SHT. NO. SHEET NAME - Barcombarcom.cc/wp-content/uploads/2017/04/AEP-V1-Structural-Plans.pdfbrick...

Transcript of SHT. NO. SHEET NAME - Barcombarcom.cc/wp-content/uploads/2017/04/AEP-V1-Structural-Plans.pdfbrick...

RTU___#

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

R

S

T

U

V

W

TYPICAL STRUCTURAL ABBREVIATIONS

WB-1

TRUSS

TYPICAL SYMBOLS LEGEND TYPICAL PLAN NOTES:

CAST IRON C.I.

APPROVED APPD.

W.I.WD.W.P.W/WDW.W.L.WBW.W.M.WPFG.WS.

PRE-ENGINEERED

WROUGHT IRONWOODWORK POINTWITHWINDOWWIND LOADWIND BRACEWELDED WIRE MESHWATERPROOFING

WATERSTOP

VERT.VERTICAL

UNLESS NOTED OTHERWISE U.N.O.

TSTR.T.O.W.T.O.S.C.T.O.S.T.R.W.T.O.P.C.T.O.P.T.O.F.T.O.B.

T & BT & GTHK.TERR.TTEMP.

TUBE STEELTREADTOP OF WALLTOP OF STRUCTURAL CONCRETETOP OF STEELTOP OF RETAINING WALLTOP OF PIER CAPTOP OF PIERTOP OF FOOTINGTOP OF BEAM

TOP AND BOTTOMTONGUE & GROOVETHICKTERRAZZOTENSIONTEMPERATURE

SUPT(S).SUBCONTR.SYM.STRUCT'L.STRUCT.STIR.STR.STIFF.STL.STD.S.F.SPEC'D.SPEC(S)SPA.SIM.SW.SHT.VSECT.SCHED.

SUPPORT(S)SUBCONTRACTORSYMMETRICALSTRUCTURALSTRUCTURESTIRRUPSSTRAIGHTSTIFFENERSTEELSTANDARDSQUARE FOOT (FEET)SPECIFIEDSPECIFICATION(S)SPACESIMILARSIDEWALKSHEETSHEARSECTIONSCHEDULE(D)

RND.RM.RF. OPNG.R.D.RF.RIS.REQ'D.RET. SYS.REQ.REM. OR RREINF.RCPR

ROUNDROOMROOF OPENINGROOF DRAINROOFRISERREQUIREDRETENTION SYSTEMREQUIREREMAINDERREINFORCE(ING) (ED) (MENT)REINFORCED CONCRETE PIPERADIUS

PROJ.PRELIM.PREFAB.

P/CP.S.I.P.S.F.PT.PL.PC.PERP.

PARTN.PAR.P

PROJECTIONPRELIMINARYPREFABRICATED

PRECAST CONCRETEPOUNDS PER SQUARE INCHPOUNDS PER SQUARE FOOTPOINTPLATEPIECEPERPENDICULAR

PARTITIONPARALLELPAN

OSTG.O.D.O.F.O.H.OPP.OPNG(S).O.C.

OUTSTANDINGOUTSIDE DIAMETEROUTSIDE FACEOPPOSITE HANDOPPOSITEOPENING(S)ON CENTER

NO. OR #N.T.S.N.I.C.N.S.NOM.N.F.

NUMBERNOT TO SCALENOT IN CONTRACTNON-SHRINKNOMINALNEAR FACE

M.C. ORMMISC.MIN.MID.MEZZ.MECH.MAX.MAT.M.O.MFR.

MOMENT CONNECTION(S)MOMENTMISCELLANEOUSMINIMUMMIDDLEMEZZANINEMECHANICALMAXIMUMMATERIALMASONRY OPENINGMANUFACTURE(R)

L.P.LLVLLHLONG.LLLWT. CONC.

LOW POINTLONG LEG VERTICALLONG LEG HORIZONTALLONGITUDINALLIVE LOADLIGHTWEIGHT CONCRETE

KSFKLFk

KIP PER SQUARE FOOTKIP PER LINEAR FOOTKIPS (1000 LBS)

JST(S).JT(S).

JOIST(S)JOINT(S)

INTERM.INT.I.F.I.D.INFO.

INTERMEDIATEINTERIORINSIDE FACEINSIDE DIAMETERINFORMATION

HK.HORIZ.

H.P.HT.H.S.

HOOKHORIZONTAL

HIGH POINTHEIGHTHEADED STUDS

GR. BM.GR.GOVT.GEN. CONTR.

G.S.G.I.GALV.GA.

GRADE BEAMGRADEGOVERNMENT

GENERAL CONTRACTORGALVANIZED STEELGALVANIZED IRONGALVANIZEDGAGE OR GAUGE

FDN.F.D.FL.FLG.FP.FIN. FL.FIN.

F.S.FABR.F. TO F.

FOUNDATIONFLOOR DRAINFLOORFLANGEFIREPROOF(ING)FINISHED FLOORFINISH(ED)

FAR SIDEFABRICATORFACE TO FACE

X-STR.EXT.EXIST.E.J.EXP.EQUIP.EQ.ENT.ENGR.ELEV.EL.ELEC.

E.W.E.F.EA.

EXTRA STRONGEXTERIOREXISTINGEXPANSION JOINTEXPANSIONEQUIPMENTEQUALENTRANCEENGINEERELEVATORELEVATIONELECTRICAL

EACH WAYEACH FACEEACH

DWL(S).DBL.DWG(S).DS.DVTL.DIM(S).DIA.DIAG.D.B.A.DLDET.

DOWEL(S)DOUBLEDRAWING(S)DOWNSPOUTDOVETAILDIMENSION(S)DIAMETERDIAGONALDEFORMED BAR ANCHORDEAD LOADDETAIL

COV. PL.COR.C.J.CONST.CT.J.CONTR.CONT.CONN(S).CMUCONC.C OR COMP.COL.CLR.CC. TO C.C.G.C.L.CLG.C.I.P.

COVER PLATECORNERCONSTRUCTION JOINTCONSTRUCTIONCONTROL JOINTCONTRACTORCONTINUOUSCONNECTION (S)CONCRETE MASONRY UNITCONCRETECOMPRESSIONCOLUMNCLEAR OR CLEARANCECHANNELCENTER TO CENTERCENTER OF GRAVITYCENTER LINECEILINGCAST-IN-PLACE

B.L.BLDG.BRDG.B.L.E.

BRACKET BRKT.BOT.B.O.BLKG.BLK.BEV ('D)BTWN.BFFBRG.BM.BSMT.B. TO B.B.F.

BUILDING LINEBUILDINGBRIDGINGBRICK LEDGE ELEVATION

BOTTOMBLOCK-OUTBLOCKINGBLOCKBEVEL (ED)BETWEENBELOW FINISH FLOORBEARINGBEAMBASEMENTBACK TO BACKBACK FACE

AHUA/C@

ARCH'L.ARCH.APPROX.

L&A.B.ALT.

AIR HANDLING UNITAIR CONDITIONERAT

ARCHITECTURALARCHITECTAPPROXIMATE

ANGLEANDANCHOR BOLTALTERNATEAGGREGATE AGGR.ADJACENT ADJ.ADDITIONAL ADDN'LABOVE FINISH FLOOR AFF

EDGE ANGLE OFFSET E.A.O.

ARCH'L. FINISH SURFACE A.F.S.

FIELD VERIFY (F.V.)

TAPERED BEAM T.B.

ARE NOT NECESSARILY USED

PENETRATION PEN.

CANTILEVER CANT.

TOP OF T.O.

TYPICAL TYP.

ALL ABBREVIATIONS SHOWN

HOLLOW STRUCTURAL SHAPE HSS

BUILDING MANUFACTURER PEBMPRE-ENGINEEREDMETAL BUILDING PEMB

TYPICAL ABBREVIATIONS, SYMBOLS AND PLAN NOTES

A.F.S.

INDICATES TRUSS - SEE TRUSS ELEVATIONS.

INDICATES THAT COLUMN STOPS AT THIS LEVEL.

INDICATES THAT COLUMN STARTS UPWARD FROM THIS LEVEL.

INDICATES WIND BRACE - SEE WIND BRACE ELEVATIONS.

CAST-IN-PLACE CONCRETE

STRUCTURAL PRECAST CONCRETE

SAND GRAVEL, OR LOW P.I. FILL

EARTH

ROCK

ARCHITECTURAL PRECAST CONCRETE

NON-SHRINK GROUT

SAND CEMENT GROUT

C.M.U.

EXISTING

STRUCTURAL STEEL

ARCHITECTURAL FINISHED SURFACE

5. SEE ARCH'L. DWGS. FOR SIZES & LOCATIONS OF ROOF OPENINGS.

6. REPETITIVE MEMBERS SUCH AS PURLINS SHALL BE EQUALLY SPACED BETWEEN DIMENSIONEDPOINTS, U.N.O.

CENTERLINE OF PIERS NOT SPECIFICALLY LOCATED ON PLAN BY NOTE OR DIMENSION SHALL BELOCATED ACCORDING TO THE FOLLOWING INFORMATION, U.N.O.:

A. FREESTANDING COLUMNS: CENTERLINE OF THE COLUMN

B. GRADE BEAMS AND WALLS: CENTERLINE OF THE GRADE BEAM OR WALL IN ONE DIRECTION,GRID OR AS NOTED IN THE OTHER DIRECTION. AT CORNER CONDITIONS, CENTERLINES OFINTERSECTING GRADE BEAMS OR WALLS.

C. COLUMNS EMBEDDED IN GRADE BEAMS OR WALLS (PILASTERS): CENTERLINE OF THE COLUMN

4.

STEEL COLUMN SIZE, SEE PLAN

BASE PLATE TYPE, SEE SCHEDULE

PIER TYPE, SEE PIER SCHEDULE

TOP OF PIER DETAIL

HSS6X6X1/4, BP-1

P1, 4/S302

7.

OF MATERIALS AND CONSTRUCTION.

FIELD VERIFY ALL EXISTING DIMENSIONS & ELEVATIONS PRIOR TO FABRICATION

NOTE TO CONTRACTOR:

ROOF TOP MECHANICAL UNIT ON PLAN

INDICATES MOMENT CONNECTION -SEE MOMENT CONNECTION DETAILS.

INDICATES STEEL BEAM SPLICE -SEE STRUCTURAL STEEL SIMPLE BEAM CONNECTION DETAILS S501 & S501A.

INDICATES STRUCTURE OVER VOID -SEE EXPANSIVE CLAY SOIL DETAILS S301.

STRUCTURAL SYMBOLSTHE FOLLOWING SYMBOLS ARE USED TO REPRESENT THE MATERIALS SHOWN ON THESTRUCTURAL DRAWINGS. SEE SPECIFICATIONS AND GENERAL NOTES FOR MATERIALQUALITIES REQUIRED.

1. SEE ARCHITECTURAL DRAWINGS FOR ACTUAL SEA LEVEL ELEVATION RELATED TO DATUM ELEVATION =100'-0" SHOWN ON DRAWINGS.

- SEE PLAN FOR TOP OF STRUCTURAL CONCRETE (T.O.S.C.) ELEVATION.- T.O.S. EL. = BOTTOM OF METAL DECK ELEVATION SEE PLAN FOR TOP OF STEEL (T.O.S.) ELEVATION.

2. SHEET INDEX:THE DETAILS IN THE DRAWINGS, INCLUDING THOSE DRAWINGS REFERENCED BY THIS INDEX, WHICH AREDESIGNATED AS "TYPICAL DETAILS", APPLY GENERALLY TO THE CONSTRUCTION IN ALL AREAS WHERETHE CONDITIONS ARE SIMILAR TO THOSE DESCRIBED IN THE DETAILS, REGARDLESS OF WHETHER OR NOTTHE DETAILS ARE SPECIFICALLY REFERENCED IN THE DRAWINGS.

3. SEE ARCHITECTURAL DRAWINGS FOR LOCATION OF FLOOR DROPS, FLOOR SLOPES, CURBS, MISCELLANEOUS ELEVATIONS, DETAILS AND DIMENSIONS NOT SHOWN ON PLAN.

G.C.

STYROFOAM

THE FOLLOWING GENERAL NOTES CONSTITUTE A MAJOR PART OF THE PLANS AND SPECIFICATIONS. STRICTCOMPLIANCE WITH THESE NOTES IS ESSENTIAL TO THE PROPER CONSTRUCTION OF THE BUILDING.

1. REFER TO THE PLAN NOTES, LOCATED IN THESE GENERAL NOTES, FOR APPLICATION OF DETAILS WHICH AREDESIGNATED AS "TYPICAL DETAILS" IN THIS SET OF DRAWINGS.

2. SLEEVES AND BLOCKOUTS REQUIRED FOR PASSAGE OF DUCTWORK, PIPING, DRAINS, CONDUIT, ETC., ANDANCHORS REQUIRED FOR ANCHORING EQUIPMENT AND PIPING ARE NOT GENERALLY INDICATED ON THESTRUCTURAL DRAWINGS. THE CONTRACTOR SHALL DETERMINE SUCH REQUIREMENTS FROM OTHER SERIESDRAWINGS, SUBCONTRACTORS, AND SUPPLIERS AND SHALL COORDINATE THE LOCATIONS AND DETAILS FORTHESE ITEMS PRIOR TO FABRICATION OR CONSTRUCTION OF THE STRUCTURE. ANY CONFLICTS BETWEEN THESE ITEMS AND THE BUILDING STRUCTURE SHALL BE BROUGHT TO THE ATTENTION OF THE ARCHITECT FORRESOLUTION.

3. VERIFY, OR ESTABLISH, LOCATIONS AND DIMENSIONS OF ALL FRAMED OPENINGS RELATED TO EQUIPMENT ORDUCTWORK, INCLUDING INSULATION, IF ANY. WHERE SUBSTANTIAL RELOCATION OR RECONFIGURATION ISREQUIRED, SUBMIT A DRAWING TO THE ARCHITECT FOR REVIEW.

4. LOCATE EXISTING REINFORCEMENT, USING APPROPRIATE IMAGING EQUIPMENT, PRIOR TO CUTTING OR DRILLINGINTO EXISTING CONCRETE. DO NOT CUT OR DAMAGE EXISTING REINFORCEMENT. IF THE REQUIRED OPERATIONSMAKE DAMAGING EXISTING REINFORCING UNAVOIDABLE, INFORM ARCHITECT SO THAT THE CONDITION MAY BEEVALUATED AND ALTERNATIVE DIRECTIONS GIVEN.

5. MATERIALS OR PRODUCTS SUBMITTED FOR APPROVAL WHICH ARE NOT AS SPECIFIED IN THE DOCUMENTS SHALLBE ACCOMPANIED BY A CURRENT ES REPORT (BY ICC EVALUATION SERVICE, INC.) OR ICBO REPORT (BYINTERNATIONAL CONFERENCE OF BUILDING OFFICIALS). MATERIALS OR PRODUCTS THAT DO NOT HAVE AN ES ORICBO REPORT INDICATING THE SUBSTITUTED MATERIAL OR PRODUCT TO BE EQUAL TO THAT SPECIFIED, WILL NOTBE CONSIDERED.

GENERAL

1. ALL REQUESTS FOR SUBSTITUTIONS OF MATERIALS OR DETAILS SHOWN IN THE CONTRACT DOCUMENTS SHALL BESUBMITTED FOR APPROVAL DURING THE BIDDING PERIOD. ONCE BIDS ARE ACCEPTED, PROPOSED SUBSTITUTIONSWILL BE CONSIDERED ONLY WHEN THEY ARE OFFICIALLY SUBMITTED WITH AN IDENTIFIED SAVINGS TO BEDEDUCTED FROM THE CONTRACT.

SUBSTITUTIONS

DESIGN LOADS1. DEAD LOADS INCLUDE THE WEIGHT OF THE STRUCTURAL COMPONENTS AND ALLOWANCES FOR

PERMANENT PARTITIONS, PERMANENT FIXTURES, FINISHES, ROOFING, MECHANICAL, ELECTRICAL,PLUMBING AND FIRE PROTECTION MATERIALS SHOWN OR SPECIFIED.

2. LOADINGS FOR MECHANICAL ROOMS ARE BASED ON THE WEIGHTS OF ASSUMED EQUIPMENT, ASINDICATED ON THE MECHANICAL DRAWINGS (INCLUDING THE WEIGHT OF CONCRETE PADS, WHEREINDICATED). ANY CHANGES IN TYPE, SIZE, LOCATION OR NUMBER OF PIECES OF EQUIPMENT SHALL BE REPORTED TO THE ARCHITECT FOR VERIFICATION OF THE ADEQUACY OF SUPPORTING MEMBERS PRIOR TO THE PLACEMENT OF SUCH EQUIPMENT.

3. DESIGN LIVE LOADING IS AS FOLLOWS:ROOF ...................................................................................................................................................... 20 PSFALL SLABS-ON-GRADE, U.N.O....................................................................................................................100 PSFSTORAGE (LIGHT).................................................................................................................................. 125 PSFSTORAGE (HEAVY)............................................................................................................................... 250 PSFMECHANICAL ROOM (MIN.).................................................................................................................... 150 PSFLINE TRUCK STORAGE AND REPAIR AREAS................................................................................................250 PSFTRUCK LOADING (AASHTO).................................................................................................................. HS-20

4. LIVE LOAD REDUCTIONS, WHERE PERMISSIBLE, ARE COMPUTED IN ACCORDANCE WITH THE BUILDING CODE.

5. THIS BUILDING HAS BEEN DESIGNATED BY THE OWNER AS AN ESSENTIAL FACILITY AND IS DESIGNED TO MEET THERECOMMENDATIONS OF ICC 500-2014 AND ASCE 7-10. LOADING AND CONTROLLING CONDITIONS AREA ASFOLLOWS (NOTE: PER ASCE 7-10, WIND LOADS ARE ULTIMATE. SERVICE LOADS MAY BE OBTAINED BY DIVIDINGTHE STATED LOADS BY 1.6.):

MAIN WIND FORCE RESISTING SYSTEM:WIND DESIGN OPTION..................................................................................................... DIRECTIONAL PROCEDUREBASIC WIND SPEED (3-SECOND GUST)............................................................................................ 185 MPHRISK CATEGORY............................................................................................................................... IIINOMINAL WIND SPEED (SERVICE)............................................................................................ 146 MPHEXPOSURE CATEGORY..................................................................................................................... CENCLOSURE................................................................................................................................. ENCLOSEDINTERNAL PRESSURE COEFFICIENT.................................................................................................0.18

COMPONENTS AND CLADDING:WIND DESIGN OPTION..................................................................................................... DIRECTIONAL PROCEDUREBASIC WIND SPEED (3-SECOND GUST)............................................................................................ 165 MPHRISK CATEGORY............................................................................................................................... IIINOMINAL WIND SPEED (SERVICE)............................................................................................ 131 MPHEXPOSURE CATEGORY..................................................................................................................... CENCLOSURE....................................................................................................................... PARTIALLY ENCLOSEDINTERNAL PRESSURE COEFFICIENT.................................................................................................0.55

ROOF PRESSURE(+)/ SUCTION(-) LOADS (NET – INCLUDING INTERNAL PRESSURE – LOADS MAY BELINEARLY INTERPOLATED BETWEEN VALUES FOR THE GIVEN TRIBUTARY AREAS)

INTERIOR ZONES – MORE THAN 14’ FROM EDGE, HIP, OR RIDGE (ZONE 1) (10 SQ.FT. OF TRIBUTARY AREA)................................ +15.53 / -38.17 PSF

(100 SQ.FT. OF TRIBUTARY AREA).............................. +12.29 / -34.94 PSF END ZONES - WITHIN 14’ OF EDGE, HIP, OR RIDGE (ZONE 2)

(10 SQ.FT. OF TRIBUTARY AREA)................................. +15.53 / -64.05 PSF(100 SQ.FT. OF TRIBUTARY AREA)............................... +12.29 / -41.41 PSF

CORNER ZONES - WHERE ZONE 2 AREAS OVERLAP (ZONE 3)(10 SQ.FT. OF TRIBUTARY AREA)................................. +15.53 / -96.40 PSF

(100 SQ.FT. OF TRIBUTARY AREA)............................... +12.29 / -41.41 PSF ON CANOPIES AND OVERHANGS ENDS (ZONE 2) (10 SQ.FT. OF TRIBUTARY AREA).....................+18.76 / -54.99 PSF

(100 SQ.FT. OF TRIBUTARY AREA)............................... +12.29 / -51.76 PSF CORNERS (ZONE 3)(10 SQ.FT. OF TRIBUTARY AREA)................................. +18.76 / -90.58 PSF

(100 SQ.FT. OF TRIBUTARY AREA)............................... +12.29 / -25.88 PSFCURTAINWALL DESIGN PRESSURE/SUCTION

INTERIOR ZONE (ZONE 4)(10 SQ.FT. OF TRIBUTARY AREA)................................. +34.94 / -37.85 PSF(100 SQ.FT. OF TRIBUTARY AREA)............................... +26.20 / -29.11 PSF

EXTERIOR ZONE (ZONE 5) (10 SQ.FT. OF TRIBUTARY AREA)................................ +34.94 / -46.58 PSF(100 SQ.FT. OF TRIBUTARY AREA).............................. +26.20 / -29.11 PSF

RELIABLE ROOF DEAD LOAD TO RESIST UPLIFT (SERVICE)8..8888888888888888860 PSFINTERIOR PRESSURE ON STRUCTURAL ELEMENTS............................................................................. 5 PSF

6. SEISMIC DESIGN DATA (IBC):RISK CATEGORY.............................................................................................................. IIIMAPPED SPECTRAL RESPONSE ACCELERATIONS, SS & S1..........................................0.064 / 0.021SITE CLASS...................................................................................................................... CSPECTRAL RESPONSE COEFFICIENTS SDS /SD1............................................................0.051 / 0.023SEISMIC DESIGN CATEGORY........................................................................................... ABASIC SEISMIC-FORCE-RESISTING SYSTEM....................................... ORDINARY CONCRETE

SHEAR WALLSDESIGN BASE SHEAR....................................................................................................... 215KSEISMIC RESPONSE COEFFICIENT, CS.............................................................................0.010RESPONSE MODIFICATION FACTOR, R............................................................................1.5ANALYSIS PROCEDURE USED........................................................... EQUIVALENT LATERAL FORCEDEFLECTION AMPLIFICATION FACTOR.............................................................................3

7. SNOW LOADING (ASCE 7, SECTION 7):GROUND SNOW LOAD..................................................................................................... 0 PSF

8. STACKS OF MATERIALS OR OTHER CONSTRUCTION LOADS PLACED ON THE STRUCTURE SHALL NOT EXCEEDTHE STATED DESIGN LIVE LOAD FOR THE AREA AFFECTED UNLESS ADEQUATELY SHORED.

© 2

016 M

oody/

Nola

n I

nc.

Dwg. Coord.: Tech. Coord.:

5001 Spring Valley RoadSuite 225EDallas, TX 75244

Phone: (214) 377-8662

KEY PLAN

A B

C

PORTIONS OF THIS DRAWING MAY NOT BE TO SCALE. THEREFORE, THIS DRAWING SHALL NOT BE SCALED. COPYRIGHT © 2017 DATUM ENGINEERS, INC.

Datum Engineers IncorporatedWWW.DATUMENGINEERS.COM | CO REG. NO. F-2819

Datum Project No.

Dallas San Antonio214-358-0174 210-858-2869

Austin512-469-9490

4/2

6/2

017 9

:01:5

2 A

MC

:\U

sers

\kelly

.DA

TU

M\D

ocu

ments

\Revit

2016 L

oca

l\16146 A

EP

Corp

us C

hristi

- S

truct

_kt

hib

odeaux.r

vt

16578

04-25-17

CORPUS CHRISTI

AMERICAN ELECTRICPOWER

Author Checker

BIDDING AND PERMIT DOCUMENTS

ABREVIATIONS, SYMBOLS &GENERAL NOTES

S101

16146

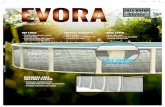

SHEET LISTSHT. NO. SHEET NAME

S101 ABREVIATIONS, SYMBOLS & GENERAL NOTES

S102 GENERAL NOTES

S103 GENERAL NOTES

S201 OVERALL FOUNDATION FRAMING PLAN

S201A FOUNDATION FRAMING PLAN - AREA A

S201B FOUNDATION FRAMING PLAN - AREA B

S201C FOUNDATION FRAMING PLAN - AREA C

S202 PARTIAL PLANS

S203 OVERALL ROOF PLAN

S203A ROOF FRAMING PLAN - AREA A

S203B ROOF FRAMING PLAN - AREA B

S203C ROOF FRAMING PLAN - AREA C

S204 SITE STRUCTURES

S301 EXPANSIVE CLAY SOIL DETAILS

S302 BELLED PIERS

S303 SLAB-ON-GRADE TYPICAL DETAILS

S304 TYPICAL FOUNDATION DETAILS

S305 FOUNDATION DETAILS

S401 LOAD-BEARING MASONRY TYPICAL DETAILS

S402 PEMB DETAILS

S501 SIMPLE BEAM CONNECTION DETAILS

S501A SIMPLE BEAM CONNECTION DETAILS

S502 COMPOSITE STEEL BEAM DETAILS

S502A COMPOSITE STEEL BEAM DETAILS

S503 TYPICAL STEEL COLUMN & BEAM DETAILS

S504 STEEL SECTIONS & DETAILS

S505 CANOPY STEEL SECTIONS

S601 TILT-WALL ELEVATIONS

S602 TILT-WALL ELEVATIONS

S603 TILT-WALL ELEVATIONS

S604 TILT-WALL ELEVATIONS

S605 TILT-WALL DETAILS

S701 WIND BRACE ELEVATIONS & DETAILS

# DATE CHANGE DESCRIPTION

04/27/17

1. BUILDING CODE: INTERNATIONAL BUILDING CODE 2012.

2. STRUCTURAL STEEL: AISC 360-10 "SPECIFICATIONS FOR STRUCTURAL STEEL BUILDINGS" AND AISC 341-10"SEISMIC PROVISIONS FOR STRUCTURAL STEEL BUILDINGS."

3. STRUCTURAL CONCRETE: "BUILDING CODE REQUIREMENTS FOR REINFORCED CONCRETE (ACI 318-11),"THE AMERICAN CONCRETE INSTITUTE.

CODES & DESIGN SPECIFICATIONS

1. THE STRUCTURAL SYSTEM AND CONSTRUCTION DETAILS ARE DESIGNED TO COMPLY WITH THE REQUIREMENTS OF THE FOLLOWING:ROOF ASSEMBLY: 1 HOURSSTRUCTURAL FRAME: 3 HOURSEXTERIOR BEARING WALLS: 4 HOURSINTERIOR BEARING WALLS: 4 HOURS

2. STRUCTURAL FRAME CONSISTS OF COLUMNS AND MEMBERS FRAMING INTO COLUMNS, INCLUDING GIRDERS, BEAMS, TILT-WALLS AND BRACING.

3. THE STRUCTURAL ROOF FRAMING IS CONSIDERED TO BE "RESTRAINED" IN ACCORDANCE WITH THE U.L."FIRE RESISTANCE DIRECTORY," FOR PURPOSES OF ESTABLISHING THE FIRE RESISTANCE RATING.

4. STEEL BEAMS WHICH ARE LIGHTER THAN THE MINIMUM SIZE SET FORTH IN THE REFERENCED U.L.ASSEMBLY SHALL RECEIVE ADDITIONAL SPRAYED FIREPROOFING AS REQUIRED TO ACHIEVE THEDESIGNATED RATING.

FIRE RESISTANCE

1. THOSE LIMITED OBSERVATIONS ARE NOT A SUBSTITUTE FOR INSPECTIONS AND TESTING PERFORMED BY THEOWNER’S QUALIFIED, INDEPENDENT TESTING LABORATORY, NOR ARE THEY INTENDED TO IDENTIFY ALL DEFECTSAND DEFICIENCIES IN THE WORK BY THE CONTRACTOR. THOSE OBSERVATIONS DO NOT FULFILL ANY PART OF THESPECIAL INSPECTIONS REQUIREMENTS GIVEN IN THE SPECIFICATIONS. THE DESIGNATED SPECIAL INSPECTOR ISSOLELY RESPONSIBLE FOR FULFILLING THE SPECIAL INSPECTION REQUIREMENTS AS OUTLINED HERE AND DEFINEDIN THE SPECIFICATIONS.

2. REFER TO THE SPECIFICATIONS FOR CODE MANDATED MATERIALS TESTING AND INSPECTION REQUIREMENTS FORSTRUCTURAL WORK.

3. ITEMS OF STRUCTURAL CONSTRUCTION WHICH REQUIRE SPECIAL INSPECTION INCLUDE, BUT ARE NOT LIMITED TO,THE FOLLOWING:

FOUNDATION EXCAVATIONS AND FILL OPERATIONSINSTALLATION OF AUGER-CAST GROUT PILESPLACEMENT OF STRUCTURAL CONCRETEPLACEMENT OF CONCRETE REINFORCINGERECTION OF PRECAST CONCRETE MEMBERS, INCLUDING TILT-WALLSPLACEMENT OF ANCHOR BOLTS PLACED IN CONCRETE OR MASONRYINSTALLATION OF DRILLED-IN CONCRETE OR MASONRY ANCHORS (EXPANSION, FRICTION, CEMENTED, OR GROUTED ANCHORS)CONSTRUCTION OF REINFORCED MASONRYFABRICATION AND ERECTION OF STRUCTURAL STEELWELDING AND BOLTING OF STEEL CONNECTIONSFIELD WELDING OF SHEAR STUDS

4. ARCHITECTURAL, MECHANICAL, AND ELECTRICAL COMPONENTS REQUIRING SPECIAL INSPECTIONS PER SECTION 1705 OF THE IBC HAVE NOT BEEN LISTED HERE. REFER TO ARCH/MEP FOR SPECIAL INSPECTION REQUIREMENTS FORTHESE COMPONENTS.

SPECIAL INSPECTION REQUIREMENTS

CONCRETE MIX1. PROVIDE CONCRETE HAVING THE FOLLOWING GENERAL CHARACTERISTICS:

28-DAY MAX. STRENGTH SLUMP AGG. SIZECLASS (PSI) (IN) TYPE (IN.) USAGEA 3000 4-6 HDRK 1 1/2" DRILLED BELLED PIERSB 3000 3-5 HDRK 1 GRADE BEAMS, SLABS-ON-GRADEC 4000 3-5 HDRK 1 FORMED SLABS, BEAMS, TILT-UP WALLSD 3000 3-5 HDRK 3/4 SLABS ON METAL DECK (RATED ASSEMBLY)

2. WORKABILITY ADMIXTURES MAY BE UTILIZED, PROVIDED THAT BATCH PROPORTIONS ARE DETERMINED IN THEMANNER DESCRIBED IN THE SPECIFICATIONS.

3. FLY ASH WILL NOT BE PERMITTED IN ARCHITECTURALLY EXPOSED CONCRETE. FLY ASH MAY BE USEDELSEWHERE, WITHIN THE SPECIFIED PROPORTION LIMITS, BUT THE CONTRACTOR SHALL FIRST VERIFYCOMPATIBILITY WITH CURING COMPOUNDS, SEALERS, BOND BREAKER, FLOORING ADHESIVES AND OTHERMATERIALS PROPOSED TO BE IN CONTACT WITH THE CONCRETE.

4. PROVIDE FIVE PERCENT (PLUS OR MINUS 1 1/2 PERCENT) AIR ENTRAINMENT IN CONCRETE PERMANENTLYEXPOSED TO THE WEATHER. USE OF AIR ENTRAINMENT, AND CORRESPONDING REDUCTION OF THE WATER/CEMENT RATIO, MUST BE NOTED ON THE MIX DESIGNS. DO NOT USE AIR IN SLABS WHICH HAVE ATROWEL FINISH.

5. USE OF ACCELERATING OR SET-RETARDING ADMIXTURES REQUIRES PRIOR APPROVAL OF THE ARCHITECT. INGENERAL, USE OF CALCIUM CHLORIDE WILL NOT BE PERMITTED.

6. CEMENT SHALL BE TYPE I OR TYPE III (ASTM C 150), EXCEPT AS FOLLOWS:CLASS OF CEMENTCONCRETE TYPEA I/II

7. MAXIMUM WATER-CEMENT RATIO FOR TILT WALL PANELS SHALL BE 0.47.

8. MAXIMUM WATER-CEMENT RATIO FOR CONCRETE SLABS-ON-GRADE SHALL BE 0.50. CONTRACTOR SHALL USELOWER WATER-CEMENT RATIO IF IT IS DETERMINED THAT THIS IS NEEDED TO PLACE FLOORING AS SCHEDULED.

9. SLUMP LIMITS APPLY AT THE TRUCK AT THE TIME OF DISCHARGE EXCEPT THAT PUMPED CONCRETE SHALL BESAMPLED AT THE DISCHARGE END OF THE HOSE. WHEN A SUPERPLASTICIZER IS USED, THE SLUMP SHALL BEMEASURED AT THE TRUCK BEFORE INTRODUCING THE SUPERPLASTICIZER; OR, IF SUPERPLASTICIZERS AREADDED AT PLANT, SLUMP SHALL BE 6-8 INCHES AT TIME OF DISCHARGE. STRENGTH TESTS SHALL BE MADE ONCONCRETE AS PLACED WITH ALL ADDITIVES.

10. REFER TO SPECIFICATIONS FOR AGGREGATES AND SANDBLAST FINISH REQUIRED AT EXPOSED CONCRETE INTILT WALL PANELS.

1. REINFORCING STEEL SHALL BE NEW OR RECYCLED DOMESTIC DEFORMED BILLET STEEL, CONFORMING TO ASTM A615, GRADE 60.

2. REINFORCING STEEL SHOWN IN SECTIONS OF BEAMS, WALLS AND COLUMNS IS SCHEMATIC INDICATION THATREINFORCING EXISTS. SEE SCHEDULES, SECTION NOTES, AND GENERAL NOTES FOR ACTUAL REINFORCINGREQUIRED.

3. REFER TO DOWEL SCHEDULE, SHEET S304, FOR ALL BARS MARKED "DWL" ON THE DRAWINGS.

4. DETAIL REINFORCING BARS AND PROVIDE BAR SUPPORTS AND SPACERS IN ACCORDANCE WITH THE ACI DETAILINGMANUAL.

5. WHERE BAR TYPES FROM THE BAR BENDING DIAGRAM ARE SPECIFIED, PROVIDE BARS ACCORDINGLY.OTHERWISE, DETAIL BARS IN BEAMS, COLUMNS, SLABS, AND WALLS AS FOLLOWS:

A. RUN TOP AND BOTTOM BARS CONTINUOUS, WITH SPLICES AND HOOKS AS DESCRIBED BELOW.B. PROVIDE STANDARD 90 DEGREE HOOK ON TOP BARS AT CANTILEVER ENDS.C. SPLICE TOP AND INTERMEDIATE BARS AT THE CENTER LINE BETWEEN MEMBER SUPPORTS, UNLESS

NOTED OTHERWISE.D. SPLICE BOTTOM BARS DIRECTLY OVER MEMBER SUPPORTS, UNLESS NOTED OTHERWISE.E. SPLICE VERTICAL BARS IN WALLS ONLY AT FLOOR LINES, UNLESS NOTED OTHERWISE.

HORIZONTAL BARS SHALL BE SPLICED AS SPECIFIED FOR TOP, BOTTOM, AND INTERMEDIATE BARS OF BEAMS.

F. CENTER BARS NOTED AS "AT SUPT'S." OVER MEMBER SUPPORTS, AND CENTER BARS NOTED AS "BTWN. SUPT'S." BETWEEN SUPPORTS.

G. ALL BAR SPLICES IN BEAMS AND SLABS SHALL BE 66 BAR DIAMETERS.H. PROVIDE CORNER BARS FOR EACH HORIZONTAL BAR AT THE INSIDE AND OUTSIDE FACES OF

INTERSECTING BEAMS OR WALLS. REFER TO CORNER BAR DETAILS ON SHEET S304.

6. BARS SHOWN IN THE SCHEDULE TO HOOK AT DISCONTINUOUS ENDS SHALL HAVE THE HOOK PLACEDHORIZONTALLY AT EXTERIOR CORNERS.

7. PROVIDE NO. 3 DOWELS X 2'-0" AT 1'-6" ON CENTER, WITH A 90 DEGREE HOOK AT ALL EDGES OF CONCRETESLABS, UNLESS DETAILED OTHERWISE.

8. PROVIDE FOUNDATION DOWELS TO MATCH MASONRY WALL REINFORCEMENT. DOWELS SHALL EXTEND A MINIMUMOF 60 BAR DIAMETERS ABOVE AND 30 BAR DIAMETERS BELOW TOP OF FOUNDATION.

9. CONCRETE COVER FOR REINFORCING STEEL SHALL BE AS FOLLOWS, MEASURED TO NEAREST BAR, STIRRUP OR TIE:

A. AT SLABS-ON-GRADE, BEAM AND WALL SURFACES DEPOSITED AGAINST THE GROUND (WITH OR WITHOUT VAPOR RETARDER): 3".

B. AT FORMED FACES OF BEAMS, COLUMNS AND WALLS EXPOSED TO RAIN OR IN CONTACT WITH THEGROUND: 2".

C. AT FORMED FACES OF BEAMS NOT EXPOSED TO RAIN OR SOIL: 1 1/2”.D. AT INTERIOR AND PROTECTED EXTERIOR FACES OF WALLS: 1".E. TOP STEEL IN SLABS AND JOISTS:

INTERIOR EXPOSURE: 1"EXPOSED TO WEATHER: 2"

F. TOP STEEL IN BEAMS:INTERIOR EXPOSURE: 1 1/2"EXPOSED TO WEATHER: 2"

10. MAINTAIN THE SPECIFIED COVER DIMENSION WITHIN A TOLERANCE OF PLUS OR MINUS 3/8" EXCEPT FOR SLABS-ON-GRADE AND SOIL-FORMED MEMBERS, WHERE 5/8" TOLERANCE IS PERMITTED. EXTRA COVER WEAKENS THEMEMBER AND REDUCED COVER LEADS TO CORROSION.

11. REFER TO TYPICAL STEEL CONNECTION DETAIL SHEET (S501 AND S501A) FOR ADDITIONAL REINFORCING REQUIREDAT STEEL BEAM CONNECTION EMBED PLATES.

12. PROVIDE 5 TONS OF ADDITIONAL REINFORCING STEEL (#3 BARS AND LARGER) TO BE USED IN THE FIELD ASDIRECTED BY THE ARCHITECT/ENGINEER. LABOR FOR DETAILING, CUTTING, BENDING, AND PLACEMENT SHALL BEINCLUDED. ANY UNUSED PORTION OF THIS QUANTITY SHALL BE CREDITED TO THE OWNER AT THE RATE OF $1200PER TON.

CONCRETE REINFORCEMENT

1. CONSTRUCTION JOINTS IN BEAMS, SLABS AND WALLS SHALL ONLY OCCUR WITHIN 2'-0" OF MIDSPAN BETWEENSUPPORTS. CONSTRUCTION JOINTS IN SOIL SUPPORTED SLABS-ON-GRADE SHALL BE WHERE SHOWN ON PLAN.SEE NOTES ON TYPICAL SLAB-ON-GRADE DETAILS ON SHEET S303 FOR LOCATING SLAB JOINTS. COLUMNPILASTERS ON THE SIDES OF GRADE BEAMS AND WALLS SHALL BE CAST MONOLITHICALLY WITH THE GRADEBEAM OR WALL UNLESS SHOWN OTHERWISE. SUBMIT A DIAGRAM OF ALL PROPOSED CONSTRUCTION JOINTSWHICH ARE NOT SPECIFICALLY SHOWN ON THESE DRAWINGS (REFER TO SPECIFICATIONS).

2. SLEEVES, MECHANICAL OPENINGS, CONDUITS, PIPES, RECESSES, DEPRESSIONS, CURBS AND ALL EMBEDDED ITEMSSHALL BE PROVIDED FOR AS SHOWN ON THE ARCHITECTURAL AND MECHANICAL DRAWINGS AND AS REQUIREDBY EQUIPMENT MANUFACTURERS. MINIMUM CONCRETE BETWEEN SLEEVES SHALL BE 6". INSTALLATION OF THESEITEMS SHALL BE COORDINATED WITH SHOP DRAWINGS OF TRADES REQUIRING THESE ITEMS.

3. SET FORMS TO FOLLOW SLOPES AND GRADES DEFINED ON PLAN, KEEPING MEMBER DEPTHS CONSTANT ATDEPTHS DETAILED OR SCHEDULED, UNLESS NOTED OTHERWISE. SLOPE UNIFORMLY BETWEEN ELEVATIONS GIVEN.BUILD IN CAMBER WHERE SPECIFIED.

4. ALL CONDUITS AND PIPES EMBEDDED IN CONCRETE SHALL COMPLY WITH ALL PROVISIONS SPECIFIED IN ACI 318,SECTION 6.3, WITH THE FOLLOWING SPECIFIC REQUIREMENTS:

A. THE MAXIMUM OUTSIDE DIAMETER OF THE CONDUITS AND PIPES SHALL BE 1 1/2". NONE PERMITTED INSLABS THINNER THAN 4 1/2".

B. THE MINIMUM CLEAR DISTANCE BETWEEN CONDUITS AND PIPES SHALL BE 6".

C. AT FORMED SLABS, LOCATE IN MIDDLE THIRD OF SLAB THICKNESS BETWEEN THE TOP AND BOTTOMMAT OF REINFORCING. AT BEAMS, LOCATE INSIDE BEAM STIRRUP. IN JOISTS, LOCATE AT CENTER LINE, AT LEAST 6" FROM BOTTOM.

D. NONE PERMITTED IN SLABS-ON-GRADE WHICH WILL BE PERMANENTLY EXPOSED OR SCHEDULED TORECEIVE THIN SET TILE. PLACE ALL PIPES AND CONDUITS IN THE FILL BENEATH THE VAPOR RETARDER. RECOMPACT AS SPECIFIED.

E. IN NON-EXPOSED SLABS-ON-GRADE, LIMIT SIZE TO 1" O.D. IN 5" SLAB SPACE 12" APART AND TIE TOUNDERSIDE OF REINFORCING MAT. WHERE LINES CONVERGE AT SOURCE, DOUBLE UP THE SLAB REINFORCING IN THE CONVERGENCE ZONE AND 3'-0" BEYOND. PLACE ALL LARGER LINES IN THE FILL BENEATH THE VAPOR RETARDER.

F. NONE PERMITTED IN COMPOSITE SLABS ON DECK.

G. DO NOT DISPLACE REINFORCING STEEL FROM ITS PROPER POSITION.

H. SLEEVES OR PIPES PASSING HORIZONTALLY THROUGH BEAMS OR JOISTS MUST BE LOCATED IN THEMIDDLE THIRD OF THE SPAN AND WITHIN THE MIDDLE THIRD OF THE BEAM DEPTH. MAXIMUM DIAMETER SHALL BE ONE THIRD OF THE MEMBER DEPTH. SPACE AT LEAST 3 DIAMETERS CLEAR APART AND ADD ONE STIRRUP EACH SIDE OF EACH SLEEVE.

5. PROVIDE SHEAR KEYS IN ALL CONSTRUCTION JOINTS IN BEAMS AND WALLS, IN ACCORDANCE WITH THE TYPICAL CONCRETE DETAILS.

6. TOP SURFACES OF CONCRETE BEAMS WHICH SUPPORT TILT-WALL PANELS SHALL RECEIVE A TROWELED SMOOTH FINISH AND SHALL BE STRAIGHT, TRUE AND LEVEL.

7. DOCK HEIGHT GRADE BEAMS SHALL BE BRACED FROM THE EXTERIOR DIRECTION PRIOR TO PLACING FILL.BRACING SHALL REMAIN IN PLACE UNTIL THE FLOOR SLAB HAS BEEN POURED AND HAS CURED FOR AT LEAST 7DAYS.

8. THE HOUSEKEEPING PADS UNDER MECHANICAL EQUIPMENT ARE SHOWN AND SPECIFIED ON THE MECHANICALDRAWINGS. REINFORCE HOUSEKEEPING PAD WITH #3@8" ON CENTER EACH WAY, UNLESS SHOWN OTHERWISE ONMECHANICAL DRAWINGS.

9. WHERE GRADE BEAMS ARE TRENCH FORMED, THE TOP OF THE EXTERIOR FACE SHALL BE WOOD FORMED TO ATLEAST 1'-0" BELOW EXTERIOR FINISHED GRADE LEVEL

10. PROVIDE 40 CUBIC YARDS OF ADDITIONAL CONCRETE TO BE USED IN THE FIELD AS DIRECTED BY THEARCHITECT/ENGINEER. LABOR FOR PLACEMENT AND FINISHING SHALL BE INCLUDED. ANY UNUSED PORTION OFTHIS QUANTITY SHALL BE CREDITED TO THE OWNER AT THE RATE OF $130 PER CUBIC YARD.

CAST-IN-PLACE CONCRETE

1. REFER TO CONCRETE MIX GENERAL NOTES FOR MINIMUM COMPRESSIVE STRENGTH REQUIRMENTS AND MAXIMUMWATER-CEMENT RATIO. CONCRETE SHALL HAVE ATTAINED AT LEAST 75 PERCENT OF THE SPECIFIED 28 DAYSTRENGTH AT LIFTING, UNLESS GREATER STRENGTH IS REQUIRED BY LIFTING ANALYSIS.

2. SEE DETAILS ON S605 SERIES SHEETS FOR PANEL REINFORCING, EMBEDS, DIMENSIONS, ETC.

3. CONCRETE COVER OVER REINFORCING STEEL SHALL NOT BE LESS THAN 1 1/2" FROM ALL EXTERIOR EDGES AND1" FROM INTERIOR FACES. WHERE DOUBLE LAYERS OF STEEL ARE ENCLOSED IN TIES, COVER LISTED SHALL BEMEASURED TO THE OUTSIDE EDGE OF THE TIE.

4. ADD 1#5 EACH FACE MINIMUM AROUND ALL OPENINGS. EXTEND REINFORCING 2'-6" PAST OPENINGS, UNLESSNOTED OTHERWISE ON PANEL ELEVATIONS.

5. REFERENCE ARCHITECTURAL DRAWINGS AND SPECIFICATIONS FOR PANEL FINISHES, OPENINGS, CHAMFERS ANDREVEALS.

6. LIFTING INSERTS AND REINFORCING AT THE PICK-UP POINTS SHALL BE DESIGNED AND SELECTED BY THECONTRACTOR.

7. A PANEL ENGINEER SHALL COORDINATE ALL ASPECTS OF THE TILTWALL PANELS INCLUDING CAD-GENERATEDSHOP DRAWINGS WHICH SHALL SHOW THE DETAILS AND LOCATION OF ALL OPENINGS, EMBEDDED ITEMS,REINFORCING, CHAMFERS, REVEALS, MEP ROUGH-INS, BRACING AND ERECTION REQUIREMENTS. SEESPECIFICATIONS FOR COMPLETE LIST OF COORDINATOIN ITEMS REQUIRED FROM PANEL ENGINEER.

8. ALL INSERTS, BRACES, STRONGBACKS, AND OTHER REQUIRED LIFTING ACCESSORIES SHALL BE DESIGNED,FURNISHED AND INSTALLED BY THE CONTRACTOR, AND SHALL BE LOCATED IN ACCORDANCE WITH ACCEPTEDPUBLISHED LITERATURE, SUCH AS RICHMOND BULLETIN NO. 8, "PRODUCTS FOR PRECAST/PRESTRESSED CONCRETECONSTRUCTION." LOCATIONS AND SIZES OF INSERTS, BRACES, OR STRONGBACKS SHALL BE DESIGNED TOPREVENT CRACKING DUE TO ERECTION STRESSES, INCLUDING A 50 PERCENT FORCE INCREASE FOR IMPACT. THECONTRACTOR SHALL BE RESPONSIBLE FOR PROVIDING SPECIAL REINFORCING, AS MAY BE REQUIRED, TO PREVENTFLEXURAL CRACKS FROM OCCURRING IN THE PANELS DURING LIFTING AND HANDLING OPERATIONS.

9. AIR RELIEF HOLES SHALL BE PROVIDED IN THE HORIZONTAL SURFACES OF ALL EMBEDDED PLATES AND ANGLESOVER 3" IN WIDTH, WHEN SUCH SURFACES ARE ABOVE THE BOTTOM OF THE PRECAST MEMBER IN THE CASTINGPOSITION.

10. BRACE PANELS SECURELY IN POSITION UNTIL THEY CAN BE PERMANENTLY ANCHORED AND BRACED AT FLOORAND ROOF. ROOF DECK SHALL BE COMPLETELY INSTALLED BEFORE REMOVING PANEL BRACES.

11. PANELS ARE DESIGNED TO BE BRACED BY AND ANCHORED TO THE FLOOR SLAB. THEREFORE, TEMPORARY PANELBRACING SHALL REMAIN IN PLACE UNTIL AFTER THE ADJOINING FLOOR SLAB HAS BEEN POURED.

12. PROVIDE HIGH-STRENGTH NON-SHRINK GROUT UNDER PORTIONS OF PANELS OVER BEARING POINTS. PROVIDESAND-CEMENT GROUT UNDER REMAINING PORTIONS OF PANELS BETWEEN BEARING POINTS. SEE DETAILS ONS605.

13. SEE MEP DRAWINGS FOR CAST-IN BOXES AND OPENINGS FOR EQUIPMENT. PROVIDE 2” COVER ON CONDUIT.

14. GROUTED POCKETS SHALL HAVE SMOOTH RUBBED FINISH. GRIND SMOOTH, IF NECESSARY, PRIOR TO PAINTING.

15. FACE OF PANELS SHALL BE SKIM COATED AND RUBBED PRIOR TO PAINTING INTERIOR SURFACE.

16. DOCK HEIGHT PANELS SHALL BE BRACED FROM THE EXTERIOR DIRECTION PRIOR TO PLACING FILL ON INTERIOR OFPANEL. BRACING SHALL REMAIN IN PLACE UNTIL THE FLOOR SLAB HAS BEEN POURED AND CURED FOR AT LEASTSEVEN DAYS.

PRECAST CONCRETE TILT-UP PANELS

1. SLABS USED AS CASTING BEDS SHALL BE PREPARED SO AS NOT TO TELEGRAPH IMPERFECTIONS OR IMPACTVISUAL QUALITY OF PANELS. SUPPLEMENTAL CASTING BEDS IN ADDITION TO THE SLABS WITHIN THE BUILDINGFOOTPRINT MAY BE REQUIRED TO ACHIEVE THE LEVEL OF QUALITY REQUIRED AND/OR TO MEET THECONSTRUCTION SCHEDULE.

2. CASTING SLAB SURFACE SHALL BE PREPARED SO THAT IT WILL PRODUCE THE DESIRED LEVEL OF FINISH ANDSMOOTHNESS NEEDED FOR THE FINAL CONDITION OF THE PANELS. THIS MAY INCLUDE FILLING SHRINKAGECRACKS AND CHIPS IN THE SLAB WITH TAPING MUD.

3. SEE MEP DRAWINGS FOR SLAB BLOCKOUT DETAIL AT PLUMBING AND CONDUIT RISERS WITH TEMPORARYCONCRETE PLUG FOR PANEL CASTING BED ((DETAIL 1/CSG-A)). PROVIDE 1#4 X 4’-0” DIAGONAL CORNER BAR ATALL SLAB BLOCKOUTS FOR PLUMBING AND CONDUIT.

4. SEE SHEET S303 FOR OTHER SLAB-ON-GRADE NOTES.

5. SEE SPECIFICATIONS FOR SLAB FINISH TOLERANCES.

SLABS USED AS CASTING BEDS FOR TILT-UP PANELS

1. WHERE FIELD DRILLED EXPANSION BOLTS ARE PROPOSED FOR AN APPLICATION OR LOCATION NOT SHOWN ON THESE DRAWINGS, THE PRODUCT AND ITS INTENDED APPLICATION SHALL BE SUBMITTED FOR APPROVAL.

2. EXPANSION BOLTS SHALL CONFORM TO THE REQUIREMENTS OF THE SPECIFICATIONS.

3. ONLY ONE LENGTH OF BOLT SHALL BE PRESENT ON THE JOBSITE FOR EACH BOLT DIAMETER, UNLESS OTHERWISE SPECIFIED ON THE DRAWINGS.

4. EXPANSION BOLTS, OF THE DIAMETER AND EMBEDMENT SHOWN ON THE DRAWINGS, SHALL BE INSTALLED BYPERSONNEL TRAINED TO INSTALL EXPANSION BOLTS AND SHALL BE INSTALLED IN ACCORDANCE WITH THE CONTRACT DOCUMENTS AND THE MANUFACTURER’S PRINTED INSTALLATION INSTRUCTIONS (MPII). WHERE PROVISIONS OF THE ABOVE REFERENCED DOCUMENTS ARE IN CONFLICT, THE MOST STRINGENT REQUIREMENTSHALL GOVERN.

5. ALL POST-INSTALLED ANCHORS SHALL BE INSPECTED BY A SPECIAL INSPECTOR IN ACCORDANCE WITH THE BUILDING CODE. INSTALLATION OF EXPANSION BOLTS SHALL BE CONTINUOUSLY INSPECTED BY THE TESTINGLABORATORY, TO ENSURE THAT HOLES ARE OF PROPER DIAMETER AND LENGTH, THAT MINIMUM INSTALLATION TORQUES ARE OBTAINED, AND THAT BOLTS ARE INSTALLED IN ACCORDANCE WITH THE MANUFACTURER’S PRINTED INSTALLATION INSTRUCTIONS (MPII).

6. BOLTS SHALL BE INSTALLED PERPENDICULAR TO THE FACE OF THE CONCRETE. THE MAXIMUM DEVIATION FROM PERPENDICULAR SHALL BE 6 DEGREES. ALL BOLTS INSTALLED OUTSIDE OF THE SPECIFIED TOLERANCESHALL BE CONSIDERED UNACCEPTABLE.

7. THE CONTRACTOR SHALL CREATE A TEMPLATE FOR EACH BOLT GROUP PRIOR TO FABRICATING HOLES IN CONNECTION PLATES. TEMPLATES SHALL BE MADE AFTER LOCATING EXISTING REINFORCING STEEL WITH FERROSCAN OR SIMILAR NON-DESTRUCTIVE REINFORCING IMAGING DEVICE. POSITION BOLT HOLES SO AS NOT TO CONFLICT WITH THE EXISTING REINFORCING. BOLT POSITIONS MAY BE ADJUSTED IN THE FIELD A MAXIMUM OF 1 1/2" FROM THE DIMENSIONS SHOWN ON THE DETAILS, TO AVOID CONFLICTS WITH THE EXISTINGREINFORCING STEEL.

8. SUBMIT DRAWINGS OF TEMPLATES SHOWING HOLE LOCATIONS PRIOR TO FABRICATION OF CONNECTION PLATES.

9. HOLES SHALL BE DRILLED IN A CONTINUOUS OPERATION AVOIDING FREQUENT REMOVAL OF THE DRILL FROMTHE HOLE. AFTER DRILLING, ALL DUST AND OTHER FOREIGN MATTER SHALL BE BLOWN OUT OF THE HOLE WITH COMPRESSED AIR.

10. HOLES DRILLED IN THE CONCRETE SHALL BE SAME NOMINAL DIAMETER AS THE BOLT. USE THE BIT TYPE ANDSIZE RECOMMENDED BY THE BOLT MANUFACTURER. HOLES SHALL NOT BE ENLARGED OR REDIRECTED ANYWHERE ALONG THEIR LENGTH.

11. ALL ABANDONED HOLES DRILLED IN THE CONCRETE SHALL BE COMPLETELY FILLED WITH EPOXY GROUT.

12. TIGHTEN NUTS AGAINST SMOOTH WASHERS TO THE MINIMUM TORQUE RECOMMENDED BY THE MANUFACTURER.

13. HOLES IN CONNECTION PLATES SHALL BE NO MORE THAN 1/16" LARGER THAN THE BOLT DIAMETER. IF LARGER DIAMETER HOLES ARE NECESSARY FOR ERECTION PURPOSES THE CONTRACTOR SHALL PROVIDE PLATE WASHERS SUFFICIENTLY WELDED TO THE CONNECTION PLATE TO TRANSFER THE SPECIFIED LOAD.

FIELD DRILLED EXPANSION BOLTS IN CONCRETE

1. WHERE DRILLED EXPANSION BOLTS OR ADHESIVE ANCHORS ARE PROPOSED FOR AN APPLICATION OR LOCATION NOT SHOWN ON THESE DRAWINGS, THE PRODUCT AND ITS INTENDED APPLICATION SHALL BE SUBMITTED FOR APPROVAL.

2. EXPANSION BOLTS SHALL BE ONE OF THE SYSTEMS SPECIFICALLY INCLUDED IN THE MASONRY SPECIFICATIONS.

3. ONLY ONE LENGTH OF BOLT SHALL BE PRESENT ON THE JOBSITE FOR EACH BOLT DIAMETER, UNLESS OTHERWISE SPECIFIED ON THE DRAWINGS.

4. ADHESIVE ANCHORS SHALL BE ONE OF THE SYSTEMS SPECIFICALLY INCLUDED IN THE MASONRY SPECIFICATIONS.

5. EXPANSION BOLTS AND ADHESIVE ANCHORS, OF THE DIAMETER AND EMBEDMENT SHOWN ON THE DRAWINGS, SHALL BE INSTALLED IN ACCORDANCE WITH THE CONTRACT DOCUMENTS, THE CURRENT ICC-ES REPORT FOR THE BOLT OR ANCHOR, AND THE RECOMMENDATIONS OF THE MANUFACTURER. WHERE PROVISIONS OF THE ABOVE REFERENCED DOCUMENTS ARE IN CONFLICT, THE MOST STRINGENT REQUIREMENTSHALL GOVERN.

6. BOLTS AND ANCHORS SHALL BE INSTALLED PERPENDICULAR TO THE FACE OF THE CONCRETE. THE MAXIMUMDEVIATION FROM PERPENDICULAR SHALL BE 10 DEGREES. ALL BOLTS INSTALLED OUTSIDE OF THE SPECIFIEDTOLERANCE SHALL BE CONSIDERED UNACCEPTABLE.

7. THE CONTRACTOR SHALL CREATE A TEMPLATE FOR EACH BOLT GROUP PRIOR TO FABRICATING HOLES IN CONNECTION PLATES. TEMPLATES SHALL BE MADE AFTER LOCATING EXISTING REINFORCING STEEL WITH A PACHOMETER. POSITION BOLT HOLES SO AS NOT TO CONFLICT WITH THE EXISTING REINFORCING. BOLT POSITIONS MAY BE ADJUSTED IN THE FIELD A MAXIMUM OF 1 1/2" FROM THE DIMENSIONS SHOWN ON THE DETAILS, TO AVOID CONFLICTS WITH THE EXISTING REINFORCING STEEL AND COORDINATE WITH MASONRY CELLS, JOINTS, AND BULKHEADS.

8. SUBMIT DRAWINGS OF TEMPLATES SHOWING HOLE LOCATIONS PRIOR TO FABRICATION OF CONNECTION PLATES.

9. HOLES SHALL BE DRILLED IN A CONTINUOUS OPERATION, AVOIDING FREQUENT REMOVAL OF THE DRILL FROMTHE HOLE. AFTER DRILLING, ALL DUST AND OTHER FOREIGN MATTER SHALL BE BLOWN OUT OF THE HOLE WITH COMPRESSED AIR.

10. HOLES DRILLED IN THE MASONRY SHALL BE AS SPECIFIED BY THE BOLT MANUFACTURER FOR THE PROPOSEDPRODUCT. USE THE BIT TYPE AND SIZE RECOMMENDED BY THE BOLT MANUFACTURER. HOLES SHALL NOT BEENLARGED OR REDIRECTED ANYWHERE ALONG THEIR LENGTH.

11. ALL ABANDONED HOLES DRILLED IN THE MASONRY SHALL BE COMPLETELY FILLED WITH EPOXY GROUT.

12. INSTALLATION OF EXPANSION BOLTS AND ADHESIVE ANCHORS SHALL BE CONTINUOUSLY INSPECTED BY THETESTING LABORATORY, TO ENSURE THAT HOLES ARE OF PROPER DIAMETER AND LENGTH, THAT BOLTS ANDANCHORS ARE INSTALLED CORRECTLY, AND THAT MINIMUM INSTALLATION TORQUES ARE OBTAINED.

13. TIGHTEN EXPANSION BOLT NUTS AGAINST SMOOTH WASHERS TO THE MINIMUM TORQUE RECOMMENDED BY THE MANUFACTURER.

14. HOLES IN CONNECTION PLATES SHALL BE NO MORE THAN 1/16" LARGER THAN THE BOLT OR ANCHOR DIAMETER. IF LARGER DIAMETER HOLES ARE NECESSARY FOR ERECTION PURPOSES THE CONTRACTOR SHALL PROVIDE PLATE WASHERS SUFFICIENTLY WELDED TO THE CONNECTION PLATE TO TRANSFER THE SPECIFIED LOAD.

EXPANSION BOLTS AND ADHESIVE ANCHORS IN MASONRY

© 2

016 M

oody/

Nola

n I

nc.

Dwg. Coord.: Tech. Coord.:

5001 Spring Valley RoadSuite 225EDallas, TX 75244

Phone: (214) 377-8662

KEY PLAN

A B

C

PORTIONS OF THIS DRAWING MAY NOT BE TO SCALE. THEREFORE, THIS DRAWING SHALL NOT BE SCALED. COPYRIGHT © 2017 DATUM ENGINEERS, INC.

Datum Engineers IncorporatedWWW.DATUMENGINEERS.COM | CO REG. NO. F-2819

Datum Project No.

Dallas San Antonio214-358-0174 210-858-2869

Austin512-469-9490

4/2

6/2

017 9

:01:5

3 A

MC

:\U

sers

\kelly

.DA

TU

M\D

ocu

ments

\Revit

2016 L

oca

l\16146 A

EP

Corp

us C

hristi

- S

truct

_kt

hib

odeaux.r

vt

16578

04-25-17

CORPUS CHRISTI

AMERICAN ELECTRICPOWER

Author Checker

BIDDING AND PERMIT DOCUMENTS

GENERAL NOTESS102

16146

# DATE CHANGE DESCRIPTION

04/27/17

1. COORDINATION OF THE ROOF STRUCTURE AND THE ARCHITECTURAL SECTIONS AND ELEVATIONS IS CRITICALTO PROPER STRUCTURAL STEEL FABRICATION. ELEVATIONS OF TOP OF STRUCTURAL STEEL ARE SHOWN ONTHE ARCHITECTURAL PLANS AND SECTIONS. REFER TO THESE SECTIONS AND DETAILS TO SET THE STEEL ELEVATIONS AND TO UNDERSTAND THE ARCHITECTURAL INTENT.

2. TOLERANCE REQUIREMENTS - STRUCTURAL DRAWINGS INDICATE MISCELLANEOUS STEEL ELEMENTS SUCH AS SHELF ANGLES, LINTELS, SUPPORT MEMBERS FOR CURTAIN WALLS OR MASONRY, AND EDGE ANGLES FOR OPENINGS AND PERIMETER CONDITIONS WHICH ARE INTENDED TO SUPPORT OR BE COORDINATED WITH MATERIALS FURNISHED BY OTHER TRADES. IT IS THE INTENT OF THESE DRAWINGS THAT THESE ELEMENTS BEFIELD ATTACHED BY FIELD WELDING OR BOLTING TO MEET THE TOLERANCES REQUIRED BY OTHER TRADES, WHICH MAY BE MORE STRINGENT THAN A.I.S.C. TOLERANCES FOR STRUCTURAL STEEL. CONTRACTOR SHALLCOORDINATE TRADES AND FIELD INSTALL MISCELLANEOUS STEEL ELEMENTS AND THE STRUCTURAL STEEL FRAME TO COMPLY WITH THE TOLERANCE CRITERIA FOR PROPER INSTALLATION OF MATERIALS BY OTHER TRADES.

3. STRUCTURAL STEEL MATERIAL SHALL CONFORM TO THE FOLLOWING DESIGNATIONS:WIDE FLANGE (W) SHAPES AND TEES A 992 (50 KSI YIELD)OTHER ROLLED SHAPES, PLATES AND RODSA 36 (36 KSI YIELD)HOLLOW STRUCTURAL SHAPES (HSS) A 500, GRADE B (42 KSI YIELD ROUND/46 KSI YIELD SQUARE)PIPEA 53, GRADE B (35 KSI YIELD)BOLTS FOR CONNECTIONS A 325NANCHOR BOLTS (ANCHOR RODS)F 1554 (36 KSI YIELD)

4. PREDESIGNED BEAM CONNECTION DETAILS ARE SHOWN ON SHEETS S501 AND S501A. OTHER TYPICAL CONNECTIONS ARE SHOWN IN TYPICAL DETAILS. CONNECTIONS WHICH ARE NOT SPECIFICALLY DETAILED SHALL BE DESIGNED BY THE FABRICATOR IN ACCORDANCE WITH THE CONNECTION NOTES AND SPECIFICATIONS.

5. ALL MOMENT CONNECTIONS SHALL BE FULL WELDED CONNECTIONS DESIGNED TO DEVELOP THE FULL CROSS-SECTION OF THE MEMBER. STIFFENER PLATES, WHERE SHOWN, ARE MANDATORY AND MAY NOT BE OMITTED.MOMENT CONNECTIONS ARE INDICATED ON THE PLANS BY A TRIANGULAR BULB ON THE END OF THE BEAM, OR BY THE LETTERS "MC".

6. CANTILEVER BEAMS MOMENT CONNECTED TO THE FRAME SHALL BE THE SAME SIZE AS THE BACK-UP SPAN IFNO SIZE IS GIVEN.

7. ALL BOLTS SHALL BE TIGHTENED TO A "SNUG TIGHT" CONDITION.

8. BACK TO BACK CHANNELS OR DOUBLE ANGLES ACTING AS COMPRESSION MEMBERS SHALL BE CONNECTEDTO EACH OTHER AT THIRD POINTS ALONG THE LENGTH BY WELDING IN SPACER PLATES OF EQUAL THICKNESSTO THE GUSSET PLATES. UNEQUAL LEG ANGLES SHALL BE ORIENTED LONG LEG DOWN UNLESS NOTED OTHERWISE.

9. TEMPORARY CONSTRUCTION BRACING OF STRUCTURAL STEEL FRAME SHALL REMAIN IN PLACE UNTIL AFTERALL PERMANENT BRACING COMPONENTS HAVE BEEN COMPLETED. THE LATERAL-LOAD-RESISTING SYSTEM OF THE BUILDING INCLUDES DESIGNATED WIND BRACES, CONCRETE TILT WALLS, AND CONNECTING DIAPHRAGM ELEMENTS. THE COMPLETED CONCRETE FILL ON METAL DECK IS AN ESSENTIAL DIAPHRAGM COMPONENTS OF THE PERMANENT BRACING SYSTEM.

10. WIND BRACES IN THE VERTICAL PLANE ARE DENOTED BY "WB" ON THE PLAN. SEE WIND BRACE DETAILS FOR CONFIGURATIONS.

11. SHELF ANGLES SHOWN AS CONTINUOUS IN THE SECTIONS SHALL BE INSTALLED IN 20'-0" MAXIMUM LENGTHS,LEAVING A 1/4" GAP BETWEEN ENDS AND AT CORNERS. LOCATE GAPS TO MATCH MASONRY CONTROL JOINTS. AT BUILDING EXPANSION JOINT, LEAVE A GAP TO MATCH EXPANSION JOINT WIDTH.

12. CONNECT MISCELLANEOUS STEEL MEMBERS USING FILLET WELDS SUFFICIENT TO DEVELOP THE TENSILE STRENGTH OF THE SMALLER MEMBER AT THE JOINT UNLESS SHOWN OTHERWISE.

13. ALL STEEL SHALL BE FURNISHED WITH SHOP COAT OF RUST INHIBITIVE PRIMER EXCEPT STEEL DESIGNATED TOBE GALVANIZED.

14. WHERE ANGLES ARE NOTED TO BE CONTINUOUS, PROVIDE FULL BUTT WELD AT SPLICES.

15. PROVIDE 5 TONS OF ADDITIONAL STRUCTURAL STEEL TO BE USED IN THE FIELD AS DIRECTED BY THE ARCHITECT/ENGINEER. LABOR FOR DETAILING, FABRICATION, AND ERECTION SHALL BE INCLUDED. ANY UNUSED PORTION OF THIS QUANTITY SHALL BE CREDITED TO THE OWNER AT THE RATE OF $3800 PER TON.

STRUCTURAL STEEL

1. ROOF MOUNTED MECHANICAL UNIT LOCATIONS AND DESIGN WEIGHTS ARE SHOWN ON THE ROOF FRAMING PLANS.CONTRACTOR SHALL NOTIFY THE ENGINEER IF ACTUAL SIZES, WEIGHTS, OR LOCATIONS DIFFER FROM THOSESHOWN ON THE ROOF FRAMING PLANS. PROVIDE ADDITIONAL STEEL FRAMING, AS DETAILED, FOR SUPPORT OFRTU CURBS.

ROOF MOUNTED MECHANICAL UNITS

1. FIELD DRILLED DOWELS AND ANCHOR RODS TO BE SET IN HARDENED CONCRETE SHALL CONFORM TO THE REQUIREMENTS OF THE SPECIFICATIONS.

2. DOWELS AND THREADED RODS, OF THE SIZE, TYPE, AND EMBEDMENT SHOWN ON THE DRAWINGS, SHALL BEINSTALLED BY PERSONNEL TRAINED TO INSTALL ADHESIVE ANCHORS AND SHALL BE INSTALLED IN ACCORDANCE WITH THE MANUFACTURER'S PRINTED INSTALLATION INSTRUCTIONS (MPII) AND AS INDICATEDON THE DRAWINGS. A MANUFACTURER’S REPRESENTATIVE SHALL BE PRESENT DURING INITIAL INSTALLATION TO PROVIDE ONSITE TRAINING OF INSTALLERS.

3. WHERE INSTALLATION OF ADHESIVE ANCHORS IS HORIZONTALLY OR UPWARDLY INCLINED TO SUPPORT SUSTAINED TENSION LOADS, THE INSTALLING PERSONNEL SHALL BE CERTIFIED IN ACCORDANCE WITH THE ACI/CRSI ADHESIVE ANCHOR INSTALLER CERTIFICATION PROGRAM, OR EQUIVALENT.

4. AT CORED HOLES, WET HOLES, OR HOLES DEEPER THAN 18 INCHES, SUBSTITUTE A SLOW CURE EPOXY ADHESIVE OR OTHER APPROPRIATE PRODUCT RECOMMENDED BY THE MANUFACTURER FOR THE SPECIAL APPLICATION.

5. ALL POST-INSTALLED ANCHORS SHALL BE INSPECTED BY A SPECIAL INSPECTOR IN ACCORDANCE WITH THEBUILDING CODE. INSTALLATION OF GROUTED DOWELS AND RODS SHALL BE CONTINUOUSLY INSPECTED BYTHE TESTING LABORATORY, TO ENSURE THAT HOLES ARE OF PROPER DIAMETER AND LENGTH, ARE PROPERLY CLEANED, AND THAT DOWELS AND RODS ARE INSTALLED IN ACCORDANCE WITH THE MANUFACTURER’S PRINTED INSTALLATION INSTRUCTIONS (MPII).

6. ANCHORS SHALL BE INSTALLED PERPENDICULAR TO THE FACE OF THE CONCRETE, UNLESS OTHERWISE INDICATED ON THE DRAWINGS.

7. THE CONTRACTOR SHALL CREATE A TEMPLATE FOR EACH ANCHOR ROD GROUP PRIOR TO FABRICATING HOLES IN CONNECTION PLATES. TEMPLATES SHALL BE MADE AFTER LOCATING EXISTING REINFORCING STEEL WITH FERROSCAN OR SIMILAR NON-DESTRUCTIVE REINFORCING IMAGING DEVICE. POSITION ANCHORHOLES SO AS NOT TO CONFLICT WITH THE EXISTING REINFORCING. ANCHOR POSITIONS MAY BE ADJUSTEDIN THE FIELD A MAXIMUM OF 1 1/2" FROM THE DIMENSIONS SHOWN ON THE DETAILS, TO AVOID CONFLICT WITH THE EXISTING REINFORCING STEEL.

8. SUBMIT DRAWINGS OF TEMPLATES FOR ANCHOR ROD GROUPS SHOWING HOLE LOCATIONS PRIOR TO FABRICATION OF CONNECTION PLATES.

9. HOLES SHALL BE DRILLED WITH A HAMMER DRILL. CORED HOLES ARE NOT PERMITTED. DIAMETER OF HOLESDRILLED IN THE CONCRETE SHALL BE THE SIZE RECOMMENDED BY THE MANUFACTURER FOR THE RESPECTIVE ANCHOR SIZE.

10. IMPORTANT: AFTER DRILLING, ALL DUST AND OTHER FOREIGN MATTER SHALL BE BLOWN OUT OF THE HOLEWITH COMPRESSED AIR. DO NOT FLUSH WITH WATER. CLEAN SIDES OF HOLE AS RECOMMENDED BY MANUFACTURER. HOLES MUST BE DRY.

11. ALL ABANDONED HOLES DRILLED IN THE CONCRETE SHALL BE COMPLETELY FILLED WITH NONSHRINK GROUT.

12. HOLES IN CONNECTION PLATES SHALL BE NO MORE THAN 1/16" LARGER THAN THE ANCHOR DIAMETER. IF LARGER DIAMETER HOLES ARE NECESSARY FOR ERECTION PURPOSES, THE CONTRACTOR SHALL PROVIDEPLATE WASHERS SUFFICIENTLY WELDED TO THE CONNECTION PLATE TO TRANSFER THE SPECIFIED LOAD.

FIELD DRILLED DOWELS AND ANCHOR RODS

PRE-ENGINEERED METAL BUILDING FRAME AND ROOF PURLINS1. THE PARKING STRUCTURE AND TRANSFORMER STORAGE BUILDING ARE TO BE PRE-ENGINEERED METAL

BUILDINGS. THE FOLLOWING ARE TO BE DESIGNED AND FURNISHED BY A QUALIFIED METAL BUILDING MANUFACTURER WHO IS CURRENTLY AISC CERTIFIED:

A. ALL ROOF FRAMING.B. ALL RIGID FRAMES AND PORTAL FRAMES.C. ALL PURLINS.D. WALL GIRTS AND RELATED BRACING.E. ROOF AND WALL BRACING.F. ALL PIPE OR TUBE COLUMNS SUPPORTING METAL BUILDING FRAMES.G. STEEL WIDE FLANGE COLUMNS AT END WALLS ARE TO BE SUPPLIED BY THE PRE-ENGINEERED

METAL BUILDING MANUFACTURER. SOME OF THESE END WALL COLUMNS MAY SUPPORT CONVENTIONAL STEEL BEAM FRAMING AS WELL. REFER TO THE FRAMING PLANS.

2. GENERAL CONTRACTOR SHALL PROVIDE AND SET ANCHOR BOLTS, DESIGNED BY THE PRE-ENGINEERED BUILDING MANUFACTURER, PER PRE-ENGINEERED BUILDING MANUFACTURER'S DRAWINGS. ANCHOR BOLTS TO BE A307 WITH STANDARD HEX HEADS OR A36 THREADED RODS WITH STANDARD NUTS ON BOTTOM WITHTHREADS FULLY ENGAGED. J-BOLTS ARE NOT ALLOWED.

3. DESIGN LOADS SHALL BE APPLIED IN THE FOLLOWING ULTIMATE COMBINATIONS:1.2 DL + 1.2 CL + 1.6 LL + 0.5 WL DL = BUILDING DEAD LOAD1.2 DL + 1.2 CL + 1.6 LL LL = ROOF LIVE LOAD OR SNOW0.9 DL + WL WHERE: CL = COLLATERAL LOADS1.2 DL + 1.2 CL + 1.0 WL + 0.5 RLL WL = WIND LOAD1.2 DL + 1.2 CL + 1.0 E + 0.5 RLL E = SEISMIC LOAD

4. FOR THE PURPOSE OF CALCULATING WIND FORCES ON THE METAL BUILDING SYSTEM, ALL BUILDINGS SHALLBE CONSIDERED PARTIALLY ENCLOSED.

5. SUBMIT DESIGN CALCULATIONS, SEALED BY A PROFESSIONAL ENGINEER, REGISTERED IN THE STATE OF TEXAS FOR FRAMING PLANS, ERECTION DRAWINGS, ETC., TO THE ARCHITECT AS SPECIFIED.

6. PROVIDE WASHERS AT BOLTED CONNECTION IF CALIBRATED TORQUE WRENCH IS USED FOR TIGHTENING OF NUTS. COORDINATE WITH ERECTOR.

7. THE METAL BUILDING MANUFACTURER’S ENGINEER SHALL PERFORM SITE OBSERVATIONS DURING THE COURSE OF THE METAL BUILDING CONSTRUCTION TO CONFIRM THAT THE WORK IS PROGRESSING IN ACCORDANCE WITH THE CONTRACT DOCUMENTS AND SHOP DRAWINGS. A PROJECT OBSERVATION REPORTSHALL BE PROVIDED TO THE OWNER AND ARCHITECT. THE CONTRACTOR SHALL MAKE ALL CORRECTIVE WORK REQUIRED TO MAKE ALL NON-COMPLIANT ITEMS ACCEPTABLE TO THE ENGINEER PRIOR TO CONTINUINGWITH ANY FINISH WORK. AT THE END OF THE JOB, THE MANUFACTURER’S PROFESSIONAL ENGINEER, REGISTERED IN THE STATE OF TEXAS, SHALL SUBMIT A SEALED LETTER TO THE OWNER AND ARCHITECT STATING THAT THE DESIGN AND CONSTRUCTION OF THE METAL BUILDING IS IN COMPLIANCE WITH THE CONTRACT DOCUMENTS, THE PROJECT SHOP DRAWINGS, AND ALL APPLICABLE BUILDING CODES.

8. PRE-ENGINEERED STEEL STRUCTURE AND CONNECTIONS, ETC., SHALL ALSO BE SUBJECT TO INSPECTION BY AN INDEPENDENT LABORATORY, AS SPECIFIED.

9. THE FOLLOWING SHALL APPLY TO ALL ROOF PLANS IN THESE DRAWINGS:

A. WIND BRACING SHOWN IN THE PLANE OF THE ROOF IS SCHEMATIC AND IS PROVIDED TO BRACE THEBUILDING UNDER WIND PERPENDICULAR TO PRIMARY RIGID FRAMES. DIAGONAL ROD BRACING WITHTURNBUCKLES OR CLEVISES SHALL BE USED.

B. WALL WIND BRACING MUST BE PROVIDED AT LOCATIONS SHOWN, EXCEPT AS NOTED BELOW. FORBRACES RUNNING PARALLEL TO PRIMARY RIGID FRAMES ONLY, BRACES MAY BE OMITTED IF METALWALL PANELS ACTING AS A DIAPHRAGM CAN RESIST THE REQUIRED WIND FORCES.

C. WALL WIND BRACING SHALL CONSIST OF EITHER DIAGONAL ROD BRACING OR PINNED-BASE PORTAL FRAMES, UNLESS NOTED OTHERWISE. WHERE ROD BRACING IS USED, LOCATE RODS AS CLOSE AS POSSIBLE TO OUTSIDE FLANGE OF COLUMN. REFER TO PLAN LOCATIONS NOTED "X-BRACE" FOR AVAILABLE WALL AREAS.

D. REFER TO SPECIFICATIONS FOR LATERAL DRIFT OF PRIMARY FRAMES. LATERAL DRIFT LIMIT FOR WIND PERPENDICULAR TO PRIMARY FRAMES SHALL BE HEIGHT TO ROOF (IN INCHES) /300.

E. PROVIDE TEMPORARY WIND BRACING AS REQUIRED UNTIL FINAL BRACING IS IN PLACE.

10. ROOF PURLINS SUPPORTING THE STANDING SEAM METAL DECK SHALL BE STANDARD ROLL-FORMED "Z" SECTIONS OR EQUIVALENT SHAPES COMPATIBLE WITH THE ROOF DECK SYSTEM. MATERIAL, GAUGE, SPLICING AND CROSS-SECTION ARE TO BE DETERMINED BY THE METAL BUILDING MANUFACTURER.

11. DESIGN LIGHT-GAUGE STEEL MEMBERS IN ACCORDANCE WITH AISI "SPECIFICATION FOR DESIGN OF COLD-FORMED STEEL STRUCTURAL MEMBERS," LIVE LOAD DEFLECTIONS LIMITED TO L/240 TYPICAL AND L/360 OVERAREAS WITH PLASTER CEILINGS. WHERE HOLES ARE REQUIRED IN PURLIN BOTTOM FLANGE FOR MECHANICALAND ELECTRICAL HANGERS, REDUCTION OF SECTION SHALL BE ACCOUNTED FOR IN DESIGN.

12. LOCATE ROOF PURLINS WHERE INDICATED ON THE ARCHITECTURAL DRAWINGS AT GUTTERS, RIDGES, ETC., AND WHERE INDICATED ON THE STRUCTURAL DRAWINGS FOR INTERFACE WITH THE STRUCTURAL STEEL ROOFBRACING. PROVIDE ADDITIONAL PURLINS WHERE CLOSER SPACING AT PERIMETER IS REQUIRED BY LOADING,OTHERWISE ROOF PURLIN SPACING SHALL NOT EXCEED 5'-0".

13. BASIC DESIGN LOADS AND COLLATERAL LOADS SHALL BE AS FOLLOWS:

A. BASIC DESIGN LOADS, IN ADDITION TO DEAD LOAD, INCLUDE LIVE LOAD AND WIND LOAD.

B. COLLATERAL LOADS INCLUDE ADDITIONAL DEAD LOADS OVER AND ABOVE WEIGHT OF METAL BUILDING SYSTEM SUCH AS MECHANICAL, ELECTRICAL, PLUMBING, FIRE PROTECTION SYSTEMS, AND CEILING SYSTEMS. INSULATION WEIGHT IS CONSIDERED PART OF METAL BUILDING SYSTEM.

C. DESIGN EACH MEMBER TO WITHSTAND FORCES RESULTING FROM COMBINATIONS OF LOADS THAT PRODUCE MAXIMUM STRESSES IN THAT MEMBER, AS FOLLOWS:

1) ROOF LIVE LOAD: 20 PSF

2) ROOF DEAD LOAD: WEIGHT OF PURLINS, DECK, AND INSULATION CALCULATED BY MANUFACTURER.

3) COLLATERAL LOAD:

A) MECHANICAL, ELECTRICAL, PLUMBING 5 PSF. CONCENTRATED LOADS GREATER THAN 200 POUNDS REQUIRE SPECIAL DESIGN.

B) ADDITIONAL LOADS: ADDITIONAL ROOF PURLINS MAY BE REQUIRED. REFER TO THEDRAWINGS FOR LOCATIONS OF ADDITIONAL EQUIPMENT. THE CONTRACTOR/MANUFACTURER SHALL COORDINATE PURLIN DESIGNS WITH ALL MECHANICAL, ELECTRICAL, OR OTHER EQUIPMENT REGARDLESS OF WHETHER IT IS LOCATED ON DRAWINGS. REVIEW PIPE HANGER CLAMPS TO BE USED TO MINIMIZE TORSION ON THE PURLINS.

4) WIND LOADS: REFER TO SPECIFICATIONS FOR WIND LOADS.

14. DESIGN BRIDGING OR OTHER LATERAL BRACING AS REQUIRED TO PREVENT BUCKLING AND TWISTING DUE TOUPLIFT PRESSURE AND OTHER LOADS.

15. PROVIDE CROSS BRIDGING OR BLOCKING BETWEEN PURLINS AT HANGERS SUPPORTING MORE THAN 75 POUNDS.

16. THE MANUFACTURER IS RESPONSIBLE FOR ALL PURLIN MEMBER DESIGN, CONNECTIONS, BRACING AND ATTACHMENTS TO THE STRUCTURAL FRAME. SUBMIT CALCULATIONS WITH ENGINEER'S SEAL FOR ALL DESIGNS.

17. RIGID BENTS ELEVATIONS SHOWN ARE A SCHEMATIC REPRESENTATION AND MAY OR MAY NOT REFLECT ACTUAL GEOMETRIC CONFIGURATION OF BEAMS AND COLUMNS. WHERE INDICATED, MEMBER SIZE LIMITS MUST BE ADHERED TO. ALSO REFER TO ARCHITECTURAL PLAN DETAILS FOR MAXIMUM FRAME AND WIND BENT COLUMN DIMENSIONS. INCREASE THICKNESS OF FLANGES AND WEBS AS REQUIRED TO MAINTAIN THESEDIMENSIONS.

18. WALL GIRTS ARE TO BE DESIGNED TO SPAN AND BRACE THE TOP OF EXTERIOR STUD WALLS AS DEFINED ONTHE ARCHITECTURAL WALL SECTIONS. LIMIT DEFLECTION OF GIRTS TO THE FOLLOWING WHEN SUBJECTED TO70 PERCENT OF FULL DESIGN WIND PRESSURE OR SUCTION:IF BRACING MASONRY VENEER L/600IF BRACING FINISHED DRYWALL INTERIOR L/360WITH FLEXIBLE SHEATHING L/240

PRE-ENGINEERED METAL BUILDING FRAMEAND ROOF PURLINS 1. ROOF DECK SHALL BE 1 1/2" DEEP, 22 GAUGE, WIDE RIB, GALVANIZED METAL DECK, WITH 6" RIB SPACING, MEETING

THE REQUIREMENTS OF THE STEEL DECK INSTITUTE.

2. ROOF DECK SHALL BE CONTINUOUS OVER THREE OR MORE SPANS.

3. TYPICAL DECK CONNECTIONS SHALL BE AS FOLLOWS:AT EACH SUPPORT: PUDDLE WELDS AT EACH SIDE LAP AND AT INTERMEDIATE RIBS AT AN AVERAGE SPACING OF 12" ON CENTER, NOT TO EXCEED 18" ON CENTER.AT SIDE LAPS: SCREWS EQUALLY SPACED BETWEEN SUPPORTS, NOT TO EXCEED 36" ON CENTER.AT EXTERIOR SIDES, PARALLEL TO DECK SPAN: PUDDLE WELDS AT 12" ON CENTER.

4. SCREWS SHALL BE "TEKS" #12-14X3/4" HWH #2.

5. PUDDLE WELDS SHALL BE FULL-FUSION, 5/8" DIAMETER (MINIMUM) OR EQUIVALENT WELDS, MADE THROUGH WELDWASHERS. METAL AROUND WELDS SHALL BE COMPLETELY INTACT AFTER WELDING.

6. THE METAL ROOF DECK ON THIS PROJECT IS REQUIRED TO PERFORM AS A STRUCTURAL DIAPHRAGM. ALLWELDS AND SCREWS ARE CRITICAL TO THE SUCCESSFUL PERFORMANCE OF THE DIAPHRAGM.

7. SUSPENDED CEILING, LIGHT FIXTURES, DUCTS OR OTHER UTILITIES SHALL NOT BE SUPPORTED BY THE STEEL DECK.

METAL ROOF DECK

© 2

016 M

oody/

Nola

n I

nc.

Dwg. Coord.: Tech. Coord.:

5001 Spring Valley RoadSuite 225EDallas, TX 75244

Phone: (214) 377-8662

KEY PLAN

A B

C

PORTIONS OF THIS DRAWING MAY NOT BE TO SCALE. THEREFORE, THIS DRAWING SHALL NOT BE SCALED. COPYRIGHT © 2017 DATUM ENGINEERS, INC.

Datum Engineers IncorporatedWWW.DATUMENGINEERS.COM | CO REG. NO. F-2819

Datum Project No.

Dallas San Antonio214-358-0174 210-858-2869

Austin512-469-9490

4/2

6/2

017 9

:01:5

3 A

MC

:\U

sers

\kelly

.DA

TU

M\D

ocu

ments

\Revit

2016 L

oca

l\16146 A

EP

Corp

us C

hristi

- S

truct

_kt

hib

odeaux.r

vt

16578

04-25-17

CORPUS CHRISTI

AMERICAN ELECTRICPOWER

Author Checker

BIDDING AND PERMIT DOCUMENTS

GENERAL NOTESS103

16146

# DATE CHANGE DESCRIPTION

04/27/17

BB

22

22

21

21

20

20

19

19

18

18

17

17

16

16

15

15

13

13

12

12

10

10

8

8

7

7

6

6

5

5

4

4

CC

EE

GG

HH

JJ

LL

MM

NN

PP

F.2F.2

H.5H.5

L.3L.3

RR

3

3

2

2

1

1

FF

14

14

11.6

11.6

AA

DD

23

23

11

11

TW-1/S601

TW

-2/S

601

TW-3/S601

TW-5/S601

TW

-6/S

601

TW-7/S601

TW

-4/S

601

TW

-8/S

602

TW-15/S603

TW

-16/S

603

TW-17/S603

TW

-9/S

602

TW-11/S602

TW-10/S602

TW

-14/S

602

4/S602

TW

-13/S

602

TW-18/S603

TW

-19/S

603

TW-20/S604

TW

-21/S

604

D.1 D.1

10.1

10.1

2.1

2.1

3.1

3.1

5.2

5.2

12.9

12.9

14.3

14.3

J.2J.2

15.1

15.1

22.9

22.9

WB-11/S701

WB-22/S701

WB

-33/S

701

H.4 H.4

© 2

016 M

oody/

Nola

n I

nc.

Dwg. Coord.: Tech. Coord.:

5001 Spring Valley RoadSuite 225EDallas, TX 75244

Phone: (214) 377-8662

KEY PLAN

A B

C

PORTIONS OF THIS DRAWING MAY NOT BE TO SCALE. THEREFORE, THIS DRAWING SHALL NOT BE SCALED. COPYRIGHT © 2017 DATUM ENGINEERS, INC.

Datum Engineers IncorporatedWWW.DATUMENGINEERS.COM | CO REG. NO. F-2819

Datum Project No.

Dallas San Antonio214-358-0174 210-858-2869

Austin512-469-9490

4/2

6/2

017 9

:01:5

5 A

MC

:\U

sers

\kelly

.DA

TU

M\D

ocu

ments

\Revit

2016 L

oca

l\16146 A

EP

Corp

us C

hristi

- S

truct

_kt

hib

odeaux.r

vt

16578

04-25-17

CORPUS CHRISTI

AMERICAN ELECTRICPOWER

Author Checker

BIDDING AND PERMIT DOCUMENTS

OVERALL FOUNDATIONFRAMING PLAN

S201

16146

1/16" = 1'-0"

1 FIRST FLOOR OVERALL

# DATE CHANGE DESCRIPTION

04/27/17

B

121087654

C

E

G

H

J

L

321

F

11.611

TW-1/S601

TW-1

TW

-2/S

601

TW-3/S601

TW-5/S601

TW

-6/S

601

TW-7/S601

TW

-2

TW-3

TW

-4/S

601

TW

-4

TW-5

TW

-6

TW-7

TW

-9

TW-11

TW-12

TW

-13

TW

-14

TW

-9/S

602

TW-11/S602

TW-10/S602

TW

-14/S

602

4/S602

TW

-13/S

602

TW-10

40'

-0"

20'

-0"

20'

-0"

20'

-0"

20'

-0"

40'

-0"

20'

-0"

9 1

/4"

13'-4 1/2"

5"

26'-5 3/4"

5"

24'-7" 25'-0" 6'-11 1/8" 18'-0 7/8" 25'-0" 25'-0" 25'-0" 10'-0 3/4" 14'-11 1/4" 17'-1 7/8" 7'-10 1/8"

HSS6X6X1/4, BP-1 HSS6X6X1/4, BP-1 HSS6X6X1/4, BP-1 HSS6X6X1/4, BP-1 HSS6X6X1/4, BP-1

HSS6X6X1/4, BP-1

HSS6X6X1/4, BP-1 HSS6X6X1/4, BP-1 HSS6X6X1/4, BP-1

HSS6X6X1/4, BP-1 HSS6X6X1/4, BP-1 HSS6X6X3/8, BP-1 HSS6X6X3/8, BP-1

HSS6X6X1/4, BP-1

HSS6X6X1/4, BP-1

HSS6X6X1/4, BP-1

HSS6X6X1/4, BP-1

10.1

6" MIN. SLAB-ON-VOIDBOX REINF. W/ #5 @ 8"T & B (SHORT SPAN)#4 @ 12" T & B (LONGSPAN).

12

S305

1/4" / 12"

11

S305

2.1 3.1 5.2

8" SLAB-ON-GRADE@ TELECOM &NETWORK SHOPSSEE S303 FORDETAILS & REINF.

8" SLAB-ON-GRADE@ METER SHOPSEE S303 FORDETAILS & REINF.

100'-0"T.O.S.C. EL.

99'-10"T.O.S.C. EL.

100'-0"T.O.S.C. EL.

SLO

PE

5" SLAB-ON-GRADESEE S303 FORDETAILS & REINF.TYP., U.N.O.

@ TRENCH DRAIN

P6, 6/S302P4, 6/S302P3, 6/S302

2

S305

3

S305

TYP. @ROLL-UPDOORS

TYP. @EXT.DOORS

3

S605

3

S605

3

S605

15/S304

TYP. @COLUMNRE-ENTRANTCORNERS

13/S304

TYP. @PERIMETERCOLUMNS

3

S605

3

S605

3

S605

8

S305

9

S305

8

S305

9

S3058

S305

9

S305

8

S305

8

S305

2

S305

3

S305TYP. @ROLL-UPDOORS

TYP. @EXT.DOORS

W8X24, BP-3

W8X24, BP-3

P1, 6/S302

P1, 6/S302

P4, 6/S302P4, 6/S302P4, 6/S302P4, 6/S302P4, 6/S302P2, 6/S302

P2, 6/S302

P5, 12/S302 P3, 7/S302 P3, 7/S302 P3, 7/S302 P3, 7/S302 P3, 7/S302

P3, 7/S302

P3, 6/S302

P2, 6/S302

P4, 12/S302 P4, 7/S302 P4, 7/S302 P3, 7/S302 P3, 7/S302

P4, 12/S302 P4, 7/S302 P3, 7/S302 P4, 7/S302 P4, 7/S302

P4, 6/S302

P2, 6/S302

P3, 6/S302 P4, 6/S302 P4, 6/S302 P3, 6/S302

P4, 6/S302 P4, 6/S302 P5, 6/S302 P5, 6/S302 P5, 6/S302 P5, 6/S302

P5, 6/S302

P2, 6/S302

P2, 6/S302

P6, 6/S302

P4, 6/S302

P4, 6/S302

P6, 6/S302 P6, 6/S302 P6, 6/S302

P6, 6/S302

P5, 6/S302 P6, 6/S302 P6, 6/S302 P6, 6/S302

P4, 6/S302 P5, 6/S302

P4, 6/S302P3, 6/S302

5" Slab-On-Grade

TYP. @EXT.DOOR

3

S305

9 1/4" 9 1/4"

9 1/4"

9 1/4"

9 1

/4"

9 1

/4"

© 2

016 M

oody/

Nola

n I

nc.

Dwg. Coord.: Tech. Coord.:

5001 Spring Valley RoadSuite 225EDallas, TX 75244

Phone: (214) 377-8662

KEY PLAN

A B

C

PORTIONS OF THIS DRAWING MAY NOT BE TO SCALE. THEREFORE, THIS DRAWING SHALL NOT BE SCALED. COPYRIGHT © 2017 DATUM ENGINEERS, INC.

Datum Engineers IncorporatedWWW.DATUMENGINEERS.COM | CO REG. NO. F-2819

Datum Project No.

Dallas San Antonio214-358-0174 210-858-2869

Austin512-469-9490

4/2

6/2

017 9

:01:5

7 A

MC

:\U

sers

\kelly

.DA

TU

M\D

ocu

ments

\Revit

2016 L

oca

l\16146 A

EP

Corp

us C

hristi

- S

truct

_kt

hib

odeaux.r

vt

16578

04-25-17

CORPUS CHRISTI

AMERICAN ELECTRICPOWER

Author Checker

BIDDING AND PERMIT DOCUMENTS

FOUNDATION FRAMINGPLAN - AREA A

S201A

16146

1/8" = 1'-0"

1 FOUNDATIO PLAN - AREA A

# DATE CHANGE DESCRIPTION

04/27/17

BB

22212019181716151312

C

E

H

L

F.2

H.5

L.3

14

A

D

23

TW

-8/S

602

TW

-8

TW-15/S603

TW15

TW

-16/S

603

TW

-16

TW-17/S603

TW17TW-18/S603

TW18

D.1

14

S303

14

S303

2

S605

5'-7

"

W14X82, BP-3 W14X82, BP-4

W14X82, BP-5

W14X82, BP-4 W14X82, BP-3 W14X82, BP-3 W14X68, BP-3W14X82, BP-3

W14X82, BP-3W14X82, BP-3 W14X82, BP-4 W14X82, BP-5 W14X82, BP-4 W14X82, BP-3 W14X82, BP-3 W14X68, BP-3

HSS6X6X1/4, BP-2

HSS6X6X1/4, BP-1 HSS6X6X1/4, BP-6

HSS6X6X1/4, BP-6

HSS8X8X1/4, BP-2 HSS8X8X1/4, BP-2 HSS8X8X1/4, BP-2 HSS8X8X1/4, BP-2 HSS8X8X1/4, BP-2 HSS8X8X1/4, BP-2

HSS8X8X1/4, BP-2 HSS8X8X1/4, BP-2

HSS8X8X3/8, BP-2

W14X68, BP-3

W14X68, BP-3

1'-2

1/4

"5'-7

"49'

-9"

1'-2

1/4

"

44'

-5 3

/4"

44'

-6 1

/2"

1'-1

1/2

"

38'

-11"

16'

-5"

1'-2

1/4

"

12

S304

12

S304

12

S304

8" SLAB-ON-GRADE@ TELECOM &NETWORK SHOPSSEE S303 FORDETAILS & REINF.

12.9 14.3

J.2

15.1

SLO

PE

SLO

PE

100'-0"T.O.S.C. EL.

99'-10"T.O.S.C. EL.

100'-0"T.O.S.C. EL.

@ TRENCH DRAIN

22.9

8" SLAB-ON-GRADESEE S303 FORDETAILS & REINF.TYP. @ LINETRUCKBAYS & STORAGEAREA B

WB-11/S701

WB-22/S701

100'-0"T.O.S.C. EL.

99'-10"T.O.S.C. EL.

100'-0"T.O.S.C. EL.

@ TRENCHDRAIN

SLO

PE

SLO

PE

WB

-33/S

701

2

S605

5

S305

6

S303

TYP. @WINDBRACE

TYP. @NON-LOADBEARINGCMU WALLU.N.O.

2

S305

3

S305

TYP. @ROLL-UPDOORS

TYP. @EXT.DOORS

20'-6 5/8" 4'-5 3/8" 16'-4 1/8"

2'-0 1/8"

6'-4 3/4"

7"

24'-8" 25'-0" 25'-0" 25'-0" 25'-0" 25'-0" 25'-0" 27'-5"

7"

1'-2 1/4"

9 3/8"

1'-2 1/4"9 1/4"

3

S605

8

S305

8

S305

5

S305

6

S303

TYP. @WINDBRACE

TYP. @NON-LOADBEARINGCMU WALLU.N.O.

P2, 11, 12/S302

P3, 11/S302P5, 7/S302

P5, 7/S302

P5, 16/S302 SIM.

P3, 6/S302

P5, 6/S302

P6, 6/S302P4, 6/S302

P6, 6/S302 P6, 6/S302 P6, 6/S302 P6, 6/S302 P6, 6/S302 P6, 6/S302 P6, 6/S302 P6, 6/S302

P4, 16/S302 P4, 16/S302 P4, 11/S302 P4, 11/S302 P4, 11/S302 P4, 16/S302 P4, 16/S302

P3, 6/S302

P4, 12/S302 P4, 7/S302 P4, 7/S302 P4, 7/S302

P4, 16/S302 P4, 16/S302 P4, 16/S302

P3, 6/S302

P5, 6/S302P6, 6/S302

P6, 6/S302

P3, 6/S302

P3, 6/S302

P5, 6/S302

5

S305

SIM. @WINDBRACE

3

S305SIM.

3

S305

TYP. @EXT.DOOR

TYP. @TRENCHDRAIN

4

S305

2

S305

3

S305

TYP. @ROLL-UPDOORS

TYP. @EXT.DOORS

P6, 12/S302

P4, 7/S302 P4, 7/S302 P4, 7/S302

P4, 6/S302

P6, 16/S302

P4, 6/S302

P4, 7/S302

P2, 7/S302

SLO

PE

2

S305

TYP. @ROLL-UPDOORS

13/S304

TYP. @PERIMETERCOLUMNS

P6, 15/S302P4, 16/S302P4, 16/S302P4, 11/S302

P4, 11/S302

P4, 11/S302

6

S305

TYP. @SCALE

P4, 6/S302

TYP. @AREA B,U.N.O.

P6, 6/S302 P6, 6/S302 P6, 6/S302 P6, 6/S302 P6, 6/S302 P6, 6/S302 P6, 6/S302 P6, 6/S302

TYP. @TRENCHDRAIN

TYP. @TRENCHDRAIN

T.O. WALL EL. = 100'-0"

P4, 6/S302

TYP. @EXT.DOOR

3

S305P5, 6/S302

8

S305

H.4

© 2

016 M

oody/

Nola

n I

nc.

Dwg. Coord.: Tech. Coord.:

5001 Spring Valley RoadSuite 225EDallas, TX 75244

Phone: (214) 377-8662

KEY PLAN

A B

C

PORTIONS OF THIS DRAWING MAY NOT BE TO SCALE. THEREFORE, THIS DRAWING SHALL NOT BE SCALED. COPYRIGHT © 2017 DATUM ENGINEERS, INC.

Datum Engineers IncorporatedWWW.DATUMENGINEERS.COM | CO REG. NO. F-2819

Datum Project No.

Dallas San Antonio214-358-0174 210-858-2869

Austin512-469-9490

4/2

6/2

017 9

:01:5

8 A

MC

:\U

sers

\kelly

.DA

TU

M\D

ocu

ments

\Revit

2016 L

oca

l\16146 A

EP

Corp

us C

hristi

- S

truct

_kt

hib

odeaux.r

vt

16578

04-25-17

CORPUS CHRISTI

AMERICAN ELECTRICPOWER

Author Checker

BIDDING AND PERMIT DOCUMENTS

FOUNDATION FRAMINGPLAN - AREA B

S201B

16146

1/8" = 1'-0"

1 FOUNDATION PLAN - AREA B

# DATE CHANGE DESCRIPTION

04/27/17

15

L

M

N

P

Q

L.3

R

1411.611

TW-18/S603

TW

-19/S

603

TW-20/S604

TW

-21/S

604

TW18

TW

-19

TW-20

TW

-21

1'-2

1/4

"21'

-4 5

/8"

20'

-0"

20'

-0"

20'

-0"

9'-5

"5'-7

"

12

S304

12

S304

100'-0"T.O.S.C. EL.

99'-10"T.O.S.C. EL.

@ TRENCH DRAIN

W14X82, BP-3 W14X82, BP-3

W14X82, BP-3 W14X82, BP-3

100'-0"T.O.S.C. EL.

100'-0"T.O.S.C. EL.

99'-10"T.O.S.C. EL.

@ TRENCH DRAIN

P6, 6/S302

2

S305

TYP. @ROLL-UPDOORS

8

S305

9 1/4"

P5, 6/S302

P6, 6/S302P4, 6/S302

3

S305SIM.

17'-1 7/8" 49'-2 1/4" 8'-4 7/8"

1'-2 1/4" 1'-2 1/4"

TYP. @TRENCHDRAIN

TYP. @TRENCHDRAIN

TYP. @EXT.DOOR

3

S305P5, 6/S302 P5, 6/S302

P5, 15/S302 P5, 15/S302

P5, 15/S302P5, 15/S302

P5, 6/S302

P6, 6/S302P6, 6/S302

P4, 6/S302

P5, 6/S302

10

S305TYP.

2

S305

TYP. @ROLL-UPDOOR

2

S605TYP. @AREA CU.N.O.

2

S305

TYP. @ROLL-UPDOOR

TYP. @EXT.DOOR

3

S305

8

S305

P2, 6/S302 P2, 6/S302 P2, 6/S302

P2, 6/S302

P2, 6/S302P2, 6/S302P2, 6/S302

P2, 6/S302

EQ EQ

EQ

EQ

© 2

016 M

oody/

Nola

n I

nc.

Dwg. Coord.: Tech. Coord.:

5001 Spring Valley RoadSuite 225EDallas, TX 75244

Phone: (214) 377-8662

KEY PLAN

A B

C

PORTIONS OF THIS DRAWING MAY NOT BE TO SCALE. THEREFORE, THIS DRAWING SHALL NOT BE SCALED. COPYRIGHT © 2017 DATUM ENGINEERS, INC.

Datum Engineers IncorporatedWWW.DATUMENGINEERS.COM | CO REG. NO. F-2819

Datum Project No.

Dallas San Antonio214-358-0174 210-858-2869

Austin512-469-9490

4/2

6/2

017 9

:01:5

9 A

MC

:\U

sers

\kelly

.DA

TU

M\D

ocu

ments

\Revit

2016 L

oca

l\16146 A

EP

Corp

us C

hristi

- S

truct

_kt

hib

odeaux.r

vt

16578

04-25-17

CORPUS CHRISTI

AMERICAN ELECTRICPOWER

Author Checker

BIDDING AND PERMIT DOCUMENTS

FOUNDATION FRAMINGPLAN - AREA C

S201C

16146

1/8" = 1'-0"

1 FOUNDATION PLAN - AREA C

# DATE CHANGE DESCRIPTION

04/27/17

2221201918171615

F.2

H.5

D

23

TW

-8/S

602

TW

-16/S

603

D.1

15.1 22.9

WB-11/S701

WB-22/S701

H.4

1'-2

1/4

"44'

-5 3

/4"

44'

-6 1

/2"

1'-1

1/2

"

W14X43 W14X43

C10X30 (LOW) C10X30 (LOW) C10X30 (HIGH) C10X30 (LOW) C10X30 (LOW) C10X30 (HIGH) C10X30 (LOW) C10X30 (LOW)

C10

X30

(LO

W)

C10

X30

(HIG

H)

C10X30 (LOW)

C10

X30

(LO

W)

C10X30 (LOW) C10X30 (LOW) C10X30 (HIGH) C10X30 (LOW) C10X30 (LOW) C10X30 (LOW) C10X30 (HIGH) C10X30 (LOW)

W14X43 W14X43

7" 24'-8" 25'-0" 25'-0" 25'-0" 25'-0" 25'-0" 25'-0" 27'-5" 7"

3

S202

4

S202

H

4/S602

10.1

H.5H.4

C10X30 (HIGH)

C10X30 (LOW)

W14X43

B.O.S. EL. = 112'-0"

B.O.S. EL. = 108'-0"

H.5H.4

C10X30 (HIGH)

C10X30 (LOW)

W14X43

C10X20

B.O.S. EL. = 112'-0"

© 2

016 M

oody/

Nola

n I

nc.

Dwg. Coord.: Tech. Coord.:

5001 Spring Valley RoadSuite 225EDallas, TX 75244

Phone: (214) 377-8662

KEY PLAN

A B

C

PORTIONS OF THIS DRAWING MAY NOT BE TO SCALE. THEREFORE, THIS DRAWING SHALL NOT BE SCALED. COPYRIGHT © 2017 DATUM ENGINEERS, INC.

Datum Engineers IncorporatedWWW.DATUMENGINEERS.COM | CO REG. NO. F-2819

Datum Project No.

Dallas San Antonio214-358-0174 210-858-2869

Austin512-469-9490

4/2

6/2

017 9

:01:5

9 A

MC

:\U

sers

\kelly

.DA

TU

M\D

ocu

ments

\Revit

2016 L

oca

l\16146 A

EP

Corp

us C

hristi

- S

truct

_kt

hib

odeaux.r

vt

16578

04-25-17

CORPUS CHRISTI

AMERICAN ELECTRICPOWER

Author Checker

BIDDING AND PERMIT DOCUMENTS

PARTIAL PLANSS202

16146

1/8" = 1'-0"

1 INTERMEDIATE STEEL FRAMING PLAN - AREA B

# DATE CHANGE DESCRIPTION

1/8" = 1'-0"

2 STAIR INTERMEDIATE LANDING 3/4" = 1'-0" 3 3/4" = 1'-0" 4

04/27/17

BB

22

22

21

21

20

20

19

19

18

18

17

17

16

16

15

15

13

13

12

12

10

10

8

8

7

7

6

6

5

5

4

4

CC

EE

GG

HH

JJ

LL

MM

NN

PP

F.2F.2

H.5H.5

L.3L.3

RR

3

3

2

2

1

1

FF

14

14

11.6

11.6

AA

DD

23

23

11

11

TW-1/S601

TW

-2/S

601

TW-3/S601

TW-5/S601

TW

-6/S

601

TW-7/S601

TW

-4/S

601

TW

-8/S

602

TW-15/S603

TW

-16/S

603

TW-17/S603

TW

-9/S

602

TW-11/S602

TW-10/S602

TW

-14/S

602

4/S602

TW

-13/S

602

TW-18/S603T

W-1

9/S

603

TW-20/S604

TW

-21/S

604

D.1

D.1

10.1

10.1

2.1

2.1

3.1

3.1

5.2

5.2

12.9

12.9

14.3

14.3

J.2J.2

15.1

15.1

22.9

22.9

WB-11/S701

WB-22/S701

WB

-33/S

701

H.4 H.4

© 2

016 M

oody/

Nola

n I

nc.

Dwg. Coord.: Tech. Coord.:

5001 Spring Valley RoadSuite 225EDallas, TX 75244

Phone: (214) 377-8662

KEY PLAN

A B

C

PORTIONS OF THIS DRAWING MAY NOT BE TO SCALE. THEREFORE, THIS DRAWING SHALL NOT BE SCALED. COPYRIGHT © 2017 DATUM ENGINEERS, INC.

Datum Engineers IncorporatedWWW.DATUMENGINEERS.COM | CO REG. NO. F-2819

Datum Project No.

Dallas San Antonio214-358-0174 210-858-2869

Austin512-469-9490

4/2

6/2

017 9

:02:0

0 A

MC

:\U

sers

\kelly

.DA

TU

M\D

ocu

ments

\Revit

2016 L

oca

l\16146 A

EP

Corp

us C

hristi

- S

truct

_kt

hib

odeaux.r

vt

16578

04-25-17

CORPUS CHRISTI

AMERICAN ELECTRICPOWER

Author Checker

BIDDING AND PERMIT DOCUMENTS

OVERALL ROOF PLANS203

16146

1/16" = 1'-0"

1 ROOF - OVERALL

# DATE CHANGE DESCRIPTION

04/27/17

B

121087654

C

E

G

H

J

L

321

F

11.611

TW-1/S601

TW

-2/S

601

TW-3/S601

TW-5/S601

TW

-6/S

601

TW-7/S601

TW

-4/S

601

TW

-9/S

602

TW-11/S602

TW-10/S602

TW

-14/S

602

4/S602

TW

-13/S

602

13'-4 1/2" 26'-10 3/4" 25'-0" 25'-0" 25'-0" 25'-0" 25'-0" 25'-0" 25'-0" 25'-0"

7'-10 1/8"