SOLVE ALL YOUR HEATING AND COOLING PROBLEMS REDUCE · PDF filesolve all your heating and...

Transcript of SOLVE ALL YOUR HEATING AND COOLING PROBLEMS REDUCE · PDF filesolve all your heating and...

SOLVE ALL YOUR HEATING AND COOLING PROBLEMSREDUCE YOUR CYCLE TIMEREDUCE SCRAPIMPROVE PARTY QUALITY

Where Isobars® Come FromAcrolab's Isobar® heat pipes have their roots in thermosyphons. Thermosyphons

function as a super-thermal conductor only in a vertical or near vertical plane. In a thermosyphon, a small quantity of working fluid is placed in an evacuated tube. Heat is applied to the base of the tube, causing the temperature of the working fluid to rise —as this fluid heats, it vaporizes. This vapor then migrates to the colder end of the tube where it is condensed. The condensate is returned to the heated tube end by gravity. Since the latent heat of evaporation is large, considerable quantities of heat can be transferred with a very small temperature difference from end to end. The thermosyphon is limited in application because the evaporator region must be situated lower than the condenser region.

How Isobars® WorkThe Isobar® Heat Pipe improves on this in that it incorporates a sophisticated solid-

state pump to return the condensate to the evaporator site. This pump takes the form of a fine metallic wick that resides tight to the inner wall of the Isobar®. This wick, through its capillary action, returns the working fluid to the evaporator without regard to orientation. In a normal environment, the wick permits equal function in vertical and horizontal planes. In applications where the evaporator site is above the condenser, the performance of the Isobar® Heat Pipe is controlled by the capillary action of the wick structure.

How Much Better Are They?Isobar® Heat Pipes are super-thermal conductors and have the capacity to transfer

large amounts of heat at high speeds in both heating and cooling applications. In fact, Isobar® Heat Pipes have, in some applications and orientations, a thermal conductivity in excess of 20,000 times the rate of a solid copper bar of the same geometry.

How Isobars® Are Used

Acrolab Isobar® Heat pipes can be used in a wide variety of applications. Primarily they are used in injection molding, die casting, and electronic applications. They can take the place of copper bars, bubblers, cascades, or baffles. Isobars® transfer heat rapidly into the cooling stream rather then the coolant having to travel into the heated area.

Acrolab Isobars® can also be used to distribute heat to problem areas of a tool.

Core Applications

Types AvailableAcrolab engineers and customizes

Isobar® heat pipes to all different shapes and sizes. Commonly used Isobars® are: straight, baffled, finned, and stepped. For these types of Isobars®, temperatures can range from 50°F to 550°F.

Acrolab can engineer Isobars®that operate under 50°F. These special Isobars® are application dependent and are available upon request.

BAFFLE:

For Thermoset SystemsAcrolab’s Thermoset Isobar®

System can be incorporated into new or existing tool designs solving cycle time, curing time, and part quality issues.

Acrolab’s Isobar® heat pipes are widely used in the thermoset industry. Isobars® can bring heat rapidly and accurately to molding surfaces. This results in increased productivity.

Acrolab supplies a full range of engineering services for thermoset tools from design, to installation, to hands on customer service. Acrolab engineers will work closely with you to achieve the optimal thermal design for you applications.

Acrolab’s Isobars® require no upkeep, therefore eliminating lengthy maintenance downtimes.

Acrolab’s Isobars® will last the length of the tool save you time and money on replacement parts.

ISOPLATENS ®

Acrolab’s Isoplaten® (“The Intuitive Platen”) redistributes the energy generated by standard cartridge heaters to give molders rapid thermal recovery and unparalleled and linear temperature distribution along the whole platen surface. Your tools operate with reduced energy demands, produce better quality molded parts and allow you to use faster curing compounds with narrower thermal processing windows.

• Uniformly Cure Parts Resulting In Better Quality• Reduce Cycle Time• Reduce Thermal Energy Required From Heaters• Energy Cost Savings• Save On Time• Evenly Heat Thermal Sensitive Parts• Eliminate Hot Spots• Reduce Scrap

Acrolab’s Isoplatens® provide high levels of thermal stability to press platen applications and can be designed for electric, oil, or steam heating. Integral water cooling lines for fast process temperature changes are available . The standard Isoplaten® is electronically heated and has an operating range of ambient to 500°F.

Acrolab engineered bi-level Isoplatens® can hold a thermal uniformity of +/- 5°F over 90% of the surface of the Isoplaten® . These results allow a substantial improvement in cycle times, start up times, thermal recovery rates, and improved part quality.

The Isoplaten’s® Unique thermal uniformity permits the use of one single zone temperature controller for the entire platen. No special multi-zone controls, heaters, or thermocouples are required.

CORE TECHNOLOGY

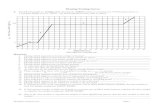

Acrolab offers innovative Isobar® core technology. With Isobar® infiltrated cores you can heat or cool parts in almost half the time as solid steel core pins. With Acrolab Isobar® core technology cores are heated or cooled more quickly and more uniformly.

Above Figure Shows Temperature Uniformity Of Acrolab Isobar® Core pinvs. Standard Solid Core pin.

Heating of Core Pins to Steady StateIsobar® vs. Solid Core Pin

25

50

75

100

125

150

175

200

0 5 10 15 20 25 30 35 40

Time (Minutes)

Tem

pera

ture

(C

)

With Isobars

Without Isobars

ELECTRONIC COOLING

Acrolab Engineers Electric Cooling Systems

•Cooling Diagnostic Equipment•Gas Analyzing Equipment

•Fluid Analyzing Equipment•Blood Warming•Aircraft Cooling•Water Purification•Aircraft Engine Heating•LED Cooling