Statistical quality__control_2

-

Upload

techmx -

Category

Technology

-

view

779 -

download

3

description

Transcript of Statistical quality__control_2

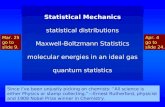

- 1. Statistical Quality Control (SQC)DEFINITION:Statistical Quality Control is the term used to describe the set of statistical tools to evaluate organizational quality. CLASSIFICATION OF SQC: 1.Descriptive statistics 2.Statistical process control 3.Acceptance sampling

2. DESCRIPTIVE STATISTICSStatistics used to describe quality characteristics and relationships.Eg: Mean, Standard deviation, Range 3. STATISTICAL PROCESS CONTROLA statistical tool that involve inspecting arandom sample of the output from a process anddeciding whether the process is producingproducts with characteristics that fall within apredetermined range.It answers the question whether the processis functioning properly or not. 4. ACCEPTANCE SAMPLING The process of randomly inspecting a sample of goods and deciding whether to accept the entire lot based on the results. It determines whether a batch of goods should be accepted or rejeted 5. VARIATIONIt is the change in some qualitycharacteristic of the product or process. CLASSIFICATION OF VARIATION:1. In-control variation2.Out-of-cotrol variation 6. IN-CONTROL VARIATION: Due to common causes(random causes) that cant be identified. OUT-OF-CONTROL VARIATIONDue to assignable causes(outside influences) that can be identified and eliminated. 7. CONTROL CHART(PROCESS CHART / QUALITY CONTROL CHART) A graph that shows whether a sample of data falls within the normal range of variation. It has two horizontal lines, called the upper and lower control limits It has a central line that represents the average value of the quality characteristic when the process is in control. 8. Control Chart UCLVariations Nominal LCL Sample number 9. Types of the control chartsVARIABLES CONTROL CHARTS Variable data are measured on a continuous scale. Forexample:time, weight, distance, temperature, volume, length,width can be measured in fractions or decimals. Applied to data with continuous distribution 10. ATTRIBUTES CONTROL CHARTS Attribute data are counted and cannot have fractions ordecimals. Attribute data arise when you are determining onlythe presence or absence of something. success or failure, accept or reject, correct or not correct.Example: a report can have four errors or five errors, but it cannot havefour and a half errors. Applied to data following discrete distribution 11. WHY CONTROL CHARTS ? Predicting the expected range of outcomes froma process. Determining whether a process is stable (instatistical control). Analyzing patterns of process variation fromassignable causes or common causes . 12. PROCEDURE TO DRAW CONTROLCHART Choose the appropriate control chart forthe data. Determine the appropriate time periodfor collecting and plotting data. Collect data, construct the chart andanalyze the data. Look for out-of-control signals on thecontrol chart. When one is identified,mark it on the chart and investigate thecause. 13. General model for a control chartUCL = + kCL = LCL = kwhere is the mean of the variable,and is the standard deviation of the variable. UCL=upper control limit; LCL = lower control limit; CL = center line. 14. where k is the distance of the control limits from the center line, expressed in terms of standard deviation unitsWhen k is set to 3, we speak of 3-sigma control charts. 15. NORMAL DISTRIBUTION:A variable control chart follows normaldistribution(since,variable is a continuous random variable)A continuous random variable X having aprobability density function given by the formula 21 x 1 2 f ( x) e, x2is said to have a Normal Distribution with parameters and 2. It is a theoretical distribution.Symbolically, X ~ N( , 2). The distribution with = 0and 2 = 1 is called the standard normal 16. Graph of generic normaldistribution 17. where parameter is the mean or expectation (location ofthe peak) and 2 is the variance. is known as the standarddeviation. where x is an observation from a normallydistributed random variable It is a continuous distribution of a random variable withits mean, median, and mode equal. The normal distribution is considered the most prominentprobability distribution in statistics. 18. PROPERTIES OF NORMAL DISTRIBUTION 1. The curve extends infinitely to the left and to theright, approaching the x-axis as x increases inmagnitude, i.e. as x , f(x) 0. 2. The mode occurs at x= . 3. The curve is symmetric about a vertical axis throughthe mean 4. The total area under the curve and above thehorizontal axis is equal to 1.i.e.21 x12 edx 1 2 19. The mean identifies the position of the center and thestandard deviation determines the height and width of thebell All normal density curves satisfy the following propertywhich is often referred to as the Empirical Rule or 68-95-99.7 rule 20. EMPERICAL RULE: 68% of the observations fall within 1 standard deviationof the mean (i.e between - and + ) 95% of the observations fall within 2 standard deviationsof the mean (i.e between -2 and + 2) 99.7% of the observations fall within 3 standarddeviations of the mean(i.e between -3 and +3) 21. A NORMAL CURVE 22. Eg: A good example of a bell curve or normal distributionis the roll of two dice. The distribution is centeredaround the number 7 and the probability decreases asyou move away from the center 23. STANDARDIZING PROCESSThis can be done by means of the transformation.The mean of Z is zero and the variance is respectively,xz X XVar( Z ) Var E (Z ) E12Var( X )1E X12Var( X )1[E( X ) ] 12201 24. Standard Normal Distribution andStandard Normal Curve 25. TYPES OF VARIABLE CONTROL CHART Control of the process average or mean qualitylevel is usually done with the control chart for mean calledxbar chart. Process variability can be monitor with eithera control chart for the standard deviation, called the s chart,or a control chart for the range, called an R chart. We can use X-bar and R charts for any process with asubgroup size greater than one. Typically, it is used whenthe subgroup size falls between two and ten, 26. Determining an alternative valuefor the standard deviationm Ri i 1 Rm UCL XA2 R LCL XA2 R 27. x-bar Chart Example: Unknown OBSERVATIONS (SLIP- RING DIAMETER, CM)SAMPLE k 12 3 4 5xR15.02 5.01 4.944.99 4.96 4.980.0825.01 5.03 5.074.95 4.96 5.000.1234.99 5.00 4.934.92 4.99 4.970.0845.03 4.91 5.014.98 4.89 4.960.1454.95 4.92 5.035.05 5.01 4.990.1364.97 5.06 5.064.96 5.03 5.010.1075.05 5.01 5.104.96 4.99 5.020.1485.09 5.10 5.004.99 5.08 5.050.1195.14 5.10 4.995.08 5.09 5.080.15 105.01 4.98 5.085.07 4.99 5.030.10Totals 50.09 1.15 Copyright 2011 John Wiley & Sons, Inc. 3-38 28. 5.10 x- bar 5.08 Chart5.06 UCL = 5.08Example5.04 5.02 = = 5.01Mean x 5.00 4.98 4.96 4.94 LCL = 4.94 4.92 ||||| | | | | | 12345 6 7 8 9 10 Sample numberCopyright 2011 John Wiley & Sons, Inc.3-39 29. R-Chart Example OBSERVATIONS (SLIP- RING DIAMETER, CM)SAMPLE k 12 3 4 5xR15.02 5.01 4.944.99 4.96 4.980.0825.01 5.03 5.074.95 4.96 5.000.1234.99 5.00 4.934.92 4.99 4.970.0845.03 4.91 5.014.98 4.89 4.960.1454.95 4.92 5.035.05 5.01 4.990.1364.97 5.06 5.064.96 5.03 5.010.1075.05 5.01 5.104.96 4.99 5.020.1485.09 5.10 5.004.99 5.08 5.050.1195.14 5.10 4.995.08 5.09 5.080.15 105.01 4.98 5.085.07 4.99 5.030.10Totals 50.09 1.15 Copyright 2011 John Wiley & Sons, Inc. 3-40 30. R- Chart UCL = D4RLCL = D3RRR=kWhereR = range of each samplek = number of samples (sub groups) Copyright 2011 John Wiley & Sons, Inc. 3-41 31. R-Chart Example _UCL = D4R = 2.11(0.115) = 0.243_ LCL = D3R = 0(0.115) = 0Retrieve chart factors D3 and D4 Copyright 2011 John Wiley & Sons, Inc. 3-42 32. R-Chart Example 0.28 0.24 UCL = 0.243 0.20 0.16 Range R = 0.115 0.12 0.08 0.04 LCL = 00 |||||| || | | 123456 78 9 10Sample numberCopyright 2011 John Wiley & Sons, Inc.3-43 33. THANK YOU..