Some special applications of Electrochemical...

Transcript of Some special applications of Electrochemical...

Some special applications of

Electrochemical Machining

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 2

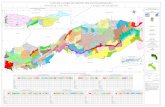

Electro chemical cutting off Electro chemical milling

Electro chemical turning

Electro chemical turning of thin plate

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 3

Electro Chemical Shaping

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 4

Full Form Electro Chemical Shaping

Design of cathode tool shape to obtain profile of turbine blade

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 5

Electro Chemical Machining of Irregular Shaped Hole

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 6

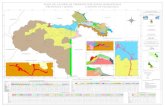

Electrochemical Grinding

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 7

Electro Chemical Grinding

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 8mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 9

Grinding wheel with metallic bond in ECG

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 10

Electrochemical dissolution and Mechanical abrasion in the

Machining Gap during ECG

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 11

Conventional grinding Electro chemical grinding

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 12

Phases of material removal in electro chemical grinding

Phase 1: pure ECM, Phase 2: mechanical grinding, Phase 3: electrochemical polishing

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 13

Process variables

Voltage –Low voltage less electrochemical action more abrasive cutting with minimal deburring. Higher voltage more electrochemical and less abrasive action. Too much voltage electrical arcing.

Electrolyte Flow –Enough flow creates electrochemical cell at the point of the cut and complete the processToo much flow may remove metal beyond the desired cut area.

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 14

Process variables

Feed Rate – Feed rate in ECG is similar to creep feed grinding generally in the 13 to 100 mm/minute range depending on size of the cut and cross section of the material. A precise servo driven feed best for a uniform cut and accuracy. Slow feed allows more electrochemical action and lowers cutting forces. Faster feed increases the amount of abrasive action in the cut.

Wheel Type – Apart from standard metal bonded wheels, ECG wheel is also made from Aluminum Oxide on Copper in a conductive resin bond. Diamond, CBN and Ceramic abrasives are also widely used in conductive resin bonds.

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 15

Automatic Electrochemical Flat Grinding Machine

Model: ECHA Uni 501 (source: www.justur.sk)

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 16mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 17

1. Machining parts made from difficult-to-cut materials, such as sintered carbides, creep resisting (Inconel, Nimonic) alloys, titanium alloys, and metallic composites.

2. Removal of fatigue cracks from steel structures

3. Production of tungsten carbide tools, fragile parts and thin walled tubes.

Applications of ECG

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 18

Advantages of ECG

1. Absence of work hardening

2. Elimination of grinding burrs

3. Absence of distortion of thin fragile or thermo-

sensitive parts

4. Good surface quality

5. Production of narrow tolerances

6. Longer grinding wheel life (10 times more)

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 19

Disadvantages of ECG

1. High capital cost than conventional machines

2. Process limited to electrically conductive

materials

3. Corrosive nature of electrolyte

4. Requires disposal and filtering of electrolyte

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 20

Electro Chemical Honing (ECH)of internal hole

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 21

Applications of Electro Chemical Honing (ECH)

Removing roundness error

Correcting straightness error

Correcting small taper

ECH effects on bore errors

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 22

Small Hole Drilling Techniques by

Electrochemical Machining

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 23

Small Hole in Fuel Injector Nozzles

Nozzle outlet diameter around 100 micron

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 24

Electro Chemical Drilling

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 25

Deep Hole Drilling by Electro Chemical Action

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 26

At - A - Glance

• In conventional electrochemical drilling hollow metal tube as

cathode

• Electrolyte flows at high velocity

• Cathode penetrates the hole

• Hole diameter Cathode outside diameter

To Drill a small hole – Electrostream drilling

• Application – small cooling hole in super alloys

• Negatively charged acid electrolyte stream with high velocity

• 0.127 mm < Hole diameter < 0.890 mm

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 27

⇒Dwell drilling => Shallow and less accurate holes

• Limited depth of hole

• Work piece configuration or machine capability does not allow nozzle movement

• Maximum depth upto 5 mm

• High applied voltage 150V – 800V

Electro-stream Drilling with Zero feed rate

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 28

Electro-Stream (Capilary) DrillingElectro-stream Drilling with finite feed rate

Drilling inclined holes

⇒Maximum depth 19mm

• H2SO4 /HCl electrolyte

• HCl for Aluminum & Titanium

• H2SO4 for Carbon steel, Cobalt alloy, SS

• Titanium wire is placed inside sleeve

• Individual wire runs in each nozzle

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 29

Advantages of ES Drilling

· High depth-to-diameter ratios are possible

· Many holes can be drilled simultaneously

· Blind and intersecting holes can be machined

· Burr-free holes are produced

· Absence of recast and metallurgical defects

· Powder metallurgy hard materials can be drilled

Electro-Stream (Capilary) Drilling…..

ES Drilling in inaccessible positions

Use of small titanium wire to charge electrolyte

mech14.weebly.com

4/12/2018 P Saha, Mech Engg, IIT Kharagpur 30

Thank You

mech14.weebly.com

![Electrochemical miRNA Biosensors: The Benefits of ...€¦ · electrochemical nanobiosensors [6, 7]. The electrochemical nanobiosensors are pulling together the advantages of electrochemical](https://static.fdocuments.net/doc/165x107/5f5dab2fa5702b13b4580399/electrochemical-mirna-biosensors-the-benefits-of-electrochemical-nanobiosensors.jpg)