Structure Borne NVH Basics -...

Transcript of Structure Borne NVH Basics -...

NVH Workshop© www.AutoAnalytics.com, 2003

Structure Borne NVH BasicsSAE 2003 NVH Conference; Traverse City, Michigan

Wednesday Evening, May 7, 2003

Presenters:

A. E. Duncan Automotive Analytics, Inc.

G. Goetchius Material Sciences Corp.

S. Gogate Altair Engineering, Inc.

Sponsored By:Material Sciences Corporation

NVH Workshop© www.AutoAnalytics.com, 2003

NVH Workshop Topic Outline• Introduction• Ride Balance in the Ride Range• NVH Load Conditions• Low Frequency Basics• Live Noise Attenuation Demo• Mid Frequency Basics• Utilization of Simulation Models• Closing Remarks

NVH Workshop© www.AutoAnalytics.com, 2003

The Fundamental Secret ofStructure Borne

NVH Performance

The Fundamental Secret ofStructure Borne

NVH Performance

Revealed here tonight !

NVH Workshop© www.AutoAnalytics.com, 2003

Primary References (Workshop Basis: 4 Papers)

1. A. E. Duncan, et. al., “Understanding NVH Basics”, IBEC, 1996

2. A. E. Duncan, et. al., “MSC/NVH_Manager Helps Chrysler Make Quieter Vibration-free Vehicles”, Chrysler PR Article, March 1998.

3. B. Dong, et. al., “Process to Achieve NVH Goals: Subsystem Targets via ‘Digital Prototype’ Simulations”, SAE 1999-01-1692, NVH Conference Proceedings, May 1999.

4. S. D. Gogate, et. al., “’Digital Prototype’ Simulations to Achieve Vehicle Level NVH Targets in the Presence of Uncertainties’”,

SAE 2001-01-1529, NVH Conference Proceedings, May 2001

Structure Borne NVH Basics References

Available online at www.AutoAnalytics.com

Structure Borne NVH Workshop - on Internet

NVH Workshop© www.AutoAnalytics.com, 2003

Supplemental References5. T.D. Gillespie, Fundamentals of Vehicle Dynamics, SAE 1992

(Also see SAE Video Lectures Series, same topic and author)6. D. E. Cole, Elementary Vehicle Dynamics, Dept. of Mechanical

Engineering, University of Michigan, Ann Arbor, Michigan, Sept. 1972

7. J. Y. Wong, Theory of Ground Vehicles, John Wiley & Sons, New York, 1978

8. Kompella, M. S., and Bernhard, J., “Measurement of the Statistical Variation of Structural-Acoustic Characteristics of Automotive Vehicles”, SAE No. 931272, 1993

9. Freymann, R., and Stryczek, R., “A New Optimization Approach in the Field of Structural-Acoustics”, SAE No. 2000-01-0729, 2000

Structure Borne NVH Basics References

NVH Workshop© www.AutoAnalytics.com, 2003

NVH Workshop Topic Outline• Introduction

• Ride Balance in the Ride Range

• NVH Load Conditions

• Low Frequency Basics

NVH Workshop© www.AutoAnalytics.com, 2003

Rideand

Handling

NVH Durability

ImpactCrashWorthiness

Competing Vehicle Design Disciplines

NVH Workshop© www.AutoAnalytics.com, 2003

Structure Borne NoiseAirborne Noise

Res

pons

e

Log Frequency

“Low”Global Stiffness

“Mid”

Local Stiffness+

Damping

“High”

Absorption+

Mass+

Sealing

~ 150 Hz ~ 1000 Hz ~ 10,000 Hz

Automotive NVH Frequency Range

NVH Workshop© www.AutoAnalytics.com, 2003

NVH Workshop Topic Outline• Introduction

• Ride Balance in the Ride Range

• NVH Load Conditions

• Low Frequency Basics

NVH Workshop© www.AutoAnalytics.com, 2003

Study of Ride Balance

• Demonstrate the First Order Vehicle Modes

• Demonstrate Transient Response in Time Domain

• Derive Transition into the Frequency Domain

NVH Workshop© www.AutoAnalytics.com, 2003

Ride Balance StudyVehicle Traversing a Bump

Impact at Front Suspension Followed by Impact at Rear Suspension

Response at Rear

Rear Suspension is in-phase with FrontAfter one cycle of ride motion, thusminimizing pitch motion.

Response at Front

See Ref. 5, Gillespie

NVH Workshop© www.AutoAnalytics.com, 2003

Total 2178.2 Kg (4800LBS)Mass Sprung 1996.7 Kg

Unsprung 181.5 Kg (8.33% of Total)Powertrain 181.5 Kg

Tires 350.3 N/mmKF 43.8 N/mmKR 63.1 N /mmBeam mass lumped on grids like a beam M2,3,4 =2 * M1,5

31

8

2

6

4

7

5

NVH Model of Unibody Passenger CarSymbolic Outline

From Reference 6

NVH Workshop© www.AutoAnalytics.com, 2003

Excitation Bump Profile

0.0

5.0

10.0

15.0

20.0

0 100 200 300 400 500

Distance (mm)

Pro

file

Hei

ght

(mm

) Profile

On to 100,380

NVH Workshop© www.AutoAnalytics.com, 2003

Pitch at Mid-Car DOF3

-1.0E-04

-8.0E-05

-6.0E-05

-4.0E-05

-2.0E-05

0.0E+00

2.0E-05

4.0E-05

6.0E-05

8.0E-05

1.0E-04

0 1 2 3Time (sec.)

Ro

tati

on

- R

adia

ns Base Model

NVH Workshop© www.AutoAnalytics.com, 2003

Pitch Response - Baseline Model

1.E-08

1.E-07

1.E-06

1.E-05

1.E-04

0.0 5.0 10.0 15.0 20.0Frequency Hz

Ro

tati

on

Rad

ian

s

Base Model

NVH Workshop© www.AutoAnalytics.com, 2003

X ( f ) = Fourier Transform of X ( t ){X ( f ) } = [ H ( f ) ] ∗∗∗∗ { F ( f ) }{

Fourier transformof the input forces,vector of all inputpossibilities

Fourier transformof the outputfor unit input forcessystem OUT / IN FRF(Known Load = Unity)

Spring Analogy ( C = 1 / K ) X = C * F

{

CaveatCaveat X ( t ) must be PeriodicLinear System

5 sec

F(t) is Periodic

NVH Workshop© www.AutoAnalytics.com, 2003

FFT of the Input Bump

1.E-06

1.E-05

1.E-04

1.E-03

1.E-02

1.E-01

0.E+00 4.E-03 8.E-03 1.E-02 2.E-02 2.E-02

Cycles / mm

Ampl

itude

mm

Bump FFT

Transform Input Force to F(f)

20 Hz @ 45 MPH

NVH Workshop© www.AutoAnalytics.com, 2003

FFT of the Input Bump

1.E-06

1.E-05

1.E-04

1.E-03

1.E-02

1.E-01

0.E+00 4.E-03 8.E-03 1.E-02 2.E-02 2.E-02

Cycles / mm

Ampl

itude

mm

Bump FFT

Transform Input Force to F(f)

20 Hz @ 45 MPH

0.0 20.0 Hz

Amplitude is Approximately Constant over the Frequency Range

Constant Displacement

NVH Workshop© www.AutoAnalytics.com, 2003

Pitch at M id -C ar D O F 3

1 .0 E-0 8

1 .0 E-0 7

1 .0 E-0 6

1 .0 E-0 5

1 .0 E-0 4

0 5 1 0 1 5 2 0F req u en cy H z

Ro

tati

on

Rad

ian

s Tim e Dom ain FF T

F F T of Input

NVH Workshop© www.AutoAnalytics.com, 2003

Ride Balance Study Summary

• Demonstrated the Fundamental Bounce and Pitch Modes in the Ride Range

• Demonstrated Transient Response in Time Domain then Obtained the FRF

• Derived Direct Computation of FRF in the Frequency Domain

NVH Workshop© www.AutoAnalytics.com, 2003

NVH Workshop Topic Outline• Introduction

• Ride Balance in the Ride Range

• NVH Load Conditions

• Low Frequency Basics

NVH Workshop© www.AutoAnalytics.com, 2003

Two Main Sources

Noise and Vibration Sources

Suspension Powertrain

NVH Workshop© www.AutoAnalytics.com, 2003

Typical NVH Pathways to the Passenger

PATHS FOR

STRUCTURE BORNE

NVH

NVH Workshop© www.AutoAnalytics.com, 2003

Suspension Excitation Load Conditions

WheelUnbalance

RoadRoughness

NVH Workshop© www.AutoAnalytics.com, 2003

Medium Rough Road Spectrums from Wong, Ref. 7

1.0E+01

1.0E+02

1.0E+03

1.0E+04

1.0E+05

1.0E+06

0 20 40 60 80 100

Displacement*

Acceleration*Velocity

Constant Velocity

Road Spectrum at Constant Speed of 45 MPH

Frequency Hz

Velo

city

mm

2 /sec

2 /hz

P ow

er S

p ect

ral D

e ns i

ty (P

SD)

*Spectrums were scaled to plot with Velocity

CONCLUSION: With respect to the Ride Balance example at constant disp.,a typical road spectrum disp. decreases and thus exhibits even more response attenuation beyond the ride modes.

NVH Workshop© www.AutoAnalytics.com, 2003

NVH Workshop Topic Outline• Introduction

• Ride Balance in the Ride Range

• NVH Load Conditions

• Low Frequency Basics

NVH Workshop© www.AutoAnalytics.com, 2003

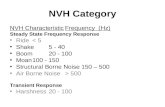

Low Frequency NVH Basics

• Subjective to Objective Relationships

• Single Degree of Freedom Vibration

• Vibration and Noise Attenuation Strategies

NVH Workshop© www.AutoAnalytics.com, 2003

Subjective to Objective Conversions

Subjective NVH Ratings are typically based on a 10 Point Scale resulting from Ride Testing

A 2 ≈≈≈≈ 1/2 A 1Represents 1.0 Rating Change

TACTILE: 50% reduction in motion

SOUND : 6.dB reduction in sound pressure level ( long standing rule of thumb )

Receiver Sensitivity is a Key Consideration

NVH Workshop© www.AutoAnalytics.com, 2003

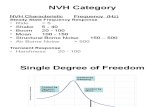

m

APPLIED FORCE

F = FO sin 2 π f t

k c FT

TR = FT / F

TransmittedForce

Single Degree of Freedom Vibration

=√ f 2fn

2) 2

ffn

( 2 d ) 21 +1 + ffn

( 2 d ) 21 +

( 1- ffn

( 2 d ) 2+

d = fraction of critical damping

fn = natural frequency √(k/m)

f = operating frequency

NVH Workshop© www.AutoAnalytics.com, 2003

0 1 2 3 4 50

1

2

3

4Tr

ansm

issi

bilit

y R

atio

1.414

0.5

0.1

0.15

0.375

1.0

0.25

Frequency Ratio (f / fn)

Vibration Isolation Principle

m

APPLIED FORCEF = FO sin 2 π f t

k c FT

TR = FT / F

TransmittedForce

Isolation RegionIsolation Region

NVH Workshop© www.AutoAnalytics.com, 2003

Excitation Force Comingfrom Engine F0

FT

Transmissibility Force Ratio is FT/F0

Isolation from an Applied Force

Support Forces Transmitted to Body

Example:A 4 Cyl. Excitation for Firing

Pulse at 700 RPM has a second order gas pressure torque at 23.3 Hz. Thus, to obtain isolation, the engine roll mode must be below 16.6 Hz.

NVH Workshop© www.AutoAnalytics.com, 2003

Body on Suspension Single DOF ModelIsolation from Base Excitation

Xin

Xout

Transmissibility Ratio is Xout / Xin

Example: Vertical Ride Mode at 1.3 Hz provides isolation starting at 1.8 Hz. This provides isolation for the first order Hop and Tramp modes.

NVH Workshop© www.AutoAnalytics.com, 2003

Simplified Models from 1 to 8 DOF’s

1 DOF 2 DOF

fYO

x

YO

x

4 DOF 8 DOF

YO

x

Enforced Base Motion

YO

x

XYO

Isolation Region

NVH Workshop© www.AutoAnalytics.com, 2003

8 Degree of Freedom Vehicle NVH Model

1 2 4 5

6 7

8

3

TiresWheels

SuspensionSprings

Engine Mass

EngineIsolator

Flexible Beam for Body

NVH Workshop© www.AutoAnalytics.com, 2003

Vibration and Noise Attenuation Methods

Main Attenuation Strategies• Reduce the Input Forces from the Source

• Provide Isolation

• Mode Management

• Nodal Point Mounting

• Dynamic Absorbers

NVH Workshop© www.AutoAnalytics.com, 2003

Vibration and Noise Attenuation Methods

Main Attenuation Strategies• Reduce the Input Forces from the Source

• Provide Isolation

• Mode Management

• Nodal Point Mounting

• Dynamic Absorbers

NVH Workshop© www.AutoAnalytics.com, 2003

Reduction of Input Forces from the Source

Road Load Excitation• Use Bigger / Softer Tires• Reduce Tire Force Variation• Drive on Smoother Roads

Powertrain Excitation• Reduce Driveshaft Unbalance Tolerance• Use a Smaller Output Engine• Move Idle Speed to Avoid Excitation Alignment• Modify Reciprocating Imbalance to alter Amplitude or

Plane of Action of the Force.

NVH Workshop© www.AutoAnalytics.com, 2003

Vibration and Noise Attenuation Methods

Main Attenuation Strategies• Reduce the Input Forces from the Source

• Provide Improved Isolation

• Mode Management

• Nodal Point Mounting

• Dynamic Absorbers

NVH Workshop© www.AutoAnalytics.com, 2003

8 Degree of Freedom Vehicle NVH ModelForce Applied to Powertrain Assembly

Forces at Powertrain could represent a First OrderRotating Imbalance

1 2 4 5

6 7

8

3

Feng

NVH Workshop© www.AutoAnalytics.com, 2003

Engine Isolation Example

Response at Mid Car

0.0001

0.0010

0.0100

0.1000

1.0000

5.0 10.0 15.0 20.0Frequency Hz

Velo

city

(mm

/sec

)

Constant Force Load; F ~ A 15.9 Hz8.5 Hz7.0 Hz

700 Min. RPM First Order UnbalanceOperation Range of Interest

NVH Workshop© www.AutoAnalytics.com, 2003

Concepts for Increased Isolation“Double” isolation is the typical strategy for further improving isolation of a given vehicle design.

Subframe is Intermediate Structure

Suspension Bushing is first level

Second Level of Isolation is at Subframe

to Body Mount

NVH Workshop© www.AutoAnalytics.com, 2003

8 Degree of Freedom Vehicle NVH ModelRemoved Double Isolation Effect

1 2 4 5

6 7

8

3

WheelMass

Removed

NVH Workshop© www.AutoAnalytics.com, 2003

Double Isolation ExampleVertical Response at DOF3

0.0E+00

1.0E+00

2.0E+00

3.0E+00

4.0E+00

5.0E+00

6.0E+00

5.0 10.0 15.0 20.0Frequency Hz

Velo

city

(m

m/s

ec)

Base Model

Without Double_ISO

1.414*fn

NVH Workshop© www.AutoAnalytics.com, 2003

Vibration and Noise Attenuation Methods

Main Attenuation Strategies• Reduce the Input Forces from the Source

• Provide Isolation

• Mode Management

• Nodal Point Mounting

• Dynamic Absorbers

NVH Workshop© www.AutoAnalytics.com, 2003

Mode Management Chart

0 5 10 15 20 25 30 35 40 45 50HzFirst Order Wheel/Tire Unbalance V8 Idle

Hot - Cold

EXCITATION SOURCESInherent Excitations (General Road Spectrum, Reciprocating Unbalance, Gas Torque, etc.)Process Variation Excitations (Engine, Driveline, Accessory, Wheel/Tire Unbalances)

Hz

Hz0 5 10 15 20 25 30 35 40 45 50

0 5 10 15 20 25 30 35 40 45 50

CHASSIS/POWERTRAIN MODES

Ride ModesPowertrain Modes

Suspension Hop and Tramp ModesSuspension Longitudinal Modes

Exhaust Modes

BODY/ACOUSTIC MODES

Body First Bending First Acoustic Mode

Steering Column First Vertical BendingBody First Torsion

(See Ref. 1)

NVH Workshop© www.AutoAnalytics.com, 2003

8 Degree of Freedom Vehicle NVH ModelBending Mode Frequency Separation

1 2 4 5

6 7

8

3

Beam Stiffness was adjusted to align Bending

Frequency with Suspension Modes and then

progressively separated back to Baseline.

NVH Workshop© www.AutoAnalytics.com, 2003

Response at Mid Car

0.10

1.00

10.00

100.00

5 10 15 20Frequency Hz

Velo

city

(mm

/sec

)

18.2 Hz Bending13.Hz Bending10.6 Bending

8 DOF Mode Separation Example

18.2 Hz13.0 Hz

10.6 Hz

NVH Workshop© www.AutoAnalytics.com, 2003

Vibration and Noise Attenuation Methods

Main Attenuation Strategies• Reduce the Input Forces from the Source

• Provide Isolation

• Mode Management

• Nodal Point Mounting

• Dynamic Absorbers

NVH Workshop© www.AutoAnalytics.com, 2003

Front input forces Rear input forces

First Bending: Nodal Point Mounting ExampleMount at Nodal Point

Locate wheel centers at node points of the first bending modeshapeto prevent excitation coming from suspension input motion.

NVH Workshop© www.AutoAnalytics.com, 2003

Passenger sits at node point for First Torsion.

Side View

First Torsion: Nodal Point Mounting ExamplesMount at Nodal Point

Transmission Mount of a3 Mount N-S P/T is nearthe Torsion Node.

Rear View

Engine

NVH Workshop© www.AutoAnalytics.com, 2003

Powertrain Bending Mode Nodal Mounting

1 2 4 5

6 7

3

Mount system is placed to support Powertrain at the Nodal Locations of the First order Bending Mode. Best compromise with Plan View nodes should also be considered.

NVH Workshop© www.AutoAnalytics.com, 2003

8 Degree of Freedom Vehicle NVH ModelBending Node Alignment with Wheel Centers

1 2 4 5

6 7

8

3

Redistribute Beam Masses to move Node Points to

Align with points 2 and 4

NVH Workshop© www.AutoAnalytics.com, 2003

Response at Mid-Car

0.0E+00

1.0E+00

2.0E+00

3.0E+00

4.0E+00

5.0 10.0 15.0 20.0Frequency Hz

Velo

city

(m

m/s

ec)

Node ShiftedBase Model

First Bending Nodal Point Alignment

NVH Workshop© www.AutoAnalytics.com, 2003

T

= 1 / T= 1 / T

< is more important than >< is more important than >

NVH Workshop© www.AutoAnalytics.com, 2003

Vibration and Noise Attenuation Methods

Main Attenuation Strategies• Reduce the Input Forces from the Source

• Provide Isolation

• Mode Management

• Nodal Point Mounting

• Dynamic Absorbers

NVH Workshop© www.AutoAnalytics.com, 2003

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

0.0 0.5 1.0 1.5 2.0Frequency Hz

Dis

plac

emen

t m

m

YO

xSDOF

Dynamic Absorber Concept

MYO

x

Auxiliary Spring-Mass-Damperm = M / 10

2DOFM

NVH Workshop© www.AutoAnalytics.com, 2003

Powertrain Example of Dynamic Absorber

Anti-Node Identifiedat end of Powerplant

k c

Absorber attached at anti-node acting in the Vertical and Lateral plane.

Tuning Frequency = √√√√ k/m

m

[Figure Courtesy of DaimlerChrysler Corporation]

NVH Workshop© www.AutoAnalytics.com, 2003

Baseline Sound Level63 Hz Dynamic Absorber63 + 110 Hz Absorbers

Baseline Sound Level63 Hz Dynamic Absorber63 + 110 Hz Absorbers

[Figure Courtesy of DaimlerChrysler Corporation]

NVH Workshop© www.AutoAnalytics.com, 2003

Vibration and Noise Attenuation Methods

Main Attenuation Strategies• Reduce the Input Forces from the Source

• Provide Isolation

• Mode Management

• Nodal Point Mounting

• Dynamic Absorbers

NVH Workshop© www.AutoAnalytics.com, 2003

NVH Workshop Topic Outline• Introduction• Ride Balance in the Ride Range• NVH Load Conditions• Low Frequency Basics• Live Noise Attenuation Demo• Mid Frequency Basics• Utilization of Simulation Models• Closing Remarks

Greg Goetchius

NVH Workshop© www.AutoAnalytics.com, 2003

NVH Workshop Topic Outline• Introduction• Ride Balance in the Ride Range• NVH Load Conditions• Low Frequency Basics• Live Noise Attenuation Demo• Mid Frequency Basics• Utilization of Simulation Models• Closing Remarks

Sachin Gogate

NVH Workshop© www.AutoAnalytics.com, 2003

RECEIVER

PATH

SOURCE

Mid Frequency NVH Fundamentals

This looks familiar!Frequency Range of Interest has changed to

150 Hz to 500 Hz

NVH Workshop© www.AutoAnalytics.com, 2003

Typical NVH Pathways to the Passenger

PATHS FOR

STRUCTURE BORNE

NVH

Noise Paths are thesame as Low

Frequency Region

Noise Paths are thesame as Low

Frequency Region

NVH Workshop© www.AutoAnalytics.com, 2003

Mid-Frequency Analysis CharacterStructure Borne Noise

Airborne Noise

Res

pons

e

Log Frequency“Low”

Global Stiffness“Mid”

Local Stiffness+

Damping

“High”

Absorption+

Mass+

Sealing

~ 150 Hz ~ 1000 Hz ~ 10,000 Hz

High modal densityand coupling insource, path andreceiver

• Mode separation is less practical inmid-frequency

• Effective isolation of energy betweensource and receiver at key noise pathsis the basis of mid-frequency analysis

•• Mode separation is less practical inMode separation is less practical inmidmid--frequencyfrequency

•• Effective isolation of energy betweenEffective isolation of energy betweensource and receiver at key noise pathssource and receiver at key noise pathsis the basis of midis the basis of mid--frequency analysisfrequency analysis

NVH Workshop© www.AutoAnalytics.com, 2003

Mid-Frequency Analysis Character

• Important characteristics of mid frequency analysis

&

Identifying Key Noise Paths

Effective Isolation

NVH Workshop© www.AutoAnalytics.com, 2003

Mid-Frequency Analysis Character

&

• Important characteristics of mid frequency analysis

Identifying Key Noise Paths

Effective IsolationEffective Isolation

NVH Workshop© www.AutoAnalytics.com, 2003

Classical SDOF Rigid Source and Receiver

T ran

smis

sib i

lity

Rat

io

1.0 1.414 10.0

f / f n

“Real Structure”Flexible (Mobile)Source and Receiver

Isolation Effectiveness

Effectiveness deviates from the classical development as resonances occur in the receiver structure and in the foundation of the source.

Isolation RegionIsolation Region

1.0

NVH Workshop© www.AutoAnalytics.com, 2003

Mobility• Mobility is the ratio of velocity response at the excitation point on structure

where point force is applied

Mobility =Velocity

Force

• Mobility, also referred as Admittance, characterizes Dynamic Stiffness of the structure at load application point

Mobility =Frequency * Displacement

Force

=Frequency

Dynamic Stiffness

NVH Workshop

• The isolation effectiveness can be quantified by a theoretical model based on analysis of mobilities of receiver, isolator and source

• Transmissibility ratio is used to objectively define measure of isolation

TR =Force from source without isolator

Force from source with isolator

Isolation

V r

V ir

V is

F r

F ir

Receiver

Source

F is

Fs V s

Isolator

VF s=

Y i + Y r + Y s

V r

F r

Receiver

Source

F s V s

VF s=

Y r + Y s

VV

2003, 2005 ERRATA

NVH Workshop

• The isolation effectiveness can be quantified by a theoretical model based on analysis of mobilities of receiver, isolator and source

• Transmissibility ratio is used to objectively define measure of isolation

TR =Force from source without isolator

Force from source with isolator

Isolation

V r

V ir

V is

F r

F ir

Receiver

Source

F is

Fs V s

Isolator

VF s=

Y i + Y r + Y s

V r

F r

Receiver

Source

F s V s

VF s=

Y r + Y s

VV

NVH Workshop

Isolation

TR = ⏐ ( Y r + Y s ) / ( Y i + Y r + Y s ) ⏐

• For Effective Isolation (Low TR) the Isolator Mobility must exceed the sum of the Source and Receiver Mobilities.

Y r : Receiver mobility

Y s : Source mobility

Y i : Isolator mobility

V m

V im

V if

F m

F im

Receiver

Source

F if

F f V f

Isolator

TR = Force from source without an isolator Force from source with an isolator

NVH Workshop© www.AutoAnalytics.com, 2003

Mid-Frequency Analysis Character

Effective Isolation

&

• Important characteristics of mid frequency analysis

Identifying Key Noise PathsIdentifying Key Noise Paths

NVH Workshop© www.AutoAnalytics.com, 2003

Identifying Key Noise Paths• Key noise paths identified by Transfer Path Analysis (TPA)

Fi

TactileTransferTactile

TransferAcousticTransfer

AcousticTransfer

Operating loads Operating loads

• TPA is a technique to perform phased summation of partial responses through all noise paths to give total tactile or acoustic response under operating loads at a given frequency

• TPA is applicable in both testing and simulation scenarios to identify key noise paths

NVH Workshop© www.AutoAnalytics.com, 2003

Transfer Path Analysis

Fi

Operating loads Operating loads

• Total operating Response (Tactile/Acoustic) is summation of partial responses through all noise paths

Rt = ΣΣΣΣ paths [Ri ] = ΣΣΣΣ paths [ Fi * (R/F) i ]

Acoustic Transfer (P/F)iAcoustic Transfer (P/F)iTactile Transfer (T/F)i

Tactile Transfer (T/F)i

Ri : Partial contribution of path i due to operating force

Operating loads createForces (Fi) into body atAll noise paths

(R/F) i : Tactile or Acoustic Transfer Function

NVH Workshop© www.AutoAnalytics.com, 2003

Transfer Path Analysis

( contributors + )

( reducers - )

…

FrontUpperControlArm

FrontShockAbsorber Rear

ShockAbsorber

RearUpperArm

TotalNoise

(((( AllPaths))))

FrontStabilizer

FrontSpring

• TPA allows path rankings based on contribution to total response of noise paths at a given frequency

• TPA thus helps identify key noise paths

• TPA is mainly used for acoustic response in mid frequency range

NVH Workshop© www.AutoAnalytics.com, 2003

Designing for Mid Frequency

• Important characteristics of mid frequency analysis

Effective Isolation

&

Identifying Key Noise Paths

NVH Workshop© www.AutoAnalytics.com, 2003

Designing for Mid Frequency

While designing a new vehicle, generic targets are set for key parameters along all noise paths in order to achieve effective isolation.

What are these generic targets andkey parameters ?

What are these generic targets andkey parameters ?

NVH Workshop© www.AutoAnalytics.com, 2003

Generic Noise Path Targets

Operating loads Operating loads

Acoustic Transfer (P/F)iAcoustic Transfer (P/F)i

∆∆∆∆ XKBsng

V/F

P/VP/F

F

Ksource

(Kbody)

Transmissibility along a given noise path (TRi)TR = ( Y r + Y s ) //// ( Y i + Y r + Y s )

TR = ( ) //// ( ) K body

1K source

1+ K body

1 + K iso.

1K source

1+

NVH Workshop© www.AutoAnalytics.com, 2003

Generic Noise Path TargetsTR = ( ) //// ( ) K body

1K source

1+ K body

1 + K iso.

1K source

1+

K iso

K source.

K iso

K body.1.0 5.0 Infinite

1.0

5.0

Infinite

0.67 0.54 0.50

0.54 0.28 0.17

0.50 0.17 0.00

As a generic target, body to bushing stiffness ratio ofat least 5.0 and very high source to bushing stiffnessratio (~ infinite) is desired to achieve “good” TR of 0.17

NVH Workshop© www.AutoAnalytics.com, 2003

0

0.1

0.2

0.3

0.4

0.5

1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9 9.5 10

Series2

0.0

0.1

0.2

0.3

0.4

0.5

1 2 3 4 5 6 7 8 9 10

Stiffness Ratio; K body / K bsg

Tran

smis

sibi

lity

Rat

io

TR = ( K bsg ) //// ( K bsg + K body ) For infinitely stiff (immobile) source

Target Min. = 5

Relationship of Body-to-Bushing Stiffness ratio to Transmissibility

NVH Workshop© www.AutoAnalytics.com, 2003

Generic Noise Path Targets

Fi

Operating loads Operating loads

Acoustic Transfer (P/F)iAcoustic Transfer (P/F)iTactile Transfer (T/F)i

Tactile Transfer (T/F)i

Operating loads createForces (Fi) into body atAll noise paths

Rt = ΣΣΣΣ paths [Ri ] = ΣΣΣΣ paths [ Fi * (R/F) i ] = ΣΣΣΣ paths [ Fi * (R/V) i * (V/F)i]

Response Rt could be either Tactile or Acoustic Response

NVH Workshop© www.AutoAnalytics.com, 2003

Generic Noise Path Targets

• For a given force generated at suspension attachment to body, lowering sensitivities (P/F) or (V/F) along a pathwould reduce total response

• As a generic target,

- Acoustic sensitivity (P/F) in 55-60 dBL/N range- Structural Mobility (V/F) less than 0.312 mm/sec/N

For example, for Acoustic Response Pt

Pt = ΣΣΣΣ paths [Pi ] = ΣΣΣΣ paths [ Fi * (P/F) i ] = ΣΣΣΣ paths [ Fi * (P/V) i * (V/F)i]

NVH Workshop© www.AutoAnalytics.com, 2003

Generic Noise Path TargetsHow does one achieve these generic targets :

K iso

K body >= 5.0K iso

K source ~ infinite

AcousticMobility <<55

dBL/N60

dBL/N

StructuralMobility < 0.312 mm/sec/N

NVH Workshop© www.AutoAnalytics.com, 2003

Generic Noise Path TargetsHow does one achieve

• Increase local body attachment stiffness (Kbody) through structural modifications

K iso

K body >= 5.0

• Reduce attachment isolator stiffness (Kiso) while balancing the conflicting requirement of other functionalities such as Ride & Handling

StructuralMobility < 0.312

NVH Workshop© www.AutoAnalytics.com, 2003

Generic Noise Path Targets

How does one achieve

• Increase source side attachment stiffness (Ksource)

• Reduce attachment isolator stiffness (Kiso)

K iso

K source ~ infinite

In automotive structures, it is realistic to expect that source to isolator stiffness ratio is almost infinite since source usually corresponds to stiff structure (such as powertrain or axle)

NVH Workshop© www.AutoAnalytics.com, 2003

Source Excitation Characteristics

Other means of reducing source input to paths

- Add lumped mass on component

- Use tuned absorber

- Bring nodal points toward path

Applicable when Rigid BodyResonance of Source SideComponent are present

Applicable when flexible modesof source side componentare present

NVH Workshop© www.AutoAnalytics.com, 2003

Generic Noise Path Targets

How does one achieve AcousticMobility <<55 60

• At a given frequency, Acoustic Mobility (P/F) is

P/F = (P/V) X FrequencyBody stiffness

• Based on the above equation, increasing body stiffness usually reduces acoustic mobility

NVH Workshop© www.AutoAnalytics.com, 2003

Generic Noise Path Targets

How does one achieve AcousticMobility <<55 60

• In such cases, means of reducing acoustic mobility are to reduce overall body panel velocity through application of damping and acoustic treatment

• There are situations when increasing body stiffness does not reduce acoustic mobility

NVH Workshop© www.AutoAnalytics.com, 2003

Application of Damping TreatmentEffect on sound response of damping treatment applied on key identified contributing panels

[Figure Courtesy of DaimlerChrysler Corporation]

12.5dBA Reduction

Floor with no damping treatment

Floor with damping treatment

Frequency (Hz)

5.0 dBA

SPL

(dB

A)

NVH Workshop© www.AutoAnalytics.com, 2003

Designing for Mid Frequency

While designing a new vehicle, generic targets are set for key parameters along all noise paths in order to achieve effective isolation.

is it really necessary to achieve generic targets forall noise paths ?

is it really necessary to achieve generic targets forall noise paths ?

Probably Not !!Probably Not !!

NVH Workshop© www.AutoAnalytics.com, 2003

Designing for Mid FrequencyDriver’s Ear Noise

Vehicle Level Response

Original Noise Path Contributions

Transfer Path Analysis

Some noise paths are more dominant than others

Impose more strict requirements for these dominant paths and relax requirements for other paths to achieve more “rebalanced”noise

Original Noise Path Contributions

Driver’s Ear Noise

Vehicle Response to Meet NVH Targets

Original NoiseReduced Noise

NVH Workshop© www.AutoAnalytics.com, 2003

Designing for Mid Frequency

Principles to follow

• At the beginning of program, work towards generic targets for key parameters for all noise paths in order to achieve effective isolation.

• As the design is firmed out, evaluate key noise paths using Transfer Path Analysis in order to meet target for all NVH operating load conditions.

• Perform path “rebalancing” to arrive at revised path targets (more strict for dominant paths) for all NVH operating load conditions.

NVH Workshop© www.AutoAnalytics.com, 2003

Yesor

Time Out

No

Re-DesignSub-System

Evaluate Sub-SystemPerformance

Evaluate Sub-SystemPerformance

No

Meet VehicleGoals?

RebalanceTrade-OffRebalanceTrade-Off

Meet Sub-System

Goals? Evaluate Vehicle GoalsEvaluate Vehicle Goals

Mid Frequency NVH Goal Achievement Process

Initial Sub-System Targets

Yesor

Time Out

NVH Workshop© www.AutoAnalytics.com, 2003

Mid Frequency NVH Improvement (Sports Utility Vehicle Example)

Full Vehicle ModelFull Vehicle Model

[Figure Courtesy of DaimlerChrysler Corporation]

NVH Workshop© www.AutoAnalytics.com, 2003

Mid Frequency NVH Improvement(Sports Utility Vehicle Example)

Powertrain/Axle/Suspension ModelPowertrain/Axle/Suspension Model[Figure Courtesy of DaimlerChrysler Corporation]

NVH Workshop© www.AutoAnalytics.com, 2003

Mid Frequency NVH Improvement(Sports Utility Vehicle Example)

Acoustic Cavity ModelAcoustic Cavity Model[Figure Courtesy of DaimlerChrysler Corporation]

NVH Workshop© www.AutoAnalytics.com, 2003

Mid-Frequency NVH improvementAxle Whine Example : 300-500 Hz

θθθθθθθθ

θθθθθθθθ

Trimmed Body

Interior Acoustic Cavity

Chassis

Front and Rear Axle Gear-Pinion Mesh Transmission Error

SOURCE ------------- PATH ---------------- RECEIVER[Figure Courtesy of DaimlerChrysler Corporation]

NVH Workshop© www.AutoAnalytics.com, 2003

Axle Whine Example• Design work was focused in the beginning towards achieving generic targets for all noise paths

• As the design was firmed out, full vehicle analysis revealed under target performance for Driver’s ear SPL response which was dominated by rear excitation

[Figure Courtesy of DaimlerChrysler Corporation]

400 Hz 500 Hz300 Hz

10dBA

FR + RR Excitation

FR Excitation Only

RR Excitation Only(Dominates Total Content)

Target Level

Sound Response with Varying Excitation

Frequency (Hz)

SPL(

dBA

)

NVH Workshop© www.AutoAnalytics.com, 2003

Axle Whine Example• Before embarking on identifying the root cause for under-target performance at dominant noise paths, it is a good practice to perform reasonableness check on the response• Steps for Reasonableness Determination

! Judging the response based on system knowledge• Total response content is dominated by rear excitation. This is

reasonable since vehicle has IFS and solid axle rear suspension which is harder to isolate for noise

! Forced mode Animation • Operating deformed shape motion is rear axle pitching about ring

gear axis. This was expected since input excitation is MTE imposed as enforced angular rotation between ring and pinion gear

!Disconnect Studies• Disconnecting rear suspension noise paths (shock in particular) in

pair had the most significant effect on Driver’s SPL response

NVH Workshop© www.AutoAnalytics.com, 2003

Axle Whine Example• Transfer Path Analysis

• Dominant Paths• Rear left shock vertical• Rear LCA vertical : Left is positive whereas right is negative contributor • Rear Right shock vertical

• The conclusion matches with reasonableness checks[Figure Courtesy of DaimlerChrysler Corporation]

NVH Workshop© www.AutoAnalytics.com, 2003

Rt = ΣΣΣΣ paths [Ri ] = ΣΣΣΣ paths [ Fi * (R/F) i ]

• Is it high forces or high acoustic sensitivity at shock to body attachment ?

Acoustic sensitivity is better than generic targetAcoustic sensitivity is better than generic target

Axle Whine Example

• The issue is with high forces into the body through shock attachment due to stiff shock bushings• Stiff shock bushings gave low body-to-bushing stiffness ratio

[Figure Courtesy of DaimlerChrysler Corporation]

5dBL/N

Aco

ustic

Sen

sitiv

ity (d

BL/

N)

NVH Workshop© www.AutoAnalytics.com, 2003

Axle Whine ExampleSolution• Soften shock vertical bushings by 65%

• To balance this against handlingrequirement of stiff bushing, local attachment stiffness between shock and body was improved through a new bracket design

• This addition of bracket improved right shock mobility 3 times

whereas left shock mobility by 1.5 times thereby improving isolation effectiveness of shock bushing

[Figure Courtesy of DaimlerChrysler Corporation]

NVH Workshop© www.AutoAnalytics.com, 2003

Axle Whine ExampleResponse Improvement due to proposed solution

[Figure Courtesy of DaimlerChrysler Corporation]

NVH Workshop© www.AutoAnalytics.com, 2003

Axle Whine ExampleHow Robust is the proposed solution ?• Parameter variations such as weld deletion in “new bracket” and gage changes were considered to study robustness of solution

10 dBA

Deterministic Responseof Model with proposal

Scatter of modelWith proposals

Baseline ModelScatter

Vehicle Speed (mph)49.5 50.7 51.9 53.2 54.4

Driv

er’s

Ear

SPL

(dB

A)

48.2

Deterministic Responseof Baseline Model

- Response scatter of modelwith proposal does notoverlap baseline model response scatter indicatinga robust solution

- The problem peak has nowshifted to a new vehiclespeed of 50.7 mph whichrequires a new contributionanalysis

[Figure Courtesy of DaimlerChrysler Corporation]

NVH Workshop© www.AutoAnalytics.com, 2003

Final Remarks on Mid Frequency Analysis• Effective isolation at dominant noise paths is critical• Effective isolation at dominant noise paths is critical

• Reduced mobilities at body & source and softenedbushing are key for effective isolation

• Reduced mobilities at body & source and softenedbushing are key for effective isolation

• It is important to balance NVH requirement againstother functionalities (Ride and Handling, Impact)

• It is important to balance NVH requirement againstother functionalities (Ride and Handling, Impact)

• It is important to understand the robustness ofdesign recommendations

• It is important to understand the robustness ofdesign recommendations

• Other means of dealing high levels of source input(Tuned dampers, damping treatments, isolatorplacement at nodal locations) are also effective

• Other means of dealing high levels of source input(Tuned dampers, damping treatments, isolatorplacement at nodal locations) are also effective

NVH Workshop© www.AutoAnalytics.com, 2003

NVH Workshop Topic Outline• Introduction• Ride Balance in the Ride Range• NVH Load Conditions• Low Frequency Basics• Live Noise Attenuation Demo• Mid Frequency Basics• Utilization of Simulation Models• Closing Remarks Alan Duncan

NVH Workshop© www.AutoAnalytics.com, 2003

NVH Workshop Topic Outline• Introduction

• Ride Balance in the Ride Range

• NVH Load Conditions

• Low Frequency Basics

• Live Noise Attenuation Demo

• Mid Frequency Basics

• Utilization of Simulation Models

NVH Workshop© www.AutoAnalytics.com, 2003

Utilizing NVH Simulation Models

Considerations• Some Agreement: Math Models can be used as Trend Predictors.

(but not for absolute levels, yet.)

• Q. How do I make design decisions before hardware is available?• ANS. Correlation must be performed on existing hardware to

establish modeling methods to be applied to the future design. (The Reference Baseline Ref. 3)

A model of the new design is built with the same Methodology as the Reference Baseline to predict the change in performance as the design process progresses but before prototypes are available.

• Q. How do I know my model is good?• ANS. We require correlation work to know the simulation compares

to test values to some degree.

NVH Workshop© www.AutoAnalytics.com, 2003

Utilizing NVH Simulation Models

Considerations• Q. How do I compare my model to test measurement and how close

does it have to be to assure it can be used as a trend predictor?• ANS. If model predictions were within the band of variability of the

test measurement, for a statistically significant number of samples, this would increase confidence in the predictive capability.

• Q. How wide is the band of variability?• ANS. Don’t Ask !!!

NVH Workshop© www.AutoAnalytics.com, 2003

Discussion of Product Variability

Topics

• Kompella and Bernhard Observations

• Freyman NVH Scatter Results

• Model Confidence Criteria

• Conclusions

NVH Workshop© www.AutoAnalytics.com, 2003

Frequency ( Hz )

Mag

. of F

RF

Magnitude of 99 Structure – borne FRF’s for theRodeo’s for the driver microphone( Ref. 8 ) 1993 Society of Automotive Engineers, Inc.

NVH Workshop© www.AutoAnalytics.com, 2003( Ref. 9 ) 2000 Society of Automotive Engineers, Inc.

Frequency ( Hz )

Soun

d Pr

essu

re [

dB( l

in)]

Frequency ( Hz )

Phas

e [o

]

Acoustic scatter numerically determined in the vibro – acoustic behavior of a vehicle due to possible tolerances in the component area and in the production process

NVH Workshop© www.AutoAnalytics.com, 2003

Reference Baseline Confidence CriterionFor Operating Response Simulations

Test Upper BoundTest Band AverageTest Lower Bound

Test Variation Band10. dB; 50-150 Hz20. dB; 150-500 Hz

REF. 8

Confidence Criterion:Simulation result mustfall within the band oftest variation.

Simulation Prediction

FUDGEFACTORS

NVH Workshop© www.AutoAnalytics.com, 2003

Axle Whine Example• Design work was focused in the beginning towards achieving generic targets for all noise paths

• As the design was firmed out, full vehicle analysis revealed under target performance for Driver’s ear SPL response which was dominated by rear excitation

[Figure Courtesy of DaimlerChrysler Corporation]

400 Hz 500 Hz300 Hz

10dBA

FR + RR Excitation

FR Excitation Only

RR Excitation Only(Dominates Total Content)

Target Level

Sound Response with Varying Excitation

Frequency (Hz)

SPL(

dBA

)

Must define Targets for the Simulation to know when goal is reached!!!

NVH Workshop© www.AutoAnalytics.com, 2003

Conclusions:Significant Product Variation exists even in best-in-class vehicles.

Correlation should be considered as being within the band of variability whether test or simulation.

The Confidence Criteria, for operating responses, is a relatively challenging condition to meet when considering the following:

" It uses the same bandwidth as Kompella (Ref. 8), determined from simple FRF’s, while the criteria is for operating responses which are subject to additional variation in the operating loads.

" It assumes that one test will generate the mean response level in the band subject to the condition that a “qualified” median performer will be tested. This requires a test engineer extremely experienced with the vehicle line in order to “qualify” the vehicle.

Best hope for reduced product development times is a coordinated effort of Virtual Vehicle Simulation and Reference Baseline and Physical Prototype Testing to grasp the complexities of NVH responses and the robustness of their sensitivity to variation.

NVH Workshop© www.AutoAnalytics.com, 2003

Rideand

Handling

NVH Durability

ImpactCrashWorthiness

Competing Vehicle Design Disciplines

NVH Workshop© www.AutoAnalytics.com, 2003

The Fundamental Secret ofStructure Borne

NVH Performance

The Fundamental Secret ofStructure Borne

NVH Performance

Revealed here tonight !

NVH Workshop© www.AutoAnalytics.com, 2003

Fundamental Secret to Making Money

in the Stock Market

Buy Low and Sell High !

NVH Workshop© www.AutoAnalytics.com, 2003

The Fundamental Secret of Structure Borne NVH Performance

The Fundamental Secret of Structure The Fundamental Secret of Structure Borne NVH PerformanceBorne NVH Performance

Meets Conditions of the Attenuations Strategies• Minimize the Source Load• Manage Mode Placement• Provide Isolation• Mount at Nodal Points• Provide Dynamic Absorber•Reduce Source - Receiver Mobility

To Minimize Structure Borne NVH response, always connect Sub-systems at locations

where motion is at a Minimum.

NVH Workshop© www.AutoAnalytics.com, 2003

The Fundamental Secret of Structure Borne NVH Performance

The Fundamental Secret of Structure The Fundamental Secret of Structure Borne NVH PerformanceBorne NVH Performance

Meets Conditions of the Attenuations Strategies• Minimize the Source Load• Manage Mode Placement• Provide Isolation• Mount at Nodal Points• Provide Dynamic Absorber•Reduce Source - Receiver Mobility

That’s All Folks !Thank You for Attending the

SAE Structure Borne NVH Workshop

Your Presenters tonight were:

Alan Duncan, Automotive Analytics, Inc.

Greg Goetchius, Material Sciences Corp.

Sachin Gogate, Altair Engineering, Inc.Visit: www.AutoAnalytics.com/papers.html

to download the Structure Borne NVH Workshop ( May 12 )

To Minimize Structure Borne NVH response, always connect Sub-systems at locations

where motion is at a Minimum.