State of Michigan Agriculture Logistics and Supply Chain ... · Logistics and Supply Chain ......

Transcript of State of Michigan Agriculture Logistics and Supply Chain ... · Logistics and Supply Chain ......

State of Michigan Agriculture Logistics and Supply Chain Assessment and Strategy

Recommendations

Michigan State University Department of Supply Chain Management

and Product Center Food-Ag-Bio

in association with

State of Michigan Department of Agriculture and Rural Development

Final Report

Submitted By:

Spartan Consulting Inc.

May 31, 2015

2

Table of Contents

Executive Summary 3 Supply Chain Overview 5 Introduction & Purpose 9 Data Collection & Analysis 12 Design Specification Analysis: 17

Animal Processing 17 Feed Processing 21 Food Processing 24 Intermodal Transportation 26

Commodity Scenario Analysis: Soybeans 33 Corn 53 Wheat 66 Dry Beans 71

Summary of Findings and Next Steps 78 Proposed Implementation Planning and Next Steps 82 Appendix A: List of Figures 84 Appendix B: List of Tables 86 References 87

3

Executive Summary

The initiative is funded through a Strategic Growth Initiative grant provided

by The Michigan Department of Agriculture and Rural Development (MDARD).

The Michigan Department of Agriculture & Rural Development Strategic Growth

Initiative began in the spring of 2014. The focus of this Strategic Growth Initiative

project is identifying potential logistics and supply chain improvements and

strategy recommendations for the State of Michigan Agriculture sector and how

these recommendations benefit value added processing and exports. The

commodities being studied are soybeans, corn, wheat and dry beans.

The engagement focuses on the assessment of the end to end agriculture

supply chain which begins with the purchase and application of seeds and

fertilizers, planting of the seeds, continues with the harvest and the transport of

products from the field to processing locations, continues with food/feed

processing, and ends with the sale of processed product for animal livestock or

consumer use. The supply chain for each agriculture commodity is unique and is

explained in greater depth in each commodity’s respective section of this report.

The information presented in this report is intended to demonstrate that the value

associated with implementing the logistics and supply chain strategy

recommendations will be substantial and the economic benefits will include

reduced cost or cost avoidance for all stakeholders, improved service for the

agriculture supply chain by reducing cycle times and delays for transport and

4

processing, reduced supply chain risks for all stakeholders, and creation of new

jobs for the State of Michigan.

The primary recommendation includes further research into the building of

a new soybean processing plant. Primarily, research must be done to determine

the possibility of increasing Michigan’s animal processing industry in order to

justify additional soybean processing capacity.

Michigan State University’s assessment approach of analyzing the integrated

end-to-end supply chain provided excellent insights for Michigan agriculture economic

development benefits. Soybeans appear to be the most promising opportunity for

economic development given the livestock demand increase, new food/feed processor

opportunity and new animal processor opportunity. Soybeans will need an

implementation champion to assure the benefits of the integrated end-to-end supply

chain will become a reality. Implementation challenges may arise given the lack of

project participation by several stakeholders.

The purpose of this Spartan Consulting Inc. report is to provide thorough

documentation of the deliverables to date and provide the framework necessary for

implementing the project results. This report provides detailed documentation of the

proposed and validated methodology for industry assessment and provides supporting

documents necessary for data analysis developed by Michigan State University and

validated by stakeholders at five stakeholder workshops throughout the project

duration.

5

Supply Chain Overview

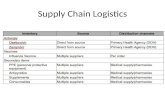

The supply chain for agriculture commodities has many steps as shown in Figure

1. It begins with the purchase of raw materials including seeds as well as chemicals

and fertilizers that ensure proper development of the crop. Following the growing

season, the crop is harvested and moved to either an elevator for storage or directly to

a processor. Depending on the crop, several stages of processing might be required

including preparing the crop for human consumption or for livestock feed. If the crop

becomes animal feed, then the next step in the supply chain would be processing the

animals. At this point, the crop has reached the end of its supply chain and is ready to

be sold within the state or exported.

Figure 1: End to End Supply Chain for Commodities

6

The supply chain for agriculture commodities is complex as shown in Figure 2.

The complexity exists because each commodity has a unique supply chain including

different requirements and input for each stage. Each commodity also requires different

processes to transform the crop into the final end product. The end product then will be

sent to a wide variety of end customers. During the team’s research, the complexity of

each commodity’s supply chain was recognized. The uniqueness of each supply chain

was also considered.

Throughout each commodity’s supply chain, there is a constant exchange of

information through various processes (Figure 3). The process starts as the raw

materials and ends with the product being delivered to the end consumer. Along the

supply chain, information is exchanged both internally and externally. Information

Figure 2: Complexity in the Supply Chain

(Hope, 2005)

7

sharing allows for timely transactions and efficient use of materials. The supporting

functions that enable information sharing and relationship building are key to proper

execution throughout the supply chain.

The integrated supply chain incurs numerous expenses throughout the product

lifecycle as Figure 4 illustrates. It is the sum of all of these expenses that determine the

end product’s total cost. By further studying each cost component of the supply chain,

opportunities for cost savings can be identified. The goal in total cost analysis is to

breakout individual costs so that a stakeholder can identify how to save money

implementing recommendations that offer solutions that reduce or eliminate costs

incurred during the supply chain.

Figure 3: End to End Integrated Supply Chain Model

8

Figure 4: End to End Integrated Supply Chain (The Total Cost Analysis)

9

Introduction and Purpose

The project scope includes soybeans, corn, wheat and dry beans. Spartan

Consulting, Inc. has orchestrated data collection activities, reviewed data

collection and research methods, developed supply chain recommendations, and

vetted recommendations with the participating stakeholders shown below.

• Michigan Soybean Promotion Committee • Corn Marketing Program of Michigan • Michigan Wheat Program • Michigan Bean Commission • Michigan Farm Bureau • MSU Department of Supply Chain Management • MSU Product Center • MDARD • MEDC • MDOT

Spartan Consulting, Inc. was responsible for data collection, analysis and

modeling, developing supply chain recommendations, validating

recommendations with stakeholders, and proposing implementation guidelines.

Throughout the project, the Spartan Consulting team conducted a series of five

workshops to review findings with stakeholders as well as to consider feedback

from the stakeholder group. The final deliverable for Spartan Consulting is to

summarize project findings through this stakeholder report.

The first workshop was conducted on February 21, 2014 and primarily

focused on data collection. During this phase of the project the team conducted

10

preliminary interviews with stakeholders to analyze the current state of the

agricultural supply chain in Michigan.

Data Collection Define data collection needs Collect information on the current state of operations Collect information on current supply chain and logistics infrastructure

assets Collect information on global best practice deliverables

The second workshop on April 17, 2014 summarized the current state of

agricultural commodity flows and created process flow maps for each commodity.

During Workshop 2, the team worked with the stakeholders to create templates

to send out to Michigan elevators to obtain additional data to support supply

chain recommendations.

Analysis & Modeling Define network modeling tool to use for analysis Prepare data in format to be used in the analysis and modeling step Input data into modeling tool and validate model Analyze alternative agriculture logistics and supply chain improvement

scenarios using network modeling tool Workshop 3 was conducted on November 20, 2014. Unfortunately, there

was limited participation from Michigan elevators. Due to this there was a limited

data set to analyze. Therefore, the main focus of Workshop 3 was on best

practices surrounding potential supply chain improvements, as well as insights

into potential supply chain recommendations.

Develop Supply Chain Recommendations Develop logistics and supply chain improvement recommendations Refine supply chain improvement recommendations Document recommendations for review by various stakeholders

11

The fourth workshop was held on March 3, 2015. The primary focus of

Workshop 4 was to develop supply chain scenarios for each commodity group.

For example, the Spartan Consulting Inc. team presented a preliminary soybean

model developed based on the scenario of an additional soybean processor in

the state. During the workshop the stakeholders provided feedback that was

used to improve the recommendations for the final workshop.

Validate Recommendations with Stakeholders Meet with stakeholders to discuss logistics and supply chain

recommendations Discuss opportunities and obstacles to solution implementation Document agreed upon and recommended supply chain solutions Share solution with all stakeholders to assure buy-in of solution

The final workshop was conducted on May 1, 2015 and centered on

developing supply chain recommendations and implementation planning. For

example, the final soybean model was presented to stakeholders and the team

discussed how the soybean model could be used by external users to assess the

feasibility of a new soymeal processing facility.

Implementation Planning Document the proposed implementation plan and assign resources to

work on activities in the implementation plan Work with all stakeholders regarding next steps to implement project

The Purpose of This Document is Threefold:

1. Clarify proposed and validated methodology for supply chain improvement recommendations. This document should assist others attempting to replicate this research and evaluation model.

2. Present Spartan Consulting findings and next steps. 3. Itemize the data and other documents created by Spartan Consulting.

12

Data Collection and Analysis

Data Collection for Elevators

Process:

Elevators play a crucial role in the agricultural supply chain because they

store grain after harvesting and before processing. The team wanted to further

understand the role elevators played in the supply chain by studying their

capacity and how they

were utilized. The team

first identified where the

elevators were located.

Figure 5 shows the

location and capacity of

all the grain elevators in

the Lower Peninsula

(MDARD, 2014). The

figure illustrates that most

of the grain handling in

Michigan occurs south of

the Saginaw Bay area.

Figure 5: Location and Capacity of Michigan Elevators (MDARD, 2014)

13

In order to simplify the data collection process, the team contacted general

managers of 13 major elevator firms within Michigan via email. Most of the firms

contacted operate more than one elevator. Each email contained an excel

spreadsheet designed to collect information from the past 3 years regarding:

Elevator Inflows • Year, Month, Commodity, Origin of Commodity, and Volume

Elevator Outflows

• Year, Month, Commodity, Destination of Commodity, Next Step in the Supply Chain, Transport Mode, and Volume

The signature line of this email included Dr. Chris Peterson and Dr. David Closs.

Result:

Two larger elevators in the state provided useable data for analysis.

Major Challenges: • Lack of participation • Companies unwilling to share information • Data that was returned did not follow the given template • Inconsistencies between sources

Processor Data Collection

Process:

The team contacted 21 processors via email. Each email contained an excel

spreadsheet designed to collect information from the past 3 years regarding:

Elevator Inflow • Year, Month, Commodity, Origin of Commodity, and Volume

Elevator Outflow

• Year, Month, Commodity, Destination of Commodity, Next Step in the Supply Chain, Transport Mode, and Volume

14

The signature line of this email included Dr. Chris Peterson and Dr. David Closs.

Result:

We received limited responses from the processors we contacted, and

almost no useable data.

Major Challenges: • Lack of participation • Companies unwilling to share information

Initial Interviews

The team conducted initial interviews with each of the participating

stakeholders to determine:

• Roles of stakeholders and their relationship to the commodities • Opportunities or problems the stakeholders saw within their supply chain • Contribution opportunities of each stakeholder to the Growth Initiative

Issue Prioritization

During Workshop 1, the team worked with the stakeholders to identify some

of the problems they saw in their respective supply chains. Prior to Workshop 2,

stakeholders were asked to rank their priorities for what they saw as the greatest

opportunity to focus the project on. These scores were then summarized to

create a prioritization matrix with the highest scores being the most important.

The top four issues, each with a score of 50 or greater were:

• Michigan Food Processing • Transport & Logistics • Exports and Value Chain • Michigan Animal Processing

15

Once priorities were determined, the team began to research current state

situations and best practices for each of the issues. The stakeholder’s priorities

are outlined in Table 1.

Table 1: Stakeholder Issue Prioritization Matrix

Overall Soybeans Corn

Dry Bean

Wheat General Stakeholders

Inbound Fertilizer 36 1 2 5 8 4 2 1 2 7 2 2 2.86

MI Food Processing 74 7 6 8 5 7 8 8 6 5 7 7 6.86

MI Animal Processing 50 6 8 4 1 5 4 3 5 3 6 5 4.43

Border Congestion 26 2 5 1 3 1 1 2 1 2 4 4 2.14

Exports & Value Chain 51 3 7 3 2 6 5 6 7 4 5 3 5.14

Transport & Logistics 66 5 3 7 6 8 7 7 8 1 8 6 6.43

IT & Decision Aids 47 4 1 6 4 3 3 4 3 8 3 8 4.57

Regulatory Congestion 46 8 4 2 7 2 6 5 4 6 1 1 3.57

*Score each issue with a number of 1-8, where 1 is the lowest priority and 8 is the highest priority. No number may be provided twice.

Data Analysis

End to End Supply Chain Process Maps were created using a combination

of stakeholder interviews and industry research. Process maps were evaluated

and critiqued by stakeholders during Workshop 1 with refinements made prior to

Workshop 2.

Supply and Demand Heat Maps were created using the software Tableau.

Harvest volumes were provided by United States Department of Agriculture

16

(USDA) from the National Agricultural Statistics Service (NASS). Elevator

capacities were provided by MDARD, and elevators volumes were collected from

MDARD.

All of the above mentioned data analysis tools such as The Process Maps,

Commodity Percentage Flow Through, and Supply and Demand Heat Maps, will

be displayed and discussed in each commodity’s respective section.

17

Design Specification Analysis

Research regarding design specifications was conducted regarding the topics of

animal processing, feed processing, food processing, and intermodal transportation.

Best practices were collected by researching online, interviewing stakeholders, and

conducting primary research. The focus of the research was in two key areas, structure

and operations. Within these two areas, additional information was collected on a

number of subcategories:

Structure: • Optimal Global Architecture • Supplier Integration • Internal Integration • Customer Integration • Strategic Alignment • IT Integration • Insourcing/Outsourcing • Visibility

Operations:

• Talent Management • Inovation Management • Risk Management • Agility (Parameterization) • Planning Effectiveness • Supply Chain Segmentation • Performance Management • Change Management

Animal Processing Design Specifications

Four major design specifications specific to animal processing were identified,

these consisted of physical environment, sanitation and hygiene, safety and shelf life,

and odor management.

18

Physical Environment:

Permanent equipment should be completely sealed to the floor, wall or ceiling.

Floor mounted equipment should be sealed or elevated six inches to allow for easy

cleaning (Saskatchewan Ministry of Health, 2011). Ventilation systems should be

designed, installed and maintained in order to prevent contaminants from collecting on

walls and ceilings and dripping on food and food contact surfaces (Saskatchewan

Ministry of Health, 2011). In areas where food is processed, packaged, stored or

received, and where utensils and equipment are kept or cleaned, the floors, walls and

ceilings should be constructed using specific material. This materials should be easily

cleaned, durable, impervious, light in color, smooth, non-toxic, and non-corrosive

(Saskatchewan Ministry of Health, 2011).

Sanitation/Hygiene:

There are several principles of meat hygiene that should be considered.

Microbial contamination should be reduced or eliminated by applying heat treatment at

the final processing state for extension of shelf life of products. It is important to

minimize microbial growth in raw materials, semi-manufactured goods, and final

products by storing them at a low temperature (Saskatchewan Ministry of Health,

2011). Companies can prevent microbial contamination of raw materials, semi-

manufactured goods, and final products during meat product manufacture through

absolute cleanliness of tools, working tables, machines, as well as hands and outfits of

personnel (Saskatchewan Ministry of Health, 2011).

19

Safety and Shelf Life:

Safety and shelf life involves employing predictive models to predict how well

products are protected against the growth of pathogenic bacteria. The use of predictive

growth models reduces the requirements for laboratory tests and documentation of

food safety and shelf life (Christensen, 2010). Results are presented using growth

curves and relevant values in order to allow the quality manager to easily evaluate

safety of a specific recipe or establish shelf life at different storage conditions

(Christensen, 2010).

Odor Management:

The meat processing industry has the potential for generating large quantities of

solid wastes and waste water, which can lead to offensive odors. Some management

techniques are simple odor masking systems. The most efficient long term solution is a

mixture of wastewater treatment, solid waste encapsulation, and plant scrubbing and

direct injection to the stacks (OMI Industries, 2014).

Examples of Best Practices:

Craig Mostyn Group’s Linley Valley Facility:

Australia’s first laser guided pork cutting robot was installed by this organization.

This robot uses a highly accurate laser imaging system to take measurements of a

carcass to produce cuts that are based on an animal’s individual anatomical features

(Mu, 2011). High precision cutting reduces contamination and wastage of meat due to

20

accidental cutting of the stomach from 4% to less than 1%. This also delivers a more

predictable cut of meat with consistent quality and increased yield of 1% per carcass

(Mu, 2011).

Karan Beef:

South Africa’s premier beef

product supplier which

accommodates 130,000 heads of

cattle. They utilize trimmings from

on-site deboning plant to pack a

range of value added products

including marinated, pickled, and

par-cooked products and

hamburger patties (Interpack,

2014). The packaging line is

composed of a box forming machine and four in line Triaflex Delta Robots (shown in

Figure 6), which by means of a smart vision system can pick flow-wrapped frozen

hamburgers, and load them into three flap lid boxes with different configurations and

sizes (Interpack, 2014). This reduces component costs and the number of interfaces by

using a single controller for the entire system based on a standard technology which

can be managed by a single engineer (Interpack, 2014).

Figure 6: Karan Beef Triaflex Delta Robot (Interpack, 2014)

21

Feed Processing Design Specifications

In animal feeding operations, animals are kept and raised in confined

facilities that handle animals, feed, manure, urine, and operational equipment. In

feed processing facilities, feed is brought to the animals rather than animals

grazing outside in fields. The team started by collecting data for animal feeding

operations in Michigan to model the current situation. Major design

specifications identified include equipment, personnel training and safety.

Equipment:

Feed processing plant equipment technology is expensive and advances

rapidly. Under these circumstances, proper equipment selection is a very

important factor in plant design. Currently, many plants are using manual control

of operating conditions and mix measurement monitoring. In the last few years,

technologies have changed, and the ability for software to analyze large amount

of data quickly provides more advanced real time conditions (FAO and IFIF,

2010). The team recommends that plants should move from manual to computer

controls of operating conditions and mix measurement monitoring.

Personnel Training:

Employees engaged in manufacturing and operations should be trained in

all national regulations and industry standards relating to product quality and

22

safety regulations (FAO and IFIF, 2010). These trainings sessions should be

documented to keep track of training level and gaps in training. Also,

effectiveness of trainings should be evaluated by several pre and post training

skill evaluation. Providing employees with job previews and making them aware

about their roles and responsibilities will be helpful to maintain feed safety (FAO

and IFIF, 2010). Government regulations are getting stricter in food processing

and better understanding of those regulations is critical to operate effectively in

today’s changing environment. Along with developing skillset in employees

processing units should also ensure that employees are qualified to maintain

equipment within regulations (FAO and IFIF, 2010). Food borne illnesses, along

with higher number of recalls, have resulted in increased demand for regulations,

guidelines and economic losses.

Food Traceability

Through research, the team identified opportunities to change food

traceability processes that would result in better food traceability, and in times of

recall, a quicker response with batch level data (Bailey, Robb, and Checketts,

2005). This will culminate into significant economic and reliability benefits in the

long term. In current scenario major stages involved in beef processing at a

packing plant are illustrated in Figure 7 (Bailey, Robb, and Checketts, 2005).

23

This current process breaks traceability at several stages. Our recommendation

is to develop two-step process. The first step of this process is the

implementation of identification system from farm to slaughter. The second step

of the process would be to track meat after it leaves the packing plant. This two-

step approach creates a "break" in traceability at the processing plant.

Figure 7: Schematic of Wholesale (Packer) Sector Stages and Linkage (Bailey, Robb, and Checketts, 2005)

24

Food Processing Design Specifications

Major design specifications for food processing involved internal food

traceability and a new microwave technology used for soybean processing.

Internal Food Traceability:

In today’s ever changing world, global supply chains are more complex than ever

and food items often pass through several touch points. Today more than ever, food

products regularly cross national boundaries. When any problem arises with the food

quality and food items must be recalled, a robust food traceability program becomes

critical to minimize the damage, economic loss and diminished brand value (Opara and

Mazaud, 2001). During the team’s research, the team identified a strong need to trace

food back to its origin during a food related recall or outbreak. Traceability to and from

storage elevators is important, but at the same time internal traceability is equally

important (Opara and Mazaud, 2001). Our research suggest to focus on two important

points:

• Capture all information related to all incoming, internal and outgoing commodity lot activities to track time and efficiency.

• Analyze information to define new handling procedures to optimize logistics costs and to minimize food safety risk.

Food Traceability Optimization:

Currently, elevators are using the elevator optimization model, which is limited to

identifying food items on the lot level. Based on research, the team recommends using

a lot aggregation optimization model for minimizing traceability effort. This method uses

25

a mathematical multi-objective mixed integer programming model (MIP) with a goal to

reduce costs and increase traceability in food supply chain (Thakur, Wang, and

Hurburgh Jr., 2009). This method uses grain lots from different bins for blending while

using the minimum number of storage bins. This model provides an effective method

for minimizing the traceability effort by minimizing the food safety risk. Moreover this

model also allows in using the maximum volume of grain present in a given bin

(Thakur, Wang, and Hurburgh Jr., 2009). The use of fewer bins for blending shipments

is also easier logistically and can lead to additional savings in terms of grain handling

cost and time.

Benefits of multi-objective mixed integer model will be to: • Minimize level of lot aggregation • Minimize number of storage bins used for blend grain for a shipment • Minimize discounts from blending

Examples of Best Practices:

Progressive Processing LLC:

A subsidiary of Hormel Foods Corp, based in Austin, TX. Hormel Foods is

a multinational manufacturer and marketer of consumer-branded food and meat

products. The Progressive Processing site is a state-of-the-art production facility

in Dubuque, Iowa spanning over 348,000 square feet. It is the first new

production facility that the company has built in more than 25 years and when

complete it will cost $89M. It currently employs about 90 team members and can

expand up to 300 people (Hormel Foods Corporation, 2010).

26

Progressive Processing was built according to the Leadership in Energy

and Environmental Design (LEED) Green Building Rating System, developed by

the U.S. Green Building Council for environmentally sustainable construction. It is

expected to be one of the first manufacturing plants and the only refrigerated

food processing facility to be LEED certified at any level (Hormel Foods

Corporation, 2010). The facility will use at least 25% less energy and water than

a plant built to meet current building codes and industry standards and was

constructed using materials with more than 36% recycled content. Hormel Foods

believes they will recoup the extra cost necessary to construct the

environmentally friendly facility during the first two years of operation (Hormel

Foods Corporation, 2010).

Intermodal Transportation Design Specifications

The goal for this analysis is to better understand the current transportation

and intermodal facilities being used by Michigan agriculture, study the gaps and

understand what improvements could be made.

The key improvement areas the team identified to narrow these gaps are:

• Achieve cost savings through efficient transportation modes • Increase the speed of commodity movement • Protect the quality of the commodity being moved • Enhance intermodal transportation.

Metrics measured regarding transportation include (Agora, 2010): • Increase of flow factor • Control of shunting services • Supply of road trucking services

27

• Extension of terminal opening time • Bonus-malus incentives for the use of interim storage space • Separation of rail-side and roadside handling • Task management according to pre-notification • Punctual rail services

The team first looked to understand where the crops were grown. Then, they

sought to understand the transportation available at these locations. Accordingly, the

team looked at the cropland distribution overlaid with the freeway and rail lines. The

cropland road interface is shown in Figure 8. This figure shows the thumb region is not

connected by the interstate system which provides difficulty to those looking to move

crops from this region. Next, the team sought to identify how the crop location is

influenced by railroad. Figure 9 shows the railroad connections are well distributed.

However, research revealed that there is a need for maintenance and repair on many

railroads in the Upper Peninsula as well as the Thumb region. The maintenance on

these rail routes will be essential to move crops away from the major product areas

such as the Saginaw Bay area.

28

National Railway

CSX Transportation

Norfolk Southern Railway

Consolidated Rail Corporation (Owned by CSX and NS) Other Railroads

Cropland Data Layer:

Figure 8: Cropland with Interstates and Highways (NASS, 2014)

Figure 9: Major Railways (MDOT, 2014)

29

Transloading facilities transfer material by using several modes of

transportation. While in transit, shipments are often transferred from one mode

of transportation to another. Figure 10 provides all the transloading facilities in

Michigan where the mode of transportation can be changed.

Examples of Best Practices

The State of California

California has the following intermodal hubs which are considered state-of-

the-art facilities. Michigan can look at these major projects for building intermodal

facilities and making modernizing existing intermodal facilities.

Figure 10: Transload Locations (MDOT, 2014)

30

• Intermodal Container Transit Facility (ICTF) modernization (Intermodal Transfer Facility, 2008)

• Southern California International Gateway (SCIG) construction (Port of Los Angeles, 2013)

• Alameda Corridor- near dock and on dock rail facilities (Alameda Corridor Transportaion Authority, 2014)

The State of Wisconsin

Wisconsin has a similar geographical location to Michigan as well as

similar harvest volumes, therefore it makes for a good comparison state.

Wisconsin has introduced a number of rural and light density rail funding

programs to improve connectivity. Two programs of interest are the Freight

Railroad Preservation Program and Freight Rail Infrastructure Improvement

Program, which aim to maintain continued rail service in abandoned rail tracks

and remote regions (Huntington, 2012). Also, the Wisconsin Department of

Transportation Multimodal Freight Network prioritizes highway corridors and

segments and gives WisDOT planning and programming staff more information

to prioritize freight projects (Huntington, 2012)..

BoxXpress:

BoxXpress is a licensed private rail operator in Germany specializing in

reliable and fast transportation of overseas containers between the German

seaports and inland destinations. Port of Hamburg has EUROKOMBI-Terminal,

which is an efficient rail station for combined cargo transport that helps with the

movement of goods.

31

RETRACK Consortium:

The RETRACK Consortium is a long-haul cargo transport from road to rail,

creating an effective and scalable freight corridor. The main objective of the

RETRACK project is to develop, demonstrate and implement an innovative and

market-tested rail freight service along an East-West trans-European corridor

(Retrack, 2015). High level of intra-rail competition will stimulate improvement in

rail service quality, the competitive position of rail operators in international

freight market, and the volumes of freight carried by intermodal rail operations

(Retrack, 2015).

Diverging Diamond Interchange:

Implementation of Diverging Diamond Interchange (DDI) in new roadways

servicing Intermodal centers (ATS/American, 2014). There are many safety and

operational benefits from the implementation DDI. The safety benefits include

fewer conflict points (14 for DDI, 26 for conventional) and better sight distance at

turns. The operational benefits include better storage between the ramp

terminals, lanes with multiple assignments in all directions and better signal

network synchronization (ATS/American, 2014).

Key Improvement Opportunities:

Through its research the team identified key improvement opportunities that

would be benefit Michigan agriculture. The recommendations are as follows:

32

• Leverage Michigan Department of Transportation (MDOT) financing programs for shipper and railroad loans to fund track improvements and trans load facilities.

• CSX’s Grain Express Load/Unload Program offers financial incentives for enrolled customers to load or unload a unit grain train within 15 hours. Michigan elevators can utilize this program to obtain substantial cost savings and also invest in efficient equipment for material handling (CSX Corporation, 2012).

• Maximize use of CSX TRANSFLO terminals in Detroit, Grand Rapids, Wixom, and Melvindale to obtain cost advantage (CSX Corporation, 2012).

• CN is offering Fleet Integration Program for grain shippers who are using privately owned, covered hopper cars (CN, 2014).

• EModal.com provides a way for intermodal customers to manage truck registries, appointments, dispatching, chassis rental billing and maintenance and repair (Advent Intermodal Solutions, 2012).

• Transitioning shipping from truck to railway has cost savings potential. As Table 2 shows below, each commodity could save millions of dollars by moving 10% of its transportation to rail.

Table 2: Railway Shipment Opportunities (Michigan Agri-Business Association, n.d.) Commodity Volume

Shipped Current Rail Shipment

Current Rail Quantity

10% increase in Rail Shipments

Cost Savings

Corn (bushels) 40M 50% 20M 24M $2M Soybeans (bushels) 40M 80% 32M 36M $2M

Wheat (bushels) 40M 40% 16M 20M $2M

Dry Beans (hundredweight) 3M 50% 1.5M 1.8M $3M Total Potential Savings $9M

A 10% increase in rail shipments leads to $9M in cost savings (based on savings of $0.50 per bushel)

33

Soybean Scenario Analysis Current State

Soybeans move through different stages and pass through several touch points.

The process starts with preparation and cultivation of the crop at the farm. Soybeans

then move from the farm either directly to a processing facility or to a storage elevator

and then to a processing facility. Approximately 80% of soybeans are sent to be

processed into soy meal, and 20% are processed into soy oil (Reinholt, 2014). The

end use of soybean products in the United States is human consumption, animal feed,

or export to other countries. Figure 11 below shows the end to end supply chain of

soybeans and details the life cycle of soybeans from crop preparation to consumption

(Reinholt, 2014).

Figure 11: End to End Supply Chain of Soybeans (Reinholt, 2014)

34

Production

In 2012, Michigan farmers produced 83.2M bushels of soybeans throughout 43

counties. The process map, current flow, and production locations of Michigan’s

soybean supply chain can be seen below in Figure 12 (Reinholt, 2014).

Table 3 provides the Michigan production volume in 2013 compared to the entire

U.S. this was provided by NASS. In 2013, 1.9M acres of soybeans were planted in

Michigan, or 2.48% of the total acres planted in the U.S. Per acre productivity for 2013

in Michigan was higher than the U.S. average, but prices were lower (NASS, 2014).

Figure 12: Soybean Process Map Current Base Case (Reinholt, 2014)

x

35

Table 3: Michigan Production Volume Comparison With US (2013) (NASS, 2014) Amount Produced (bu/acre) 2012 Price

Michigan 44 bu/acre (83.16 M bushel) $12.50/bu

United States 43.30 bu/acre (3317.33 M bushel) $12.70/bu

Table 4 outlines the quantity of soybean flows through different steps of the supply

chain. Quantities are in terms of soybeans produced in Michigan.

Table 4: Soybean Flow Through Supply Chain (Reinholt, 2014)

Figure 13 illustrates where Michigan soybeans are produced and the

number of elevators by county. In Figure 13, on the left side image, darker colors

represent higher levels of soybean production (NASS, 2014). On the right image, the

numbers refer to the number of elevators in the county while the colors represent total

elevator capacity for the county, with darker colors representing higher capacities

36

(MDARD, 2014). There is a strong correlation between soybean production, the

number of elevators and elevator capacity at the county level.

Demand

The demand for soybeans in Michigan is approximately 21M bushels. Michigan is

home to one soybean processing plant, located in Zeeland, which has processing

capacity of 10M bushels annually (Reinholt, 2014). The remaining 11M bushels of

soybeans used in Michigan must, therefore, be transported out of state to be

processed. The processes soybeans are then transported back to Michigan, primarily

for animal consumption. Table 5 provides a detailed grain flow analysis of Michigan

Figure 13: Soybean Production & Elevator Location by County (MDARD, 2014; NASS, 2014)

37

soybean use. In addition, Figure 14 shows the breakdown of soybeans exported to

various locations. Export data was provided by only one major elevator, which handles

approximately 2.76M bushels, or 3.5% or Michigan’s production. The assumption

being made is that the export ratios remain consistent for the majority of Michigan’s

soybeans.

Figure 14: Soybean Outflow Locations (Confidential Elevator Data, 2014)

Table 5: Soybean Outflow Analysis (Confidential Elevator Data, 2014)

38

Figure 15 shows soybean demand throughout Michigan, based on zip code,

separated by whether it is likely being fulfilled by the current in-state processor or by

an out-of-state processor. The assumption being made in this figure is that the current

facility in Zeeland is fulfilling the demand for the locations nearest to it until reaching it’s

10M bushel capacity, and everything else is being fulfilled by out-of-state processors.

Export Markets

Michigan provides approximately 2.5% of the U.S. soybean export market.

Soybeans make up approximately 21% of all U.S. agriculture commodity exports (Ye,

2014). Figure 16 shows the breakdown of various commodities and their relative sizes.

Figure 15: Demand Fulfillment for In-State and Out of State Processors

39

Figure 17: US Soybean Exports (% Share by Volume) (Ye, 2014)

Figure 16: US Agriculture Commodity Exports (Ye, 2014)

40

Of all soybeans exported from the U.S., approximately 63% are sent to China.

Figure 17 shows the breakdown of international export locations from the U.S..

While it makes up 63% of the total market, China primarily buys soybean oil.

Figure 18 shows the top export locations of both soybean meal and soybean oil. Figure

19 shows Michigan’s major export locations for 2013 and 2014.

Figure 18: Soybean Product Export Locations (unit: millions of bushels) (USDA, 2015)

02,0004,0006,0008,000

2013 Volume 2014 Volume

Figure 19: Volume for Export Locations (unit: bushels) (USDA, 2015)

41

Analysis The team’s analysis involves the quantitative and qualitative benefits and risks that

would likely arise from building an additional soybean processing plant in

Michigan. The model built for this analysis considers factors such as the optimal

location for a potential processing plant, a range of capacity ratings for a new plant, as

well as variables such as the amount of increase in animal production and various cost

assumptions. Assumptions of the soybean model include:

Increase in animal consumption will be proportional among all counties Soymeal yield of 47.5lbs per bushel Crush Margins will vary between domestic and export commodity soymeal, as

well as domestic and export specialty soymeal Market share assumption is applied on the net demand for MI soymeal Cost data for new plant is from a Remco Study done in 2004 One time new facility cost uses a 10 year compound average growth rate

based on PPI Annual operating cost uses a 10 year compound average growth rate of 2%

per year Assets are depreciated using straight line method over 10 years with 10%

salvage value Transportation rates are equal everywhere ($.18 per ton-mile) For transportation costs, “export” is the distance to South Bend, IN Soybean basis will increase $.10-$.35 for new processing facility Job creation based on IMPLAN software

Stakeholders who contributed to development and testing of the soybean model

include:

Michigan Soybean Promotion Committee Michigan Farm Bureau Economic Development Alliance, St. Clair County Michigan Department of Transportation

42

Model Findings This report assesses the potential for an additional soybean processing plant in

the state. In order to justify additional soybean processing in the state, additional

animals need to be raised. In order to justify additional livestock numbers, additional

livestock processing capacity needs to be created. It appears that the dairy, eggs and

perhaps the turkey and broiler industries are willing to expand their production and

processing capacity (Michigan Soybean Association, 2015). A new soybean processing

plant in Michigan would increase processing capacity beyond the current demand.

Therefore, we also looked into how an increase in Michigan’s animal processing

industry would increase current demand.

Hog production is likely to increase but whether or not it will increase enough to

justify a processing plant is a critical consideration. The recent agreement with

Clemens Food Groups to open a 10,000 head per day facility in Coldwater dramatically

improves the likelihood that a soybean processing plant would be successful. Hogs are

the dominant species with respect to soybean meal consumption in Michigan, and an

increase in their numbers will drive soybean meal demand more than other animal

species (Michigan Soybean Association, 2015).

Current conditions are well suited to expanded livestock production. Meat prices

are high and feed prices are declining. Livestock production appears to be moving back

to the Midwest from the Southeast and the West. Water issues and transportation

costs appear to favor the Midwest over other parts of the country. Increased production

in Michigan reflects this. Egg production in Michigan has increased at a faster rate than

43

any other state. Substantial increases in soybean production have driven the interest in

increased soybean processing (Michigan Soybean Association, 2015).

Another market fundamental that supports the growth of the livestock industry is

the growth of the global middle class, particularly in China. As incomes increase in

developing countries the demand for animal protein will increase at a faster rate than

the demand for other types of food. The U.S. food supply is considered safer than the

food supply in many other countries, which also bodes well for future exports.

We found that in order to achieve economies of scale that provide the most cost

effective operations, the optimal capacity of a new processing plant is 3000 tons per

day (tpd). However, there are risks associated with a processing plant that large, which

include, but are not limited to the need to significantly increase the livestock production

in-state, the ability to market excess soymeal outside the state of Michigan, as well as a

heavy reliance on higher crush margins for specialty soymeal. Table 6 shows the

baseline livestock data for Michigan as of 2012, as well as the proposed increase in

Michigan livestock used in this scenario.

44

Table 6: Baseline and Assumed Increase in the Number of Animals

Baseline (2012) % Increase

Livestock

(# of heads)

Dairy 375,000 10%

Layers & Broilers 14,500,000 20%

Turkey 5,000,000 0%

Hogs 2,300,000 50%

The proposed increase would boost Michigan soymeal consumption from

500,000 tons annually to 682,000 tons. The total demand for soymeal in Michigan

would amount to 1894 tpd, or 1044 tpd net demand after accounting for demand

fulfilled by current in-state processing.

Table 7 shows the soybean model output and the amount of soymeal in tpd that

would need to be marketed outside of Michigan under the initial proposed increase in

Michigan livestock, as well as what would still need to be marketed outside of the state

if livestock further increased in the state of Michigan. As the table shows, there would

need to be 1,498 tpd of commodity soymeal sold outside of Michigan, or 539,280 tons

annually, which is more than Michigan’s entire soymeal consumption as of 2012.

45

Table 7: Results of the Soybean Model

Scenario 2B above also shows that if livestock numbers increased enough to

nearly triple the current in-state soymeal demand, a 3000 tpd facility would still need to

market 865 tpd or 311,400 annual tons of commodity soymeal outside of Michigan.

Table 8 shows the same scenario, but with a 1500 tpd facility.

With flat net demand of 1044 tpd; IRR = 12.9% and Payback period = 7 Yrs

Scenario 2 New processor supply (tpd)

Domestic Balance (tpd) Export Balance (tpd) Total Margin for Processor

Commodity Specialty Commodity Specialty

3,000 752 84 1,498 666 $24,060,000

With increased net demand of 1923 tpd; IRR = 13.8% and Payback period = 7 yrs

Scenario 2b New processor supply (tpd)

Domestic Balance (tpd) Export Balance (tpd) Total Margin for Processor

Commodity Specialty Commodity Specialty

3,000 1,385 154 865 596 $25,130,000

46

Table 8: Results of Soybean Model with 1500 tpd Facility

In Scenario 1, the 1500 tpd facility is a better fit for Michigan demand with the

initial increase in livestock numbers, as the facility would only need to market 373 tpd or

134,280 tons of commodity soymeal annually. If demand were to increase further, the

1500 tpd facility would not have to export any soymeal even if they only captured 80%

of the net demand in Michigan. The 1500 tpd facility is a better fit to fill in-state demand

for soymeal, but with an IRR of 6% and a payback period of 10 years it would not

realize the economies of scale that a 3000 tpd facility represents.

Another risk of a 3000 tpd facility under the proposed scenario would be the

reliance on improved crush margins for specialty soymeal. Table 9 highlights the

impact of a 20% increase, as well as a 20% decrease to in-state and export specialty

crush margins.

With flat net demand of 1044 tpd; IRR = 6% and Payback period = 10 Yrs

Scenario 1 New processor supply (tpd)

Domestic Balance (tpd) Export Balance (tpd) Total Margin for Processor

Commodity Specialty Commodity Specialty

1,500 752 84 373 291 $10,890,000

With increased net demand of 1923 tpd; IRR = 6% and Payback period = 10 yrs

Scenario 1b New processor supply (tpd)

Domestic Balance (tpd) Export Balance (tpd) Total Margin for Processor

Commodity Specialty Commodity Specialty

1,500 1,125 154 0 221 $11,760,000

47

Table 9: Impact of Changing Specialty Margins

It is clear to see that the specialty margins have a large impact on the profitability

of a new plant, as a 20% decrease in specialty margins results in an internal rate of

return (IRR) drop of 2.84 percentage points. Likewise, a 20% increase in specialty

crush margins would result in an IRR increase of 2.69 percentage points. Overall a

3,000 tpd would present the highest returns for a new soybean processor in Michigan

due to the economies of scale advantages, but there are significant risks associated

with a facility of that size that would need to be addressed.

The study analyzed current consumption of soybean meal and looked at three

scenarios involved with increased animal production. Current consumption would

make a soybean processing plant problematic; however, a 30% increase in livestock

numbers would make a small scale but still commercial sized soybean processing plant

feasible. Increased hog production would have a particularly large impact on soybean

meal demand. Figure 20 shows results of a sensitivity analysis for a 3,000 tpd facility.

48

Assumptions in the analysis include:

Facility will fulfill 80% of Michigan's net demand Demand ratio of 90% commodity, 10% specialty Production ration is 75% commodity, 25% specialty

Figure 20: Model Livestock Demand and Export Sensitivity

In order to increase the probability of success, a soybean processing plant

should be located near the center of the Lower Peninsula or in the Saginaw Bay area.

This is near major areas of soybean production and the region is becoming increasingly

important in livestock production, especially dairy. This location would also be far

enough away from existing soybean processing plants to minimize competition from

those plants.

49

Figure 21 shows the

potential demand that

could be fulfilled by adding

an additional processor in

Michigan. This map

assumes that the new

processor is located in

Ithaca, and that demand is

fulfilled based on sending

products to locations

nearest the processor until

their capacity is met.

While the focus on

much of this report is on

the demand for soybean

meal, soybean processing also generates soybean oil. A firm that has experience in

both processing and marketing soybean oil as well as meal is more likely to be

successful than a new entrant into this industry. Soybean processing is a low margin

industry and the ability to control costs is extremely important, which is another reason

why an experienced firm is more likely to be successful.

Despite the positive trends in livestock production, there are several barriers to

increased livestock production and livestock processing, which is a necessary

Figure 21: Future State Potential Demand Fulfillment

50

precondition for increased soybean processing. It is important to determine which

communities are interested in increased animal processing. Community support is

important to overcome whatever opposition to a processing plant may exist. Also,

developing new labor saving technologies would improve the acceptance of animal

processing. The perceived problems of animal processing are greatest for pork

processing and to a lesser extent turkey and broiler processing. It is less of an issue

for egg and dairy processing. Employment opportunities for agri-food firms are not well

advertised, which is a barrier to the growth of the entire agri-food system. Despite the

state’s relatively high unemployment rate, there does not appear to be a strong interest

among workers in agri-food jobs. Finding qualified workers that are interested is a

particular barrier to the dairy industry.

A factor that hurts Michigan’s competitiveness is the poor state of its

infrastructure. Roads are in poor shape. Additional funding, most likely in some type of

tax or registration fees, will be necessary to improve the state of the roads. Improved

access to Canada through the construction of a second bridge in the Detroit/Windsor

region would improve access to the Canadian market. The state has good rail service

connected to the larger cities but short line service on rural routes heading north and

south is generally not considered as good. This is not likely to change as long as

demand on the short lines is high in the fall and early winter and tapers off during the

rest of the year. Improved internet access would improve the economic performance of

rural areas. The state also needs a natural gas policy. Michigan has a great deal of

natural gas and large storage facilities for storing natural gas, but pipelines to rural

51

areas are lacking. The lack of access to natural gas increases the cost of handling

grain and maintaining grain quality.

Regulations are a consistent point of contention between members of the agri-

food system and the general public. The reality is that regulation will continue to be an

issue. Consumers, retailers and other groups are becoming more demanding with

respect to how food is produced throughout the supply chain. Farmers and processors

will need to be more responsive to these demands. Environmental sustainability will be

of increasing importance for farmers and processors as retailers and other firms

institute their sustainability policies. Animal welfare will be another concern that will

need to be addressed in order to meet the demands of retailers and consumers.

Increasingly, these issues will be determined by economic agents other than

government agencies. Research and extension will need to play a role in aiding the

affected industries in developing policies to address these regulatory issues.

Soybean processing creates two primary products, soybean meal which is used

for animal feed and soybean oil which is primarily used as a cooking oil, and is also

used an input into other food products. To be successful a soybean processor will

need to effectively market both those products. An experienced firm will be more

successful than a new entrant. Soybean processing is a narrow margin industry that

exhibits economies of scale; as a result the ability to control costs will be very

important.

There is one soybean processing plant located in Zeeland. This location is

excellent to meet the needs of the growing poultry industry and there are some large

52

hog and dairy farms in the area as well. However, there is no room for growth at that

location and a new facility in the region may create too much competition. A facility

located in Central Michigan or the Saginaw Bay region would have the potential to

obtain soybeans without excessive competition from the facility in Zeeland or the large

soybean crushing plants located in Ohio and Indiana.

Determining the impact of a soybean plant on soybean prices is difficult to

determine. A conservative estimate is that the price would rise 5 to 10 cents a bushel

in the area that is serviced by the plant. While there is some variability in price from

year to year it should be noted that soybean prices in Ohio and Indiana tend to be

around 30 cents a bushel higher than the price in Michigan. In addition to these states

having closer access to major markets, they are also home to several large soybean

processing plants. The most likely scenario is that soybean prices will increase about

20 to 30 cents in Michigan if there were another soybean processing plant in the state.

Increased soybean processing in Michigan would increase the profitability of soybean

farming and has the potential to reduce the feed cost of some livestock producers in the

state.

53

Corn Scenario Analysis Current State

Corn moves through different stages and passes through several touch points

along its supply chain. The process starts with preparation and cultivation of the crop at

the farm. Corn then is moved from farms to elevators and then to processors. From

processors, processed corn is directed to either ethanol production, human

consumption, used as livestock feed or sold in the export market (Zook, 2014). Figure

22 provides end to end supply chain map of corn. It explains life cycle of corn from crop

preparation to consumption in detail.

Figure 22: Corn End to End Supply Chain (Zook, 2014)

Figure 23 shows the current state process map for corn in Michigan. As the map

highlights, there are four main uses for Michigan corn; exporting corn directly, food-

54

processing use, feed processing, and ethanol production. The team’s analysis of the

corn supply chain in Michigan was centered on these four uses.

Figure 23: Corn Process Map (Zook, 2014)

The amount of Michigan corn that flows through the various stages of the supply

chain and final markets is shown in Table 10. Currently, 115M bushels or 34% of

Michigan’s crop is used in-state to produce ethanol. In total, 145M bushels or 43% of

the crop is exported out of Michigan, and 80M bushels or 23% of the crop is consumed

in-state for feed use (Zook, 2014).

55

Table 10: Corn Flow Through Supply Chain for 2013 (Zook, 2014)

Production

Figure 24 highlights where corn is grown in Michigan, as well as where Michigan

grain elevators are located throughout the state. As the figure indicates, the elevators

are concentrated in the counties that produce the most corn in Michigan.

56

Figure 24: Corn Production and Elevator Capacity by County (NASS, 2014); (MDARD, 2014)

Table 11 provides comparative data of Michigan corn acreage with U.S. corn

acreage. In 2013, Michigan planted 2.6 Million acres of corn, 2.73% of total acreage

devoted to corn in the U.S. This figure compares growth efficiency (bushels per acre)

as well as prices per bushel for Michigan and the rest of the U.S.

Table 11: Michigan Corn Production Volume Comparison with U.S. (2013) (NASS, 2014)

Production Efficiency 2013 Price

Michigan 155 bu/acre $4.05/bu

United States 158.8 bu/acre $6.15/bu

57

Locations of in-state corn processors and ethanol plants are highlighted in Figure

25, along with elevator capacities by county. The darker the color in the production map

the greater the level of corn production. The number of elevators and capacity is

strongly correlated with the level of corn production. As the figure indicates, the corn

processors in Michigan are not concentrated around the highest producing counties in

the state.

Figure 25: Locations of Corn Processors and Grain Elevator Capacity (MDARD, 2014)

Demand

Data analysis was hindered by the lack of participation from in-state elevators,

but the data that was collected helped to highlight where Michigan corn is shipped to

58

out of state. As Figure 26 indicates, the majority of MI corn is sent to the southeast

United States. It is assumed that the data that we could not collect would represent a

similar outflow map

Figure 26: Corn Outflow Locations

The corn being sent to the Southeast United States is used for primarily for hog

and poultry feed, as well as some ethanol production (Confidential Elevator Data,

2014).

(Confidential Elevator Data, 2014)

59

Again, due to limited participation the data represents a small portion of Michigan

production, but it is assumed that the rest of the data would reflect similar end users of

Michigan corn.

Historical usage statistics are represented in Table 12. As the historical data

shows the corn usage in Michigan stays within a small range in terms of percentage of

Michigan production. It should be noted that the 2014-15 figures are estimates.

Table 12: Michigan Corn Usage Statistics (numbers in millions of bushels) (The ProExporter Network, 2014)

Figure 27 shows the largest export markets of U.S. and Michigan corn. As

pictured Japan, Mexico, and China are the leading buyers of U.S. corn.

2012-13

Percent of Supply 2013-14

Percent of Supply 2014-15

Percent of Supply

Production 318 349 342

Supply 343 369 371

Feed / Residual use 72 21% 103 28% 91 25%

Feed use 62 18% 74 20% 69 19%

Dairy 29 8% 35 9% 33 9%

Beef cattle 5 1% 6 2% 6 2%

Hogs 16 5% 18 5% 17 5%

Poultry 10 3% 11 3% 11 3%

Other 3 1% 3 1% 3 1%

Dry milling-Ethanol/

Processing in state 93 27% 101 27% 101 27%

Total use in state 165 48% 203 55% 192 52%

Net Exports 178 52% 166 45% 179 48%

60

However, as Figure 28 shows, Canada is the leading buyer of Michigan corn

followed by Mexico and Jamaica. Canada is a natural market for Michigan corn due to

Figure 28: Top Exporters of Michigan Corn by Percentage of Crop (USDA, 2015)

Figure 27: Top Exporters of US Corn by Percentage of Crop (USDA, 2015) (

Japan37%

Mexico25%

China13%

Venezuela6%

Taiwan3%

S. Korea2%

Canada2%

Saudi Arabia2%

Cuba2%

Jamaica1% Others

7%

00.050.1

0.150.2

0.250.3

0.350.4

0.450.5

0.550.6

0.650.7

0.750.8

0.850.9

0.951

Canada Mexico Jamaica Honduras Trinidad &Tobago

Sweden Barbados

20132014

61

the close proximity. However, the spike in 2014 Canadian consumption was a product

of a poor crop year, and should not be considered typical in terms of export potential.

Figure 29 highlights what MI corn is used for, as well as which livestock groups

are consuming the most Michigan corn.

Figure 29: Michigan Corn Utilization

Analysis

Figure 30 is a description of the proposed scenario analysis that was the

foundation for developing the corn model. This scenario is a result of discussions with

industry leaders and project stakeholders.

(Michigan Corn Growers Association, 2013)

62

Figure 30: Corn Supply Chain Scenario Proposal

The model was used to analyze the impact of additional livestock in Michigan,

increased in-state ethanol production, as well as shipping corn to Canadian processors

directly from the farm. The rationale behind the model was to assess how increasing

livestock and ethanol production in Michigan would impact corn consumption, as well

as the total supply chain savings that could result from large Michigan farmers shipping

corn directly to Canadian feed processors. There are some constraints associated with

the model. First, there needs to be a strategy in place to increase the livestock numbers

in Michigan in order to increase consumption. Next, there must be a market for the

increased ethanol production. Finally, Michigan farmers must have the trucking

capability to ship corn to Canadian processors directly.

63

Assumptions that were used to develop the corn consumption model include:

Livestock consumption was computed on a per head basis from the 2012 baseline data

Any livestock increases in the model would impact corn consumption in Michigan instantly

A new ethanol plant is intended to compute only the impact on Michigan corn consumption and basis improvements, and does not take into account the feasibility of a new plant.

The model does not take into account whether Canadian processors would be willing or able to accept shipments directly from Michigan farmers

The baseline margin savings calculated if farmers were to ship to Canadian processors directly is computed as $0.25 per bushel, but the number can be adjusted to reflect different ranges of total system savings between Michigan farmers and Canadian processors

The basis impact of a new ethanol producer in Michigan is computed as $0.0193 per additional million gallons of ethanol produced

Ending stocks in the model are calculated as an average percent of total supply, or 6.8% annually.

Figure 31 summarizes the key findings from the model. Increasing the total

number of livestock in Michigan (10% increase in dairy, 20% increase layers and

broilers, 0% change turkeys, and 50% increase for hogs) would boost Michigan corn

consumption for feed from 67M bushels to 77M.

64

Figure 31: Corn Model Findings

Table 13 shows the total system savings that could be achieved if Michigan

farmers were to ship directly to Canadian corn processors. The savings were calculated

by assuming exports to Canada would remain constant around 10M bushels.

Production was calculated on a per county basis with 38% of corn leaving each county

by rail. Next, out of the remaining production in each county, it was assumed that only

35% of the production would be from farmers large enough to ship directly to Canadian

processors. Finally, the nearest 10M bushels were calculated from each county to

London, Ontario, using a standard rate of $0.18 per ton mile in order to calculate the

transportation cost. The overall system savings split between Michigan farmers and

Canadian processors is represented by the total bushels shipped multiplied by the

margin savings from bypassing elevators.

65

Table 13: Impact of Shipping 10 Million Bushels of Corn Directly to Canada

In conclusion, additional livestock in Michigan, ethanol production in Michigan, and

increased farm direct shipments to Canadian processors could result in significant

supply chain improvements. The proposed livestock increase in Michigan would result

in an additional 10M bushels of corn consumed in-state, which would reduce

transportation costs, as well as increase local basis for farmers. A new ethanol

processor using 20M bushels of corn would have a $21.6M impact on Michigan’s

economy as a result of the increased basis. Finally, Michigan farmers shipping corn

directly to Canada would result in a $2.5M savings split between MI farmers and

Canadian processors.

66

Wheat Scenario Analysis Current State

Michigan is home to approximately 6,300 wheat producers throughout 40

counties, and they produced 45M bushels of wheat in 2013 (NASS, 2014). The wheat

production process starts with preparation and cultivation of the crop at the farm. Wheat

then moves from the farm to storage facilities either on the farm itself or to one of 112

storage elevators (MDARD, 2014). From storage facilities, wheat moves to milling

processors. The end use of wheat products in the United States is human consumption

or exportation to other countries. Figure 32 below shows the end to end supply chain of

wheat and details the life cycle of wheat from crop preparation to consumption.

Figure 32: Wheat End to End Supply Chain (Pollock-Newsom, 2014)

67

Figure 33 shows wheat production and processors location in the state. It shows

that Huron, Sanilac and Lenawee counties are the largest wheat producing counties.

Four of the six large wheat processors are located in the southern part of the state.

The complete wheat process map is shown in Figure 34.

= processor

Figure 33: Wheat Production and Processor by County (NASS, 2014); (MDARD, 2014)

68

Figure 34: Wheat Process Map (Pollock-Newsom, 2014)

Demand

Michigan’s 112 wheat storage elevators have the capacity to store approximately

30M bushels to be processed by the six wheat milling facilities, which are primarily

located in the southern portion of the state. The milling companies process

approximately 40M bushels annually, with the remainder being exported for processing.

The processed wheat is then sent either to bakeries or cereal companies to be used in

consumer goods (70%) or exported to be used out of state (30%) (Pollock-Newsom,

2014). This supply chain flow is shown in more detail in Table 14.

69

Table 14: Wheat Flow Through Supply Chain (Pollock-Newsom, 2014)

Analysis Our analysis follows the wheat from harvest through its end use, which is either

human consumption or animal feed. The purpose of our analysis was to identify

opportunities for cost savings and increased efficiencies throughout Michigan’s wheat

supply chain. A general trend across the U.S. of reducing the amount of acreage

devoted to wheat creates an opportunity for Michigan wheat farmers to fill this demand.

Michigan wheat can be used to supplant wheat currently coming from other states. A

20% increase in wheat production compared to the 2013 figures would increase wheat

revenue by $60.3M, and would have total economic activity of $105M while providing

70

an additional 785 jobs in grain production and 1,131 jobs overall. The primary

implications of our wheat analysis include:

A reduction in wheat acreage in the U.S. creates an opportunity for increased

wheat production and processing in Michigan Increased production of red wheat varieties could increase demand for Michigan

wheat and refined milling process increase market for red wheat Potential for increased milling capacity in Michigan

Key assumptions in our research include:

There is an increased interest in locally produced and sourced food The market for white wheat remains relatively strong Most bakeries are located relatively close to population centers Cereal companies and others have a vested interest in maintaining the white

wheat industry Growers remain interested in producing wheat

Primary constraints and obstacles include:

Market research must be done to determine the varieties of wheat that processors prefer

White wheat disease (deoxynivalenol) issues need to be addressed Increase in resource allocations for research and development of the wheat

supply chain

Moving forward, determining the optimal balance between red/white wheat and

spring/winter will be helpful to formulate a long term strategy. In addition, changes in

prices of other commodities such as soybeans and corn could encourage farmers to

devote more or less acreage to wheat.

71

Dry Beans Scenario Analysis Current State

Michigan farmers produce approximately 3.4M hundredweight (cwt) of dry beans

annually (NASS, 2014). Unlike the other crops, dry bean production is concentrated in

a few counties in the Central and East Central part of the state. Huron and Tuscola

counties are the leading producers. Figure 35 shows Michigan’s dry bean production

and processors by county.

Figure 36 shows the process map of the dry bean supply chain, beginning with

the production and going through to retail locations.

Figure 35: Michigan Dry Bean Production and Processing by County (NASS, 2014), (MDARD, 2014) and (Cramer, 2014)

72

Figure 36: Dry Beans Process Map (Cramer, 2014)

Due to the nature of the industry and confidentiality concerns, dry bean

stakeholders were unwilling to provide us with significant data. The team was able to

put together a supply chain flow through map (Table 15), but were unable to fill in all of

the details based on the information provided. The stakeholders did share that

domestically, dry beans are primarily transported by truck or railroad. Internationally,

beans staying in North America are often transported via railroad, or via container ships

overseas.

73

Table 15: Dry Beans Flow through Supply Chain

Analysis

The team’s analysis looks into increasing the supply of dry beans produced to

increase the quantity exported, and the additional revenue and job opportunities that

would be created. In addition to increasing the supply of Michigan dry beans, we

looked into potential opportunities to alter the mix of beans grown throughout Michigan.

Recent years have seen changes in taste preferences, partially due to an increase in

the population of Latin Americans throughout the U.S. shown in Figure 37. In 2009,

there were approximately 48.4M Latin Americans in the U.S., which made up 15.75% of

the U.S. population. By 2013, there were nearly 54M, making up 17.1% of the

population (United States Census Bureau, 2014). The countries with the most

representation are Mexico, Puerto Rico and Cuba (United States Census Bureau,

2014).

74

Figure 37: The Growth of the Hispanic Population 2009-2013 (United States Census Bureau, 2014)

One major commonality among those populations is high demand for chickpeas,

a bean with a $115M U.S. market that Michigan farmers do not participate in. Table 16

shows popular beans in a variety of countries as well as varieties grown in Michigan.

48.36

50.74

51.94

52.96

53.99

15.75%

16.40%

16.67%

16.87% 17.08%

15.0%

15.5%

16.0%

16.5%

17.0%

17.5%

47

49

51

53

55

2009 2010 2011 2012 2013

Millio

ns

Hispanic Population Hispanic as % US

75

Key Implications of this scenario analysis consider the following:

An increase in Hispanic populations in the U.S. is driving a change in varieties of dry beans in demand

An increased supply of dry beans and expanded exports will generate increased revenue and job opportunities

Will potentially create a need for additional processing capacity and shipping capacity, particularly in the Saginaw Bay & Thumb region

May not drive the creation of new assets, but could lead to increased utilization of current assets

Key assumptions of scenario include:

Hispanic populations throughout the U.S. will continue to increase Consumption of beans is changing based on changing population demographics Lower corn and soybean prices will increase the acreage devoted to dry beans Normalization of relations between Cuba & the U.S. will increase the demand for

dry beans in Cuba

Table 16: Popular Dry Bean Varieties in Various Countries (The Bean Institute, 2015)

76

Apart from changes due to Hispanic populations, consumption trends of legume

crops worldwide show increasing demand going to Africa, Asia and the Americas (see

Figure 38) (Akibode and Maredia, 2011).

Figure 38: World Pulse Consumption Projections (Akibode and Maredia, 2011)

Based on the assumption that Hispanic populations in the US will continue to rise

and that these changing demographics will continue to alter the consumption mix, it

makes sense for Michigan farmers to consider changing the varieties that they are

currently growing. In addition, if we see lower prices of other commodities such as corn

and soybean, farmers can begin devoting more acreage to dry beans. A 20% increase

in dry bean output compared to 2013 will increase revenue by approximately $28M. It

77

would also provide additional employment opportunities in bagging and processing

facilities.

In order to accomplish this, Michigan farmers must overcome increasing

competition from Minnesota and the Dakotas, as well as Canadian farmers. The team

also considered that there might be increasing demand for dry beans coming from

Cuba as U.S. relations are normalized with the country. The White House has recently