Since its establishment as Korea’s first steelmakerShip Unloader (CSU) No.6 Continuous Ship...

41

Transcript of Since its establishment as Korea’s first steelmakerShip Unloader (CSU) No.6 Continuous Ship...

2 3

First Since its establishment as Korea’s first steelmaker in 1953, Hyundai Steel Company has been at the forefront of the nation’s steel industry.

Best Hyundai Steel Company has grown into a comprehensive global steelmaker with a top-quality, globally competitive product line-up.

Last The construction of Hyundai Steel Company’s Blast Furnace No.3 is in progress, and will enable us to create value that can last.

le ad

in g

us t

o a

su st

ai na

bl e

fu tu

2010 2011 2012

Sales 10,235 15,260 14,146

Operating income margin 10.3% 8.4% 6.2%

Sales Volume (Unit: Thousand tons)

Long steel 7,400 7,581 7,357

Flat steel 4,645 8,700 8,981

Total 12,045 16,281 16,338

Q1 Q2 Q3 Q4

Operating income 156 324 227 164

% 4.4 8.4 6.7 5.0

% 5.1 5.5 7.8 8.2

% 4.3 4.8 6.8 6.7

*Consolidated, K-IFRS based

*Consolidated, K-IFRS based

Acquired CE-Mark certification for steel plates for pressure equipment directive

Sales channels in overseas markets especially in Europe are expected to scale up driven by the acquisition of the PED certification for six steel plates besides P355NL2 from Lloyd’s Register Quality Assurance(LRQA).

Held the cornerstone ceremony for fire bricks at coke plants of Blast Furnace No.3 at the Dangjin Works

A cornerstone ceremony to wish for stable construction and operation was held where writing was inscribed on fire bricks that are the cornerstones for coke plants.

Installed the blast furnace shell tier10 of Blast Furnace No.3

The last 10th row of Blast Furnace shell has been installed, and the overall BF Proper is now completed. It symbolizes the finalization of refractory installation and integration of all facilities with Blast Furnace in their center.

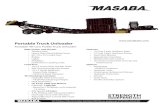

Installed Continuous Ship Unloader (CSU) No.6

Continuous Ship Unloader (CSU) No.6 was installed on the wharf of Hyundai Steel Company in Dangjin Port. The 2,650-ton machinery can load/unload iron ore of 3,500 tons/hour and coal of 2,500 tons/hour

19 JANUARY 12 APRIL 10 JULY19 APRIL

Achieved cumulative production of 20 million tons of steel making at Dangjin Works (BF No.1&2)

After the first heats on January 11, 2010, we have reached 20 million tons of cumulative production within 1,033 working days. We have established clean steel making production system through improving facility with operation.

Acquired three JIS certifications

Acquired three Japanese Industrial Standards (JIS) certifications for hot rolled mild steel plate, sheet & strip for automobile structures (JIS G3113), carbon steel for pipe & tubes (G3132), and carbon steel for machine structural use (G4051)

Blast Furnace No.3 held the cornerstone ceremony for fire bricks

We held a ceremony to wish for stable construction and operation by inscribing words on fire bricks that protect a blast furnace body from hot metal

Acquired a certification for energy management systems (ISO50001)

We acquired the ISO50001, the international standard for energy management systems from LRQA for our efforts to enhance energy efficiency and continuously save energy.

07 NOVEMBER02 AUgUSt 26 NOVEMBER 20 DECEMBER

06

08 09

In 2012, the Hyundai Motor Group continued to grow and develop despite the difficult business environment at home and abroad. Hyundai Motor and Kia Motors have now together established a global production system of 30 plants in 9 countries around the world. This enabled the production and sale of 7.12 million units, up approximately 8% over the previous year, further solidifying their positions as global car makers.

Hyundai Steel Company has contributed significantly to enhance the quality of completed cars by developing and supplying top-quality steel sheets for automobiles. Once Blast Furnace No.3, currently under construction, is completed, a blast furnace production system of 12 million tons per year will be up and running.

2013, however, is expected to be more challenging both in Korea and overseas, mainly due to the continuing financial crisis in Europe and a wider global economic downturn.

Nevertheless, we have the potential for outstanding performance, overcoming crises and hardships through an unparalleled spirit of challenge and passion. In 2013, we will further strengthen our fundamentals through qualitative growth and focus on competitiveness for the future, which will enable us to overcome these obstacles. To this end, we are committed to initiating quality-driven brand innovation.

We will do our best to fulfill our role as a model corporate citizen, contributing to the well-being of the public and the development of the national economy. In line with this, we will spearhead growth alongside our partner companies and offer our hands to the underprivileged in these times of difficulty.

2013 will see us lay the foundations of new growth by completing the construction of Blast Furnace No.3. We will make 2013 a year when we leap higher towards being a top-tier global company, achieving our dreams through change and innovation.

Hyundai Steel 2012 Annual Report Chairman’s Message

Mong-koo Chung Chairman

Hyundai Motor Group

10 11Hyundai Steel 2012 Annual Report Vice-Chairman’s Message

Dear valued shareholders and customers, I wish you good health and happiness.

2012 was a continuum of unpredictability. Amidst the global economic downturn resulting from the financial crisis in Europe, the uncertainty of overall business circumstances continued.

Nevertheless, Hyundai Steel Company strived to develop new materials and products, and successfully completed the development of high-quality steel sheets for automobiles within three years of the first operation of the blast furnace. We also tapped into new demand by developing steel for offshore structures such as thick H-beams with strong low-temperature impact resistance and steel plates for ultra-low temperature, and high-strength earthquake-resistant rebar and beams.

We improved the processes for making high-strength products, and also reduced our use of high cost ferro-alloys by developing the QST (quenching and self-tempering) technique. To raise the yield of the metal content in slags and to cut electric power requirements, we adopted dual doors for our electric arc furnaces. These measures have added to our cost- competitiveness.

As a result of efforts such as these, we achieved 16.3 million tons of sales volume, KRW 14,146 billion of financial sales and KRW 872 billion of operating income in 2012. No.3 Blast Furnace will be completed in September this year. Currently 95% of the construction has been completed, and it reaffirms the smooth process of its work.

I would like to extend my profound gratitude to shareholders for their unparalleled interest in our company and their encouragement to us to be what we are now.

In 2013, with the completion of No.3 Blast Furnace, we will become the only steelmaker with 12 million tons of production capacity in blast furnaces and 12 million tons in electric arc furnaces. At the same time, we plan to solidify our fundamentals and thus grow to become a No.1 steelmaker in the world.

The business environment for steel, however, is expected to be even gloomier this year as the global economic downturn continues, and market competition at home and abroad will be ever fiercer due to global over-supply of steel. The construction and shipbuilding companies that are our main customers are failing to come out of an abyss of sluggish growth, while growth in the auto sector is expected to slow down.

Given the economic and industrial environment at home and abroad, the steel market in 2013 is expected to see sluggish demand and over-supply, resulting in low profitability. In particular, over-supply in China and Japan will lead to a large inflow of low- priced imports, further worsening the already fierce competition.

We have, therefore, established the following management principles to focus on overcoming the crisis and responding to change in order to resolve the challenges to come.

Firstly, we will develop a 24 million-ton management system. The successful completion of No.3 Blast Furnace and getting its operation under way as early as possible will mean that we can focus on creating synergy between the Integrated Steel Mill operations and the electric arc furnaces. Moreover, we will equip ourselves internally for strong external growth. We will strengthen our human resources to build the technological prowess that will allow us to lead the market through top-grade product quality and services, and we will improve our management systems to maximize efficiency.

Secondly, we will foster differentiated competitiveness. We cannot win against our competitors if we are no different from them. We will therefore develop new products and new types of steel to meet customer needs, while finding practical ways to satisfy customers’ further needs by making sure that our business operations are market-oriented, by giving ourselves a stronger competitive edge in the non-pricing sector, and by looking for innovation in sales. We will also strive to make ourselves be cost competitive by extending the use of low-cost raw materials and the development of low-cost processes.

Thirdly, our change response systems will be solidified. We will improve our fundamentals, so that we can adapt to the changing environment faster and more flexibly. We will promote company- wide crisis management to constantly keep an eye on market changes, and to pre-emptively explore and respond to risks at a corporate level.

Based on these management principles, we have set targets of 16.7 million tons of product sales and KRW 13.4 trillion of revenues for this year.

Distinguished shareholders and customers,

This year is a significant year for us – it marks Hyundai Steel Company’s 60th anniversary and the completion of the grand history of steel industry in Korea. For last 60 years, production in electric arc furnaces led us to be a No.1 steel maker in Korea. Furthermore we hope the next 60 years will be a period of hopes and dreams by carrying out electric arc furnaces and blast furnaces together and it will lead us to be No.1 steel maker in the world. Road ahead of us could be challenging, but there is in no doubt that our advances are for a better tomorrow, so we will never cease as we show our belief in overcoming crisis and passion for challenges.

I ask for your continuing support and encouragement and I wish you and your family good health and happiness for this year.

Thank you.

12 13

Board of Directors

Hyundai Steel Company’s Board of Directors (BOD) consists of four executive directors and five outside directors. With a wealth of knowledge and experience in areas such as taxation, business administration, environment, fair trade and law, the outside directors provide the Company with operational and management advice in relation to their fields of expertise. The BOD’s primary focus is on promoting long- term shareholder value by ensuring the Company’s commitment to transparent and sound management.

Audit Committee The Audit Committee is responsible for auditing the Company’s businesses and property, reviewing the validity and appropriateness of important changes to its accounting standards, and appointing outside auditors.

Ethics Committee The Ethics Committee makes decisions regarding the Company’s ethics management. Its goal is to enable the Company to put into practice transparent management, and to develop an open and honest corporate culture.

Outside Director Candidate Recommendation Committee The Committee recommends candidates for outside directors.

Composition of Shareholders

The proportion of shares held by foreign shareholders has risen slightly year-on-year as of December 31, 2012.

Hyundai Steel Company will maximize its corporate value through sound corporate governance and transparent management. In addition, we will fulfill our obligations to all our shareholders and create the best value through responsible management, thereby growing into a respected company.

Hyundai Steel 2012 Annual Report Corporate Governance

Treasury shares

Name Position

Executive Directors

Park Seung-ha Vice-Chairman & CEO, Hyundai Steel Company

Woo Yu-cheol President & CEO, Hyundai Steel Company

Outside Directors

Chon Hyong-soo Advisor to Kim & Chang law firm (Tax Theory)

Oh Jeong-seok Professor at College of Business Administration, Seoul National University (Business Administration)

Kim Seung-do Professor at Department of Environmental and Bio Engineering, Hallym University (Environment)

Sung Nak-il Professor at School of Economics, University of Seoul (Industrial Organization)

Chung Ho-yul Professor at Law School, Sungkyunkwan University (Economic Law, Commercial Law)

Sub-Committees

The BOD operates several sub-committees to ensure an efficient decision-making process.

(As of March 31, 2013)

Name Audit Committee

Executive Directors

Chung Mong-koo

Chung Eui-sun

Park Seung-ha

Woo Yu-cheol

Outside Directors

Chon Hyong-soo

Oh Jeong-seok

Kim Seung-do

Sung Nak-il

Chung Ho-yul

Chairman Member

14 15

group Vision

Hyundai Motor Group’s vision, ‘Together for a better future’, embodies its determination to offer the highest levels of satisfaction to customers. Under this vision, the Group continues to grow in line with its status as a leading global group through ultimate sense of responsibility for its customers, realization of possibilities, and respect for humanity as a corporate citizen.

Company Vision

Hyundai Steel Company’s vision is ‘Leading the new era of steel’. We have set three strategies to fulfill this vision: maximizing customer value, expanding networks around the world, and promoting future growth strategy. Accordingly, we will strive to provide sophisticated products and services, and to achieve global competitiveness.

Synergy Creation

Hyundai Motor Group has designated steel, automobiles, and construction as its three key growth engines. Hyundai Steel Company plays an essential role in supplying steel products to the Group to fuel those engines of growth.

Hot-rolled coils produced by Hyundai Steel Company become major materials for the cars manufactured by Hyundai Motor and Kia Motors, after it is processed by Hyundai Hysco. In addition, the Company carries out joint research with Hyundai Motor, Kia Motors, and Hyundai Hysco to develop new steel sheets for automobiles, securing the very best in technology. We have thus jointly succeeded in developing new steel sheets for mass production ahead of their competitors.

Hyundai Steel Company supplies Hyundai E&C and Hyundai Amco with rebar, beams, and heavy plate. This ensures that Hyundai E&C and Hyundai Amco have a stable supply of high-quality steel products, and that Hyundai Steel Company has a loyal customer. This in turn helps to maximize the Group’s synergies.

Steel scrap generated in the car-making process and at construction sites serves as raw material for the electric arc furnace division of Hyundai Steel Company, which produces long steel. This eco-friendly resource-circulation system benefits the entire Group.

Strategy

As an eco-friendly and resource-circulation company, we will lead a new era for the steel industry by providing high value-added products and services,

and by achieving global competitiveness based on cooperation with all our customers.

Vision Statement

Vision Slogan

• Promoting new businesses in eco-friendly steel

• Enhancing the execution of resource-circulation business model

Promoting future growth strategy

• Expanding coordinative alliances

• Enhancing product portfolio

• Providing value-added services

• Improving marketing strategy

Maximizing customer value

Construction We build tomorrow

Electric Arc Furnace

Hyundai Motor Group aims to create ultimate value and promote harmonious growth for all customers through eco-friendly management and respect for mankind, with the focus on its management philosophy of ‘creating a new future through innovative thinking and pushing towards new frontiers’.

Hyundai Steel Company has been at the forefront of the steel industry in Korea. We have grown into a leading global producer of high value-added steel products, and we are now expanding our business to meet the demands of a growing world.

Company Profile | Steel Mills | Key Products | Product Innovation | Product Portfolio & Performance

1716

12 8

16,338 16,281

20 21

Company Overview

Launched under the name ‘Korea Heavy Industry Corporation’ in 1953, Hyundai Steel Company was privatized in 1962, and became a member of the Hyundai Group in 1978. In 2000, the Company seized the initiative to restructure the Korean steel industry by merging with Kangwon Industries and Sammi Steel, and moved on to achieve expotential growth. The Company joined the Hyundai Motor Group in 2001, and then acquired the Dangjin plant from Hanbo Steel in 2004. These steps turned the Company into the world’s leading electric arc furnace steel producer with works in Incheon, Pohang, and Dangjin.

The Company’s history of challenge, change and innovation also brought about the development of a fully-integrated steel mill to manufacture high-end products. It began building its first two blast furnaces at the Dangjin Works in 2006, and completed them in 2010. Their annual capacity of four million tons each helped the Company to create a high-quality flat steel supply system. The third blast furnace is scheduled for completion in September 2013, and with a production capacity of 12 million tons, the Company is now evolving into a comprehensive global steelmaker.

Through this process of steady change and growth, the Company has developed a balanced portfolio of electric arc furnaces and blast furnaces. Hyundai Steel Company’s product portfol io includes long and flat steel, and offers a top- quality, globally competitive product line-up. We will offer leadership in creating a new era of steel through change and innovation, making lives more prosperous and convenient with higher quality steel.

Hyundai Steel 2012 Annual Report Lead the Growth

Company History

Commenced operation of the reinforcing bar mill

Merged with Kangwon Industries

Acquired Sammi Steel Company

Blow-in of Blast Furnace No.1

Manufactured first HRC products from the Blast Furnace

Manufactured first heavy plate product

Completed the construction of the integrated steel mill

Commenced operation of the C-HRC mill

Blow-in of Blast Furnace No.2

Hyundai Steel Company’s 60th Anniversary

Blow-in of Blast Furnace No.3

Commenced operation of the large H-beam mill

Renamed as Hyundai Steel Company

Commenced operation of the B-HRC mill

Held groundbreaking ceremony for the integrated steel mill

Acquired the assets of Hanbo Steel’s Dangjin plant

1953 19721953 20001978 1982 2004 2005 2006 2009 2010 2011 2013(E)2001

Incorporated into the Hyundai Group

Commenced commercial production at Blast Furnace No.2

Began the construction of Blast Furnace No.3

Commenced operation of the A-HRC mill

First arrival of raw materials at the integrated steel mill

Commenced operation of coke, sinter, and heavy plates plant

22 23

Incheon Works

The pioneer of Korea’s steel industry, the Incheon Works is equipped with eco-friendly, high-efficiency facilities and the world’s largest electric arc furnace plant. It boasts purification equipment that brings in waste water and turns it into industrial-grade water through an advanced water treatment process. It also has an iron pier with two 50,000 ton berths, completed in January 2007 at the North Incheon Port, leading to substantial reductions in logistics costs.

Dangjin Works

The Dangjin works began to operate a blast furnace mill in 2010. This was a ‘first’ among domestic private companies, allowing the company to begin rewriting the history of Korean steel yet again. The site is divided into an electric arc furnace area and a blast furnace area. The former comprises a rebar mill which uses steel scrap as its raw material, and the A-HRC mill. The latter consists of Blast Furnaces No.1 and No.2, the B-HRC and C-HRC mills, and a heavy plate mill. Blast Furnace No.3 is now under construction with completion scheduled for September 2013.

Hyundai Steel Company operates global standard steel mills in Incheon, Pohang and Dangjin. In particular, the Dangjin Works is the first steel works owned by a private company in Korea to operate a blast furnace steel mill, opening a new chapter in Korea’s steel industry. The Company is now actively expanding into wider customer base.

Hyundai Steel 2012 Annual Report Lead the Growth

Size 920,000 m2

Major products

H-beams, Section beams, Rebar, Steel casting products and ingots, Stainless steel sheets

Size 7,400,000 m2

Major products Hot-rolled coil, Heavy plate, Rebar

Qingdao Works

The Qingdao Works, established in 1999, assembles and produces components for track shoe assemblies. It ranked first in China’s undercarriage market – a component for excavators – within two years of its start, becoming a pioneer for the Company in the Chinese market of potentials and opportunities.

Size 660,000 m2

Pohang Works

The Pohang Works manufactures a variety of steel products, including H-beams, rebar, round bars, and heavy equipment. It was the second steel plant in the world to succeed in developing magnetic levitation train rails. It is also the only Korean supplier of rapid transit railway rails. It leads the market for high value-added steel products with its rolling rolls and track shoe assemblies.

Size 660,000 m2

Production capacity 3.3 million tons

Major products H-beams, Rebar, Rails, Round bars, Rolls, Track shoe assemblies

01 Incheon Works, a birthplace of Korea’s steel industry

02 Dangjin Works, an integrated steel mill achieving global standards

03 Pohang Works, manufacturing a variety of steel products

04 Qingdao Works, a springboard to advance into the global market

03 04

24 25

Reinforcing Bar

Rebar is produced at the Company’s Incheon, Pohang, and Dangjin Works, and varies in size from D10mm to D57mm. It is widely used in the construction of steel and concrete reinforcing structures, nuclear power plants, and other buildings. We focus on developing custom-tailored products that enable client companies to reduce costs. In 2001, Hyundai Steel Company developed ‘Super-Bars’ with a 25% higher yield strength; these bars add to the amount of usable space in buildings and skyscrapers, and also significantly reduce construction costs.

H-Beams/Section Beams

Hyundai Steel Company produces various types and sizes of beams. We were the first company in Korea to develop H-beams, and they are one of our key products. Asymmetric H-beams, extra thickness/large- size H-beams, high-strength H-beams, and beams that can withstand extreme cold, are high value-added products that require sophisticated technology and quality control. We produce various section beams, including H-beams, angles, channels, and I-beams, and are the only company in Korea that can produce large angles as they require high-level design and rolling technology.

Heavy Machinery and Others

Hyundai Steel Company manufactures steel casting products for sterns and ingots for forged steel, and supplies them directly to shipbuilders. The Company also produces industrial-grade steel casting products for a number of uses. We are one of the major suppliers of rolls, producing various casting rolls including centrifugal casting HSS rolls and ADM rolls made with state-of-the-art materials. Hyundai Steel Company is the only company in the world where track assembly and other products for heavy machinery, such as excavators, are produced from raw materials to finished goods in the same factory.

Stainless Steel

Hyundai Steel Company’s technology has given it a global reputation for stainless steel which is very popular at the moment as an eco-friendly material because it is harmless to the body and 100% recyclable, and shuts off air pollutants. We also ensure appropriate quality levels and production capacity for customer demand in the low-nickel stainless steel market. Stainless steel is used in home appliance, transportation equipment, steel pipes, and many other products.

Hyundai Steel Company develops, produces and supplies a wide range of top quality products based on know-how built through long experience and the highest caliber of technology. By introducing customized products that meet the needs of an ever-changing world, we are leading the global steel market.

Hyundai Steel 2012 Annual Report Lead the Growth

01 02 03

Hot-Rolled Coil

HRC (Hot-Rolled Coil) is rolled into its final shape by applying very high temperatures to steel slabs which are part-finished steel products shaped like flat boards, and by pressing and expanding them to be thinned. Hyundai Steel Company is a leading supplier of HRC in Korea, with production capability begun by completing Blast Furnace No.1 at the Dangjin Works in 2010. The Dangjin Works is equipped with fully- automated facilities that guarantee the quality of its products, and has completed R&D activities for all type of steel for automobiles within two years from the operation of the blast furnace. Hyundai Steel Company can thus provide high-quality HRC for automobiles, enabling the Company to play an essential role in Hyundai Motor Group’s production. The Dangjin Works also produces HRC products used for home appliances, construction materials, machinery bodies, and oil pipelines.

Heavy Plate

With the completion of its Integrated Steel Mill, Hyundai Steel Company established complete heavy plate production from materials to parts. The Company now has fully-automated production lines to meet customer needs, and, within two years of beginning production of heavy plate, has completed the development of almost every type of heavy plate for shipbuilding. Hyundai Steel Company has won approvals for its manufacturing processes from classification bodies in various countries, and is now able to produce steel for general shipbuilding and high-strength steel through the successful development of heavy plate for use at low temperature and high-strength plate. In addition, it manufactures a wide range of high-quality heavy plate products for use in boilers, pressure vessels, welding and structural work, bridges, industrial machinery, oil pipelines, and plants.

Hyundai Steel 2012 Annual Report Lead the Growth

Products made in the blast furnaces of Hyundai Steel Company have written a new chapter in the history of the steel industry in Korea, and are highly acclaimed at home and abroad due to their outstanding quality and develop new types of steel. We will push towards a new horizon in the global steel industry by always looking to enhance product quality.

01 Blast furnace

02 Heavy plate

03 Hot-rolled coil

28 29

* The ‘World-Class Products of Korea’ designation, awarded annually by the Korean Ministry of Knowledge Economy, is given to products that rank in the top five in terms of world market share, and which also have more than 5% of the world market. They must also have an annual export value of at least USD 5 million, or their global market must be more than USD 50 million and more than twice the domestic market.

Hyundai Steel 2012 Annual Report Lead the Growth

Six of our products have earned the honor of acquiring the ‘World-Class Product’ certification*, thanks to our continuous product innovation. These include H-beams, high-speed steel rolls, steel-casting products for ship parts, inverted angles and track shoe assemblies. This shows how we apply the highest standards to all our products.

Hyundai Steel Company was the first steelmaker in Korea to produce H-beams. These are often used in beams and pillars for skyscrapers, factories and gymnasiums, thanks to their strength, shock absorbency, and the ease with which they can be welded. They are also used in apartments, shopping centers, subways, and bridges. Demand is rapidly increasing, driven by the increasing need for buildings in earthquake-prone areas to be more resistant to shocks and shaking.

H-beams Track shoe assemblies form the substructure for excavators, distributing their weight evenly and helping them maintain their grip over wet land, sand and gravel. Hyundai Steel Company has been supplying major construction and machinery companies in Korea and abroad since 1985, and now boasts a domestic market share of 75%, an Indian market share of 45%, and a Japanese market share of 10%.

track Shoe Assemblies

Inverted Angles Inverted angles minimize the weight of vessels as they become larger, and reduce the effects of shocks when vessels collide. In 1982, Hyundai Steel Company became the second company in the world to develop inverted angles, and the Company is pushing the development of high-strength steel products to be used in high value-added ships. Our inverted angles are sold to Hyundai Heavy Industries and other shipyards in Korea, Japan, and China.

High-Speed Steel (HSS) Rolls

First developed in 1993, Hyundai Steel Company’s HSS rolls received the World-Class Product certification in 2001. With enhanced abrasion and thermal resistance, HSS are mainly used to make rebar, beams, and ship parts. The Company is also developing carbide steel plate rolls. Hyundai Steel Company produces more than 20,000 tons of HSS rolls a year, 70% of which goes to the domestic market.

Sheet Piles Sheet piles are used to bear the horizontal and vertical loads created by upper-level pressure. Prior to the development of sheet piles, log piles were buried underground to prevent landslides, but they are not durable and were too weak for use with large structures, so sheet piles were developed to remedy this problem. They are widely used in permanent structures, flood control, and temporary earth-retaining structures.

Steel Casting Products for Ship Parts

Most ship structures require steel casting products, including the rudder horns that support rudders and stern bosses to hold thrusters. These require high quality control and specialist technology as they must be resistant to corrosion, vibrations, and foam under the sea. Hyundai Steel Company boasts a 40% global market share in this sector.

30 31

Hyundai Steel Company’s portfolio of world- class products enables us to stand out from our competitors in the global steel market.

Production Portfolio & Performance

2010 3,319

2011 3,163

2012 3,114

SALES VOLUME (Unit: Thousand tons)

Sales of high-strength rebar recorded 488,000 tons, up 189,000 tons year-on-year as we increased sales of value-added products such as SD500/600 rebar. We intensified our efforts to attract turn-key orders for large-scale projects, leading to a good performance with sales of 3,114,000 tons despite global economic downturn and increasing difficulties in construction.

19% Hot-rolled coil is our main product, making up 46% of total sales in 2012. Steel sheets for automobiles, a main focus for 2012, saw sales volume of 2.97 million tons, up more than 23% over the previous year. In addition, we are strengthening our competitiveness through continual product development in general hot-rolled coil products. Sales volume for hot-rolled coil as a whole increased by 327,000 to 7,560,000 tons.

46% We aimed to sell strategic products such as ultra-large track assemblies and high value-added steel castings for offshore plants in order to overcome sluggish demand for steel castings for excavators and ships. Sales volume of heavy machinery and others reached 1,095,000 tons in 2012.

We expanded the sales of 200 series and 400 series to improve profitability, and efforts are under way to explore new markets. Sales volume for stainless steel in 2012 was 89,000 tons.

7%

(Unit: Thousand tons)

H-beams, along with rebar, have been major products of Hyundai Steel Company. We sought to expand the sales of SHN and supply new products for TMC H-beams. Sales volume for SHN/large-size H-beams was 404,000 tons, up 16,000 tons over the previous year. Our focus was on securing stable profitability by serving each client company with differentiated services, and by increasing overseas orders. The sales volume of H-beams in 2012 was 3,234,000 tons.

20%

2010 3,610

2011 7,233

2012 7,560

(Unit: Thousand tons)

8% The sales volume of high-quality steel in 2012 was 244,000 tons, up 11.4% year-on-year, as we increased sales of strategic products like TMCP heat-treated steel. Efforts were made to win turn-key contracts, increase profitability, and to develop new products. In 2012, the Company sold 1,249,000 tons of heavy plate.

2010 815

2011 1,343

2012 1,249

3332

Hyundai Steel Company has become a leading global steelmaker. However, this is not enough for us – there is always room to improve, and we continue to do our utmost to achieve profitable growth and to build the foundations for future success.

Production & Sales Plan | Research & Development | Facility Enhancement | Next Step | Manufacturing Process

34

Hyundai Steel Company seeks opportunities to solidify and diversify our business. In 2012, despite challenging market conditions, as a part of our continuing efforts to drive our business forward, we continued to make investments into products and facilities, including the on-going construction of Blast Furnace No.3.

35

02 Expansion of production and sales of HRC for automobiles

03 Expansion of production and sales for high value-added products such as mega-size work rolls

03

Hyundai Steel 2012 Annual Report Power the Future

By operating its blast furnaces, Hyundai Steel Company is able to balance the production of long steel and flat steel products, and to supply high value-added products both to the construction sector and automobile and shipbuilding industries. We continue to increase sales volumes and profitability by offering competitive products and services.

Production

Long steel and flat steel products 75% and 25%, respectively, of company sales in 2009 before its blast furnaces came on-stream. Most products were supplied to the construction sector, and therefore results and earnings were strongly influenced by that sector’s successes and failures.

Blast Furnace No.1 began commercial production in April 2010, enabling flat steel sales to increase to 38.5% of the company’s total, and a matching fall in long steel to 61.5%. When Blast Furnace No.2 started commercial production in January 2011, flat steel rose to 53%, and became the main driver of sales.

The Company has accordingly focused more on the automobile and shipbuilding industries than on the construction sector, and, as a result, the volatility of revenues and profits has been significantly reduced. In addition, its product mix has diversified and solidified to meet various needs of our customers.

The Company continues to work to maximize efficiency and synergies within its long steel business and blast furnace business. Such efforts are expected to improve its profitability over the long haul.

2013 Sales Plan

Hyundai Steel Company has built an 8 million ton production system through the operation of Blast Furnaces No.1 and No.2 on top of the existing electric arc furnace business. When Blast Furnace No.3 is completed in September 2013, Hyundai Motor Group’s steel independency will be completed. Moreover, the completion of Blast Furnace No.3 will mean that sales of hot rolled steel will rise in 2014. forecast sales volume for 2013 is 16.7 million tons, with KRW 13.6 trillion in revenues. This forecast comprises 8.7 million tons from existing businesses, including the electric arc furnace business, and 8.0 million tons from the blast furnace business, with revenues from the existing businesses expected to be KRW 6.2 trillion and KRW 7.4 trillion from the blast furnaces.

Hyundai Steel Company aims to increase its sales of automotive steel, with a focus on large-scale actual demand, and will also expand sales to large construction companies in 2013. With the completion of Hyundai Hysco’s Cold Rolling Plant No.2 in May 2013, demand for automotive steel is expected to rise, which will solidify the Company’s position as a leading specialist in steel for automobiles. Sales of higher- margin steel will grow to 20% of total revenues through the sale of products such as API and earthquake- resistant steel. This effort to expand the sales of high value-added steel will help the company strengthen its profit-oriented sales structure.

In 2013, the Company will stabilize sales volumes and add to its earnings. This will be achieved through enhanced customer management, increasing sales of strategic products, and pro-active responses to market changes. Major operational strategies are as follows: first, we will secure a stable sales base by strengthening our sales network with a focus on large-scale actual demand. And we will gain an early edge in the market by responding preemptively to demand from new markets and improving our ability to cope with low-priced imports. Secondly, we will strengthen our customer relationships and enhance customer satisfaction. This will be achieved by diversifying and solidifying the communication channels with customers, and improving the competitiveness of our sales staff. Thirdly, we will maximize sales of strategic products and increase the range of high value-added steel products to lift profitability.

38 39Hyundai Steel 2012 Annual Report Power the Future

02

03

03 Development of High strength H-beam (SHN570)

01

Electric Arc Furnace

High-strength Rebar Hyundai Steel Company was the first steel company in Korea to succeed in commercializing SD600 rebar, achieving joint growth with construction companies. This product boasts a 20% higher yield strength than SD500, reducing construction costs by 10-15% by allowing for wider spacing between each rebar. With the trend towards building larger and higher buildings and strengthening earthquake-resistant designs, there is continuing higher demand for high-strength rebar.

High-strength Rebar for Nuclear Power Plants Hyundai Steel Company pioneered the development of high-strength rebar for nuclear power plants. The Company supplies high-strength rebar to domestic power plants and is initiating a push into overseas markets. Product quality and reliability have been improved through technological cooperation with entities such as the Korea Concrete Institute and Korea Hydro & Nuclear Power Co. The development of high-strength nuclear rebar is expected to allow lower rebar workloads, shorter construction periods and about 20% savings in the application of high-strength structures.

Earthquake-resistant Steel The extreme damage caused by the devastating earthquake in Japan led many countries to enact laws making the construction of earthquake-resistant buildings mandatory. This means that the need for earthquake-resistant steel has increased substantially. Hyundai Steel Company is ramping up its development of earthquake-resistant steel to meet this challenge head-on. Its efforts will also include the introduction of a quality guarantee system.

H-beams for Offshore Structures With increases in the construction of offshore plants near the North Sea and greater demand for large-scale facilities like FPOs, demand for lighter products with greater resistance to extreme climates has risen. In order to respond actively to these trends, we completed the development of S355G11, our H-beams for offshore structures. This enabled us to attract turn-key orders for both high- specification H-beams and heavy plate for a single project.

Acquisition of KEPIC Certification The Korea Electric Power Industry Code, a certification which inspects power operators, designers, manufacturers, constructors and materials makers, guarantees the quality in constructing utilities, especially nuclear power plants. In 2012, Hyundai Steel Company acquired KEPIC certification, which will enable the Company to increase sales of materials for power plant construction, thus improving corporate value and solidifying its product competitiveness.

Blast Furnace

Achievements of Collaborative R&D The Dangjin Works has become essential to Hyundai Motor Group’s value chain, as its blast furnaces ensure the timely supply of high-quality HRC. Hyundai Steel Company, Hyundai Hysco, Hyundai Motor and Kia Motors jointly established a research institute at Dangjin Works in 2007, prior to the construction of blast furnaces, to ensure a collaborative R&D system. As of the end of

Hyundai Steel Company is engaged in a myriad of R&D activities in a bid to drive sustainable growth and to lead the future of the global steel industry. To this end, we have expanded our specialist workforce and strengthened the relevant infrastructure to make sure we secure the distinctive technology we need.

40 41

2012 2013 2014 2015-2016

Specialized/ Strategic

Automobiles

• High-strength hot-rolled alloy steel (60kg, 80kg)

• Ultra high strength steel with high formability (120kg, 150kg)

• Next-generation steel (High Mn steel, etc.)

• Joint development of steel types using new technologies • Developing module testing/interpretation technologies

HRC

• Guaranteeing API low- temperature toughness (-40)

• High-alloy steel

Development of product/technology package (jointly winning large-scale project orders) • Developing customized steel • Developing extreme materials for special environments • Securing applied technologies for extreme materialsHeavy Plate

• Hull structure • Architectures and

• Application for extreme atmosphere

Hyundai Steel 2012 Annual Report Power the Future

2012, 325 researchers were taking part in the research. This has enabled the current engineering system to be put in place, through which material development takes place simultaneously with the initial design stage, thus significantly reducing development costs and time.

Through these R&D efforts, we had completed the development of basic steel types – 81 for automobiles, 122 for general HRC, and 128 for heavy plate – by 2012, and shown that we can develop and produce every type of steel demanded by the market. In 2013, we will strive to develop next-generation and proprietary steel technology such as ultra- high-strength steel sheets for automobiles and heavy plate for extreme environments. This will enable us to remain competitive in the future and brace ourselves against rapidly changing product trends.

Technological Competitiveness We cover multiple fields in R&D to build our technological skills to the highest levels. We have expanded our focus on R&D through the addition of specialists, and bolstered our research capabilities through technological training and education programs. In addition, we have built strategic alliances through technological cooperation with major companies and institutions, and product competitiveness is being built up through the securing of vital patents.

R&D Performance and Planning

Completing R&D for basic steel grade (331 grades) Coverage ratio 99%

R&D for next-generation steel grades Expanding unique steel type (leading future market)

SPECIALIzED AUtOMOtIVE HIgH-StRENgtH SHEEt

Next-generation steel sheet (light weight)

HIgH PERFORMANCE HIgH-QUALItY StEEL

High toughness HRC for earthquake-resistance

HIgH-StRENgtH HEAVY PLAt FOR ExtREME CONDItION

High strength, ultra-low temperature resistant plate for offshore structures (-60)

Sour resistant API (60kg) for line pipe

AUtO (HRC)

HEAVY PLAtE

2012 2013-2016

42 43

Streamlining Large-scale Plants

Construction took place to streamline facilities at our large plants in Incheon, enhancing productivity and the quality of large-scale H-beams, and establishing an appropriate facility for the production of H-beams for extreme climates. This has improved the production specification of larger products, thus diversifying our product portfolio. It also increased our ability to win construction orders, which enabled us to build a strong position in the market for ultra-large structures.

Increasing Facilities for the Production of Specialty Steel

We expanded our molding and fettling facilities for round steel in response to such factors as higher demand for specialty steel for automobiles and other industrial usages, reduced rebar operation of ours, and increased rebar development and production by other companies. This investment enabled us to increase the supply of specialty steel for automobiles to Hyundai Motor and Kia Motors.

Replacing with LNg Fuel

Facility construction began to replace Bunker C oil with LNG as the fuel for our rebar and H-beams plants. This is expected to raise fuel efficiency and reduce costs, while cutting greenhouse gas emissions by 31%.

Investing in Facilities for Heavy Machinery

Facility investment for heavy machinery is complete, so that we can respond to increases in demand for heavy machinery in overseas markets, including China, and particularly from the second half of 2013. With the completion of this facility investment, we now have a full heavy machinery product line-up at our Pohang Works, and can offer better quality and greater reliability to the market.

Increasing Capacity for Hot-rolled Coils

Hyundai Steel Company plans to increase facility capacity at both the B-HRC and C-HRC mills in 2013. With the completion of Blast Furnace No.3, annual production capacity of the C-HRC mill will increase by 2 million tons to 5.5 million tons, so that the Company will be able to provide high-quality HRC. In addition, a 7th stand will be added at the B-HRC mill, which will enable annual production capacity to rise to 3.25 million tons, up 250,000 tons. The additional stand will reduce roll overload and increase productivity.

Investment to boost productivity and efficiency is essential in order to accelerate growth and create a sustainable future. Hyundai Steel Company makes investments on multiple fronts in order to establish market-leading and eco-friendly facilities.

Hyundai Steel 2012 Annual Report Power the Future

The construction of Blast Furnace No.3 has seen rapid progress, and it is scheduled to be complete in September 2013. As a result, Hyundai Motor Group’s long-cherished hope of being able to go from hot metal to completed automobiles will be realized.

#1 #2

the Significance of Blast Furnace No.3

Blast Furnaces No.1 and No.2 have enabled the successful production of such high-quality steel as heavy plate for ships and HRC for automobiles. We will have a total production capacity of 12 million tons – 8.5 million tons of HRC and 3.5 million tons of heavy plate – when Blast Furnace No.3 (4 million tons of full capacity – 2 million tons of HRC and 2 million tons of heavy plate) is completed. This higher level of production and sales of HRC for automobiles will complete the value chain of Hyundai Motor Group. As well as improving stability of supply, this will ensure the stable operation of the Integrated Steel Mill, which will in turn enable us to enhance flexibility in our production.

Progress of the Blast Furnace No.3 Project

The construction of Blast Furnace No.3 began in April 2011 based on our successful construction experiences of Blast Furnaces No.1 and No.2. The construction period will be about 30 months from beginning to end, and the cost will be around KRW 3,255 billion. Commitments have already been made for the financing of the construction of Blast Furnace No.3, with loans to be extended as construction proceeds. With the additional revenues being made at Blast Furnace No.2, over 50% of financing is expected to come from internal profits. Other financing includes export credit agency loans from prestigious overseas banks, backed by guarantees from several Government agencies, as well as syndicated loans made through a consortium of Korean banks, similar to Blast Furnaces No.1 and No.2.

We are making good use of the experience and expertise we gained in constructing Blast Furnaces No.1 and No.2 in the construction of Blast Furnace No.3. This includes sourcing locally where possible, and making best possible use of existing infrastructure. Structural construction began in 2011, and we made good progress in civil engineering, building construction, and the equipment of facilities in 2012. Pilot operation and final construction at each facility will be completed in 2013, and we expect commercial production will begin within 2013, after the scheduled blow-in of No.3 Blast Furnace on September 27th, 2013. At the end of 2012, the project was 85% complete, and everything was progressing smoothly.

Investment Effects of Blast Furnace No.3

Economies of Scale With annual production capacity of 12 million tons after the completion of Blast Furnace No.3, we expect to achieve dramatic economies of scale. We will be in a stronger position to negotiate lower prices for the 30 million tons of raw materials that we will need. We also anticipate an appreciable increase in production efficiency and decrease in costs as we enhance our production capacity by 50% through the share of existing infrastructure such as piers and facilities including railway lines.

Stable Production Blast furnaces need major repairs, including the replacement of refractories, every ten to fifteen years. These repairs take approximately one to two quarters to complete, significantly reducing the operating ratio of a facility with only two furnaces. The same applies to unexpected and unscheduled interruptions to operations. As a result, many of the world’s leading steelmakers operate two or more blast furnaces.

(Unit: KRW billion)

‘11

816

‘12

1,652

‘13

787

(Unit: Thousand tons)

HSC Contribution

6,550

‘12

3,816

4,240

150

3,430

218

3,440

240

3,167

100

3,082

If three blast furnaces are in operation, a mill can theoretically maintain an operating ratio of at least 67%, and sometimes up to 70% or more through increases in transient production at other blast furnaces during renovations or in the case of emergencies. The completion of Blast Furnace No.3, therefore, will give Hyundai Steel Company a stable production system.

Market Opportunities The increasing production of Hyundai Motor and Kia Motors both at home and abroad and the continuing satisfactory performance of Korea’s heavy industry companies mean that demand for flat steel in Korea is expected to increase. The 4 million additional tons of molten metal produced by Blast Furnace No.3 will be used to make 2 million tons of HRC and 2 million tons of heavy plate. Given current and expected market conditions, we expect all of this increase will be readily absorbed by the market.

Status of No.3 Blast Furnace Construction Project

(as of March 31, 2013)

Total progress

Equipment production

95.7 98.2 100.0 92.0 99.3 97.1 90.5 82.6

Future Vision and goals

Synergy Effects between Electric Arc Furnaces and Blast Furnaces With the completion of Blast Furnace No.3, we will make a greater leap forward as a global steelmaker equipped with a balance portfolio of electric arc furnaces and blast furnaces compared to world-class global steelmakers. A robust product mix of long steel products including rebar, H beams, beams, stainless steel and heavy machinery, and flat steel products including HRC and Heavy plate will strengthen our competitiveness by catering to diverse customer needs. Synergies of electric arc furnaces and blast furnaces will lead to more efficient and cost and sales systems. This will put in place superior income and financial structures compared to competitors.

Satisfying Steel Needs of the Hyundai Motor Group We will become a steelmaking affiliate playing a pivotal role for the growth of the Hyundai Motor Group by catering to its steel needs under an ideal parent-subsidiary model. We will provide even more competitive solutions driven by the Group’s essential technologies and competency in acquiring orders – Hyundai Steel Company and Hyundai Motor Group will be able to jointly take part in large-scale projects at home and abroad. High-quality steel will be mass produced in tandem with the product and quality innovation of the Group specialized in automobiles. With the integrated steel mills specialized in automobiles, we will be able to enhance the competitiveness of Hyundai Motor and Kia Motors in developing forward-looking vehicles.

Global Leader in Steel Industry We are at the forefront of Korea’s steel industry by merging with Kangwon Industries, and acquiring Sammi Steel and Hanbo Steel, contributing to streamlining the steel industry in Korea. Such pioneering efforts will be carried one as all staff at Hyundai Steel Company will do the utmost to make the company a global leader in steel.

46 47Hyundai Steel 2012 Annual Report Power the Future

Major Process of No.3 Blast Furnace Construction Project Project period: April 2011 ~ September 2013 (30 months)

2011

2012 REFRACtORY CONStRUCtION

StRUCtURE CONStRUCtION

01

01 The construction site of Blast Furnace No.3, which was 96% complete (as of 31 March, 2013)

02 Installed the Blast furnace shell tier10 (10 July, 2013)

03 Pulverized Coal Injection facility of Blast furnace No.3 is under construction (31 March, 2013)

02 03

48 49

Hyundai Steel Company’s electric arc furnaces and blast furnaces are known for their state-of-the-art technology and high levels of efficiency.

Hyundai Steel 2012 Annual Report Power the Future

5150

Hyundai Steel Company believes that to be a truly successful company, we must also fulfill our environmental and social responsibilities. We will face tomorrow’s challenges today and lend our hands out to where they are needed.

Environmental Management | Social Responsibility | Core Values

We aim to be a good corporate citizen and to operate our business in a responsible way for the good of society and the environment. Hyundai Steel Company commits to socially responsible and green management to create long-lasting value for our stakeholders.

5352

Sustainability is fundamental to our values- based business model, and that is why we respect nature.

Jung Seung-hoon

Jeon So-young

Assistant Manager, Seoul Office

I am very proud and pleased to be a part of a team which is very talented and purpose- driven.

When I grow up, I want to be an engineer, so that I can make the world a better place to live in just like my dad does at his work.

Kim Hyun-min, Child of Kim Young-hwan

Deputy Manager, Dangin Works

Environmental Management Policies Hyundai Steel Company has put into place comprehensive environmental management guidelines, and we implement sector/stage-specific action plans. As a part of these efforts, we have strengthened environmental management both inside and outside the Company. The core elements of our environmental strategy are: establishing a system for managing and recycling resources; facilitating communication with the local community; responding to climate change; minimizing the emission of pollutants; and establishing an environmental management system. Accordingly, we set a management strategy for each core element. We also have classified our environmental management into stages – foundation, supplementation, expansion, and strengthening – and set specific goals for each.

For our enterprise-wide environmental management, we integrated the environment management system certification (ISO14001) previously divided between the Incheon, Pohang, and Dangjin Works in 2012. In 2011, we became the first in the steel industry in Korea to acquire pilot certification for our energy management system (ISO50001). We have conducted Carbon Footprint Management projects since 2009 to expand environmental management to our partner companies.

Environmental Organization To ensure more efficient and systematic environmental management, divisions at each business site and the Seoul office deal with separate functions. The Planning Division does our environmental and energy management business planning, and gives policy directions. Each site focuses on complying with the relevant laws and maintaining its facilities. Hyundai Steel R&D Center looks at how to reduce pollutants through technology, while environmental management is interlinked amongst different sectors within the company.

Hyundai Steel Company is committed to ensuring its sustainability by conducting its business in an environmentally responsible way. This is a core management policy, and, guided by this principle, we do our utmost to respect and protect the environment to achieve healthy growth.

Hyundai Steel 2012 Annual Report Lend a Hand

0302

02 Hyundai Steel Green Guardians

03 Development of HRC for electric vehicles (Blue on EV)

AMOuNT OF RECyCLE FOR SALG

(Unit: Thousand tons, As of December 31, 2012)

In-house

Better Energy Usage

We have established a target to reduce energy usage by 1.5% every year, and to save energy and maximize the recycling of waste energy in our processes, so that we can improve our energy cost competitiveness to global levels. To this end, the energy saving task force at each business site shares its energy reduction technologies and examples of energy usage improvements to ensure efficiency in energy performance.

Response to Climate Change INtERNAL SYStEM: Hyundai Steel Company has completed a GHG (greenhouse gas) inventory system to help in the implementation of the GHG & Energy Target Management System, specifying the potential for energy usage reduction in each production process in line with company-wide reduction targets. We have completed our environmental analysis for each product and at each business site, and have thus been able to set goals for lowering GHG emissions over the mid to long- term, and to develop technologies that will reduce our energy usage and curtail our GHG emissions.

VERIFIED CARBON StANDARD: In collaboration with Korea Midland Power (KOMIPO), Hyundai Steel Company has developed the VCS (Verified Carbon Standard) on the byproduct gas power plant of Hyundai Green Power within its Dangjin Works. The program uses gas byproducts from the Integrated Steel Mills instead of fossil fuels to generate power, contributing to a reduction in fossil fuel use. We will strive to reduce the output of GHG while recycling waste energy. We also continue to explore how we can reduce the emission of GHG both inside and outside the Company.

CARBON FOOtPRINt MANAgEMENt WItHIN tHE SUPPLY CHAIN: Hyundai Steel Company participated in the Large Company / Small & Medium Enterprise Carbon Partnership project from the Ministry of Knowledge Economy. Through this project, the Company supported 40 partners – raw material suppliers, scrap suppliers, and car component makers – in reducing and controlling their GHG emissions between June 2009 and May 2011. In particular, we supported the establishment of GHG management systems for their products, the creation of GHG inventory and energy management systems for their business sites, the establishment of energy management systems, the conducting of due diligence and the setting of goals for energy usage.

Energy Saving Efforts

Energy usage Targets: ENERgY USAgE tARgEtS: Beginning in 2009, our Incheon Works set and implemented targets for reducing energy usage under the Energy Usage Target Management Pilot Project of the Ministry of Knowledge Economy and the Korea Energy Management Corporation (KEMCO). Led by its energy conservation taskforce, the Incheon Works improved its processes, replaced worn-out facilities, and increased its overall operational efficiency. Our efforts led to a reduction in CO2 emissions of about 200,000 tons ahead of schedule, and were rated highly by the Ministry and KEMCO.

ENERgY MANAgEMENt SYStEM CERtIFICAtION: We take part in projects certified under ISO 50001, the international standard on energy management systems, and were the first Korean steelmaker to earn this energy management system certification, receiving global recognition.

SEOUL OFFICE INCHEON WORkS &

PRODUCtION tECHNOLOgY OFFICE

Energy Technology Team

PRODUCtION SUPPORt OFFICE

key Performance Review

Home Repairs for Hope Hyundai Steel Company runs a “Home Repairs for Hope – Enhancing Energy Efficiency in the Home” program. This improves the living conditions of low-income families, reduces CO2 emissions, and creates jobs.

Environmental Classes for Children Hyundai Steel Company offered classes on global warming and climate change to 1,000 children from Incheon, Dangjin, and Pohang. These included camps, quizzes, and environmental projects. These “Green Guardians”, children who practice environmental preservation and protection in their daily lives, go on to learn about the importance of the environment through personal experience and lectures.

Donations on New year’s Day and Chuseok (Korean Thanskgiving) On New Year’s Day and at Chuseok, Hyundai Steel Company staff delivered 3,000 gift sets to underprivileged families in the community. These included articles for the celebration of ancestral rites. The company also donated KRW 150 million worth of traditional market gift certificates to local charities.

Blood Donation Campaign The company participates in an annual blood donation drive. It offers healthcare products to every employee who participates, as a gesture of appreciation.

Sustainability Management Awards Hyundai Steel Company was incorporated in the DJSI (Dow Jones Sustainability Index) Asia-Pacific for the fourth consecutive year in 2012. Our efforts for joint growth, human resource development, and health and security were highly praised, and as a result, we ranked in the top 20% amongst the 600 companies evaluated in the Asia-Pacific region. Total of 33 Korean companies were incorporated in the Index.

Hyundai Steel Company is actively engaged in social contribution activities that aim to make a better future for everyone. We are driven ‘to contribute to people’s happiness and to create a sustainable society through eco-friendly economic activities and the active fulfillment of our social responsibilities.’

SOCIAL CONTRIBuTIONS

Education and Training

04

03 Home Repairs for Hope for low-income families

04 Volunteer work for the underprivileged

05 Junior Engineering Classes for children

60 61

We also performed well in the DJSI Korea, against which Korea’s 200 highest market capitalizations were evaluated; only 52 companies were incorporated in the Index, and we were in the top 30% of these. These sustainability awards have improved our corporate image, and we have established a number of Socially Responsible Investment funds.

CSR Committee

Hyundai Steel Company formed a Corporate Social Responsibility (CSR) Committee in April 2008. It plays a leading role in the company’s growth by ensuring that it carries out all of its legal, ethical, and social responsibilities.

Social Contributions Investments

Hyundai Steel Company’s goal is to be a sustainable, respected company that grows alongside the communities in which it operates. It encourages staff participation in a broad range of community engagement programs, and addresses the specific needs of each community and region.

In 2012, Hyundai Steel Company took part in various social contribution activities involving social welfare, culture, arts and sports, environmental protection and preservation, education and training. We strived to continue to share despite the economic challenges we face in our business. Investment into CSR in 2012 reached KRW 31,306 million, up KRW 19,089 million over the previous year.

Employee Volunteer Performance

Hyundai Steel Company encourages its staff to participate in a variety of volunteer activities, and takes these activities into consideration during staff performance reviews In 2012, the ratio of staff taking part in social contribution activities was 97%, up 15%p over the previous year, and the number of total volunteer hours continued to rise, up to 111,140 hours.

Social Contributions Investment by Sector

(Unit: KRW million)

2010 2011 2012

Culture, Arts, and Sports 3,341 3,675 5,341

Environmental Protection and Preservation 250 252 306

Education and Training 848 1,364 1,194

Total 9,440 12,217 31,306

SECREtARIAt

COMMIttEE MEMBERS

Hyundai Steel 2012 Annual Report Lend a Hand

(Unit: %)

111,140

‘12

99,496

‘10

100,008

‘11

CSR Core Values All staff at Hyundai Steel Company share and practice the core values of our corporate social responsibilities, and aim to make the world a happier place through hope and sharing. In doing so, we take the lead in creating a sustainable society.

Make efforts to quickly respond to social needs of the world

Make efforts to fulfill its social responsibilities as a corporate citizen

Make efforts to realize social values to promote human dignity and happiness

Make efforts for eco-friendly business activities and environment conservation

Work together with civil groups to build a sustainable society

CSR CORE VALuES

62 63

Guided by our core values of Challenge, Collaboration, Customers, Globality, and People, we create sustainable value for all of our stakeholders.

We respect the diversity of cultures and customs, aspire to be the world’s best at what we do, and strive to become a respected global corporate citizen.

We refuse to be complacent, embrace every opportunity for greater challenge, and are confident in achieving our goals with unwavering passion and ingenious thinking.

We believe the future of our organization lies in the hearts and capabilities of individual members, and will help them develop their potential by creating a corporate culture that respects talent.

gROUP CORE VALUES

All members of the Hyundai Motor Group must follow 5 core values of behavior and decision-making. The Group’s goal is to build a highly-creative corporate

culture based on challenge, cooperation, and respect for its customers and workers.

This goal will be reached through the sharing and internalization of its core values.

We create synergy through a sense of “togertherness” that is fostered by mutual communication and cooperation within the company and with our business partners.

We promote a customer-driven corporate culture by providing the best quality and impeccable service with all values centered on our customers.

Hyundai Steel 2012 Annual Report Lend a Hand

65

Independent Auditors’ Report 71

Consolidated Statements of Changes in Equity 75

Consolidated Statements of Cash Flows 76

Global Network 78

64

Hyundai Steel Co, Ltd. (“the Company”) is the only steelmaker in Korea to run both fully integrated steel mills and mini-mill operations. As Korea’s oldest steelmaker, the Company is a leader in mini-mill steel production in Korea, and is growing globally.

When commercial production began at its new state-of-the-art, eco-friendly integrated steel mill facilities in April 2010, the Company became one of only two integrated steel producers in Korea. It now plans to expand its integrated mill production capacity to approximately 12 million tons per year by 2014.

The Company manufactures and sells a diverse line of steel products, including reinforcing bars, H-beams, structural sections, HRC products, heavy plate, stainless steel products and other steel products for heavy machinery. These products meet a broad range of customer needs across manufacturing and other industries that consume steel, including construction, automotive, shipbuilding, home appliances, engineering and machinery industries.

Long steel products (such as reinforcing bars and H-beams) and flat steel products (such as HRC and heavy plate) constitute substantially all of the Company’s sales, accounting for approximately 47% and 53%, respectively, of the Company’s total sales volume in 2012.

Industry Overview

Due to the on-going financial crisis in Europe and sluggish economic growth in emerging countries, the growth in the steel industry that had been supported by an economic recovery from 2009 onwards came to a halt in the second half of 2011.

In 2012, the growth rate in consumption and production of steel materials was down as a result of the continuing European financial crisis, sluggish economic growth in China and inflows of low-cost steel imports. However, a slow but a gradual recovery is expected in 2013, thanks to a global economic rebound.

Demand and supply in the steel industry

(Unit: Thousand tons)

Total Demand 85,482 10.6 85,449 0.0 86,270 1.0

Domestic Demand 56,391 7.6 55,019 (2.4) 55,470 0.8

Exports 29,091 16.9 30,430 4.6 30,800 1.2

Production 72,283 9.6 72,910 0.6 74,060 1.6

Imports 23,121 (7.8) 20,766 (10.2) 20,200 (2.7)

Source: Korea Iron & Steel Association (Nov. 2012)

Steel supply and demand in korea

(Unit : Thousand tons)

Heavy Plate

Rebar

Beams

Cold-Rolled Coil*

Steel Pipes

Source: Korea Iron & Steel Association (Nov. 2012) * Excluding stainless steel

Business Highlights Due to slowing growth in the downstream industries, sales in 2012 were KRW 14,146 billion, down by 7.3% year on-year. Sales volumes rose slightly, but unit prices dropped in line with trends in the steel industry.

Hyundai Steel 2012 Annual Report Financial Review

YoY

Products Production (Thousand Tons) 16,045 16,181 (136) (0.8)

Sales Volume (Thousand Tons) 16,338 16,281 57 0.4

Sales (KRW 100 Million) 141,464 152,595 (11,131) (7.3)

Operating Income (KRW 100 Million) 8,718 12,745 (4,027) (31.6)

Earnings Rate (%) 6.2 8.4 (2.2) N/A

Net Income (KRW 100 Million) 7,964 7,471 493 6.6

EBITDA (KRW 100 Million) 15,926 19,767 (3,841) (19.4)

Results of Operations

Income Operating income in 2012 was KRW 872 billion and operating income rate was 6.2%, decrease by 2.2%p year-on-year, resulting in deteriorating the Company’s profitability. However, the Company had better profitability than most competitors globally thanks to cost reductions in raw materials, efforts to expand lower-cost production, and increasing domestic sales in the face of falling prices in overseas markets.

Net income recorded KRW 796.4 billion, up by 6.6% year-on-year, in part thanks to favorable foreign exchange rates.

(Unit: KRW billion)

Cost of Sales 12,730 13,447 (716) (5.3)

Gross Profit 1,416 1,814 (397) (21.9)

SG&A 545 539 5 1.0

Operating Income 872 1,275 (403) (31.6)

Financial Income 45 (420) 465 (110.7)

Income from Investment in Related Companies 18 25 (7) (28.0)

Other Income (4) 30 (34) (114.5)

Income Before Income Taxes 931 909 22 2.4

Income Tax Expenses 134 162 (28) (17.1)

Net Income 796 747 49 6.6

66 67

Hyundai Steel 2012 Annual Report Financial Review

Financial Condition As of the end of 2012, total assets had risen by KRW 1,175 billion, or 5.4% year-on-year, to KRW 22,951 billion. Current assets were down by KRW 1,132 billion due mainly to falls in trade receivables and inventories. However, new investments, including the construction of Blast Furnace No.3, enabled tangible assets to rise by KRW 2,276 billion.

Liabilities were KRW 13,121 billion, up by 3.7% from end-2011, as a result of a rise in corporate bonds and long-term borrowings associated with the construction of Blast Furnace No.3. Total shareholders’ equity was KRW 9,831 billion, up 7.8% from the previous year, mainly due to an increase in retained earnings of KRW 730 billion.

Liabilities went up, but equity rose more, which lowered the debt-to-equity ratio by 5.3%p to 133.5%.

Sales by Segment Sales volumes for flat steel products increased by 3.2% year-on-year thanks to stable production in the Company’s blast furnaces. Volumes for long steel, however, were down by 3.0% year-on-year due to a slowdown in demand from the construction industry, the source of most long steel demand. As a result, the total sales increased by 0.4% year-on-year.

Sales Volume

Total 16,338 16,281 57 0.4

Sales for flat steel fell by 6.3% year-on-year, and long steel was down by 8.6%, lowering total sales by 7.4%. These falls came about because of the drop in sales unit prices due to the weak steel market.

Sales

Total 14,146 15,260 (1,114) (7.3)

(Unit: KRW billion, %)

Total Shareholders’ Equity 9,831 9,119 712 7.8

Capital Stock 427 427 0 0.0

Other Contributed Capital 320 320 0 0.0

Retained Earnings 7,871 7,141 730 10.2

Other Comprehensive Income 1,231 1,248 (18) (1.4)

Treasury Stock (17) (17) 0 0.0

Total Liabilities & Shareholders’ Equity 22,951 21,777 1,175 5.4

Debt-to-Equity Ratio 134 139 (5)

Long-term borrowings rose by KRW 688 billion, but short-term borrowings decreased by KRW 520 billion.

(Unit: KRW billion, %)

Cash and Cash Equivalents 879 987 (108) (11.0)

Short-term Financial Instruments 176 447 (271) (60.7)

Total Borrowings 10,322 10,154 168 1.7

Short-Term Borrowings 3,871 4,391 (520) (11.8)

Long-Term Borrowings 6,451 5,763 688 11.9

Net Borrowings 9,268 8,721 547 6.3

EBITDA 1,593 1,977 (384) (19.4)

Net Borrowings/EBITDA 6 4 1 31.9

68 69

The first quarter saw a seasonal drop in demand and lower prices for steel products. The second quarter was more successful, with increases in sales and a drop in the unit prices of raw materials outweighing falls in product prices. In the second half of the year, shrinking demand led to weak sales prices, resulting in lower profits.

(Unit: Thousand tons, KRW billion)

Q1 Q2 Q3 Q4

Sales 3,558 3,862 3,410 3,316

Operating Income 156 324 227 164

Operating Margin (%) 4.4 8.4 6.7 5.0

7170

Future Plan Industry Outlook for 2013 Global economic growth for 2013 is forecast to hover around 2.4%, about the same as in 2012.

Demand growth for steel worldwide will continue to be sluggish in 2013. Demand volume is projected to be 1.45 billion tons, up 3.2% year-on-year; global steel production is forecast to be 1.59 billion tons, up 2.5% from the previous year.

Domestic demand for steel is forecast to continue to slow, mainly due to a delayed economic turnaround. The weak economy will negatively affect the construction market. On the other hand, the automobile industry is expected to maintain sales at the level of the previous year driven by a turnaround in exports which will counter the slowdown in domestic demand. There will be reductions in sales volumes for shipbuilding due to low prices for new ships and continuing reductions in order backlogs.

The price of iron ore, the Company’s basic raw material, is likely to drop as a consequence of the global economic slowdown, while the price of coal is expected to rise slightly driven by sustained increases in demand for coking coal.

There are some hopes for an economic boost from the installation of three new Governments in North-east Asia, such as South Korea, China and Japan. It is possible that this may help demand, adding to signs of a global economic recovery. However, the Company has remained conservative in its outlook for 2013, and has not reflected this positive geopolitical trend in its forecasts.

2013 Business Strategy Hyundai Steel Company will implement business strategies to help the Company overcome the current difficulties, and lay the foundation for sustainable growth.

First, we will build a stable profit base. This will be achieved by expanding sales of high value-added products and domestic sales, and by putting into place significant cost reductions through low-cost production and careful management.

Second, the construction of Blast Furnace No.3 will be completed on time in September 2013, and our experience with Blast Furnaces No.1 and No.2 will be used to stabilize operations in Blast Furnace No.3. Every effort will be made to make our steel mills globally competitive.

Third, we will focus on our technology and systems. We will secure the technology for the mass production of steel sheets for automobiles, develop next-generation types of steel, and establish plant-specific optimal production systems and portfolios.

Performance Outlook for 2013 Sales volumes in 2013 are forecast to hit 16.7 million tons, up 2.5% year-on-year. Sales prices are forecast to be KRW 13.4 trillion, down 5%, as the average selling price is expected to fall slightly due to surplus supply in the global steel industry.

The first and third quarters are off-seasons for the Company, while second and fourth quarters are peak seasons. Thus, the latter seasons are expected to witness a change in the sales volume of long steel products. As for flat steel products, a stable sales structure will take place compared to long steel ones throughout the year.

The Board of Directors and Stockholders Hyundai Steel Company: