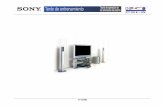

Sony PDP-01 Plasma Training

Transcript of Sony PDP-01 Plasma Training

Training Manual

Course: PDP-01

Plasma TelevisionModels: KE-37XS910

KE-42XS910KE-50XS910KDE-42XBR950KDE-50XBR950KDE-61XBR950

Diagnostics and Troubleshooting

KE-61XBR950

Table of Contents

Introduction...........................................11. Plasma Panel Troubleshooting ....3Overview ................................................................. 3Pixel Control ........................................................... 4

Plasma Panel Troubleshooting ............................ 4

2. Troubleshooting theKE37/42XS910 .....................................13Overview ................................................................ 13

Signal Processing ................................................ 13The Plasma Panel ................................................ 15Troubleshooting ..................................................... 17Disassembly .......................................................... 26

3. Troubleshootingthe KE50XS910 ....................................37Overview ................................................................ 37Signal Processing ................................................ 37

The Plasma Panel ................................................ 39

Troubleshooting ..................................................... 41Disassembly .......................................................... 52

4. Troubleshooting theKDE42/50/61XBR950 ..........................64Overview ................................................................ 64Plasma Panel Block Diagram ............................. 64

Troubleshooting ..................................................... 66Disassembly .......................................................... 72

5. Disassembling theKDE61XBR950 .....................................79Overview ................................................................ 79Disassemblyling the KDE61XBR950 ................ 79

1

PDP-01 - Introduction

PDP-01 - Introduction

Plasma display devices are becoming the choice of many consumers, as evidenced by the amount of thisproduct on the display floor of any electronics goods store and the increasing number of sale ads. Although stillrelatively high in price when compared to other display devices such as CRT and LCD, the gap is rapidly narrowing.The appeal of owning a futuristic “flat” television that can be configured to virtually any installation layout keepsthe demand for plasma growing every year. Geometric distortions, beam landing errors and convergence issuesare non-existent. The narrow viewing angle of rear-projection televisions is also overcome.Although one would normally think of plasma devices as relatively new in the display market, the technology isnot new. Development of plasma-type displays began in 1971 using a monochrome platform. Color displaysbegan to appear in the early 1980s. New developments in panel designs have increased the brightness, resolutionand contrast, along with greater longevity in panel life. Claims of 60,000 hours of useful brightness are beingheard, equating to about ten years of normal viewing time.

The amount of research and development, along with highly sophisticated manufacturing processes are whatkeep plasma displays in the relatively high price range. This factor gives the product great viability in the serviceindustry. The complex circuitry, however, requires today’s technician to keep abreast on these changes indisplay methods to remain competitive. The purpose of this manual is to help the technician better understandthis technology to accomplish this.

Once of the unique aspects of these display devices is the modular construction of the unit itself. The abundantuse of LSI devices, along with a greater demand for on-site repairs, requires that technicians perform mostrepairs at board level. The glass-plasma panel itself can be replaced in about the same amount of time asreplacing picture tubes in a CRT projection set if being done for the first time. Once you become familiar with theprocedure and the chassis, the time will become even less due to the lack of extensive alignment proceduresrequired in CRT sets.

This course is written with a primary emphasis on practical troubleshooting approaches to plasma-type displaydevices, particularly the 2003/2004 models introduced by Sony. In-depth theory will not be discussed. If basicplasma theory is desired, refer to training manual TVP-13.

The technician merely needs to learn the basics of plasma technology, particularly how the panel is controlled, inorder to appropriately diagnose the point of failure. This will require a fresh, new approach in responding to whatmay or may not appear on the screen. Self-diagnostic circuits also provide a valuable tool in isolating a particularfailure. Knowledge of the basics and practical approaches presented in this manual should convince mosttechnicians that servicing plasma displays is no more difficult than any other display device.

This manual will cover six different models ranging from 37" to 61". The model series includes the XS910(available in 37", 42" and 50"), and the XBR950 series (available in 42", 50" and 61"). There are several distinctionsamong these models. The XBR series uses a separate media box to receive ATSC and NTSC broadcasts andcable DTV signals along with analog and digital inputs, making them a true “High Definition” television. TheXS910 series does not have a media box. It has a built-in NTSC tuner and relies on external devices to supplystandard and high definition signals. These types of televisions are known as “High Definition Ready”.

From a repair standpoint, the key difference among each model is the design of the plasma panel. Four differentdesigns are used. In attempting to cover such a large variety of designs, this manual will be arranged so thatbasic panel operation and troubleshooting is covered first. Even though there are different panel designs, theunderlying concept of controlling a plasma panel is universal among them. Understanding how the panel iscontrolled is important for troubleshooting purposes. The remaining task is identifying the boards and theirnomenclature. Once this is clear, it is only a matter of becoming familiar with the unique layout of the differentpanels. The subsequent chapters will cover each model based on its panel usage along with procedures andtips to aid in properly servicing the specific design.

2

PDP-01 - Introduction

Detailed procedures will also be covered for the proper disassembly, re-assembly and adjustments (if required).The first item the technician will notice is that plasma televisions use a large number of screws. Removal of therear cover can involve up to 60 screws of varying type and size. Many other screws are used for shielding andpanel support brackets, not to mention circuit board mounting. It is important to return all screws to their originallocation. Placement of all wires is also crucial for minimizing signal interference and to prevent damage to wiringwhen re-assembling the unit. This is especially true when installing support brackets and the rear cover.

3

1. Plasma Panel Troubleshooting

Chapter 1 - Plasma Panel Troubleshooting

HV OR Y SCANBOARD

COMMONOR

X SCANBOARD

DATA OR ADDRESS BOARD

LOGIC CONTROL BOARD

RGB DATA

FIGURE 1-1 BASIC PLASMA DISPLAY CONTROL PDP01.1-1 3/23/04

SECOND ADDRESS BOARDS FOR DUAL SCAN

PLASMA DISPLAY PANEL

OverviewLCD and plasma display devices are similar in how they control light output from a particular pixel. Although theyeach generate a source of light in a different manner, the use of horizontal and vertical control grids allows fortiming a particular pixel for display.In Figure 1-1, a typical layout for a plasma display panel is shown. The horizontal control lines (usually referredto as scan control lines) determine which horizontal line of red, green and blue pixels will be ready to be activatedat a particular time. High voltage pulses of up to 230 volts are sent to the scan lines. Notice the use of separateX and Y driver boards. Each board handles every other scan line. Working in unison, the odd and even scanlines are energized with alternately phased pulses to place the plasma chambers in a “sustain” condition.

The Y-Drive (or High Voltage) board sends scan-drive pulses to a group of drive ICs since the initial charging foreach scan requires the most power. These ICs are mounted on separate circuit boards (usually two) or directlyonto the flexible PC cable molded into the panel, depending on the design. The X-Drive board connects to thepanel without drive ICs since its primary function is to reverse the plasma chamber charge.

The moment a certain horizontal row of pixels is activated, the appropriate intersecting, vertical control linesdetermine which pixels will light. These are known as address or data lines. All of this is timed by a logic controlcircuit (sometimes referred to as a digital board) that receives the incoming digital RGB signal and allocates theinformation to the appropriate pixel. This forms a grid pattern to control each intersecting point. It is a simpleconcept and the understanding of this sequence is critical to analyzing any abnormalities noted on the display.

Some panel designs use addressing lines at the top and bottom of the panel. This is known as a dual-scan andis found in newer panel designs, particularly in larger ones. The amount of addressing control is shared so thatonly half of the vertical distance of the screen is controlled by each of the upper and lower addressing line inputs.

4

1. Plasma Panel Troubleshooting

FIGURE 1-2 - PLASMA CELL STRUCTURE

SUSTAIN ELECTRODE(TRANSPARENT)

SCAN ELECTRODE(TRANSPARENT)

FACE PLATE

ELECTRICLAYER RIB

PHOSPHOR (GREEN)

PHOSPHOR (RED)

DATA ELECTRODE

PHOSPHOR (BLUE)

PROTECTIONLAYER

BACK PLATE

PDP01.1-2 3/1/04

DISCHARGE

Pixel ControlLighting a PixelIn Figure 1-2, a simplified layout of a plasma discharge chamber is shown. Inert gases (usually xenon and neon)are exited by an electrical charge. In order to sustain this state, the electrical charge must be constantly changing.As mentioned previously, the X and Y drivers send alternating pulses to accomplish this. This voltage is at a levelnear the required amount to “excite” the gasses by introducing free electrons. The address lines apply thenecessary voltage to complete the “firing” of the plasma material. This phenomenon causes a release of ultravioletlight.

Each plasma gas chamber resides over a particular red, green or blue phosphor stripe applied vertically on thepanel. By controlling the amount of UV radiation from the plasma chamber across each vertical stripe, colorimages can be displayed with great accuracy.

Creating a PictureReferring back to Figure 1-1, the scan lines determine which pixel row is active at a given time. The electrodesof the scan control lines are transparent, allowing the light from each phosphor stripe to emit from the panel. Theaddress lines work in a unique method to control light output from each pixel.

Whenever a particular scan line is active, the address lines will determine which pixel along that line will light.This is done eight times for each field of video information and is controlled by an 8-bit data word. These arecalled sub-fields. Unlike CRT displays, which are controlled by varying the level of electron beam emissions,each pixel is controlled eight times at 256 possible levels. The more times a particular pixel is fired during thesub-field scan period, the brighter the pixel. If the incoming video signal is sampled at a 10-bit rate for each of theRGB components, a color combination of 700 million is achieved!

Plasma Panel TroubleshootingGeneralDue to the use of different display panel designs, this chapter of the manual will attempt to cover troubleshootingtechniques universal to plasma displays. Differences among the panel designs will only require separate boardlayouts and disassembly procedures. These differences will be covered in the chapters to follow.The first critical item to determine is whether the display panel is the cause of the defect. In most cases, it is quiteevident if the panel is the cause. Other failures may not be so obvious. The main reason for eliminating a fault

5

1. Plasma Panel Troubleshooting

in the panel is to prevent wasted time. A complete disassembly of the unit is required to access the various circuitboards and flexible cables for further diagnosis and visual inspection. This is very time consuming. Plasmapanel failures are not common and most are caused by improper handling and shipping damage resulting incracks to the glass envelope and the release of the internal gasses. They are also quite expensive and, therefore,not something that should be replaced needlessly.

The use of scan, addressing and timing pulses can produce interesting symptoms on the display. Single lines,vertically or horizontally, may be lit when they are not supposed to be. Entire halves or quadrants of the screenmay be lit bright white or appear completely dark. Failures on the logic control board or distortions and leveldrops of the scan pulses produce a myriad of rainbow color effects. The panel may not display any video at all.

The remainder of this chapter will attempt to cover the various symptoms that can develop with each particularcircuit or panel defect. Once again, keep in mind that in most cases the panel itself is usually not the cause of thedefect. There are some panel designs that have driver components mounted directly to the flexible cablesencased within the glass assembly and this would force a replacement of the panel.

NOTE: Due to the complex digital processing involved with plasma displays, unusual symptoms may appear onthe screen that may make it difficult to determine the failure. Always check the Sony Service website at HTTP://service.sel.sony.com for any FPR or service bulletins that may be present regarding the model you are about toservice. An abundance of information is located on the ESI site and is updated daily. Do this before going on theservice call to minimize the amount of time needed to complete the repair.

Troubleshooting a “No Display” ConditionThis tends to be the most difficult symptom to approach since there are many potential sources to prevent thepanel from going active. Failures of any number of B+ lines, the scan and address drivers, or a loss of videoinformation could be the cause. In the case of B+ lines, most units will go into protect shutdown and may noteven generate indications of having done so. There is, however, one important observation that can assist inisolating the panel and/or drivers as the cause.A unique phenomenon occurs whenever a plasma display is powered up. It is known as “priming”. Priming isperformed by the scan drivers. A large positive and negative pulse is sent to each X and Y scan-line at initial turn-on. Residual charges in each pixel are cleared along with the necessary boost to begin discharging from thegasses. Once the pixels are primed, they will continue to discharge a small amount of light, known as “sustaining”.This generates a raster similar to that found on CRT devices although it is lower in level and lacks scan lines. Itis easier to detect in low ambient light conditions. The easiest way to identify pixel lighting is to observe thescreen while turning the unit on and off. With the unit off, you have an idea of what “true black” is. If the pixelsare lighting, you will see the difference between the true black and “reference black”. The use of a magnifyingglass (such as those used for beam landing on a CRT) helps to see if the pixels are emitting light at a low level.

This is an important function to verify. It tells you the panel is functioning and the scan and addressing pulses arepresent along with all of the necessary B+ voltages. It usually indicates a loss of video signal data entering thelogic board and troubleshooting should focus on the video processing circuits rather than the panel and driverassembly. It is possible that a failure could have occurred on the logic board but this is unlikely.

The absence of priming or sustaining a raster brings the focus of troubleshooting to the panel and associatedcircuits to drive it. If the plasma panel’s glass envelope is compromised, allowing the escape of the gasses andthere is no evidence of breakage, it becomes necessary to check for the presence of scan and addressingpulses to isolate the failure to the panel or driver circuits. The means to accomplish this varies between paneldesigns. They will be covered in the chapters of this manual pertaining to each model.

If an oscilloscope is available, scan-pulses can be verified by connecting to the inputs of the scan driver board(s).These boards are easily identified by their location on the side of the panel. Figure 1-3 shows a typical scan-driver layout. There will be one or two boards with several IC drivers. The driver boards will be connected to a

6

1. Plasma Panel Troubleshooting

FIGURE 1-3 - TYPICAL SCAN DRIVER LAYOUT PDP01.1-3 3/1/04

CHECK FOR PULSES ATINPUT PINS

scan generator known as a Y-SUS or High Voltage board depending on the panel design. Placing a scope probeon the pins of the connector to the scan drivers will display high-voltage pulses around 230VPP at about 4µs induration. If these pulses are present, the panel should be priming the pixels. If priming is not occurring, there isa possibility of a compromise in the panel glass.

Distortions in the Display VideoAs mentioned earlier, distortions displayed on the screen will present new and sometimes interesting patternsthat will be unfamiliar to most television technicians. Like CRT displays, however, the symptoms on the screengive excellent clues as to where the problem may lie. CRT display abnormalities are diagnosed based on whatthe technician knows about video processing and scanning technology. Likewise, abnormalities on plasmadisplays are generally clear pointers to a particular circuit involved in the pixel scanning. Once the concept isunderstood, troubleshooting is as easy, if not easier, than CRT symptoms. Remove the need for purity,convergence, geometry, picture sizing and centering, and you will find plasma technology is not quite so intimidating.

The sections to follow will attempt to cover different types of distortions you may encounter, along with generaltests and recommended solutions. Keep in mind that an attempt is being made to generalize up to four differentpanel design layouts but the idea is to get the technician familiar with resulting display abnormality. Detailedanalysis specific to each panel can be found in its corresponding section.

Vertical Line AbnormalitiesSince the addressing lines time the vertical plane of the pixels, attention is focused in this area of the panel drivesignals. In cases where multiple lines appear with color across the entire screen, the addressing lines are not thecause. Figure 1-4 illustrates two examples of address drivers utilizing single or multiple ICs. In both cases, theaddress information from the logic board is de-multiplexed by the drivers to control the vertical address lineswithin the panel. Notice the drivers are mounted directly to the flexible PC cable, which is part of the glass panel.They are not replaceable with conventional equipment and a failure at this point requires replacement of theentire plasma panel.

7

1. Plasma Panel Troubleshooting

FIGURE 1-4 - EXAMPLE OF ADDRESS DRIVERS PDP01.1-4 3/1/04

MULTIPLE DRIVE ICs SINGLE DRIVE IC

FIGURE 1-5 - SINGLE VERTICAL LINE FAILURE

ADDRESS BOARD ADDRESS BOARD

SINGLE DARK, WHITE, ORDIFFERENT COLORED LINE

SCAN DRIVER, FLEX CABLEOR PANEL.MUST REPLACE PANEL

PDP01.1-5 2/27/04

Below are some examples of the different symptoms that can appear.

Single Black, White, or Colored Vertical Line: Figure 1-5 illustrates an externally generated red raster in which asingle vertical line appears. The line may be dark, white or one of the primary pixel colors. A dark or white lineindicates a loss of drive to a single row of pixels and the type of panel used determines whether it will display aswhite or black. A colored line is caused by that particular address location being turned on continuously. Thiscan be caused by a defective drive IC, or leakage or shorts between the pads of the flexible PC connector pads.

If the panel is a single-scan design (address drivers only on the bottom), the lines usually extend from top tobottom. In a dual scan panel, the line(s) will begin at the top or bottom and end exactly at the middle of thescreen.

8

1. Plasma Panel Troubleshooting

FIGURE 1-6 - MULTIPLE VERTICAL LINE FAILURE

LINE MAY BE BLACK ORWHITE DEPENDING ON

PANEL DESIGN

ADDRESS BOARD ADDRESS BOARD

DRIVE IC OR ADDRESSBOARD FAILURE

PDP01.1-6 2/27/04

Multiple Cluster of Black or White Lines: In Figure 1-6, an example is shown where multiple adjacent lines arenot receiving a signal. In almost all cases, the lines affected correspond directly to the number of outputs de-multiplexed by a drive IC. The problem can be a failed drive IC or loss of signal to that particular IC. A closeinspection of the drive IC at the point where the abnormality is located should be performed first. Most failuresof the drive IC will reveal signs of overheating such as cracks or burn holes. If this is found, the panel must bereplaced. If the drive IC appears intact, inspection of the flexible PC cable should be performed paying closeattention to the contact pads and the locking connector. Corrosion or foreign material could be the cause. If thecable and connector appear OK, it will be necessary to check signals at the connector. This is easily done sincethere are other drive connectors in which to compare proper voltages and signals.

TIP: Some panel designs (such as the KE50XS910) have a relay board to distribute the drive signals from thelogic board. In this case, the cables for adjacent address lines at the relay board can be swapped. If the linedefect moves to another part of the screen, the drive IC was not receiving a signal. If the line defect remains inthe same place, the drive IC is defective and the panel must be replaced.

Multiple Colored Vertical Lines: Figures 1-7 illustrates another vertical line distortion. Although this may appearto be an addressing line failure, the fact that they contain colors eliminates this possibility. Notice the distinctcutoff point at the middle of the screen. All current plasma designs used in Sony products split the horizontalscan signals between two driver boards. Although this appears to be a vertical issue, it is caused by the scancircuits, not the address circuits. Suspect a failure in the Y-SUS board. Other models refer to this circuit as ahigh voltage board.

9

1. Plasma Panel Troubleshooting

FIGURE 1-7 - MULTIPLE COLORED LINES PDP01.1-7 2/27/04

SCAN DRIVE BOARDSAND DRIVERS

DRIVE IC, FLEX CABLE, ORDEFECTIVE PANEL

FIGURE 1-8 - SINGLE SCAN LINE FAILURE PDP01.1-9 2/27/04

Horizontal Line AbnormalitiesIn figure 1-8, a thin line of missing video indicates a loss of signal to an individual line. This can be caused by anindividual scan line being inoperative due to an open connection to the panel or a failure of the drive IC to providethe necessary voltage to that line. Since the scan driver IC performs a de-multiplexing of the incoming signal, thefailure lies either within or after the drive IC. If the panel design uses a scan drive board in which the flexiblecable is part of the panel and driver board, or if the drive ICs are part of the flexible PC, the panel must bereplaced. In panel designs where the driver board contains connectors to the panel flex-cables, a thoroughinspection of the flexible cable connecting the panel to the driver board should be performed. If the pads on theflexible cable are OK, a check of each scan-drive output from the driver IC must be made with an oscilloscope toeliminate the panel assembly as the cause.

10

1. Plasma Panel Troubleshooting

FAILED IC

SCAN BOARDSAND DRIVERS

FIGURE 1-9 - MULTIPLE SCAN LINE FAILURE PDP01.1-9 2/27/04

BURN HOLE

SURFACE CRACK

FIGURE 1-10 - DAMAGED SCAN DRIVE IC PDP01.1-10 2/27/04

Figure 1-9 illustrates a failure of a large number of horizontal scan lines. Most panel designs use two separateboards for the scan drivers. The point to note is that any failure of a scan IC will prevent display of succeedinglines to the point where the board ends at the middle of the panel. The first IC that fails to light up the scan linesis the culprit. In some cases, a visual inspection of the drive ICs may reveal the failed component. Look for anysigns of scorching or burn holes as shown in figure 1-10. Scan ICs damaged due to overheating will usuallycause the self-diagnostics circuits to indicate a panel failure alarm. How this alarm is displayed varies frommodel to model and is covered in training material specific to that model.

11

1. Plasma Panel Troubleshooting

FIGURE 1-11 - ABNORMAL COLORS PDP01.1-11 2/27/04

FIGURE 1-12 - SCAN DRIVE DISTORTION PDP01.1-12 2/27/04

Abnormal Luminance and/or ColorIn Figure 1-11, one of any number of symptoms is shown that can be caused by a failure in the scan drivecircuitry. Background video may or may not be present. There might only be luminance component. The keysymptom to observe is the “analog” appearance of the distortion. Video signals processed before reaching thepanel will usually have a digital-appearing distortion. If the scan drive board is at fault, the distortion will tend tohave a smear to it and will appear whether a signal is input or not.

Another example of distortion caused by the scan circuits is shown in Figure 1-12. The upper or lower half of thescreen video will have distortion similar to colored snow. This symptom is deceiving and leads one to believe thelogic or scan drive board to be at fault due to the “digital” appearance. The clue here, once again, is how thedistortion occurs in exactly one half of the screen. The two boards containing the scan driver ICs should beexamined for any signs of component overheating by looking at or carefully touching any semiconductor devices.Distortions such as this can be caused by leaky components causing a load on the voltage lines or unwantedoscillations.

12

1. Plasma Panel Troubleshooting

Replacing a Defective PanelOnce it is determined that the plasma panel needs replacement, the proper procedures must be followed toremove it from the unit. This procedure varies from model to model. This is covered in the additional chaptersof this training manual.

Due to varying tolerances of plasma panels, certain voltage settings must be adjusted for that particular panel.Most replacement panels will come with the Logic, Address and Scan boards installed and pre-adjusted. Incases where the panel does not, a label is located on the rear of the panel indicating the proper voltages settingsunique to that panel. All panels require the proper setting of the scan (Vs) and address (Va). Other panels mayrequire one or two additional voltages to be properly adjusted. These will also be indicated on the label. Figure1-13 illustrates a typical label indicating the proper scan and address voltages. Note the two additional voltages(Vw and Vx) indicated on the label. The method for adjusting panel voltages is dependent on the panel designused. Some can be adjusted on the power supply board and others will appear on the scan boards. Certainmodels require an interface jig to change EEPROM data. Be certain to check for the latest updates regardingpanel voltage adjustments pertaining to the model you are servicing by accessing the Sony service website atHTTP://service.sel.sony.com.

PANEL TYPE PANEL SERIAL NUMBER

VOLTAGESETTINGS

FIGURE 1-13 - TYPICAL PANEL LABELSPDP01.1-13 3/23/04

13

2. Troubleshooting the KE37/42XS910

Chapter 2 - Troubleshooting the KE37/42XS910

OverviewThe KE37/42XS910 is a high-definition-ready plasma television with a built-in NTSC tuner along with the necessaryvideo processing circuitry to accept composite, Y/C, component, and DVI video sources along with analog L/Raudio. Other plasma models function as monitoring devices and rely on an external receiver (known as a MediaBox) to receive and process video and audio.

This chapter will point out the circuits that are unique to this model along with a description of each board’sfunction. Practical troubleshooting methods will be discussed followed by a systematic procedure for disassemblingand re-assembling the unit. Plasma televisions rely on a large gassed-filled glass panel to generate video. It isimportant that this glass panel be properly braced and secured by brackets and the back cover assembly. Aconsiderable amount of shielding is also required due to the high voltage levels generated by the scan drivers.Because of this, a large number of screws are utilized. A full disassembly can require the removal of a hundredscrews or more!

Another factor is the use of a number of circuit boards spread throughout the rear of the large panel assembly.This requires the use of many wiring harness mounts and paths. It is extremely important to route these wires intheir correct configuration to minimize interference and prevent any wires from being pinched or cut. Clearancesbetween shields, brackets and the rear cover are minimal so this is quite important. An extensive use of illustrationswill be used to assist the technician in routing the wiring correctly and return all of the screws back to their originallocation.

Signal ProcessingOverall Block DiagramReferring to Figure 2-1, an overall block diagram demonstrates the various paths for the different video andaudio inputs. A NTSC tuner is located on the A board. A/V inputs 1, 2 and 3 accept composite or Y/C video alongwith L/R audio. A/V inputs 4 and 5 accept component video only, along with L/R audio. Video resolutions of 480i,480p, 1080i and 720p are supported.

The DVI input receives differential RGB digital video information along with analog L/R audio. The UD boardcontains the receiver/decoder to convert the digital signal to Y/CB/CR along with HDCP control.

The HM board contains a Memory Stick™ slot for display of JPEG still pictures and MPEG1 audio/video playback.The information from the memory stick is processed and sent via a LVDS (Low Voltage Differential Signal)transmitter to the MS2F board. The video and/or audio signals are processed and D/A converted. Audio is sentto A/V switch2 while video information is sent to the DIC2 board.

NOTE: The MS2F board is enclosed within a shielded assembly (known as the DM Block) containing the DIC2and DE2 boards. Although the service manual refers to this as a replaceable assembly, it is not. The boardsinside must be replaced individually.

All non-component video signals and analog L/R audio are controlled by AVSW1 and AVSW2. Component andDVI video are routed through a component interface and applied to a video switch. This video switch allows theselection of DVI, component, Y/C or composite video signals to be routed to the main video process path. Thesub-video path can only accept signals from the tuner and inputs 1 through 3 and is, therefore, limited to 480iresolutions only. The main and sub video are routed to the DIC2 (Digital Imaging Core) board.Necessary standby and switched voltages are generated by the regulator block (sometimes referred to as PSU).Analog audio is received by the K board where it is amplified to drive a set of speakers.

14

2. Troubleshooting the KE37/42XS910

FIGURE 2-1 - KE37/42XS910 SERIES OVERALL BLOCK

ANTIN

INPUT 1

INPUT 2

INPUT 3

INPUT 4

DVIINPUT

MEMORYSTICKINPUT

REGULATORBLOCK

NTSC TUNER

AVSW1H2

BOARD

COMPI/FINPUT 5

UDBOARD

MS2FBOARD

VIDEOSW

MAIN V

A BOARD

AUDIOPROCESS

AVSW1SUB V

AUDIO

HMBOARD

CCP2MAIN

DIC2 BOARD

CCP2MAIN

MID

DRC

MIDUC

DCPPANELDRIVER

DE2 BOARD

TVMICRO

PANELMICRO

K BOARD

AUDIOAMP

TOPANEL

TOSPEAKERS

LR

PDP01.2-1 3/23/04

Video Signal ProcessingReferring to Figure 2-2, the main, sub and memory stick paths are shown entering the DIC2 board. Main videois processed by CCP2 (Composite to Component Processor) if it is component. If the main video signal is 480i,the DRC performs the necessary line doubling to 960i. The sub video path only receives composite or Y/Csources. It is, therefore, impossible to display a side-by-side twin view of two signals higher than 480i resolution.480p resolutions and above can only be processed by the main path and the picture will always be on the left sidewhen Twin View™ is selected.

All video signals above 480i are processed by MID and D/A converted to 16bit component (8bit Y and 8bit CB/CR). The digital component signal is sent via a LVDS transmitter to the DE2 board.

The DE2 board serves as an interface between the video processing circuits and display panel. DCP (DigitalComponent Processor) performs the necessary scaling of the video signal to conform to the native resolution ofthe panel. The scaled video is sent to the panel driver as 4:2:2 and is processed to 4:4:4 10bit RGB where thelogic board (not shown) allocates the video information to its corresponding pixels.

Note that the DE2 board contains two micro-controllers. One controls the television functions and user interfacewhile the other controls the panel driver. The TV micro-controller generates menu and service OSD. Keep thisin mind as it becomes an important tool in troubleshooting video problems when trying to isolate the DIC2 andDEC2 boards as the cause. A NVM IC contains the customer preference settings along with service setup data.The NVM IC connected to the panel micro-controller contains necessary information for the panel such as whitebalance and gamma settings.

15

2. Troubleshooting the KE37/42XS910

FIGURE 2-2 - KE37/42XS910 SERIES VIDEO PROCESSING

MAIN VIDEO

CV/YC/YUVLPF

MID

CCP2MAIN

DRC

LPFCCP2SUB

SUB VIDEO

CV/YC

DIC2 BOARD

LVDSTX

FROMA BOARD

DE 2 BOARD

DE 3 BOARD

(KE37/42SX910)

(KE50SX910)

DCPPANEL

DRIVERLVDS

TX

PANELMICRO

CTL SIG OUTCTL SIG INI2C BUS

LVDSRX

NVM NVM

SIRCSI2CBUS

TVMICRO

OSD LOCAL BUS

IC4408 IC4001

TOPLASMAPANEL

PDP01.2-2 3/23/04

MS VIDEO

The Plasma PanelFigure 2-3 shows a layout of the plasma panel and associated circuit boards necessary to control the pixels. TheY-SUS and X-SUS boards generate the necessary pulses to sustain each horizontal line of pixels so that theaddress lines controlled by the ABUSL and ABUSR boards can light each vertical row of pixels. The scan andaddress line timing is controlled by the logic board.Notice the use of eight drive ICs from the Y-SUS board to the panel. The Y-drive signal utilizes the most energyto sustain the pixel lighting. This circuit consumes the most power and is a likely suspect when a failure occurscausing a completely dead panel display. These drivers should always be inspected when the panel does notlight, especially if a panel failure warning appears from the diagnostics circuits. They are also part of the flexiblecable molded into the panel, so the entire panel must be replaced. A new panel assembly is supplied with thelogic, scan and address boards installed, thereby eliminating the need for most panel alignments (especiallygamma).The logic board receives RBG digital data at CN1 from the DE2 board (not shown). Data from the DE2 isreceived via LVDS transmission and converted back to 30-bit parallel RGB to be allocated to each necessarypixel in accordance with scan and address timing. The logic board also contains NVM data for voltage settingsunique to the panel installed in the unit. If the logic board is replaced to complete a repair, the NVM IC can bephysically swapped to transfer these settings for the existing panel. It is an eight-pin surface mounted IC designatedas M19 on this model.

The necessary voltages for the audio, video and panel drive circuits are generated by the PSU board. Powercontrol is achieved via a logic high command from the DE2 board. The logic board sends several control lines tothe PSU board to turn on certain voltages for the Y and X-SUS boards. Voltage and current protection ismonitored by several circuits.

16

2. Troubleshooting the KE37/42XS910

FIGURE 2-3 - KE37/42XS910 PANEL AND DRIVERS

CN51

FROMDE2BOARD

RGB INPUT (LVDS)

Y-SUSBOARD

CN31

PLASMA PANEL

ADM1 ADM2 ADM3 ADM4 ADM5 ADM6 ADM7 ADM8

ABUSLBOARD

ABUSRBOARD

XBB

XBB

CN21

CN41

CN4CN6

CN3 CN2

CN1

PDP01.2-3 3/23/04

FPC ANDSCAN ICs

FPC FPC FPC FPC FPC FPCFPC FPC

FPC

FPC

LOGICBOARD

POWER SUPPLYACIN

PSUBOARD

TO A, DIC2, DE2BOARDS

TO PANELBOARDSPOWER CTL

X-SUSBOARD

Protect and Self-DiagnosticsThe power/standby LED will indicate certain faults detected by the protection monitoring circuits to assist indiagnosing where a potential failure may be located. Any of the five fault indications will result in a unit that willnot power up or may power up and then shut down. The LED will blink in 0.5-second intervals followed by a threesecond separation period. They are as follows:

Four blinks: One or more of the cooling fan motors is not functioning. Fan rotation feedback lines for each fanare monitored. If one fan is not rotating, check for B+ to that fan. If present, replace the fan. If B+ is present, orif all fans are not rotating, replace the A board.

Six Blinks: This indicates a B+ power error. The switched 5V line on the power supply board is not present. Ifthe power control line (VCEGO) at CN7 pin 8 is going high, replace the PSU board. If not, the DE2 board may beat fault.

Seven Blinks: A DC voltage has been detected on one or more of the speaker lines. Replace the K board.Eight Blinks: An over-voltage condition has been detected at the DC-DC converter located on the X-SUS board.Replace the board.

Nine Blinks: A panel module or over-temperature failure has been detected. There are two thermistors locatedon the panel. One detects the temperature of the large heat sink on the Y-SUS board and the other, the overalltemperature of the panel assembly. Over-current is also detected for the scan drive circuits. If the LED blinks

17

2. Troubleshooting the KE37/42XS910

panel alarm when first turned on, the panel monitoring circuits have detected a fault. This fault can be caused bya loss of the scan or address voltages. An over-current condition on these lines will also trigger a panel alarm.This is usually caused by a shorted scan-drive IC. Signs of overheating, such as cracks and/or blistering, usuallyoccur on the IC surface. Over-temperature conditions will usually occur if the unit has been running for a while.This can be caused by excessive ambient room temperatures or improper installation of the display device.

TroubleshootingOverviewDue to the large amount of digital processing, along with scan and address methods used, plasma televisionscan generate symptoms that are unfamiliar to most technicians. The following troubleshooting techniques shouldhelp to isolate the cause in most cases. Documentation of unusual symptoms or known failures will be keptupdated on the ESI server. Check the service website at HTTP://service.sel.sony.com for the latest bulletinsregarding the model you are servicing.

Circuit failures in a plasma television generally fall into three categories:

1. Dead set

2. Protection events

3. No or distorted video

Units that exhibit no signs of operation require a few checks be done to determine if the power supply is at fault.The DE2 board contains the television micro-controller that is responsible for turning on certain switched voltageson the power regulator board along with telling the panel circuits to begin operating.Protect shutdown events are identified by the number of times the timer LED blinks. Most protect events arecaused by excessive current on a voltage line or the loss of a certain voltage.A no video condition requires elimination of the plasma panel and its associated drive circuits before analyzingthe video process circuits. The most important item to remember when servicing plasma displays is: If anylighting of the pixels is seen, the panel, along with the scan and address boards, is OK. It also indicatesthe presence of the required voltages for these circuits.Video distortions are easily isolated between the process circuits and panel/drive circuits by how they appear onthe screen. Panel failures will usually display a fixed distortion or missing video on a horizontal or vertical axis.Video process circuit failures tend to be more random and usually across the entire screen.Since all repairs are board level, each scenario above will be approached using flowchart diagrams to properlyisolate the failure to a particular board.

Troubleshooting a No Power ConditionIf a set fails to turn on or appears “dead” the first item to check is whether the power supply is operational. ThePSU board has a standby section generating a 3.3V and 5V source. If these are operating, the unit is not “dead”.The flowchart in Figure 2-4 is an initial starting point to determine this. If the standby circuit is operational, thenext step is to determine if the power supply is at fault or is not being told to turn on. There are other voltagesturned on by the Logic board. The symptom will usually be no picture with audio and the pixels on the panel arenot priming. Using the flowchart in Figure 2-5 should lead you in the right direction.

18

2. Troubleshooting the KE37/42XS910

FIGURE 2-4 - KE37/42XS910 DEAD SET PRELIMINARY CHECK

Unit will not turn on

STBY LED lit orblinking?

No

Replace PSU board

Yes

Continuousblinking orgroups?

Go to protectdiagnostics chart

Fig 2-6

Groups

Does panel light?

STBY 3.3V atCN9002 pins 1~4?

No

Replace DE2 board

Continuous

Yes

PSU board probablyOK. Go to videoTroubleshooting

No Go to power supplytroubleshooting chart

Fig 2-5

PDP01.2-4 3/23/04

Yes

19

2. Troubleshooting the KE37/42XS910

FIGURE 2-5 - KE37/42XS910 POWER SUPPLY TROUBLESHOOTING

Power Supply Troubleshooting(Standby OK)

High at CN7pin 8 on PSU

board?

No

Replace Logic board

Yes

VCC 5V atCN23 pin 3PSU board?

5V reg failureReplace PSU board

High at CN7pin 6 on PSU

board?

High atCN3301 pin 5 on

DE2 board?

Yes

Replace DE2 board

Yes

NoReplace Logic board

No

No

Yes

63VDC (VA) atCN23 pin 1 onPSU board?

No

High atCN7 pin 12 onPSU board?

85VDC (VA) atCN23 pin 9 onPSU board?

Replace Logic boardNo

Yes

Replace PSU board

High atCN7 pin 14 onPSU board?

Yes

NoReplace Logic board

No

Replace Logic board

Yes

Replace PSU board

PDP01.2-5 4/16/04

20

2. Troubleshooting the KE37/42XS910

FIGURE 2-6 - KE37/42XS910 DIAGNOSTICS TROUBLESHOOTING

Self-diagnostics indication

Four blinks ofSTBY/PWR LED?

No

Check connections tofan. Replace fan if

OK

Yes

Six blinks?

More than one fannot rotating?

YesCheck for 14VDC at

CN9002 pin 10 of PSUboard. Replace PSU ifnot present. Replace A

board if present

Replace PSU board

No

No

Yes

Seven blinks?

No

Eight blinks?

Replace K boardYes

5VDC atCN9002 pin 9PSU board?

No

Yes

Replace DE2 board

Replace X-SUSboard

Yes

PDP01.2-6 4/16/04

Nine blinks?Yes

Go to "No Video"troubleshooting

flowchart Figure 2-7

Self-Diagnostics TroubleshootingFigure 2-6 shows a flowchart to aid in locating the cause of self-diagnostics indications displayed by the standby/power LED. A history of any diagnostics events can be viewed by pressing “Display”, “5”, “Volume –”, and the“Power” buttons, in order, on the remote commander when the unit is off.

21

2. Troubleshooting the KE37/42XS910

Video Circuit TroubleshootingVideo circuit failures manifest themselves in two different ways: No video at all or abnormalities in the picturedisplay. In cases where no video is displayed, it is crucial to determine if the plasma panel is able to “prime”.Priming involves the generation of scan signals on the horizontal address lines to light the pixels just to the pointwhere they emit a small amount of light. Once this is accomplished, the address lines complete the necessary“firing” of each pixel to generate the appropriate level of each pixel color to reproduce and image. If the panel ispriming, it is a good indication that everything is OK with the glass panel and associated drive circuits. Focus willnow turn to the video process circuits.

If the panel is not priming and there is audio, a check of the required voltages is necessary to eliminate powersupply line failures as the cause. Use the flowchart in Figure 2-5 to determine if this is the cause. If the powersupply voltages appear OK, there may be a failure of the Y-SUS or X-SUS board. Only these boards arerequired to function to prime the panel. If the panel has been compromised and there are no visible signs ofcracks, the only way to determine this is to check for scan pulses exiting the Y-SUS board. These pulses arequite large (170 to 230VPP). If present, it indicates the panel has lost its inert gas.

A panel alarm may also be indicated by the standby/power LED. It will be flashing in sequences of nine. This isusually caused by an over-current condition and the likely suspect is a shorted scan drive IC. These driversusually exhibit signs of overheating damage with burn holes and cracks appearing on their surface. The paneldesign used in this model incorporates the drivers on the flexible cable, which is part of the glass panel.Replacement of the panel is required if this occurs.

Figure 2-7 is a flowchart that is helpful as a starting point for a “no video” condition with functional audio. If audiocannot be heard, it is best to return to the power supply troubleshooting flowcharts. If the problem is determinedto be in the video process circuits, the A, DIC2 and DE2 boards must be isolated as the cause. The flowchart inFigure 2-8 will provide assistance.

NOTE: The DIC2 and DE2 boards are enclosed within a shielded assembly known as the DM block. In order toaccess these boards for removal, the shield assembly must be taken apart. There is a LVDS cable connectingthe two boards and this cable is looped outside of the shields. It is protected by a plastic cover. It is veryimportant to remove this plastic cover and unplug both ends of the LVDS cable before attempting to separate theboards from the housing. Failure to do so will cause the shield to snag the LVDS connectors and damage them.The connectors are easily removed by pinching the release tabs and pulling them out. This is shown in Figure 2-9

22

2. Troubleshooting the KE37/42XS910

No Video

Signs ofoverheating onany scan-drive

ICs?

Yes

No

Replace panel assembly

VS (85VDC)CN23-8 on PSU

board?

Go to power supplytroubleshooting flowchart

Figure 2-5

No

VS (85VDC)CN23-8 on PSU

board?

Yes

Go to power supplytroubleshooting flowchart

Figure 2-5

No

Is panel Priming?* Go to flowchart Figure 2-8Yes

No

*Panel priming is determined byobserving the screen for signs ofpixel lighting. It is a dark raster

similar to reference black in CRTunits. It is best detected by turning

the unit on and off to distinguish thedifference between "true black"

(panel off) and reference black (panellit).

FIGURE 2-7 - KE37/42XS910 INITAL "NO VIDEO" CHECK PDP01.2-7 4/20/04

Yes

Check for 85VPP scanpulses on connectorsbetween Y-SUS board

and scan drive ICs.Replace Y-SUS if none

present. Replace Panel ifpulses present.

23

2. Troubleshooting the KE37/42XS910

FIGURE 2-8 - KE37/42XS910 VIDEO PROCESS TROUBLESHOOTING

No videoPanel is primed, audio OK

Can OSD bedisplayed?

No

Re-seat connector

Yes

Picture on rightside when TwinView engaged?

Replace DIC2 board

LVDS connectorfrom DE2 to Logicboard connected?

Yes

Replace DE2 boardNo

No

Yes

No

No

Does componentvideo input display

picture?Replace DIC2 boardYes

Can picture fromMemory Stick be

displayed?

Yes Replace A board

Replace DIC2 board

PDP01.2-8 3/2/04

24

2. Troubleshooting the KE37/42XS910

FIGURE 2-9 - DM BLOCK LVDS CONNECTORS PDP01.2-9 3/4/04

DM BLOCK

REMOVEPLASTIC COVER

LVDSCONNECTORS

Troubleshooting Display Panel AbnormalitiesSymptoms appearing on the screen during panel and drive circuit failures are generally easy to identify. Sincethe panel is controlled by intersecting scan and address lines, distortions, abnormal colors or missing pixel datawill manifest themselves as horizontal or vertical lines or may occur in entire blocks. If you have acquired thisonly this chapter for troubleshooting the KE37/42XS910 model, obtain the section in Chapter 1, which containsadditional information applying to general plasma theory and troubleshooting.

In Figure 2-10, some examples of address circuit failures are shown. If one or more vertical lines of videoinformation are missing or filled with a solid color, the panel will likely have to be replaced. Address informationis sent to the right and left address boards (ABUSL and ABUSR). Each board processes the RBG digital data,which is then sent to each ADM processor. The ADM processors send ten lines of multiplexed data to theFlexible PC connectors. Each FPC contains three drive ICs where the signals are de-multiplexed to 57 lineseach for the address lines on the panel.

Single line failures are caused by problems in the drive outputs. Since the drivers are mounted to the FPCassembly, the panel must be replaced. Multiple lines of missing video, creating a block of no information, can becaused by the logic or address boards. It is unlikely that three drive ICs have failed. Suspect the address boardfirst, followed by the logic board.

Figure 2-11 illustrates potential symptoms that might be seen if a failure occurs in the scan drive circuits. Thescan drive ICs are mounted to flexible PC cables so any single missing lines of video will require a panelreplacement. If one-half of the picture is missing information, examine the drive ICs on the FPC adjacent to thefailure for signs of overheating to determine whether the panel or Y-SUS board should be replaced.

25

2. Troubleshooting the KE37/42XS910

FIGURE 2-10 - KE37/42XS910 PANEL ADDRESS FAILURES

Y-SUSBOARD

ADM1 ADM2 ADM3 ADM4 ADM5 ADM6 ADM7 ADM8

ABUSLBOARD

ABUSRBOARD

XBB

XBB

FPC ANDSCAN ICs

FPC FPC FPC FPC FPC FPCFPC FPC

FPC

FPC

LOGICBOARD

BLANK OR DIFFERENTCOLORED LINE

MULTIPLE MISSING LINES

PDP01.2-10 3/23/04

X-SUSBOARD

FIGURE 2-11 - KE37/42XS910 PANEL SCAN FAILURES

Y-SUSBOARD

ADM1 ADM2 ADM3 ADM4 ADM5 ADM6 ADM7 ADM8

ABUSLBOARD

ABUSRBOARD

XBB

XBB

FPC ANDSCAN ICs

FPC FPC FPC FPC FPC FPCFPC FPC

FPC

FPC

LOGICBOARD

ONE-HALF SCREEN MISSINGSINGLE MISSING SCAN LINES

PDP01.2-11 3/23/04

X-SUSBOARD

26

2. Troubleshooting the KE37/42XS910

FINGER HOLES FOR REMOVAL

FIGURE 2-12 - SPEAKER COVER REMOVAL PDP01.2-12 3/4/04

DisassemblyOverviewThis section will cover the required steps to disassemble the unit down to panel replacement. Due to the largenumber of screws involved, be sure to have a container to place them in during the procedure. It is extremelyimportant to place the plasma television on a repair stand of adequate size along with a piece of foam padding toprotect the screen. Be certain the padding is at least ¾ of the screen size to prevent flexing of the glass panel,which is easily damaged. The glass can withstand moderate bending but the barrier ribs separating the verticallines of pixels are easily damaged by minor flexing.

HINT: Most of the screws securing shields and circuit boards are 3mm machine with attached flat washers.Larger machine and self-tapping screws are allocated to support brackets and the rear cover.

Speaker Housing and Rear Cover RemovalAs shown in figure 2-12, remove the left and right rear speaker covers by pulling upward, using the finger accessholes. This exposes the rear cover screws on each side. Remove the following screws for the rear cover:

• Four 5X25 machine (black) securing the stand. The stand must be removed first.

• Fourteen 4X16 black, self tap (black)

• Sixteen 3X6 machine (black)

• Six 4X10 machine (black)• Six 5X10 machine (black)

27

2. Troubleshooting the KE37/42XS910

Y-SUS BOARD PSU BOARD X-SUS BOARD

A BOARD(UNDER SHIELD)

DM BLOCK(DIC2, DE2, MS2A)

K BOARD

FIGURE 2-13 - KE37/42XS910 BOARD LAYOUT PDP01.2-13 3/23/04

FIGURE 2-14 - SPEAKER HOUSING REMOVALPDP01.2-14 3/2/04

REMOVE 9 SCREWS(4x12 SELF TAP)

Once the rear cover has been removed, the view shown in figure 2-13 is seen. The Y-SUS, X-SUS, Logic, ScanDrive and Address boards are not visible as they are located under the shields. Use this view as a guide whenre-assembling the unit to properly dress the cable harnesses.Removal of the left and right speaker housing is shown in Figure 2-14. This step is not necessary if the plasmapanel is to be replaced.

28

2. Troubleshooting the KE37/42XS910

REMOVE FOUR 6x12SELF-TAP SCREWS AND

GROUND WIRE

REMOVE TWO 3X6 MACHINESCREWS AND NYLON LOCK

PINS

FIGURE 2-15 - VIDEO INPUT COVER AND SHIELD REMOVAL PDP01.2-15 3/4/04

REMOVE NUTSSECURING DVICONNECTOR

A Board and DM Block RemovalFigure 2-15 illustrates the location of the video input and processing circuit boards. The cover over the videoinput jacks must be removed. This cover also secures the AC input receptacle. The earth ground wire must alsobe removed as shown. The metal shield above the input connectors covers the A board. Use caution whenremoving the nylon lock nuts as it is easy for them to fall out when lifting the shield.The DM block must be removed after the video input cover and A board shield since it attaches to the A boardwith a large connector (CN8001). Remove two connectors CN1813 and CN1814 (not shown) at the bottom ofthe DM block. Loosen the four machine screws securing the DM block and GENTLEY lift it from the A board.

There is a LVDS connector located on the upper part of the DM block connected to the Logic board. LVDScables use thin wires. They are easily damaged. Remove the two LVDS and one communication connector asshown in Figure 2-16.

29

2. Troubleshooting the KE37/42XS910

MEMORY STICK LVDSCONNECTOR

DE2 TO LOGICBOARD LVDSCONNECTOR

COM CONNECTOR

FIGURE 2-16 - DM BLOCK REMOVAL PDP01.2-16 3/4/04

CN8003

CN8002

CN8005

CN8601

CN8230

FIGURE 2-17 - A BOARD REMOVAL PDP01.2-17 3/4/04

CN8001

In Figure 2-17, removal of the A board is shown. The listed connectors are removed along with the RF inputcable to the tuner. Four 3X6 machine screws secure the board. Remove the board and place in a safe location.

30

2. Troubleshooting the KE37/42XS910

CN3062

CN3061 CN3001

GROUNDCONNECTORS

FIGURE 2-18 - K BOARD REMOVAL

UNPLUG ALL CABLECONNECTORS

PDP01.2-18 3/4/04

K Board RemovalIn Figure 2-18, removal of the K board is shown. The board has a shield on top that has been removed. Theshield is secured with two 3X6 machine screws. The bottom shield securing the K board is attached to thechassis with four 3X6 machine screws. Remove the three cable and two ground connectors as shown. Removethe cables from the purse-lock retainers. Unplug all connectors attaching cables to cables. Set cable harness tothe right side and out of the way. Note the layout of the cables in this picture. It will be useful when re-assemblingthe unit.

Power Supply RemovalFigure 2-19 shows the power supply (PSU) board after the fan bracket (not shown) has been removed. Theboard is secured by seven 3X6 machine screws. If the board is going to be removed for replacement of thepanel, only CN6, CN7 and CN23 need to be removed. The remaining connectors are for the K and DM block.Simply place the DM block on top of the PSU board and remove the assembly with the K board and fan cablesas shown in Figure 2-20.

31

2. Troubleshooting the KE37/42XS910

CN23

CN7CN6

FIGURE 2-19 - POWER SUPPLY REMOVAL PDP01.2-19 3/4/04

FIGURE 2-20 - DM AND PSU REMOVAL PDP01.2-20 3/4/04

32

2. Troubleshooting the KE37/42XS910

REMOVE FOUR 3X6MACHINE SCREWS

LOOSEN SELF-TAPPING SCREWS

FIGURE 2-21 - LOWER SHIELD REMOVAL PDP01.2-21 3/23/04

Lower Shield RemovalIf the panel is going to be replaced, the lower shield assembly that held the A board and DM block must beremoved. Figure 2-21 illustrates this. It is secured by four 3x6 machine and two 3X12 self-tapping screws. Theself-tapping screws only need to be loosened.

Y-SUS and X-SUS Shield RemovalFigure 2-22 shows the Y-SUS board shield and its removal procedure. This shield must be removed to accessthe Y-driver boards and ICs for inspection and/or replacement. This photo shows the K board installed. Unlessthe K board needs replacement, it can be left intact. Two 3X6 machine and four 3X12 self-tap screws aresecuring the unit. Pay close attention to the self-tap screw located below the fan motor. Unplug the fan motorand remove the shield.Figure 2-23 demonstrates the removal of the X-SUS shield. Note the layout or the wiring in the purse-lockretainers and the removal of ground connections for reference when re-installing the shield.

33

2. Troubleshooting the KE37/42XS910

FIGURE 2-22 - Y-SUS SHIELD REMOVAL

REMOVE TWO3x6 MACHINE

SCREWS

REMOVE FOUR4x12 SELF-TAP

SCREWS

UNPLUGFAN CABLE

PDP01.2-22 3/4/04

FIGURE 2-23 - X-SUS SHIELD REMOVAL PDP01.2-23 3/4/04

REMOVE TWO 3x6MACHINE SCREWS

REMOVE ONE 3x6MACHINE SCREW AND

GROUND CABLE

REMOVE FOUR 3x6SELF-TAP SCREWS

UNPLUG FAN

UNPLUG SPEAKERCONNECTORS AND

GROUND LUGS

34

2. Troubleshooting the KE37/42XS910

REMOVE FOUR 4x16SELF-TAP SCREWS AT

BOTTOM

REMOVE FOUR 4x8MACHINE SCREWS AT

TOP

LOGIC BOARD

ADDRESSBOARDS

FIGURE 2-24 - PANEL BRACKET REMOVAL PDP01.2-24 3/4/04

Panel RemovalOnce all of the above circuit boards and shields have been removed, the panel is ready for removal. Two largebrackets are attached to the panel with four 5X10 machine screws. Although the brackets do not come with thepanel, they should be left intact to ease the removal. The replacement panel will come with disposable bracketsto assist in installation. The original brackets can then be transferred to the new panel.By removing the four 4X8 machine and four 4X12 self-tap screws securing the bracket to the top and bottom ofthe filter glass assembly, the panel can be lifted out. This is illustrated in Figures 2-24 and 2-25. Notice thelocation of the Logic and Address boards in Figure 2-24.NOTE: Panel replacement should only be performed in the shop. The removal of a large number of self-tapscrews creates a considerable amount of plastic contaminants. Accumulated dust, along with the plastic pieces,can easily fall onto the backside of the filter glass. This must be thoroughly removed using air from a compressor.It is extremely important to remove all contaminants before installing the new panel.The replacement panel will come with the Logic, Address, Y-SUS and X-SUS boards installed. The serial numberof the panel will need to be documented if it is replaced. The label containing the serial number is visible abovethe Y-SUS board after the shield has been removed as outlined in Figure 2-22. A view of the label will be shownnext in the Y-SUS board removal.

35

2. Troubleshooting the KE37/42XS910

FIGURE 2-25 - KE37/42XS910 PANEL REMOVAL PDP01.2-25 3/23/04

REMOVE NINE SILVER3x6 MACHINE

SCREWS

FIGURE 2-26 - Y-SUS BOARD REMOVAL PDP01.2-26 3/23/04

Y-SUS and X-SUS Board RemovalShould the need arise to replace the Y-SUS or X-SUS boards, removal is illustrated in Figure 2-26 for the Y-SUSboard and Figure 2-27 for the X-SUS board. Note Figure 2-27 and the location of the panel serial number andvoltage adjustment labels. Also note the Y-Scan drive ICs located on the large flexible PC cables attached to theplasma panel in Figure 2-26.Both boards require the removal of nine screws each in order to properly unplug the large connectors. Themounting holes on the boards sit on top of a post with a shank that prevents horizontal movement of the boardsunless lifted slightly.

36

2. Troubleshooting the KE37/42XS910

REMOVE NINE 3X6 MACHINESCREWS

FIGURE 2-27 - X-SUS BOARD REMOVAL PDP01.2-27 3/23/04

LABELS FOR PANELID AND VOLTAGE

SETTINGS

37

3. Troubleshooting the KE50XS910

Chapter 3 - Troubleshooting the KE50XS910OverviewThe KE50XS910 is a high-definition-ready plasma television with a built-in NTSC tuner along with the necessaryvideo processing circuitry to accept composite, Y/C, component and DVI video sources along with analog L/Raudio. Other plasma models function as monitoring devices and rely on an external receiver (known as a MediaBox) to receive and process video and audio.

This chapter will point out the circuits that are unique to this model along with a description of each board’sfunction. Practical troubleshooting methods will be discussed followed by a systematic procedure for disassemblingand re-assembling the unit. Plasma televisions rely on a large, gassed-filled glass panel to generate video. It isimportant that this glass panel be properly braced and secured by brackets and the back cover assembly. Aconsiderable amount of shielding is also required due to the high voltage levels generated by the scan drivers.Because of this, a large number of screws are utilized. A full disassembly can require the removal of a hundredscrews or more!Another factor is the use of a number of circuit boards spread throughout the rear of the large panel assembly.This requires the use of many wiring harness mounts and paths. It is extremely important to route these wires intheir correct configuration to minimize interference and prevent any wires from being pinched or cut. Clearancesbetween shields, brackets and the rear cover are minimal so this is very important. An extensive number ofillustrations will be used to assist the technician in routing the wiring correctly and returning all of the screws backto their original location.

Signal ProcessingOverall Block DiagramReferring to Figure 3-1, an overall block diagram demonstrates the various paths for the different video andaudio inputs. A NTSC tuner is located on the A board. A/V inputs 1, 2 and 3 accept composite or Y/C video alongwith L/R audio. A/V inputs 4 and 5 accept component video only along with L/R audio. Video resolutions of 480i,480p, 1080i and 720p are supported.

The DVI input receives differential RGB digital video information along with analog L/R audio. The UD boardcontains the receiver/decoder to convert the digital signal to Y/CB/CR along with HDCP control.

The HM board contains a Memory Stick™ slot for display of JPEG still pictures and MPEG1 audio/video playback.The information from the memory stick is processed and sent via a LVDS (Low Voltage Differential Signal)transmitter to the MS2F board. The video and/or audio signals are processed and D/A converted. Audio is sentto A/V switch2 while video information is sent to the DIC2 board.

NOTE: The MS2F board is enclosed within a shielded assembly (known as the DM Block) containing the DIC2and DE3 boards. Although the service manual refers to this as a replaceable assembly, it is not. The boardsinside must be replaced individually.

All non-component video signals and analog L/R audio are controlled by AVSW1 and AVSW2. Component andDVI video are routed through a component interface and applied to a video switch. This video switch allows theselection of DVI, component, Y/C or composite video signals to be routed to the main video process path. Thesub-video path can only accept signals from the tuner and inputs 1 through 3 and is, therefore, limited to 480iresolutions only. The main and sub video are routed to the DIC2 (Digital Imaging Core) board.

Necessary standby and switched voltages are generated by the regulator block (sometimes referred to as PSU).Analog audio is received by the K board where it is amplified to drive a set of speakers.

38

3. Troubleshooting the KE50XS910

FIGURE 3-1 - KE50XS910 SERIES OVERALL BLOCK

ANTIN

INPUT 1

INPUT 2

INPUT 3

INPUT 4

DVIINPUT

MEMORYSTICKINPUT

REGULATORBLOCK

NTSC TUNER

AVSW1H2

BOARD

COMPI/FINPUT 5

UDBOARD

MS2FBOARD

VIDEOSW

MAIN V

A BOARD

AUDIOPROCESS

AVSW1SUB V

AUDIO

HMBOARD

CCP2MAIN

DIC2 BOARD

CCP2MAIN

MIDDRC

MIDMICRO

DCP PANELDRIVER

TVMICRO

PANELMICRO

K BOARD

AUDIOAMP

TOPANEL

TOSPEAKERS

LR

DE3 BOARD

PDP01.3-1 4/16/04

Video Signal ProcessingReferring to Figure 3-2, the main, sub and memory stick paths are shown entering the DIC2 board. Main videois processed by CCP2 (Composite to Component Processor) if it is component. If the main video signal is 480i,the DRC performs the necessary line doubling to 960i. The sub video path only receives composite or Y/Csources. It is, therefore, impossible to display a side-by-side twin view of two signals higher than 480i resolution.480p resolutions and above can only be processed by the main path and the picture will always be on the left sidewhen Twin View™ is selected.

All video signals above 480i are processed by MID and D/A and converted to 16bit component (8bit Y and 8bitCB/CR). The digital component signal is sent via a LVDS transmitter to the DE3 board.

The DE3 board serves as an interface between the video processing circuits and display panel. DCP (DigitalComponent Processor) performs the necessary scaling of the video signal to conform to the native resolution ofthe panel. The scaled video is sent to the panel driver as 4:2:2 and is processed to 4:4:4 10bit RGB where theDigital Video board (not shown) allocates the video information to its corresponding pixels.

Note that the DE3 board contains two micro-controllers. One controls the television functions and user interfacewhile the other controls the panel driver. The TV micro-controller generates menu and service OSD. Keep thisin mind as it becomes an important tool in troubleshooting video problems when trying to isolate the DIC2 andDE3 boards as the cause. A NVM IC contains the customer preference settings along with service setup data.The NVM IC connected to the panel micro-controller contains necessary information for the panel such as whitebalance and gamma settings.

39

3. Troubleshooting the KE50XS910

FIGURE 3-2 - KE50XS910 SERIES VIDEO PROCESSING

MAIN VIDEO

CV/YC/YUVLPF

MID

CCP2MAIN

DRC

LPFCCP2SUB

SUB VIDEO

CV/YC

DIC2 BOARD

LVDSTX

FROMA BOARD

DE 3 BOARD

DCPPANEL

DRIVERLVDS

TX

PANELMICRO

CTL SIG OUTCTL SIG INI2C BUS

LVDSRX

NVM NVM

SIRCSI2CBUS

TVMICRO

OSD LOCAL BUS

IC4408 IC4001

TOPLASMAPANEL

PDP01.3-2 4/16/04

The Plasma PanelFigure 3-3 shows a layout of the plasma panel and associated circuit boards necessary to control the pixels. 30-bit RGB data is received by the interface board and processed for timing by the scan and address circuits. TheDigital Video board distributes the properly timed information.The Y-SUS and X-SUS boards generate the necessary pulses to sustain each horizontal line of pixels so that theaddress lines, which are controlled by the left and right address boards, can light each vertical row of pixels. Thescan and address line timing is controlled by the digital video board.Notice the use of 12 drive ICs from the Y-SUS board to the panel. The Y-drive signal utilizes the most energy tosustain the pixel lighting. Consequently, this circuit consumes the most power and is a likely suspect when afailure occurs causing a completely dead panel display. These drivers should always be inspected when thepanel does not light, especially if a panel failure warning appears from the diagnostics circuits. They are mountedon a two circuit boards and the flexible PC cables between the panel and the boards are permanently attached,requiring an entire panel replacement if there is a failure.The Interface board receives RBG digital data from the DE3 board (not shown). Data from the DE3 is receivedvia LVDS transmission and converted back to 30-bit parallel RGB to be allocated to each necessary pixel inaccordance with scan and address timing. The Interface board also contains NVM data for the voltage settingsspecific to the panel installed in the unit. If the Interface board is replaced to complete a repair, the NVM IC canbe physically swapped to transfer these settings for the existing panel.

The necessary voltages for the audio, video and panel drive circuits are generated by the Regulator board.Power control is achieved via a logic high command from the DE3 board.

40

3. Troubleshooting the KE50XS910

ADDRESS BOARD ADDRESS BOARD

ADDRESS BOARD ADDRESS BOARD

PLASMA PANELXSUS

BOARD

DIGITAL VIDEOBOARD

YSUSBOARD

INTERFACEBOARD

SCAN DRIVERBOARDS

LVDS FROMDE3 BOARD

FPC

FPC

FPC

FPC

REGULATORBOARD

AC INPUT

FIGURE 3-3 - KE50XS90 PANEL AND DRIVE BOARDS PDP01.3-3

CONTROLTO PANELBOARDS

3/23/04

Protect and Self-DiagnosticsThe power/standby LED will indicate certain faults detected by the protection monitoring circuits to assist indiagnosing where a potential failure may be located. Any of the five fault indications will result in a unit that willnot power up or, may power up and then shut down. The LED will blink in 0.5-second intervals, followed by athree second separation period. They are as follows:

Four blinks: One or more of the cooling fan motors is not functioning. Fan rotation feedback lines for each fanare monitored. If one fan is not rotating, check for B+ to that fan. If present, replace the fan. If B+ is present orif all fans are not rotating, replace the A board.

Six Blinks: This indicates a B+ power error. The switched 5V line on the power supply board is not present. Ifthe power control line (VCEGO) at CN7 pin 8 is going high, replace the PSU board. If not, the DE3 board may beat fault.

Seven Blinks: A DC voltage has been detected on one or more of the speaker lines. Replace the K board.Eight Blinks: An over-voltage condition has been detected at the DC-DC converter located on the X-SUS board.Replace the board.

Nine Blinks: A panel module or over-temperature failure has been detected. There are two thermistors locatedon the panel. One detects the temperature of the large heat sink on the Y-SUS board and the other the overalltemperature of the panel assembly. Over-current is also detected for the scan drive circuits. If the LED blinks a

41

3. Troubleshooting the KE50XS910

panel alarm when first turned on, the panel monitoring circuits have detected a fault. This fault can be caused bya loss of the scan or address voltages. An over-current condition on these lines will also trigger a panel alarm.This is usually caused by a shorted scan-drive IC. Signs of overheating, such as cracks and/or blistering, usuallyappear on the IC surface. Over-temperature conditions will usually occur if the unit has been running for a while.This can be caused by excessive ambient room temperatures or improper installation of the display device.

TroubleshootingOverviewDue to the large amount of digital processing, along with scan and address methods used, plasma televisionscan generate symptoms that are unfamiliar to most technicians. The following troubleshooting techniques shouldhelp to isolate the cause in most cases. Documentation of unusual symptoms or known failures will be keptupdated on the ESI server. Check the service website at HTTP://service.sel.sony.com for the latest bulletinsregarding the model you are servicing.

Circuit failures in a plasma television generally fall into three categories:

1. Dead set

2. Protection events

3. No or distorted video

Units that exhibit no signs of operation require a few checks be done to determine if the power supply is at fault.The DE3 board contains the television micro-controller that is responsible for turning on certain switched voltageson the power regulator board along with telling the panel circuits to begin operating.Protect shutdown events are identified by the number of times the timer LED blinks. Most protect events arecaused by excessive current on a voltage line or the loss of a certain voltage.A no video condition requires elimination of the plasma panel and its associated drive circuits before analyzingthe video process circuits. The most important item to remember when servicing plasma displays is: If anylighting of the pixels is seen, the panel along with the scan and address boards are OK. It also indicatesthe presence of the required voltages for these circuits.Video distortions are easily isolated between the process circuits and panel/drive circuits by how they appear onthe screen. Panel failures will usually display a fixed distortion or missing video on a horizontal or vertical axis.Video process circuit failures tend to be more random and usually across the entire screen.Since all repairs are board level, each scenario above will be approached using flowchart diagrams to properlyisolate the failure to a particular board.Self-Diagnostics TroubleshootingFigure 3-4 shows a flowchart to aid in locating the cause of self-diagnostics indications displayed by the standby/power LED. A history of any diagnostics events can be viewed by pressing “Display”, “5”, “Volume –”, and the“Power” buttons, in order, on the remote commander when the unit is off.

42

3. Troubleshooting the KE50XS910

FIGURE 3-4 - KE37/42XS910 DIAGNOSTICS TROUBLESHOOTING

Self-diagnostics indication

Four blinks ofSTBY/PWR LED?

No

Check connections tofan. Replace fan if

OK

Yes More than one fannot rotating?

Yes

Check for 14VDC at CN3pin 10 of Regulator board.Replace Regulator if not

present. Replace A boardif present

Replace Regulatorboard

No

No

Yes

Seven blinks?

No

Eight blinks?

Replace K boardYes

No

Yes

Replace DE2 board

Replace X-SUSboard

Yes

Nine blinks?Yes Panel alarm. Go to

"No Video" flowchartFigure 3-7

PDP01.3-4 4/20/04

5VDC at CN3 pin 9Regulator board?

Six blinks?

Troubleshooting a No Power ConditionIf a set fails to turn on or appears “dead”, the first item to check is whether the power supply is operational. TheRegulator board has a standby section generating a 3.3V and 5V source. If these are operating, the unit is not“dead”. The flowchart in Figure 3-5 is intended as a guide to determine if the Regulator board is at fault. One ofthe items referred to in the flowchart is a red and green LED located on the Interface board. The red LEDindicates standby while the green indicates power-on. This board is difficult to see but looking down the bottomof the regulator board from the top of the unit, a lit LED is easily detected. If unit is laying face down with the rearcover removed, the lower shield assembly holding the A board can be lifted after the screws are removed. This

43

3. Troubleshooting the KE50XS910

FIGURE 3-5 - KE50XS910 POWER SUPPLY FLOWCHART

Unit will not power up

Is red or greenLED on Interface

board lit?

No

Is 3V (approx) onPin 4 of R6 on Interface

Board?Replace DE3 board

No

Does the symptomstill occur?

Finish

Replace Interfaceboard

3.3VDC atpin 11 of R1 onInterface board?

Replace PowerSupply board

No

Check Pin 2 of D17connector on DIGITAL

VIDEO assembly.

Yes

Is there 3.3V at thecheck point?

ReplaceDigital Video

board

Yes

Disconnect flexiblecable between D15 onDIGITAL VIDEO andR4 on INTERFACE

assembly. Clean edgecontacts of the flexiblecable and reconnect it

to the connectors.

Which LED is lit?

YesPower supply is onGo to "No picture

(black screen)" flowchart

Green(D4001)

Red (D4002)

Disconnect flexible cablebetween D15 on DIGITAL

VIDEO and R4 on INTERFACEassembly. Clean edge contacts

of the flexible cable andreconnect it to the connectors.

Yes

No

Does the symptomstill occur?

FinishNo

Replace Digital Video board

Yes

Is there 3.3V at Pin 11of D17 on D VIDEO?

ReplaceInterface

board

No

Yes

No

PDP01.3-5 3/18/04

is covered later in this chapter in the disassembly section. The red LED may be flashing three times and is avaluable indicator when troubleshooting a “no video” condition. It is mentioned in the flowcharts to follow. Figure3-6 shows the Interface board and the LED locations.

44

3. Troubleshooting the KE50XS910

D4001 STBY (RED)D4002 PWR-ON (GREEN)

FIGURE 3-6 - LED INDICATORS ON INTERFACE BOARD

CAN BE VIEWED BY LIFTING A BOARDAND LOWER SHIELD ASSEMBLY

PDP01.3-6 3/18/04

45

3. Troubleshooting the KE50XS910