Skrip Tana Engle s Kom

-

Upload

ognjenristic -

Category

Documents

-

view

20 -

download

1

description

Transcript of Skrip Tana Engle s Kom

An introduction to prestressed concrete

A. H. Allen MA, BSc, FICE, FIStructE

BRITISH CEMENT ASSOCIATION

Foreword

This booklet is intended for the student requiring an introduction to prestressed concrete, without the complicated mathematical manipulation usually found in text-books on the subject. The hope is that this approach will also appeal to the young architect o r engineer who needs a basic understanding of the principles of the technique.

Prestressed concrete is introduced by words and pictures, but the use of technical terms cannot be avoided and some design equations have been used. For those to whom a mathematical approach is desirable, the first Appendix is devoted to the basic theory.

In this second edition, apart from minor changes, the text of the chapter on Materials has been revised to take account of new British Standards relating to tendons and particularly of some new terminology used therein.

Contents

Foreword

Brief history and development

Principles

Methods Pre-tensioning Post- tensioning

Materials Concrete Steel

Equipment Pre-tensioning Post-tensioning BBRV Dividag ~ a c a l l o ~ CCL Losinger PSC SCD Stronghold General

Applications Pre-tensioning

Sleepers Roofs and floors Beams

For buildings For bridges

Piles Handling

Post-tensioning Buildings Bridges Reservoirs and silos Piles

Offshore structures

Conclusion

Appendix 1: Basic theory

Appendix 2: Suggestions for further reading

Appendix 3: Acknowledgements

Figure 1: Sydney Opera House.

Brief history and development

Although a patent for the material was taken out in California in 1886, it was not until the late 1940s that prestressed concrete really began to develop. The acute shortage of steel that occurred in Europe after the Second World War opened the way for the use of prestressed concrete in the period of reconstruction that followed the war. One tonne of prestressing strand can result in up to 15 times the amount of building that is made possible by one tonne of structural steel.

Eugene Freyssinet of France is generally regarded as the 'father' of prestressed con- crete. His interest in the subject and tests carried out by him in the early 1900s led him to believe that prestressing would be a practical proposition if high-strength steel and high-quality concrete were available. These were slow in coming, and it was not until 1928, when he took out his first patent, that Freyssinet was able to establish his theory of prestressing. His first publication on the subject was aptly entitledA revolution in the art of building. It certainly was a revolution; indeed, it was regarded by many engineers as a new-fangled idea that would never catch on.

There were a few, however, such as Magnel in Belgium and Hoyer in Germany, who recognized its potential, and most of the basic ideas on prestressing systems had emerged by the time they were needed- after the war. The tools and materials were available and European engineers led the world in this new method of construction. Not that the rest of the world took a great deal of interest, in those early years. In the USA, for example, there was some early use of prestressed concrete in construction of water tanks, pressure pipes and piles, but it was 1951 before North America's first major prestressed concrete structure - a bridge - was completed.

In 1952, an international society (the FCdCration Internationale de la PrCcontrainte, or FIP) was created at a meeting in Cambridge. The main objective of this group of far- sighted engineers was to spread the message and enlighten the world about the relatively unknown (at that time) concept of prestressed concrete construction. FIP was to do this by encouraging the formation of national groups in all countries which had a special interest in the subject and by providing an international forum for the exchange of information. Great Britain, together with a few other European countries, already had its own group (the Prestressed Concrete Development Group, or PCDG), the work of which has now been taken over by The Concrete Society.

Much of FIP's work is done quietly by technical commissions, which investigate particu- lar aspects of prestressed concrete technology, and draw up recommendations on design and construction methods, but every four years there is a congress which attracts most of the world's leading authorities on the subject.

Prestressing has made new methods of construction possible and enabled entirely new types of structure to be built, which could not have been conceived without it. However, there is only a limited number of ways in which cables and rods can be tensioned and anchored, and scope for innovation must now be small. There is still plenty of detailed work to be done in refining the concept and there are still possibilities for extending its use.

Two of the most challenging and useful applications in recent years have been for large sea structures (harbours, offshore terminals, fixed and floating platforms for oil produc- tion) and nuclear power stations.

There is still scope for prestressed concrete to increase its role in bridge construction, with the supporters of high-strength concrete vying with the supporters of lightweight concrete as to the better way in which to go. The industry looks to the future with confidence, and the view of Sydney Opera House (Figure 1) must surelygive a boost to the morale of any budding architect, engineer or constructor.

Principles

Figure 2

Figure 3

Figure 4

Prestressed concrete can most easily be defined as precompressed concrete. This means that a compressive stress is put into a concrete member before it begins it working life and is positioned to be in areas where tensile stresses will develop under working load.

Why are we concerned with tensile stresses? For the simple reason that, although concrete is strong in compression, it is weak in tension.

Consider a beam of plain concrete carrying a load.

As the load increases, the beam deflects slightly and then fails abruptly. Under load, the stresses in the beam will be compressive in the top fibres, but tensile in the bottom fibres.

We can expect the beam to crack at the bottom and break, even with a relatively small load, because of concrete's low tensile strength. There are two ways of countering this low tensile strength - by using reinforcement or by prestressing.

In reinforced concrete, reinforcement in the form of steel bars is placed in areas where tensile stresses will develop under load.

The reinforcement absorbs all the tension and, by limiting the stress in this reinforcement, the cracking of the concrete is kept within acceptable limits.

In prestressed concrete, the compressive stresses introduced into areas where tensile stresses develop under load will resist or annul these tensile stresses.

Figure 5

Figure 6

Figure 7

So the concrete now behaves as if i t had a high tensile strength of its own and, provided the tensile stresses do not exceed the precompression stresses, cracking cannot occur in the bottom of the beam.

An everyday example of the fundamental principle of prestressing is used by a person moving several bricks. As an alternative to stacking them vertically, one on top of the other and supporting them underneath, they can be lifted and moved in a horizontal stack by exerting pressure with a hand at each end.

The tensile strength of the row of bricks is zero, but as long as sufficient pressure is applied, the whole row can be lifted together. If the pressure is applied near the top, it will be found that the 'unit' is not very stable and will tend to open up at the bottom. With the pressure applied below mid-height, i t will be possible to stack bricks on top, so our unit is also carrying a load. The more load we put on, the more pressure we need to exert at each end. A simple demonstration can also be made by using a few empty matchboxes placed end to end and held together by an elastic band going right around them. The amount of load that can be carried varies with the amount of pressure applied by the elastic band.

This basic idea of using several separate units becomes a very practical structural solution when we need to span a wide opening. Precast concrete units are erected on falsework; they are pressed together; the falsework is taken away. As long as the pressure remains, we have a load-carrying member.

However, bending is only one of the conditions involved; we also have shear. Vertical and horizontal shear forces are set up within a beam and these will cause diagonal tension and diagonal compression stresses of equal intensity. As concrete is weak in tension, cracks in a reinforced concrete beam will occur where these diagonal tension stresses are high, usually near the support.

In prestressed concrete, the precompression stresses can also be designed to overcome these diagonal tension stresses.

Under load, a prestressed beam will bend, gradually reducing the built-in compression; when the load is removed, the compression reasserts itself and the beam returns to its

Figure 8

original condition, illustrating the resilience of prestressed concrete. Furthermore, tests have shown that a virtually unlimited number of such reversals of the loading can be carried out without affecting the beam's ability to carry its working load or impairing its ultimate load capacity. In other words, 'prestressing' endows the beam with high fatigue resistance.

It has already been stated that if, at working load, the tensile stresses due to load do not exceed the prestress, the concrete will not crack in the tension zone but, if the working load is exceeded and the tensile stresses overcome the prestress, cracks will appear. However, even after a beam has been loaded to a high proportion of its ultimate capacity, removal of the load results in complete closing of the cracks and they do not reappear under working load.

How is this precompression applied? For ground-floor slabs or pavings, it can be achieved by the use of externally applied jacks which, after compressing most of the slab between two fixed abutments, can be replaced by the remainder of the slab.

This is not a practical method for most structural members, however, and the usual method is to use tensioned steel 'tendons' incorporated permanently in the member. The tendons are usually in the form of a high-strength wires, strands or bars, used singly or made up into cables. Using tendons there are two basic methods called:

(a) pre-tensioning;

(b) post-tensioning;

which will now be described in more detail.

Methods

In pre-tensioning, as the word implies, first the steel is tensioned between abutments and then the concrete is placed in moulds around it. When the concrete has achieved sufficient compressive strength, the steel is released from the abutments, transferring the force to the concrete through the bond that now exists between the steel and the concrete - see Figure 9.

Stage 1

Stage 2

Stage 3

Figure 9: Pre-tensioning.

In post-tensioning, the concrete is cast first in the mould and allowed to harden before the steel is tensioned. The steel may be placed in position to predetermined profile and cast into the concrete, bond being prevented by enclosing the steel in a protective metal sheathing. Or ducts may be formed in the concrete and the steel passed through after hardening has taken place. When the required concrete strength has been achieved, the steel is stressed against the ends of the unit and anchored off, thus putting the concrete into compression. The curved profile of the steel, which usually occurs in post-tensioning, permits the effective distribution of prestress within the section to the designer's require- ments - see Figure 10.

Pre-tensioning may be used on site where large numbers of similar precast units are required, but is usually carried out in a factory where permanent stressing beds have already been constructed. The most effective method is long-line production, whereby a number of similar units are produced at the same time. The steel tendons, usually wire for small units and strand for larger units, are tensioned between anchor plates at opposite

Stage 1

Stage 2

Stage 3

Figure 10: Posr-tensioning.

steel jo~sts

ends of a long stressing bed. These anchor plates are supported by large steel sections embedded in a block of concrete at each end of a casting surface. The base slab may act as a strut between these blocks of concrete but, with long stressing'beds, each block is made massive enough to remain stable, i.e. it will not slip or rotate. In very long stressing beds, there are sometimes intermediate blocks with preformed pockets so that temporary steel joists can be inserted to give a shorter stressing bed if the need arises. At one end, the anchor plate bears directly onto the supporting steel joints and is referred to as the fixed abutment. At the other end, the jacking end, temporary steel struts are introduced between the anchor plate and the supporting joists. The anchor plates are usually thick steel plates with holes through which the wires or strands can be passed and anchored. The ends of each unit will have a stop-end, which will be drilled to the layout of tendons required and for the size of wire or strand being used. A typical arrangement for long-line production is shown in Figure 11.

temporary

stop-end - struis 1,

Figure 11: Long-line production. The designed number of wires or strand are drawn down the full length of the stressing

bed, threaded through the stop-ends and anchor plates and anchored off a t the fixed abutment. At the other end of the bed, when all the wires have been positioned, jacking begins. The slack is taken up and the load applied. h he extension can also be read off and compared with a calculated value but, as the tendons are virtually free to move (which they are not in the case of post-tensioning), it is the force in the tendon which is of primary importance.] The wire is then anchored off and the jack released. The operation is then repeated on the remaining wires. The sequence of stressing is not very important in pre-tensioning but, as with all prestressing, accurate stressing is essential.

If any secondary reinforcement is to be used, the amount necessary for each unit will have been bunched together near the stop-ends and the tendons threaded through when the wires were being drawn down the bed. When stressing has been completed, reinforce- ment is fixed in its required position. The moulds are then assembled in preparation for concreting. In pre-tensioning, the bond between the stressed steel and the concrete is

Figure I2

vitally important, and in all the operations carried out care must be taken to ensure that this steel is kept clear of any material, such a s mould oil, that would interfere with this bond.

To achieve full compaction o f the concrete. vibrators are used and these can be internal o r external. Internal vibrators, badly handled, can produce pockets of water adjacent t o the stressed steel, which will reduce the effective bond. External vibratorsdo not cause this problem, but on the other hand. the moulds need to be much more rigid.

A s with all concrete, curing is necessary. The process is sometimes accelerated by introducing steam under suitable cover, and a rapid production turn-round can be achieved.

When the concrete has attained sufficient strength, the temporary struts are replaced by jacks which can be slowly released. As the tensioned steel tries t o return to its original length, the bond between the concrete and steel prevents this and so the concrete is put into compression. Provided the units are free to slide along the bed, the tension in the steel between the units is released, thus enabling the steel t o be cut quite safely at the ends of the units. A t these points, the tendons will revert to their original diameter, s o there is also a wedge action, in addition to the bond. The force in each tendon is transferred to the concrete over a certain length, which is called the 'transmission' length. This length is considerably affected by the surface condition in the case of wires but is much less variable for strand. In both cases, however, the length is affected by the degree of compaction.

Other arrangements involve the tendons being tensioned simultaneously. In this case, jacks are inserted between the anchor plate and steel joists instead of temporary struts. T h e jacks are then operated to tension all the tendons. A s the jacks are also used for releasing the stress, they usually form an integral part of the stressing bed.

For small proprietary units, secondary reinforcement is often unnecessary and, in one system, the concrete is continuously extruded around the tendons and subsequently sawn to length (Figure 12). A s the wires are still under tension when cut, the bond has to be very good o r the wires will disappear into the unit.

As soon as the units in a long-line bed have been separated they can be stacked, but they should be handled with great care, lifted at the correct points and kept the 'right way up' at all times. This will be dealt with more fully under Applications (page 41).

Pre-tensioning may also be applied to individual units and, in this case, the steel is stressed and anchored in each mould. These units, too, must be handled with great care.

In the arrangements discussed so far, the tendons have all been straight and have all been continuously bonded to the concrete. Although the majority of pre-tensioned units are made this way, which demonstrates that it is an economically viable arrangement, it does not provide the most efficient use of the prestressing force in the case of flexural members of constant section.

In large units, where the self-weight is significant, advantage can be obtained by increasing the eccentricity of the tendons within the central portion of the span. The eccentricity of a tendon is the distance from the centre of the tendon to the centre of gravity of the section. If the section of a unit is constant over its whole length, it can be readily seen that, with straight tendons, the eccentricity is constant over the length of the unit. As the effectiveness of the prestressing force is a function of the force multiplied by the eccentrici- ty, this can be increased by increasing the eccentricity for the same force. Alternatively, the same effectiveness can be achieved by using a smaller force a t a larger eccentricity. This principle is the basic criterion in post-tensioning, but can be applied to pre-tensioning if we deflect the tendons o r debond some of the tendons.

As we have tendons stretched between abutments, we can only hold down o r hold up the tendons a t points within their length, the tendons still following a straight line between these points. This is illustrated diagramatically in Figure 13.

Figure 13: Deflected tendons. The additional cost of operating and maintaining these hold-up o r hold-down mechanisms

does seem to have deterred manufacturers, although many units using this system have been made.

Debonding does not require such sophisticated equipment. It is the prestressing force at the ends of the unit which is decreased by sheathing some of the tendons in plastics tubing so that bond is prevented. The transmission length, therefore, starts a t the end of the sheathing. Figure 1 4 shows how the prestressing force is reduced a t the end of a unit.

plastics tubing

d m

I J

J I

Figure 14: Debonded tendons.

1 2 3 4

Number of tendons effective

Post-tensioning may be used in the factory production of large, special-purpose precast units, both on-site and off-site. A s previously described for pre-tensioning, the use of straight tendons is not the most efficient use of the prestressing force when it comes to large

Figure 15: End of posr-tensioned unir.

units. The maximum effective prestress is required at positions where the maximum bending moment occurs and, conversely, the minimum effective prestress where the minimum bending moment occurs. With a constant prestressing force, this can be achieved by varying the eccentricity of the force so that, at any section along a beam, the prestressing effect will counteract the loading effect.

If the tendons are within the concrete section, they will be positioned in a curved profile, so the sheathing, usually preformed circular metal ducting, has to be fixed to the required profile. This ducting has to be positioned accurately and is usually fixed to the reinforce- ment cage, which has already been set up on the mould bed. The permanent anchorage at the ends of the ducts is fixed to the end mould. Figure 15 shows a typical detail at the end of a unit using preformed ducts.

\Links lo contain bursting forces

Ducts can also be formed in the concrete unit by using removable solid or inflatable rubber formers. As these have to be withdrawn after the concrete has hardened, the permanent anchorage cannot be cast into the unit, but provision has to be made for it in the end mould.

The tendons can also be on the outside of the unit, in which case deflecting saddles are provided at appropriate places. The effect is then similar t o that obtained with deflected tendons, as described for pre-tensioning.

When preformed metal sheathing is being used, it is important to remember that grout must not be allowed to enter the duct; if it does, it has to be removed while still in a plastic state. As the sheathing will be in lengths, the joints have to be protected with tape. Even with the tendons inside the duct, there will be a tendency for the duct to float and, although it has been fixed accurately in position, it is important to remember that it also has to remain in this position during concreting.

With the moulds assembled, the concrete is placed. It is then essential that the unstres- sed units are properly cured, to avoid shrinkage cracking during the hardening process. When the concrete has achieved sufficient strength, the tendons are tensioned by anchor- ing one end of the tendon and jacking against the face of the anchorage at the other end, or by jacking at both ends simultaneously. The tendons in each duct may be tensioned individually, by attaching a single-strand or bar jack to each tendon in turn, o r simultane- ously, by attaching a multiple-wire o r strand jack to all the tendons at the same time. With post-tensioning, it is important to verify the extension in the tendon as well as the load. The movement of the tendon in the duct cannot be seen; it can only be registered by the extension of the jack. The load being applied and the extension it causes should be observed, so that any irregularities in the rate of extension for a given rate of loading will be quickly seen. If a tendon becomes 'locked' somewhere along the duct, the amount of extension will decrease indicating a fault. Remedial action can now be taken.

When the designed load has been reached, the extension is recorded and, if this has reached the calculated value, the tendon can be anchored off. The load should never be increased beyond the specified value, particularly in an attempt to achieve the required extension. Where tendons are stressed separately, the sequence should be such that those stressed first do not interfere with the movement of those stressed later. If several cables are used in separate ducts, the order of stressing specified by the engineer must be followed, as failure to do so may damage the unit.

With all tendons stressed and anchored off, the ducts are normally filled with a colloidal cement grout under pressure. The hardened grout is mainly to prevent corrosion of the

tendons, but also provides a bond between the tendons and the concrete. The amount of bond has little effect upon the behaviour of the member under normal load conditions but does affect the nature o f the cracking that would occur in the event of overloading and the factor of safety against rupture of the section.

Different stressing systems use different equipment, as will be described later. Whichever system is used, the anchorages are permanent and form part of the finished unit. These anchorages are quite expensive and, o n short units, the cost of these (together with the ducts and grouting) far outweighs the saving made in steel tendons compared with pre-tensioning.

At the ends of post-tensioned units, the tendons apply a large force through an anchor- age of relatively small area. The effect is like driving a wedge into a block of wood and, unless this 'bursting' force can be contained until it has dispersed over the section, the end of the unit will break up.

Attention has to be given to this in the design calculations and usually results in a concentration of links in these end zones. The concrete must also be of good quality and thoroughly compacted in this area, despite the congestion of reinforcement, ducts and anchorages. In some cases, the end-block may be precast, by turning it through 90" t o give better access for concreting, and subsequently incorporated in the structure during con- struction.

Materials

The concrete and the prestressing cables form two systems which may be considered in theory as externally connected, although in practice it is usually more convenient to encase the cable system within the concrete section. However, this theoretical independence enables the separate properties of the two materials to be studied.

Concrete

The design of concrete mixes and the various treatments to which they may be subjected is adequately dealt with elsewhere and does not fall within the scope of this booklet. It is sufficient here to mention some of the factors which have a direct bearing on prestressing, namely the production of high-strength concrete and the changes which take place in the material under stress.

A concrete mix for prestressed work should be workable when it is fresh and strong when it has hardened. The workability of fresh concrete is increased by increased water content and by good grading of the aggregates, whilst the strength of hardened concrete, which increases with age, is increased by a reduced waterfcement ratio and by increased compaction. These conflicting requirements have been the subject of much study and sufficient is now known for us to be able to meet these requirements and also to predict a minimum crushing strength after a specified time. This latter item is very relevant to prestressed concrete as the strength of the concrete in the member when the prestress is applied is a very important factor. This is generally referred to as the 'initial' o r 'transfer' condition.

With long-line pre-tensioning, the stress cannot be applied to the unit and hence the units removed, until the concrete has reached its specified transfer strength. So, for production purposes, it is important to know when the bed can be emptied for re-use. The stiffening and hardening of concrete is due to a chemical reaction between the cement and water in the mix. At normal temperatures, it takes several days for the concrete to develop sufficient strength. Various methods of accelerating hardening are available, internally by the use of chemical admixtures and externally by heating. O n e admixture which must never be used is calcium chloride and codes of practice prohibit its use.

External heating includes saturated steam-curing and electrical heat curing (the former being the more widely used) and the required strength can be achieved after a very short time. Strengths normally attained after 28 days may be reached after a few hours but, as a result of heating the concrete and hence the steel, there may be a loss of prestress due to the proper bond not being obtained between the heated wires and the concrete. This only applies to pre-tensioning as, even if steam-curing is applied to post-tensioned units which have the cables in, the steel will not be stressed and grouted under these conditions.

Whatever method is used for curing, there is generally, with normal cements, ashrink- age when hardening takes place. Although the majority of the shrinkage takes place early in the life of the unit, shrinkage continues t o occur for many months and this can also be affected by the exposure conditions. For example, with a humid exposure of, say, 90% relative humidity, the shrinkage is about one-third of what occurs with a normal exposure of 70% relative humidity.

Concrete is also an elastic material and, as soon as the stress is applied to the unit, the unit will shorten, thus reducing the extended length of the steel and hence the stress in it. This loss of prestress is called elasfie deformation of the concrete and is a function of the modulus of elasticity, E,, of the concrete, the modulus of elasticity, E,, of the steel, and the

stress in the concrete at the transfer condition. Although the modulus of elasticity is primarily dependent upon the crushing strength of the concrete, it is also influenced by the elastic properties of the aggregate and, to a lesser extent, the conditions of the curing and age of the concrete, the mix proportions and the type of cement. Codes of practice give values for E , related to the concrete strength, but these do not cover all cases and, if an accurate figure is required, i t should be found from tests where a stress-strain curve is obtained.

In pre-tensioned work where all the stress is applied at the same time, the greatest loss due to elastic deformation occurs. In post-tensioned work where all the stress is applied at the same time, the loss is nil since the concrete forms the anchorage and the stress in the concrete is reached by direct transfer as the steel is stressed. In post-tensioned work where the stress is applied in stages, there is a progressive loss during stressing as the member gradually shortens under progressive stressing, reducing the stress in all the steel that has been previously stressed. The loss is therefore intermediate between nil and the full amount which occurs in pre-tensioned work.

A third and very important property of concrete in connection with its use for prestres- sed structures is creep. This can be defined as the inelastic deformation due to sustained stress. Where concrete is subjected to a sustained compressive stress, it will therefore reduce in length, which again reduces the stress in the steel. It has been shown that the rate at which creep takes place is dependent upon the stress and the time for any given specimen of concrete. Thus, for a constant value of stress, the strain-time curve has a shape as shown in Figure 16, where it will be noticed that there appears to be a limiting value for strain.

Figure 16: Typical creep curve for concrete.

Steel

The steel used in prestressing work is usually in the form of cold-drawn high-tensile wires or alloy steel bars. The wires can be used singly or twisted together to form strand. At this stage, it will be useful to define the terms used for steel in prestressed concrete work.

Cable: a group of tendons.

Tendon: a stretched element used in a concrete member to impart prestress to the concrete. Tendons may consist of individual hard-drawn wires, bars or strands.

Wire: reinforcement of solid section complying with the requirements of BS 5896: 1980 and generally supplied in coil form.

Bar: reinforcement of solid section complying with the requirements of BS 4486:1980 and generally only supplied in straight lengths.

Strand a group of wires spun in helical form around a common longitudinal axis (the latter being formed by a straight wire) complying with the requirements of BS 5896:1980 for 7-wire strand.

Wire varies in diameter from 7 mm down to 3 mm, but the smallest diameter in general use for structural members is 4 mm. It can be supplied either 'as drawn' or 'straightened and stress-relieved'. In the 'as-drawn' condition, it will be in mill coils and will have a

Figure 17: Types of tendon. natural curvature approximately equivalent to the capstan of the wire-drawing machine.

A s such, it will not pay out straight. This defect can be overcome by subsequent straighten- (a) Wire

ing on site, but the manufacturer will also supply specially wound large coils from which the (h) Standard strand wire will pay out straight. This wire has been straightened by a process which involves a

stress-relieving heat treatment which induces enhanced elastic properties and leads t o (c) Drawn strand what is now designated 'relax class 1' (previously 'normal' relaxation); o r a similar ( d ) Cable of seven stress-relieving heat treatment carried out under plastic deformation, e.g, under condi- sfrands tions of longitudinal strain, which also induces high elastic properties but, in addition, (e) Div ida~ bar improves the relaxation characteristics and is now designated 'relax class 2' (previously

'low' relaxation). (f) MacaNoy bar The terms 'relax class 1' and 'relax class 2' a re applied t o strand, as well as to wire, and

relaxation is defined as the loss in stress after a period of time when a prestressing tendon is stressed to a given load under constant length and temperature conditions. It has been found that, for a given steel, the rate of relaxation is a function of the initial stress and the duration of its application. This rate decreases with time and the British Standards give a maximum relaxation after a period of 1000 hours, the loss being expressed as a percentage of the initial load. 'Relax class 2' wire or strand will have a smaller loss of stress than the 'relax class 1' wire o r strand. Codes of Practice and British Standards give guidance on how a preliminary assessment o f this loss can be made but, for an accurate assessment, details should be obtained from the manufacturers who have carried out a large number of tests on their own materials.

In order to ensure the maximum bond between the steel and concrete, it is general practice to supply the wire in a de-greased condition. In addition to de-greasing, the wire is often indented o r crimped to achieve better bond characteristics.

Concerning the mechanical properties of the steel, the latest British Standards seem to prefer using the term 'breaking load' to 'tensile strength'. Both are defined but, whereas the breaking load has one value, the tensile strength, in terms of tensile stress, can be based o n the actual area o r the nominal area of the tendon. Prestressing steel does not have a definite yield point and, in order to obtain an indication of the curvature of the load- elongation curve, the concept of a 'proof load' is used (or a 'proof stress' if the tensile stress is used). T h e proof load is defined as the load at which the applied load produces a permanent elongation equal t o a specified percentage of the gauge length. T h e British Standards use the value of 0.1% proof load, which is the value of the load on the load- elongation curve where a straight line, starting from 0.1% elongation and drawn at an angle equal to the modulus of elasticity (i.e. parallel to the elastic part of the curve) crosses the actual curve, as indicated in Figure 18.

Fi,qrirc 18: Trpictrl lor~tCrlotigtrtio,r crrr1.c. fbr .sirt111(1. A: 0 I C i proof lorrtl R: Locrcl rri I '4 rlorljiniiorl

An alternative value which can be used for treated wire and strand is to determine the load at I% elongation. This is also shown on Figure 18 and gives a slightly higher value than the 0.1% proof load. It should be noted that, as no value for the modulus of elasticity is given for 'as-drawn' wire, this alternative value is the only one which can be determined.

Prestressing strand is virtually all 7-wire strand and is available in sizes from 8 mm to 18 mm nominal diameter. Although a large range of sizes is available, manufacturers have preferred sizes and reference should be made to trade literature before choosing a size which fits the calculations. A list of organizations manufacturing wire and strand at the time ofgoing to print is given at the end of this section.

As stated in the definitions, to make seven-wire strand, six wires are helically wound to form a single layer about the straight inner core wire. If the wires were all parallel, their diameters would have to be identical to form the pattern shown in the cross-section in Figure 19a. However, as this is not the case and the sections of the outer wires in this view will be slightly elliptical, their diameters must be smaller than that of the core wire.

Figure 19: Sever!-wire srrand.

Three types of seven-wire strand are available - standard, super and drawn. All are subjected to heat treatment as for wire, and so we have 'relax class 1' and 'relax class 2'. T o reduce the percentage of voids in the cross-section of standard and super, the strand can be drawn through a die which compresses it. So, for the same 'nominal' diameter, the amount of steel is higher, thus enabling a larger force to be exerted. This type of strand is classed as 'drawn' and a cross-section is shown in Figure 19b.

Figure 20: Srarionary strand coil dispenser

Figure 20 shows a type of stationary strand coil dispenser, where the strand is pulled out from the centre. The strapped coil is placed in the frame, security rods are fastened and the straps on the coil are then cut. The strand is pulled out from the inside of the coil, and this method puts a twist into the strand. This twist must be released by rotating the strand. so protective gloves are essential.

High-tensile alloy-steel bars vary in diameter from 20 mm to 50 mm and can be smooth or ribbed. With the smooth bars, threads are rolled on at the ends which can be used for anchorage purposes or coupling together. The ribbed bars hae rolled-on ribs for the entire length and these ribs act as threads for anchorage purposes o r coupling. The required lengths for the smooth bars are therefore critical, whereas for the ribbed bars they are not. The relaxation of alloy-steel bars is now specified in the British Standard, and is between class 1 and class 2 as related to strand.

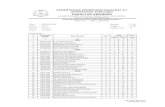

The table below gives a list of the more commonly used sizes and types of steel with the appropriate specified characteristic breaking load. As referred to earlier, prestressing steel does not have a yield strength, but a column has been added called Nominal tensile strength so that the reader can make a quick comparison with high yield bars for reinforced concrete where the yield strength is 460 N/mm2.

Nominal Speciried Nominal diameter characteristic tens~le

breaking load strength (mm) ( k N ) (N/mm21

Wire 7 60.4 1570

Strand 'Standard'

'Super'

'Drawn'

Bar Hot rolled

Processed

In the section on the history of prestressed concrete, i t was stated that high-strength steel and high-quality concrete were essential for the satisfactory performance of this type of construction. As we have just been reading, loss of prestress occurs through the inherent properties of the materials themselves. I t is convenient at this point to give a summary of losses that can occur, even though some have still to be discussed. I t should also be borne in mind that not all the losses listed occur in both pre-tensioned and post-tensioned members.

(a) Shrinkage of concrete.

(b) Elastic deformation of concrete.

(c) Creep of concrete.

(d) Relaxation of steel.

(e) Steam curing.

(0 During anchorage.

(g) Friction in the jack and anchorage.

(h) Friction in the duct

The amount of total loss of prestress cannot be given as a precise value, either for pre- tensioning or for post-tensioning. It is usually quoted as a percentage based on the force in the tendons immediately after transfer and is of the order of 20%. The losses which occur before and during transfer are of the order of 5% for post-tensioning and 10% for pre-tensioning.

I t can now be appreciated that steel capable of being highly stressed initially is a necessary requirement if a stress of sizeable magnitude is to remain in the member.

The following organizations manufacture and supply wire and strand for prestressed concrete and may be approached for further details.

Bridon Ropes Limited Bridon Wire Sales Car Hill, Doncaster, Yorkshire DN4 8DG

Johnson & Nephew (Ambergate) Limited Ambergate Wire Mills, Ambergate, Derbyshire DE56 2HE

Somerset Wire P.O. Box 56, Pengam Works, Cardiff, South Wales CF l 1RW

The following organizations supply bars for prestressed concrete and may be approached for further details.

Dywidag Systems International Limited Westfield Road, Southam, Leamington Spa, Warwickshire CV33 OJH

McCalls Special Products P.O. Box 71, Hawke Street, Shefield, South Yorkshire S9 2LN

Equipment

With pre-tensioning, the most important item of equipment consists of the temporary grips which hold the wires or strand during, and after, tensioning. The method of tension- ing may vary, but the grip today consists of a barrel and wedge, see Figure 21.

Figure 21: Grip nssembly for pre-tensioning.

The wedge is generally in two or three pieces with a collar and wire clip to keep them in the same relative position, as it is important that the wedge should be fixed around the wire o r strand and in the barrel in a concentric position, with all segments of the wedge driven the same distance into the barrel. The wedge has grooves on the surface in contact with the tendon and, although they will be used many times, they should be carefully examined each time before use.

At the fixed anchorage, the grips are forced onto unstressed tendons close to the anchor plate. At the stressing end, where individual tendons are being stressed, the grip is only placed on the unstressed tendon against the anchor plate. The jack is then positioned on the tendon and stressing begins, with the tendon being pulled through the grip. When the required load and extension have been reached, the wedge is forced onto the tendon, the stressing jack is released and, as the tendon tries to pull through the wedge, it forces the wedge onto itself and is firmly gripped. When the full length of the bed is not being used, double-ended joints as shown in Figure 22 are used; these enable precast works to join together lengths of wire o r strand and so avoid wastage.

Figure 22: Double-ended joints.

Where tendons a re stressed individually, the jacks are relatively small and generally power-operated. A popular jack in precast work is the CCL Stressomatic jack (Figure 23) which, once the controls have been set to predetermined requirements, carries out the stressing and anchoring operations automatically. This enables the stressing to be carried out quickly and efficiently.

Figure 23: CCL S~ressornatic jack.

The equipment required for post-tensioning depends upon which system is being used. There are several systems in operation in this country and these are listed in alphabetical order of the organization with the trade name of the system and the type of tendon used. Although the list .is meant to be comprehensive, it can only be so a t the time of going to print, and other systems may subsequently be formed.

Organization Svctem Tendon

Balvac Whitley Moran Limited VSL Strand (M) P.O. Box 4, Aschroft Road, Kirkby, Liverpool, Merseyside L33 7ZS

CCL Systems Limited 201 Elland Road, Leeds, West Yorkshire LSI I 8BH

Cabco Multifhrce Strandforce Llnbonded

Strand (S) Strand (M) Strand (S) Strand (S)

Dywidag Systems International Limited Dvwidag Single Bar Bar (S) Westfield Road, Southam, Leamington Spa, Warwickshire CV33 OJH

McCalls Special Products Macalloy Bar (S) P.O. Box 71 Hawke Street, Shefield, South Yorkshire S9 2LN

Multi Design Consultants Limited BBRV Wire (M) Birdhall Lane, Cheadle Heath. Stockport. Strand (S and M) Cheshire SK3 OXP

PSC Freyssinet Limited 'K' Range Strand (M) Ridgeway, Off Thorney Lane North. Iver, Monostrand Strand (S) Buckinghamshire SLO 9JE

PSR Services Limited Circular Strand (S and M) Unit 1 Dolphin Park, Ardglen Road, Evingar Trading Estate, Whitchurch, Hampshire RG28 7BB

Stronghold International Limited Stronghold Star House, Oxford Road, Stone, Aylesbury, Buckinghamshire HP17 8PL

Strand (M)

M indicates multiple stressing S indicates single stressing

Although other methods of classification could equally well be selected, a convenient one is to group the systems by the method adopted to anchor the tendons, and here we have either a threaded-nut system or a wedge system. In the first category, we have BBRV. Dividag and Macalloy. All the other systems use wedges.

A brief description of each system will now be given, but full details of any particular system can be obtained from the organization concerned. It will be seen that several of the systems have similarities.

This system is classed as a threaded-nut system as, in the lower half of the range of forces available, i t is a lock nut which bears against a steel bearing plate and transfers the compression into the concrete. In the upper half of the range of forces, the stress is transferred by means of metal chocks inserted between the stressing anchor and the bearing plate. In all cases, the basic element consists of steel cylinder with a number of machined axial holes to accommodate the separate wires. Anchoring of each wire is by means of a preformed button head and Figure 24 shows a typical example of the two types of anchorage. In the smaller anchorage, the basic element is threaded internally to receive a draw bar for jacking, and externally to receive the locking nut. In the larger anchorage, a thread is provided externally only to receive a temporary pull-sleeve, which is attached to the jack.

The button heads are formed at both ends of the wire after i t has been passed through the anchor head. The length of the cable is therefore fixed and has to be determined

Figure 24: BBRv stressing crrrdrors. accurately so that, when the cable has been tensioned, the anchor head will be in the

correct position in relation to the bearing plate. Figure 25 shows an intermediate stage in the stressing operation at the jacking end and the length of the end trumpet depends upon the extension of the scale.

Where possible the whole cable, including preformed sheathing and anchorages at both ends, is made up in the factory and then transported to site. If it is not possible to predetermine the cable length, the button heads at one end are formed on site by using a portable machine.

Although wires of other diameters can be used, 7 mm is the preferred size and the number of wires varies between 8 and 163, giving jacking forces which vary between 34 and 790 tonnes.

pull-rod

Figure 25: Inrermediare stage in stressing.

temporary pull-rod />-/-v - - temporary lock nut

lock nut

Dividag

This system uses an alloy steel bar as the tendon. Two types of bar are used, the Smoothbar and the Threadbar. For the Smoothbar the threads are cold-rolled onto the ends of the bar only, whereas the Threadbar has rolled-on deformations on two sides over its entire length. The force is transmitted to the end bearing plate by means of a nut which screws onto the ends of the bar. Figure 26 shows typical anchorages of the bell and solid-plate types.

The Smoothbar is available in diameters of 12.2, 26, 32 and 36 mm and is always stressed singly. The Threadbar is available in diameters of 15,16,26.5,32 and 36 mm, and although usually stressed singly, the 16 mm bars can be stressed in multiples of 3 to 9. Two grades of steel are offered. Prestressing forces range from 13 to 96 tonnes for single stressing and from 63 to 202 tonnes for multiple stressing. Tendons of any length can be assembled on site by means of hollow steel couplers threaded internally to receive the Smoothbar or Threadbar.

During the stressing operation, as the bar is being stretched by the jack, the anchor nut is continuously screwed down and then transfers the load to the anchorage once the jack has been released.

~ n c h o r a ~ e s for Dividag system.

Figure 27: Macalloy anchorages for four bars and one bar.

Macalloy

Macalloy prestressing is a smooth bar system with threads rolled on the ends of the bars. The force is transferred to the concrete by means of a threaded nut bearing against steel washers onto a solid steel distribution plate, see Figure 27, or a ribbed cast-iron sleeve, or by a tapped steel plate at a dead anchorage.

Bars of 20,25, 32 and 40 mm diameter are available. The bars are always stressed singly but can be arranged in cables of 1 ,2 ,3 or 4 bars, giving stressing forces ranging from 23 to 350 tonnes.

With all threaded-nut systems, the load can be applied at intervals to suit construction or design requirements, or losses can be taken up at any time prior to grouting. The anchorage is completely positive and there is no loss of prestress on transfer of the load from the jack to the nut.

Figure 28: A typical Mulriforce/C(~hco anchorage.

Figure 29: CCL Strandforce anchorage.

CCL

As can be seen from the list of manufacturers, C C L has three main systems, all of which use strand. Cabco and Multiforce use exactly the same anchorage with the strands in a circular pattern, but in the Cabco system the strands a re stressed separately whereas in the Multiforce they are stressed simultaneously. Figure 28 shows the stressing anchorage, which comprises individual wedges to grip each strand, a bearing plate to transmit the load from the strands onto the tube unit and a tube unit to transmit the load into the concrete.

The individual two-piece wedges are seated in tapered holes in the bearing plate and are similar t o earlier C C L anchorages, but the strands a re now grouped as closely as possible to the centre of the bearing plate, thus reducing its diameter and making the anchorage more compact.

Where the non-stressing end of the tendon is buried in the structure o r where there is no access to the anchorage at the time of stressing, Dead End Anchorages are available using a compression grip to terminate the strands. The compression grip is a metal sleeve which is swaged o r extruded onto the strand.

All sizes of strand from 13 mm standard to 18 mm compacted are used, giving stressing forces ranging from 5 0 to 575 tonnes, and for very large structures such a s nuclear pressure vessels, one of the systems has a stressing force of 850 tonnes.

The Strandforce system has the strands arranged linearly in one o r two rows of five, each strand being stressed separately. T h e anchorages, therefore, cater for ten o r for five strands which pass through slots and anchor directly on the anchorage faces, using barrels and wedges at the stressing end, and compression grips a t the dead end, Figure 29 shows a typical 10 strand stressing anchorage.

Figure 30: V S L stressing anchor.

In simply supported box girders with narrow webs, the tendons can be placed with the major axis vertical to obtain the maximum possible prestressing force over the narrow width. With continuous construction, pockets should be boxed out at the reverse curves and saddle plates inserted after threading to prevent the trapping of strands; 1 8 o r 19 mm diameter strand is generally used, giving forces ranging from 130 to 320 tonnes. For single-strand stressing, the Stressomatic jack is generally used, as illustrated under Pre- tensioning, but a much larger jack, known as the Multimatic, is required when multiple stressing is being carried out and this requires mechanical equipment for setting up and moving about. The strands are gripped for tensioning near the nose of the jack, thus using the minimum amount of strand for stressing. When the required load has been reached, the permanent wedges are forced into the bearing plate. A long cable can therefore be stressed in stages without moving the jack from the cable.

All the stressing jacks, including the larger ones, are equipped with accurate load-cells in order to measure directly the load applied to the tendon.

Losinger

The VSL Strand System is multiple-strand stressing in a circular pattern. All strands are stressed simultaneously and are anchored by means of wedges forced into tapered holes in the anchor head, which transmits the force to the concrete by means of a steel bearing plate. Figure 3 0 shows a typical stressing anchor.

The VSL jack has the pulling head at the end of the jack remote from the unit. When the required force has been reached, the jack pressure is released and the strands pull the wedges into the tapered holes. At the dead end, the strand can either be taken in a loop round a curved plate and led back to the stressing end o r terminated with a compression fitting bearing onto a steel plate.

In the first case the loop and curved steel plate are concreted into the unit, whereas in the second case bond can be prevented over the end length by wrapping tape around the exposed strand.

A combination of force transfers by bond and bearing is achieved with the third type, the H-anchorage, which is completely embedded in the concrete (Figure 31).

The number of strands can vary from a single 1 3 mrn diameter to fifty-five 15 mm diameter, giving forces ranging from 11 to 1150 tonnes.

PSC

As importers of the Freyssinet 12-wire system, PSC developed multiple stressing and also single stressing but have now phased out the original system of cones. All the systems now

Figure 3 1 : Dead-end anchornge.

Figure 32: PSC MonogrouplMultistrand anchorage.

Figure 33: PSC Monostrand anchorage.

Figure 34: PSC Titan jacks.

use wedges and the anchorages are identical in concept for both Monogroup and Mono- strand systems. T h e stressing anchorage consists of an iron guide which is cast into the concrete, a forged steel anchor block and three-piece wedges to anchor the strand. Figure 32 shows a MonogroupIMultistrand anchorage and Figure 33 shows a Monostrand anchorage.

T h e strands are arranged in a circular pattern and the holes in the anchor blocks are not only tapered but drilled a t an angle in relation to the tendon pattern so that kinks in the strand are avoided.

Where access to the anchorage is not available, two types of dead end anchorages are available called Blind-end in the PSC system. There is the looped anchorage, where the strand passes around a metal saddle, and there is also the swaged and capped anchorage, where ends of the strand have swaged grips for anchoring.

Various types of jack are available. For single stressing there are the Titan jacks, a s illustrated in Figure 34, and for multiple stressing there is the 'S' 'T and 'K' range. T h e S and T models, originally for the small and intermediate forces, have positions around the outside of the jack for fixing 12 strands, with various numbers of strands passing through a hole in the centre of the jack, for stressing and a T model is shown in Figure 35.

T h e K model was originally introduced for the large forces but is now available in different sizes t o cover the whole range of forces from 100 to 1400 tonnes. A s can be seen

Figure 35: PSC rype T jack

re 36: type K jack.

from Figure 36, all the strands are within the jack and are held in a temporary anchor plate I. at the end remote from the permanent anchor block.

SCD

Stressed Concrete Design Limited have two basic systems, circular and rectangular. In the circular system, the strands are arranged in a circular pattern and can be stressed individu- ally, known as Monogrip, o r stressed simultaneously, known as Multigrip. The strand is anchored in each case by means of a taper hole barrel with three-piece collet o r wedges. The distribution and bearing plate is the same for both circular systems. A typical 7-strand anchorage for 12.7, 15.2 and 1 8 mm Dyform strand is shown in Figure 37. Nineteen- strand 15.2 and 18 mm cables are also available.

The rectangular system is a development of the early Magnel-Blaton system, where the wires were held by flat wedges in a sandwich plate. The modern version is a series of triple blocks, each block having three tapered circular holes taking a standard collet t o anchor individual strands. The strands are stressed individually and Figure 3 8 shows a typical anchorage assembly where the anchorage blocks are laid horizontally and placed one on top of the other. The whole assembly can be turned through 90°, if required.

With the rectangular system, ducts can be formed with the use of extractable rubber cores o r metal sheathing. A wide range of forces is available, varying from 12 tonnes with a single 1 3 mm strand to 400 tonnes with twenty-seven 1 3 mm strands arranged in multiples of three (as shown for the 12 strand in Figure 38), which permits each strand t o be fully grouted by the use of grille separation.

Stronghold

Wires o r strands can be used and are stressed simultaneously. The anchorage consists of a trumpet of cast o r fabricated steel, together with an anchor block having tapered holes to accommodate individual wires o r strands and two-piece wedges. A t the dead end, i.e. the non-jacking end, wire tendons usually terminate with button heads, avoiding the use of wedges. Figure 3 9 shows a typical live anchorage for wire and strand.

The Stronghold jack gripr all the wires o r strands a t the same time and, having stressed them through the anchorage wedges, it then forces the wedges into the tapered holes. The tendon projection required outside the anchorage is only 200 to 300 mm, thus reducing

Figure 3 7: SCD seven-srrand anchorages.

Figure 38: SCD rectangular anchorage assembly

anchorages. 'i

wastage of steel. The forces most commonly used range from 34 t o 340 tonnes, but larger forces are available.

General

Except for the rectangular SCD Stress Block system, preformed circular metal ducts o r sheaths are used. They have to be sufficiently flexible to be bent to a radius and a t the same time strong enough t o maintain their shape when being concreted in. Although the sheathing can be made to any length, in several cases a standard length is made which means that the sections of sheathing have to be joined together. This has to be done very carefully to ensure that no mortar can get into the duct during concreting. Special couplers are available for this purpose. As the cables are usually grouted when stressing has been completed, grout or air vents have to be provided a t intervals; these are usually formed at the required positions by drilling the sheathing and attaching a plasticsgrout vent as shown in Figure 40.

Figure 40: Crour venl.

(a) Components

C -

(b) Assembled

Applications

In practice, it is generally found that for certain applications of prestressing the pre- tensioning method is preferable, whilst for others post-tensioning is more satisfactory.

The pre-tensioning method is most suitable for units of small cross-section which could not easily accommodate the comparatively bulky post-tensioning cable. The system is also well adapted to the mass production of large numbers of similar units, such as railway sleepers, floor joists, beams, floor units, poles, piles etc., when i t is found to be very economical.

It has, however, certain disadvantages which make its use more limited than that of the other method in the case of very large members. The wires are generally straight, so that the shear resistance from curved-up cables is not available; the loss of prestress is greater; the effectiveness of a given force is not so great; and so on.

The deciding factors in the use of pre-tensioning are therefore:

(1) the size of the member;

(2) the number of units required;

(3) the suitability of straight wires.

When these conditions are satisfied, units of excellent quality can be produced econom- ically, and are in fact being produced in large numbers both in this country and abroad.

Sleepers

During the 1939-45 War, it became essential to find an alternative to timber for railway sleepers and the manufacture of prestressed concrete sleepers was developed. Factories were set up to produce these units and are now highly mechanized with a low labour

Figure 41: content. Stressing beds are in the region of 135 m long and each accommodates 100 The manlrfac/ttre of prestressed concrete sleepers. Figure 41 shows a factory layout for the production and Figure 42 is a section and railway sleepers by the elevation of a sleeper. long-line process.

Figure 42: A prestressed concrete railway sleeper, showing the position of the rein forcement.

(a) End section

(b) Middle section

(c) Sectional elevation

Figure 43: Precast beams.

(a) Rectangular D = 300, 350, 400, 450, 500 or 600 mm

(b) Inverted T D = 150, 200, 250 or 300 mm

Figure 44: Floor components.

(a) Joist and infill blocks

(b) Wide slab

Roofs andfloors

Much work has been done in the manufacture of pre-tensioned flooring and roofing units. Beams, which span between columns and support structural flooring, are generally rectan- gular o r of inverted T section. The rectangular beam is the cheaper from a structural point of view, but it has the deeper downstand and can be expensive in over-all building costs. The inverted T is more expensive to produce, but gives a smaller downstand and may be more economical in the over-all building sense. Figure 4 3 gives typical arrangements and the floor components indicated can be of prestressed concrete joists and lightweight concrete infiler blocks or prestressed concrete hollow slabs. In several cases, the prestres- sed concrete units are produced by long-line pre-tensioning systems in which the concrete is extruded by machines. Figure 44 shows the smaller range of joists and infill blocks and the larger range of the slab units. For the smaller range, as used in domestic dwellings, a span of approximately 5 .8 m can be achieved with a floor component depth of 140 mm. With the larger slab unit, the span can be more than doubled for the same loading, but the depth will have to be increased to 250 mm.

In their catalogues, manufacturersstate that larger openings can be trimmed and that for smaller holes check-outs can be preformed in the factory for the slab units. What has to be remembered, however, is that the pre-tensioning long-line system is based on standard units with the minimum interference. Check-outs, recesses, changes in width all interfere with the mass production and are regarded as 'specials'. These involve additional costs, which should not be overlooked.

Various other types of hollow floor slab are available and one of the manufacturers has slabs 2700 mm wide, which reduces the number of units required but increases slightly the handling problems. Figure 45 shows concrete blocks combined with precast prestressed beams. Slab units similar to those shown diagrammatically in Figure 44 can also be used for vertical wall panels as shown in Figure 46.

Another popular type of floor unit is the double T, as is shown in Figure 47. This is most useful on long spans where depth is not restricted, as multi-storey car parks (Figure 48), or in the concourse to a racecourse grandstand (Figure 49). They can also be used vertically as wall units (Figure 50).

Beams

For buildings. Although beams were discussed under Roofs and floors, they were an

Figure 45: integral part of the floor. There are occasions, however, where a large uninterrupted floor Floor assembly. space is required in a single-storey shed type of structure. Portal frames with a pitched roof

Figure 46: Industrial 1 warehouse

nanels wall.

Figure 47: Double T.

Figure 48: Multi-srorey car park nr Rorherham.

F~gure 49 Concourse fo racecolrrse

/- -+-

ar Sandown Park.

Figure 50: Double T wall unifs used for ofice block for Norfll Tharnes Gas Board.

Figure 51: Pre-tensioned roof beams.

Figure 52: Standard bridge beams

(a ) Inverted T (showing three different positions for services)

(b ) Box

can be used, but a popular form of construction is as shown in Figure 51. Here the top of the beam has a 4" slope and the roof sheeting is supported on prestressed concrete purlins. All the concrete units are prestressed and large open spaces are easily achieved.

For bridges. There has been a big development in the bridge field, and although other standard types of beam have been developed, the most popular have been those developed by the Prestressed Concrete Development Group in co-operation with the Ministry of Transport in the early 1960s. These were the inverted T , box section and I sections as shown in Figure 52. The most popular of these was the inverted T for spans up to 16 m. Experience had shown that a slab deck was the most economical in this range and a very simple method of constructing this type of bridge was to use precast inverted T beams of prestressed concrete, with in situ concrete placed between and over the beams.

For large spans up to 36 m, the box beam and I section were required. The box beams a re placed side by side with narrow in situ joints between, whereas the I section, more widely spaced, is made composite with an in situ slab on top, thus acting as a T beam.

Figure 53: Standard bridge construction using M beams.

(a) With top and bottom slab

( b ) With top slab only b

The design assumptions used in preparing standard booklets on these beams took into account the extensive research on bridge-deck construction carried out at the research laboratories of the Cement and Concrete Association. It was logical, therefore, that in the next development the Ministry of Transport should co-operate with the C & C A. The new beams were an extension of the inverted T and were called the M beams. As can be seen from Figure 53, the beams are placed at 1 m centres and two forms of construction can be achieved, the pseudo-box and the T-beam.

In the pseudo-box, transverse reinforcement is placed through the preformed holes in the webs of the beams and covered with in situ concrete. A doubly reinforced concrete top slab is cast on permanent formwork to complete the pseudo-box. In the T-beam, only the top slap is cast. These beams cover the range of spans 15 to 29 m, but in the longer spans will require the use of deflected or debonded tendons. As explained earlier, debonding is the more popular solution at the moment.

Piles

Solid square pre-tensioned piles are cast on the long-line process; they vary from 250 mm to 450 mm square in 50 mm intervals. The use of precast piles is usually only economic in uniform ground conditions, as otherwise the work and wastage involved in the trimming of over-long piles or the delays in casting extensions render this type of pile unsuitable. But, in the right conditions, there are several advantages in using prestressed concrete driven piles. The stresses set up due to handling are significant and can be better resisted by a prestressed pile. A reduced cross-section can therefore be achieved, but this requires a greater penetration of the pile into the ground. During driving, tensile stresses in the concrete at the head of the pile are reduced by prestress and the chances of cracking the pile are minimized.

Where pile sections greater than 450 mm square are required, it may be more economi- cal to use hollow sections, which will be post-tensioned.

Figure 54: Merhod of stacking pre-rensioned units.

Handling

The handling and stacking of pre-tensioned units is of great importance and, although a manufacturer's work force will have received instructions regarding this, a contractor's staff may not. Most units are designed as single-span members, simply supported at their ends. This is how they will be used in a structure, so this is how they should be handled and stacked, unless lifting hooks have been cast in. Slings or other lifting devices should be positioned near the ends of the units. Where units are stacked, the timber spacing blocks should also be near the ends, but equally important, positioned vertically above one another. Pre-tensioned, single-span members cannot act as cantilevers, which they will try to d o if the packing pieces do not line up (Figure 54).

i Correct Incorrect

Post-tensioning is more versatile than pre-tensioning and makes more efficient use of the prestressing forces. The losses are less, and curving the cable upwards a t the supports increases the shear resistance. But it must be remembered that ducts and permanent

Figure 55: anchorages are involved. In small units the extra cost may not be worth while, but in large Portal frame for units the proportionate increase will be small. warehouse, Avonmourh.

Buildings

Mention has already been made of roof and floor beams made by pre-tensioning but, for very long spans or making the beams act as continuous members over intermediate supports, post-tensioning has to be used. For single-span members, the beam can be cast and post-tensioned on the ground, the cables grouted up and then hoisted into position. An alternative is to use smaller precast sections, either precast reinforced o r pre- tensioned, hoisted into position onto falsework, and then feed the cables through the preformed ducts, post-tension and grout. Figure 55 shows a concrete portal frame with an internal clear span of 31 m. The frame was cast in four units, erected with only an apex prop, post-tensioned and grouted, and then the apex prop was removed.

Another example is shown in Figure 56 where concrete units are prestressed together to form a concrete lattice girder. Structural frames made of reinforced precast concrete units stressed together can be not only a satisfactory structural solution but also aesthetically attractive. Figure 57 shows the external elevation of a car park where the main structural elements of precast double-diamond shaped units are post-tensioned longitudinally, forming an edge beam onto which span 16 m prestressed floor beams. The units them- selves are 3 m high by 3 m wide (Figure 58).

Figure 59 shows the use of vertical prestressing. The facades are constructed with a

F~gltre 56: series of precast concrete cruciform frames, the vertical frame members being stressed Abbolsinch Air together and tensioned as each cruciform element was erected. The horizontal members Terminal, Glasgo w. are linked by reinforced concrete edge beams.

I

Frgure 57: Unrcorn Hotel and car park, Brrstol.

Figure 58: Manufacrure of precast units for Urricorn Hole1 and car park.

Figurt Heinz Park,

: 59: Buildings, Hayes London.

Shell roofs with single o r double curvature are a further example of the versatility of post-tensioning. Shells of single curvature are essentially segments of cylinders supported by the four corners (Figure 60). In the direction of the curvature the action is that of an arch, whilst axially the action is that of a beam. The beam action tends to produce compressive stresses towards the crown and tensile stresses at the edges. In order to localize the tensile zone and increase the edge stiffness, it is usual to build edge beams into the shell which become the tension members of the structure (Figure 61). Prestressing is particularly useful for these members to take up the large tensile forces. Where several shells of similar size are required side by side, the edge beams are often dispensed with. In this case, the tensile zone occurs in the shell element itself and this can be prestressed with small cables well spaced.

Shells of double curvature can be segments of spheres o r paraboloid. With a sphere, the boundary condition needed is a centrally directed radial force in addition to the support reaction. In masonry domes, this force was generally supplied by a mass structure. Wren, in the dome of St Paul's Cathedral, used a ring chain. This is essentially the same as modern prestressing of concrete domes except, of course, that the ringing cable is initially stressed. This technique is frequently used in the Preload system, as will be described later under Reservoirs, but can also be used for covering a sportsdome, as illustrated in Figure 62.

A single elliptical paraboloid shell is shown in Figure 63. The shell covers an area of 6 9 X

39 m with a rise of 12 m from the corners to the centre. The edge beams are of in situ prestressed concrete and follow the curve of the shell with columns a t 7 .6 m centres.

Some of the most famous shells are shown in the opening section of this booklet - those of Sydney Opera House. These shells are built up of sections from spheres of the same radius- 75 m. The sections comprise precast concrete ribs of varying length glued together with epoxy resin and post-tensioned.

Figure 60: The elements of n cylindrical shell.

Figure 62: Sport.~dome, Edinburgh.

Figure 61: A cylindrical shell with edge beam.

,,, -i--

Figure 63: Smithfield Poultry - - . . . .

l _ <l . .~.

Market, London. . > . _ .

-- Figure 64: Transport Depor, London.

I

Figure 65: Medway Bridge, Kerzr (a) Under consrruction (b) Cornplered - - - - -

Large spans usingin situ construction can also be achieved a s shown in Figure 64. In this case, a saving in weight was also achieved by using lightweight concrete.

Bridges

Post-tensioning has mainly been responsible for the use of concrete in long-span bridges and elevated motorways. For spans from 10 to 60 m, prestressed beams or slabs provide a very efficient form of construction, as described under pre-tensioning. In situ construction is possible, but more flexible methods using post-tensioning are also available. The solid slab provides the maximum moment o f resistance for given depth but at the cost of using a large part of its material inefficiently. Voided slabs are used t o reduce the dead load, but in short spans the extra cost of materials involved in a solid slab can often be outweighed by the cost of labour and materials involved in forming a voided slab. Short spans of less than 10 m are not really economic for post-tensioning unless a curved plan is required, which would not easily be constructed by using straight pre-tensioned units. Beam bridges are a combination of beam and slab where, although the over-all depth will be greater than with a solid slab, the material is used much more efficiently and less prestressing force is required.

As bridge spans got longer and elevated motorways appeared o n the scene, attention was focussed on the use of box girders, either cast in situ and post-tensioned, or con- structed of smaller precast units brought t o site and stressed together.

With in situ construction, the formwork for a section is cantilevered out from the previously finished work, and the concrete is cast and allowed to harden. This section is then stressed back to the completed sections. So there is no supporting falsework and, by casting sections on opposite sides of the pier, the out-of-balance moments for stability a re kept to a minimum. The bridge therefore works out over itself until the middle is reached. T h e final stressing is now applied so that the prestress is in the correct place for its working condition. Figure 65 is a well-known example of this type of construction.

Elevated roads over ground tend to use a different method. Here a form of construction generally referred to as bay-by-bay is used. A length equal to a complete span is cast but generally starts a t approximately a quarter of the span from one support and cantilevers approximately a quarter o f the span beyond the next support. Figure 66 shows a typical example of this type of construction for an elevated road, curved in plan.

Figure 66: Chester Viaduct, Cheshire.

Figure 67: Western A venue, London.

(a) Unit being lift6 position

( b ) Completed

?d into

- -

Fiaure 68: ind don Bridge rrndtr constructron. Instead ofin situ construction, precast concrete segments can be used in exactly the same

manner. With the cantilever construction, the segments are generally cast in a factory and transported to site. A segment is lifted into position, in situ concrete placed between this segment and the previously completed work, and when this concrete has reached the required strength, prestress is applied. With the bay-by-bay construction, the required length is set up on falsework, the spaces between the units are concreted in and the completed span is stressed. Figures 67 and 68 are good examples of segmental construc- tion.

The use ofin situ concrete, either by itself o r between precast segments, does mean that stressing cannot be carried out until the concrete has reached the required strength. In Europe, a different method, using precast units, has been evolved. This system is generally referred to as counter casting and involves casting large portions of the bridge on the ground, in segments. A segment having been cast is then used as the end formwork for the next segment. This ensures an accurate lock for the concrete and ducts between the adjacent segments. A bond breaker is applied to the surface of the previously cast segment so that when the required length of the span has been cast, the individual segments can be parted quite easily and stacked.

For construction on site, a thin layer of epoxy resin is applied to the contact surfaces and stressing is then carried out immediately. The erection can therefore be much more rapid but does have its complications and has not been used to a great extent in this country. Figure 69 shows (a) the units cast on the ground prior to being separated, (b) the units being assembled into the structure.

Figure 69: Counter casting.

(a ) Units as cast on the ground

(b) Units being assembled into the structure

Reservoirs and silos