Spiral Welded Tube and Pipe • Tube and Pipe Fittings ...spiralproducts.com.my/SP_Brochure_LR.pdfSP...

Transcript of Spiral Welded Tube and Pipe • Tube and Pipe Fittings ...spiralproducts.com.my/SP_Brochure_LR.pdfSP...

www.spiralproducts.com.my

• Spiral Welded Tube and Pipe• Tube and Pipe Fittings• General Fabrication• Pipe and tube spooling• Acid treatment of stainless steel

Contents1. Contents

2. Overview

3. Stainless Steel Tube, Pipe and Fittings

4. Carbon Steel and Galvanised Tube, Pipe and Fittings

5. Structural Steel Fabrication and Tube and Pipe Spooling

6. Typical Applications

7. Typical Industries

8. Services

9. Useful Information

10. Pressure Chart SS

11. Contact Us

1

OverviewSpiral pipe can be used as an alternative to schedule pipe for many applications. It is an adaptable product and is available over a wide range of ferrous alloys. Aluminium alloys are also produced.

Spiral Products (SP) has extensive experience in this industry with much of the plant designed and built in house.

Spiral pipe systems can be tailored to customer requirements. This can be extremely cost competitive compared to schedule systems. For example, the spiral mill can be set to produce to exact length requirement (avoiding off cuts). Delivery is generally improved as well.

In addition to spiral tube and pipe, Spiral Products offer a complete range of associated fittings, including bends, tees, reducers and flanges. We can also fabricate pipe support structures including the structural steel components and brackets.

Our value added services including pickling and passivation of stainless steel product and hot dip galvanising and painting of carbon steel product. We also offer plasma cutting of sheet metal. Our in house drafting services produces high quality detailed drawings using the latest CAD software for our customers.

2

Stainless Steel Tube, Pipe and Fittings

Spiral Products offers spiral tubing from76mm to 2,240mm in diameter with a wall thickness from 1mm to 6mm. The

outside diameters are typically the same as the tube and pipe sizes (although special sizes are regularly manufactured) so that standard tube and pipe flanges can be used with our product. We also offer a complete range of associated fittings such as tees, reducers, bends and flanges.

The range includes alloys from typical Austenitic grades such as 304 and 316 to ferritic alloys such as 409, 410 and 3CR12. We can also mill duplex and lean duplex alloys.

All stainless steel product is pickled and passivated prior to delivery ensuring highest possible level of corrosion resistance. This presents as an aesthetically pleasing silver colour.

3

Carbon Steel and Galvanized Tube, Pipe and Fittings

The spiral process of tube making is readily interchangeable between the range of ferrous alloys.

Carbon steel is a major product line and is produced across the same range as stainless steel. The difference is the finish. Acid pickling is not used on carbon steel.

The product is supplied as follows:-

• “As is” off the Mill• Painted to required specification• Hot dipped galvanised• Hot dipped galvanised and painted• Powder coated

4

Structural Steel Fabrication and Tube and Pipe Spooling

SP is able to offer complete structural fabrication including walkways, platforms, ladders and pipe support brackets. This

includes pipe spooling to customers drawings leading to efficient installation. This saves time and is highly effective.

• Stainless steel assemblies are acid pickled and passivated in our large pickling tanks.

Assemblies, when welded together, on site, or in our plant, are then hand pickled.

• Carbon steel assemblies are painted or galvanised with the joined components similarly treated “as above” with either cold galvanizing paint, or painted.

5

Typical Applications

• Rainwater down pipes in stainless steel offer long life, and can be supplied to length. Offsets, collector boxes, and brackets can be included.

• Prison Barrier Tubes are placed on top of Prison walls as a superior barrier and provides a humane, attractive solution compared to razor wire.

• Supplied complete with perforation for filtering processes. Oil reclamation is a typical application.

• Street sweeper barrels.

• Non-standard diameter and wall thickness, to suit customer requirements.

• Flag Poles.

• Process pipe for industrial plants.

• Mine ventilation.

• Dust and fume extraction.

• Potable water supply.

• Pontoon boat tubes.

6

Typical Industries

• Water and sewage treatment plants.

• Paper and pulp processing.

• Hospital exhaust stacks.

• Prison Walls.

• Palm oil processing.

• Oil and gas.

• Desalination.

• Structural supports

• Irrigation.

• Shipbuilding.

• Mining.

• Machinery manufacture.

• Residential and Commercial Construction.

7

ServicesMill to Set Length

This is offered to save time and costs.

Acid pickling and Passivating

SP uses this line for its stainless spiral tube manufacture.

It contains heated caustic soda for cleaning, acid pickling and rinse tanks. It can handle six meter lengths of pipe.

SP offers this flexibility to our customers and fabricators to pickle and passivate their own stainless steel assemblies. This is a fast and competitive turnaround and is far superior than pickling by hand.

Drafting

SP can offer high quality drawings using our latest CAD software.

Plasma Cutting

SP cut sheet and plate to your requirements using our state of the art plasma cutting machine.

8

Useful InformationStandardsASTM A 778 - Standard Specification Welded, Unannealed Austenitic Stainless Steel Tubular Products.

ASTM A 554 - Standard Specification for Welded Stainless Steel Mechanical Tubing.

ASTM A 774 - As-Welded Wrought Austenitic Stainless Steel Fittings for General Corrosive Service at Low and Moderate Temperatures

ASTM A 134 - Specification for Pipe, Steel, Electric-Fusion (Arc)- Welded

ASTM A380 - Standard Practice for Cleaning, Descaling and Passivation of Stainless Steel Parts, Equipment and System

AS1554 - Structural Steel Welding

AS 4041 - Pressure Piping

A number of other standards are used for structural steel and pipe welding as well as manufacture of tube and pipe.

Pickling and PassivationPickling is the removal of any contaminants, high temperature scale and any adjacent low chromium layer of metal from the surface of stainless steel by chemical means. Typically a combination of Nitric and Hydrofluric acids are employed.

Passivation is the treatment of the surface of stainless steels, often with acid solutions (or pastes), to remove contaminants and promote the formation of the passive film on a freshly created surface (eg through grinding, machining or mechanical damage).

SP will employ the appropriate process. ASTM A380 Standard Practice for Cleaning, Descaling and Passivation of Stainless Steel Parts, Equipment and System is employed.

Pressure CalculationsBarlows Thin Wall Formula is widely employed in industry for calculating a suitable working pressure.

P= 2ST/D

A weld joint efficiency of 85% should be used. A safety factor of 1.5, to 5 is often employed depending on the nature of pressure fluctuations and the product being conveyed.

Alternatively, some piping standards have recommended calculations for tube and pipe pressure. The following table is an example of this from AS4041 Pressure Piping.

9

Where: P = Internal Pressure (MPa) S = Yield Strength (MPa) T = Wall Thickness (mm) It is prudent to use minimum tolerance for this. D = Nominal Outside Diameter (mm)

10

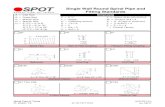

Basis: AS 4041-2006 Class 3 Material: T304 / T316 (to ASTM A240)

OutsideDiameter

(mm) 1.6 2.0 2.5 3.0 4.0 5.0 6.0102 2747 3433 4291 5150114 2454 3067 3834 4601127 2200 2750 3437 4124140 1993 2492 3115 3737152 1834 2293 2866 3440 4484168 1658 2073 2591 3109 4053203 1370 1713 2141 2569 3350219 1269 1587 1984 2380 3103254 1094 1367 1709 2050 2673273 1017 1271 1589 1907 2486305 910 1137 1422 1706 2224324 856 1070 1338 1605 2093356 779 974 1217 1461 1904 2380406 683 853 1067 1280 1669 2086457 606 758 947 1137 1482 1852508 545 682 852 1022 1333 1666559 495 619 774 929 1211 1514610 567 709 851 1109 1387 1664660 524 655 786 1025 1281 1538711 487 608 730 951 1189 1427762 454 567 681 888 1110 1332813 425 532 638 832 1040 1248864 400 500 600 783 978 1174914 378 473 567 740 925 1110965 448 537 701 876 10511016 425 510 665 832 9981118 386 464 605 756 9071168 370 444 579 723 8681219 354 425 554 693 8321372 315 378 493 616 7391524 283 340 443 554 6651676 258 309 403 504 6051829 236 283 369 462 554

ASSUMPTIONS INHERENT IN THE CALCULATIONSDesign Strength (f) = 137000 kPa = 205000 kPa Minimum Yield / 1.5Weld Joint Factor (e) = 0.85Piping Class Factor (M) = 0.7

e*M = 0.7 the product e*M need not be taken as less than 0.7

These figures calculated according to AS 4041 - 2006 and are supplied for information only.

Wall Thickness (mm)Design Positive Pressure @ 50oC (kPa)

Pressure Capacity - Stainless Steel Spiral Weld Tube

SP does not warrant the use of these figures for any particular use. It is up to the system designer to verify their calculations and the suitability of the product.

Contact Us

Spiral Products5 Jalan Masai LamaKawasan Perindustrian Kota Puteri 1Johor, Masai MALAYSIA 81750

Ph: +60 7380 5281Fax: +60 7380 5276

11