Sprint 2 - Optical Design Manufacturing NSN 2.5 Manual Rev B.pdf · AC 015 Pelican Style Hard Carry...

Transcript of Sprint 2 - Optical Design Manufacturing NSN 2.5 Manual Rev B.pdf · AC 015 Pelican Style Hard Carry...

Sprint 2.5

Fiber Inspection and Testing Procedures

NSN Radio

Optical Design Manufacturing, Inc.

Technical Support Document

2

Table of Contents

I. Introduction...................................................................................................

II. Test Site Overview.........................................................................................

III. Equipment....................................................................................................

IV. Fiber Optic Endface Inspection and Cleaning...............................................

V. dB Loss Testing.............................................................................................

VI. Closeout Documentation.............................................................................

VII. Technical Support and FAQ........................................................................

3

4

5

7

14

18

22

3

I. IntroductionThis document will serve as a guide to perform the testing procedures for the fiber optic portion of the Sprint NSN 2.5 GHz cellular tower build. Technicians will utilize equipment from Optical Design Manufacturing to inspect, clean, and save images of fiber endfaces, as well as test for light loss on the optical cables.

This user guide contains the following sections:

• “Test Site Overview” describes the layout of the optical fibers in the cellular tower installation.

• “Equipment” provides detailed information on the TTK 650 Test kit and how to use it for the Sprint NSN 2.5 GHz installation.

• “Fiber Optic Endface Inspection and Cleaning” outlines the steps taken to ensure endface quality prior to testing installed systems.

• “dB Loss Testing” describes how to test the dB loss of the trunk cable and the full system.

• “Closeout Documentation” explains how to save and report images and loss values.

• “Technical Support and FAQ” provides contact information for ODM technical support and answers several frequently asked questions.

4

II. Test Site Overview

ODC Connection

Base Unit

Trunk Cable (24 pairs)

Paired Sector Cable (6 primary pairs per sector)

Remote Radio Unit (RRU)

Tower fiber optic installations will contain:

• One (1) Base Unit

• One (1) Trunk Cable consisting of twenty four (24) LC-ODC pairs

• Eighteen (18) ODC-LC Sector Cables (6 per sector)

• Three (3) Remote Radio Units (RRU’s)

Tower installations require a certified climber to perform the test procedures associated with the top of the tow-er. The illustration below shows the typical installation to be tested.

5

This section provides details on the equipment required to perform the following tasks associated with the Sprint NSN 2.5 installation:

• System dB loss

• Portable video inspection of all optical fiber connectors

• Complete endface cleaning of all connector interfaces

• Closeout documentation

III. Equipment

TTK 650 Test Kit

6

TTK 650 Test Kit - Bill of Materials

MODEL DESCRIPTION APPLICATION QTY.DLS 355 Dual Laser Source 1310nm/1550nm SC Conn. Single mode fiber light source for dB loss testing 1RP 460 Power Meter w/ Zero dB/Set Ref, 1000 data point

store & USB download to OpTest SoftwarePower meter used with light source for dB loss measurement and storage, and USB transfer to PC for closeout documentation

1

VIS 400 Video Inspection Scope w/USB and InSpec™Software, LC, SC, 1.25mm and 2.5mm adapter tips included

Portable connector inspection device to view connector endfaces and ensure connectors meet IEC standard after proper cleaning

1

TAB 008 Dell Tablet (or equivalent) with Case and Charger Allows for touch-based fiber endface inspection with the VIS 400 HDP probe and inSpec application

1

AC 029 LC Adapter for RP460 Optical Power Meter Allows LC connection to optical power meter 1AC 300 CR2 Battery Kit / 5 per pack Spare Battery Kit 1AC 523 LC-clipped LC-SC, SM, 9/125 Fiber, 1 Meter Cable Fiber patch cord to allow calibration of test instruments for

complete system dB loss test1

AC 4500 SM Loopback with Lanyard Allows for calibration of equipment and test of loopback installations

1

VF 610 635nm Red Laser Allows user to observe bends and breaks in optical fiber 1AC 602 LC-LC Adapter LC adapter to allow access to LC duplex connector on Optical

Jumper Cable1

AC 805 Micro USB Cable Stream live images of fiber endfaces from VIS 400 to Dell Tablet for endface inspection and closeout documentation

1

CK 092 SqR Pad with Fiber Wash Pen Wet/Dry cleaning system for connector endfaces 1AC 089 One Click Connector Cleaner For LC connector ends and bulkheads for quick “dry” clean

only1

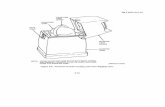

AC 015 Pelican Style Hard Carry Case Large protective carrying case for all instruments and accessories

1

AC 063 Accessory Kit - Sprint NSN 2.5

MODEL DESCRIPTION APPLICATION QTY.AC 062 Paired Pin and Socket ODC Cables Two cables allow for calibration of equipment and dB loss

test on ODC connectors1

AC 153 ODC Adapter Kit Allows for inspection of fiber optic endfaces in ODC-style connectors, both pin and socket

1

AC 014 Soft Padded Accessory Pouch Protective carrying case for instruments and accessories 1

7

IV. Fiber Optic Endface Inspection and Cleaning

Contamination of fiber connector surfaces is the top reason for link failure in the installation of optical fibercable. It is imperative for installers and technicians to follow the guidelines in this section in order to ensure thequality of the connector endface prior to testing installed systems.

The following inspection and cleaning procedures should be used before installing or testing any fiber optic jumper or trunk cable. Only use approved test sets, inspection equipment, and cleaning supplies. Any move-able debris on a fiber optic connector endface is not allowed. After three dry cleaning attempts to remove debris, a “wet/dry” cleaning process is recommended. Pass or Fail ratings on fibers are determined according to the IEC document 61300-3-35 Ed 1.0.

CleaningThe inSpec software offers automated pass/fail of fiber endfaces when receiving images from the VIS 400inspection scope. Inspect fiber endfaces to determine viability; always clean until all moveable debris is clearand endface is as clean as possible.

Before Cleaning After Cleaning

Auto-analyzed images from VIS 400 using inSpec software

8

Dry Cleaning

One-click cleaner - Push fiber ends into the adapter on the one-click cleaner until the unit clicks. For fibers in-side bulkheads, remove plastic cap from one-click cleaner and insert into the bulkhead opposite the fiber. Push until unit clicks.

Cletop cleaner - Using the lever on the side of the unit, retract the sliding door to reveal the lint-free wipe. Press the fiber endface into the top of the wipe and drag downward with moderate pressure.

The one-click cleaner can be used similarly on the ODC-style connectors. For ODC-Pin connectors, the adapt-er cap on the cleaner allows the unit to reach the recessed ferrules. For ODC-Socket connectors, remove the plastic cap from the cleaning tool and insert the thin tip of the cleaner into the socket, then push to clean.

9

Wet/Dry Cleaning

SqR pad and fiber wash pen - Isolate a lint-free wipe using the attached card, then apply a coin-sized spot of cleaning solution to the top of the wipe using the fiber wash pen. Press the fiber endface into the wet spot on the wipe, then drag the fiber downward to the dry portion of the wipe, applying moderate pressure.

NOTE: To verify the most recent test, inspection, and closeout documentation requirements, or if cleaning does not produce acceptable results, contact your construction manager or follow the appropriate Sprint 2.5 escalation procedure.

1.25mm and 2.5mm swabs - Moisten the tip of a cleaning swab on a wet SqR pad, then gently insert and wipe across the appropriate fiber endface. A gentle twisting and “pumping” motion is most effective.

10

Inspection

Installations will require the inspection and grading of all fiber ends in the trunk and sector cable to comply with IEC 61300-3-35. Technicians will archive all trunk and sector fiber ends as a pre-test when required. Saving im-ages is vital to the correct documentation of services rendered for the customer; saved images may be needed for future troubleshooting.

1. To connect the VIS 400 to the tablet, plug the micro USB adapter cable into the tablet’s micro USB port, then plug the VIS 400 into the USB 2.0 port on the adapter cable. To connect the VIS 400 to a PC, simply plug the VIS 400 into a USB 2.0 port on the computer.

2. Open the inSpec software and navigate to the “Test Settings” tab at the top of the window. Set theAnalysis Mode to Automatic, the Fiber Type to Single Mode, and the IEC Profile to Single Mode UPC, asshown below. The VIS 400 will show up in the Video Source drop-down menu under “ODM HDP Probe”or “USB 2.0 Camera”.

3. To save site location and other data along with images, navigate to the “Report Settings” tab in inSpec and fill out all of the fields in the window. This information will be available in VIS reports.

4. Navigate to the “Main” tab in the inSpec window.

11

5. Using the 1.25mm universal inspection tip on the VIS 400, inspect the endfaces of trunk and sector LC pairs.

6. Use the focus wheel on the VIS 400 probe to obtain a focused image in the inSpec window. The blue barbelow the image window indicates the current focus level. A higher focus will give a clearer image.

Focus Method

12

7. Touch or click the Analyze button to the left of the image to begin the auto pass/fail analysis.

8. When the analysis has finished, inSpec will display a still image of the fiber endface with a green PASS orred FAIL marker in the top left corner. If the fiber end does not pass automatic analysis, clean the fiber,re-focus the image, and try again.

9. If the image receives a PASS, touch or click the button that reads “Capture Image,” just under theanalyze button. A “Save As” dialogue box will pop up. At this point, you can create a new folder in whichto save the images. It is a good idea to name the folder with the location information to helpdifferentiate between sites.

10. Name images using ODM’s naming convention for optical fiber endface images. See chart below.

13

11. To inspect the the paired ODC pin connectors (at the top of the riser cable), use the ODC pin inspection tip for the VIS 400. Repeat steps 6-9 to perform the automatic analysis procedure.

12. Name images using ODM’s naming convention for optical fiber endface images. See chart on page 12.

13. To inspect the paired ODC socket connectors (at the bottom of the sector cables), use the ODC-socket in-spection tip for the VIS 400. It may be necessary to use the keyed adapter plate to align the inspection tip with the sockets. Repeat steps 6-9 to perform the automatic analysis procedure.

14. Name images using ODM’s naming convention for optical fiber endface images. See chart on page 12.

NOTE: To verify the most recent test, inspection, and closeout documentation requirements, or if cleaning does not produce acceptable results, contact your construction manager or follow the appropriate Sprint 2.5 escalation procedure.

14

V. dB Loss TestingdB loss testing is the process of determining how much light is lost along the length of fibers under test. Techni-cians must use an approved light source and power meter along with appropriate test jumpers to complete the test. The dB loss test procedures outlined below will be performed on the fiber runs for each sector.

Technicians will perform two separate sweeps for dB loss readings:

1. All fibers as a pre-test - readings do not need to be saved2. Full system as an on-site test - 8 readings per sector

Pre-Test

1. Connect the RP 460, DLS 355, AC 523 loopback jumper, AC 062 ODC assembly, and loopback module together using LC bulkhead adapters as shown below.

2. Turn on both the RP 460 and the DLS 355 and set them to a wavelength of 1550nm.

3. Put the RP 460 into dBm mode by pressing the dB/dBm key on the unit. The RP 460 should read between -3 and -5 dBm when all fibers are clean and connected correctly.

4. Once the RP 460 is holding a steady reading in dBm mode, hold down the dB/dBm key for four seconds. The RP 460 will switch to dB mode and read 0.00dB. Do not switch the unit back to dBm mode; all testing will be done in dB mode.

15

5. At this point, the equipment has been calibrated. In order to test the loss of the riser and sector cables, those cables must be inserted into the full system that was established in Step 1. Accordingly, the reference cable from the AC 062 jumpers which corresponds to the riser or sector cable must be removed and replaced by the cable under test.

Example: The riser cable consists of 24 fiber pairs, which are LC pairs at the bottom and ODC-Pin pairs at the top. To test the riser cable, the user must remove the cable with those same connectors from the full test setup and place the first riser pair into the system. See image below.

ODC-Pin Connector

LC Pair Connector

As shown here, the first ODC cable in the full system setup (established in Step 1) has the same connectors as the riser cable. When this cable is removed and the riser pair is clipped/inserted into the system setup, the loss of the riser pair will be shown.

6. When all jumpers are in the correct position, the loss along the riser and sector cables will be displayed in dB on the RP 460 screen. This number may not exceed 3.0 dB. If this number is between 0 and 3.0dB, insert the next riser pair and move on. If this number is over 3.0 dB, clean all connections and try again. Negative read-ings are not acceptable. Readings do not need to be saved.

NOTE: The pre-test procedures must be carried out for each pair in the riser and sector cables as outlined above. When testing sector cables, remember that they will contain the opposite connectors (ODC-Socket) as shown above, so a different cable must be replaced in the full system setup.

16

On-Site Test - 8 Loss Readings Per Sector

The RP 460 Optical Power Meter and the DLS 355 Dual Laser Source will be used to perform the dB loss pro-cedure on the riser/sector cable combination.

1. Connect the RP 460, DLS 355, AC 523 Duplex Jumper and the loopback module together as shown in the image below. Power on the RP 460 and DLS 355. Set both units to 1550nm. Set the RP 460 to dBm mode.

2. Make sure the RP 460 is reading between -3dBm and -5dBm. If the reading is outside of this range, inspect and clean all optical fiber connector endfaces, including the output connector of the DLS 355, and try again.

3. Press and hold the dB/dBm key for 4 seconds until you hear a second beep. The RP 460 will now display 0.00 dB. The reading may fluctuate up to 0.05 dB in either direction; this is normal.

17

4. Remove the loopback module with LC duplex bulkhead adapter from the paired cable and send it to the top of the tower. Connect the loopback module to the first sector cable pair (that will be plugged into the radio) at the top of the tower.

5. Connect the paired calibration cable end (that was attached to the loopback) to the first pair of the main trunk cable at the base of the tower using an LC-LC duplex bulkhead adapter.

7. Continue to perform the dB loss test procedure on each remaining fiber run between the bottom of the riser and top of the sector cables, then perform the same tests on the trunk/sectors for the Beta and Gamma sec-tors. In total, 24 dB loss readings (6 primary and 2 spare per sector) will be taken and reported.

8. Upload the dB loss readings saved to the RP 460 into the OpTest software from ODM. For detailed instruc-tions on completing closeout reports, refer to section VI: Closeout Documentation.

6. When all jumpers are in the correct position, the loss along the riser and sector cables will be displayed in dB on the RP 460 screen. This number may not exceed 6.0 dB. If this number is between 0 and 6.0dB, press the Save button on the RP 460 to save the reading. If this number is over 6.0 dB, clean all connections and try again. Negative readings are not acceptable.

18

VI. Closeout Documentation

1. Connect the RP 460 to a computer using the supplied USB cable.

2. Open the OpTest software and place the software into “Dump” mode by navigating to Settings>Data Mode>Dump Mode.

3. Click Settings>Report Settings to access the Report Settings box. Check “Enable” next to the 1550 wave-length to set the software to report Pass/Fail on the report. Set the maximum dB loss at 6.0, as shown below.

19

4. In the Report Settings box, select the cable color configuration that corresponds to the loss test that is being reported from the drop-down list. When the final report is exported to a spreadsheet, the colors of the cables in the Sprint NSN 2.5 build will populate in the “Comments” section. Click OK to exit Report Settings.

6. Press the USB button on the RP 460. All of the data points saved to the device’s internal memory will appear in the window to the left of the Test Site and Customer Information windows.

5. Fill out the Test Site, Customer. and User information on the right side of the OpTest window. All of this infor-mation will appear in the final closeout report.

7. Click File>Export to Excel to create an Excel file with all of the dB loss readings, cable codes, and testing information included.

21

Sample Closeout Report - Fiber Endface Images

NOTE: There are many fiber endface images that must be recorded in the Sprint NSN 2.5 build. Multiple pages like the one shown above must be submitted to satisfy the closeout documentation requirements.

22

VIII. Technical Support and FAQ

Frequently Asked Questions

Q. What is the difference between dBm and dB? A. dB (decibel) is a unit used to express values of power level on a logarithmic scale. dBm is an absolute optical power measurement referenced to 1 milliwatt of optical energy. It is the starting measurement of the dB loss measurements.

Q. Why do I get a negative dB reading? A. This reading is often the result of the calibration cables not being as clean and aligned as the cable under measurement. This negative reading is common while measuring short-distance cables (less than 100 feet). Always keep reference patch cables clean and free from contamination. Negative readings greater than -.5dB are indicative of other problems in the measurement. In this case, call our technical support group at (603) 524-8350.

Q. Will my reading be saved in the RP 460 memory while the battery is changed? A. Yes the RP 460 will retain measurements in a non-volatile memory.

Q. Why do I need to inspect all fiber connections? A. Short-distance fiber systems typically fail as a result of contaminated connector ends. More than 90 percent of all failures are due to endface debris. The use of a Video Inspection Scope ensures quality in a connected fiber system.

Technical Support

If you need technical assistance or have specific questions about any procedures or guidelines in this guide, please contact our technical support team:

During Business Hours8AM to 5PM Eastern Standard TimePlease call us at 603-524-8350

Evenings/WeekendsEmail us at [email protected] include your phone number and we will contact you.

On YouTubeVisit our YouTube page for helpful videos

Visit Our Websitewww.odm-inc.com