Study on chemical composition of Agaricus blazei … PDF21(1)/27Rozsa Sandor...Study on chemical...

-

Upload

truongkiet -

Category

Documents

-

view

232 -

download

2

Transcript of Study on chemical composition of Agaricus blazei … PDF21(1)/27Rozsa Sandor...Study on chemical...

Volume 21(1), 150- 157, 2017 JOURNAL of Horticulture, Forestry and Biotechnology www.journal-hfb.usab-tm.ro

150

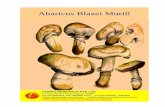

Study on chemical composition of Agaricus blazei Murrill mushroom, produced on different substrates Rózsa S.1*, Măniuțiu D.N.1, Gocan Tincuța-Marta1, Sima Rodica1, Rózsa Melinda2

1University of Agricultural Sciences and Veterinary Medicine, Faculty of Horticulture 3-5 Mănăștur St.,

400372, Cluj-Napoca, România; 2 SC Ciupercăria SRL, 332 Aghireșu-Fabrici, 407010, Cluj County,

România, www.ciupercaria.com *Corresponding author. Email: [email protected] Abstract All edible mushrooms are high in vitamin B plus other vitamins such as vitamin C and ergosterol. Bioactive compounds from edible mushrooms have become new products for health therapy, especially anti-cancer therapies. Almond mushroom - Agaricus blazei Murrill was discovered and popularised as late as the 20th century. However, it has been known for its exceptional properties in the places of its origin for a long time. Studies have been conducted worldwide for several decades, aiming at the precise determination of these properties and their applicability in medicine. This study was carried out to evaluate the effect of four growing substrates of Agaricus blazei Murrill mushroom on the chemical composition of mushrooms.

Key words compost, Agaricus blazei Murrill, vitamin B, vitamin C, ergosterol

The fruiting bodies of Agaricus blazei Murrill contain

89-91% water, which is in general less than that of A.

bisporus. Almost 48% of total dry matter consists of

crude protein and 18% of carbohydrates, but the lipid

content is only 0.5% [6]. The fruiting bodies of

Agaricus blazei Murrill contain high levels of valuable

minerals, e.g. potassium, phosphorus, calcium,

magnesium and zinc. Nevertheless, a minute amount of

cadmium was also detectable [6].

Bioactive compounds of mushrooms can be isolated

from their fruiting bodies, or culture extraction from

pure culture of mycelia [1]. Agaricus blazei Murrill has

been reported to produce various bioactive compounds

that have potential to treat many diseases [5]. This

mushroom has been used as a medicinal food for the

prevention of cancer, diabetes, hyperlipidaemia,

arteriosclerosis, and chronic hepatitis, and is known to

stimulate the immune system [20].

Several categories of molecules are involved in

beneficial effects of Agaricus blazei Murrill and most

of them are common to the entire fungal kingdom [10].

Some compounds (such as ergosterol and b-glucans)

are considered as biochemical markers for the kingdom

and are ubiquitous. β-Glucans are cell wall constituents

that can be found in many fungi [10].

Agaricus blazei Murrill is a well-known medicinal

mushroom used in many countries, and thus

consumption of this mushroom is used as an alternative

way to cure diseases. Various pharmaceutical activities

have been found associated with Agaricus blazei

Murrill and researches to reveal the function of

bioactive compounds are extensive. Recent studies

have been performed in vitro and in vivo to confirm the

mushrooms therapeutic properties [5]. Identification of

(novel) immunomodulating bioactive compounds from

the mushroom may also help in new treatments for

patients suffering from cancer and immunodeficiency

[13].

Almond mushroom is a saprophytic species, growing

well on soils rich in ligno-cellulose residue [19]. As it

was reported by Stamets [19], Wasser [21] and Dias

[4], natural habitats for this species include mixed

forests, first of all their margins, as well as fields in

upland and mountainous areas of Brazil and Peru.

Almond mushroom is the so-called secondary

saprophyte, developing on partially processed

substrate, in which microorganisms reduced complex

ligno-cellulose compounds [2]. Numerous authors have

shown that due to the similar life cycle in the

cultivation of almond mushroom technologies

developed for white button mushroom may be applied.

However, almond mushroom requires high temperature

and high humidity as well as access to light to form

fruiting bodies [2,3,4,11,18]. In Brazil, due to the

advantageous climatic conditions this species is

frequently grown outdoors; however, in other countries

- mainly due to its high temperature requirements -

such cultivation system is risky and may only be

successful during very warm summers [9,18,19].

The results of Agaricus cultivation to a considerable

degree are determined by the composition of the

substrate. Unfortunately, there is a limited body of data

concerning growing media for almond mushroom

cultivation. Frequently producers, particularly in Brazil

and Japan, use substrate with the composition

developed for white button mushroom [11]. However,

151

both species may respond differently to an identical

substrate composition. For this reason, it is essential to

develop a substrate meeting requirements of almond

mushroom [22]. The primary components in such a

substrate are most frequently locally available

materials, subjected to composting, e.g. agricultural

waste rich in ligno-cellulose complexes, i.e. straw,

cotton burrs, grasses, sawdust, enriched with animal

manure, poultry dung, wheat or rice bran and calcium

[7,8,9,12,14,17].

Material and Method

Given that in the experience we made, the culture

substrate presents 4 graduations (a1-classic compost,

a2- synthetic compost, a3-mixed compost, a4-original

compost) to achieve directed composting, were

conducted 4 identical tanks to control, perform and

record optimal environmental conditions necessary for

the composting and pasteurization process. (figure no.

1-6).

For the experiments, we used four recipes of compost, presented in table no. 1

7

4

6 5

1

2 3

8

9

1

0

Module a1

11

7

4

6 5

1

2 3

8

9

1

0

Module a2

7

4

6 5

1

2 3

8

9

1

0

Module a3

7

4

6 5

1

2 3

8

9

1

0

Module a4

Figure no. 1. Sketch for the composting facility - 4 modules:

1 - tank with capacity of 1 m3 for compost components; 2 – rack for compost; 3 - tank heating system for composting;

4 - tank for the collection and recirculation the water excess; 5 - heating elements for wetting water (purine); 6 –

water/purine recirculation pump; 7 - recirculation pipes for wetting water/ purine; 8 - compost discharge door; 9 - air

flow control valve for aerobic composting; 10 - air inlet pipe to aerobic composting from the compressor; 11 -

ground level.

Figure 2. Composting facility - 4

modules

Source: original photo

Figure 3. Tank for the collection and

recirculation of the water excess

Source: original photo

Figure 4. Compressor for the air flow

Source: original photo

152

Table 1

Recipes for compost used in experience

Type of compost

Components Quantity for 1 tone of

compost

C1 - Classical Horse manure (horse manure and wheat bedding straw 70-75%)

Gypsum (calcium sulphate)

Superphosphate

Ammonium sulphate

500 kg

25 kg

7 kg

7 kg

C2 - Synthetic Wheat straw

Poultry litter

Gypsum (calcium sulphate)

Urea

350 kg

150 kg

20 kg

7 kg

C3 - Mixt Horse manure (horse manure and wheat bedding straw 70-75%)

Poultry litter

Wheat straw

Gypsum (calcium sulphate)

Urea

250 kg

100 kg

150 kg

24 kg

2 kg

C4 - Original shredded reed

Horse manure (horse manure and wheat bedding straw 70-75%)

Poultry litter

Gypsum (calcium sulphate)

Urea

100 kg

200 kg

150 kg

24 kg

2 kg

Each type of compost was prepared in a composting

tank, respecting the proportions of raw and auxiliary

materials.

The compost pasteurization was achieved by raising

the temperature of compost at 58-60 °C for a period of

about 8 hours, then lowering the temperature of the

compost at 50°C by mixing fresh air and continued

cooling to 45°C. The temperature of 45°C was

maintained until the ammonia content of the compost

has not fallen below 0.05% and the pH has stabilized in

the range of 7.3-7.5. [15,16]. In experience, we used

protein additives as follows: A1 – without protein

additives, A2 - 3% wheat bran and A3 - Corn flour 3%.

Results and Discussions

Table no. 2 presents the effect of compost and protein

additives (A x C) on the dry matter of mushrooms

during year 2015 and 2016 of experience.

The maximum value of total dry matter (9.43%) and

soluble dry matter (8.50%) was recorded by mushroom

harvested from C3 A2 combination, the minimum

value of total dry matter was recorded by C4 A1

combination (7.13%) and the minimum value of

soluble dry matter was recorded by C4 A3 combination

(7.07%).

Table no. 3 presents the effect of the interaction

between protein additives A and compost C to the

soluble dry matter content of mushrooms, during year

2015 and 2016 of experience.

Figure 5. Tank for composting, internal view.

Source: original photo

Figure 6. Compost components pre-soaking.

Source: original photo

153

Table 2

Effect of compost and protein additives (A x C) on the dry matter of mushrooms during two years of experience

Experimental

factors

Content of:

Total dry matter % Soluble dry matter % Insoluble dry matter %

Variant Combi

nation 2015 2016 media 2015 2016 media 2015 2016 media

V1 C1 A1 9.03 8.23 8.63 7.73 7.07 7.40 1.30 1.16 1.23

V2 C1 A2 9.43 8.70 9.07 8.80 8.13 8.47 0.63 0.57 0.60

V3 C1 A3 9.73 8.87 9.30 8.07 7.40 7.73 1.66 1.47 1.57

V4 C2 A1 8.20 7.57 7.87 8.17 7.30 7.75 0.13 0.27 0.12

V5 C2 A2 9.10 8.50 8.80 8.50 7.77 8.13 0.60 0.73 0.67

V6 C2 A3 8.70 7.77 8.23 8.33 7.73 8.03 0.37 0.04 0.20

V7 C3 A1 9.40 8.60 9.00 7.93 7.27 7.60 1.47 1.33 1.40

V8 C3 A2 9.77 9.10 9.43 8.83 8.17 8.50 0.94 0.93 0.93

V9 C3 A3 8.47 7.80 8.13 7.43 6.77 7.10 1.04 1.03 1.03

V10 C4 A1 7.60 6.83 7.13 7.37 6.67 7.10 0.23 0.16 0.03

V11 C4 A2 8.37 7.83 8.10 7.63 6.87 7.25 0.74 0.96 0.85

V12 C4 A3 7.70 7.17 7.43 7.57 6.57 7.07 0.13 0.60 0.36

Table 3

The effect of the interaction between protein additives A and compost C

to the soluble dry matter content of mushrooms

Experimental

variant Combination

Soluble dry

matter SDM% Significance*

V6 A2 C2 8.80 A

V7 A2 C3 8.50 B

V5 A2 C1 8.47 B

V11 A3 C3 8.13 C

V8 A2 C4 8.10 C

V10 A3 C2 8.03 C

V2 A1 C2 7.87 CD

V9 A3 C1 7.73 D

V3 A1 C3 7.60 E

V12 A3 C4 7.43 F

V1 A1 C1 7.40 F

V4 A1 C4 7.10 G

DS 0.16-0.18

*Values marked with different letters are significant

Taking into account the combined influence of protein

additives and the compost on the soluble dry matter

content of mushrooms, the best value was recorded by

A2 C2 combination with 8.80% SDM, followed by A2

C3 combination with 8.50% SDM. On the last places

was A1 C4 combination with 7.10% SDM.

Table no. 4 presents the results obtained for B1 vitamin

(thiamine), in μg, during year 2015 and 2016 of

experience.

154

Table 4

B1 vitamin (thiamine), in μg, during year 2015 and 2016 of experience

Experimental factors B1 vitamin μg B1 vitamin processing value with Duncan Test

(2015-2016) μg

Variant Combination 2015 2016 Variant Combination Value Signification

V1 C1 A1 1053 1007 V9 A3 C1 1151.67 A

V2 C1 A2 1123 1077 V5 A2 C1 1100.00 B

V3 C1 A3 1180 1123 V1 A1 C1 1030.00 C

V4 C2 A1 923 877 V10 A3 C2 956.67 D

V5 C2 A2 963 917 V6 A2 C2 940.00 D

V6 C2 A3 980 933 V2 A1 C2 900.00 E

V7 C3 A1 600 547 V11 A3 C3 635.00 F

V8 C3 A2 640 593 V7 A2 C3 616.67 F

V9 C3 A3 667 603 V3 A1 C3 573.33 G

V10 C4 A1 403 360 V12 A3 C4 423.33 H

V11 C4 A2 427 363 V8 A2 C4 395.00 HI

V12 C4 A3 447 400 V4 A1 C4 381.67 I

Mean of

experience 783.83 733.33 DS 35.68----41.15

Following the values from table no. 4, we can see that

the maximum content of B1 vitamin was recorded by

C1 compost (1007-1180μg), followed by C2 compost

(877-980μg) harvested mushrooms.

On the last place was mushrooms harvested from the

C4 compost (363-447μg). As we can see the protein

additives did not influenced the B1 vitamin content so

much as the type of compost. On the first place is

situated A3 protein additives, followed by A2 and A1

protein additives.

Table no. 5 presents the results obtained for B2 vitamin

(riboflavin), in μg, during year 2015 and 2016 of

experience.

Table 5

B2 vitamin (riboflavin), in μg, during year 2015 and 2016 of experience

Experimental factors B2 vitamin μg B2 vitamin processing value with Duncan Test

(2015-2016) μg

Variant Combination 2015 2016 Variant Combination Value Signification

V1 C1 A1 5300 4667 V7 A2 C3 5983.33 A

V2 C1 A2 5667 5233 V9 A3 C1 5616.67 AB

V3 C1 A3 5800 5433 V5 A2 C1 5433.33 ABC

V4 C2 A1 4033 3600 V11 A3 C3 5350.00 ABCD

V5 C2 A2 4533 4100 V1 A1 C1 4983.33 ABCD

V6 C2 A3 4767 4333 V3 A1 C3 4800.00 BCDE

V7 C3 A1 5000 4600 V10 A3 C2 4550.00 CDEF

V8 C3 A2 5300 4667 V6 A2 C2 4316.67 DEFG

V9 C3 A3 5533 5167 V2 A1 C2 3816.67 EFGH

V10 C4 A1 3400 2967 V12 A3 C4 3533.33 FGH

V11 C4 A2 3700 3200 V8 A2 C4 3450.00 GH

V12 C4 A3 3767 3300 V4 A1 C4 3183.33 H

Mean of

experience 4733.3 4272.2 DS 944.83----1089.71

Following the values from table no. 5, we can see that

the maximum content of B2 vitamin was recorded in

2015 by C1 compost with A3 protein additives

(5800μg), followed by C1 compost with A2 protein

additives (5667μg) harvested mushrooms. On the last

place was mushrooms harvested from the C4 compost

with A1 protein additives (3400μg). In 2016 that the

maximum content of B2 vitamin was recorded by C1

compost with A3 protein additives (5443μg) and the

minimum value was recorded also by C4 compost with

A1 protein additives (2967μg).

As we can see the combined factors, protein additives

and compost, A2 C3 combination recorded the

maximum value (5983.33μg), followed by A3 C1

combination. On the last place is situated the A1 C4

combination (3183.33μg).

Table no. 6 presents the results obtained for B9 vitamin

(folic acid), in μg, during year 2015 and 2016 of

experience.

155

Table 6

B9 vitamin (folic acid), in μg, during year 2015 and 2016 of experience

Experimental factors B9 vitamin μg B9 vitamin processing value with Duncan Test

(2015-2016) μg

Variant Combination 2015 2016 Variant Combination Value Signification

V1 C1 A1 580 567 V1 A3 C3 671.67 A

V2 C1 A2 610 587 V9 A3 C1 631.67 B

V3 C1 A3 643 620 V7 A2 C3 631.67 B

V4 C2 A1 443 427 V3 A1 C3 618.33 B

V5 C2 A2 467 450 V5 A2 C1 598.33 C

V6 C2 A3 483 467 V1 A1 C1 579.33 D

V7 C3 A1 643 593 V10 A3 C2 475.00 E

V8 C3 A2 673 590 V6 A2 C2 458.33 F

V9 C3 A3 687 657 V2 A1 C2 435.00 G

V10 C4 A1 290 277 V12 A3 C4 313.33 H

V11 C4 A2 303 280 V8 A2 C4 291.67 I

V12 C4 A3 323 303 V4 A1 C4 283.33 I

Mean of

experience 512.08 484.8 DS 13.77----15.88

Following the values from table no. 6, we can see that

the maximum content of B9 vitamin was recorded in

2015 by C3 compost with A3 protein additives

(687μg), followed by C3 compost with A2 protein

additives (673μg) harvested mushrooms. On the last

place was mushrooms harvested from the C4 compost

with A1 protein additives (323μg). In 2016 that the

maximum content of B9 vitamin was recorded by C3

compost with A3 protein additives (657μg) and the

minimum value was recorded also by C4 compost with

A1 protein additives (277μg).

As we can see the combined factors, protein additives

and compost, A3 C3 recorded the maximum value

(671.67μg), followed by A3 C1 combination. On the

last place is situated the A1 C4 combination

(283.33μg).

Table no. 7 presents the results obtained for B12

vitamin (cobalamin), in μg, during year 2015 and 2016

of experience.

Table 7

B12 vitamin (cobalamin), in μg, during year 2015 and 2016 of experience

Experimental factors B12 vitamin μg B12 vitamin processing value with Duncan Test

(2015-2016) μg

Variant Combination 2015 2016 Variant Combination Value Signification

V1 C1 A1 527 510 V11 A3 C3 906.67 A

V2 C1 A2 540 523 V7 A2 C3 866.67 B

V3 C1 A3 560 557 V3 A1 C3 828.33 C

V4 C2 A1 727 680 V10 A3 C2 761.67 D

V5 C2 A2 747 710 V6 A2 C2 728.33 E

V6 C2 A3 767 757 V2 A1 C2 703.33 E

V7 C3 A1 843 813 V12 A3 C4 573.33 F

V8 C3 A2 877 857 V9 A3 C1 558.33 FG

V9 C3 A3 913 900 V8 A2 C4 538.33 GH

V10 C4 A1 487 440 V5 A2 C1 531.67 GH

V11 C4 A2 550 527 V1 A1 C1 518.33 H

V12 C4 A3 583 563 V4 A1 C4 463.33 I

Mean of

experience 676,75 653.08 DS 32.40----37.37

Following the values from table no. 7, we can see that

the maximum content of B12 vitamin was recorded in

2015 by C3 compost with A3 protein additives

(913μg), followed by C3 compost with A2 protein

additives (877μg) harvested mushrooms. On the last

place was mushrooms harvested from the C4 compost

with A1 protein additives (487μg). In 2016 that the

maximum content of B12 vitamin was recorded by C3

compost with A3 protein additives (900μg) and the

minimum value was recorded also by C4 compost with

A1 protein additives (440μg).

As we can see the combined factors, protein additives

and compost, A3 C3 recorded the maximum value

(906.67μg), followed by A2 C3 combination. On the

156

last place is situated the A1 C4 combination

(463.33μg).

Table no. 8, presents the unilateral influence of the

compost on the mushroom C vitamin contents, in mg,

during year 2015 and 2016 of experience

Table 8

The unilateral influence of the compost on the mushroom C vitamin contents

C

O

M

P

O

S

T

Year

2015 2016

C vitamin

Ascorbic acid

C vitamin

Ascorbic acid

Absolute

value

Relative

value

± D

%

Signification of

difference

Absolute

value

Relative

value

± D

%

Signification of

difference

C1 22.56 120.8 3.89 ** 16.89 111.4 1.72 *

C2 15.89 85.1 -2.78 0 13.0 85.7 -2.17 0

C3 21.00 112.5 2.33 * 18.22 120.1 3.06 **

C4 15.22 81.5 -3.44 00 12.56 82.8 -2.61 00

Avg. 18.67 100.0 0,00 Mt. 15.17 100.0 0.00 Mt

DL/LSD 5% 1.88 1.58

DL/LSD 1% 2.84 2.39

DL/LSD 0,1% 4.56 3.83

Following the values from table no. 8, we can see that

mushroom harvested from C1 and C3 composts,

presented significant C vitamin differences from the

average.

Conclusions

Following the results presented of the above, the

mushrooms harvested on C3 compost with A2 protein

additives presents the highest total and soluble dry

matter content. If we want to obtain mushrooms with a

high level of B1 and B2 vitamin, we can use the C1

compost with A3 protein additives.

For obtaining mushrooms with a high level of B9 or

B12 vitamin, we recommended to use the C3 compost

with A3 protein additives. For obtaining mushrooms

with a highest level of C vitamin, we can use C1 or C3

composts.

The A3 protein additive is more efficient in increasing

the vitamin content of harvested mushrooms.

References

1.Chang. S.T., Miles. P.G., 2004. Mushrooms

cultivation, nutritional value, medicinal effect and

environmental impact, 2nd ed. CRC Press LIC.

2.Chen A., 2003, A practical Guide to the Cultivation

of Agaricus blazei, a Mushroom of Culinary and

Biomedical Importance. MushWorld website:

http//www.mushworld.com

3.Dias E.S., 2010, Mushroom cultivation in Brazil,

challenges and potential for growth, Cienc. agrotec.

Lavras 34(4). 795-803.

4.Dias E.S., Abe C., Schwan R.F., 2004, Truths and

myths about the mushroom Agaricus blazei. Sci. Agric.

61. 545-549.

5.Firenzuoli. F., Gori. L., Lombardo. G., 2008, The

medicinal mushroom Agaricus blazei Murrill: Review

of literature and pharmaco-toxicological problems.

Advance Access Publication 27. 3-15.

6.Gyorfi. J., Geosel A., Vetter. J., 2010, Mineral

composition of different strains of edible medicinal

mushroom Agaricus subrufescens Peck. Journal of

Medicinal Food 13 (6), 1510-1514.

7.Horm V., Ohga S., 2008. Potential of compost with

some added supplementary materials on the

development of Agaricus blazei Murill. J. Fac. Agr.

Kyushu Univ, 53(2), 417-422.

8.Iwade I., Mizuno T., 1997, Cultivation of

Kawariharatake (Agaricus blazei Murill). Food Rev.

Int. 13(3). 338-390.

9.Largeteau M.L., Llarena-Hernandez R.C., Regnault-

Roger C., Savoie J.M., 2011, The medicinal Agaricus

mushroom cultivated in Brazil, biology, cultivation and

non-medicinal valorisation. Appl. Microbiol.

Biotechnol. DOI 10.1007/s00253-011-3630-7

10.Levitz. S.M., 2010. Innate recognition of fungal cell

walls. PLOS Pathogens 6 (4). e1000758.

doi:10.1371/journal.ppat.1000758.

11.Mantovani T.R.D., Linde G.A., Colauto N.B., 2007,

Effect of addition of nitrogen sources to cassava fibre

and carbon-to-nitrogen ratios on Agaricus brasiliensis

growth. Can. J. Microbiol, 53, 139-143.

12.Oei P., 2003, Mushroom cultivation 3rd edition,

Appropriate technology for mushroom growers,

Backhuys Publishers, Leiden, The Netherlands, 429 pp.

13.Ohno. N., Furukawa. M., Miura. N.N., Adachi. Y.,

Motoi. M., Yadomae. T., 2001. Antitumor-b-glucan

from the cultured fruiting body of Agaricus blazei.

Biological and Pharmaceutical Bulletin 24 (7), 820-828

14.Pokhrel C.P., Ohga S., 2007, Cattle bedding waste

used as a substrate in the cultivation of Agaricus blazei

Murill, J. Fac. Agr. Kyushu Univ, 52(2), 295-298.

157

15.Rózsa S., D.N. Măniuțiu, Tincuța-Marta Gocan,

Stela David, Felicia-Suzana Butuza-Bumb, 2016,

Influence of pasteurization on different composts used

for Agaricus ssp. mushroom cultivation on changing

the ammonia concentration and the pH level,

Agriculture – Science and Practice Journal. Year XXV.

no 3-4 (99-100)/2016, pp. 34-39

16.Rózsa S., Măniuțiu D.N., Lazăr V., Tincuța-Marta

Gocan, Susana-Felicia Butuza-Bumb, 2016, The

influence of culture technology on production and

chemical content in Agaricus blazei Murrill

mushrooms, Lucrări Ştiinţifice – vol. 59(2)/2016, seria

Agronomie, Iasi, pp. 237-242

17.Siqueira F.G., Dias E.S., Silva R., Martos E.T.,

Rinker D.L., 2009, Cultivation of Agaricus blazei ss.

Heinemann using different soils as source of casing

materials, Sci. Agric. 66(6), 827-830.

18.Siwulski M., Sobieralski K., 2004, Uprawa grzybów

jadalnych i leczniczych w warunkach naturalnych,

Kurpisz, Poznan, 158 pp

19.Stamets P., 2000, Growing Gourmet and Medicinal

Mushrooms, Ten Speed Press, Berkeley, CA, 574 pp.

20.Takaku. T., Kimura. Y., Okuda. H., 2001, Isolation

of an antitumor compound from A. blazei Murrill and

its mechanism of action. American Society for

Nutritional Sciences, 1409-1413

21.Wasser S.P., Didukh M.Y., Amazonas M.A.L.,

Nevo E., Stamets P., Eira A.F., 2002. Is a widely

cultivated culinary-medicinal royal sun Agaricus (the

Himematsutake Mushroom) indeed Agaricus blazei

Murrill. Int. J. Med. Mushr, 4. 267-290.

22.Zied D.C., Minhoni M.T.A., Kopytowski Filho J.,

Andrade M.C.N., 2010, Production of Agaricus blazei

ss. Heinemann (A. brasiliensis) on different casing

layers and its environments, World J. Microbiol.