specs

description

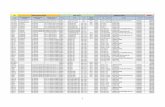

Transcript of specs

-

1Project execution and operation of the worlds first FDPSO Azurite- Claes W. Olsen, Prosafe Production

-

2Content

Introduction

Project overview

FDPSO specifics

Project execution

Operations

Lessons learned

The future

Summary

-

3Company Profile

One of the worlds leading FPSO contractors

Fleet of 11 units, including

Large Gas FPSO (ca 20,000T topside)

Worlds first FDPSO

Harsh weather disconnectable FPSO

Two FSOs

VLCC conversion candidate

Solid project execution and operational experience built over more than 20 years

Proven proprietary turret/swivel mooring technologies, including dis-connectable turret

Excellent operational uptime (>99%)

Excellent HSE records

Cost efficiency, innovative solutions and sustainable growth

-

4Global Presence

Singapore

Houston

Rio de Janeiro

Amsterdam

Cyprus

Lagos

Perth

New Plymouth

Mumbai

FPSO ESPOIR IVOIRIEN(Cote D'Ivoire)

FPSO PETROLEO NAUTIPA(Gabon)

FSO ENDEAVOR(India)

FPSO POLVO(Brazil)

FSO MADURA JAYA(Indonesia)

FPSO ABO(Nigeria)

FPSO CIDADE DE SAO MATEUS (Brazil)

FDPSO AZURITE(Congo)

FPSO NINGALOO VISION(Australia)

FPSO UMUROA(New Zealand)

Abidjan

Pointe Noire

Vittoria

- Offices

- Vessels

-

5Safety First Always L

os

t T

ime

In

cid

en

t F

req

ue

nc

y

ag

ain

st

Mil

lio

n M

an

-ho

urs

0

0,2

0,4

0,6

0,8

1

1,2

1,4

1,6

2006 2007 2008 2009

Prosafe Production Project Safety Statistics 2006 - 2009

The Azurite Field Development delivered without Lost Time Injuries !

-

6FDPSO Azurite - A Success

Murphy Oil Corporations President and CEO, David M. Wood:

The Azurite project marks an innovative approach to minimizing the cost and maximizing the value of a

deepwater development. Production from the field will continue to ramp up for the remainder of the year as

additional wells are brought on stream.

Source: Press Release , 10 August 2009

-

7Key Project Milestones

Concept definition late 2006

Long lead items placed early 2007

Left shipyard January 2009

Ready for drilling April 2009

First oil August 2009

Fast track project execution in a heated and challenging market environment

-

8FDPSO Specifics

260,000 dwt VLCC conversion

Oil Production: 40,000 BOPD

Gas production: 75 mmscfd

Water injection: 60,000 BWPD

Oil storage: 1.4 mmbbls

Accommodation: 136 POB

12 line active spread mooring solution

Modular drilling derrick capacity:

1,250kip hook load

Top Drive: 500T x 1,150HP

Simultaneous drilling, production and water injection

-

9Experience Cooperation

Production

Well intervention

&

Drilling

Innovation

Integrated FDPSO Concept

Prosafe Production Murphy Oil Nabors Drilling

A unique concept based on proven technology and entrepreneurship

FDPSO Design Process

-

10

Strong Project Partners

Murphy Oil supported by Doris and WJM

- operatorship, functional specifications and follow-up

Keppel Shipyard, Benoi

- Vessel R&LE and conversion + drilling modules integration

Nabors Drilling

- Modular drilling equipment set + drilling services

Kencana, Malaysia

- Provision of topside modules

Det Norske Veritas (DNV)

- Classification and design reviews

Licence partners PA Resources and Socit Nationale des Ptroles du Congo

-

11

Offshore Installation Phase

Field located in 1,400 m of water depth

80 nautical miles offshore

12 line active spread mooring system

3 flexible risers (2 prod + 1 WI) connected

to subsea manifold

Good planning and close co-operation

between involved parties

Offshore hook-up / installation

management by Prosafe Production

Installation campaign offshore Congo done in record time of 8 days

-

12

Field Layout

-

13

Simultaneous Operations

Simultaneous drilling and production

Drilling services by Nabors

All other operations done by Prosafe Production

Coherent HSE philosophy

Operations and maintenance managers in country

Training program for national employees

All support activities managed locally

A strong in-country presence ensuring safe and efficient operations

-

14

Lessons Learned

The general challenges of a heated market

Interpretation of class rules for new concepts

Optimization of drilling and FPSO yard

integration work

Definition of interfaces drilling/production

Freeze of conceptual designs

Close co-operation between Operations and

Project teams a key to success

Communication over time zones

Optimizations will be realized during the next FDPSO project

-

15

FPSO - Demand

Pipeline of floating production projects continue to grow

Drivers for F(D)PSO concept remains intact

Leading indicators point to strong long-term demand

Supply side decreasing

No. of FPU projects in planning stage

Bright long-term outlook

119

134141 143

156 160170

Nov-07 Mar-08 Jul-08 Nov-08 Mar-09 Jul-09 Nov-09

Source: IMA

-

16

Leading Indicators

Oil price has remained high for several years

(except of a few

months late 2008/early

2009)

Deepwater drilling activity is set to remain

high for several years

to come

97112

10189

7462

40

1

850 81 97

110132

0

20

40

60

80

100

120

140

160

180

2009 2010 2011 2012 2013 2014 2015

Rig

years

Available

Contracted

Brent oil price high for several years

Deepwater drillers high activity level expected

Positive leading indicators

Source: First Securities

-

17

FDPSO Drivers

Marginal fields

Increased exploration in difficult areas

Deep waters

Remote areas

Marginal

fields

High cost for production and drilling units

Lack of infrastructure

High cost for mobilization of drilling rigs

Short lifetime of fields and need of well intervention capabilities

Yes

Yes

Yes

FDPSO Benefits?Implications Main Challenges

Needs for early production and extended life of fields are important drivers

-

1818

Future Drilling Market

-

1919

Commercial Benefits of FDPSO

* Indicative rates for 1,500 m drilling rig, single hull FPSO with 1.5 mill bbls storage in benign area, 50,000 bopd, 50,000 b/d water inj., Spread moored, 15 year life

Lower combined cost of drilling and production*

USD 300k/day vs. USD 470k/day(FDPSO) (Drilling rig + FPSO)

Accelerated production

FDPSO production from 1st wellFPSO production from arrival of FPSO

Lower cost of logistics and consumables

Sample Production Profile

FDPSO vs. Drilling Unit + FPSO

0

10,000

20,000

30,000

40,000

50,000

60,000

0 20 40 60 80 100

Months

Oil P

rod

ucti

on

b/d

FDPSO

Drilling Unit + FPSO

Benefit from accelerated production depends

on timing of arrival of FPSO

Dayrate of FDPSO vs. Drilling Unit and FPSO

0

50,000

100,000

150,000

200,000

250,000

300,000

350,000

400,000

450,000

500,000

Time

Da

yra

te i

n U

SD

pe

r d

ay

Drilling rig + FPSO

FDPSO

Completion of drillingArrival of FPSO

Topside drilling rig removed from FDPSO

-

20

FDPSO Competitiveness

Benefits from fast tracking the field development

Availability and cost of drilling rigs

The length of the drilling program, and need for future wells

The number of wells that can be drilled with active spread mooring

The complexity of the wells and need for future well intervention

Benefits from simultaneous drilling and production

Benefits from a phased field development (EWT period, EPS etc)

Re-deployment on future fields

The environmental conditions at the field

Competitiveness is determined by a range of factors

-

21

Offering a Range of Services

FDPSO design and project execution

Co-operation with modular drilling package providers

Delivery of different sizes modular rigs

- Well intervention

- Well completions, in-fill drilling/side-tracks

- Full drilling capacity

Simultaneous operations

- Including drilling and well services

Split of responsibilities dependant upon client and contractor team

- Experience and capabilities

Prosafe Production will expand the range of FDPSO services

-

22

Summary

A unique FDPSO successfully delivered

Exceptional safety performance

World class operational performance

Cost efficient solution

A Catalyst for marginal, remote and deep-

water fields

Expanding the range of FDPSO services

Optimizations of the next project execution

FDPSO Azurite An innovative stepping stone for the industry

-

23

Thank You for Your Attention