Streamlines Drip Irrigation - Automatic Filters Inc. · How can you assure adequate water quality...

Transcript of Streamlines Drip Irrigation - Automatic Filters Inc. · How can you assure adequate water quality...

How can you assure adequate water quality to keep your drip system functioningat an optimal level? Start by choosing the right filtration for your particular conditions.To a degree, filtration is as much art as science. But there are several quantifiableparameters that can help you determine the right size filter for your needs. Theseinclude:1. Minimum and Maximum Operating Flow. This is the most critical factor when

sizing a filter. Do not confuse flow rate with line size; they often are notcompatible. For example, a two-inch filter that accommodates a 100 GPM (gallonper minute) flow rate will not work for a system with a 150 GPM flow rate; inthat case you would need to go up to the next larger size, or a three-inch filter.

2. Water Source. This determines what kind of debris you are you trying to trap.Generally speaking, well water contains inorganic debris such as sand, whilepond or surface water contains largely organic matter such as algae and leaves.Inorganic matter requires a smaller screen to trap the sand and sediment thatwould pass through a larger screen.

3. Minimum and Maximum Operating Pressure. Accurate pressure readings areimportant for two reasons: 1) each filter type has a maximum rated pressure ofoperation; and 2) if your system calls for an automatic, self-cleaning filter,minimum operating pressure must be maintained when the filter’s flushingmechanism is engaged.

4. Size of Downstream Orifice to be Protected. Generally speaking, a filter isnecessary to keep debris from clogging downstream sprinklers or other emissiondevices. The size of those orifices will determine the pore (i.e. micron) size ofyour filter element. As a rule of thumb, the proper filter porosity should maintaina ratio of 1:5 for drip irrigation and 1:3 for sprinklers. More specifically: drip80-100 micron (200-150 mesh); micro sprinklers (jets) 150-200 micron (100-80 mesh); impact sprinklers and rotors 200-400 micron (40-80 mesh).

5. Budget: This parameter is complex. One should take into account not only theinitial cost of a filter but also the cost of maintaining a system without filtration.Automatic, self-cleaning filters are more expensive than manual filters, but whenlabor costs are factored in may be less expensive in the long run.

Automatic Water Filter

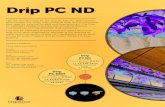

rip irrigation systems take the worry outof watering – unless emitters become

clogged with dirt and other contaminants that spewforth from the water source. Then watering becomesa labor-intensive process requiring constant monitoringand frequent cleaning, often canceling out the timeand money saved by the drip system itself.

Water quality is a key factor in the success ofdrip irrigation systems. The purity of the water canbe affected by many factors including seasonalchanges, pipeline conditions and flow velocity, rateof turnover of ponds, and changing sources of water,among others.

The Tekleen Automatic Filter is self cleaning and operates on line pressurealone, eliminating the need for an external power source. The filter offersthe following benefits:• Fully automatic and self-cleaning• Environmentally friendly• Cost-effective• Maintenance free• Compact design

Automatic Filters, Inc.2672 S. La Cienega Blvd.Los Angeles, CA 90034T (310) 839 2828T (800) 336 1942F (310) 839 [email protected]

Streamlines Drip Irrigation

TEKLEEN NEWSLINE®

FEB 2003

* 1,000 micron (µ) = 1 millimeter (mm)** 1 inch (in) = 25.4 millimeter (mm)

20406080

100140200325550

850400250177150100755025

.033

.016

.010

.007

.006

.004

.003

.002

.001

Mesh(holes perlinear inch)

Micron* Inches**

© 2003 Automatic Filters, Inc. Tekleen, Catalog on Disk and the Tekleen logo are trademarks of Automatic Filters, Inc. U.S.A.

© 2003 Automatic Filters, Inc. Tekleen, Catalog on Disk and the Tekleen logo are trademarks of Automatic Filters, Inc. USA Irrigation 2/03

Have a local Tekleen representative contact me

Send me a FREE catalog

AUTOMATIC FILTERS, NC.2672 La Cienega Blvd., Los Angeles, CA 90034 USATel (800) 336-1942 (310) 839-2828 Fax (310) 839-6878

AFFIX BUSINESS CARD

Email _______________________________________________

Phone (_____ )________________________________________

Fax (_____)___________________________________________

Name _______________________________________________

Title _________________________________________________

Company ____________________________________________

Address _____________________________________________

______________________________________________

City _____________________State _______ Zip _____________

Country ______________________________________________

The

Next Generation inW

aterFiltra

tion®

www.tekleen.com2672 S. La Cienega Blvd. Los Angeles, CA 90034 U.S.A.

Tel: (800) 336-1942 (310) 839-2828 Fax: (310) 839-6878

AUTOMATIC FILTERS, NC.

The

Nex

t

Generation in Water Filtration

®

www.tekleen.com

2672 S. La Cienega Blvd. Los Angeles, CA 90034 U.S.A.

Tel: (800) 336-1942 (310) 839-2828 Fax: (310) 839-6878AUTOMATIC FILTERS, NC.

The

Next

Gener

at

ion

inWater Filtration

®

www.tekleen.com

2672 S. La C

ienega Blvd. L

os Angeles, C

A 90034

U.S.A

.

Tel: (

800) 336-1942 (3

10) 839-2828 Fax: (

310) 839-6878

AUTOM

ATIC

FILT

ERS,

NC.

www.tekleen.com

Please Circle:My need is Current 6 Months

Crop Golf Greenhouse Nursery Trees Turf Other

Irrigation Type: Drip Jet Sprinkler

Water Source: Ditch Lake Well

Flow (gpm) ___________________________________

Pressure (psi) _________________________________

Line Size (inch) ________________________________

with installation drawingsFREEMovie!

On CD-ROM

On VHS Tape

Model

BELL

Connectioninches

Screen Areasq. ft.

Max Flowgpm

Empty Wt.lbs.

Bell - 1.5Bell - 2Bell - 3Bell - 3LBell - 4Bell - 4LBell - 6

1.5” NPT2” NPT3” NPT3” ANSI4” ANSI4” ANSI6” ANSI

0.50.50.50.80.81.71.7

50100150200300400500

6060608090

150200

Carbon steel body with baked onpowdered epoxy coating. Maximum150 psi, 150° F, Stainless steel screenmesh 35µ to 400µ. 2 gallons per rinsewith a 1” valve & 8 gallons per rinsewith a 2” valve.

Specifications

Model

MTF

Connectioninches

Screen Areasq. ft.

Max Flowgpm

Empty Wt.lbs.

Stainless steel body, 316L. Maximum150 psi, 200° F, 3 layers sinteredstainless steel screen Mesh sizesfrom 5µ to 400µ. 5 second rinseduration, using 2 gallons per rinsewithout interrupting main flow. 1”flushing valve.

MTF1MTF1.5MTF2MTF2 - LMTF3MTF4

1” NPT1.5” NPT2” NPT2” NPT3” ASA4” ASA

0.60.60.61.51.51.5

305080

150200300

303030608090

Specifications

Model

ABW

Connectioninches

Screen Areasq. ft.

Max Flowgpm

Empty Wt.lbs.

ABW2 - LPABW3ABW3 - LPABW4ABW4 - LABW4 - LPABW6 - LABW6 - LPABW6 - XLPABW8ABW8 - PABW8 - LPABW10ABW10 - PABW12ABW12 - PABW14ABW14 - PABW16 - LPABW20 - TPABW24 - TP

233444666888

101012121414162024

0.50.51.70.83.33.33.33.34.93.33.35.04.44.46.66.67.47.4

10.020.020.0

100150250350500500800800800

1,3001,3001,6001,8001,8002,5002,5004,0004,0006,0008,000

12,000

120150200170250250350350400400400500500500700700800800

1,0001,8002,000

Stainless steel body at the carbonsteel price (stainless steel 316Lbody or carbon steel body withbaked on powder epoxy coating atthe same price.) Internal parts:stainless steel dirt collector,stainless steel screen on a PVCsleeve. Maximum 150 psi, 150° F. Standard screen mesh 50µ to1000µ. Optional 3 layer stainlesssteel screen to 10µ, h ightemperature, and high pressure.

Specifications