Soft Start LV Brochure

Transcript of Soft Start LV Brochure

-

BENSHAWADVANCED CONTROLS & DRIVESADVANCED CONTROLS & DRIVES

Programmable, Intelligent, High PerformanceSolutions for any Motor Control ApplicationProgrammable, Intelligent, High PerformanceSolutions for any Motor Control Application

Reduced Voltage StartingPump ControlGenerator StartingReversingTwo SpeedBrakingSynchronousWound Rotor

Reduced Voltage StartingPump ControlGenerator StartingReversingTwo SpeedBrakingSynchronousWound Rotor

RediStart - Low VoltageSlid State Starters 200 to 600V, 1 to 2500HP

RediStart - Low VoltageSlid State Starters 200 to 600V, 1 to 2500HP

RediStart - Low VoltageSolid State Starters 200 to 600Volts, 1 to 2500HP

TM

-

Choose Your Level of Control... Programmable...MX SeriesMX Series

Standard I/O:

Digital Metering:

Enhanced Motor Protection:

More Flexibility:

Standard Communication Port:

Configurable Analog Output:

Configurable Analog Input:

Configurable Digital Input:

Multiple Starting Ramps:

User Interface:

4 digital inputs, 1 analog output, 3Form C relay outputs

Average Current, L1 Current,L2 Current, L3 Current, Current Imbalance %,Ground Fault Amps, Average Volts, L1-L2 Volts,L2-L3 Volts, L3-L1 Volts, Overload %, PowerFactor, Watts, VA, kW Hours, MW Hours, PhaseOrder, Line Frequency, Analog Input Value,Analog Output Value, Run Time-Days, RunTime- Hours, # of Starts, Tru Torque %,Power %

Motor ThermalOL, Independent Starting and Running OL, Upto Speed Protection, Low Line Voltage, HighLine Voltage, Low Line Frequency, High LineFrequency, Phase Reversal, Phase Loss,Instantaneous Over Current, Over Current,Under Current, Current Imbalance, Ground Fault

Over 70 ConfigurableFeatures

ModBUSbuilt-in and others via option boards.

4-20mA signalConfigurable to: current, kW, 0-100%V, OL%

phase controller,low trip limit, high trip limit

Local/Remote,Auto/Manual, Serial Link, 2-wire/3-wire, DualRamps

All with initial andmaximum settings, programmable ramp timesand adjustable kick current

Open loopfor standard applicationsfor pumping applications to

reduce pressure surgesfor limited power applications i.e.

generators or weak systems

4 Digit, 7 Segment board mountedLED Interface

2 Line, 16 characters per line LiquidCrystal Display

Voltage Ramp -Current Ramp -Torque Ramp -

Power Ramp -

Standard:

Optional:

OPTIONALLCD KEYPAD KIT

PART#MX-2M-RKP-00

Only Benshaw has a three year guarantee.

the Benshaw Promise.

Every Benshaw Solid State Starter is guaranteed for

Other manufacturers limit their

warranties to just one year. At Benshaw, we

believe that because we build them better, we guarantee

them longer. We call that

three full years. U LLISTED

USC

QUICK STARTMENU

All of Benshaws low voltage power stacks can be integrated with two levels

of control - the MX Series or the Micro II Series. The MX Series Control

provides the user with a powerful group of programming parameters designed

for flexibility in industrial applications. MX controls provide simple setup and

commissioning via the quick start menu and include the following functions:

Group Description Setting Range

QST 00 Jump to parameter 1-9

QST 01 Motor FLA 1 6400

QST 02 Motor Service Factor 1.001.99

QST 03 Motor Overload Class Running Off, 140

QST 04 Local Source

QST 05 Remote Source

Keypad

Terminal

Serial

QST 06 Initial Motor Current 50600

QST 07 Maximum Motor Current 100800

QST 08 Ramp Time 0300

QST 09 UTS Time / Transition Time 1900

MX Single Board Controller

120V

Control

Relay

Outputs

Digital

Inputs

Modbus

Serial

Port

Reset

Pushbutton

CT

Switch

LED

Keypad

Analog

Output

Analog

Input

Quick

Connect

SCR

Terminals

-

Micro II SeriesMicro II SeriesThe Micro II Series multiboard design is modular and can be configured to solveany motor control application, including:

JoggingReversingSynchronousPower Outage Ride Thru

DC Injection BrakingWound RotorTwo Speed Two WindingTwo Speed Single Winding

...Intelligent, Motor Control & Protection

MX vs Micro II Comparison

Function MXControl

MIIControl

Function MXControl

MIIControl

CONTROL FUNCTIONS YES YES METERING

Current Ramp YES YES Current-Average YES YES

Torque Ramp YES YES Current-Phase-Phase YES YES

KW Ramp YES YES Voltage-Average YES YES

Voltage Ramp YES YES Voltage-Phase-Phase YES YES

Max Current YES YES % Current Imbalance YES YES

Initial Current YES YES Power Factor YES YES

Up to Speed Timer YES YES Watts YES YES

Kick Start YES YES VA YES YES

Kick Time YES YES KW Hours YES YES

Decel YES YES MW Hours YES YES

Tachometer Ramp NO OPTION Phase Order YES YES

Line Frequency YES YES

I/O FUNCTIONS Ground Fault Current YES YES

2 Wire Start/Stop YES YES Overload % YES YES

3 Wire Start/Stop YES YES Power % YES YES

Network Start/Stop YES YES Tru Torque % YES YES

Keypad Start/Stop OPTION YES User Run Time YES YES

Local/Remote Digital Input YES NO # of Starts YES YES

Dual Ramps YES YES User Elapsed Time Meter

Resettable

YES YES

External Fault Input YES YES Elapsed Time Meter Non-Resettable

NO YES

DC Space Heater Function YES YES RTD Temperature NO OPTION

Up to Speed Output YES YES Real Time Clock NO YES

Fault Output YES YES

Running Output YES YES I/O

Alarm Output YES YES Standard Digital Inputs 4 9

Ready Output YES YES Standard Relay Outputs 3 3

OL Alarm Output YES YES Optional Relay Outputs NO 4 OR 7

Shunt Trip Output YES YES Analog Input YES NO

Undercurrent Output YES YES Analog Output YES OPTION

Over Current Output YES YES

Ground Fault YES YES MOTOR PROTECTION

Running Output YES YES Running OL YES YES

Starting OL YES YES

SPECIAL FUNCTIONS Phase Loss YES YES

Reversing YES YES Phase Reversal YES YES

Wound Rotors YES YES Low or High Frequency fault YES YES

Voltage Follower YES NO Low Line Voltage YES YES

Motor Space Heater YES YES Overcurrent YES YES

Energy Saver YES YES Undercurrent YES YES

Jogging NO YES Current Imbalance YES YES

Reverse Jogging NO YES Ground Fault YES YES

DC Injection Braking LightDuty

NO YES Shorted SCR YES YES

DC Injection Braking Heavy

Duty

NO OPTION UTS Timer Exceeded YES YES

Synchronous Motor Control NO OPTION Record previous ten faults YES YES

Power Outage Ride Thru NO YES W/UPS Time Date Stamp last 99 Events NO YES

8 Channel RTD Protection NO OPTION

COMMUNICATIONS Time Between Starts NO YES

Modbus YES OPTION Starts Per Hour NO YES

Devicenet NO YES Backspin Timer NO YES

R485 YES OPTION

Micro II Modular

Multi Board Controller

-

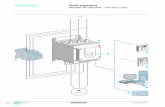

Choose Your Power Section... Integral Bypass...RB Series Integral Bypass Power StackRB Series Integral Bypass Power Stack

The RB Series integrated bypass power stack is a rugged, heavy duty, solid state starter assembly. The modular designincludes separate power poles for each phase for ease of maintenance. Each power pole is designed with an integralbypass contactor for a compact, efficient profile. All of Benshaws power stacks are available with MX or Micro IIcontrol and are guaranteed for three years... standard!

RBX Power Pole - 150A

RBX-1-S-240A-15C

Stack Ratings:

Service Factor:

Standard Duty: 350% for 30 secsHeavy Duty: 500% for 30 secsSevere Duty: 600% for 30 secs

Standard Duty: 115% continuousHeavy Duty: 125% continuousSevere Duty: 125% continuous

RBX-1-S-838A-20C

Integral

Bypass

Contactor

Stack Over

Temperature

Protection

NEMA 2

Hole Pattern

Bottom Entry/

Bottom Exit

1600 PIV

SCRs In

Reverse Parallel

Configuration

DI/DT

Protection

NEMA 2

Hole Pattern

Top Entry/

Top Exit

-

UL Service

&

- Designed for Emergency Full Voltage Starting

- Panel Mounted Selector Switch RVSS-OFF-ATL

- NEMA or IEC Rated Contator

- Separate Electronic OL Relay for ATL Protection

- Phase Reversal

- Class 1-30 Selectable

- Phase Loss

- Current Imbalance

- Adjustable OL Setting

- Jogging Applications

- Energy Saver Applications

- High Duty Cycle Starting

- Long Starting Times

- High Inertia Starting

- 1.25 S.F.

Select MX or Micro II Controls to Match Your ApplicationSelect MX or Micro II Controls to Match Your Application

RBX Series Solid State StartersSelection Information

Standard Duty

MODEL NUMBER HORSEPOWER RATINGSTANDARD DUTY = 350%CURRENT FOR 30 SECS

DIMENSIONS(INCHES)

208V 230V 460V 600V H x W x D

RBX-1-S-027A-11C 7.5 10 20 25 14.0 x 10.0 x 6.9RBX-1-S-040A-11C 10 15 30 40 14.0 x 10.0 x 6.9RBX-1-S-052A-12C 15 20 40 50 14.0 x 10.0 x 6.9RBX-1-S-065A-12C 20 25 50 60 14.0 x 10.0 x 6.9RBX-1-S-077A-13C 25 30 60 75 15.0 x 10.0 x 7.7RBX-1-S-096A-13C 30 40 75 100 15.0 x 10.0 x 7.7RBX-1-S-125A-14C 40 50 100 125 21.6 x 12.3 x 8.9RBX-1-S-156A-14C 50 60 125 150 21.6 x 12.3 x 8.9RBX-1-S-180A-14C 60 75 150 200 21.6 x12.3 x 8.9RBX-1-S-240A-15C 75 100 200 250 22.0 x 12.3 x 9.2RBX-1-S-302A-15C 100 125 250 300 22.0 x 12.3 x 9.2RBX-1-S-361A-16C 125 150 300 400 23.9 x 12.9 x 9.2RBX-1-S-414A-17C 150 - 350 - 28.3 x 18.5 x 11.3RBX-1-S-477A-17C - 200 400 500 28.3 x 18.5 x 11.3RBX-1-S-515A-17C 200 - 450 - 28.3 x 18.5 x 11.3RBX-1-S-590A-18C - 250 500 600 28.3 x 18.5 x 11.3RBX-1-S-720A-19C 250 300 600 700 28.3 x 18.5 x 11.3RBX-1-S-838A-20C 300 350 700 800 29.3 x 18.5 x 11.3

Heavy Duty

MODEL NUMBER HORSEPOWER RATINGHEAVY DUTY = 500% CURRENT

FOR 30 SECS

DIMENSIONS(INCHES)

208V 230V 460V 600V H x W x D

RBX-1-S-027A-11C 7.5 10 20 25 14.0 x 10.0 x 6.9RBX-1-S-040A-11C 10 15 30 40 14.0 x 10.0 x 6.9RBX-1-S-052A-12C 15 20 40 50 14.0 x 10.0 x 6.9RBX-1-S-096A-13C 30 40 75 100 15.0 x 10.0 x 7.7RBX-1-S-125A-14C 40 50 100 125 21.6 x 12.3 x 8.9RBX-1-S-180A-15C 60 75 150 200 22.0 x 12.3 x 9.2RBX-1-S-361A-16C 75 100 200 250 23.9 x 12.9 x 9.2RBX-1-S-414A-17C 125 150 300 400 28.3 x 18.5 x 11.3RBX-1-S-590A-18C 200 200 450 500 28.3 x 18.5 x 11.3RBX-1-S-720A-19C - 250 500 600 28.3 x 18.5 x 11.3

Severe Duty

MODEL NUMBER HORSEPOWER RATINGHEAVY DUTY = 600% CURRENT

FOR 30 SECS

DIMENSIONS(INCHES)

208V 230V 460V 600V H x W x D

RBX-1-S-027A-11C 5 7.5 15 20 14.0 x 10.0 x 6.9RBX-1-S-040A-11C 10 10 30 40 14.0 x 10.0 x 6.9RBX-1-S-052A-12C - 15 - - 14.0 x 10.0 x 6.9RBX-1-S-096A-13C 25 30 60 75 15.0 x 10.0 x 7.7RBX-1-S-125A-14C 30 40 75 100 21.6 x 12.3 x 8.9RBX-1-S-180A-15C 50 60 125 150 22.0 x 12.3 x 9.2RBX-1-S-361A-16C 60 75 150 200 23.9 x 12.9 x 9.2RBX-1-S-414A-17C 100 125 250 300 28.3 x 18.5 x 11.3RBX-1-S-590A-18C 150 200 450 500 28.3 x 18.5 x 11.3

RB3 Dual Redundant Stack

RC Continuous Rated Stack

Benshaws RB3 Series utilize a separate bypasscontactor for the most flexibility in yourapplication. The panel mounted selectorswitch offers the user the option of selectingSoft Start or Across the Line Mode.

Benshaws RC Series Solid State Starter is a rugged,non-bypassed unit. It is an economical solution atlow horsepower. In addition, the fan cooled stackprovides high duty cycle and high inertia starting andenergy saver operation.

* For Micro II Control - Substitute M for X

in the model number (Increases depth by 1)

-

RSE II Starters provide solid state reduced voltage starting for normal operation and full voltage emergency back-up starting with complete electronic motor protection at the flip of a switch. This unique designis the ideal solution for critical applications where downtime is extremely disruptive to production operations andcan not be tolerated. Benshaws Micro II solid state controls provide precise digital starting and stopping,motor protection, metering, diagnostics and communications...standard.

Dual Redundant

Product Highlight - RSE Series StarterII

NEMA 12, Combination, Dual Redundant Solid State StarterSolid State Reduced Voltage Starting - Normal OperationsSwitch Selectable Emergency Backup Full Voltage Starter500% - 30 seconds, 125% Continuous Duty RatedUL Listed, 1800 PIV Rated SCRsAuto Switch Dual Redundant Electronic Motor Protection

Micro II - TruTorque Solid State Control SystemEmbedded Digital Metering, Power Quality Protection & Diagnostics

TM

Benshaw RSE Series Starters are supplied to thefollowing specifications

II

standard:

1. NEMA 12, Dual redundant, Combination/Circuit Breaker2. 500% - 30 seconds rated solid state starter - UL certified & listed3. 1800 PIV rated SCRs -UL Certified & Listed4. 125% continuous duty rated solid state starter - UL certified and listed5. Selector switch for selecting solid state or full voltage operation mounted inside enclosure6. Full HP rated bypass contactor with a 1.15 service factor, wired for normal bypass operation

and full voltage start and run operation, with normally open auxiliary contact.7. Separately mounted SPE Series overload relay wired for full voltage starting and run

operation. The SPE Series overload has the following standard features:Class 1-30, adjustable1 NO/1 NC trip contactTrip free designPhase imbalance protectionPhase reversal protectionPhase loss detectionTest Function/trip indicationFault Indication

8. 110 Volt control power transformer with primary and secondary fuses9. Door mounted start and stop pushbuttons10. Door mounted key pad11. Door mounted run indicating light12. Door mounted local-off remote switch13. Door mounted overload reset14. Terminal strip mounted inside enclosure for remote start - stop connection15. Auxiliary relay with (2) form C run contacts16. Benshaw Micro II, Programmable Motor Controller with complete soft start, soft stop and motor

protection capabilities (see details on next page)17. Devicenet Communications

RSE Operator ControlsII

UL Service

Entrance

Rated

&

Labeled

RSE Dual RedundantSevere Duty Starter

II

Full Voltage

Emergency

Back-Up

Switch

Solid State

Reduced

Voltage

Starting &

Stopping

ULLISTED

USC

Customer Solutions...Standard Stock PackagesStandard Stock Packages

-

Built to Your Specifications

Typical

Customer

Solutions

Control modificationswhatever you specify

Combination startersto meet your system requirements

Power Stacks to fityour application

Enclosuresto match your environment

Communication Modulesto match your network

RS232/485ModbusDeviceNetCustom Interfaces

Over 250 modifications and accessoriesare available, including: pilot devices,PLCs, control power transformersswitches, meters, relays, space heatersand protective devices.

15 to 2000 amp circuit breaker40 to 2000 amp non-fused disconnect30 to 800 amp fusible disconnectFlange or rotary handle mechanism

Integral BypassDual RedundantContinuous RatedStandard, Heavy & Severe Rated

Standard designs - NEMA 1,12, 4, chassisOEM/unit mount, custom designs as specifiedSpecial enclosures - 3R, 4X, 7, 9, as specifiedABS/DNV approved for marine dutyMotor Control Centers

Customer specific

control logic

Severe Duty

Soft Starter

Benshaw has developed engineering, drafting, materials management and Quality Systemsfocused on designing and building customer solutions. This capability combinedwith an extensive inventory of control components, protective relays, circuit breakers, contactors,enclosures and other electrical/electronic devices provides our customers with the quickest shipmentof engineered products in the industry.

AdvancedBuild to Order

Synchronous

Motor Starter

Engineered ProductsEngineered Products

-

General Purpose, Pump Control, Generator StartingGeneral Purpose, Pump Control, Generator Starting

General Purpose Varying Load Conditions

Generator ControlPump Control

Ramp Profile 1

Ramp Profile 2

Initial Current 2

Kick Level

Maximum

Current 2

Initial Current

Maximum

Current

Kick Time

Ramp Time 2

Ramp Time

Kick Level 2

Kick Time 2

Current

Time

Kick Time Ramp Time

Up To Speed Timer

Initial

Current

Kick

Current

Max

Current

Start

command

Motor

FLA

Motor Input

Power

Time

Kick Time Ramp Time

Up To Speed Timer

Running

Power

Initial

Power

Kick

Current

Max

Power

Start

command

Designed for Pump Control Applications

Reduces harmful torque/pressure surges

Protects against water hammer

Torque control in Start & Stop Modes

Provides initial torque, max torque, and ramp time

Simple Setup

Provides Initial Current, Max Current and Ramp

Time Settings

Limits inrush current and mechanical stress

Dual Ramps

Current Ramp

Tru Torque RampKW Ramp

TRUTORQUE vsTM

PUMP DECEL WITH VOLTAGE CONTROL

Torque Spikes & Water Hammer

without TruTorque

TruTorqueControlled Decel

Voltage

Controlled Decel

Designed for Generator or soft

source applications

Minimizes power consumption

during start

Provides initial power, max

power and ramp time settings

-

For any ApplicationReversing, Braking, Two Speed, Synchronous, Wound RotorReversing, Braking, Two Speed, Synchronous, Wound Rotor

RSM7 RSM10

RSM10/12TS:

RSM11

SMRSM6 WRSM6

Micro II Control with 7 SCRs

for integrated/programmable

DC-injection braking.

Standard or heavy duty

braking torque

Micro II Control with 10 SCRs

for integrated/programmable

reversing operation

Programmable soft

start/stop with

forward/reverse capability

Micro II Control with additional

SCRs for programmable two

speed operation

Single winding or two winding

motors

Micro II Control with 11

SCRs for integrated

programmable DC

injection braking and

reversing capability

Micro II Control with

integrated/programmable

synchronous excitation

controls

Automatic power factor

control

Micro II Control with

integrated/programmable

wound rotor controls

High Torque starting or speed

control

Non-reversing

DC BrakeReversing Reversing

DC Brake

SynchronousNon-reversing

Two-speed Wound Rotor

-

Integrated Motor and Load ProtectionIntegrated Motor and Load Protection

Programmable Motor Protection, Diagnostics...

Real-Time I T Thermal Modeling2

Percent Voltage UnbalanceNEMA MG1 Motor Thermal Effect

Nor

mal

Pow

er/Q

uality

Volta

ge,C

urre

nt,P

hase

Normal Run

1) PORT Subcycle DetectionPower/Quality Outage

4) PORT SubcycleDetectionPower/Quality Return

PORT - Power Outage Ride ThroughTM

Normal RunTransientPower Outage

Normal Run

Micro II - I T

Thermal Memory

2

Micro II - I T

36 Samples per Cycle

2

Control Circuit UPS Normal Run

3) Power LossCoast Stop

5) TruTorqueSpinning SoftRestart

6) PORT Time Out

2) PORT ControlledShutdown/Recovery Sequence

Power System Recovery

Power System Outage

Time

Programmable Motor/Load

Fault Protection

Permissive Inputs

Electronic OL

% Current Imbalance

Over Current

Under Current

Phase Reversal

Phase Loss

Machine Ground Fault

Shorted SCR

UTS Time Limit Exceeded

High Frequency

Low Frequency

Number of Auto Resets

Number of Starts per Hour*

Time Between Starts*

Back Spin Timer*

Zero Speed Timer*

* Micro II Series Only

MX and Micro II Controls provided comprehensivemotor/process protection. Their integrated voltageand current sensing, high speed sampling rates

(36 I T samples per cycle) and advanced algorithmsprovide unequaled protection for motors, machinesand critical processes. Users can select the specificclass (1 to 40) overload curve desired and over 25other protective functions to match the uniquerequirements of their application. An overview ofthese precision protective functions is outlined below:

2

Overload Curves

*Programmable RTD Module

-

Digital Metering & Communications

MX LCD Keypad Micro II - 99 Event Recorderw/Time Date Stamp

MX and Micro II controls calculate, analyze and present monitoring and diagnostics data in plain english displays to ensure operatingpersonnel have Real-Time visibility of the motor, load and power system. Embedded digital meters, programmable alarms, outputs,revolving events and communications are presented to the operator via the LCD keypad or RediView Windows interface. Data isdisplayed in straight forward messages that provide complete visualization of the Real-Time status and prior events for supportingoperating and maintenance personnel requirements. An overview of the Real-Time data functions is summarized below:

RediView MX

Monitoring Screen

Starter Communication

Setup Screen

On Line and

Off Line Programming

Print/Save/Document

Parameters

E-Mail Parameters

RediView Micro II

Monitoring Screen

DIGITAL METERING

Currrent - Average

Current - Phase - Phase

Voltage - Average

Voltage - Phase - Phase

% Current Imbalance

Power Factor

Watts

VA

KW hours

MW hours

Phase Order

Line Frequency

Ground Fault Current

Overload %

Power %

Tru Torque %

User Run Time

# of Starts

User Elapsed Time Meter - Resettable

Elapsed Time Meter - Non Resettable)*

RTD Temperatures*

Smart Maintenance Data & DisplaysSmart Maintenance Data & Displays

Plain English LCD Display...and Real Time Windows Interface

-

Sales & Service

The widest range ofmotor controls and drivesavailable anywhere...

The widest range ofmotor controls and drivesavailable anywhere...

7x24customerservice...

Benshaws customer serviceorganization is dedicatedto providing comprehensive7-day-a-week, 24-hour-a-day phone support,repairs, spare parts, fieldengineering, retrofits andtraining services...whenand where you need us.Whether its Benshaw orthird-party equipment, youcan count on our experi-enced team, backed by thelatest diagnostics and repairtools and a two milliondollar parts inventory tosupport your operations.

.................

Repairs are made onBenshaw and third-partyequipment by trained, exper-ienced personnel, using thelatest diagnostic and testequipment to repair:

Printed circuit boards.Power electronic controlassemblies.Electrical controlassemblies.

Repairs

Field Services are performedon-site by skilled technicians,engineers or complete teams,if needed, including:

Start-up commissioning.Field repairs.Field analysis/datacollection.Preventative maintenance.

Training is provided in botha classroom and a hands-onenvironment that providesthe student with practicalskills, including:

Basic electricalmaintenance.Electronic maintenanceand diagnostics.Benshaw product courses.Customized systemscourses (maintenance-or operations-based).

Benshaw Express is anew worldwide program thatguarantees a two-houremergency response on avariety of starters, drives andparts from our dedicatedwarehouse at the airport.It includes:

7x24 Same day shipment.Either air or truck delivery.Airport pick-up or door-to-door service.

7x24 Hotline Support fromour operations in Pittsburgh,Listowel (Canada), Detroitand Phoenix, including:

Technical phone support.Overnight parts shipment.24-hour service dispatch.Coordination of all servicecapabilities.

Solid state startersfractional up to60,000 HP at 15kVAC drives to 1000 HPElectromechanicalcontrols to 800 amps

BENSHAW

United States

Canada

South America

Shanghai

Australia

Singapore

BENSHAW, Inc.

BENSHAW West

BENSHAW Canada

Pittsburgh, PennsylvaniaDayton, OhioSyracuse, New YorkBoston, MassachusettsWilmington, DelawareCharlotte, North CarolinaJacksonville, FloridaBirmingham, AlabamaLos Angeles, CaliforniaSan Francisco, CaliforniaDetroit, MichiganLaCrosse, WisconsinChicago, IllinoisKansas City, MissouriPhoenix, ArizonaSeattle, WashingtonDenver, ColoradoHouston, TexasMinneapolis, MinnesotaNewark, New Jersey

Listowel, OntarioToronto, OntarioMontreal, QuebecCalgary, Alberta

Sao Paulo, BrazilSantiago, ChileLima, PeruBogota, Colombia

1659 E. Sutter RoadGlenshaw, PA 15116Phone: (412)487-8235Fax: (412)487-4201

7820 East Evans DriveSuite 900Scottsdale, AZ 85260Phone: (480)905-0601Fax: (480)905-0757

550 Bright St. E.Listowel, Ontario N4W 3W3Phone: (519)291-5112Fax: (519)291-2595

Visit or E-mail Benshawon the worldwide web atwww.benshaw.com,benshawexpress.com,or contact:

BCAM-04-013-00