Spring 2001 Gems & Gemology - Ammolite

Transcript of Spring 2001 Gems & Gemology - Ammolite

pg. 74

EDITORIAL

REGULAR FEATURES

pg. 43

4

FEATURE ARTICLES

A comprehensive report on the history, occurrence, and properties of thisvividly iridescent gem material, which is mined from just one area in Canada.

Keith A. Mychaluk, Alfred A. Levinson, and Russell L. Hall

Ammolite: Iridescent Fossilized Ammonite from Southern Alberta, Canada

1

Alice S. Keller

The Dr. Edward J. GübelinMost Valuable Article Award

42

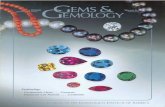

Grown to mimic the beautiful red beryl from Utah, this synthetic can beidentified by its internal growth zoning, chemistry, and spectral features.

James E. Shigley, Shane F. McClure, Jo Ellen Cole, John I. Koivula, Taijin Lu, Shane Elen, and Ludmila N. Demianets

Hydrothermal Synthetic Red Beryl from the Institute of Crystallography, Moscow

26

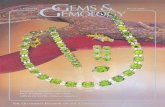

Learn about the development of Australia’s first major diamond mine,the world’s largest source of diamonds by volume.

James E. Shigley, John Chapman, and Robyn K. EllisonDiscovery and Mining of the Argyle Diamond Deposit, Australia

56• Unusual andradite garnet • Synthetic apatite • Beryl-and-glass tripletimitating emerald • Diamond with hidden cloud • Diamond with pseudo-dichroism • Surface features of synthetic diamond • Musgravite • Five-strand natural pastel pearl necklace • Dyed quartzite imitation of jadeite

Gem Trade Lab Notes

79 2001 Gems & Gemology Challenge

83 Gemological Abstracts

81 Book Reviews

64• White House conference on “conflict” diamonds • Tucson 2000: GIA’sdiamond cut research • California cultured abalone pearls • Benitoite minesold • Emeralds from Laghman, Afghanistan • Emeralds from Piteiras,Brazil • Educational iolite • “Hte Long Sein” jadeite • Kunzite from Nigeria• “Rainbow” obsidian • New production of Indonesian opal • Australianprehnite • “Yosemite” topaz • Tourmaline from northern Pakistan • A23.23 ct tsavorite • TGMS highlights • Vesuvianite from California • Opalimitations • Green flame-fusion synthetic sapphire • Platinum coating ofdrusy materials • Gem display • Micromosaics

Gem News International

pg. 27

pg. 5

VOLUME 37, NO. 1SPRING 2001

MOST VALUABLE ARTICLE AWARD GEMS & GEMOLOGY SPRING 2001 1

T he ballots are in, and we are pleased to announce the winnersof this year’s Dr. Edward J. Gübelin Most Valuable ArticleAward. We extend our sincerest thanks to all the subscribers

who participated in the voting.The first-place article, “Gemstone Enhancement and Detection

in the 1990s” (Winter 2000), examined the prominent gem treat-ments of the last decade and discussed methods for their detection.Finishing in a close second place was “GE POL Diamonds: Beforeand After” (Fall 2000), which provided important clues to the identi-fication of type IIa diamonds that had undergone high pressure/hightemperature (HPHT) processing by General Electric. Third place wasawarded to “Gem Localities of the 1990s” (Winter 2000), a review ofthe decade’s new gemstone sources and its most important produc-ing localities.

The authors of these three articles will share cash prizes of$1,000, $500, and $300, respectively. Following are photographs andbrief biographies of the winning authors.

Congratulations also to Ron Suddendorf of Darnestown, Maryland,whose ballot was drawn from the many entries to win a leather portfolioand a five-year subscription to Gems & Gemology.

See some changes in this issue? With the new decade-century-mil-lennium, we’ve been updating the design of Gems & Gemology andhave expanded the Gem News section to Gem News International.Please be assured that there has been no change in the quality of theinformation provided throughout. Just a more contemporary look for apublication—now 67 years young—that will continue to keep you onthe leading edge of gemology as we enter this new era.

Alice S. Keller, [email protected]

The Dr. Edward J. Gübelin Most Valuable Article Award

Shane McClure Christopher Smith

First PlaceGemstone Enhancement and Detection in the 1990sShane F. McClure and Christopher P. Smith

Shane McClure, G.G., is director of West Coast Identification Services atthe GIA Gem Trade Laboratory in Carlsbad. With over 20 years of laborato-ry experience, Mr. McClure is well known for his articles and lectures ongem identification. He is also an editor of the Gem Trade Lab Notes sec-tion. Chicago native Christopher Smith, G.G., is director of the GübelinGem Lab in Lucerne, Switzerland. A prolific author, Mr. Smith is a mem-ber of the Gems & Gemology Editorial Review Board.

2 MOST VALUABLE ARTICLE AWARD GEMS & GEMOLOGY SPRING 2001

Second PlaceGE POL Diamonds: Before and AfterChristopher P. Smith, George Bosshart, Johann Ponahlo,Vera M. F. Hammer, Helmut Klapper, and Karl Schmetzer

Christopher Smith is profiled in the first-place entry. George Bosshart,who holds a degree in mineralogy from the Swiss Federal Institute ofTechnology in Zürich, is chief gemologist at the Gübelin Gem Lab. Hecurrently is involved in research on HPHT-enhanced diamonds. JohannPonahlo has been an independent research associate at the Museum ofNatural History in Vienna since 1990. A physicochemist with a degreefrom the Technical University of Vienna, Dr. Ponahlo specializes in thestudy of cathodoluminescence in gems, particularly diamonds and jade.Vera M. F. Hammer has been the curatorial assistant for the mineral andgem collection of the Federal Gem Institute at the Museum of NaturalHistory in Vienna since 1992. Dr. Hammer studied mineralogy and crys-tallography at the University of Vienna. Her research specialties are X-ray diffraction analysis, the gemology of colored diamonds, and UV-Vis-IR-spectroscopy of colored gemstones. Helmut Klapper received his doc-torate in crystallography from the University of Cologne. Since 1990, hehas been professor of mineralogy and crystallography and head of thecrystal growth laboratory of the University of Bonn. Dr. Klapper’s mainresearch fields are crystal physics, crystal growth, and the characteriza-tion of crystal defects by X-ray diffraction topography. Karl Schmetzer,who obtained his doctorate in mineralogy and crystallography fromHeidelberg University, is a research scientist residing in Petershausen,near Munich, Germany. Dr. Schmetzer has written numerous articles onnatural and synthetic gems, and is also a member of the G&G EditorialReview Board.

Third PlaceGem Localities of the 1990sJames E. Shigley, Dona M. Dirlam, Brendan M. Laurs,Edward W. Boehm, George Bosshart, and William F. Larson

James Shigley is director of GIA Research in Carlsbad. Dr. Shigley, whoreceived his Ph.D. in geology from Stanford University, has published anumber of articles on natural, treated, and synthetic gems. He is also amember of the G&G Editorial Review Board. Dona Dirlam, G.G., is direc-tor of the Richard T. Liddicoat Library and Information Center at GIA inCarlsbad. She has a B.Sc. from the University of Minnesota and an M.Sc.in geology and geophysics from the University of Wisconsin, Madison.Brendan Laurs, G.G., is senior editor of Gems & Gemology. He obtained aB.Sc. in geology from the University of California at Santa Barbara and anM.Sc. in geology from Oregon State University. Prior to joining GIA, Mr.Laurs gained experience as an exploration geologist specializing in coloredgems. Edward Boehm, G.G., is a gem dealer and gemological consultant.President of JOEB Enterprises in Solana Beach, California, Mr. Boehm hasa degree in geology and German from the University of North Carolina inChapel Hill. George Bosshart is profiled in the second-place entry. WilliamLarson is president of Pala International (Fallbrook, California), a companythat has been involved with gem-mining projects worldwide. Mr. Larsonholds a degree in geological engineering from the Colorado School ofMines. He has traveled extensively to gem deposits, including 135 tripsinto the Far East and more than 40 visits to Africa.

George Bosshart Johann Ponahlo

Vera Hammer Helmut Klapper

Karl Schmetzer

James Shigley Dona Dirlam

Brendan Laurs Edward Boehm

William Larson

4 AMMOLITE GEMS & GEMOLOGY SPRING 2001

mines at Bleiberg, Austria (Niedermayr, 1994).However, any similarities between Ammolite andother iridescent shell materials are superficial.Although the iridescence of lumachelle is associatedwith an ammonite, specifically Carnites floridus,this species is significantly older (Late Triassic inage) than those that give rise to Ammolite, and thetwo materials have different geologic occurrences.Further, lumachelle differs from Ammolite inappearance (e.g., most Ammolite has a characteristicfracture pattern). The former has been used primari-ly for nonjewelry purposes (i.e., as an ornamentalstone) and, according to some who have seen thetwo materials (e.g., Sinkankas, 1976; Pough, 1986),Ammolite has superior iridescence.

Ammolite layers are typically thin (0.5–8 mmbefore polishing and 0.1–3 mm after polishing). Theyare composed predominantly of soft aragonite (31/2–4on the Mohs scale), yet they are sufficiently thick and

By Keith A. Mychaluk, Alfred A. Levinson, and Russell L. Hall

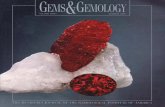

AMMOLITE: IRIDESCENT FOSSILIZEDAMMONITE FROM SOUTHERN

ALBERTA, CANADA

See end of article for About the Authors information and acknowledgments.GEMS & GEMOLOGY, Vol. 37, No. 1, pp. 4–25© 2001 Gemological Institute of America

A relative newcomer to the world gem market (since the 1960s), Ammolite is a form of aragonite that isobtained from vivid iridescent fossilized ammonite shells mined in Alberta, Canada. The gem material,from the extinct species Placenticeras meeki and P. intercalare, is found only in certain horizons of theBearpaw Formation of Late Cretaceous age (about 70–75 million years old). Because the iridescent layer isgenerally thin and fragile, most Ammolite is fashioned into assembled stones. This article describes thehistory of Ammolite as a gem material and the geologic setting of the main producing mines; offers anexplanation for the formation of Ammolite and the origin of its color (i.e., iridescence caused by an interfer-ence phenomenon); presents production data, gemological properties, and a grading classification; anddescribes the manufacturing process.

mmolite is one of the few new natural gemmaterials to enter the marketplace in thelast 50 years (figure 1). Like tanzanite and

sugilite—which were introduced to the trade in1967 and 1980, respectively—Ammolite occurs insufficient quantities to be economically significant.Ammolite is a trade name for the iridescent, nacre-ous layer of the shell of specific fossil ammonites(figure 2) found in the Bearpaw Formation of LateCretaceous age (figure 3). Commercial quantities ofgem-quality Ammolite have been reported onlyfrom southern Alberta and only from the twoammonite species Placenticeras meeki and P. inter-calare. Ammonite is a paleontologic term applied toa group of extinct marine cephalopods (squid-likeorganisms with disk-shaped coiled shells that aredivided internally into chambers) that were particu-larly abundant during the Jurassic and Cretaceousperiods (about 200–65 million years ago).

Ammolite has similarities to some modern shellssuch as abalone and paua, but the only fossil shellthat resembles Ammolite with respect to play ofcolor is lumachelle (Sinkankas, 1997), the iridescentfossiliferous marble that is best known from the lead

A

AMMOLITE GEMS & GEMOLOGY SPRING 2001 5

durable (including the ability to take a polish) to bemanufactured into jewelry. In fact, freeform pieces ofsolid Ammolite over 100 ct have been reported(Wight, 1995). Iridescence produces the vivid colorsin this material. The fact that Ammolite can be man-ufactured into jewelry distinguishes it from other iri-descent materials obtained from various fossils(including other ammonites) that are frequently film-like, have dull colors, or are otherwise unsuited forgem purposes. Nevertheless, because Ammolite usu-ally occurs as thin, soft plates, it is found in jewelryprimarily as assembled stones, such as triplets—athin layer of Ammolite attached to a shale backingand covered with a synthetic spinel or quartz cap.Since 1980, both solid Ammolite and assembledAmmolite gemstones have become increasinglyavailable. It is estimated that a total of about 600,000pieces of Ammolite jewelry have been producedsince significant commercial production began 20years ago (P. Paré, pers. comm., 2001).

The purpose of this article is to update gemolo-gists and jewelers on this unique gem material. Forthis study, we focused almost exclusively on mate-rial from the mining and manufacturing opera-tions of Korite International Ltd. (henceforthKorite), Calgary, Alberta, because: (1) about 90% ofthe commercially available material historicallyhas, and still does, come from Korite’s mines; (2)almost all published information on Ammolite isbased on specimens obtained from this company;(3) several other smaller Ammolite miners andmanufacturers were offered the opportunity to par-ticipate in this study, but only one (S. Carbone)

agreed to do so; and (4) Korite allowed us unre-stricted visitation to their mining and manufactur-ing operations, and supplied us with productiondata as well as specimens for research. In addition

Figure 2. Ammonites are extinct mollusks of theclass Cephalopoda, order Ammonoidea. Thisbrightly colored ammonite (47.3 cm in diameter)of the species Placenticeras intercalare, obtainedfrom the Bearpaw Formation, near Lethbridge,Alberta, lived about 70 million years ago. Theouter iridescent layer is the material from whichgem Ammolite may be obtained, although morecommonly it comes from naturally compacted andcrushed specimens; complete specimens, such asthe one pictured here, are typically more valuableleft intact. Photo courtesy of Canada Fossils Ltd.

Figure 1. These Ammolites are from theSt. Mary River area, Alberta, Canada.The rough specimen (3 × 4 cm) is typi-cal of the high-quality Ammolite seenon the market today. Note the numer-ous iridescent color panes (i.e., flatareas of uniform color) that are separat-ed by thin “healed” fractures. The twoloose stones are Ammolite triplets(each 1.5 × 2.0 cm); the one on the leftis made with type 2 sheet Ammolite,and the other with the more commontype 1 fractured Ammolite. Thebrooch, by Llyn Strelau of Jewels ByDesign (Calgary), contains a 17.85 ctone-sided solid Ammolite set in 18Kgold with ruby, fire opal, yellow sap-phire, chrome tourmaline, blue sap-phire, amethyst, and diamond.Courtesy of Korite International; photo © Harold & Erica Van Pelt.

6 AMMOLITE GEMS & GEMOLOGY SPRING 2001

Figure 3. This map of the Bearpaw Formation of southern Alberta, Canada, shows both the bedrockgeology and the location of the main Ammolite mining and collecting areas discussed in the text.Open circles represent areas of significant Bearpaw Formation outcrop, which is usually exposed inriver valleys, where: 1 = St. Mary River, 2 = Oldman River, 3 = Little Bow River, 4 = Bow River, 5 =Red Deer River, 6 = Battle River, 7 = Cypress Hills, 8 = Milk River, and 9 = Crowsnest River.Ammonites can be collected at all locations, but Ammolite has only been reported from areas 1through 5, with 1 being the best. Outcrops at 9 are located in the foothills of the Rocky Mountain foldand thrust belt. (Map modified from Tsujita and Westermann, 1998.) Inset: This “close-up” mapshows the location of the three main mine sites discussed in this article: Kormos, Oxbow, and Zone 4.All are along the St. Mary River (location 1; map modified from Ward et al., 1982).

to the gemological research described below, westudied outcrops and collected specimens from theSt. Mary, Bow, Red Deer, and South Saskatchewanrivers, as well as the Cypress Hills area.

HISTORY OF AMMOLITEAS A GEM MATERIALDowling (1917) provided the first description of thesouthern Alberta ammonites that yield Ammolitefrom samples recognized in 1908. However, the firstrecorded use of ammonite shell as a gem materialwas not until 1962, by amateur lapidaries who dis-played their creations at a local gem show inNanton, Alberta (Stafford, 1973a,b). Marcel Char-bonneau, owner of a Calgary jewelry store, intro-duced the name Ammolite (the first trade name forthis material) in 1967. He and Mike Berisoff, a geol-ogist from Calgary (with whom he formedAmmolite Minerals Ltd.), were the first to collectAmmolite and create doublets for commercial pur-poses (Hadley, 1981a,b; Barnson, 2000). AmmoliteMinerals Ltd. (1967–1970) collected rough Ammo-lite from the Kormos family ranch along the St.Mary River, near Lethbridge; this valley remains thesource for most commercial Ammolite (see MiningOperations below). However, these early assembledAmmolites developed flaws (layers would separate),so they contacted Santo Carbone, a geologic techni-cian with the Geological Survey of Canada, toimprove the cutting and manufacturing techniques.Subsequently, Mr. Carbone was the first to discoverfractured (type 1) Ammolite (see below; Hadley,1981a,b; Kraus, 1982; Brown, 1984) on the Kormosranch, in an area that would later be labeled the KZone. The first published description of Ammolitein a major trade magazine appeared in 1969 (Leiper,1969).

In the 1970s, Mr. Carbone formed a new com-mercial venture with Dr. Wayne Bamber andThomas McArthur, both of Calgary. They intro-duced a second trade name, Calcentine, in 1975(Crowningshield, 1977; Zeitner, 1978; Barnson,2000). Coined in honor of the city of Calgary centen-nial (in 1975), the name was seldom used after 1981.In 1977, Mr. Carbone joined with Roy, Albert, andSylvia Kormos to form Canadian Korite Gems (nowKorite International). In 1979, Rene Vandervelde ofCalgary (currently the chairman of Korite) pur-chased the Kormos family interests in Korite andbrought modern business practices to the fledglingindustry (Barnson, 2000). Mr. Carbone left Korite in

1980 and is currently manufacturing assembledAmmolite (see Manufacturing below). In 1981,Korite introduced a third trade name, Korite (Wight,1981; Kraus, 1982; Brown, 1984). By the end of1983, however, Ammolite had reappeared (Boyd andWight, 1983; Pough, 1986). It was trademarked byKorite, who placed it in the public domain in 1997,so that Ammolite is now the standard designationfor this material (Sinkankas, 1997).

Ammolite has also been referred to as “ammoniteshell” (Stafford, 1973a,b,c) and simply as “gemaragonite” or “gem ammonite” (Barnson, 2000).Aapaok (Gem Reference Guide, 1995) was a tradename given to this material by certain members ofthe Blood Indian band during their brief (1980–1981)manufacture of Ammolite triplets from materialobtained on their land (P. Paré, pers. comm., 2000).The first commercial appearance of Ammolite in theUnited States was in 1968, at gem shows in Seattleand Anaheim (Barnson, 2000). Ammolite was intro-duced in Germany, at Idar-Oberstein, in 1979(Gübelin, 1980).

In the 1980s, Ammolite expanded its presence inthe world market, the result not only of increasedjewelry-grade supplies and improved methods ofprocessing raw material into gemstones, but also ofarticles by a number of respected gemologists(Gübelin, 1980; Wight, 1981; Pough, 1986). In 1981,the CIBJO Colored Stones Commission recognizedAmmolite as a gemstone, more specifically, as a“Permitted Name” in the “Variety and Commercial”columns against aragonite in their glossary (letterdated March 31, 1982 from E. A. Thomson to R.Vandervelde; Boyd and Wight, 1983; Dick, 1991). Asa consequence of heavy Japanese tourism to theCanadian Rockies (in particular, Banff, Alberta) dur-ing the 1980s, which accounted for about 50% ofsales of Ammolite and Ammolite triplets in 1985,this gem material became widely known in Japan(“Organic Alberta gemstone posed …”, 1985;Pough, 1986). Since 1983, when mining started atthe open-pit Kormos mine, high-quality materialhas been offered regularly at the Tucson gem shows.

By 1998, the Canadian mining industry had alsorecognized the economic potential of Ammolite. Atthat time, the government of Alberta approved 119leasing agreements for Ammolite mining, whichcovered 13,350 hectares in the names of 42 individ-uals and companies. Nevertheless, Korite is current-ly the only major producer. Today, work at theKormos mine is temporarily suspended, and produc-tion comes from Korite’s nearby (0.5 km) Oxbow

AMMOLITE GEMS & GEMOLOGY SPRING 2001 7

(figure 4) and (12 km) Zone 4 mines (the latter twowere activated only after arrangements were madewith the Blood Indian band, which owns the miner-al rights at these locations). Korite manufactures allits production into gems; it does not sell Ammoliterough (P. Paré, pers. comm., 2000). Presently, 70%of Korite’s production is sold in Canada, half ofwhich is purchased by overseas visitors (“Gemstoneunique to Canada…,” 1999). Elsewhere on theBlood Indian Reserve, various tribe members andgroups (such as Black Horse Mines) collectAmmolite and either sell rough (to other manufac-turers, such as Korite) or finished triplets (Barnson,2000).

In 1998 Ammolite was declared to be a mineralrather than a fossil under Alberta law (Hembroff,1998). If Ammolite had been declared a fossil, min-ing could have been greatly restricted or evendenied on the basis of certain legislation (A.Ingelson, pers. comm., 2000).

LOCATION AND ACCESS Southern Alberta is primarily prairie with gentlyrolling hills (again, see figure 4). Natural vegetation

includes a variety of grasses and low-growing bush-es; trees are limited to stands of cottonwood in theriver valleys. The region is dry, with the principalland use being farming and ranching. Several val-leys, including that of the St. Mary River, cut acrossthe prairie landscape, exposing rocks deposited dur-ing the latter part of the Cretaceous period.

The Oxbow and Kormos mines are easilyaccessed by driving 15 km (9 miles) south fromLethbridge, Alberta, on Highway 5 (again, see figure3). One kilometer north of the town of Welling, anunmarked gravel road leads to the mines approxi-mately 10 km (6 miles) to the west, on the eastbank of the St. Mary River. Prior permission to visitthe site must be obtained from Korite International.

GEOLOGY AND OCCURRENCEThe living ammonite closely resembled a modernsquid, and both are members of the class Cephalo-poda. Ammonites populated the Jurassic andCretaceous seas worldwide in large numbers; theywere apparently victims of the same extinctionevent that wiped out the dinosaurs at the end of theCretaceous period (65 million years ago). Theammonite has been compared to Nautilus, a dis-tantly related cephalopod that survives today in thesouthwest Pacific, around places such as thePhilippines, Fiji, Indonesia, and northern Australia.

Fossil ammonoids occur throughout the BearpawFormation in southern Alberta. The most commonare Placenticeras meeki and P. intercalare, whichshow no particular geographic distribution patterns.Because their shells (typically 70 cm in diameter atmaturity) are equally abundant in sediments origi-nally deposited in both offshore and near-shoremarine environments, they are thought to haveinhabited the upper 10–30 m of the water column(Tsujita and Westermann, 1998).

To date, marketable Ammolite has been found in,and commercially exploited from, only the BearpawFormation of southern Alberta, which consists pri-marily of dark-colored marine shales that areinterbedded with several sandstone units. These sedi-ments were deposited 70–75 million years ago (duringLate Cretaceous time), when the interior of NorthAmerica was inundated by the Bearpaw Sea (alsoknown as the Western Interior Seaway or the PierreSea), which extended from the present-day Gulf ofMexico to the Arctic Ocean (Tsujita andWestermann, 1998). Dominating the marine faunaswithin this seaway were vast numbers of ammonites,

8 AMMOLITE GEMS & GEMOLOGY SPRING 2001

Figure 4. The open-pit Oxbow mine, located on theBlood Indian Reserve, currently is the main source of

Ammolite. An orange-colored backhoe, sittingdirectly on the K Zone (see text), is barely visible in

the center of the photograph. The St. Mary River (notvisible) runs along the base of the cliff in the dis-

tance. Note on the left side of the pit that the lightersoil represents alluvial deposits, whereas the under-

lying gray stratum is the Bearpaw Formation. Thecliff on the right caps the gray Bearpaw Formation

with tan-colored glacial sediments. Photo takenlooking north; courtesy of Korite International.

whose shells are now the source of Ammolite. Outcrops of the Bearpaw Formation are recognized

in the Canadian provinces of Alberta andSaskatchewan, and in the U.S. state of Montana,where the type locality was first described and namedafter the Bearpaw Mountains (Hatcher and Stanton,1903); the formation is known by a variety of othernames in other states and provinces. However, thereare no commercial occurrences of Ammolite outsideof Alberta, although several attempts have been madeto find such deposits (P. Paré, P. Evanson, and A.Ingelson, pers. comms., 2000).

At the Korite mine sites along the St. MaryRiver, the Bearpaw Formation is 232 m (761 ft)thick. It contains numerous bentonite (volcanicash) layers and, in its upper two-thirds, three sand-stone members: the Magrath, Kipp, and Rye Grass(figure 5). Since Ammolite is found in distinct hori-zons within the Bearpaw Formation, knowledge of

this stratigraphy helps geologists pinpoint gemdeposits.

The Bearpaw Formation contains numerous lay-ers with hard siderite (FeCO3) concretions. Theseconcretions form by precipitation from an aqueoussolution around a nucleus (Jackson, 1997) that iscommonly a fossil, such as an ammonite. It is with-in such ironstone concretions that gem-qualityAmmolite is typically (but not exclusively) found.The concretion’s overall shape will commonlymimic the shape of its nucleus, thus giving an indi-cation of its economic potential. For example,ammonite-bearing concretions are typically diskshaped (generally 20–60 cm, but as large as 1 m; see,e.g., figure 6), whereas round or spherical concre-tions rarely contain ammonites. Small- to medium-size concretions, 15–60 cm in diameter, found inthe K Zone (see below) yield the best Ammolite forKorite (P. Paré, pers. comm., 2000).

Extensive glaciation in southern Alberta duringthe last southerly advance (22,000–36,000 years ago)of ice as part of the Pleistocene “ice age” resulted inthe deposition of glacial overburden. At the Koritemine sites, these glacial deposits are about 15–30 mthick. Fortunately, the St. Mary River has cut intoboth the glacial deposits and the BearpawFormation, exposing ammolite-bearing horizons incertain places. However, even here the BearpawFormation is buried under a veneer of alluvial grav-els and sediments, generally 2–5 m thick. Since theformation dips 3° to 6° to the west at all Korite

AMMOLITE GEMS & GEMOLOGY SPRING 2001 9

Figure 5. This stratigraphic section of the BearpawFormation shows the location of important sand-stone members, the double-ash (bentonite) layer,and the two known economic Ammolite-bearinghorizons (K Zone and Zone 4; see text) in the St.Mary River area of southern Alberta; the lateralextent of these units is limited. Modified from Linkand Childerhose (1931).

Figure 6. A Korite employee inspects a recentlyuncovered ironstone concretion from the K Zone (seetext) of the Kormos mine. The disk shape of this con-cretion is an indication that an ammonite—andtherefore Ammolite—may be found within. Photo byArt Barnson, Barnson Photography.

mine sites (P. Paré, pers. comm., 2000), the K Zoneis too deeply buried under much of the neighboringterritory to exploit at this time. A short distance tothe east, it has been eroded away. Due to the effectsof groundwater and various other natural processes(e.g., extreme temperatures, frost), the aragonite inmost ammonite shells in the oxidized zone—theupper 3 m of the Bearpaw Formation, where it con-tacts glacial or alluvial deposits—has been convert-ed to white calcite (“calcified ammonite”), whichhas no gem value.

DISTRIBUTION AND CHARACTERISTICS OF AMMONITES AND AMMOLITE IN THE BEARPAW FORMATIONGeneral. Although fossil ammonites are foundthroughout the Bearpaw Formation in southernAlberta, Ammolite distribution varies widely withrespect to both quantity and quality. Almost all theammonites that produce marketable Ammolite havebeen mined or collected in the western part of south-ern Alberta. Ammolite from other parts of theBearpaw Formation may be too thin or flaky to with-stand polishing, although some can be stabilizedwith an epoxy resin or similar material for manufac-ture into gemstones (see below). Moreover, someAmmolite-bearing horizons within the Bearpaw

Formation are too deeply buried to allow for com-mercial extraction (Korite’s current open-pit miningmethods are only economic to depths of 20 m; P.Paré, pers. comm., 2000). There have been manycommercial failures as a result of these factors.

There is no known exploration technique (e.g.,geophysical, remote-sensing) to locate or evaluateburied ammonites (although ground-penetratingradar may have potential in this regard). Onlyexpensive test mining has proved helpful. Koritealone has excavated 20 trenches (6 m deep × 15 mwide × 5–30 m long) and 30 test pits (9 m deep × 5m diameter) throughout southern Alberta since1977 (P. Paré, pers. comm., 2000).

In the course of exploration and mining, Koritehas identified two horizons or “zones” within theBearpaw Formation—the K Zone and Zone 4—thatcontain commercial quantities of Ammolite. Thecompany also has recognized two distinct types ofAmmolite that are associated with these two zones.Type 1 is fractured Ammolite (same as Barnson’s[2000] “compacted Ammolite”), that is, Ammolitethat has undergone compaction and fracturing, withthe fractures subsequently “healed” naturally withcarbonate and/or clay matrix material. This typedoes not require stabilization for manufacture intojewelry (again, see figure 1). Ammolite from the KZone is typically found in concretions that yield

10 AMMOLITE GEMS & GEMOLOGY SPRING 2001

Figure 7. This exceptionalspecimen of Zone 4Ammolite shows(almost) the completecolor spectrum. Suchmaterial, which is of non-concretionary origin,occurs as sheets (referredto as type 2; see text) andhas not been fractured bygeologic processes. Notethe large color panes (flatareas of uniform color),typical of type 2Ammolite, as comparedto the smaller color panesof type 1 material (again,see figure 1). The speci-men is 11 cm along thelongest (bottom) edge.Courtesy of KoriteInternational; photo ©Harold & Erica Van Pelt.

type 1 material. Type 2 is sheet Ammolite (same asBarnson’s [2000] “noncompacted Ammolite”), thatis, Ammolite that has undergone compaction butnot the fracturing and subsequent healing stages(figure 7). For manufacture into jewelry, some type 2Ammolite must first be stabilized, as it may have atendency to delaminate. Ammolite from Zone 4that does not originate from concretions is com-monly type 2 material. Table 1 lists the characteris-tics of each type of Ammolite and the zone inwhich it is typically found.

K Zone. The vast majority of commercially avail-able Ammolite has been derived from concretionsin the K (for Korite) Zone. About 3.6 m thick, it islocated approximately 120 m (400 ft) below thetop of the Bearpaw Formation, between the Kippand Magrath sandstone members (again, see figure5) and 9–12 m (30–40 ft) above the double-ash(bentonite) layer identified by Link andChilderhose (1931), as seen in figure 8. Complete,museum-quality ammonites (such as the one pic-tured in figure 2) from the K Zone are very rare;most have been crushed (P. Paré, pers. comm.,2000). Both the Oxbow and Kormos open-pit

AMMOLITE GEMS & GEMOLOGY SPRING 2001 11

TABLE 1. Characteristics of K Zone and Zone 4 ammonites and Ammolite.

Attribute K Zone Zone 4 Zone 4Concretionary Non-concretionary

1. Fossil specimen Poor-quality fossil speci- Poor-quality fossil speci- Few complete fossils; potential and mens (due to compaction mens and lower-quality most ammonites are com-quality of and presence within con- Ammolite than K Zone pacted but not fractured;Ammolite cretions); high-quality (constitutes 50% of Zone high-quality Ammolite

Ammolite 4 material)

2. Type and thick- Type 1 (fractured); film- Same as K Zone Type 2 (sheet); thicknessness of Ammolite like to 8 mm thick in same as K Zonelayer rough

3. Durability of Stable, does not deterio- Same as K Zone Sheet-like material may Ammolite rate, resists wear with delaminate

normal jewelry usage

4. Stabilization of Rarely required Rarely required Commonly, but notAmmolite always, required

5. Size of Ammolite Small panes (average 2–5 Larger panes than in K Relatively large panespanes (i.e., flat mm, maximum 1 cm); Zone (average 5–7 mm, (typically 2–3 cm, maxi-areas of uniform fracture fillings between maximum 1 cm); healed mum 10 cm); no fracturescolor); and thick- panes average 1 mm; in fractures between panes ness of healed general, smaller panes are thicker (2–3 mm) thanfractures between with thin healed fractures in K Zone Ammolite, whichpanes result in the most durable detracts from beauty

Ammolite

6. Color display of Red, orange, yellow, Orange, yellow, and green Same colors as K ZoneAmmolite green, and blue are char- are most common, with (except blue is more

acteristic. “Full color spec- no red and little blue common), but usually trum” is common except only two predominatefor violet, which is rare

Figure 8. This view shows a cliff face in theBearpaw Formation (the gray stratum right abovethe green valley floor) on the St. Mary River, 0.5 kmnortheast of the Kormos mine. The thin, white dou-ble-ash layer (see arrows) helps geologists locate themost important Ammolite-bearing horizon (the KZone), which is typically 9–12 m (30–40 ft) abovethis marker. Also visible on the surface (tan colorat the right forefront) are the glacial sediments thatblanket this area. Photo taken looking north; cour-tesy of Korite International.

mines are positioned to take advantage of the out-cropping of the K Zone.

Zone 4. This approximately 2-m-thick horizon (alsoknown as the Blue Zone) is about 4.5 m (15 ft)above the base of the Bearpaw Formation (again, seefigure 5). About half of the ammonites derived fromthis unit were never encased within concretions(“non-concretionary”), and these typically yieldtype 2 sheet Ammolite. The concretionaryammonites from Zone 4, similar to those in the KZone, have been compacted, fractured, and healed(type 1 Ammolite) and do not need to be stabilized.However, this Zone 4 fractured material has certainfeatures (e.g., it displays none of the red and little ofthe blue colors) that are less desirable than K Zonefractured Ammolite; consequently, Korite does notcurrently manufacture it into gemstones. The twovarieties of Ammolite are also found in distinct lay-ers within Zone 4.

THE ORIGIN OF AMMOLITEWhile Jurassic and Cretaceous rocks all over theworld contain abundant fossil ammonites, so farAmmolite has been obtained from only a few locali-ties in southern Alberta and only within the Bear-paw Formation. To date, just two species of ammo-nite, Placenticeras meeki and P. intercalare, haveyielded marketable Ammolite; other fossilammonoids found in the same formation, such asBaculites compressus, have not yielded iridescentmaterial of sufficient thickness and durability foruse in jewelry (P. Paré, S. Carbone, and P. Evanson,pers. comms., 2000). These facts suggest that someunusual circumstances are responsible for the for-mation of Ammolite.

The Depth-of-Burial Factor. As part of our fieldwork,we collected Ammolite from various parts of Albertaand met with several individuals involved inAmmolite exploration. Our findings indicate thatthe quality of Ammolite improves westward insouthern Alberta. For example, the colors exhibitedby fossil ammonites from the Cypress Hills area(white with faint iridescence) and the Bow River area(typically red-brown)—in southeast and south-cen-tral Alberta, respectively (again, see figure 3)—aresignificantly less vivid than those found inammonites along the St. Mary River valley in thesouthwest. As shown in Mossop and Shetsen (1994),rocks in the western part of southern Alberta (e.g.,

the St. Mary River area) underwent significantlymore burial than those in the eastern part (e.g., theCypress Hills area). On the basis of thermal matura-tion studies of organic material of the Judith RiverGroup, which immediately underlies the BearpawFormation (England and Bustin, 1986), we estimatethat the Bearpaw Formation was buried to a depth ofabout 4 km in the St. Mary River area (and has sincebeen uplifted and exposed at the surface). TheBearpaw Formation in southeast and south-centralAlberta, on the other hand, was not buried as deep.

We propose that the increased depth of burialresulted in a form of diagenesis (i.e., alterationsundergone by sediment subsequent to deposition),as yet unidentified, on ammonite shells within theBearpaw Formation of southwestern Alberta, specif-ically in the St. Mary River area. The diagenesisintensified the colors on some ammonite shells.During this process, however, the aragonite did notconvert to calcite, the more stable form of CaCO3,as would be expected in 70-million-year-old materi-al. If such conversion had occurred, Ammolitewould not have formed. Niedermayr and Oehner(1995) and Niedermayr (1999) suggested that highamounts of Fe and/or Mg in the Bearpaw Formation(including the concretions) might be a factor ininhibiting the conversion.

Pough (1986) was the first to suggest that alter-ation by burial (accompanied by compression andalteration of the organic matter within the nacre)might be a factor in the formation of Ammolite, buthe did not discuss the effects of the relative differ-ences in the depth of burial of ammonite shells inthe Bearpaw Formation between eastern (little or noiridescence) and western (vivid iridescence) Alberta.However, P. Paré (pers. comm., 2000) has noted thatonly rarely can shell from Placenticeras ammonitesobtained from the Kipp sandstone member (sandyshale; again, see figure 5) of the Bearpaw Formation,in the St. Mary River valley, be used as a source ofAmmolite. This suggests that the high sand contentof the Kipp member may have prevented or imped-ed Ammolite formation. Clues to the origin ofAmmolite may also be found in the original archi-tecture or chemical constituents (e.g., the organiccomponent, trace elements) of the shell, since onlycertain ammonite species are predisposed to form-ing Ammolite. Additional research is needed toexplain fully the process that has occurred.

Fractured (Type 1) versus Sheet (Type 2) Ammolite.An explanation for the origin of the two types of

12 AMMOLITE GEMS & GEMOLOGY SPRING 2001

Ammolite, fractured (type 1) and sheet (type 2), canbe found in the rate and extent of sediment infill intoammonite shells following the death of the animal.After Placenticeras ammonites died, their shells sankto the bottom of the Bearpaw Sea. Some of theseshells were quickly buried, with little or no sedimentfilling the empty shell chambers. Their internallyunsupported shells were subsequently compactedand fractured (and later healed), which resulted intype 1 Ammolite (K Zone material; again, see figure1). However, it is likely that the chambers in thoseshells that were not buried rapidly would have filledwith sediment, so that the ammonite shell was inter-nally supported. Such shells would resist fracturingduring compaction, thus giving rise to type 2Ammolite (sheet material characteristic of Zone 4;again, see figure 7). Ward et al. (1982) were the first tonote that the lack of sediment infill into the emptychambers of Placenticeras shells following burialresulted in a high ratio of compacted shells in severalzones; however, they did not extend this observationto the origin of fractured type 1 Ammolite within theBearpaw Formation. Type 1 Ammolite is usually (butnot always) found within ironstone concretions,whereas type 2 Ammolite is not (again, see table 1),which suggests that concretions play a role in devel-oping the type 1 material.

MINING OPERATIONSSurface Collecting. Since the early 1960s, Ammolitehas been collected by amateurs and small commer-cial lapidaries from the vicinity of the St. MaryRiver (e.g., Stafford, 1973a). These finds occur in theriverbed and along the valley walls, whereammonites are exposed by erosion. Subsequently,Ammolite was discovered in the gravel bars ofnumerous other rivers throughout southern Albertawhere the Bearpaw Formation is exposed (again, seefigure 3); mining claims currently are held on theBow, Little Bow, Oldman, and Red Deer rivers. Weestimate that 5%–7% of current Ammolite produc-tion is derived from surface-collected material, allby small producers. An additional 2% of the total isobtained by small producers from small test pits inthe Bearpaw Formation. Similarly, about 1% ofKorite’s production is from concretions collected onthe surface in the St. Mary River valley (P. Paré,pers. comm., 2000).

Open-pit Mines. Only two mines—Kormos andOxbow—have produced gem-quality Ammolite in

significant quantities. Both are open-pit operationson the banks of the St. Mary River (again, see figures3 and 4). Essentially all (99%) of Korite’s productionhas come from open-pit mines, with the remainderfrom the surface source mentioned above (P. Paré,pers. comm., 2000). The Kormos mine was activefrom 1983 to 1994; since then, operations have beensuspended, although long-range plans are to reacti-vate the mine. Production at the Oxbow mine start-ed in 1994 and has continued to the present.

In recent years, Korite has mined between 2 and5 acres annually to achieve a production of about57,000 finished pieces of Ammolite and assembledAmmolite gems per year (P. Paré, pers. comm.,2001). Between 1983 and 1999, Korite excavated 40acres of land, of which 35 acres have been restoredto their natural state.

Mining Methods. Initially, the topsoil, sand, andgravel layers are stripped and stockpiled for later sitereclamation. The underlying Bearpaw Formation isthen excavated with a large backhoe (again, see fig-ure 4). Blasting is not required because the shalesare so easily worked. Mining is conducted fromMarch through November, as winter operations ofthis type are difficult in Canada.

Most Ammolite is protected in concretions thatare more durable than the surrounding shale. Thishas led to the development of a rather simple, buteffective and economical, mining process. Korite’smining team consists of four individuals: a backhoeoperator, a dump truck operator, and two sorters or“spotters.” The backhoe operator excavates theshale and then “sifts out” the soft, uneconomicmaterial with a side-to-side motion of the machine,leaving the hard concretions in the shovel. Thespotter carefully observes material in the bucket ofthe backhoe, looking for disk-shaped concretions(figure 9), which represent only about 10% of theconcretions found in the K Zone (P. Paré, pers.comm., 2000). Waste shale is removed by dumptruck and also stockpiled for reclamation.

After the spotter has closely inspected the disk-shaped concretions, he uses a sledgehammer tobreak open those he feels have the potential forAmmolite (figure 10). The Ammolite attached toironstone matrix is placed in “tubs,” each of whichholds about 45 liters of material. The Oxbow mineproduces about five tubs of raw material daily (P.Paré, pers. comm., 2000). After the concretions aretrimmed with hammers and a rock saw at the mine,daily production is reduced to about one tub of

AMMOLITE GEMS & GEMOLOGY SPRING 2001 13

Ammolite on matrix, which eventually is shippedto the main manufacturing facility in Calgary. Theauthors did observe much colorful material beingrejected at the mine site and thrown back into thepit. It was explained that this material was too thin,patchy, or irregular to use in jewelry.

The mining method described above is onlyeffective for Ammolite encased in concretions andundoubtedly would destroy less durable material.For example, Zone 4 non-concretionary (type 2sheet) material is mined by Korite in a slightly dif-ferent manner. After the overburden has beenremoved, excavators dig into the zone until any signof Ammolite colors appear. Material is then collect-ed by hand, which makes this a much slower opera-tion. The economic potential of Zone 4 was firstrecognized in 1996, and mining at the Zone 4 pitbegan in August 1999.

Exploitation of the K Zone and Zone 4 in otherareas of southern Alberta is constrained by theamount of overburden that must be removed foropen-pit mining (again, see figure 8). Undergroundmining is not feasible in the soft, friable shales ofthe Bearpaw Formation.

AMMOLITE PRODUCTIONKorite has the only ongoing mechanized miningoperation; all other Ammolite mining activities areartisanal, that is, small workings for which accuraterecords are seldom available. Thus, we are aware ofno reliable production statistics for Ammolite otherthan those from Korite. Production of finishedAmmolite by Korite consists predominantly oftriplets, but there are also “solids” and doublets (P.Paré, pers. comm., 2001). Triplets (sold by size) con-sist of a colorless cap and a dark backing that areattached to a thin Ammolite layer (again, see figure1), whereas doublets (sold by carat weight) are anAmmolite layer attached to a backing (without acap). Two types of solids are produced: two-sided(Ammolite on both sides; figure 11), and one-sided(a natural assemblage of Ammolite attached to itsshale backing); each is sold by the carat (see VisualAppearance below for average weights and dimen-sions in each category). At Korite, stabilization withan epoxy resin is applied to some, but not all, solidsand doublets, but never to the Ammolite used intriplets; material derived from the K Zone is rarelystabilized (P. Paré, pers. comm., 2001). Other manu-facturers have recently introduced other types ofassembled stones (see Manufacturing below), but

14 AMMOLITE GEMS & GEMOLOGY SPRING 2001

Figure 10. This close-up shows a “spotter” after hehas broken open a promising concretion (note thecolors on the broken layer). Only disk-shaped con-cretions, which represent about 10% of the concre-tions in the K Zone, will contain Ammolite. Photoby Art Barnson, Barnson Photography.

Figure 9. As the backhoe removes the Bearpaw shaleat the Oxbow mine, a ”spotter” searches the bucket

for disk-shaped concretions. Note how friable theshale is. Photo courtesy of Korite International.

their impact on overall Ammolite availability hasnot yet been felt.

Major production began in 1983, with the open-ing of the Kormos mine. That first year, 12,211 fin-ished pieces were fashioned (12,004 Ammolitetriplets, 183 one-sided solids, and 24 two-sidedsolids; none of this material was stabilized) from20,500 tonnes of excavated shale (P. Paré, pers.comm., 2001). However, much of this early produc-tion included low-grade Ammolite that would nothave been manufactured into gems in recent years(P. Paré, pers. comm., 2001). Some reports of earlyKorite production (“Ammolite. New gems from…”,1984; “Organic Alberta gemstone posed …”, 1985;Vandervelde, 1993) suggested that less than 6,000tonnes of shale was excavated in 1983, but this isnot correct (P. Paré, pers. comm., 2001). Korite’sproduction in 1999 (the most recent year for whichKorite made data available to the authors), consistedof 55,000 Ammolite triplets, 1,500 Ammolite dou-blets (about 50% stabilized), 500 one-sided solids(about 50% stabilized), and only 25 two-sided solids(none stabilized); for a total of 57,025 finishedstones (P. Paré, pers. comm., 2001). This productionwas derived primarily from the Oxbow mine, withthe exception of small amounts from the Zone 4mine and surface-collected material. At present, the

Zone 4 mine contributes about 10% by volume, butonly 5% by value, to Korite’s overall production (P.Paré, pers. comm., 2001). The authors believe thatthe Korite operations represent about 90% of theproduction throughout Alberta. As such, we esti-mate that the total annual production of Ammolite(all categories) is currently more than 63,000 fin-ished stones.

Huge amounts of rock are mined to obtain a rel-atively small amount of gem-quality Ammolite. In1999, from 165,000 tonnes of excavated shale only105,000 carats (21 kg) of Ammolite solids andassembled gemstones (including the backings butnot the caps) were obtained (P. Paré, pers. comm.,2001). This is equivalent to a mere 0.64 ct per tonneof shale. Because the Ammolite layer in an averagetriplet is only 0.1 mm thick, the actual finishedcarat weight/tonne of Ammolite is, therefore, con-siderably less once the backing weight is subtracted.

STABILIZATION OF AMMOLITEStabilization—that is, impregnation of the materialunder pressure with an epoxy or other substance—is usually required to strengthen type 2 (sheet)Ammolite so that it can be manufactured into jew-elry as solids or doublets. (As stated above, the

AMMOLITE GEMS & GEMOLOGY SPRING 2001 15

Figure 11. This rare two-sided solid Ammolite (3.1 × 4.2 cm) shows predominantly red and green on one side(left) and blue and green on the other. This piece was polished from unstabilized sheet material from Zone 4and is 2 mm thick. Courtesy of Santo Carbone; photo © Harold & Erica Van Pelt.

Ammolite incorporated into triplets is not stabi-lized.) Although it is likely that some Ammolitewas stabilized and sold as early as the 1970s (see,e.g., Sinkankas, 1997), details of such treatments are

lacking. Koivula and Kammerling (1991) were thefirst to document the stabilization of Ammolite,specifically a plastic impregnation that was used asearly as 1989.

Korite began stabilizing some type 2 (sheet)Ammolite from Zone 4 in 1998. Before fashioning,Korite impregnates the rough material under pres-sure (1500 psi) by forcing a commercially availablepolymer (an epoxy resin) into the Ammolite layerswith nitrogen gas (P. Paré, pers. comm., 2000).Other manufacturers may use different proceduresand materials.

During the stabilization process, the entire sam-ple is immersed in polymer. Subsequent polishingremoves the epoxy on the surface, and the onlyremaining epoxy is between the layers. We studiedsix such specimens by viewing them microscopically(incident illumination) on their polished edges. It waspossible to recognize the impregnation, though withdifficulty, at magnifications greater than 30×. Theimpregnation appears as very thin seams of epoxybetween the layers, and as small epoxy-filled voids.

Approximately 50% of the Ammolite solids anddoublets that Korite placed on the market in 1999were stabilized. Korite sells stabilized Ammolite forbetween one-third to one-half the price of untreatedmaterial of equivalent grade (P. Paré, pers. comm.,2000). The authors believe that perhaps one-third ofthe non-Korite production is also stabilized in someway, since it is mainly derived from surface-collect-ed sheet material.

Some color enhancement of Ammolite tripletshas been reported by Barnson (2000), where tripletbackings (see Manufacturing below) are paintedblue, green, or pink to enhance otherwise poorlycolored Ammolite. We could not confirm use of thistechnique (P. Paré and S. Carbone, pers. comms.,2001). Other enhancement techniques that areeffective with some gemstones, such as heat treat-ment and irradiation, are not applied to Ammoliteas they would damage the material.

MANUFACTURINGEarly descriptions of Ammolite manufacturing proce-dures, which were based on surface-collected materi-als (Stafford, 1973b,c; Jarand, 1982), are of historicalinterest only; for example, freeforms are no longertumbled in sawdust. Further, early Ammolite tripletswere made with surface-collected type 2 (sheet)Ammolite; many of these early gems tended to sepa-rate along the glued layers. Santo Carbone was the

16 AMMOLITE GEMS & GEMOLOGY SPRING 2001

Figure 13. Auroralite is a patented assembledstone made by using fragments of Ammolite thatare attached with epoxy to a carborundum back-ing and then capped with a transparent colorlessmaterial. The resulting mosaic exhibits a glittereffect. The larger of the two stones shown heremeasures 16 × 12 mm, and the smaller is 14 × 10mm. Courtesy of Aurora Canadian Jewellery.

Figure 12. “Quadruplets”—here, the 1.9 × 1.5 cmoval on the left and the 2.0 × 1.5 cm oval on theright—are fashioned from two Ammolite layers witha shale backing and a synthetic spinel or quartz cap.The pear-shaped piece in the center is a triplet.Quadruplets courtesy of Santo Carbone; tripletcourtesy of Korite International. Photo © Harold &Erica Van Pelt.

first to correct these problems and perfect the manu-facturing techniques that are now used to producehigh-quality assembled gems. Today, the modernmanufacturing facilities of Korite in Calgary, whichemploys about 20 full-time cutters (about 50 staffmembers total), dominate the production ofAmmolite for the world market, although there areseveral smaller operations throughout Alberta.

Rough Ammolite that is sufficiently thick anddurable for manufacture into solids goes throughthe following steps: slabbing; trimming; stabilizing,if necessary; grinding to optimum colors; polishing;and shaping. Note that the cutter will constantlygrind a piece of Ammolite until it shows the mostattractive color display; this delicate techniquetakes years of experience to perfect—too muchgrinding could destroy a good color suite and pat-tern. Material that is made into triplets (again, seefigure 1) goes through a similar set of early steps,but after a first grinding to reach optimal colors (theAmmolite will still be relatively thick), a spinel or

quartz cap is attached with epoxy to the Ammolite,the back of the gem material is ground again toreduce thickness, and a piece of shale (typicallyfrom the Bearpaw Formation) that has been coatedwith lampblack is attached with epoxy to form abacking. A final trimming provides calibrated sizes.Using much the same process, Korite will attach anatural shale backing to polished pieces ofAmmolite that are too thin and fragile for use assolids to create doublets. For some of his assembledstones, Mr. Carbone uses two individual Ammolitelayers together with the backing and the cap (form-ing an Ammolite “quadruplet”), which increasesthe quantity and intensity of colors in the finishedpiece (see figure 12). Barnson (2000) provides step-by-step details of the manufacturing process.

Mr. Carbone also creates a unique mosaic-likeAmmolite “triplet” that has been marketed exclu-sively since 1997 by Aurora Canadian Jewellery asAuroralite (figure 13). These triplets have a glittereffect produced by a patented process (Carbone,1991) in which multi-colored fragments ofAmmolite (0.5–3 mm wide) are attached withepoxy to a synthetic spinel or quartz cap. Airtrapped in the epoxy is removed in a vacuum unitand then the cap is placed in a preheated oven toharden the epoxy to a gel-like state. At this point,grains of carborundum are sprinkled on the epoxy toform the base. Recently, Johnson et al. (2000)described these triplets, which Korite had providedfor examination and were erroneously attributed totheir mining operation.

In recent years, other innovative uses havebeen found for material that is not suited for man-ufacture into solids or assembled stones. Forexample, mosaics of small Ammolite fragmentshave been cemented into watch faces and otherforms of jewelry.

QUALITY GRADING OF AMMOLITEAlthough an internationally accepted grading sys-tem for Ammolite does not exist, Korite has devel-oped its own in-house grading system. A number ofabbreviated versions of this same system have beenpublished (Barnson, 1996; “Gemstone unique toCanada …,” 1999; Barnson, 2000).

There are six recognized grades of Ammolite asdescribed in table 2: Extra Fine, Fine, Good, Fair,Poor, and Commercial (which correspond toKorite’s AA, A+, A, A-, B, and C). The three factorsin determining the grade of a polished (unmounted)

AMMOLITE GEMS & GEMOLOGY SPRING 2001 17

TABLE 2. Grading categories of Ammolite.

Grade Description

Extra fine Stone exhibits three or more sharp and brilliantcolors (usually red, yellow, green, and/or blue).Colors are naturally bright with no obvious darkareas. Show of color does not depend on orien-tation. Fractures are in aesthetically pleasing pat-terns and, more importantly, are narrow. Stoneswith rare colors, specifically blue and purple, aremost desirable.

Fine Stone exhibits at least two distinct colors. Colorsare not as bright as those in “Extra Fine” grade,and the stone may have some dark areas. Showof color does not depend on orientation.Fractures may distract somewhat from the beautyof the stone.

Good Stone exhibits at least one distinct color or play ofcolor. Dark areas are more apparent than in“Fine” grade material. The color may be direction-al. Fracture patterns may be distracting.

Fair Colors and color changes are less distinct than“Good” grade. Colors commonly are from themiddle of the spectrum, i.e., yellow and green.Directional color display is more apparent than in“Good” grade stones. Fracture patterns may bedistracting. This category represents most of thecurrent production (38%).

Poor Faint colors or play of color, sometimes with abrown overtone; Noticeably poor brilliance.

Commercial Dark brown or gray body color with faint colorpatches. May have unappealing fracture patterns.Lowest quality; currently not offered or commer-cially available from Korite although it isbeing kept in inventory.

Ammolite solid or assembled stone are: color rangeand display, intensity of iridescence, and pattern.The grade distribution, as a percent of Korite’s totalsales for 2000 (P. Paré, pers. comm., 2001), was:Extra Fine—6%, Fine—5%, Good—21%, Fair—38%, and Poor—30% (“Commercial” grade materi-al was not sold).

Color Range and Display. In general, the more col-ors displayed, the higher the grade. Thus, stonesthat exhibit the full color spectrum, and especiallyblue and violet or purple (the latter is particularlyrare), are most desirable. Stones that exhibit onlyone color, especially entirely red or brown (which,after white, are the most common colors found onBearpaw Formation ammonite), are less desirable.

Intensity of Iridescence. The ideal Ammolite showssharp color sections and bright hues. Although somestones exhibit a full color spectrum, the colors mayappear dark when illuminated from different direc-tions. Such a directional display of color detractsfrom the beauty, and hence the value, of a stone andcan generate a grade no higher than Fine.

Pattern. Pattern is the composite appearance of thecolor panes in relation to the dark, non-iridescentfracture system that permeates the specimen andframes them (commonly referred to as “stainedglass window” effect; see figure 14 and otherAmmolite photos in this article). Quality gradingfor pattern is usually more applicable to type 1Ammolite. Stones with wide fractures on the sur-face are graded lower than stones with few or verynarrow fractures. Some stones may also exhibit a“suture” pattern derived from the original shellstructure (see figure 15). Although common tomany types of fossil ammonites, suture patterns infinished Ammolite gems are rare.

18 AMMOLITE GEMS & GEMOLOGY SPRING 2001

Figure 15. Among the rarest of the patterns seen inAmmolite is this suture pattern, which mimics theinternal structure of the original shell. These Ammo-lites (both one-sided solids) measure 4.1 × 3.1 cmand 3.2 × 2.6 cm. Courtesy of Santo Carbone; photo© Harold & Erica Van Pelt.

Figure 14. These threepieces of jewelry illus-trate some of the manypatterns seen inAmmolite, includingthe broad panes ofindividual colors insheet material (the ear-rings) and the narrowfractures (pendant at

upper right, 40 × 25mm) and broader fractures(clasp at lower left, 25 × 20mm) associated with frac-tured material. Earringscourtesy of Carolyn Tyler;pendant and clasp courtesyof Korite International.

CHARACTERIZATION OF AMMOLITEMaterials and Methods. Korite provided samples ofboth rough and polished Ammolite from theOxbow and Zone 4 mines. Every variety ofAmmolite was represented: fractured (type 1) andsheet (type 2); all colors, but particularly red, green,and blue; two-sided solids, one-sided solids, doub-lets, and triplets in various stages of production; andstabilized and unstabilized material. In addition, westudied two concretions. In total, 93 samples weresubjected to some type of analysis from amongmany hundreds of specimens placed at our disposalby Korite. We performed visual and microscopicobservation on approximately 50 additional samples.

Samples were examined with magnificationranging from 10× to 45×, usually with a GIA GemInstruments Mark VI Gemolite microscope.Refractive indices (10 samples) were measured on aGIA Gem Instruments Duplex II refractometer witha monochromatic sodium-equivalent light source.Specific gravity (7 samples) was measured by thehydrostatic method with a Mettler H31 balance.Fluorescence (8 samples) was determined with aGIA Gem Instruments ultraviolet lamp. Thin sec-tions—four of type 1 (fractured) and three of type 2(sheet) material—were studied and photographedwith a Zeiss Axioplan binocular polarizing micro-scope. Hardness (4 samples) was estimated byscratching Ammolite with calcite and fluorite.

X-ray diffraction patterns (10 samples) wereobtained on a Scintag Model XDS 2000 instrument,and the data were interpreted using the MaterialData Inc. “Jade XRD Processing” software package.We conducted scanning electron microscope studieswith a Cambridge Stereoscan 250 instrument todetermine the microstructural characteristics ofAmmolite layers and their correlation with color (ifany). We had 41 samples (all rough; consisting ofboth type 1 and type 2 Ammolite) mounted and pre-pared (e.g., coated with gold) “on edge” so that thehorizontal layers were perpendicular to the electronbeam. Only red, green, or violet/purple material wasused, as these colors represent the long, intermedi-ate, and short wavelengths of visible light as well asthe range of colors found in Ammolite. An attachedKevex Micro-X 7000 Analytical Spectrometer wasused for energy-dispersive elemental analysis (SEM-EDX) on 6 rough samples (three of type 1 and threeof type 2), which were analyzed parallel to the uppersurface. Prof. G. R. Rossman obtained visible/near-infrared spectra (2 samples) with a custom-madereflectance spectrometer.

Results. The results of our research are given intable 3 and discussed below.

Composition. The X-ray diffraction (XRD) studiesconfirmed that the composition of Ammolite isessentially pure aragonite; organic matter, which isundoubtedly present (see below, Mineralogy ofAmmolite) is not detected by this technique. Onlycalcium was detected (by SEM-EDX) on the irides-cent Ammolite surfaces, except for trace amountsof strontium and iron.

The material that comprises the non-iridescent

AMMOLITE GEMS & GEMOLOGY SPRING 2001 19

TABLE 3. Properties of Ammolite.

Property Description

Mineral name Aragonite

Composition CaCO3

Crystal system Orthorhombic

Morphology (of rough) Type 1 (fractured): Flat iridescent layersare fractured and the fractures arehealed with non-iridescent material,resulting in a mosaic textureType 2 (sheet): Flat areas have no frac-tures and no special features (exceptrare suture patterns)Thickness of layers rarely exceeds 8 mm

Iridescent color All colors, with red and green mostabundant; blue is rare and purpleextremely rare

Clarity Normally opaque; transparent or trans-lucent in very thin sheets

Luster Vitreous to resinous

Hardness 3.5

Toughness Red Ammolite is relatively tough, butblue and purple are brittle

Refractive indices Low values: 1.525–1.530High values: 1.665–1.670

Birefringence 0.135–0.145

Specific gravity 2.76–2.84

UV fluorescence Iridescent material inert to both long-and short-wave UV; non-iridescenthealed fracture material has weak yellowfluorescence, stronger to long-wave UV

Parting Parting along flat layers most commonin rough type 2 Ammolite

Inclusions Pyrite, organic matter; these only occurbetween Ammolite layers and cannot beseen from the surface of polished stones

Durability Solids should be handled carefullybecause of softness and susceptibility tochemicals, household products, andexcessive heat; triplets (with quartz orsynthetic spinel caps) are stable undernormal conditions

May be confused with Opal, fire agate, labradorite, and variousmodern (e.g., abalone) or other fos-silized (e.g., lumachelle) shell materials

healed fractures is also predominantly aragonite (asreported by Wight, 1981), but calcite was the mainfiller in some of the fractures. In addition, S. Carbone(pers. comm., 2000) has identified clay minerals(species unidentified) in some fractures, and this isconsistent with our detection by SEM-EDX of Aland Si (the main chemical components of clays) dur-ing qualitative analysis of several fracture fillings.

XRD analysis of the host concretions showedthat they contain siderite (FeCO3), which is inagreement with Niedermayr (1999).

Visual Appearance. In the rough, type 1 (fractured)Ammolite ideally appears as a collage of vivid iri-descent colors (all colors of the spectrum, with redand green the most abundant), separated by healedfractures. However, the number and quality of thecolors can vary over short distances (e.g., a few mil-limeters). Type 2 (sheet) Ammolite, on the otherhand, usually has two predominant spectral colors,which vary by the piece (color panes up to severalcentimeters are common). Although the iridescentareas in both types are generally less than 20 cm (~8inches) in maximum dimension, only much smallerareas, particularly in the type 1 variety, will haveuniform color, quality, or thickness. The Ammolitelayers, which are supported on shale or concre-tionary material, may vary in thickness from about8 mm to film-like in the same sample.

Data supplied by Korite, and verified by theauthors, for fashioned material indicate that an aver-age Ammolite triplet will consist of a 0.1-mm-thickAmmolite layer with a 1-mm-thick shale backingand a 1.5-mm-thick synthetic spinel cap, weigh atotal of 2.5 ct, and measure 11 × 9 mm (oval).Average doublets have a 1-mm-thick Ammolitelayer with a 2.5-mm-thick shale backing, weigh 18ct, and measure 29.5 × 28.5 mm. An average one-sided solid also consists of a 1-mm-thick Ammolitelayer, which is naturally attached to a 2.5-mm-thickshale matrix; it weighs 17 ct and measures 29 × 28mm. Average two-sided Ammolite solids are typical-ly 3 mm thick, weigh 15 ct, and measure 28 × 24mm. In general, stabilized Ammolite solids and dou-blets are larger than their unstabilized counterpartsand can range up to 50 mm (and, rarely, as large as100 mm) in longest dimension.

Diaphaneity and Luster. Ammolite is transparent ortranslucent to transmitted light only in extremelythin sheets, such as those used for assembled stones.Because these always have a dark backing, however,

the material seen in jewelry (including one- and two-sided solids) is opaque. Luster ranges from vitreousto resinous, and the intensity may vary considerablybetween samples, from very dull to intense.

Hardness. The Mohs hardness of Ammolite is 3.5;it can be scratched by fluorite (H=4) but not by cal-cite (H=3).

Refractive Indices and Birefringence. We recordedR.I. values for 10 polished stones, five each of type 1(fractured) and type 2 (sheet). Five were red, fourwere green, and one was blue. The low valuesranged from 1.525 to 1.530, and the high valuesmeasured were 1.665–1.670. We found no relation-ship between color and R.I. Birefringence was0.140–0.145 in eight of the 10 samples; for twogreen samples—one of each type—the birefringencewas 0.135, but we are unable to attach any signifi-cance to this difference. These data are very similarto those reported by Wight (1981).

Specific Gravity. The seven samples selected forS.G. determinations were all double-sided solids andpredominantly red (purposely chosen to minimizeany possible variance related to color). The S.G. ofthe four type 1 (fractured) Ammolites ranged from2.81 to 2.84. The values obtained for the three type2 (sheet) Ammolites averaged 2.76, 2.76, and 2.84.Wight (1981) determined the S.G. for Ammolite(type 1 from the now-closed Kormos mine; numberof samples studied not stated) to be 2.80 ± 0.01. TheS.G. of pure aragonite is 2.94 (Gem ReferenceGuide, 1995). The lower values presented here fortype 1 Ammolite can be explained by the presencewithin Ammolite of small amounts of organic mat-ter and calcite, which have lower S.G.’s; in type 2Ammolite, voids between the layers also contributeto a lower S.G. Inclusions of pyrite (S.G. about 5),discussed below, will increase the overall S.G. of theAmmolite.

Fluorescence. Yellow ultraviolet fluorescence (long-wave stronger than short-wave) was observed only inthe material healing the non-iridescent fractures oftype 1 Ammolite. Whereas Wight (1981) describesthis fluorescence as bright or intense, we classify it asweak.

Parting. All Ammolite may part into sheet-like lay-ers, although type 2 Ammolite is more susceptible.Cleavage was not observed.

20 AMMOLITE GEMS & GEMOLOGY SPRING 2001

Inclusions. Zeitner (1978), Koivula (1987), and Wight(1993) have reported pyrite blebs in finishedAmmolite. We also identified pyrite, by XRD analy-sis. This was seen in small amounts in thin sectionsas an opaque, highly reflective, yellowish mineralthat occurred as blebs or comprised very thin layerswithin the Ammolite. Both pyrite and organic matter(see Mineralogy of Ammolite below) occur betweenAmmolite layers and cannot be seen from the surfaceof polished stones. Stafford (1973b) and Sinkankas(1976) reported the occurrence of hydrocarbons in fin-ished Ammolite; however this “inclusion” was artifi-cial, in that it had been introduced by the oil-lubricat-ed saws used to cut the earliest Ammolites.

Other Microscopic Studies. Thin sections (micro-scopic studies) of the nacreous layers from type 1(from the K Zone) and type 2 (from Zone 4) Ammo-lites are shown in figure 16. In both cases, themicrostructure shows fine laminae (layers) of pris-matic aragonite crystals. In the type 1 specimen,however, these laminae are of limited lateral extentand exhibit a “shingle” structure; in addition, a nat-ural fracture-healing material (aragonite, calciteand/or clay minerals) is evident. In the type 2 speci-men illustrated, the laminae are much more contin-uous and are not cross-cut with fracture fillings. Webelieve that the material that fills fractures, and theshingle structure in the type 1 material, jointly act

as a “structural support” for the aragonite laminae,so that this material can be used in jewelry withoutstabilization. As noted above, type 2 material lacksthis structural support and may have to be polymer-impregnated before it can be manufactured intojewelry.

Scanning electron microscopy revealed addition-al details of the nacreous layer. As figure 17 illus-trates, red Ammolite is composed of stackedcolumns of aragonite tablets. The aragonite tabletsin green Ammolite are thinner and occur in a lessorganized vertical arrangement. Purple Ammolitehas even thinner tablets, which show no stackingarrangement.

Discussion. Mineralogy of Ammolite. Shell micro-structure studies of the modern Nautilus, fossilammonites, and specimens from many otherMollusca (Wise, 1970; Grégoire, 1987; Dauphin andDenis, 1999) have shown that they are all composedof layers of aragonite crystals with small amounts oforganic material (usually between 0.01 and 5 wt.%;Lowenstam and Weiner, 1989). This combination ofthin tablets of aragonite interleaved with muchthinner sheets of organic matter, frequently with amother-of-pearl luster, is known as nacre (Jackson,1997). Using SEM imaging, Dauphin and Denis(1999) established that the shells of living Nautilihave three layers, each of which is characterized by

AMMOLITE GEMS & GEMOLOGY SPRING 2001 21

Figure 16. These two thin sections of ammolite (type 1 from the K Zone on the left and type 2 from Zone4 on the right) were photographed in polarized light perpendicular to the flat surface (parallel to the edge)of each stone. Thin, prismatic crystals of aragonite are seen in both types of Ammolite. In the type 1material, however, they are in laminae (layers) of limited extent arranged with a shingle effect; fracturesare abundant (one is seen here on the left side of the photo cutting across the laminae at right angles)and are filled with coarse secondary aragonite and sometimes calcite and clays. The aragonite layers intype 2 Ammolite are essentially continuous; they are not interrupted by fractures. The relatively thickdark layer at the top of this photo contains organic matter (black) as well as minute disseminated pyritegrains (not visible). The shell layer in both samples is 2–3 mm thick. The width of each photomicrographrepresents 2.3 mm.

different shapes and arrangements of crystals: (1) anouter spherulitic-prismatic layer; (2) a middle, thick-er, nacreous layer; and (3) an inner, thin prismaticlayer. Fossilized ammonite shells usually have onlythe nacreous layer preserved.

That ammonite shells were originally composed

of aragonite has been known since the late 1800s(reviewed by Grégoire, 1987; Lowenstam andWeiner, 1989). We have confirmed that Ammoliteis also composed of aragonite, in agreement withWight (1981). Lowenstam and Weiner (1989) notedthat the oldest known sedimentary deposit withabundant aragonite fossils dates from theCarboniferous Period (about 340 million years ago);the ammonites from which Ammolite is derivedlived between 75 and 70 million years ago (seeGeology and Occurrence section above).

The Microstructure of Ammolite and Its Corre-lation with Color. In addition to the differences inthickness and organization of the aragonite tabletsnoted with SEM for the different colors ofAmmolite, we have also observed that Ammolitesof different colors have different physical attributes,which we suggest are related to their unique micro-structures. Red Ammolite is stronger (tougher, easi-er to manufacture into gemstones) than greenAmmolite, while purple Ammolite is the weakestof all. Further, cutters (e.g., S. Carbone, pers. comm.,2000) have observed (qualitatively) that the hard-ness of Ammolite, at least in polishing, varies withcolor and decreases in the order red-green-purple.We suggest that this is another manifestation of themicrostructure differences of the various coloredAmmolites illustrated in figure 17. If this is thecase, a corollary might be that the rarity of purpleand blue Ammolite can be explained by the factthat the microstructures responsible for these colorsare less likely to have survived in the natural envi-ronment due to their relative weakness.

Cause of Color in Ammolite. Several explanationshave been proposed for the cause of the iridescentcolor of Ammolite. All the explanations fall into twobasic categories: interference (Pough, 1986; Fritschand Rossman, 1988; Vandervelde, 1993; Niedermayrand Oehner, 1995; Niedermayr, 1999), or diffraction(Leiper, 1969; Wight, 1981; Brown, 1984; Vander-velde, 1991). However, none of the above referencesoffered experimental work to confirm either explana-tion. Although both interference and diffraction canproduce color in minerals when white light interactsin certain ways within a specimen, the mechanismof the reaction, and its result, will be specific for eachphenomenon (for more on these mechanisms, seeFritsch and Rossman, 1988, pp. 86–89).

The visible/near-infrared reflectance spectrumobtained from a piece of type 2 (sheet) Ammolite

22 AMMOLITE GEMS & GEMOLOGY SPRING 2001

Figure 17. Distinct differences in the arrangements,sizes, and shapes of the aragonite crystals inAmmolite can be seen in the scanning electronmicrographs of these representative red (top), green(center), and purple (bottom) samples. Scale bar is2 microns.

from Zone 4 (illuminated with white light) indi-cates that light reflected from the yellow-green por-tion of the shell is more intense in a band that iscentered at about 568 nm. This spectrum is consis-tent with what would be expected for an interfer-ence phenomenon, as light passes through andreflects back from multiple layers of aragonite ofuniform thickness (G. R. Rossman, pers. comm.,2000). This model is confirmed by the observationof uniform layers in the electron micrograph of asection of Ammolite (again, see figure 17). The lackof an array of uniform grooves or ridges, such as isfound in diffraction gratings, and the comparativelylarge width of the band in the reflectance spectrum(lack of a pure spectral color), argue against diffrac-tion to explain the color in Ammolite (G. R.Rossman, pers. comm., 2000).

Tilting has the effect of changing the relativeposition of interfering light waves, thus producing adifferent color in most Ammolites (this is the sameas directional color mentioned in the QualityGrading section). When a piece of predominantlyred Ammolite is tilted, the colors change in thesequence orange, yellow, and green. When a piece ofpredominantly green Ammolite is tilted, blue maybe obtained. There is almost no change of colorwhen a piece of purple or blue Ammolite is tilted.

In addition, as noted above, the color ofAmmolite can be shown to depend, at least to someextent, on the amount of polishing, which affectsthe final thickness of the nacre. Thus, if the originalcolor of a piece of Ammolite is blue, polishing exact-ly parallel to the surface will change the color in thefollowing sequence: blue-green-yellow-orange-red(see figure 7; also, P. Paré and S. Carbone, pers.comms., 2000). This corresponds to the changesshown in figure 17, and the final color will be relatedto the structural characteristics (including boththickness and stacking arrangement) of the nacreouslayer on the surface of the polished stone.

CARE AND DURABILITYAmmolite is used in all forms of jewelry. Because itis soft and will scratch easily, solid Ammolite is bestsuited for brooches, pendants, or earrings rather thanrings. Since Ammolite, like pearls, is delicate andconsists of aragonite, many of the care and cleaningrecommendations for pearls also apply to Ammolite.Ultrasonic and steam cleaners should never be usedfor solids; rather, a commercial pearl cleaner or amild, warm soap solution is recommended (a maxi-

mum of 20 minutes in any fluid). Contact with heat,acids, perfumes, hairsprays, and many householdcommodities can cause loss of iridescence and othertypes of damage, particularly in solids.