Stenter machine & heat set

-

Upload

mizan-rahman -

Category

Engineering

-

view

236 -

download

43

Transcript of Stenter machine & heat set

STENTER MACHINE OPERATION & HEAT SET

MAA Garment & Textiles Factory

PO Box 1976, Quiha, Mekelle, Ethiopia.

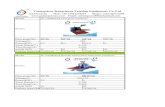

Stenter M/c Side View

Objective of stenter A machine or apparatus for stretching or stentering fabrics. The purpose of the stenter machine is to bringing the length and width to pre determine dimensions and also for heat setting and it is used for applying finishing chemicals and also shade variation is adjusted. The main function of the stenter is to stretch the fabric widthwise and to recover the uniform width.

Function of stenter Machine 1. Heat setting is done by the stenter for lycra fabric , synthetic and blended fabric. 2. Width of the fabric is controlled by the stenter. 3. Finishing chemical apply on fabric by the stenter. 4. Loop of the knit fabric is controlled. 5. Moisture of the fabric is controlled by the stenter. 6. Spirility controlled by the stenter. 7. GSM of the fabric is controlled by stenter. 8. Fabric is dried by the stentering processs 9. Shrinkage property of the fabric is controlled. 10. Curing treatment for resin, water repellent fabric is done by the stenter.

1 Brand Name Monforts2 Origin Germany3 Year of manufacture 20074 Speed range 5-80 M/Min5 Temperature range 50-250 C6 Used utilities Electricity, Thermal oil, Compress air, Steam7 Production capacities 8 ton /day (24 hours)8 No. of chamber 59 Maximum fabrics width 105”10 Minimum fabric width 30”11 Steam pressure 2 bar12 Air pressure 10 bar13 Applied for Open tube fabric14 No. of ratamatic burner 515 Extra Attachment Mahlo weft straightener16 M/C parts Nozzle, Exhaust air fan, Over feed roller, Suction

fan, Chain

Specification of a Stenter Machine:

The fabric is collected from the batcher to the scray and then it is passed through the padders where the finishes are applied and some times shade variation is corrected. The fabric is entered into the mahlo (weft straigtner) the function of the mahlo is to set the bow and also weave of the fabric is griped by the clips and pins are also provided but the pins has a disadvantage that they pins make holes at the selvedge but the stretching of the pins are greater than the clips. these clips and pins are joined to endless chain. there are 5 chambers provided on the machine each chamber contains a burner and filters are provided to separate dust from air. the circulating fans blow air from the base to the upper side and exhaust fans sucks all the hot air within the chambers. Attraction rollers are provided to stretch the warp yarn.

After stentering we can increase the width of the fabric up to 1.5-2 inch. The speed of the machine is about 7-150 m/min.3 meters fabric can run in each chamber. temperature is adjusted that according to the fabric as for,

1. PC 210 c 2. Cotton 110-130 c After dyeing 160-170c and after print 130-140c.

Working Procedure of Stenter Machine:

Finishing Process

STANDARD OPERATING PROCEDURE

Stenter Machine

Batch Card1 Check Buyer, Dia, Gauge, Stitch Length, Required GSM2 Match with Standard Parameter Sheet

Parameter1 Set Temp, Width, Overfeed, Speed As a Standard Parameter Sheet.2 If Not match with Standard Parameter sheet then Inform to Shift head.3 Prepare Softener as Buyer standard.

Manpower1 Set Manpower, Back 1 person, Operation area 1 person & Delivery side 1 person.2 Re-check set parameter & standard parameter.

Check1 Temperature, Air Pressure & Water if set up & actual same.2 Now can started machine.3 Check after delivery, GSM, Width, Hand feel & Shade , If ok as buyer standard then continue

STANDARD FINISHING PARAMETER

MAA Garment & Texile FactoryP .O Box No-1976, Quiha, Mekelle, Ethiopia

Standard Finishing Parameter Update: 21/07/2016From: 06/1/2016

SL Buyer Fabrication ColourKnitting Parameter Required Stenter Parameter Required After Stenter

Count Dia Gauge Stitch Length Grey Width Grey GSM Req

Width Req GSM Temperature Speed Overfeed Width Set Width GSM Next

1

H&M

Lycra S/J White 36 30 28 2.88 174 170 170 160 130 15 50% 170 170-175 150-155 Compactor2 Lycra S/J White 36 30 28 2.7 174 180 170 180 130 15 60% 165 165-170 165-170 Compactor3 Lycra S/J White 36 34 28 2.7 180 190 180 130 15 60% 185 185-190 165-170 Compactor 4 Lycra S/J Black 36 30 28 2.88 170 175 160 160 15 50% 175 175-180 150-155 Compactor5 Single Jersey White 28 30 28 2.85 145 180 145 130 15 50% 180 180-185 140-145 6 Single Jersey White 30 30 28 2.70 216 138 170 160 130 15 50% 170 170-175 155 7 Single Jersey Black 30 30 28 3.00 125 190 145 180 20 50% 190 190-195 140-145 New8 Single Jersey Junbug 28 30 28 2.95 135 190 145 170 16 50% 190 190-195 140 New9

NJ

Single Jersey White 28 30 28 2.85 145 180 145 130 15 50% 180 180-185 140-145 10 Single Jersey White 28 30 28 2.70 155 170 160 140 15 50% 170 170-175 150-158 11 Single Jersey Black 28 30 28 2.90 135 185 160 170 18 50% 180 180-185 150-158 12 Single Jersey Turquist 28 30 28 2.75 150 175 160 160 16 50% 175 175-180 155-160 13 Single Jersey Green 28 30 28 2.75 150 175 160 160 16 50% 175 175-180 155-160 14 Single Jersey Orange 28 30 28 2.75 155 175 160 160 16 50% 175 175-180 155-160 15 Single Jersey Black 28 30 28 3.10 125 195 145 170 18 50% 195 195-200 140-145

16 Single Jersey Mellange 28 30 28 2.85 145 180 160 160 16 50% 175 175-180 150-158

17 Single Jersey Black (PC) 28 30 28 2.95 214 135 185 160 170 15 50% 180 180-185 155-160 New

18 Single Jersey White(PC) 28 30 28 2.85 145 190 160 160 18 50% 180 180-185 155-160 New

19 Single Jersey Navy 28 30 28 2.90 140 185 160 170 16 50% 185 185-190 155-160 New20

NJ Primark

Single Jersey Mellange 28 30 28 3.1 125 190 140 160 16 50% 190 190-195 136-140 21 Single Jersey White 28 30 28 2.85 145 180 140 130 15 50% 180 180-185 136-140 22 Single Jersey Black 28 30 28 3.1 125 190 140 180 18 50% 195 190-195 136-140 23 Single Jersey Charcol 28 30 28 2.9 130 180 140 160 16 50% 185 180-185 136-140

Prepare Check Approved

MAA Garment & Texile FactoryP .O Box No-1976, Quiha, Mekelle, Ethiopia

Standard Finishing Parameter Update: 21/07/2016From: 06/1/2016

SL Buyer Fabrication ColourKnitting Parameter Required Stenter Parameter Required After Stenter

Count Dia Gauge Stitch Length

Grey Width

Grey GSM

Req Width Req GSM Temperatu

re Speed Overfeed Width Set Width GSM Next

24KIK

Single Jersey White 26 34 24 2.78 180 160 140 15 50% 180 185-190 152-160

25 Single Jersey Black 26 34 24 2.90 190 160 170 18 50% 180 185-190 155-160

26Tezenise

Single Jersey Black 28 30 28 3.1 125 195 145 170 18 50% 195 195-200 140-145

27 Single Jersey White 28 30 28 2.85 145 180 145 130 15 50% 180 180-185 140-145

28Poly

ConceptPique Dark

Colour 24 30 24 2.85 234 175 215 200 170 10 60% 220 215-220 200-210 Compactor

29 Pique White/Mellance 24 30 24 2.75 234 185 215 200 170 10 60% 220 215-220 190-200 Compactor

30Beconect

Single Jersey White 28 30 28 2.85 145 180 140 130 15 50% 180 180-185 136-140

31 Single Jersey Black 28 30 28 3.1 125 190 140 180 18 50% 195 190-195 136-140

32 Takeza Single Jersey White 20 34 24 3.25 175 195 180 160 18 50% 195 195-200 175-180

33

VF Asia

Single Jersey White 30 30 28 2.65 145 165 160 160 15 50% 165 165-170 156-160 New

34 Single Jersey Navy 30 30 28 2.75 140 170 160 160 15 50% 170 170-175 154-158

35 Lycra S/J Navy/White 40 30 28 2.85 165 170 160 160 15 50% 170 165-170 150-155 Compactor

Prepare CheckApprove

d

STANDARD FINISHING PARAMETER

KEEPING RECORD IN FINISHING

Heat Set Process

Heat Setting Heat-setting is a heat treatment by which shape retention, crease resistance, resilience and elasticity are imparted to the fibers. It also brings changes in strength, stretch ability, softness, dyeability and sometimes on the colour of the material. All these changes are connected with the structural and chemical modifications occurring in the fibre.

This operation is crucial for fabrics made of synthetic fibres (PE, PA, elastomers), for triacetate, and partly for PAC fibres (setting), since it grants excellent dimensional stabilization and crease proof properties, maintained till the fabric is exposed (by air blowing) to temperatures exceeding the heat setting one (after being treated with water at a temperature above the second order glass transition temperature, i.e. 80-85°C for acrylics).

Heat setting is carried out on gray fabrics (scarcely applied), on scoured fabrics (frequently applied) and on dyed fabrics (scarcely applied). The process grants excellent dimensional stability and good crease-proof properties. As far as operating conditions are concerned, the fabric must be treated in accurately controlled moisture and temperature conditions.

Heat setting Process

Objective of Heat set 1. Heat setting is a heat treatment by which shape retention, crease resistance, resilience and elasticity are imparted to the fibers.

2. Change in strength, stretch ability, softness , dye ability and sometimes in color.

3. Changes occur due to structural and chemical modification of fibers.

Heat setting can be carried out at three different stages:

1. In grey condition2. After scouring3. After dyeing

Stages of Heat setting

Heat setting at grey stage 1. If heat setting is carried out in loom state, mineral oils and non-ionic emulsifiers can modify the fiber. 2. Structure and rubbing and perspiration fastness may be reduced due to the solubility of disperse dye in the coning oil. 3. However, grey heat setting is useful in warp knitting industry as in that material carry less amount of lubricants. 4. Yellow color due to heat setting can be removed by bleaching. 5. Fabric is less sensitive to crease formation in next processes.

Heat setting is done after scouring if it is suspected that:

1. goods will shrink . 2. Cloth has developed stretch or other properties after scouring.

Heat setting after scouring

These fabric shows considerable resistance to stripping compared with dyeing on unset fabric.

Disadvantage of this are: 1. Yellow color developed can not b removed. 2. Handle of cloth may get altered. 3. Risk of color to get fade.

Heat setting after dyeing

Effect of heat setting on various of synthetic fibers

1. Structural changes 2. Dimensional stability 3. Stiffness 4. Crease recovery 5. Dyeability

HEAT SET PROCEDURE1 Knitting Machine wise Batch Prepare.

2 Dyeing Machine wiae Batch Prepare.

3 In Batch Card should be write M/c Dia, Gauge, Stitch Length, Yarn count & Required GSM.

4 Sewing time follow Needle line.

5 Slitting time need to be carefully follow slitting line.

6 Grey GSM & Width check also compare with standard.7 Stenter M/c parameter set as a Standard parameter sheet.

8 Width, Temperature & Speed Fixed If needed then adjust only overfeed.

9 Follow Colour wise After heat set GSM

10 After Heat set keep record Roll to roll & Within roll GSM.

11 Colour wise identify & Some rolls need to be write then not mix-up with another Colour.

HEAT SET PROCEDURELycra Grey Fabrics Relaxation Procedure

1

Knitting 1. After knitting should be Relax stage not Roll stage 2. Maximum 24 Hours.

2 Store 1. Not More the 24 hours

2. Within 24 hours hand over to Batch Section

3 Batch Section 1. Batch Knitting M/c wise & Dyeing M/c Capacity wise2. Withing 2 hours Handover to Slitting.

4 Slitting 1. Within one trolley Maximum 500 KG Keep.

2. After slitting Need 4 hours keeping.

5 Stenter 1. Check Grey GSM & Width.2. After stenter Relax minimum 2 Hours

STANDARD HEAT SET PARAMETER

MAA Garment & Texile FactoryP .O Box No-1976, Quiha, Mekelle, Ethiopia

Heat Set ParameterFrom:

06/1/2016Update: 29/9/2016

SL Buyer Fabrication Colour Knitting Parameter Required Stenter Parameter Required After Stenter

Count Dia Gauge Stitch Length

Grey Width

Grey GSM

Req Width

Req GSM

Teparature Speed Overfe

edWidth Set Width GSM

1

H&M

Lycra S/J White 36/1 30 28 2.88 174 170 165 160 200 18 35-

40% 175 175 165-170

2 Lycra S/J White 36/1 30 28 2.70 174 180 165 180 200 23 60% 165 175 185-

190

3 Lycra S/J White 36/1 34 28 2.70 180 180 195 180 200 23 60% 185 195 185-

190

4 Lycra S/J Black 36/1 30 28 2.88 180 165 170 160 200 18 30-

35% 175 175 150-155

5KIK

Lycra S/J Black 36/1 30 28 2.88 174 165 170 180 200 20 50% 170 170 180-185

6 Lycra S/J

Light Color 36/1 30 28 2.88 174 165 170 180 200 20 60% 170 170 185-190

7VF Asia

Lycra S/J White 40/1 30 28 2.88 170 175 165 160 200 18 30-

35% 170 170 165-170

8 Lycra S/J Navy 40/1 30 28 2.88 170 175 165 165 200 18 25-

30% 170 170 155-160

Prepare Check

By Approve

d

Heat Set Record

Our Expectation Good Quality with Quantity.

Thanks