Software for Selection & Sizing OF Valves

-

Upload

i-like-the-world-of-instrumentation -

Category

Education

-

view

4.214 -

download

7

Transcript of Software for Selection & Sizing OF Valves

Software for Selection Software for Selection & Sizing & Sizing

of of ValvesValves

NIDHIN MANOHARNIDHIN MANOHAR

• Introduction• Common types of valves• Control Valve selection and sizing

Data collectionSelection parametersSizing EquationsCavitation / chokingNoise calculations

• Need for Software• Software in the Market

Common Valves typesCommon Valves types

• Recommended Uses: for applications where discharge is to be maintained constant

• Sizes : max. 1800mm

Discharge control Valves (cone or Needle)

• Are provided on pressure steel mains as a safety measure against total collapse due to formation of vacuum inside the pipe on account of changed conditions of flow caused by sudden closure of valve or tripping of pumps.

• Are fixed on horizontal stretches of pipeline immediately downstream of the line valve.

Air Inlet valves (Anti Vacuum valves)

• Are used to release and introduce air into the pipeline during filling and de-watering of the pipeline.

Air Valves

• Are used when the pressure in the pipeline exceeds a pre-set value.

Pressure Relief Valves

• Are used to arrest the forward moving water column at zero momentum before any return velocity is established.

Zero velocity Valves

• Are sluice valves located at the lowest point in the section used for emptying /de-watering an isolated main.

Scour Valves

Other Valve Types

SELECTION PARAMETERSAppropriate valve selection is based on the complete knowledge of the service characteristics.

•Fluid Type and characteristicsThe fluid being handled (liquid / gas / two phase/ steam/ slurry/ solid)

and its characteristics like clean / dirty / containing large suspended solids / liable to solidification / viscous / corrosive / flammable / fouling / scaling etc.

•Pressure, temperature limitations, and chemical resistance

Valves are normally allocated a rating according to the maximum operating pressure and temperature, which is compatible with the rating of the connected piping system of flanges. The operating temperature limits the materials which may be used in the valve construction, particularly for trims, seals, linings or lubricants.

Materials may also be limited by the pressure, fluid concentration, and condition.

ANSI Pressure Class pounds of force per square

inch of surface area

Nominal Pressure (PN)

allowable pressure in bar

150 16300 40600 100900 1601500 2502500 4004500 700

•Operation and Maintenance RequirementsConsideration should be given to

-Fire resistance

-Ease and Speed of Operation

-Leak tightness

-Maintainability

-Weight and Dimensions (construction, handling, etc)

-Storage and Commissioning

-Location (eg: sea bed valves)

-Line cleaning Requirements ( eg. Ability to pass; cleaning pigs)

Selection parametersSelection parameters•Required flow characteristic

–relationship between flow through the valve and its travel

Rangeability

The rangeability of a valve is defined as the ratio of maximum and minimum controllable flow. Usually for almost 90% of requirements, a rangeability of 30:1 in valve is enough to control minimum and maximum flow requirements.

The rangeability above 30% will also be available depending upon the requirement. However, rangeability above 100:1 is seldom used. Higher rangeability of above 100:1 will call from total design change in the valve including provision of excess stroke and high thrust actuators to valves.

Selection Example

Application

- Fluid : clean water

- Temperature : 35 deg C

- Pressure : 3 bar Rating

- Size : DN 250

- Flow resistance : low

- Seat tightness : Medium

From Table A1, consider the following

Flow resistance, Type of fluid, fluid condition, pressure, temperature, size, leak tightness(Table A5). Check for desired features (Table A3) and materials (Table A4)

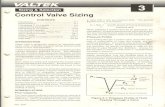

Sizing Equations and Flowchart for

Incompressible

and

Compressible Flows

R e m a r k s E q u a t i o n s V a l u e o f N S l U . S

P i p i n g G e o m e t r y F a c t o r

F o r F L P s e e “ L i q u i d ½2

2

]1)([

CdN

KFp

C h o k e d F l o w ” K K 1 1 K 2 1 K B 1 K B 2

S u m o f v e l o c i t y h e a dC o e f f i c i e n t

B e r n o u l l i C o e f f i c i e n t 421 )(1

DdKK BB

8 9 0 0 . 0 0 2 1 4

R e s i s t a n c e c o e f f i c i e n t 221 ])(1[5.0

DdK

F o r a b r u p t t r a n s i t i o n s

I n l e t f i t t i n g c o e f f i c i e n t 22 )](1[10

DdK

F o r F L P a n d X T P K i = K 1 + K B 1L i n e V e l o c i t y F e e t / S e c o n d M e t e r / S e c o n d R a n g e ( F t / s e c . )

L i q u i d22.245D

qU 2354D

qU

G a s2695 pD

qTU 2124pD

qTU

V a p o r26.19 D

wU

2354D

WU

S t e a m2

23pD

wU 2685pD

WU

5 - 1 0 N o r m .4 0 - 5 0 M a x .

2 5 0 - 4 0 0

7 0 w e t

3 0 0 s u p e r h e a t e d

A c o u s t i c V e l o c i t y ( M a c h 1 . 0 )

G a sM

kTU a 223M

kTU a 91

A i r T49U a TU a 20

S t e a m , s u p e r h e a t e d TU a 60 TU a 5.24 < 0 . 1 5 M a c h

S t e a m , D r y S a t u r a t e d 1650aU 500U a

V a p o r kpvU a 1.608 kpv1038U a < 0 . 1 0 M a c h

< 0 . 3 M a c h

R e m a r k s E q u a t i o n V a l u e o f NS l

U . SG a s v a p o r – ( A l l E q u a t i o n s : x < F k x T

116 yxpFpCvYNwg

ZGgTxYFpCvpNqg

17 1

V a r i a t i o n s f o r s e l e c t e d u n i t sZT

xMYFpCvpNwg1

18

ZMTxYFpCvpNqg

119

6 3 . 3

1 3 6 0

1 9 . 3

7 3 2 0

2 . 7 3

4 . 1 7

0 . 9 4 8

2 2 . 4

E x p a n s i o n f a c t o rFkxT

xY3

1

L o w e r l i m i t = 0 . 6 6 7S p . H t . R a t i o f a c t o r F k = k / 1 . 4 0

M f r ’ s f a c t o r s 22

8.016000

1fCCxT

X T w i t h r e d u c e r s 12

52 ]1)([ d

TT P C

NKix

FpxTx

K i = ( S e e p i p i n g g e o m e t r y f a c t o r )

1 0 0 0 0 . 0 0 2 4

S t e a m D r y a n d ( S a t u r a t e d )

F o r x < x T P ))(3(1 xx

xNFpCvpwT P

F o r x > x T P xTPNFpCvpw 1

( C h o k e d f l o w )

1 . 0

2 . 0

0 . 1 5 2

0 . 3 0 4

R e m a r k s E q u a t i o n s V a l u e o f N I V a l u e o f N U . S S l

GfpFpCvNqf

1

T u r b u l e n t a n d

N o n - c a v i t a t i n g pFpCvNMf 6

0 . 0 8 6 6 5

2 . 7 3

GfpvcpFLPCvNqf

11

GfpvcpFlpCvNMf

16

C h o k e d P v c = F f P v

F F = 0 . 9 - 0 . 2 8 pcpv

F L P = [ ½2

22 ])(1 Cd

NKi

FL

K i = ( S e e p i p i n g G e o m e t r y f a c t o r )

0 . 8 0 6 5

2 . 7 3

0 . 0 0 2 1 4

2/310 )(

FsFpCvpNqf

L a m i n a r 6/14

2

23/1

2

]1)(

[)( DN

FF

FpFdFs LPCv

LP

1 7 3

0 . 0 0 2 1 4

T r a n s i t i o n a lGf

pCvFFNqf pR

1 0 . 0 8 6 5

Sizing Example:

Given : Q = 500gpm, Gf = 0.9, differential pressure = 20 psi, Dynamic Viscosity = 20000 cp. Selected valve is butterfly with Cv/d2 =19, Fs = 0.93

For Turbulent flow,

=> Cvt = 106

For Laminar flow,

= 520

GfpFpCvNqf

1

N1 10 .

0.920(1)Cvt 1500

2/310 )(FsFpCvpNqf

5210N

32

)20(52)20000(500

93.01

vsC

21.0520106

vs

vt

CCZ

This value of Z is less than the 0.46 limit and so the flow is laminar. The Cv required is 520.

Cv = 520 = 19 d2

inchCvd 623.519520

19

If Z is between 0.46 and 20, flow is transitional and if it is more than 20, flow is turbulent. In case of transitional flows,

Cv = Cvt / FR

Where655.0

358.0044.1

vt

vsR C

CF

Plant and valve designers need time to optimize control quality, the sound level and power consumption as well as to handle increasing regulation paperwork and economic aspects. Sizing control valves from a total point of view is a challenge for the project engineer as well as for the valve manufacturer's specialists, even if they use modern powerful in-house sizing programs and tools.

In comparison to the past, the time available for major projects has been more than halved, the specification volume -including the increasing paperwork associated with standards, special regulations and tailored customer requirements have more than doubled.

Requirement for Valve Selection and Sizing Software

Negative effects of today are: valve specification sheets are often of low quality, operating points are missing or not logically sorted to qmax, qnorm, qmin, Important property data (like the vapour pressure) may be missing, no information about the worst-case conditions like during start-up, no control loop information etc. No wonder that sources of competence for high-level engineering for valves with higher demands have dried out and the risk of “quick and dirty” sizing is increasing.Some of the Valve selection and Sizing software available today looks at plant parameters (pipework, pipe devices, flow meters and valves) from an overall point of view with expert system features to compensate for the negative trends described above

Software are helpful in Identifying Planning errors and simulating real life scenarios thereby helping in optimization of the required Valve. Some cases are

1. Energy Saving by Plant and Valve Optimization

2. Noise Treatment Planning

3. Fluid Property Substitution in Sizing Equations

Software available in the market include1. Autovalv - FCRI2. CONVAL - F.I.R.S.T Germany3. Quicksize - Dresser Masoneilan4. FirstView - Fischer Rosemount5. Engineers Aide - Gulf Publishing Software Co.6. CvSpec

AUTOVALV AUTOVALV

A software for control valve

selection and sizing

The CONVAL® software treats the plant and valve sizing parameters from an overall point of view, issuing dynamic graphics with installed characteristics concerning flow, power,gain and outlet velocity as a function of the valve coefficient cv value and the valve travel. The software is a manufacturer independent optimization tool for pipelines and pipe devices, including material and property database for more than 1,000 substances including hydrocarbons. Ethylene, propylene, chlorine, natural gas AGA 8 and sixty other industrial fluids are calculated very accurately using equations of state developed by the Ruhr University of Bochum

HintsHintsThe following data may also be of help ingetting a better performance from a valve. The Line velocityLine velocity may be in the range given below Liquid 5-10 ft/sec normally

40-50 ft/sec maximumGas 250 - 400 ft/sec typical

< Mach 0.3Steam or Vapour 70-100 ft/sec 0-25 psig

100-170 ft/sec dry, saturated > 25psig

<Mach 0.1115-330 ft/sec superheated> 200 psig <Mach 0.15

THANKYOU