First Results of Experimental Analysis of Stress State and ...

Stress Tabs Results Nov06,2013

-

Upload

jose-emilio-roman-de-anda -

Category

Documents

-

view

7 -

download

1

description

Transcript of Stress Tabs Results Nov06,2013

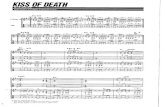

Stress tabs Study06/11/2013

Dec-13 2

Content

1. Stress tabs study silver process with cumulative layers1. Stress sum up

1. Stress sum up characterization2. Individual stress per each bath

1. Stress sum up

2. Stress tabs study copper process with cumulative layers1. Stress sum up

1. Stress sum up characterization2. Individual stress per each bath

1. Stress sum up

3. Comparison of individual stress of each layer4. Final stress: Silver vs Copper5. Stress referential6. POP plating solution using additives7. Stress measurement

ContextHigh rate of blisters present in our actual plating process. Defectdetected mainly on silver QLF.• hypothesis is that after plating the layers had a stress that could

impact in a direct way the blistering on them.• Stress study is developed to analyse the behavior of the deposit.

Compresive stress Tensile stress

1.- Stress tabs study silver process with cumulative layers

• Individual and accumulated coatings were check with the stress tabs to see how is the behavior of each deposit in our actual silver process.

Nickel electroless bath

Compressive stress

Silver bath

Compressive stress

Nickel electroless + Ag

Compressive stress

Compressive stress

Compressive stress

Line 1 + Oven

Line 1 + Oven + Ni electro previous Line 1 + Oven + Line 2

Compressive stress

Line 1 + Oven + Line 2 + oven

Compressive stress

1.- Stress tabs study SILVER process with cumulative layers

SummaryCummulative

ProcessCommulative

Stress followingElectroless nickel (EN) Compressive

Ag Compressive

EN+Ag Compressive

EN+Ag+8hr HT200°C Compressive

EN+Ag+8hr HT200°C+Flash NiElectro Compressive

EN+Ag+8hr HT200°C+Flash NiElectro+2nd EN +NiElectro Compressive

EN+Ag+8hr HT200°C+Flash NiElectro+2nd EN +NiElectro+1hrHT200°C Compressive

Observation:Comulative stress on stress tabs has shown the same type of stess on silver process.

Then is needed to evaluate the individual stress per each type of layer/process in order to have a better understanding of each coating.

1.1.- Stress sum up.

• In order to understand the impact of the stress on Blisterseach test was characterized to see its impact from:• heat treatment• Thermal shock• Scrib test

Type of characterization

Silver Process

NIX NIX+Ag NIX+AgPre+Ag NIX+AgPre+Ag+oven Line 1+NIPre Line 1+NIPre+NIX2 Line1+Line2 Line1+Line2+oven

Compresive X X X X X X X X

Tensile

Scrib test result OK OK OK OK OK OK OK OK

Thermal shock OK OK OK OK OK OK OK OK

Characterization results

1.1.1.- Stress sum up characterization.

Dec-13 8

Nickel electroless bath

Compressive stress

Silver bath

Compressive stress

Electrolytic nickel FLASH

Compressive stress

2nd Nickel electroless bath on line 2

Compressive stress

Electrolytic nickel

Compressive stress

1.2.- Individual stress per each bath

SummaryCummulative

ProcessCommulative

Stress followingElectroless nickel (EN) Low-Compressive

Ag Very low - Compressive

Nickel electrolytic FLASH Compressive

Electroless nickel Compressive

Nickel electrolytic Very high - Compressive

According to individual stress observation has been detected that the electrolytic nickel has a very high compressive stress compared with the others

Hypothesis:This high compressive stress and good adherence could lead the coating to remove the underlayers between electroless nickel and silver due to very low compression of silver that seems to be very ductil.

1.2.1.- Stress sum up.

2.- Stress tabs study COPPER process with cumulative layers

• Individual and accumulated coatings were check with the stress tabs to see how is the behavior of each deposit in our actual copper process.

Nickel electroless

Compressive stress

Line 1 + Oven + Ni electro previous+ 2nd Electroless nickel

Null tensile stressCompressive stress

Copper

High Tensile stress

Nickel electroless + Copper

Mid Tensile stress Low tensile stress

Line 1 + Oven (copper)

Low tensile stress

Line 1 + Oven + Ni electro previousLine 1 + Oven + Ni electro previous+ 2nd Electroless nickel+ Ni Eletro

Low compressive stress

Line 1 + Oven + Ni electro previous+ 2nd Electroless nickel+ Ni Eletro+Oven

Mid compressive stress

2.- Stress tabs study copper process with cumulative layers

SummaryCummulative

ProcessCommulative

Stress followingElectroless nickel (EN) Compressive

Cu High tensile

EN+Cu Mid tensile

EN+Cu+1hr HT200°C Low tensile

EN+Ag+8hr HT200°C+Flash NiElectro Mid tensile

EN+Ag+8hr HT200°C+Flash NiElectro+2nd EN Null tensile

EN+Ag+8hr HT200°C+Flash NiElectro+2nd EN +NiElectro Null Compresive

EN+Ag+8hr HT200°C+Flash NiElectro+2nd EN +NiElectro+1hrHT200°C Mid Compressive

Commulative stress on stress tabs has shown the same type of stess on silver process.

Then is needed to evaluate the individual stress per each type of layer/process.

2.1.- Stress sum up

2.1.1.- Stress sump up characterization

Type of characterization

Copper ProcessNIX NIX+Cu NIX+Cu+Oven Line 1+NIPre Line 1+NIPre+NIX2 Line1+Line2 Line1+Line2+oven

Compresive X X X

Tensile X X X X

Scrib test result OK OK OK OK OK OK OKThermal shock OK OK OK OK OK OK OK

• In order to understand the impact of the stress on Blisterseach test was characterized to see its impact from:• heat treatment• Thermal shock• Scrib test

Characterization results

First nickel layers is compresive, but immediatly after copper bath the deposit becomes tensile, and it stays in this way until electrolytic nickelwhere changes to compresive. This means that the sum of the stress of all the line 1 until electroless nickel of line 2 is not giving compresivestress, just after electrolytic nickel it has this effect.

Scrib test and thermal shock are Ok for all the accumalated coatings.

Dec-13 14

Nickel electroless bath

Compressive stress

Electrolytic nickel FLASH

Compressive stress

2nd Nickel electroless bath on line 2

Compressive stress

Electrolytic nickel

Compressive stress

2.2.- Individual stress per each bathCopper

High Tensile stress

2.2.1.- Stress sum up

SummaryCummulative

ProcessCommulative

Stress followingElectroless nickel (EN) Low-Compressive

Cu Very high tensile

Nickel electrolytic FLASH Compressive

Electroless nickel Compressive

Nickel electrolytic Very high - Compressive

According to individual stress observation has been detected that the electrolytic copper has a very high tensile stress compared with the others, in other side electrolytic copper has the opposite phenomena with very high compresive stress.

Hypothesis:The different combination of stress of copper process could explain that plated parts with copper underlayer are less sensitive to stress and thus to blisters due to the opposite forces that copper process present vs the electrolytic nickel (Tensile vs compressive)

Type of characterization

INDIVIDUAL TESTNIX Ag Cu NIPre NIX2 NIE

Compresive X X X X X

Tensile XScrib test result OK OK OK OK OK OK

Thermal shock OK OK OK OK OK OK

3. - Comparison of individual stress of each layer

• All individual stresses are compresive, only copper is tensile, this is why thehypothesis of blisters appear in silver process.

• Scrib test and thermal shock are Ok for all the accumalated coatings.

4.- Final stress: Silver vs Copper

Line 1 + Oven + Line 2 + oven

Compressive stress

Line 1 + Oven + Ni electro previous+ 2nd Electrolessnickel+ Ni Eletro+Oven

Mid compressive stress

Regarding the different stress behavior between Silver and Copper has been observed that Silver process has an important compressive stress at the end of the plating process which include EN, Silver, NiElectroFLASH+EN+Nielectro compared with the copper process.

This phenomena can be an input to issue of lack of adhesion.

5.- Stress referential

Different type of stress on metals.

Stress on plating process can be modified by the addition of organic agents on plating solutions known as carriers and brightneers, these agents have an important contribution to stress either compressive or tensile on each plating solution.

6.- POP solutions using additives.

• Copper:• CarrierD / Carrier / additive (Brightener)

• Silver:• Brightener

• Electrolytic nickel• Carrier, Brightener and wetting agent.

There is no too much information available about stress influence from the different additives there are being usedinto the plating solutions like:

Efect of min/max carrier on Tensile / Compressive stress ¿?Efect of min/max brightener on Tensile / Compressive stress ¿?Efect of min/max wetting agent on Tensile / Compressive stress ¿?

“In order to answer above questions is needed to have quantitative stress measurement”

7.- Stress measurement

This instrument is to measure in a quantitave way the stress for the different plating solutions.

The instrument is already in Obregon and in progress to start working with it, so far is not a priority