

1 3 5

4 62

1 3 5 N

N4 62

Rockwell Automation Publication 1492-TD010D-EN-P April 2011 13

-

C-Trip Characteristics Inductive Loads, 510 In

Table 6 - One Pole & One-Pole Neutral

Current rating used only in North America.

One-Pole One-Pole plus Neutral

Continuous Current Rating (In)

Catalog Number

3rd PartyCertification

Continuous Current Rating (In)

Catalog Number

3rd PartyCertification

0.5 1492-SP1C005 0.5 1492-SP1C005-N

1 1492-SP1C010 1 1492-SP1C010-N

2 1492-SP1C020 2 1492-SP1C020-N

3 1492-SP1C030 3 1492-SP1C030-N

4 1492-SP1C040 4 1492-SP1C040-N

5 1492-SP1C050

6 1492-SP1C060 6 1492-SP1C060-N

7 1492-SP1C070

8 1492-SP1C080 8 1492-SP1C080-N

10 1492-SP1C100 10 1492-SP1C100-N

13 1492-SP1C130 13 1492-SP1C130-N

15 1492-SP1C150

16 1492-SP1C160 16 1492-SP1C160-N

20 1492-SP1C200 20 1492-SP1C200-N

25 1492-SP1C250 25 1492-SP1C250-N

30 1492-SP1C300 32 1492-SP1C320 32 1492-SP1C320-N

40 1492-SP1C400 40 1492-SP1C400-N

50 1492-SP1C500 50 1492-SP1C500-N

63 1492-SP1C630 63 1492-SP1C630-N

Operational Voltage IEC 240/415V AC/48V DC IEC 240V AC

UL/CSA 277V AC/48V DC UL/CSA 277V AC

Pieces Per Package 2 1

Diagram 1

2

1

2

N

N

14 Rockwell Automation Publication 1492-TD010D-EN-P April 2011

-

Table 7 - Two-Pole, Three-Pole, & Three-Pole Neutral

Current rating used only in North America.

Two-Pole Three-Pole Three-Pole plus Neutral

Continuous Current

Rating (In)Catalog Number

3rd PartyCertification

Continuous Current

Rating (In)Catalog Number

3rd PartyCertification

Continuous Current

Rating (In)Catalog Number

3rd PartyCertification

0.5 1492-SP2C005 0.5 1492-SP3C005 0.5 1492-SP3C005-N

1 1492-SP2C010 1 1492-SP3C010 1 1492-SP3C010-N

2 1492-SP2C020 2 1492-SP3C020 2 1492-SP3C020-N

3 1492-SP2C030 3 1492-SP3C030 3 1492-SP3C030-N

4 1492-SP2C040 4 1492-SP3C040 4 1492-SP3C040-N

5 1492-SP2C050 5 1492-SP3C050

6 1492-SP2C060 6 1492-SP3C060 6 1492-SP3C060-N

7 1492-SP2C070 7 1492-SP3C070

8 1492-SP2C080 8 1492-SP3C080 8 1492-SP3C080-N

10 1492-SP2C100 10 1492-SP3C100 10 1492-SP3C100-N

13 1492-SP2C130 13 1492-SP3C130 13 1492-SP3C130-N

15 1492-SP2C150 15 1492-SP3C150

16 1492-SP2C160 16 1492-SP3C160 16 1492-SP3C160-N

20 1492-SP2C200 20 1492-SP3C200 20 1492-SP3C200-N

25 1492-SP2C250 25 1492-SP3C250 25 1492-SP3C250-N

30 1492-SP2C300 30 1492-SP3C300

32 1492-SP2C320 32 1492-SP3C320 32 1492-SP3C320-N

40 1492-SP2C400 40 1492-SP3C400 40 1492-SP3C400-N

50 1492-SP2C500 50 1492-SP3C500 50 1492-SP3C500-N

63 1492-SP2C630 63 1492-SP3C630 63 1492-SP3C630-N

Operational Voltage

IEC 415V AC IEC 415V AC IEC 415V AC

UL/CSA 480Y/277V AC, 96V DC UL/CSA 480Y/277V AC UL/CSA 480Y/277V AC

Pieces per Package

1 1 1

Diagram + DC1 3

42

1 3 5

4 62

1 3 5 N

N4 62

Rockwell Automation Publication 1492-TD010D-EN-P April 2011 15

-

D-Trip Characteristics Highly Inductive Loads 1020 In

Table 8 - One Pole & One-Pole Neutral

Current rating used only in North America.

One-Pole One-Pole plus Neutral

Continuous Current Rating (In)

Catalog Number

3rd PartyCertification

Continuous Current Rating (In)

Catalog Number

3rd PartyCertification

0.5 1492-SP1D005 0.5 1492-SP1D005-N

1 1492-SP1D010 1 1492-SP1D010-N

2 1492-SP1D020 2 1492-SP1D020-N

3 1492-SP1D030 3 1492-SP1D030-N

4 1492-SP1D040 4 1492-SP1D040-N

5 1492-SP1D050

6 1492-SP1D060 6 1492-SP1D060-N

7 1492-SP1D070

8 1492-SP1D080 8 1492-SP1D080-N

10 1492-SP1D100 10 1492-SP1D100-N

13 1492-SP1D130 13 1492-SP1D130-N

15 1492-SP1D150

16 1492-SP1D160 16 1492-SP1D160-N

20 1492-SP1D200 20 1492-SP1D200-N

25 1492-SP1D250 25 1492-SP1D250-N

30 1492-SP1D300 32 1492-SP1D320 32 1492-SP1D320-N

40 1492-SP1D400 40 1492-SP1D400-N

50 1492-SP1D500 50 1492-SP1D500-N 63 1492-SP1D630 63 1492-SP1D630-N

Operational Voltage IEC 240/415V AC/48V DC IEC 240V AC

UL/CSA 277V AC/48V DC UL/CSA 277V AC

Pieces Per Package 2 1

Diagram 1

2

1

2

N

N

16 Rockwell Automation Publication 1492-TD010D-EN-P April 2011

-

Table 9 - Two-Pole, Three-Pole, & Three-Pole Neutral

Current rating used only in North America.

Two-Pole Three-Pole Three-Pole plus Neutral

Continuous Current

Rating (In)Catalog Number

3rd PartyCertification

Continuous Current

Rating (In)Catalog Number

3rd PartyCertification

Continuous Current

Rating (In)Catalog Number

3rd PartyCertification

0.5 1492-SP2D005 0.5 1492-SP3D005 0.5 1492-SP3D005-N

1 1492-SP2D010 1 1492-SP3D010 1 1492-SP3D010-N

2 1492-SP2D020 2 1492-SP3D020 2 1492-SP3D020-N

3 1492-SP2D030 3 1492-SP3D030 3 1492-SP3D030-N

4 1492-SP2D040 4 1492-SP3D040 4 1492-SP3D040-N

5 1492-SP2D050 5 1492-SP3D050

6 1492-SP2D060 6 1492-SP3D060 6 1492-SP3D060-N

7 1492-SP2D070 7 1492-SP3D070

8 1492-SP2D080 8 1492-SP3D080 8 1492-SP3D080-N

10 1492-SP2D100 10 1492-SP3D100 10 1492-SP3D100-N

13 1492-SP2D130 13 1492-SP3D130 13 1492-SP3D130-N

15 1492-SP2D150 15 1492-SP3D150

16 1492-SP2D160 16 1492-SP3D160 16 1492-SP3D160-N

20 1492-SP2D200 20 1492-SP3D200 20 1492-SP3D200-N

25 1492-SP2D250 25 1492-SP3D250 25 1492-SP3D250-N

30 1492-SP2D300 30 1492-SP3D300

32 1492-SP2D320 32 1492-SP3D320 32 1492-SP3D320-N

40 1492-SP2D400 40 1492-SP3D400 40 1492-SP3D400-N

50 1492-SP2D500 50 1492-SP3D500 50 1492-SP3D500-N

63 1492-SP2D630 63 1492-SP3D630 63 1492-SP3D630-N

Operational Voltage

IEC 415V AC IEC 415V AC IEC 415V AC

UL/CSA 480Y/277V AC, 96V DC UL/CSA 480Y/277V AC UL/CSA 480Y/277V AC

Pieces per Package

1 1 1

Diagram + DC1 3

42

1 3 5

4 62

1 3 5 N

N4 62

Rockwell Automation Publication 1492-TD010D-EN-P April 2011 17

-

Accessories Table 10 - Auxiliary Contacts

Auxiliary Contact Description Approvals Diagram

Catalog Number

Auxiliary Contact Module Changeover 1 Form C Switches when

protective device is operated manually or tripped electrically

1492-ASPH3

Dual Auxiliary Contact Module Two auxiliary contacts Changeover contact 2 Form C Switches when the

protective device is operated manually or tripped electrically

1492-ASPHH3

Auxiliary/Signal Alarm Module Auxiliary Contact

switches when the protective device is operated manually or tripped electrically

Signal Alarm Contact trip indicating contact switches only when the protective device is tripped electrically

Changeover Contact 2 Form C Front Indicator signals

when device is tripped electronically

1492-ASPHS3

Convertible Contact Module Customer selectable Contact sets similar to

1492-ASPHH3 or 1492-ASPHS3

Customer may field select one configuration or the other

1492-ASPHSC3

11

12 14

12 14 22 24

11 21

96 98 12 14

95 11

96 98 12 14

95 11

18 Rockwell Automation Publication 1492-TD010D-EN-P April 2011

-

Table 11 - Voltage Trips

Voltage Trip Description Approvals Diagram Voltage

Catalog Number

Undervoltage Release Module Use to trip the

adjacent breaker poles when the applied voltage is less than the nominal voltage

Undervoltage trip is often used when loss of power and eventual restoration of power creates an unsafe or unknown set of conditions

50115V AC 1492-ASPU115

110240V AC 1492-ASPU230

Shunt Trip Module Use to trip the

adjacent breaker poles from a remote location. The module is actuated by applying a voltage (pickup voltage) to the trip terminals

Use in emergency shutdown circuits where multiple power circuits must be switched off from a single location

110415V AC110230V DC

1492-ASPA1

12110V AC1260V DC

1492-ASPA2

D1

D2

U

-

Allowable Combinations of Field Added Modules

Table 12 - Allowable Combinations of Field Added Modules

(1) Auxiliary Contact Module

(1) Dual Auxiliary Contact Module

(1) Auxiliary/Signal Alarm Contact Module

(1) Convertible Contact Module

(1) Shunt Trip Module

(1) Undervoltage Release Module

(1) Auxiliary Contact Module + (1) Shunt Trip Module

(1) Dual Auxiliary Contact Module + (1) Shunt Trip Module

(1) Auxiliary/Signal Alarm Module + (1) Shunt Trip Module

(1) Convertible Contact Module + (1) Shunt Trip Module

IMPORTANT All field added modules must be added to left side of supplementary protector/miniature circuit breaker.

+

Catalog Number 1492- Catalog Number 1492-

ASPHSC3 ASPH3 ASPHH3 ASPHS3 ASPA ASPU SP*

X X

X X

X X

X X

X X

X X X

X X X

X X X

X X

X X X

20 Rockwell Automation Publication 1492-TD010D-EN-P April 2011

-

Additional Accessories

The following table lists additional accessories used with all 1492-SP* Miniature Circuit Breakers.

Table 13 - Additional Accessories

Product Selection Cuttable Copper Bus Bar

Figure 4 - Bus Bar Specifications

Accessory

Catalog Number Pieces per PackageMounting Rails

1 m Symmetrical DIN 199-DR1 10

1 m Hi-Rise Symmetrical DIN 1492-DR6 2

1 m Angled Hi-Rise Symmetrical DIN 1492-DR7 2

End Anchor 1492-EAH35 50

Lockout Attachment 1492-ASPLOA 10

NOTE: The copper bus bar is 1 meter in length and may be cut to a length suitable for your application.

Bus Bar DescriptionDevices per Meter Amperage Approvals

Catalog Number 1492-

Package Quantity

Single-Phase 57 80 UL 508UL E56639Category NMTR2ULus listedCE

A1B8 1

100 A1B1

36 with Auxiliary Module

80 A1B8H

100 A1B1H

Two-Phase 29 80 A2B8

100 A2B1

22 with Auxiliary Module

80 A12B8H

100 A12B1H

Three-Phase 19 80 A3B8

100 A3B1

16 with Auxiliary Module

80 A3B8H

100 A3B1H

Rockwell Automation Publication 1492-TD010D-EN-P April 2011 21

-

Table 14 - Bus Bar Accessory Specifications

Figure 5 - Bus Bar Installation

Accessory Description Amperage Approvals

Catalog Number 1492-

Package Quantity

End Caps for use with:

Single-Phase Bus Bar UL 508UL E56639Category NMTR2ULus Listed CE

A1E 10

Two- & Three-Phase Bus Bar AME

Protective Shroud AAP

Terminal Lug 80/100 AAT1

1489-AAP

1492-SP... or1492-FB...

4 mm

Z2

Ampac

ity of De

vices

AWG lb-in Nm18...46...4

2127

2.43.1

AWG lb-in Nm10...2 50 5.5

1492-AAT1

*

22 Rockwell Automation Publication 1492-TD010D-EN-P April 2011

-

Table 15 - Bus Bar Installation Specifications

TypeNumber of 1492-SP*

Rated Operational Ie:

Approvals

Catalog Number 1492-

Pieces per Package

End Feed per Phase

Center Feed per Phase (Ie< 63 A)

Fork Style Commoning Links may be cut to length, not for use with accessories

One-Pole 1 m(56 devices/m)

63 100 ASPCL1 1

Three-Pole 1 m(19 devices/m)

63 100 ASPCL3 1

End Cap for Three-Pole

ASPEC1 10

Fork Style Commoning Links may NOT be cut to length, not for use with accessories

One-Pole 2 63 100 ASPCL102

6 ASPCL106 20

12 ASPCL112 20

Two-Pole (One-Pole plus Neutral)

2 63 100 ASPCL204 10

3 ASPCL206 10

6 ASPCL212 10

Three-Pole 2 63 100 ASPCL306 10

4 ASPCL312 10

Four-Pole 2 63 100 ASPCL408 5

3 ASPCL412 5

Fork-Style Commoning Links (for use with accessories)

One-Pole 2 63 100 ASPCL1A02 20

6 ASPCL1A06

9 ASPCL1A09

Two-Pole (One-Pole plus Neutral)

2 63 100 ASPCL1A04 10

3 ASPCL1A06

5 ASPCL1A10

Three-Pole 2 63 100 ASPCL3A06 10

4 ASPCL3A12

Three-Phase Bus Bar for Multiple One-Pole (each with one auxiliary contact)

2x3 (1p) 63 100 ASPCL3AP06 10

2x3 (1p)+2 (1p) 63 100 ASPCL3AP08 10

3x3 (1p) 63 100 ASPCL3AP09 10

Incoming Terminals for Fork Style (not for use in North America)

For Max 25 mm2 Wire

100 ASPCT25 50

For Max 25 mm2 Wire

100 ASPCLT35 10

Protective Covers for Unused Forks

ASPCLPS 10 sets (5 per set)

Rockwell Automation Publication 1492-TD010D-EN-P April 2011 23

-

Technical Information Limiting Let-Through Energy

Bulletin 1492-SP versus Conventional Breakers

The 1492-SP line features the unique ability to achieve short-circuit interruptions far more effectively than conventional breakers.

In conventional circuit breakers, the short-circuit interruption time required is approximately one or two half cycles of an AC sine wave. When the contacts open, the resulting arc continues to burn until the current level passes through zero. The arc may reignite because of the insufficient width of the contact gap. The current that flows until the arc is extinguished produces a heating effect proportional to the I2t value (let-through-energy) of the fault current.

The 1492-SP device is designed to substantially reduce the amount of let-through-current and the resulting let-through-energy that can damage protected components. The 1492-SP has the ability to interrupt short-circuit current within the first half cycle of the fault.

Limiting let-through-energy will protect against the harmful effects of overcurrent and is focused primarily on avoiding:

excessive heat and mechanical damage.

Both of these factors are proportional to the square of the current. Thermal energy is proportional to the square of the RMS value and magnetic forces are proportional to the square of the peak value. The most effective way to provide protection is to substantially limit let-through-energy. This provides the following advantages:

Far less damage at the location of the short circuit. Fast electric separation of a faulty unit from the system; in particular,

power supplies connected in parallel that are switched off when the voltage of the power bus drops below a certain level.

Far less wear on the miniature circuit breaker itself, which means more safe interruptions.

Better protection of all components in the short circuit path. Far wider range of selective action when used with an upstream protective

device; there are no nuisance shut downs from feeder line interruptions, causing a blackout in all connected branches.

24 Rockwell Automation Publication 1492-TD010D-EN-P April 2011

-

Short-Circuit Interruption

The following graphic shows the short circuit interruption from 10 kA 120V AC with an instant of initiation of 15 after a voltage of zero.

Figure 6 - Short-Circuit Interruption Conventional Breakers

Let-T

houg

h I2 t

79,000 A2s

3,500 A2s

10 kA 120V ACInstant of Initiation: 15 After Voltage Zero

Maximum Arc Voltage

Recovery Voltage

Time

A B C

Cur

rent

Volta

ge A

cros

s Br

eake

r

A B C

A = instant when the short is initiatedB = instant when the contacts open and the arc is initiatedC = instant when the arc extinguishes and the current ceases to flow

Rockwell Automation Publication 1492-TD010D-EN-P April 2011 25

-

Energy-Limiting Characteristics

Tripping Characteristics

Figure 7 - Tripping Characteristics at 30 C

Conventional Non-Tripping Current: 1nt=1.13IN: t >1h

Conventional Tripping Current: 1t=1.45: t 0.1 seconds

Type B: 51N: t < 0.1 seconds

Type C: 51N: t > 0.1 seconds

Type C: 101N: t < 0.1 seconds

Type D: 101N: t > 0.1 seconds

Type D: 201N: t < 0.1 seconds

7200

3600

1200

600

300

120

60

30

10

5

2

1

0.5

0.2

0.1

0.05

0.02

0.01

0.005

0.002

0.001

0.00051 2 3 4

Tim

e in

Sec

onds

5 6 7 8 9 10 15 20 30 40 50I / IN

2

1

3

3

4 65 7 9

8

26 Rockwell Automation Publication 1492-TD010D-EN-P April 2011

-

Specifications Table 16 - Basic Specifications

Description B Curve C Curve D Curve

Tripping Characteristic Resistive or Slightly Inductive Loads, 35 In

Inductive Loads, 510 In

Highly Inductive Loads, 1020 In

Poles (17 mm width per pole) 1, 2, 3, 1+ N, 3 + N

Approvals See Selection Tables on page 12

Maximum Voltage

Dielectric Strength 1960V AC

Shock 25 G Half Sine Wave for 11 ms (3 axes)

Vibration Frequency Range: 102000 HzMax. Amplitude (p - p) = 0.030 in.Max. Acceleration = 5 G 2 hours each of 3 axes

Operating Temperature Range -22+158 F (-30+70 C) non-condensing

Shipment & Short-Term Temperature Limits -40+185 F (-40+85 C)

Housing Material Nylon

Wire Size (Cu Only) #188 AWG(1.010 mm2)

Tightening Torque:2.4 Nm (21 lb-in.)

#64 AWG(1625 mm2)

Tightening Torque:3.1 Nm (27 lb-in.)

Recommended Wire Strip Length 0.51 in. (13 mm)

Electromechanical Life 6,000 operations (1 operation = 2 switching events) ON/OFF

Switched Neutral Rating 277V AC

Direction of Incoming Supply As Required

Contact Position Indicator Red/Green

Terminals M5 (with slotted screw PZ2)

Mounting DIN Rail (IEC60715)

Mounting Position As Required

Rockwell Automation Publication 1492-TD010D-EN-P April 2011 27

-

Table 17 - Basic Specifications, Continued

Description B Curve C Curve D Curve

Current Range 163 A 0.563 A 0.540 A

Certifications UL 1077 Recognized Component QVNU2 - E65138CSA 22.2 No. 235 Certified Components

Use Group (UG) UG A General Industrial

Terminals (FW) FW 3 Line and Load Evaluated for Field Wiring

Overload Rating OL 0 (General Use)

One-Pole, One-Pole plus Neutral

Maximum Voltage 277V AC 48V DC

Tripping Current (TC) TC1, 40 C

Short-Circuit Current Rating (SC) SC U2 SCU1

-

Auxiliary Contacts

Module Type

Auxiliary Contact, Dual Auxiliary Contact,Auxiliary /Signal Alarm Undervoltage Release Shunt Trip

Catalog Number1492-

ASPH3, ASPHH3, ASPHS3, ASPHSE3 ASPU115, ASPU230 ASPA1, ASPA 2

Degree ofProtection

IP 20 (IP 00)

Dimensions See Dimensions on page 31.

Weight in kg 0.045 0.355 0.155

MechanicalLifespan inOperations

6,000 10,000 4,000

MinimumImpulse Duration

> 15 ms

MinimumCommand Time

200 ms

OperatingVoltage

ASPU115 Un - 115V AC Umin - 50V AC

ASPA1 110 415V AC110 230V DC

ASPU230 Un - 230/240V ACUmin - 110V AC

ASPA2 12 110V AC12 60V DC

Inrush Current 3.6/44 mA (AC/DC) 25/12 mA (AC)15/2 mA (DC)

Dropout 0.7 0.35 x Us

Voltage Range 0.7 1.1 x Us

IEC MaximumOperating

Current

AC13 @ 250V AC 3 AAC15 @ 250V AC 0.5 ADC12 @ 110V DC 0.5 AUmin - 5V AC

TerminalCapacity

IEC Rigid, CU

0.52.5 mm22 x 0.52 x 2.5 mm2

0.54.0 mm22 x 0.52 x 2.5 mm2

1.025 mm22 x 1.02 x 4.0 mm2

TighteningTorque

0.8 Nm 1.1 Nm 2.4 Nm

UL 1077,CSA 22.2

No. 235

MaximumOperating

Current

@ 230V AC 2 A@ 110V DC 0.5 AUmin - 5 V DC

TerminalCapacity

CU

#18#14 AWG 2 x #18 2x #14 AWG

#18#14 AWG 2 x #18 2x #14 AWG

#18#8 AWG 2 x #182x #12 AWG

TighteningTorque

7 lb-in. 10 lb-in. 21 lb-in.

Rockwell Automation Publication 1492-TD010D-EN-P April 2011 29

-

Application Information A bus bar may be used for all 1492-SP Miniature Circuit Breakers.

Figure 8 - For 1492-ANNN Bus Bars

Figure 9 - Temperature Current Characteristic

IMPORTANT Position high current drawing devices nearest to the Feed Terminal, 1492-AAT1.

1489-AAP

1492-SP... or1492-FB...

4 mm

Z2

Ampac

ity of De

vices

AWG lb-in Nm18...46...4

2127

2.43.1

AWG lb-in Nm10...2 50 5.5

1492-AAT1

*

Temperature in Celsius

Ampacity of 1492-A_B8_Bus Bar

Ampa

city

in A

mps

Temperature in Celsius

Ampacity of 1492-A_B1_Bus Bar

Ampa

city

in A

mps

1009590858075706560

1009590858075706560

15 20 25 30 35 40 45 50 551492-FB

1492-SP

15 20 25 30 35 40 45 50 55

30 Rockwell Automation Publication 1492-TD010D-EN-P April 2011

-

Dimensions Dimensions are shown in millimeters. Dimensions are not intended for manufacturing purposes.

Figure 10 - 1492-SP Series C

Figure 11 - Bulletin 1492-A1B8

Figure 12 - Bulletin 1492-A2B8

Figure 13 - Bulletin 1492-A3B8

17.5

52.5 70.0

80.0

5.5

8.0

61.5

44.0

45.0

35.0

LISTED

1492-A1B8 Ser. A

For use with 1492-SP: 80A/480V AC, 10kA RMS Sym.Amps SCCR, 480V AC, max. Made in Germany

1492-A1EFor use with 1492-FB: 80A/600V AC, 100kA RMS Sym.Amps SCCR w/175A J Fuse, 600V AC, max.

3HXJLISTED

1492-A1B8 Ser. A

For use with 1492-SP: 80A/480V AC, 10kA RMS Sym.Amps SCCR, 480V AC, max. Made in Germany

1492-A1EFor use with 1492-FB: 80A/600V AC, 100kA RMS Sym.Amps SCCR w/175A J Fuse, 600V AC, max.

3HXJ

15.0

2.0

15.05.0

56.00 x 17.8 = 996.817.85.5

1009.0+2-0

55.00 x 17.8 = 979.017.8

(23)

1492-A2B8 Ser. A

Made in Germany

LISTED

1492-AME3HXJ

For use with 1492-SP: 80A/480V AC, 10kA RMS Sym.Amps SCCR, 480V AC, max.For use with 1492-FB: 80A/600V AC, 100kA RMS Sym.Amps SCCR w/175A J Fuse, 600V AC, max.

1492-A2B8 Ser. A

Made in Germany

LISTED

1492-AME3HXJ

For use with 1492-SP: 80A/480V AC, 10kA RMS Sym.Amps SCCR, 480V AC, max.For use with 1492-FB: 80A/600V AC, 100kA RMS Sym.Amps SCCR w/175A J Fuse, 600V AC, max.

991.0+2-0

14.0

6.0

21.2

36.523.0

1.5

1492-A3B8 Ser. A

Made in Germany

LISTED

1492-AME3HXJ

For use with 1492-SP: 80A/480V AC, 10kA RMS Sym.Amps SCCR, 480V AC, max.For use with 1492-FB: 80A/600V AC, 100kA RMS Sym.Amps SCCR w/175A J Fuse, 600V AC, max.

1492-A3B8 Ser. A

Made in Germany

LISTED

1492-AME3HXJ

For use with 1492-SP: 80A/480V AC, 10kA RMS Sym.Amps SCCR, 480V AC, max.For use with 1492-FB: 80A/600V AC, 100kA RMS Sym.Amps SCCR w/175A J Fuse, 600V AC, max.

14.0

6.017.8

21.2

23.037.0

1.5

56.0 x 17.8 = 996.8

+2-01009.0

Rockwell Automation Publication 1492-TD010D-EN-P April 2011 31

-

Figure 14 - Bulletin 1492-A1B1

Figure 15 - Bulletin 1492-A2B1

Figure 16 - Bulletin 1492-A1B1H

Figure 17 - Bulletin 1492-A1B8H

LISTED

1492-A1B1 Ser. A

For use with 1492-SP: 100A/480V AC, 10kA RMS Sym.Amps SCCR, 480V AC, max. Made in Germany

1492-A1EFor use with 1492-FB: 100A/600V AC, 100kA RMS Sym.Amps SCCR w/200A J Fuse, 600V AC, max.

3HXJLISTED

1492-A1B1 Ser. A

For use with 1492-SP: 100A/480V AC, 10kA RMS Sym.Amps SCCR, 480V AC, max. Made in Germany

1492-A1EFor use with 1492-FB: 100A/600V AC, 100kA RMS Sym.Amps SCCR w/200A J Fuse, 600V AC, max.

3HXJ

15.0

2.0

15.05.0

1009.0+2-0

56.00 x 17.8 = 996.817.85.5

1492-A3B1 Ser. A

Made in Germany

LISTED

1492-AME3HXJ

For use with 1492-SP: 100A/480V AC, 10kA RMS Sym.Amps SCCR, 480V AC, max.For use with 1492-FB: 100A/600V AC, 100kA RMS Sym.Amps SCCR w/200A J Fuse, 600V AC, max.

1492-A3B1 Ser. A

Made in Germany

LISTED

1492-AME3HXJ

For use with 1492-SP: 100A/480V AC, 10kA RMS Sym.Amps SCCR, 480V AC, max.For use with 1492-FB: 100A/600V AC, 100kA RMS Sym.Amps SCCR w/200A J Fuse, 600V AC, max.

21.2

36.5 23.0

2.0

14.0

6.017.8

56.00 x 17.8 = 996.8

1009.0+2-0

1492-A1B1H Ser. A

Made in Germany

LISTED

1492-A1E3HXJ

For use with 1492-SP: 100A/480V AC, 10kA RMS Sym.Amps SCCR, 480V AC, max.For use with 1492-FB: 100A/600V AC, 100kA RMS Sym.Amps SCCR w/200A J Fuse, 600V AC, max.

1492-A1B1H Ser. A

Made in Germany

LISTED

1492-A1E3HXJ

For use with 1492-SP: 100A/480V AC, 10kA RMS Sym.Amps SCCR, 480V AC, max.For use with 1492-FB: 100A/600V AC, 100kA RMS Sym.Amps SCCR w/200A J Fuse, 600V AC, max.

36.0 x 27.0 = 972.027.05.5

985.0+2-0

2.5

15.0

5.015.0

1492-A1B8H Ser. A

Made in Germany

LISTED

1492-A1E3HXJ

For use with 1492-SP: 80A/480V AC, 10kA RMS Sym.Amps SCCR, 480V AC, max.For use with 1492-FB: 80A/600V AC, 100kA RMS Sym.Amps SCCR w/175A J Fuse, 600V AC, max.

1492-A1B8H Ser. A

Made in Germany

LISTED

1492-A1E3HXJ

For use with 1492-SP: 80A/480V AC, 10kA RMS Sym.Amps SCCR, 480V AC, max.For use with 1492-FB: 80A/600V AC, 100kA RMS Sym.Amps SCCR w/175A J Fuse, 600V AC, max.

36.0 x 27.0 = 972.027.05.5

985.0 +2-015.0

15.0

5.0

2.0

32 Rockwell Automation Publication 1492-TD010D-EN-P April 2011

-

Figure 18 - Bulletin 1492-A2B8H

Figure 19 - Bulletin 1492-A3B8H

Figure 20 - Bulletin 1492-A2B1H

1492-A2B8H Ser. A

Made in Germany

LISTED

1492-AME3HXJ

For use with 1492-SP: 80A/480V AC, 10kA RMS Sym.Amps SCCR, 480V AC, max.For use with 1492-FB: 80A/600V AC, 100kA RMS Sym.Amps SCCR w/175A J Fuse, 600V AC, max.

1492-A2B8H Ser. A

Made in Germany

LISTED

1492-AME3HXJ

For use with 1492-SP: 80A/480V AC, 10kA RMS Sym.Amps SCCR, 480V AC, max.For use with 1492-FB: 80A/600V AC, 100kA RMS Sym.Amps SCCR w/175A J Fuse, 600V AC, max.

21.2

23.036.5

1.5

14.0

6.017.8

44.522.0 x 44.5 = 979.0

1009.0+2-0

1492-A3B8H Ser. A

Made in Germany

LISTED

1492-AME3HXJ

For use with 1492-SP: 80A/480V AC, 10kA RMS Sym.Amps SCCR, 480V AC, max.For use with 1492-FB: 80A/600V AC, 100kA RMS Sym.Amps SCCR w/175A J Fuse, 600V AC, max.

1492-A3B8H Ser. A

Made in Germany

LISTED

1492-AME3HXJ

For use with 1492-SP: 80A/480V AC, 10kA RMS Sym.Amps SCCR, 480V AC, max.For use with 1492-FB: 80A/600V AC, 100kA RMS Sym.Amps SCCR w/175A J Fuse, 600V AC, max.

14.0

21.2

23.037.0

1.5

62.3

17.8

2.0 x 17.8 = 35.615.0 x 62.3 = 934.5

982.0+2-0

6.0

1492-A2B1H Ser. A

Made in Germany

LISTED

1492-AME3HXJ

For use with 1492-SP: 100A/480V AC, 10kA RMS Sym.Amps SCCR, 480V AC, max.For use with 1492-FB: 100A/600V AC, 100kA RMS Sym.Amps SCCR w/200A J Fuse, 600V AC, max.

1492-A2B1H Ser. A

Made in Germany

LISTED

1492-AME3HXJ

For use with 1492-SP: 100A/480V AC, 10kA RMS Sym.Amps SCCR, 480V AC, max.For use with 1492-FB: 100A/600V AC, 100kA RMS Sym.Amps SCCR w/200A J Fuse, 600V AC, max.21.2

36.5 23.0

2.0

14.0

6.017.8 44.0

22.0 X 44.0 = 968.0

1009.0 +2-0

Rockwell Automation Publication 1492-TD010D-EN-P April 2011 33

-

Figure 21 - Bulletin 1492-A3B1H

Figure 22 - Auxiliary Contacts 1492-ASPHH3, ASPHS3, ASPH3, AS9HSC3P

Figure 23 - Undervoltage Release Module 1492-ASPU

Figure 24 - Shunt Trip Module 1492-ASPA

21.2

36.5 23.0

2.0982.0 +2-0

14.0

17.8

62.315.0 X 62.3 = 934.5

6.0

1492-A3B1H Ser. A

Made in Germany

LISTED

1492-AME3HXJ

For use with 1492-SP: 100A/480V AC, 10kA RMS Sym.Amps SCCR, 480V AC, max.For use with 1492-FB: 100A/600V AC, 100kA RMS Sym.Amps SCCR w/200A J Fuse, 600V AC, max.

1492-A3B1H Ser. A

Made in Germany

LISTED

1492-AME3HXJ

For use with 1492-SP: 100A/480V AC, 10kA RMS Sym.Amps SCCR, 480V AC, max.For use with 1492-FB: 100A/600V AC, 100kA RMS Sym.Amps SCCR w/200A J Fuse, 600V AC, max.

2.0 X 17.8 = 35.6

80.0

8.8 5.5 60.044.0

45.0

80.0

60.0

44.0

5.5

45.0

17.5

80.0

17.55.5

60.044.0

30.5

9.6

45.0

34 Rockwell Automation Publication 1492-TD010D-EN-P April 2011

-

Figure 25 - Bus Bar AccessoriesBulletin 1492-A1E Bulletin 1492-AAT1

For use with 1492-FB and1492-SP 100A/600V ACWire Range: 10 - 1/0 AWGTorque: 50 lb-in.M4 Hex Screw

LISTED1492-AAT1 Ser. A 3HXJ

1.0

14.0

8.5

1.7

1.1

2.15.0

28.5

3.0

21.011.0

16.2

18.5

60.0

6.8

Bulletin 1492-AME

4.012.0

24.0

9.521.6

18.6

Bulletin 1492-AAP

24.0

11.5

17.84.0 x 17.8 = 71.2

13.084.2

Rockwell Automation Publication 1492-TD010D-EN-P April 2011 35

-

Internal Resistance The following table provides the internal resistance of a one-pole at room temperature.

Table 18 - Internal Resistance of a One-Pole at Room Temperature

In [A]

R [m]*

Type B Type C Type D

0.5 4670 4670

1 1102 1100 770

2 333 333 249

3 208 130 130

4 87.2 87.2 87.2

5 72.8 72.8 65.1

6 46.3 39.1 39.1

7 35 32 28

8 30.4 30.4 19.5

10 17.4 14.0 14.0

13 13.3 13.3 10.1

15 7.9 7.9 7.9

16 7.9 7.9 7.9

20 7.1 7.1 4.9

25 4.9 4.9 3.8

30 3.9 3.9 3.5

32 3.7 3.7 3.4

40 2.5 2.5 2.6

50 2.1 2.1 1.9

63 2.0 2.0 1.5

* 50 Hz

36 Rockwell Automation Publication 1492-TD010D-EN-P April 2011

-

Power Loss In Entire Unit

Table 19 - Entire Unit Power Loss InType B, C, & D

Type B P* [W] Type C P* [W] Type D P* [W]

In [A] 1p 1pN 2p 3p 3pN 1p 1pN 2p 3p 3pN 1p 1pN 2p 3p 3pN

0.5 1.2 1.3 2.4 3.5 3.7 1.2 1.3 2.4 3.5 3.7

1 1.6 1.7 3.1 4.7 4.8 1.6 1.7 3.1 4.7 4.8 0.8 0.9 1.6 2.4 2.5

2 1.4 1.5 2.8 4.1 4.3 1.4 1.5 2.8 4.1 4.3 1.0 1.1 2.0 3.0 3.1

3 2.5 2.7 5.0 7.6 7.8 1.2 1.3 2.4 3.6 3.7 1.2 1.3 2.4 3.6 3.7

4 1.4 1.6 2.9 4.4 4.5 1.4 1.6 2.9 4.4 4.5 1.4 1.6 2.9 4.4 4.5

5 1.9 2.1 3.8 5.8 6.0 1.9 2.1 3.8 5.8 6.0 1.7 1.8 3.3 5.1 5.3

6 1.8 2.0 3.6 5.5 5.6 1.5 1.6 2.9 4.4 4.6 1.5 1.6 2.9 4.4 4.6

7 1.9 2.2 3.8 5.7 6.0 1.6 1.9 3.0 4.5 4.8 1.4 1.6 2.8 4.2 4.4

8 2.1 2.3 4.1 6.3 6.5 2.1 2.3 4.1 6.3 6.5 1.3 1.5 2.6 4.0 4.2

10 1.9 2.1 3.9 5.9 6.1 1.5 1.7 3.0 4.6 4.7 1.5 1.7 3.0 4.6 4.7

13 2.5 2.9 5.3 7.8 8.1 2.5 2.9 5.3 7.8 8.1 1.9 2.2 4.0 5.9 6.1

15 2.1 2.4 4.4 6.5 6.7 2.1 2.4 4.4 6.5 6.7 2.1 2.4 4.4 6.5 6.7

16 2.2 2.6 4.7 6.9 7.2 2.2 2.6 4.7 6.9 7.2 2.2 2.6 4.7 6.9 7.2

20 3.2 3.6 6.6 9.8 10.1 3.2 3.6 6.6 9.8 10.1 2.0 2.2 4.1 6.8 6.2

25 3.0 3.5 6.4 9.4 9.7 3.0 3.5 6.4 9.4 9.7 2.5 2.9 5.2 7.7 7.9

30 3.2 3.9 6.5 9.6 10.3 3.4 4.0 6.8 10.2 10.8 2.4 4.0 4.8 7.2 8.8

32 3.7 4.4 8.1 12.1 12.5 3.7 4.4 8.1 12.1 12.5 3.4 4.0 4.8 7.2 8.8

40 3.4 4.1 7.5 11.2 11.5 3.4 4.1 7.5 11.2 11.5 3.2 3.8 7.0 10.4 10.7

50 4.5 5.4 9.9 14.9 15.3 4.5 5.4 9.9 14.9 15.3 4.9 7.5 9.8 14.6 17.3

63 5.2 6.3 11.5 17.2 17.7 5.2 6.3 11.5 17.2 17.7 6.8 11.9 13.6 20.4 25.5

* 50 Hz

Rockwell Automation Publication 1492-TD010D-EN-P April 2011 37

-

Maximum Let-Through Energy

IEC/EN 60898

Figure 26 - Type B

Prospective Short-Circuit Current [A]

5000

6000

7000

8000

9000

1000

0

1000

1500

2000

3000

4000500

300

400

70000

50000

30000

15000

900

9000

7000

5000

3000

1500

700

500

Let-T

hrou

gh C

urre

nt I

2 t [

A2 s

ec]

80000

60000

40000

20000

10000

8000

6000

4000

2000

1000

800

600

B8

B5

B1

B2B3

B4

B6, B7

B10B13B15

, B16B20

B25B30

, B32B40

B50,

B63

38 Rockwell Automation Publication 1492-TD010D-EN-P April 2011

-

Figure 27 - Type C

Prospective Short-Circuit Current [A]

C7, C8

C5

C3C4

C0.5

C1

C2

C6

C10

C13C

15, C1

6C2

0C25

C30, C

32C40C

50C63

5000

6000

7000

8000

9000

1000

0

1000

1500

2000

3000

4000500

300

400

70000

50000

30000

15000

900

9000

7000

5000

3000

1500

700

500

80000

60000

40000

20000

10000

8000

6000

4000

2000

1000

800

600

Let-T

hrou

gh C

urre

nt I

2 t [

A2 s

ec]

Rockwell Automation Publication 1492-TD010D-EN-P April 2011 39

-

Figure 28 - Type D

Prospective Short-Circuit Current [A]

D2

D6

D5

D0.5

D1

D3D4

D10

D7, D

8D1

3

D20D

25D3

0, D32D4

0

D50D

63

5000

6000

7000

8000

9000

1000

0

1000

1500

2000

3000

4000500

300

400

70000

50000

30000

15000

900

9000

7000

5000

3000

1500

700

500

80000

60000

40000

20000

10000

8000

6000

4000

2000

1000

800

600

Let-T

hrou

gh C

urre

nt I

2 t [

A2 s

ec]

40 Rockwell Automation Publication 1492-TD010D-EN-P April 2011

-

Maximum Let-Through Current

IEC/EN 60898

Figure 29 - Type B

Let-T

hrou

gh C

urre

nt I

[A]

Prospective Short-Circuit-Current

100009000

1000

090

0080

0070

00

8000

7000

6000

5000

4000

3000

2000

1500

1000

50060

0050

00

4000

3000

2000

1500

100050

0

B8

B5

B1

B2

B3

B4

B6, B

7B1

0B13,

B15

B16B

20B2

5, B30B3

2B40B50B

63

I [A]CC

DL

Rockwell Automation Publication 1492-TD010D-EN-P April 2011 41

-

Figure 30 - Type C

C8

C5

C0.5

C1

C2

C3

C4

C6, C7

C10, C

13C15, C

16C20C

25,C3

0C3

2, C40C5

0, C63

Let-T

hrou

gh C

urre

nt I

[A]

1000090008000

7000

6000

5000

4000

3000

2000

1500

1000

500

DL

Prospective Short-Circuit-Current

1000

090

0080

0070

0060

0050

00

4000

3000

2000

1500

100050

0

I [A]

42 Rockwell Automation Publication 1492-TD010D-EN-P April 2011

-

Figure 31 - Type D10000

9000

1000

090

0080

0070

00

8000

7000

6000

5000

4000

3000

2000

1500

1000

500

6000

5000

4000

3000

2000

1500

100050

0

D2.5D2

D7,D8

D5

D0.5

D1

D1.5

D3D3.5D4

D6

D10D13D16D20

D25D30,D

32D40D63D50

Let-T

hrou

gh C

urre

nt I

[A] DL

Prospective Short-Circuit-Current I [A]

Rockwell Automation Publication 1492-TD010D-EN-P April 2011 43

-

44 Rockwell Automation Publication 1492-TD010D-EN-P April 2011

-

Rockwell Otomasyon Ticaret A.., Kar Plaza Merkezi E Blok Kat:6 34752 erenky, stanbul, Tel: +90 (216) 5698400

Publication 1492-TD010D-EN-P April 201116Supersedes Publication 1492-TD010C-EN-P - March 2002 Copyright 2011 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using its products. At http://www.rockwellautomation.com/support/, you can find technical manuals, a knowledge base of FAQs, technical and application notes, sample code and links to software service packs, and a MySupport feature that you can customize to make thebest use of these tools.

For an additional level of technical phone support for installation, configuration, and troubleshooting, we offer TechConnect support programs. For more information, contact your local distributor or Rockwell Automation representative, or visit http://www.rockwellautomation.com/support/.

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this manual.You can contact Customer Support for initial help in getting your product up and running.

New Product Satisfaction Return

Rockwell Automation tests all of its products to ensure that they are fully operational when shipped from the manufacturing facility. However, if your product is not functioning and needs to be returned, follow these procedures.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document, complete this form, publication RA-DU002, available at http://www.rockwellautomation.com/literature/.

United States or Canada 1.440.646.3434

Outside United States or Canada

Use the Worldwide Locator at http://www.rockwellautomation.com/support/americas/phone_en.html, or contact your local Rockwell Automation representative.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain one) to your distributor to complete the return process.

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

http://literature.rockwellautomation.com/idc/groups/literature/documents/du/ra-du002_-en-e.pdfhttp://www.rockwellautomation.com/support/americas/phone_en.htmlhttp://www.rockwellautomation.com/support/http://www.rockwellautomation.com/support/http://www.rockwellautomation.com/literature/http://www.rockwellautomation.com/locations/

IntroductionSupplementary Protectors & AccessoriesDescriptionInternational ApprovalsFeaturesConstructionSwitched Neutral Module (not field-mountable)Ordering InformationCatalog NumberRating DeterminationSelection TablesB-Trip Characteristics Resistive/Slightly Inductive Loads, 35 InC-Trip Characteristics Inductive Loads, 510 InD-Trip Characteristics Highly Inductive Loads 1020 InAccessoriesAllowable Combinations of Field Added ModulesAdditional AccessoriesProduct SelectionCuttable Copper Bus BarTechnical InformationLimiting Let-Through EnergyShort-Circuit InterruptionEnergy-Limiting CharacteristicsTripping CharacteristicsSpecificationsApplication InformationDimensionsInternal ResistancePower Loss InEntire UnitMaximum Let-Through EnergyIEC/EN 60898Maximum Let-Through CurrentIEC/EN 60898

/ColorImageDict > /JPEG2000ColorACSImageDict > /JPEG2000ColorImageDict > /AntiAliasGrayImages false /CropGrayImages true /GrayImageMinResolution 300 /GrayImageMinResolutionPolicy /OK /DownsampleGrayImages true /GrayImageDownsampleType /Average /GrayImageResolution 300 /GrayImageDepth 8 /GrayImageMinDownsampleDepth 2 /GrayImageDownsampleThreshold 2.00000 /EncodeGrayImages true /GrayImageFilter /FlateEncode /AutoFilterGrayImages false /GrayImageAutoFilterStrategy /JPEG /GrayACSImageDict > /GrayImageDict > /JPEG2000GrayACSImageDict > /JPEG2000GrayImageDict > /AntiAliasMonoImages false /CropMonoImages true /MonoImageMinResolution 1200 /MonoImageMinResolutionPolicy /OK /DownsampleMonoImages true /MonoImageDownsampleType /Average /MonoImageResolution 1200 /MonoImageDepth -1 /MonoImageDownsampleThreshold 1.50000 /EncodeMonoImages true /MonoImageFilter /CCITTFaxEncode /MonoImageDict > /AllowPSXObjects false /CheckCompliance [ /None ] /PDFX1aCheck false /PDFX3Check false /PDFXCompliantPDFOnly false /PDFXNoTrimBoxError true /PDFXTrimBoxToMediaBoxOffset [ 0.00000 0.00000 0.00000 0.00000 ] /PDFXSetBleedBoxToMediaBox true /PDFXBleedBoxToTrimBoxOffset [ 0.00000 0.00000 0.00000 0.00000 ] /PDFXOutputIntentProfile (None) /PDFXOutputConditionIdentifier () /PDFXOutputCondition () /PDFXRegistryName () /PDFXTrapped /False

/CreateJDFFile false /Description > /Namespace [ (Adobe) (Common) (1.0) ] /OtherNamespaces [ > /FormElements false /GenerateStructure true /IncludeBookmarks false /IncludeHyperlinks false /IncludeInteractive false /IncludeLayers false /IncludeProfiles true /MultimediaHandling /UseObjectSettings /Namespace [ (Adobe) (CreativeSuite) (2.0) ] /PDFXOutputIntentProfileSelector /NA /PreserveEditing true /UntaggedCMYKHandling /LeaveUntagged /UntaggedRGBHandling /LeaveUntagged /UseDocumentBleed false >> ]>> setdistillerparams> setpagedevice

Intro

Details of the Rockwell Automation Print Specifications sheet

This print specifications sheet is designed with multiple purposes.- It is a vehicle to get the most accurate print specifications to RA-approved print vendors.- It provides authors with an explanation of all necessary fields to complete before attaching the sheet to your PDF.- It provides separate tabs so that an author can fill in all fields related to the publication on the Generic tab or publication-specific template-type tabs to minimize the number of fields an author must complete.

To facilitate the most efficient use of this sheet, we recommend that you click on the publication-specific tab that most closely fits you publication and use that to complete the print specifications.

IMPORTANT: Because this sheet was constructed using a sheet that RR Donnelley (RRD) uses to load print specifications, there are some columns hidden. For example, the first field you must complete is Column E, or Publication Number. Columns A to D are used for RRD purposes and with information only representatives of that RA-approved printer can complete.

DO NOT delete any hidden columns from the tab you choose to use.

Definitions of Each Tab in Sheet

Generic pub print specsSingle sheet with all required columns for necessary specifications. None of the columns are completed. All must be completed before attaching the sheet to your PDF.

This tab has 44 blank fields you must complete via free text type or pull-down menus.

IN, RN pub type specsTemplates with many fields already completed according to typical default settings. We intend you use this tab with publications similar to installation instructions (IN) and release notes (RN). However, you can use this sheet for other publications that are similar to INs and RNs.

This sheet has 31 fields already completed and, if your publication uses the default values already completed, you must complete the additional 13 fields.

UM, RM, PM pub type specsTemplates with many fields already completed according to typical default settings. Use this tab with publications similar to user manuals (UM), reference manuals (RM) and programming manuals (PM). However, you can use this sheet for other publications that are similar to UMs, RMs and PMs.

This sheet has 34 fields already completed and, if your publication uses the default values already completed, you must complete the additional 10 fields.

AP, PP pub type specsTemplates with many fields already completed according to typical default settings. Use this tab with publications similar to application solutions (AP) and product profiles (PP). However, you can use this sheet for other publications that are similar to APs and PPs.

This sheet has 29 fields already completed and, if your publication uses the default values already completed, you must complete the additional 15 fields.

BR pub type specsTemplates with many fields already completed according to typical default settings. Use this tab with publications similar to brochures (BR). However, you can use this sheet for other publications that are similar to BRs.

This sheet has 27 fields already completed and, if your publication uses the default values already completed, you must complete the additional 17 fields.

Field definitionsDescription of information fields used throughout the spreadsheet tabs that may not be immediately obvious to a user.

Attach Print Specs to PDF

For Acrobat 7.0, follow these steps:1. Open the PDF.2. Click on the Attachments tab next to the publication's bookmarks. A new section appears at the bottom of the PDF.3. Click on the Add button in the bottom section of the PDF.4. Browse to the MS Excel file with the print specs and add them to the PDF.

For Acrobat 6.0, follow these steps:1. Open the PDF.2. Go to the backcover of the PDF.3. Click on the Tools pull-down menu.4. Click on this sequence of menu options - Advanced Commenting, Attach, Attach File Tool. A paper clip appears.5. Click to put the paper clip somewhere on the backcover. The browse window appears.6. Browse to the MS Excel file with the print specs and add them to the PDF.

IMPORTANT: If you are using Acrobat 5.0 or earlier, please upgrade. If you are using Acrobat 8.0, please contact RRD about attaching print specs because RA has not tested this software version yet.

Generic pub print specs

IN, RN pub type specs

UM, RM, PM pub type specs

AP, PP pub type specs

BR pub type specs

Field definitions

Generic pub print specs

Corp #17501

Bill To69

dPrint?Content/Comp #Split Shipment Indicator FlagWCSS Item NumberCustomer Item NumberItem DescriptionProducing PlantJob NumberReplenishing PlantPlant CodeProduct CodePackaging/Ordering UOMQty per Packaging/Ordering UOMList Price Per EaTransfer Cost per EaSell Price per EaStandard Cost (per Ea)Min Order Qty (in eaches)Multiple Order Qty (in EachesChargeback PriceItem Reference #1Item Reference #2Revision FieldMax Order Qty (in eaches)Sequentially Numbered Item?Sequentially Numbered Item - DetailsPriced for Digital or OffsetContent File LocationItem Category Form (F) Book (B)Item SubtypeOrientationSides PrintedCSS/JLS Stock ComponetPaper Size WidthPaper Size LengthNo of Forms to a SheetPage QtySheets QtyCSS/JLS Production StockPaper Stock TypePaper Stock WeightPaper Stock ColorStack OffsetTab Size# of TabsBinder SizeBinder ColorBinder Ring TypeBinder Transparency (clearview or matt)Thermal Tape ColorTrim Size WidthTrim Size LengthStitching LocationDrilling SizeDrilling LocationGlue Location# / PadFold TypeFold At# / Poly# / BoxCommentsCross Reference Item Number 1

Publication NumberPublication TitlePackaging/Ordering Unit Of MeasureQty per Packaging/Ordering Unit of MeasureMin Order QtyMultiple Order QtyBusiness GroupCost CenterRevision DateMax Order QtyItem CategoryForm (F) or Book (B)Binding/StitchingOrientationSides PrintedPrinting Paper Size WidthPrinting Paper Size LengthNumber of Forms to a SheetPage Count of PublicationNumber of Sheets Required to PrintCSS/JLS Production StockPaper Stock TypePaper Stock WeightPaper Stock ColorStack OffsetTab SizeNumber of Tabs NeededBinder SizeBinder ColorBinder Ring TypeBinder TransparencyThermal Tape ColorFinished Trim Size WidthFinished Trim Size LengthStitching LocationDrill Hole SizeNumber and Location of Drill HolesGlue LocationNumber of Pages per PadFold TypeFold AtNumber of Pieces per Poly wrapNumber of Pieces per BoxCommentsPart Number

Are these items being setup on dPrint? (Yes or No). If yes, Inv Mgmt to check "Print Management" flag on item setup.The content/Comp # will be provided by the CSC once the spec files are loaded to the DAS (the files must be named with the WCSS item #). The content/comp# must be hardcoded to the Item message Field in WCSS. Must be a 10 Digit number that starts with an 8.Required. Setting this to yes will allow warehouse product to ship out before the JIT item is completed. Setting this to no will hold all warehoused items until the printing of this item is complete. Please indicate Y or N.** Note: Each item with a Y will always ship separately even if produced at the same time as like items.Optional. 15 Characters Max. If the WCSS number provided already exists in the system, then Inventory Management will assign a random WCSS number.30 characters maximum.Cannot use quote symbol, that is--"--.Required. Which plant/Print Center will produce this item?Required. To be provided from the producing plant for JIT s/uRequired: What is the plant code of the plant that has owning rights to the dPrint files? If produced at multiple plants there can be only one owning plant.Required. What is the plant code of the facility that will produce this item? (see "Plant and Whse Codes" tab below)Required. Enter one of the applicable product.Method of packaging for publication shipment

Click here for explanation of each value in the pull-downRequired. This field auto-calculates (transfer cost divided by .5). Used to determine Standard Cost on WCSS (which is 50% of the list price for these product codes).Required. Transfer Cost per ordering/packaging unit of measure.Required. Price that will be billed to customer upon order. If Price Breaks, enter "Price Breaks" and note them on separate spreadsheet.Required. Replacement Cost per Packaging/ordering UOM.Click here for an explanation of this field; otherwise, type NA.Optional. Used to assist customer with internal Chargebacks to end users. (per packaging/ordering UOM)IMPORTANT: This information must match the DocMan record.

Click here for explanation of each value in the pull-down menu.IMPORTANT: This information must match the DocMan record.IMPORTANT: This information must match the DocMan record.

Date on the publication.Click here for explanation of each value in the pull-down menu.Indicate Yes or No. Enter Yes if the item is a sequentially numbered item.Describe the details behind the sequentially numbered item, such as:- Record Sequence Shipped: whse will record the sequence numbers that shipped- Ship in Sequence Record: required to ship products in particular sequence and the whse records the numbersRequired: Enter the word DIGITAL or the word OFFSET, which ever one describes the production pricing used for this itemRequired: If PDF is to be retained in the DAS enter DAS in this field, if item is part of eCreate or Custom Docs put CUSTOM in this field.Typically a Book.

Click here for explanation of each value in the pull-down menu.Click here for explanation of each value in the pull-downClick here for explanation of each value in the pull-down menu.Optional: Use when finished product stored in the warehouse is to be inserted into the construction of a JIT book.IMPORTANT: Not Trim Size width

This is the width of the paper on which the publication is printed.IMPORTANT: Not Trim Size length

This is the length of the paper on which the publication is printed.Click here for explanation of how to determine the information required.Click here for explanation of how to determine the information required.Optional: Use when product is being printed on Shell Stock. Provide warehoused WCSS Item nu,mber of product to be used in the production of JIT item.Click here for explanation of how to determine the information required.The pull-down menu lists the most common choices.

Click here for a full list of the available choices.

If you use a choice not in the pull-down list, type the value in the cell below the pull-down menu.If item uses tabs; otherwise, NA.If needed; otherwise type NA.If item used in a binder; otherwise, NA.If item used in a binder; otherwise, NA.If item used in a binder; otherwise, NA.If item used in a binder; otherwise, NA.If publication is thermal tape bound; otherwise, NA.Click here to see the available finished trim sizes.

The sizes are listed - width x length.Click here to see the available finished trim sizes.

The sizes are listed - width x length.If publication is Book [B] and stapled; otherwise, NA.Click here for a list of possible drill locationsIf publication uses padding; otherwise, NA.If publication is a notepad or message pad; otherwise, NA.Click here for explanation of each value in the pull-down menu.Click here for explanation of each value in the pull-down menu.Use this column to list:- Cover Stock- Text Stock- Cover Ink- Text Ink

Also use to indicate any other production or finishing requirements not provided in previous columns

Click here for an explanation of the available Cover Stock, Cover Ink and Text Ink values.List only if pubication is used in manufacturing; otherwise, leave blank.

1492-TD010D-EN-PSupplementary Protectors/Miniature CircuitBreakersEA1NAMarketing CommercialCMKMKE Essential Components Program - 1904104/01/2011100BSADDLEPORTRAITHEAD2HEADRRD must provide this informationRRD must provide this information44812PLAIN20#WhiteRRD must provide this informationNANANANANANANA8.511NANANANANANANA25RRD must provide this informationNA

&CItem Setup Sheet for Conversion Transfers

&LJIT-D-print Spreadsheet&CREF046&R&D &T

Click here for explanation of each value in the pull-down

Method of packaging for publication shipment

Click here for explanation of each value in the pull-down

IMPORTANT: This information must match the DocMan record.

Click here for explanation of each value in the pull-down menu.

Click here for explanation of each value in the pull-down menu.

Typically a Book.

Click here for explanation of each value in the pull-down menu.

Click here for explanation of each value in the pull-down menu.

Click here for explanation of how to determine the information required.

Click here for explanation of how to determine the information required.

Click here for explanation of how to determine the information required.

The pull-down menu lists the most common choices.

Click here for a full list of the available choices.

If you use a choice not in the pull-down list, type the value in the cell below the pull-down menu.

Click here to see the available finished trim sizes.

The sizes are listed - width x length.

Click here to see the available finished trim sizes.

The sizes are listed - width x length.

Click here for a list of possible drill locations

Click here for explanation of each value in the pull-down menu.

Click here for explanation of each value in the pull-down menu.

Use this column to list:- Cover Stock- Text Stock- Cover Ink- Text Ink

Also use to indicate any other production or finishing requirements not provided in previous columns

Click here for an explanation of the available Cover Stock, Cover Ink and Text Ink values.

Click here for an explanation of this field; otherwise, type NA.

IN, RN pub type specs

dPrint?Content/Comp #Split Shipment Indicator FlagWCSS Item NumberCustomer Item NumberItem DescriptionProducing PlantJob NumberReplenishing PlantPlant CodeProduct CodePackaging/Ordering UOMQty per Packaging/Ordering UOMList Price Per EaTransfer Cost per EaSell Price per EaStandard Cost (per Ea)Min Order Qty (in eaches)Multiple Order Qty (in EachesChargeback PriceItem Reference #1Item Reference #2Revision FieldMax Order Qty (in eaches)Sequentially Numbered Item?Sequentially Numbered Item - DetailsPriced for Digital or OffsetContent File LocationItem Category Form (F) Book (B)Item SubtypeOrientationSides PrintedCSS/JLS Stock ComponetPaper Size WidthPaper Size LengthNo of Forms to a SheetPage QtySheets QtyCSS/JLS Production StockPaper Stock TypePaper Stock WeightPaper Stock ColorStack OffsetTab Size# of TabsBinder SizeBinder ColorBinder Ring TypeBinder Transparency (clearview or matt)Thermal Tape ColorTrim Size WidthTrim Size LengthStitching LocationDrilling SizeDrilling LocationGlue Location# / PadFold TypeFold At# / Poly# / BoxCommentsCross Reference Item Number 1

Publication NumberPublication TitlePackaging/Ordering Unit Of MeasureQty per Packaging/Ordering Unit of MeasureMin Order QtyMultiple Order QtyBusiness GroupCost CenterRevision DateMax Order QtyItem CategoryForm (F) or Book (B)Binding/StitchingOrientationSides PrintedPrinting Paper Size WidthPrinting Paper Size LengthNumber of Forms to a SheetPage Count of PublicationNumber of Sheets Required to PrintCSS/JLS Production StockPaper Stock TypePaper Stock WeightPaper Stock ColorStack OffsetTab SizeNumber of Tabs NeededBinder SizeBinder ColorBinder Ring TypeBinder TransparencyThermal Tape ColorFinished Trim Size WidthFinished Trim Size LengthStitching LocationDrill Hole SizeNumber and Location of Drill HolesGlue LocationNumber of Pages per PadFold TypeFold AtNumber of Pieces per Poly wrapNumber of Pieces per BoxCommentsPart Number

Are these items being setup on dPrint? (Yes or No). If yes, Inv Mgmt to check "Print Management" flag on item setup.The content/Comp # will be provided by the CSC once the spec files are loaded to the DAS (the files must be named with the WCSS item #). The content/comp# must be hardcoded to the Item message Field in WCSS. Must be a 10 Digit number that starts with an 8.Required. Setting this to yes will allow warehouse product to ship out before the JIT item is completed. Setting this to no will hold all warehoused items until the printing of this item is complete. Please indicate Y or N.** Note: Each item with a Y will always ship separately even if produced at the same time as like items.Optional. 15 Characters Max. If the WCSS number provided already exists in the system, then Inventory Management will assign a random WCSS number.30 characters maximum.Cannot use quote symbol, that is--"--.Required. Which plant/Print Center will produce this item?Required. To be provided from the producing plant for JIT s/uRequired: What is the plant code of the plant that has owning rights to the dPrint files? If produced at multiple plants there can be only one owning plant.Required. What is the plant code of the facility that will produce this item? (see "Plant and Whse Codes" tab below)Required. Enter one of the applicable product.Method of packaging for publication shipment

Click here for explanation of each value in the pull-downRequired. This field auto-calculates (transfer cost divided by .5). Used to determine Standard Cost on WCSS (which is 50% of the list price for these product codes).Required. Transfer Cost per ordering/packaging unit of measure.Required. Price that will be billed to customer upon order. If Price Breaks, enter "Price Breaks" and note them on separate spreadsheet.Required. Replacement Cost per Packaging/ordering UOM.Click here for an explanation of this field; otherwise, type NA.Optional. Used to assist customer with internal Chargebacks to end users. (per packaging/ordering UOM)IMPORTANT: This information must match the DocMan record.

Click here for explanation of each value in the pull-down menu.IMPORTANT: This information must match the DocMan record.IMPORTANT: This information must match the DocMan record.