SOP I2R5

-

Upload

angela-walker -

Category

Documents

-

view

16 -

download

0

Transcript of SOP I2R5

Vietnam Airlines Corporation VIETNAM AIRLINES ENGINEERING COMPANY LTD.

STANDARD OPERATING

PROCEDURES

A: Noi Bai International Airport, Hanoi, Vietnam Ι T: 84-4-38843290 Ι F: 84-4-38865176 Ι W: www.vaeco.com.vn

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 1 GENERAL

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 1-1

PART 1

GENERAL

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 1 GENERAL

Issue: 02, Revision: 05, Date: 25 APR 2013 Page 1.1-1

1.1 TABLE OF CONTENT PART 1 GENERAL ................................................................................................... 1-1

1.1 TABLE OF CONTENT ........................................................................................... 1.1-1 1.2 RECORD OF REVISIONS .................................................................................... 1.2-1 1.3 SUMMARY OF AMENDMENT .............................................................................. 1.3-1 1.4 LIST OF EFFECTIVE PAGES ............................................................................... 1.4-1 1.5 DOCUMENT DISTRIBUTION ................................................................................ 1.5-1 1.6 ABBREVIATION .................................................................................................... 1.6-1 1.7 DEFINITION OF TERMS ....................................................................................... 1.7-1

PART 2 MANAGEMENT ........................................................................................... 2-1

2.1 ORGANIZATION CHARTS .................................................................................... 2.1-1

PART 3 PROCESSES .............................................................................................. 3-1

3.1 BASE MAINTENANCE PROCESS ....................................................................... 3.1-1 3.2 RAMP MAINTENANCE PROCESS ....................................................................... 3.2-1 3.3 COMPONENT MAINTENANCE PROCESS .......................................................... 3.3-1

PART 4 GENERAL SAFETY REQUIREMENTS ...................................................... 4-1

4.1 GENERAL SAFETY .............................................................................................. 4.1-1 4.2 A/C ELECTROSTATIC SAFETY ........................................................................... 4.2-1 4.3 ELECTRICITY AND AIR POWER SAFETY .......................................................... 4.3-1 4.4 FUEL TANK SAFETY ............................................................................................ 4.4-1 4.5 HIGH AREA WORKING SAFETY ......................................................................... 4.5-1 4.6 OXYGEN SYSTEM HANDLING SAFETY ............................................................. 4.6-1 4.7 MAINTENANCE CLEANLINESS AND FOD PREVENTION ................................. 4.7-1 4.8 SAFETY FOR AIRCRAFT IN HANGAR ................................................................ 4.8-1 4.9 HANDLING, STORAGE AND DISPOSAL OF WASTES ....................................... 4.9-1

PART 5 AIRCRAFT MAINTENANCE CONTROL PROCEDURES .......................... 5-1

5.1 CONTRACT MAINTENANCE IMPLEMENTATION ............................................... 5.1-1 5.2 AIRCRAFT WORK ORDER ISSUANCE AND CONTROL .................................... 5.2-1 5.3 WORK PACK PREPARATION AND REVIEW ...................................................... 5.3-1 5.4 CONTROL OF WORK PROCESS AND DOCUMENT DURING MAINTENANCE

PROGRESS .......................................................................................................... 5.4-1 5.5 DOCK CONTROL .................................................................................................. 5.5-1 5.6 MAINTENANCE DOCUMENT COMPLETION ...................................................... 5.6-1 5.7 AIRCRAFT MAINTENANCE RECORD ................................................................. 5.7-1

PART 6 RAMP AND BASE MAINTENANCE PROCEDURES ................................. 6-1

6.1 AIRCRAFT TOWING/ PUSHBACK ....................................................................... 6.1-1 6.2 A/C ARRIVAL AND DEPARTURE......................................................................... 6.2-1 6.3 AIRCRAFT MAINTENANCE.................................................................................. 6.3-1 6.4 CONTINUITY OF MAINTENANCE (SHIFT/TASK HAND-OVER) ......................... 6.4-1 6.5 LANDING GEAR, FLIGHT CONTROL FUNCTIONAL TEST ................................ 6.5-1 6.6 RETURN OF AIRCRAFT PART/ MATERIALS TO STORE .................................. 6.6-1

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 1 GENERAL

Issue: 02, Revision: 05, Date: 25 APR 2013 Page 1.1-2

PART 7 COMPONENT MAINTENANCE PROCEDURES ........................................ 7-1

7.1 WORKSHOP WORK REQUEST ISSUANCE AND MANAGEMENT .................... 7.1-1 7.2 COMPONENT MAINTENANCE WORKSHEET ISSUANCE ................................. 7.2-1 7.3 COMPONENT RECEIVING AND PRELIMINARY INSPECTION .......................... 7.3-1 7.4 COMPONENT MAINTENANCE ............................................................................ 7.4-1 7.5 COMPONENT FINAL INSPECTION AND RETURN TO SERVICE ...................... 7.5-1 7.6 COMPONENT MAINTENANCE RECORD HANDLING ........................................ 7.6-1 7.7 WORKSHOP SPARE PART & MATERIALS CONTROL ...................................... 7.7-1

PART 8 MAINTENANCE SUPPORT PROCEDURES .............................................. 8-1

8.1 MAINTENANCE DATA CONTROL ....................................................................... 8.1-1 8.2 TRANSCRIPTION OF MAINTENANCE DATA ...................................................... 8.2-1 8.3 MAINTENANCE DATA MODIFYING ..................................................................... 8.3-1 8.4 NOTIFICATION OF MAINTENANCE DATA INACCURACIES AND AMBIGUITIES TO

THE AUTHOR ....................................................................................................... 8.4-1 8.5 TECHNICAL SUPPORT ........................................................................................ 8.5-1 8.6 ENGINEERING ORDER ISSUANCE .................................................................... 8.6-1 8.7 TECHNICAL INSTRUCTION FOR PART FABRICATION .................................... 8.7-1 8.8 ACCEPTANCE OF TOOLS AND EQUIPMENT .................................................... 8.8-1 8.9 MANAGEMENT OF TOOL AND EQUIPMENT ..................................................... 8.9-1 8.10 CALIBRATION REQUIRED TOOL AND EQUIPMENT MANAGEMENT ............ 8.10-1 8.11 CALIBRATION AT VAECO CALIBRATION LABORATORY ............................... 8.11-1 8.12 MATERIALS PRODUCTION ............................................................................... 8.12-1 8.13 TRANSFER OF TOOL AND EQUIPMENT FOR MAINTENANCE ...................... 8.13-1

PART 9 LOGISTICS PROCEDURES ....................................................................... 9-1

9.1 PART/ MATERIALS INCOMING INSPECTION & RECEIVING ............................ 9.1-1 9.2 PART/ MATERIALS TAGGING, ARRANGEMENT, PRESERVING ...................... 9.2-1 9.3 SHELF LIFE PART/ MATERIALS CONTROL IN STORE ..................................... 9.3-1 9.4 ROBBERY (CANNIBALIZATION) FROM STOCKED ASSEMBLY ....................... 9.4-1 9.5 PART/ MATERIALS ISSUANCE ........................................................................... 9.5-1 9.6 RECEIVING AND SENDING UNSERVICEABLE PARTS ..................................... 9.6-1 9.7 STOCK LEVEL AND STORE INVENTORY CONTROL ........................................ 9.7-1 9.8 DISPOSITION OF CONDEMNED PARTS ............................................................ 9.8-1

PART 10 QUALITY SYSTEM PROCEDURES ......................................................... 10-1

10.1 INSPECTION AND RETURN TO SERVICE PERSONNEL ................................ 10.1-1 10.2 SUPERVISORY PERSONNEL QUALIFYING ..................................................... 10.2-1 10.3 QUALITY AUDITOR QUALIFYING ..................................................................... 10.3-1 10.4 JOB QUALIFICATION OF THE OTHER QUALIFIED EMPLOYEES .................. 10.4-1 10.5 AIRCRAFT MAINTENANCE INSPECTION ......................................................... 10.5-1 10.6 HIDDEN DAMAGE INSPECTION ....................................................................... 10.6-1 10.7 INSPECTION OF REQUIRED INSPECTION ITEM (RII) .................................... 10.7-1 10.8 CERTIFICATE OF RETURN TO SERVICE/ MAINTENANCE RELEASE ISSUANCE

(FOR AIRCRAFT) ................................................................................................ 10.8-1

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 1 GENERAL

Issue: 02, Revision: 05, Date: 25 APR 2013 Page 1.1-3

10.9 CONTINUITY OF INSPECTION .......................................................................... 10.9-1 10.10 RE-CERTIFYING A COMPONENT/ PART REMOVED FROM AIRCRAFT ...... 10.10-1 10.11 FABRICATION QUALITY CONTROL ................................................................ 10.11-1 10.12 MOR/ MALFUNCTION AND DEFECT REPORTING ........................................ 10.12-1 10.13 SUSPECTED UNAPPROVED PARTS REPORTING ....................................... 10.13-1 10.14 MAINTENANCE EVENT/ OCCURRENCE INVESTIGATION ........................... 10.14-1 10.15 QUALITY NOTICE ............................................................................................. 10.15-1 10.16 QUALITY AUDIT ............................................................................................... 10.16-1 10.17 SUPPLIER CONTROL ...................................................................................... 10.17-1 10.18 CERTIFICATED AND NON-CERTIFICATED FACILITY CONTROL ................ 10.18-1 10.19 COMPANY CERTIFICATE APPROVAL HANDLING ........................................ 10.19-1 10.20 CONCESSION FOR DEVIATION FROM ORGANISATION’S PROCEDURES 10.20-1 10.21 QUALITY MONITORING ................................................................................... 10.21-1 10.22 MAINTENANCE ERROR/ VIOLATION DETECT AND RECTIFICATION ......... 10.22-1 10.23 ASSESSOR QUALIFYING ................................................................................ 10.23-1 10.24 QUALIFYING EXAMINATION ........................................................................... 10.24-1 10.25 TEMPORARY AUTHORIZATION (DISPENSATION) ....................................... 10.25-1 10.26 INSTRUCTOR QUALIFYING ............................................................................ 10.26-1

PART 11 HUMAN RESOURCE AND TRAINING PROCEDURES ........................... 11-1

11.1 POSITION NEED ASSESSMENT ....................................................................... 11.1-1 11.2 EMPLOYEE NEED ASSESSMENT AND TRAINING RECORD ......................... 11.2-1 11.3 TRAINING COURSE ARRANGEMENT .............................................................. 11.3-1 11.4 TRAINING COURSES PREPARATION .............................................................. 11.4-1 11.5 TRAINING COURSE IMPLEMENTATION .......................................................... 11.5-1 11.6 EXAM ARRANGEMENT ..................................................................................... 11.6-1 11.7 EXAM PREPARATION ........................................................................................ 11.7-1 11.8 EXAM IMPLEMENTATION.................................................................................. 11.8-1 11.9 TRAINING RECORDS COMPLETION AND STORAGE ..................................... 11.9-1 11.10 ISSUANCE OF CERTIFICATE/ ATTESTATION ............................................... 11.10-1 11.11 TRAINING ACTIVITIES REVIEW ...................................................................... 11.11-1

PART 12 SPECIFIC PROCEDURES FOR VNA ...................................................... 12-1

12.1 AIRWORTHINESS DIRECTIVE EVALUATION AND IMPLEMENTATION ......... 12.1-1 12.2 SERVICE BULLETIN (SB) EVALUATION AND DEVELOPMENT ...................... 12.2-1 12.3 AD, SB, MOD AND EO COMPLIANCE CONTROL ............................................ 12.3-1 12.4 ENGINE CONDITION MONITORING ................................................................. 12.4-1 12.5 ESTABLISHMENT AND CONTROL OF AIRCRAFT CONFIGURATION ........... 12.5-1 12.6 SET UP TECHNICAL MANAGEMENT SYSTEM FOR NEW AIRCRAFT ........... 12.6-1 12.7 CONDITION MONITORING OF AIRCRAFT SYSTEM ....................................... 12.7-1 12.8 CONTROL OF PRELOAD REQUIREMENTS ..................................................... 12.8-1 12.9 COMPLIANCE OF AIRCRAFT MAINTENANCE REQUIREMENTS ................... 12.9-1 12.10 CONTROL OF MAINTENANCE ACTIVITIES IN AMASIS ................................ 12.10-1 12.11 VNA VARIATION/ CONCESSION CONTROL .................................................. 12.11-1 12.12 CONTROL OF HOLD COMPONENT ................................................................ 12.12-1

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 1 GENERAL

Issue: 02, Revision: 05, Date: 25 APR 2013 Page 1.1-4

12.13 CONTROL OF EMERGENCY EQUIPMENTS .................................................. 12.13-1 12.14 COMPONENT ROBBERY/SWAPPING ON VNA AIRCRAFT ........................... 12.14-1 12.15 HANDLING OF VNA AIRCRAFT EVENTS ....................................................... 12.15-1 12.16 STRUCTURE DAMAGE REPAIR...................................................................... 12.16-1 12.17 CONTROL OF ACCEPTABLE DEFERED DEFECT ......................................... 12.17-1 12.18 AIRCRAFT SOFTWARE MANAGEMENT ......................................................... 12.18-1

PART 13 FORMS ...................................................................................................... 13-1

13.1 VAECO FORM AND GUIDANCE FOR COMPLETION ....................................... 13.1-1 13.2 AUTHORITY AND CUSTOMER FORM AND GUIDANCE FOR COMPLETION 13.2-1

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 1 GENERAL 1.2 RECORD OF REVISIONS

Issue: 02, Revision: 05, Date: 25 APR 2013 Page 1.2-1

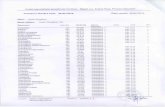

1.2 RECORD OF REVISIONS

Issue No. Revision No. Revision Date Revised by

01 00 15 JUL 2010 -

01 01 19 MAY 2011 VAECO QAD

02 00 01 FEB 2012 VAECO QAD

02 01 18 APR 2012 VAECO QAD

02 02 08 MAY 2012 VAECO QAD

02 03 20 JUL 2012 VAECO QAD

02 04 28 NOV 2012 VAECO QAD

02 05 25 APR 2013 VAECO QAD

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 1 GENERAL 1.3 SUMMARY OF AMENDMENT

Issue: 02, Revision: 05, Date: 25 APR 2013 Page 1.3-1

1.3 SUMMARY OF AMENDMENT The following table shows the summary of the latest amendment in the current issue of the VAECO SOP. Manual Name : Standard Operating Procedures Manual Code : VAECO SOP Issue Number : 02 Revision Number : 05

Part. Chapter - Page Amendment Summary

1.1-1 to 1.1-4 To update Table of content

1.2-1 To update Record of revision

1.3-1 to 1.3-3 To update Summary of amendment

1.4-1 to 1.4-6 To update List of Effective Pages

1.7-1 to 1.7-2 + To add definition of ADD Type B, ADD type C, Over and Above work

5.1-2 + To specify that RMC may perform a work package IAW SOP 12.15

5.3-1 to 5.3-3 + To revise the work pack preparation review and acceptance

5.4-1 to 5.4-4 + To add the BDD responsibilities to cooperate with

customer for approving additional work performance as requested by customer during maintenance progress.

6.1-1 to 6.1-9 + To request maintenance staff to follow towing instruction of respective maintenance center.

6.2-2 + To remove VAECO requirement of placing safety cone when customer does not have that requirement.

6.3-2 to 6.3-8

+ To specify that Non-routine Work/ Workpack Change Request (VAECO Form 6006) is submitted to BDD and customer for approval if the non-routine work is belonged to Over and Above work.

8.13-1 to 8.13-3 + To specify that the Delivery Note shall be issued and

acknowledged whenever transferring of tool/ equipment.

9.1-1 to 9.1-11 + To add the procedure to inspect and accept the part/ component returned to VAECO after loan.

9.2-1 + To revise the part/ materials tagging

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 1 GENERAL 1.3 SUMMARY OF AMENDMENT

Issue: 02, Revision: 05, Date: 25 APR 2013 Page 1.3-2

Part. Chapter - Page Amendment Summary

10.1-1 to 10.1-14

+ To clarify the experience required for I&RTS staff + To group the common requirement of I&RTS staff + To add equivalent of task training for the requirement

of Part and Material Incoming Inspection staff + To change the assessment process for NDT staff + To change the condition for maintaining the validity of

authorization + To add paragraph “Structure damage evaluation and

deferment function is applicable for all aircraft structure”

+ To clarify the privileges and limitation of borescope inspection staff and component I&RTS staff

10.2-2 + To remove the requirement that QA manager shall review records of interview result.

10.4-2 to 10.4-9

+ To add base maintenance work to the duties of MCC controller

+ To add base maintenance experience to the requirement of MCC controller

+ To clarify the privileges of Qualified Mechanic

10.8-1 to 10.8-3 + To specify the requirement for returning an A/C to service after line maintenance.

10.10-2 + To revise the requirement when Re-certifying a

component/ part removed (by VAECO staff) from an aircraft of an operator other than VNA.

10.24-1

+ To change multiple-choice questionnaire structure for category B1/B2 upgrade/ supplement

+ To delete the multiple-choice questionnaire for Engine run-up and Borescope inspection

10.26-1 to 10.26-2 + To add new procedure “Instructor Qualifying”

12.8-1 to 12.8-3 + To revise the procedure of preparation and update of preload requirements

12.9-2 to 12.9-4 + To revise responsibility of preparing spares/ materials list required to perform OPM.

12.15-1 to 12.15-4 + To revise the procedure of handling the A/C undergone an occurrences and other maintenance events.

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 1 GENERAL 1.4 LIST OF EFFECTIVE PAGES

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 1.5-1

1.5 DOCUMENT DISTRIBUTION SOP manual will be published in “PDF” format. The users who are VAECO members will access the current document on VAECO website. The VAECO Technical Library will update the document on VAECO website whenever there is a new issue/ revision. The Quality Assurance Department will notify the changes on home page of VAECO website whenever there are significant changes.

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 1 GENERAL 1.6 ABBREVIATION

Issue: 02, Revision: 04, Date: 28 NOV 2012 Page 1.6-1

1.6 ABBREVIATION

ABBREVIATION MEANING A/C Aircraft AD Airworthiness Directive BDD Business Development Department BMC Base Maintenance Center BTPD Base Technical – Planning Division CBT Computer Based Training CEO Chief Executive Officer CFR Code of Federal Regulations CHDO Certificate-Holding District Office CMC Component Maintenance Center CSI Cycles Since Inspection CSN Cycles Since New CSO Cycles Since Overhaul CTPD Component Technical – Planning Division DAD Da Nang DRO Defect Rectification Order EASA European Aviation Safety Agency EGD Engineering and IT Department EO Engineering Order ER Engineering Request ETA Estimated Time Arrival FAA Federal Aviation Administration FAR Federal Aviation Regulations FOD Foreign Object Damage GSE Ground Support Equipment HAN Ha Noi HCM Ho Chi Minh City HRD Human Resource Department HT Hard Time IAW In Accordance With IFO International Field Office IT Informatics Technology JC Job Card LGD Logistics Department LLP Life Limit Part LEP List of Effective Pages MCC Maintenance Control Center MTE Measuring and Test Equipment NDT Non-Destructive Testing NRC Non-Routine Card

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 1 GENERAL 1.6 ABBREVIATION

Issue: 02, Revision: 04, Date: 28 NOV 2012 Page 1.6-2

ABBREVIATION MEANING NRCC OOP

Non-Routine Card Continuation Out Of Phase

OPM Out of Phase Maintenance PLD Planning department QA Quality Assurance QAD Quality Assurance Department QCM Quality Control Manual QN Quality Notice RII Required Inspection Items RMC Ramp Maintenance Center RSM Repair Station Manual RSTP Repair Station Training Program RTS Return To Service SB Service Bulletin SGN Tansonnhat Airport SRO Structure Repair Order T&E Tools and Equipment TAR Technical Assistance Request TC Training Center TCD Training Director TPD Technical – Planning Division TI Technical Instruction TL Technical Library TOEFA Test of English For Aviation - Docwise TS Technical Service TSI Time Since Inspection TSN Time Since New TSO Time Since Overhaul VAC Vietnam Airlines Corporation VACBI Video and Computer Based Instruction VAECO Vietnam Airlines Engineering Company Ltd. VAR Vietnam Aviation Regulation WO Work Order WR Work Request WP Work Pack WS Worksheet

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 1 GENERAL 1.7 DEFINITION OF TERMS

Issue: 02, Revision: 05, Date: 25 APR 2013 Page 1.7-1

1.7 DEFINITION OF TERMS

TERM DEFINITION

ADD Type B A MEL/ airworthiness related defect that is accepted to defer the rectification IAW maintenance data such as MEL, CDL, AMM, SRM, EM, TA…

ADD type C A non-MEL/ non-airworthiness related defect that is accepted to defer the rectification (this defect is not specified in any maintenance data and does not concern to the airworthiness of the A/C).

Airworthiness Approval Tag/ Authorized Release Certificate

CAAV Form 1, EASA Form ONE, FAA Form 8130-3 etc.

Arrival/ departure KIT Include but not limited to necessary tool for A/C arrival and departure activities as: headset, safety pins…

Authorized inspection staff

Person authorized by VAECO to performing inspections under the Company certificate and operations specifications.

Authorized staff Person authorized by VAECO to plan, supervise, perform inspection and approve for return to service the maintenance, preventive maintenance, or alterations performed under the VAECO certificate and operations specifications.

Buy-back Re-inspection of work performed as a result of previous required inspection findings.

Critical task A maintenance task involving some element of removal/ disassembly and installation/ reassembly of several components of the same type fitted to more than one system on the same aircraft during a particular maintenance check.

Dock Control Room Area for controlling all maintenance document including processing, completing etc. during specific maintenance check.

Engineering engineer Person working in EGD and qualified IAW chapter 10.4.

Foreman Nominated person by maintenance director, who manage all maintenance activities for specific work pack.

Maintenance document Documents that used to record and certify for the work to be done such as Job card, worksheet, NRC, NRCC, JCAS etc.

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 1 GENERAL 1.7 DEFINITION OF TERMS

Issue: 02, Revision: 05, Date: 25 APR 2013 Page 1.7-2

TERM DEFINITION

Maintenance planner Person working in EGD and qualified IAW chapter 10.4.

MCC controller Person working in a Maintenance Control Center and qualified IAW chapter 10.4.

Mechanic Person working in a Maintenance Centers who is qualified IAW chapter 10.4.

Over and Above Work Any additional work which is not originally part of the contracted work package or variations to existing documents in contracted work package requested by the customer.

Production planner Person working in a Maintenance Center and qualified IAW chapter 10.4.

Store inspector Person who authorized to perform the incoming inspection on parts and/or materials to be used by the VAECO.

Supervisor Person who authorized to direct the work performed under the Company certificate and operations specifications.

Sign-off A statement by the competent person performing or supervising the work, that the task or group of tasks has been correctly completed.

Technical librarian Person qualified IAW chapter 10.4.

Technical service staff Person working in a Maintenance Center and qualified IAW chapter 10.4.

Tool controller Person working in Maintenance Center and qualified IAW chapter 10.4.

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 2 MANAGEMENT

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 2-1

PART 2

MANAGEMENT

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 2 MANAGEMENT 2.1 ORGANIZATION CHARTS

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 2.1-1

2.1 ORGANIZATION CHARTS 2.1.1 HUMAN RESOURCE DEPARTMENT

PERSONNEL DIVISION

HUMAN RESOURCE

DEPARTMENT

TRAINING & DEVELOPMENT

DIVISION

COMPENSATION & BENEFITS

DIVISION

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 2 MANAGEMENT 2.1 ORGANIZATION CHARTS

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 2.1-2

2.1.2 QUALITY ASSURANCE DEPARTMENT

SAFETY DIVISION

QUALITY ASSURANCE

DEPARTMENT

QUALITY AUDIT DIVISION

QUALITY CONTROL

DIVISION (HAN)

QUALITY CONTROL

DIVISION (HCM)

QUALIFYING SECTION

AUDIT SECTION

SAFETY STANDARD SECTION

SAFETY CONTROL SECTION

AVIONIC SECTION

AIRFRAME SECTION

AVIONIC SECTION

AIRFRAME SECTION

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 2 MANAGEMENT 2.1 ORGANIZATION CHARTS

Issue: 02, Revision: 04, Date: 28 NOV 2012 Page 2.1-3

2.1.3 ENGINEERING AND IT DEPARTMENT

MAINTENANCE PLANNING DIVISION

ENGINEERING & IT DEPARTMENT

TOOL AND EQUIPMENT CONTROL DIVISION

AIRCRAFT ENGINEERING

DIVISION

INFORMATION TECHNOLOGY

DIVISION

GROUND EQUIPMENT

SECTION

TOOL SECTION

AD/ SB CONTROL SECTION

STRUCTURE SECTION

AIRCRAFT SYSTEM SECTION

IT SECTION (HAN)

TECHNICAL LIBRARY

SECTION (HAN)

IT SECTION (HCM)

ENGINE SECTION

ELECTRIC/ AVIONIC SECTION

TECHNICAL RECORD

SECTION (HAN)

TECHNICAL LIBRARY

SECTION (HCM)

HCM ENGINEERING

SECTION

TECHNOLOGY DEVELOPING

SECTION

MAINTENANCE SCHEDULE SECTION

MAINTENANCE REQUIRED

PARTS AND EO SECTION

WORK ORDER

SECTION

PLANNING SECTION

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 2 MANAGEMENT 2.1 ORGANIZATION CHARTS

Issue: 02, Revision: 04, Date: 28 NOV 2012 Page 2.1-4

2.1.4 PLANNING DEPARTMENT

DEVELOPMENT PLANNING DIVISION

INVESTMENT PLANNING DIVISION

PLANNING DEPARTMENT

INVESTMENT PLANNING SECTION

GENERAL PLANNING SECTION

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 2 MANAGEMENT 2.1 ORGANIZATION CHARTS

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 2.1-5

2.1.5 LOGISTICS DEPARTMENT

HCM LOGISTICS DIVISION

STORE DIVISION

LOGISTICS DEPARTMENT

STOCK CONTROL DIVISION

SUPPLY DIVISION

REPAIR CONTROL DIVISION

INCOMING INSPECTION

SECTION

STORE CONTROL SECTION

STORE KEEPING SECTION

IMPORT/ EXPORT SECTION

DOMESTIC SECTION

GENERAL SECTION

INCOMING INSPECTION

SECTION

IMPORT/ EXPORT & DOMESTIC SECTION

PURCHASE SECTION

SUPPLIER CONTROL SECTION

REPAIR CONTROL SECTION

STORE KEEPING SECTION

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 2 MANAGEMENT 2.1 ORGANIZATION CHARTS

Issue: 02, Revision: 04, Date: 28 NOV 2012 Page 2.1-6

2.1.6 BUSINESS DEVELOPING DEPARTMENT

BUSINESS DEVELOPMENT DEPARTMENT

MARKETING & SALES DIVISION

CUSTOMER SUPPORT DIVISION

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 2 MANAGEMENT 2.1 ORGANIZATION CHARTS

Issue: 02, Revision: 04, Date: 28 NOV 2012 Page 2.1-7

2.1.7 MAINTENANCE CONTROL CENTER

MAINTENANCE CONTROL CENTER

MAINTENANCE CONTROL DIVISION

PRODUCTION PLANNING DIVISION

CONTROL SECTION (1, 2, 3, 4)

GENERAL SECTION

AIRBUS/ FOKKER MAINTENANCE

PLANNING SECTION

BOEING/ ATR MAINTENANCE

PLANNING SECTION

ADD CLEARANCE PLANNING SECTION

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 2 MANAGEMENT 2.1 ORGANIZATION CHARTS

Issue: 02, Revision: 04, Date: 28 NOV 2012 Page 2.1-8

2.1.8 HAN BASE MAINTENANCE CENTER

STRUCTURE REPAIR SQUAD

TECHNICAL -PLANNING DIVISION

(TPD)

HAN BASE MAINTENANCE

CENTER

AIRFRAME & CABIN SQUAD

AVIONIC & IFE SQUAD

TEAM 1

TEAM 2

TEAM 3

TECHNICAL SERVICE SECTION

PLANNING SECTION

GENERAL SECTION

STRUCTURE REPAIR SHOP

COMPOSITE SHOP

TEAM 4

TEAM 1

TEAM 2

PAINTING SECTION

POWER PLANT SQUAD

TEAM 1

TEAM 2

TEAM 3

MAINTENANCE SUPPORT

SQUAD

DOCK SECTION

ELECTRICITY SECTION

AIRCRAFT CLEANING SECTION

HANGAR SECTION

TEAM 4

TEAM 3

TEAM 4

CABIN SECTION

STORE SECTION

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 2 MANAGEMENT 2.1 ORGANIZATION CHARTS

Issue: 02, Revision: 04, Date: 28 NOV 2012 Page 2.1-9

2.1.9 HCM BASE MAINTENANCE CENTER

STRUCTURE

REPAIR SQUAD

TECHNICAL SERVICE DIVISION

HCM BASE MAINTENANCE

CENTER

AIRFRAME

SQUAD

AVIONIC SQUAD

SECTION 1 (ZONE 100, 200

AND 800)

SECTION 2 (ZONE 300 AND 400)

SECTION 3 (ZONE 500, 600

AND 700)

TECHNICAL SERVICE SECTION

PLANNING SECTION

GENERAL SECTION

STURCTURE REPAIR SHOP

COMPOSITE SHOP

PAINTING SECTION

MAINTENANCE SUPPORT

SQUAD

HANGAR SECTION

CLEANING SECTION

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 2 MANAGEMENT 2.1 ORGANIZATION CHARTS

Issue: 02, Revision: 04, Date: 28 NOV 2012 Page 2.1-10

2.1.10 HAN RAMP MAINTENANCE CENTER

MAINTENANCE SQUAD

(1, 2, 3, 4)

TECHNICAL - PLANNING DIVISION

HAN RAMP MAINTENANCE

CENTER

A320/ 321/ 330 AIRCRAFT SECTION

F70 & OTHER ẢICRAFT SECTION

INTERNATIONAL MAINTENANCE

SQUAD

CABIN INTERIOR & IFE SQUAD

NUMBER 1 SECTION

NUMBER 2 SECTION

NUMBER 3 SECTION

NUMBER 4 SECTION

NUMBER 1 SECTION

NUMBER 2 SECTION

NUMBER 3 SECTION

NUMBER 4 SECTION

TECHNICAL SERVICE SECTION (1, 2, 3, 4)

PLANNING SECTION

INFORMATIC & DOCUMENT

SECTION

VEHICLE SECTION

RAMP SECTIONS

(OUT STATIONS)

CONTROL SECTION

GENERAL SECTION

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 2 MANAGEMENT 2.1 ORGANIZATION CHARTS

Issue: 02, Revision: 04, Date: 28 NOV 2012 Page 2.1-11

2.1.11 HCM RAMP MAINTENANCE CENTER

MAINTENANCE SQUAD

(1, 2, 3, 4)

TECHNICAL - PLANNING DIVISION

HCM RAMP MAINTENANCE

CENTER

TECHNICAL SERVICE SECTION (1, 2, 3, 4)

PLANNING SECTION

ATR72 AIRCRAFT SECTION

B777 AIRCRAFT SECTION

A320/ 321 AIRCRAFT SECTION

INFORMATIC & DOCUMENT

SECTION

INTERNATIONAL MAINTENANCE

SQUAD

CABIN INTERIOR & IFE SQUAD

VEHICLE SECTION

RAMP SECTIONS

(OUT STATIONS)

NUMBER 1 SECTION

NUMBER 2 SECTION

NUMBER 3 SECTION

NUMBER 4 SECTION

NUMBER 1 SECTION

NUMBER 2 SECTION

NUMBER 3 SECTION

NUMBER 4 SECTION

A330 AIRCRAFT SECTION

CONTROL SECTION

GENERAL SECTION

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 2 MANAGEMENT 2.1 ORGANIZATION CHARTS

Issue: 02, Revision: 04, Date: 28 NOV 2012 Page 2.1-12

2.1.12 DAD RAMP MAINTENANCE CENTER

DAD RAMP STORE SECTION

TECHNICAL - PLANNING DIVISION

DAD RAMP MAINTENANCE

CENTER

RAMP SECTIONS (OUT STATIONS)

TECHNICAL SERVICE SECTION

PLANNING SECTION

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 2 MANAGEMENT 2.1 ORGANIZATION CHARTS

Issue: 02, Revision: 04, Date: 28 NOV 2012 Page 2.1-13

2.1.13 HAN COMPONENT MAINTENANCE CENTER

GROUND EQUIPMENT

MAINTENANCE WORKSHOP

TECHNICAL -PLANNING DIVISION

(TPD)

HAN COMPONENT MAINTENANCE

CENTER

CALIBRATION WORKSHOP

AIRCRAFT COMPONENT WORKSHOP

CABIN & PRODUCTION WORKSHOP

CALIBRATION SHOP

MEASUREMENT T&E CONTROL

SECTION

NDT AND BORESCOPE

SHOP

TECHNICAL SERVICE SECTION

PLANNING SECTION

MAINTENANCE RECORD SECTION

BATTERY SHOP

ATEC SHOP

IFE SHOP

CABIN SHOP

MECHANICAL SHOP

EQUIPMENT MAINTENANCE

SHOP

MAINTENANCE SUPPORT

WORKSHOP

TOOL STORE SECTION

GROUND EQUIPMENT

SECTION

SAFETY EQUIPMENT

SHOP

WHEEL SHOP

SOFT FURNISHING

SHOP

02 N2 H2O SHOP

ELECTRICAL COMPONENT

SHOP

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 2 MANAGEMENT 2.1 ORGANIZATION CHARTS

Issue: 02, Revision: 04, Date: 28 NOV 2012 Page 2.1-14

2.1.14 HCM COMPONENT MAINTENANCE CENTER

MAINTENANCE SUPPORT

WORKSHOP

TECHNICAL -PLANNING DIVISION

(TPD)

HCM COMPONENT MAINTENANCE

CENTER

CALIBRATION &

ELECTRONIC WORKSHOP

AIRCRAFT COMPONENT WORKSHOP

CABIN INTERIOR

WORKSHOP

CALIBRATION SHOP

T&E CONTROL SECTION

NDT AND BORESCOPE

SHOP

TECHNICAL SERVICE SECTION

PLANNING SECTION

MAINTENANCE RECORD SECTION

BATTERY & ELECTRICAL COMP. SHOP

MECHANICAL COMPONENT

SHOP

WHEEL & BRAKE SHOP

MECHANICAL SHOP

SOFT FURNISHING

SHOP

OXYGEN, NITROGEN, H2O

SHOP

TOOL STORE SECTION

GROUND EQUIPMENT

SECTION

EQUIPMENT MAINTENANCE

SHOP

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 2 MANAGEMENT 2.1 ORGANIZATION CHARTS

Issue: 02, Revision: 04, Date: 28 NOV 2012 Page 2.1-15

2.1.15 TRAINING CENTER

SOUTHERN TRAINING DIVISION

TRAINING DIVISION

TRAINING CENTER

ADMINISTRATIVE DIVISION

INSTRUCTOR SECTION

STANDARD SECTION

PLANNING AND CONTRACT SECTION

GENERAL SECTION

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 3 PROCESSES

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 3-1

PART 3

PROCESSES

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 3 PROCESSES 3.1 BASE MAINTENANCE PROCESS

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 3.1-1

3.1 BASE MAINTENANCE PROCESS Preliminary inspection

(10.5.7.1) Aircraft Maintenance

(6.3) CRS/ maintenance

release issuance (10.8)

Maintenance data control (8.1)

Work pack preparation and review (5.3) Management of tool and equipment (8.9)

Aircraft work request issuance and monitoring (5.2)

Aircraft contract maintenance implementation (5.1)

Hidden Damage Inspection (10.10)

Aircraft document completion (5.6)

Return of A/C parts/ materials to store (6.6)

Continuity of maintenance (Shift/ task handover) (6.4) Continuity of inspection (10.9)

Handling, storage and disposal of wastes (4.9)

MOR/ Malfunction and defect reporting (10.12)

Suspected unapproved parts reporting (10.13)

AIRCRAFT TO BE

MAINTAINED

AIRCRAFT RETURNED TO SERVICE

Dock control (5.5)

Aircraft maintenance record (5.7)

Control of work process and document in base maint. (5.4)

Aircraft towing/ push back (6.1)

Maintenance cleanliness and FOD prevention (4.7)

In-process inspection (10.5.7.2)

Final inspection (10.5.7.3)

Inspection of require inspection item (RII) (10.7)

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 3 PROCESSES 3.2 RAMP MAINTENANCE PROCESS

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 3.2-1

3.2 RAMP MAINTENANCE PROCESS

Aircraft Arrival (6.2.4.2)

Aircraft Maintenance and Service (6.2.4.3)

Aircraft departure (6.2.4.4)

Maintenance data control (8.1)

Management of tool and equipment (8.9)

Aircraft work request issuance and monitoring (5.2)

Contract maintenance implementation (5.1)

Aircraft maintenance record (5.7)

Return of A/C parts and materials to store (6.6)

Shift/ task handover (6.4)

Handling, storage and disposal of wastes (4.9)

MOR/ Malfunction and defect reporting (10.12)

Suspected unapproved parts reporting (10.13)

AIRCRAFT TO BE

MAINTAINED

AIRCRAFT RETURNED TO SERVICE

Inspection of require inspection item (RII) (10.7)

Aircraft towing/ push back (6.1)

Maintenance cleanliness and FOD prevention (4.7)

Aircraft document completion (5.6)

Preliminary inspection (10.5.7.1)

In-process inspection (10.5.7.2)

Final inspection (10.5.7.3)

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 3 PROCESSES 3.3 COMPONENT MAINTENANCE PROCESS

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 3.3-1

3.3 COMPONENT MAINTENANCE PROCESS

Aircraft component receiving and preliminary

inspection (7.3)

Component maintenance performance (7.4)

Component final inspection and return to

service (7.5)

Maintenance data control (8.1)

Tools and equipments control (8.9) Workshop Spare parts & materials control (7.7)

Worksheet preparation (7.2)

Workshop Work request Issuance and management (7.1)

Hidden Damage Inspection (10.10)

Component document handling (7.6) Unserviceable parts return to store (6.6)

Shift/ task handover (6.4)

Handling, storage and disposal of wastes (4.9)

MOR/ Malfunction and defect reporting (10.12)

Suspected unapproved parts reporting (10.13)

AIRCRAFT COMPONENT

TO BE MAINTAINED

AIRCRAFT COMPONENT

RETURNED TO SERVICE

Maintenance cleanliness and FOD prevention (4.7)

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 4 GENERAL SAFETY REQUIREMENTS

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 4-1

PART 4

GENERAL SAFETY

REQUIREMENTS

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 4 GENERAL SAFETY REQUIREMENTS 4.1 GENAERAL SAFETY

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 4.1-1

4.1 GENERAL SAFETY 4.1.1 PURPOSE

To ensure the basic safety requirements are followed by the VAECO maintenance staffs in order to achieve the best quality of maintenance work.

4.1.2 SCOPE This procedure is applied when performing maintenance activities.

4.1.3 RESPONSIBILITY 1. All VAECO personnel shall follow all the requirements set forth in this

instruction. 2. The staff on duty has responsibilities for:

a. Following the safety regulations of the jobs. b. Informing the manager immediately when the safety problems

occurred or may occur. 3. The manager has responsibilities for:

a. Ensuring all his staffs follow safety requirements. b. Providing the sufficient safe environment. c. Investigating the incident/ accident and issuing the safety report and

sending to QAD. 4.1.4 GENERAL SAFETY OPERATION

1. Fire accident prevention a. Smoking is prohibited in the ramp, the hangar and the aircraft. b. The location symbol of the fire bottle must be clear, and the expiry

must be remarkable on each one. c. It must be easy to go through/to the pavement, fire lane and fire

hydrant. d. The fire extinguisher location shall be established by Administration

department and accepted by QAD. List of all fire extinguishers shall specify the locations and expiry dates and be controlled by the Administration department. Fire extinguisher control list shall be printed out every three months. Fire control team shall perform the fire extinguishers routine checks and request to replace the expired or unserviceable one.

2. Common Safety operation a. The entire working zone must be kept neatly clean. b. The entire equipment’s using on the maintenance jobs must be fixed

to prevent the personnel in or around the working area from being hurt.

c. The maintenance staff must wear the uniform clothing and safe shoes in the working area.

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 4 GENERAL SAFETY REQUIREMENTS 4.1 GENAERAL SAFETY

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 4.1-2

d. The maintenance staff is prohibited to wear the ring, the ear-ring, the necklace and so on when working in critical area or cramped area such as fuel tank etc.

e. It is prohibited to wear the shoes showing toes in hangar or ramp. f. The manager must confirm that maintenance staff had the

necessary safety accessories before doing the maintenance jobs. g. All the personnel must have the necessary protective accessories

when go through the danger area. h. The personnel must wear the safe rope when doing the jobs on the

high area like as the wing, the aerial ladder truck and the fuselage top point.

3. Tools/ equipment safety operation a. It is prohibited to be used on the aircraft maintenance when

tools/equipment are damaged or unserviceable. b. Electrical operated drills are not allowed for aircraft work due to

possibility of sparking. c. Adjustable spanner are not allowed for aircraft work as the bolts or

nuts are prone to be rounded. d. The tools/equipment as power tools, electric machinery, electronic

tester, cybernetic equipment and self-propelled vehicles must be operated by the training-approved man.

e. The crane and the forklift must be operated by the training-approved man. The operator must check the brake or other functions one time before operation and be sure awareness of the loading restriction.

f. The mechanic must wear cotton-padded clothes and use the air-driven tools and flame-proof lamp/ lights/ torches when performing jobs in the fuel tank.

g. The maintenance staff must use the oil-free tools when performing the oxygen system maintenance jobs.

h. The maintenance staff cannot tear off/down the unserviceable tag, safety protection equipment and warning symbols.

4. Hangar and ramp safety operation a. Maintenance staff must follow all airport authority requirements when

working at ramp. b. The ramp area must be clean without anything (foreign objects). c. The aircraft must be grounded when performing heavy maintenance

visit. d. Obey the aircraft maintenance manual notice like as Warning,

Caution and Note for preventing the aircraft from damage and maintenance staff from being hurt.

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 4 GENERAL SAFETY REQUIREMENTS 4.1 GENAERAL SAFETY

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 4.1-3

e. The vehicles must follow the lane on the apron IAW the regulation of airport authority.

f. Be careful of striking the protruding flight control surface, antenna, static discharger and opened panel.

g. Be careful of tripping up by the power cable, ground wire, air condition tube or fuel tube.

h. The tear-off battery from the aircraft must cover the connector with the plastic cap from circuit shorting.

i. The personnel must wear the earplug or the ear-flap around the engine-running aircraft.

j. The maintenance staff must perform the “Walk around” inspection to clear all foreign objects before the aircraft arrival.

k. It is prohibited to perform the de-fueling or refueling jobs in hangar except approved by QC manager.

5. Shop safety operation a. All the shops must have the sufficient ventilation and illumination. b. The shop working area must have enough distance for going

through and keeping clean and preventing from slipping and falling. c. The shop must have a checklist to check and keep the machines

and tools neat and clean. d. The power source and switch must have the clear symbol. e. The operating staff of power mechanism must take care of the

environment around him/her and wear the protection accessories like as goggles and ear plug.

f. The instrument/avionics shop (ATEC, NDT, Calibration shop...) must have the capability of dust disposal and controlling of the temperature and the humidity. The maintenance staff must wear the static-free clothes and wrist-strap when performing maintenance jobs.

g. The battery shop must be isolated. 6. Starting the ground power unit and energizing aircraft electrical system

a. The ground power unit location must be near by the power connector, and the exhaust is away from the aircraft.

b. When the ground power unit is switched on, the operating staff must watch out the control panel, the ground power unit operation, output voltage and frequency to ensure they are under the normal condition. If not, remove the power cable and confirm the cause before restart.

c. The maintenance staff must check the switch and the circuit breaker panel of the aircraft for confirming the electrical system function is normal before connecting to ground power unit.

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 4 GENERAL SAFETY REQUIREMENTS 4.1 GENAERAL SAFETY

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 4.1-4

7. Radioactive ray illumination safety operation a. The radioactive objects like fuel-density meter, emergency self-

illumination exit light and illuminated switch symbol removed from the aircraft must process IAW the aircraft maintenance manual.

b. The fuel-density meter maintenance must be performed by the authorized staff or under the manufacturer supervision.

c. The maintenance staff must be careful of the high energy radioactive rays in the X-ray illumination process. The X-ray equipment must be operated by the qualified man.

d. The maintenance staff related radioactive rays operation must wear the “Film Badge” or any other measurement that can count the accumulative quantity contained of the radioactivity. The maintenance staff assists with replacing the film must do it under the qualified operation.

e. X-ray operation area must be separated and marked for no-entry. 8. The weld safety operation

a. It is possible to cause the fire accident when performing the weld or cutting operation, so the operator must prepare for the fire extinguisher on hand.

b. As any possible to remove the movable combustibles from operation area, and cover the unmovable ones with the metal plates or the incombustibility materials.

c. The gas bottles must be fixed carefully from toppling down. d. Be careful of the acetylene leaking in the closed environment and

causing the flammable or explosive situation to explode. The maintenance staff cannot contact the oxygen bottle with the oily gloves, hands or rags, and not lubricate the valve or connector.

e. The weld jobs on the aircraft must be pre-evaluated the feasibility by the Engineering & IT department, and be approved under the QAD before performing it.

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 4 GENERAL SAFETY REQUIREMENTS 4.2 A/C ELECTROSTATIC SAFETY

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 4.2-1

4.2 A/C ELECTROSTATIC SAFETY 4.2.1 PURPOSE

To ensure all the A/C will be grounded to release static electricity and keep A/C safe.

4.2.2 SCOPE These requirements are applied when performing maintenance activities on the apron and in the hangar.

4.2.3 RESPONSIBILITY The maintenance personnel are responsible to set up the ground wire and confirm the grounding is in good condition.

4.2.4 STATIC ELECTRICITY SAFETY GENERAL REQUIREMENT 1. This requirement is to prevent from igniting the spark caused by the

electric potential difference between A/C & ground, which may damage of A/C or injury to personnel.

2. Before setting the ground wire, the maintenance staff should check the condition of wire to ensure there is no broken or corrosion on the cable and the clip is properly connected with the cable.

3. The ground wire should be properly connected with the identified static ground point on A/C. Connecting to any point other than identified static ground point may cause the damage to the connecting point and lower the efficiency of grounding.

4. The A/C should be static electricity grounded whenever it parked in hangar.

5. The jack should be static electricity grounded when A/C performing the maintenance job such as gear swing, landing gear change and etc.

6. Before towing the A/C, the ground wire should be removed and stowed properly.

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 4 GENERAL SAFETY REQUIREMENTS 4.3 ELECTRICITY AND AIR POWER SAFETY

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 4.3-1

4.3 ELECTRICITY AND AIR POWER SAFETY 4.3.1 PURPOSE

To make sure the safety of the personnel and A/C when using power equipment or hangar ground power source.

4.3.2 SCOPE These requirements are applied when using or maintaining the power equipment and ground power source.

4.3.3 RESPONSIBILITY The operating staff is responsible for safe operating or maintaining of power equipment or hangar ground power source.

4.3.4 DEFINITION 1. Power equipment: Any petrol or diesel engine, electrical or pneumatic

equipment. 2. Ground power: The power source of GPU, hangar pit. 3. Ground air source: Compressor or hangar pit supply shop air.

4.3.5 POWER EQUIPMENT 1. Before starting power equipment, making sure all the aircraft, personnel

and other facilities are clear. 2. Use the suitable electrical power source (correct phase, frequency,

voltage), pneumatic source (correct pressure value) according to the operation instruction. Also, check the oil quantity before using the petrol/diesel power compressor.

3. If any fuel/oil or pneumatic leak found, the operating staff should inform the related department for repairing, and this equipment cannot be used until the problem is fixed.

4. When using external electrical or pneumatic power equipment, turn off the power switch first before cut off the external power.

5. Make sure the duct pressure is released before removing the connector between the pneumatic equipment and external source.

6. After using the equipment, the operating staff should return it back to the certain place.

4.3.6 GROUND POWER UNITS 1. Keep the ground power unit away from fueling ports, tank ventilation

ports, drain ports and wing tip area. The GPU is forbidden to use within 7.6 meters (25 feet) away from fuel tank ventilation ports or poor ventilation area.

2. Ground power equipment, any possible fire electrical equipment or connector, high temperature surface should be located at least 0.5 meter (18 inches) from ground level position when operating in hangar. It is forbidden to fill fuel into GPU cart in hangar.

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 4 GENERAL SAFETY REQUIREMENTS 4.3 ELECTRICITY AND AIR POWER SAFETY

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 4.3-2

3. The ground power equipment should equip with surge protector to prevent from irregular voltage.

4. The ground power equipment should be operated within the voltage limitation.

5. When the working area is polluted by fuel or other dangerous material, the ground power equipment should be towed away or keep at its original condition until the problem clear. Before removing ground power unit from the dangerous area, cut off the power source first, and then disconnect the power connector.

6. The electric power wire should be properly preserved to prevent from damage.

7. Prevent the wire or terminal connector from deformation. After GPU connecting to the aircraft, turn on the ground power first and then check the voltage. If the voltage is correct, then the power can be supplied.

8. Make sure the function of fire jumper is normal before power supply. Before disconnecting the power supply connector, cut off the power source first.

4.3.7 GROUND PNEUMATIC SOURCE 1. Before using ground pneumatic power, turn off the upstream shut-off

valve then connect the air tubes. Make sure the pneumatic connectors and tubes fit well before opening the valve.

2. If any air leakage found during the operation process, stop the power unit, inform the manager to have it fixed. Continue the operation after the problem is cleared.

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 4 GENERAL SAFETY REQUIREMENTS 4.4 FUEL TANK SAFETY

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 4.4-1

4.4 FUEL TANK SAFETY 4.4.1 PURPOSE

To avoid the danger while working in fuel tanks and ensure the safety of maintenance staff as to reach the goals of personnel safety, ground safety and flight safety

4.4.2 SCOPE This instruction is applied when working in or near the fuel tanks.

4.4.3 RESPONSIBILITY 1. The maintenance staff is responsible for his personal safety and the work

safety in the fuel tanks. The maintenance staff shall follow the related requirements of the manufacture to do the jobs such as refueling, fuel draining and fuel tank maintenance jobs.

2. The supervisor should monitor the safety of fuel tanks, maintenance staff, and area near the fuel tanks.

3. RTPD/BTPD on duty personnel is responsible for assisting to call ambulance in an emergency and inform the management.

4.4.4 THE SAFETY OF FUEL TANKS 1. The common regulation when implementing the jobs of fuel tanks

a. Before fuel tank open, the maintenance staff should ground the aircraft and ensure ventilation facilities are good.

b. The warning sign should be placed around A/C when fuel panels are opened.

c. The fire prevention system and emergency safe equipment should be put at easy-to-access place.

d. A/C should be stopped in the well-ventilated space, and the dangerous materials should be moved to safe area.

e. A/C, working stand and ventilation equipment should be grounded. The maintenance staff should touch the stand with bare hand before start working to balance static electricity.

f. A/C power must be off and the connectors of main and APU batteries should be disconnected from A/C.

g. A/C aviation instrument and communication system must not be operated such as mobile phone, walkie-talkie…

h. The high-power communication system cannot be used around the area near A/C.

i. The compressed air cannot be directly led into the fuel tanks. j. If possible, direct the tank exhaust air out of hangar.

2. The maintenance staff working in the fuel tanks should: a. Be good physical condition.

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 4 GENERAL SAFETY REQUIREMENTS 4.4 FUEL TANK SAFETY

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 4.4-2

b. Be well-experienced the operation procedure. c. Be familiar with the method handling the healthy problems and fire

emergency. d. Wear the proper clothes, cotton caps and shoes while working in the

fuel tanks. e. Not carry the lighter, oven, watch, pager, laptop, notebook, tablet

and mobile phone into tanks. f. Have received the training about working in fuel tanks.

3. The maintenance staff must ensure that: a. The tank should be well-ventilated. b. The volatile liquid should be kept safely in the container, and the

carrying amount should be strictly limited. c. The light used in fuel tanks should be fire-proof, and the action of

turning on/off the light should be performed out of the fuel tanks (as well as any instruments powered by electricity). The pneumatic tools should be powered by compressed air.

d. The components of A/C fuel tanks should be carefully protected. If the tools must be taken in, they should be kept in proper container.

4. Supervisor should a. Ensure all the set-up work, cautions and warnings IAW AMM task

have been completed/ followed before the maintenance staff entering fuel tank.

b. Immediately inform the maintenance staff if any abnormality in the ventilation equipment is discovered.

c. Pay attention to the physical conditions of maintenance staff working in fuel tanks.

d. Pay attention to the area near fuel tanks. e. Pay attention to the circumstance when working area is near the

purging tanks. Following requirements should be followed as detail: Prepare the fire extinguisher. If the panel of the fuel tank is removed, the tank should be

covered with protector. Remind the personnel working in the same area to take care of

their safety. With the wind behind working area, make sure no dangerous

goods are downstream of the wind and be aware the position of blower.

The maintenance actions that possibly fire the hazardous fumes cannot be done at the same time within 7.6 meters (25 feet) from the same aircraft, fuel tanks or fuel tankers.

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 4 GENERAL SAFETY REQUIREMENTS 4.4 FUEL TANK SAFETY

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 4.4-3

The radar or radio systems cannot be used or tested within the specific distance.

5. When working near the fuel tanks which were in purge or ventilation, the operator should: a. Properly ground the pneumatic or electrical equipment before

operation. b. Not expose the bare wire. c. Cut off the power of related electrical ventilation equipment before

leaving. (The pneumatic equipment can be used continuously). 4.4.5 THE OPERATION IN CASE OF EMERGENCY OR ACCIDENT

1. In an emergency case: a. The maintenance staff escapes from the tank himself: Be aware of

his physical and mental condition while in the tank, leave the tank right away if feel uncomfortable.

b. The supervisor commands the maintenance staff to leave: If the circumstance is dangerous to the maintenance staff or his condition is unusual, the supervisor should command the maintenance staff to leave the fuel tanks.

c. The supervisor should call for help to save the maintenance staff in the tank when his respond is slow.

2. In an accident case: a. Once the accident happened, the supervisor should call the medical

personnel to save the maintenance staff (call the ambulance when necessary) and inform Manager.

b. Verify the cause of accident and check the circumstance and air quality before entering the tank for rescue. The rescuer should wear the protective equipment and prevent the accident happen again.

c. The accident reason should be noted in the related instruction and on the checking list to prevent the accident happen again.

d. The dangerous elements should be cleared before work re-starting. 4.4.6 THE NOTES ABOUT FUEL TANK MAINTENANCE:

1. The residual fuel that cannot be drained out should be cleared after panel open. Perform tank ventilation procedure first, choose the safest way to clear the residual fuel and prevent to stain the surface of A/C wing or ground. Draw out the residual fuel with hose, sponge and mop.

2. The bleed orifice and fuel line between normal and under maintenance tanks should be sealed with the plug and adhesive tape.

3. The maintenance staff performing the fuel tank operation should have received the related training such as work environment and the hazardous characters of materials.

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 4 GENERAL SAFETY REQUIREMENTS 4.4 FUEL TANK SAFETY

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 4.4-4

4. The supervisor should possess of sufficient information about the fuel tanks maintenance.

5. The equipment that may cause spark or fire cannot be used in the hazardous area of volatile vapor.

6. The operating staff should wear static proof clothes. 7. During the fuel tanks operation, the operating staff should prevent from

using the electrical equipment. 8. If the volatile vapor exists in the dangerous area, all the electric cable in

the aircraft should be de-energized. 9. Prepare at least one portable fire extinguisher (20-B fire extinction

effectiveness, 15 LB (6.5kg) capacity) within 15,2m (50Ft) away from working area while performing A/C fuel tank repair work.

10. If the operating staff must bring combustible liquid into the fuel tanks for maintenance jobs, he should use the container to keep it and prevent from the liquid spilling out.

4.4.7 THE ADDITIONAL REGULATIONS OF MAINTENANCE OF INTEGRAL FUEL TANK 1. The scraper used to scrape the sealant in the tanks should be metallic or

hard-wooden product. The plastic product that may cause static electricity is not allowed to use.

2. Only pneumatic tool is acceptable to use in fuel tanks. 3. When applying the sealant on the surface of fuel tanks, the maintenance

staff should particularly pay attention on it to prevent from spark of fire.

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 4 GENERAL SAFETY REQUIREMENTS 4.5 HIGH AREA WORKING SAFETY

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 4.5-1

4.5 HIGH AREA WORKING SAFETY 4.5.1 PURPOSE

To prevent from injury of the personnel and damage to the A/C when performing work in the high area over 2 meters above ground.

4.5.2 SCOPE This instruction is applied when using aerial platform, scissors lifter and high-lift platform to perform the maintenance at the area that over 2 meters above ground.

4.5.3 RESPONSIBILITY The maintenance/ operating staff is responsible for performing all following requirements.

4.5.4 HIGH AREA WORKING SAFETY REQUIREMENT 1. Only person who has been trained and authorized can operate the lifter

IAW operation instruction. 2. If it is necessary to use the GSE (as aerial platform or scissors lifter), the

operating staff should check to ensure that the equipment is serviceable. 3. The operating staff should choose the proper GSE. For example, when

using the platform, the operating staff cannot increase the length of safety belt. If the height of platform is not enough, the operating staff should use another proper GSE to perform the maintenance.

4. Safety accessories (safety belt, barrier…) should always be used when performing the work at high area.

5. The maintenance staff should pay attention to the surrounding around the A/C, especially in a strong wind condition when performing the maintenance on the wings or platform.

6. In case of strong wind condition, the maintenance staff can coordinate with BTPD to perform the maintenance inside the hangar. If not, the maintenance staff should determine if the maintenance can be continued or not.

7. Before the maintenance, the maintenance staff should communicate with the supervisor of the A/C and attach “DO NOT OPERATE” Tag on C/B, control lever or control switch to prevent from the dangers caused by other personnel’s touching.

8. If the vehicle should be parked near A/C for maintenance, the operating staff should ensure the parking brake, chocks and support are properly set to prevent injury of personnel and damage to A/C.

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 4 GENERAL SAFETY REQUIREMENTS 4.6 OXYGEN SYSTEM HANDLING SAFETY

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 4.6-1

4.6 OXYGEN SYSTEM HANDLING SAFETY 4.6.1 PURPOSE

To stipulate the routine or non-routine maintenance on oxygen system/ assembly to prevent property from damage or personnel from injury.

4.6.2 SCOPE These requirements are applied for maintaining oxygen system/ assemblies on the A/C and in the workshop.

4.6.3 RESPONSIBILITY Maintenance staff is responsible for follow all requirements specified below.

4.6.4 OXYGEN SYSTEM HANDLING REQUIREMENT When perform maintenance task related to oxygen system, maintenance staff should follow instruction specified in maintenance data. However, the following requirement also be applied. 1. The electrical equipment, high heat source, combustible materials, oil

and metal scraps must not place near the oxygen system. 2. Wearing the gloves, clothes and tools that are contaminated with oil is

strictly prohibited. Clothes and tools shall be always kept clean and only pure cotton gloves shall be used.

3. The technician is prohibited to use grease to lubricate the screw. 4. To prevent from fire or explosion, the technician should slow down

his/her action when open or close the valve of oxygen system. 5. The valve of the oxygen system cannot be forcefully opened/closed by

the spanner, hammer or other tools. If the valve cannot be operated by hand, it should be divided into unserviceable.

6. Before removing or installing the oxygen bottle, the technician should close all the shut off valve of the oxygen system and protect the tube by the plug or cover.

7. Follow the AMM of A/C to torque the shut off valve, and do not over torque.

8. The distance between oxygen tube and electrical wire is 5 centimeters (2 inches) at least.

9. Do not connect a low pressure hose to a high pressure oxygen system. 10. Use the correct lubricant to lubricate the O-ring according to each A/C

AMM. 11. Follow the A/C AMM to do leak check with correct parts or tool. Only the

approved oxygen leak hunting liquor can be used for leaking test. 12. At least one 20-B/ 15 LB (6.8kg) portable fire extinguisher should be

provided in 15.2m (50ft) working area.

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 4 GENERAL SAFETY REQUIREMENTS 4.6 OXYGEN SYSTEM HANDLING SAFETY

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 4.6-2

13. Before replacing chemical oxygen generator on A/C, safety pin on the oxygen generator must be installed to prevent inadvertently fire that will cause 260°C (500°F) and raise up injury to personnel.

14. If the oxygen generator were inadvertently fired, the oxygen generator should be removed to a safe area that will not cause fire hazard. However, if generator was fired on aircraft it should be remained on the location and be replaced after temperature go down to operational range.

15. Oxygen must not be used to pressurize container or as blow off air or high-pressure air on painting process.

16. Different gas is prohibited to mix in one oxygen bottle. 17. Good ventilation should be kept in working area. It is restricted to work in

the closed room during oxygen system operation. 18. The maintenance staff must avoid from touching the lubricant, flammable

goods with the tools, hands, clothes, equipment or system. 19. The oxygen bottle storage and service area must be placed under the

highest safety standard, clean and neat. 20. All the oxygen equipment must be extremely careful of processing, and

be fixed to prevent from rolling or falling. It is absolutely prohibited of smoking and flame.

21. All the connectors’ surface must be absolutely clean and careful to handle it.

22. The maintenance staff must not remove the fixed-style oxygen bottles or perform any oxygen system related maintenance jobs unless the team leader agreed and the attendant had well prepared for the evacuation.

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 4 GENERAL SAFETY REQUIREMENTS 4.7 MAINTENANCE CLEANLINESS AND FOD PREVENTION

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 4.7-1

4.7 MAINTENANCE CLEANLINESS AND FOD PREVENTION 4.7.1 PURPOSE

To provide procedures for the maintenance of cleanliness of aircraft under maintenance and FOD prevention.

4.7.2 SCOPE/ RESPONSIBILITY 1. Maintenance Directors and Department Managers shall be responsible

for interpreting, disseminating and implementing FOD prevention program in their respective department. They shall ensure all production personnel are informed and strictly comply with FOD prevention practices. They shall also ensure sub-contractors who have to work on/in the vicinity of aircraft are briefed of the FOD procedures pertaining to such work. FOD procedures shall also be reviewed regularly to ensure compliance is possible and practical and for improvements

2. All employees shall be responsible to comply with the company FOD prevention practices

4.7.3 DEFINITION 1. A Foreign Object is defined as a substance or article alien to the aircraft

that has been allowed to invade it. Foreign Object in the immediate area of or in area from which migration is possible, e.g. through tooling holes, bend relief cut-outs, drain hole, etc., and which could cause a system or component malfunction or deterioration is classified critical.

2. Foreign Object Damage (FOD) is any damage attributed to a foreign object which can be expressed in physical or economic (monetary) terms which may or may not degrade aircraft safety and or performance characteristics.

3. Types of FOD broadly include but not limited to the following: a. Safety wire b. Nuts, bolts and washers c. Rivets and cotter pins d. Airframe fittings and fasteners e. Tools f. Rags, paper g. Hats, gloves and headsets h. Bags i. Rubber plugs j. Ground safety streamers k. Rocks/gravel l. Water m. Erosion and contamination products

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 4 GENERAL SAFETY REQUIREMENTS 4.7 MAINTENANCE CLEANLINESS AND FOD PREVENTION

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 4.7-2

4.7.4 SCOPE OF FOD PREVENTION MEASURES The areas which are addressed in this SOP include: 1. Aircraft Operations 2. Work Practices 3. Housekeeping 4. Inspection 5. Surveillance 6. Tools Control 7. Investigation 8. Training

4.7.5 AIRCRAFT OPERATIONS 4.7.5.1 Flight line aircraft

1. All serviced aircraft shall have protective covers installed over pitot, static tubes/ ports, engine inlets/ intakes, exhausts, bleed valve ports… after the overnight check as required by customer and applicable maintenance data.

2. FOD prevention inspections shall be conducted before and after every flight and/ or engine run-up. These inspections shall include but are not limited to: a. Compressor inlet area b. Engine intake area for security of joints or inlet hardware to confirm

that gaps or openings through which debris can enter the engine do not exist

c. Tools and general hardware accountability check 3. Engine ground run personnel shall ensure engine thrust is not directed

towards nearby aircraft or buildings during engine ground run. 4. If engine run is to be conducted after a heavy downpour, engine ground

run shall not be conducted in the vicinity of water puddles so as to avoid ingestion or large volumes of water.

4.7.5.2 Personnel precautions near operating engines 1. All staff involved in engine run shall not take articles/ personal objects

near the intake ducts of operating engines. 2. Anyone who must approach within a 10m (30 ft) radius of operating

engines must first remove items such as insignia pins and security badges, and secure them in pockets that can be fastened with Velcro tape or in pouches/ zipper pockets.

3. Ground maintenance personnel shall use only authorized headset cords for intercommunication with the cockpit in order to prevent slack being draw into the engine inlet/ intake when walking around the aircraft.

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 4 GENERAL SAFETY REQUIREMENTS 4.7 MAINTENANCE CLEANLINESS AND FOD PREVENTION

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 4.7-3

4.7.6 WORK PRACTICES 1. Maintenance/ manufacturing tasks shall be planned and sequenced in a

manner that precludes foreign object entrapment and product contamination. Documents shall contain necessary processes and procedures for controlling contamination and debris during fabrication and assembly operations.

2. Boxes or special trays shall be used for small items, such as hand drills, hardware, which are to be used in aircraft. This tray shall be used to transport tools to and from the tool crib/ shadow board and act as temporary storage container for removed hardware. The removed hardware shall be disposed of properly when the tray and tools are returned to the tool crib/ shadow board.

3. Maintenance personnel shall be extra vigilant whenever work is performed in, around, or in front of intakes, integral fuel tanks and flight deck areas. Extreme caution shall be used to prevent the introduction of foreign objects.

4. Whenever work is performed in the flight deck, all trades involved shall co-ordinate jobs to preclude the introduction of foreign objects during the performance of work and to effect thorough cleaning of the flight deck when work is completed.

5. Inlet and exhaust covers and bleed valve port covers shall be installed during aircraft maintenance and servicing if required by manufacturer or customer.

6. All engines shall be fitted with intake blanks or protective coverings when installed on engine stand.

7. All open fuel, hydraulic and air pipelines and disconnected electrical terminals shall be blanked using appropriate caps and plugs.

8. After fluid and pneumatic system lines and tubing are cut and deburred, the system fluid shall be purged and ends of lines capped.

9. Whenever large modifications, skin repairs, spar changes, etc., involving the production of large quantities of swarf, redundant parts and sealant are performed, it shall be removed as much as possible as it is produced and a systematic cleaning procedure is implemented. All corrosion control measures shall be implemented as required.

10. After the completion of each task, the area in the work vicinity shall be cleaned of all swarf and debris. The work area shall be cleaned at the end of each work day.

4.7.7 FOD PREVENTIVE PROGRAM FOR HANGAR 1. During work process

a. Fluid leaks: The maintenance staffs shall use the suitable container to collect the fluid. In case the fluid is spilled to floor, it should be absorbed by sand/sawdust…and clean up immediately to avoid the fluid from causing any possible damage to the aircraft or the personnel in that area.

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 4 GENERAL SAFETY REQUIREMENTS 4.7 MAINTENANCE CLEANLINESS AND FOD PREVENTION

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 4.7-4

b. Metal chip or debris: During the maintenance activities, metal chips or debris shall be collected using proper equipment. Suitable plate or cover shall be provided to prevent debris or tool from dropping.

2. After work cleaning a. All maintenance staffs are requested, after the work is

accomplished, to clean the ground, the racks, and work benches and the work area of the aircraft to remove any debris, scrapped hardware, rags, etc.

b. Also the maintenance staffs shall check the tools and equipment with respect the task had been removed from the working area to ensure there is nothing left when all work are accomplished. Should there be any tool/equipment missing after check, the supervisor shall be informed to perform the searching of the nearby area thoroughly to prevent any consequential damage to the aircraft or aircraft system.

3. Contract Agency Cleaning: In order to remove the oil/grease resident and other objects that might cause the unnecessary contamination, the respective BMC shall assign the contract agency use cleaning machine to clean up the hangar floor when hangar area do not have aircraft maintenance activity.

4.7.8 FOD PREVENTIVE PROGRAM FOR VAECO APRON 1. Other than the requirement to the maintenance staff to pick up any of the

foreign object from ground, when weather condition is allowable, the RTPD/BTPD will inform Sanitation team to perform an FOD check to clear FOD in the apron areas of VAECO.

2. During the FOD check, assigned personnel of relevant center shall walk around the apron and pick up any foreign object that might cause the damage to the aircraft that are parking, towing or performing maintenance in the apron area.

4.7.9 FOD PREVENTIVE PROGRAM FOR RAMP MAINTENANCE 1. The FOD checks at the ramp area are performed by the maintenance

staff before the aircraft arrived. The maintenance staffs shall walk around the parking area prior to the aircraft taxiing/pushing in and pick up all foreign objects that might cause the damage to the aircraft/ engine.

2. Special caution shall be taken for the path of the engines and the wheel where risk of damage is higher than other area.

4.7.10 INSPECTION 1. All extraneous material shall be inspected for and removed during

assembly operations. Upon completion of each major assembly, conduct a foreign object inspection and remove debris.

2. If any hardware is lost during the performance of maintenance, a systematic and thorough search shall be conducted for the lost.

VIETNAM AIRLINES ENGINEERING CO. LTD. STANDARD OPERATING PROCEDURES

PART 4 GENERAL SAFETY REQUIREMENTS 4.7 MAINTENANCE CLEANLINESS AND FOD PREVENTION

Issue: 02, Revision: 00, Date: 01 FEB 2012 Page 4.7-5