Sun Valley Ski Resort

description

Transcript of Sun Valley Ski Resort

Ski resort installs nearly three miles of tubing in one daySun Valley, a premier ski resort near Ketchum, ID, has been called the American Shangri-La. Discovered by two enterprising businessmen who wanted to create a world-class resort, Sun Valley opened to the public in 1936 and has entertained celebrities and citizens alike. Most recently, Sun Valley renovated their snow-melting systems using Viega ProRadiant™.

Chris Share, HVAC Boiler Maintenance Supervisor at Sun Valley, maintains around 80 boilers, which are mostly for snow melting, and in the summertime, he takes care of the cooling towers and chilling systems. He was in charge of the project.

“We took out a nine million BTU atmospheric boiler that covered 60,000 square feet,” Share said. “And it either had to be all on or all off. Now, I have 19 zones and I can run what I want.”

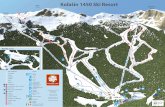

Share and his team installed ¾" ViegaPEX™ Barrier tubing, Viega PEX Press � ttings in ¾" and 2", and 12-port copper manifolds. They also used insulated Viega panels in the installation.

“All my distribution lines are ViegaPEX,” Share said. “Every loop is exactly 400-foot lengths. It was easy to do a pressure test on it once we had it laid and hooked up. With everything, including the building supplies and returns, we put in a little over 30 miles of tube installed in the ground.”

The main challenge Share and his crew faced was completing the project on time.

“To start the project we had to pull up all the pavers that had been put down,” Share said. “Basically in the beginning, we had to get all the piping from the mechanical room out to the � rst drive area and get that all back to grade so the paver guys could work. The

paver crews were covering it as fast as we could put it down and we were staying about three zones ahead of them.”

According to Share, he and his team started April 9 and � nished June 21.

“We did the River Run Bridge in one day,” Share said. “That was 37 loops in one day with six guys. That’s a good amount. If three guys can lay 3,000 feet in a day, that’s good. But with Viega systems, we laid 14,800 feet in a day and it was a nasty day too.”

Share has been installing Viega systems for many years and has attended the snow-melting course at the Viega Educational Facility in Nashua, NH.

“I’ve used other snow-melting systems,” Share said. “But they’re a pain because you’re dealing with European tools. With a lot of the other � tting systems, the rings aren’t attached. With Viega systems,

CUSTOMER: Sun Valley Ski Resort

APPLICATION: Snow-melting system

LOCATION: Ketchum, ID

CONTRACTOR: Sun Valley Ski Resort in-house maintenance

We took out a nine million BTU atmospheric boiler that covered 60,000 square feet. It either had to be all on or all off. Now, I have 19 zones and I can run what I want.

“or all off. Now, I have 19 zones and I can run what I want.”

©2014 Viega LLC

the rings are attached so you don’t have to hunt for them. If you want a system that doesn’t leak, you don’t want to be able to take it apart easily.”

Share said that Sun Valley does have a future plan to expand the system on the ski slope because its current con� guration makes it dif� cult for them to groom the snow. Ideally, they want skiers to be able to ski down to the edge of the slope and walk off on the pavers.

“I’m very excited about how much more energy ef� cient we can get,” Share said. “In January, we get into a dry cold spell. I’ll be able to run just a little bit. If I get an icy spot, I can just turn on that zone instead of having to run the whole thing.”

Share believes that his relationship with his Viega sales representative has added to the overall bene� t of working with Viega systems.

“Everyone at Viega has been really helpful in getting the project laid out for us,” Share said. “They did all the work on laying out the tube and we pretty much followed those blueprints. That was very helpful.”

Share and his team stuck so closely to the layouts Viega provided for their project that he plans to laminate them and draw in the positions of the manifolds and hang it in the mechanical room as

a guide. During installation, his team put different colored electrical tape on each line so they could tell them apart. He plans to color code the blueprints to match.

Viega snow-melting systems aren’t the only Viega solutions at Sun Valley. They’ve also installed 1⁄2" Viega FostaPEX® on the roof of a snow-making building to prevent ice buildup. Most of their manifolds are Viega manifolds and they have also installed Viega ProPress® systems in sizes 3" and 4". Additionally, they upgraded all the domestic water piping in their laundry facilities using Viega ProPress for stainless steel.

“Anything we redo, we’ll use Viega ProPress or Viega PEX Press,” Share said. “You can’t go wrong. I’ve never had any problems with them leaking. I don’t know if I’ve even ever had � ttings with � aws in them. The quality control is de� nitely up there.”

For more information on Viega products, visit www.Viega.us, or call toll free: 800-976-9819.