SHOP DRAWING REVIEW - MKC Associates, Inc. CSD/09-ED1-045B Dover...SHOP DRAWING REVIEW ......

Transcript of SHOP DRAWING REVIEW - MKC Associates, Inc. CSD/09-ED1-045B Dover...SHOP DRAWING REVIEW ......

Architecture - Engineering - Planning www.mkcinc.com

Mansfield, Ohio New Philadelphia, Ohio Powell, Ohio 419-525-1102 - phone 330-364-8871 - phone 740-657-3202 - phone 419-525-1428 - fax 330-343-3075 - fax 740-657-1717 - fax

SHOP DRAWING REVIEW

✔

REVIEWEDFURNISH AS CORRECTEDREVISE AND RESUBMITREJECTEDSUBMIT SPECIFIED ITEM

Date:By: Jun 6, 2012

Comments:

This review is only for general conformance with (1) the design concept and (2) the informationgiven in the construction documents. Corrections or comments made on a shop drawing duringthis review do not relieve the contractor from compliance with the requirements of the plans andspecifications. Approval of a specific item does not include approval of an assembly of whichthe item is a component. The contractor remains responsible for: dimensions to be confirmed andcorrelated at the job site; information that pertains solely to the fabrication process or to themeans, methods, techniques, sequences and procedures of construction; coordination of theWork with that of all other trades; and performing all Work in a safe and satisfactory manner.

Trane RTU-11 was chosen

File Name:

237413-01a-1

Westlake City Schools Submittal Cover Sheet

(To be filled out and submitted with each submittal)

School ___High School___ Contractor: _Turner Logistics Date __04/19/12___ Item:____ RTU-11___________________

Specification Section: __237413 _ Sub Specification Section: ________________ Contractor’s Submittal # __237413-01__Revision # __0____ Submittal Type ___PDF__________ Lead Time After Approval (wks) _10__ Manufacturer/Supplier: _Aaon_ Intended Area of Use, Drawing # and Detail Reference: _____________________________________

Contractor Stamp

APPROVED Aaon / Jacco Paul Hinman

_____________________________ 04-19-12

CM Stamp

TURNER/RESOURCE

Reviewed for general acceptance only. This review does not relieve the Contractor of the responsibility for making the work conform to the requirements of the contract. The Contractor is responsible for all dimensions, correct fabrication and accurate fit with the work of other trades. SUBJECT TO ARCHITECT’S APPROVAL Signed: ____________________ Date: _____________ CM Submittal #: ________________________________

Architect Stamp Engineer Stamp

Focused On The Engineered Environment

61 Milford Drive, Hudson, OH 44236

Cleveland (330) 463-0100 Akron (330) 342-9400 Fax: (330) 463-0101 http://www.jacco.com

AAON SUBMITTAL DATA For Approval For Record

AHU-11

Job Name - Westlake City Schools – New High School Contractor - Turner Engineer - Osborn

Date - 4-3-12 Submitted By: Billy Kodosky

X

61 Milford Drive, Hudson, Ohio 44236 Cleveland: (330) 463-0100 Akron: (330) 342-9400 Fax: (330) 463-0101

http://www.jacco.com Sold To: Turner Date: 4-3-12 Project: Westlake City Schools – New High School Location: Westlake, Ohio

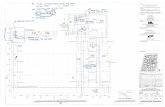

AHU-11 New High School Quantity Of One (1) AAON Model RN, Packaged Rooftop Air Handling Units, Complete With The Following:

Cabinet 2” Double Wall Foam Panel Construction (R-13) w/ G-90 Galvanized Steel Construction w/ Polyurethane Paint Stainless Steel Drain Pan Outside Air Full Modulation Economizer, DDC Actuator Standard 2” Pleated, Throwaway Filters Optional 4” Merv-13 Final Filters Energy Recovery Section Energy Recovery Section w/ Heat Wheel & Pre-Filters Heat Section In-Direct Fired Natural Gas Heating w/ SS Heat Exchanger & Modulating Gas Heat Control Refrigeration Air Cooled Condenser Section Compressorized Refrigeration System R-410a w/ DX Cooling Coil Digital Scroll Compressor – 10-100% Cooling Modulation Modulating Hot Gas Reheat w/ Digital Controller Fan Cycling Fans Direct Drive Supply Air Plenum Fan Assembly w/ ODP Premium Efficiency Motor

o Factory Installed Variable Frequency Drive Power Exhaust Fan Assembly w/ ODP (Premium Efficiency) Motor

o Factory Installed Variable Frequency Drive Electric & Controls Single Point Power Connection w/ Terminal Strip (Non-Fused NEMA-1 Disconnect Switch) & 24v Control Circuit Unit Wired For 460 / 3 / 60 Power Field Installed DDC Controls By Others UV Light Provided And Installed By Jacco Warranty & Service Standard One (1) Year Limited Equipment Warranty – Parts Only Five (5) Year Limited Compressor Warranty, Parts Only Twenty-Five (25) Year Limited Heat Exchanger Warranty, Parts Only Check, Testing & Start-Up Service First Year Labor Warranty Curbs & Accessories Knocked-Down, 14” High, Non-Insulated Roof Curb & Duct Support Rails (Shipped Loose) Spring Vibration Rail (Shipped Loose) No Curb Insulation, Gasket Material & Fasteners, Nor External Vibration Isolators & Flexible Connectors (By Others)

This Submittal Is For Equipment Only. Roof Curb, Controls, Airflow Measuring, & UV Lights Will Be

Submitted Separately. Submitted By: Billy Kodosky

2425 South Yukon Ave - Tulsa, Oklahoma 74107-2728 - Ph. (918) 583-2266 Fax (918) 583-6094AAONEcat32 Ver. 4.182 (SN: 6198192-7E1PR2FF)

1A

1B

1C

1D

2

3

4

5A

5B

5C 6A

6B

6C

7

8

9

10

11

12

13

14A

14B

15

16

17

18

19

20

21

22

23

R N- 018-3- 0-EB 0A -349 :VEDE- E0 B- DQG- AGC-CD CA HN3- 00 -000 00 00AB

Tag: Music VAV AHU-11

Job Information Unit Information

Job Name: Approx. Op./Ship Weights: Job Number: Supply CFM/ESP: Site Altitude: Pre-Filter FV / Qty: Refrigerant Final-Filter FV / Qty:

Exhaust CFM/ESP/TSP: Outside CFM: Ambient Temperature: Return Temperature:

Westlake High 3504 / 3504 lbs.Osborn 5370 / 2 in. wg.0 ft 257.76 fpm / 6R-410A 257.76 fpm / 6

4870 / 1.00 / 1.77 in. wg.336595 ºF DB / 75 ºF WB75 ºF DB / 62 ºF WB

Static Pressure

External: Economizer: Evaporator: Heating: Filters Clean: Cabinet: Dirt Allowance Heatwheel: Re-Heat Coil Total:

2.00 in. wg. 0.11 in. wg.0.25 in. wg. 0.15 in. wg.0.23 in. wg. 0.05 in. wg.1 in. wg. 0.53 in. wg.0.03 in. wg. 4.37 in. wg.

Cooling Section Heating Section

Gross Net Equivalent Total Capacity: Total Capacity: Sensible Capacity: Latent Capacity: HW Total Cooling Capacity: Mixed Air Temp: Entering Air Temp: Lv Air Temp (Coil): Lv Air Temp (Unit) Digital Comp. Capacity Ratio: Supply Air Fan: SA Fan RPM / Width: Exhaust Air Fan: EA Fan RPM / Width:

Evaporator Coil: Evaporator Face Velocity: Energy Recovery Wheel:

306.17 MBH 290.99 MBH207.19 192.02 MBH156.50 141.33 MBH50.69 MBH98.98 MBH79.49 ºF DB 65.48 ºF WB79.49 ºF DB 65.48 ºF WB52.07 ºF DB 51.97 ºF WB54.66 ºF DB 53.06 ºF WB100%1 x 270D60 @ 5.43 BHP1443 / 3.643"1 x RM220A @ 2.17 BHP1349 / 4.920"

19.9 ft² / 6 Rows / 12 FPI270.4 fpm1 x ERC-5262C

PreHeat Type: Std (No Preheat)

Heating Type: Heating CFM: Total Capacity: OA Temp: RA Temp: Entering Air Temp: Leaving Air Temp: Input: Heater Qty: Consumption:

Nat. Gas Heat5370218.7 MBH0.0 DB / 0.0ºF WB75.0 ºF DB / 62.0 ºF WB57.9 ºF DB / 51.7 ºF WB95.6 ºF DB / 65.7 ºF WB270.0 MBH1270.0 MBH

Re-Heat Coil: Capacity: 104 MBH LA DB / WB: 70.00 ºF / 59.10 ºF RH: 53%

AHRI Listing Information

Cooling Capacity (MBH): 198.0 Cooling EER: 12.2 Cooling IEER: 14.3

Application EER @ Op. Conditions: 13.2

Electrical Data

Rating: Minimum Circuit Amp: Unit FLA: Maximum Overcurrent:

460/3/60 5047 60

Qty HP VAC Phase RPM FLA RLA Compressor 1: 2 460 3 12.8 Condenser Fans: 2 0.75 460 1 1075 2.3 Supply Fan: 1 7.50 460 3 1760 11.0 Exhaust Fan: 1 3.00 460 3 1760 4.8 Combustion: 1 0.25 460 1 3200 0.9 Heatwheel: 1 0.1667 460 1 1760 0.6

Cabinet Sound Power Levels*

Octave Bands: 63 125 250 500 1000 2000 4000 8000 Discharge LW(dB): 94 92 93 92 88 88 89 85 Return LW(dB): 89 86 84 77 76 74 70 64 *Sound power levels are given for informational purposes only. The sound levels are not guaranteed.

Unit Rating

Date Created/Modified: 11/29/2011 11:48:48 AM Using Ver 4.182 (OSN# 6198192) Date Printed: 4/2/2012 1:52:45 PM

2425 South Yukon Ave - Tulsa, Oklahoma 74107-2728 - Ph. (918) 583-2266 Fax (918) 583-6094AAONEcat32 Ver. 4.182 (SN: 6198192-7E1PR2FF)

1A

1B

1C

1D

2

3

4

5A

5B

5C 6A

6B

6C

7

8

9

10

11

12

13

14A

14B

15

16

17

18

19

20

21

22

23

R N- 018-3- 0-EB 0A -349 :VEDE- E0 B- DQG- AGC-CD CA HN3- 00 -000 00 00AB Tag: Music VAV AHU-11

Job Name Westlake High Heat Wheel Type: TotalJob Number Osborn Heat Wheel Model: ERC-5262CSite Altitude 0' Heat Wheel Qty: 1

Summer Conditions Bypass: 0 CFM

Mixed Air Damper Supply Air HW Outside Air

5370 CFM 3365 CFM 3365 CFM79.49 ºF DB 82.16 ºF DB 82.16 ºF 95.00 ºF DB65.48 ºF WB 67.43 ºF WB 67.43 ºF 75.00 ºF WB71.77 gr/lb 77.33 gr/lb 99.01 gr/lbReturn Air From Space Exhaust Air

2005 CFM 2865 CFM

75.00 ºF DB 90.08 ºF 90.08 ºF DB62.00 ºF WB 71.76 ºF 71.76 ºF WB62.44 gr/lb 87.91 gr/lb

4870 CFM Ex Bypass: 0 CFM

Cooling/Dehumidification Heating/Humidification

Total Capacity: 98.98 MBH 0.00 MBHSensible Capacity: 47.64 MBH 0.00 MBH

Latent Capacity: 51.33 MBH 0.00 MBH

Winter Conditions Bypass: 0 CFM

Mixed Air Damper Supply Air HW Outside Air

5370 CFM 3365 CFM 3365 CFM58.17 ºF DB 48.14 ºF DB 48.14 ºF 0.00 ºF DB52.00 ºF WB 44.98 ºF WB 44.98 ºF 0.00 ºF WB47.92 gr/lb 39.27 gr/lb 5.51 gr/lbReturn Air From Space Exhaust Air

2005 CFM 2865 CFM

75.00 ºF DB 18.45 ºF 18.45 ºF DB62.00 ºF WB 18.45 ºF 18.45 ºF WB62.44 gr/lb 22.80 gr/lb

4870 CFM Ex Bypass: 0 CFM Frost Warning - Conditions for frost forming on the energy recovery wheel exists. Outside air preheat is required to prevent frost formation. Optionally, the return air humidity ratio could be lowered to prevent frost formation. See AAON literature titled 'AAONAIRE ENERGY RECOVERY' for details.

Cooling/Dehumidification Heating/Humidification

Total Capacity: 0.00 MBH 253.89 MBHSensible Capacity: 0.00 MBH 175.62 MBH

Latent Capacity: 0.00 MBH 78.27 MBH

Energy Wheel Rating

Date Created/Modified: 11/29/2011 11:48:48 AM Using Ver 4.182 (OSN# 6198192) Date Printed: 4/2/2012 1:52:45 PM

2425 South Yukon Ave - Tulsa, Oklahoma 74107-2728 - Ph. (918) 583-2266 Fax (918) 583-6094AAONEcat32 Ver. 4.182 (SN: 6198192-7E1PR2FF)

JOB INFORMATION: WHEEL SPECIFICATION: Job Name: Max RPM: Job Tag: Diameter x Qty: Rep Firm: Width%: Date: Tip Speed:

Inertia:

Westlake High 1,800Music VAV AHU-11 27.4 in. x 1

9904/02/2012 10,351 FPM

16 WR²

OPERATING CONDITIONS: MOTOR SELECTION: Air Flow: Rated HP / Bypass: Static Pressure: Frame Size: Plenum DP: Nominal RPM: Inlet Grill DP: VAC/PH/HZ: TSP: Efficiency Site Altitude: Enclosure Type: TSP @ Sea Level: Max Inertial Load:

5,370 CFM 7.5 / No4.37 in. Wg. 213T0.00 in. Wg. 17600.00 in. Wg. 460/3/604.37 in. Wg. Premium / 0.910.00 Ft ODP4.37 in. Wg. 64 WR²

FAN PERFORMANCE: FAN SOUND POWER (Inlet/Outlet): RPM: Octave Band: (Re 10^-12 watts) BHP: 1 2 3 4 5 6 7 8 Efficiency: In/Out Velocity: Plenum Out Velocity: SOUND POWER A-Weighted: 94 / 99 dB

14435.4368.2% 91 88 85 85 84 84 84 831402/1467 FPM 93 91 92 93 91 91 92 8889 FPM

RPM

BHP

SYSTEM

Efficiency

Supply Fan Model: 270D60 @ 1443 RPM and 99% WidthDesign Conditions: 5370 CFM @ 4.37" SP

CFM x 100087654321

SP

4

3

2

1

0

BH

P

12

11

10

9

8

7

6

5

4

3

2

1

0

60%

40%

20%

0%

RPM: 1443

BHP: 5.43

EFFICIENCY: 68.16

27.0" STAR Plenum

Date Created/Modified: 11/29/2011 11:48:48 AM Using Ver 4.182 (OSN# 6198192) Date Printed: 4/2/2012 1:52:45 PM

2425 South Yukon Ave - Tulsa, Oklahoma 74107-2728 - Ph. (918) 583-2266 Fax (918) 583-6094AAONEcat32 Ver. 4.182 (SN: 6198192-7E1PR2FF)

JOB INFORMATION: WHEEL SPECIFICATION: Job Name: Max RPM: Job Tag: Diameter x Qty: Rep Firm: CFM: Date: Tip Speed:

Inertia:

Westlake High 2,200Music VAV AHU-11 22.0 in. x 1

487004/02/2012 7,770 FPM

5 WR²

OPERATING CONDITIONS: MOTOR SELECTION: Air Flow: Rated HP / Bypass: Static Pressure: Frame Size: Relief Dampers DP: Nominal RPM:

VAC/PH/HZ: TSP: Efficiency Site Altitude: Enclosure Type: TSP @ Sea Level: Max Inertial Load:

4,870 CFM 3 / No1.46 in. Wg. 182T0.31 in. Wg. 1760

460/3/601.77 in. Wg. Premium / 0.8950.00 Ft ODP1.77 in. Wg. 29 WR²

FAN PERFORMANCE: FAN SOUND POWER (Inlet/Outlet): RPM: Octave Band: (Re 10^-12 watts) BHP: 1 2 3 4 5 6 7 8 Efficiency: In/Out Velocity: Plenum Out Velocity: SOUND POWER A-Weighted: 89 / 89 dB

13492.1762.8% 89 87 89 84 78 77 73 671489/1640 FPM 89 87 89 84 78 77 73 6781 FPM

RPM

BHP

SYSTEM

Efficiency

Exhaust Fan Model: RM220A @ 1349 RPM and 100% WidthDesign Conditions: 4870 CFM @ 1.77" SP

CFM x 1000654321

SP

2

1

0

BH

P

5

4

3

2

1

0

60%

40%

20%

0%

RPM: 1349

BHP: 2.17

EFFICIENCY: 62.81

22.0" STAR Plenum

Date Created/Modified: 11/29/2011 11:48:48 AM Using Ver 4.182 (OSN# 6198192) Date Printed: 4/2/2012 1:52:45 PM

2425 South Yukon Ave - Tulsa, Oklahoma 74107-2728 - Ph. (918) 583-2266 Fax (918) 583-6094AAONEcat32 Ver. 4.182 (SN: 6198192-7E1PR2FF)

1A

1B

1C

1D

2

3

4

5A

5B

5C 6A

6B

6C

7

8

9

10

11

12

13

14A

14B

15

16

17

18

19

20

21

22

23

R N- 018-3- 0-EB 0A -349 :VEDE- E0 B- DQG- AGC-CD CA HN3- 00 -000 00 00AB Tag: Music VAV AHU-11

Job Name: Westlake High Unit Submittal For: Job Number: Osborn Unit Submittal Date: November 29, 2011

Base Option Description

R Series Roof Top Unit

N Generation Ninth Generation

018 Unit Size Eighteen

3 Voltage 460V/3Ø/60Hz

0 Interior Protection Standard

E Refrigerant Style R-410A Variable Capacity Scroll Compressor (VCC)

B Unit Configuration Air-Cooled Cond. + 6 Row Evap. Coil

0 Coil Coating Standard

A Cooling/Heat Pump Staging Modulating - All Variable Capacity Compressors

3 Heating Type Natural Gas Stainless Steel

4 Heating Designation Heat 4 - 270 MBtuh

9 Heating Staging Modulating Gas - Temperature Control

Feature Option Description

V 1A. RA/OA Section AAONAIRE® Energy Recovery Wheel + Bypass Damper - Total + High CFM

E 1B. RA/EA Blower Configuration 1 Blower + Premium Efficiency Motor + 1 VFD

D 1C. RA/EA Blower 22" Backward Curved Plenum

E 1D. RA/EA Blower Motor 3.0 hp - 1760 rpm

E 2. OA Control DDC Actuator

0 3. Heat Options Standard

B 4. Maintenance Options 115V Convenience Outlet - Factory Wired

D 5A. SA Blower Configuration 1 Blower + Premium Efficiency Motor + 1 VFD

Q 5B. SA Blower 27'' Direct Drive Backward Curved Plenum - 60% Width

G 5C. SA Motor 7.5 hp - 1760 rpm

A 6A. Pre Filter Type 2" Pleated Pre Filter - 30% Eff

G 6B. Unit Filter Type 4" Pleated - 85% Eff - MERV 13

C 6C. Filter Options Clogged Filter Switch + Magnehelic Gauge

C 7. Refrigeration Control Fan Cycling

D 8. Refrigeration Options Modulating Hot Gas Reheat

C 9. Refrigeration Accessories Sight Glass + Compressor Isolation Valves

A 10. Power Options Power Switch - 100 amps

H 11. Safety Options Remote Safety Shutdown Terminals

N 12. Controls ERW Defrost + ERW Rotation Detection

3 13. Special Controls VAV Single Zone Unit Controller - VAV Cool + VAV Heat

0 14A. Preheat Configuration Standard - None

0 14B. Preheat Sizing Standard - None

0 15. Glycol Percent Water or No WSHP

0 16. Interior Cabinet Options Standard - Double Wall + R-13 Foam Insulation + Stainless Steel Drain Pan

0 17. Exterior Cabinet Options Standard

0 18. Customer Code Standard

0 19. Code Options Standard - ETL U.S.A. Listing

0 20. Crating Standard

0 21. Water-Cooled Cond. Standard - None

A 22. Control Vendors Wattmaster Controls

B 23. Type Standard - Includes AAON Gray Paint

Unit Submittal

Date Created/Modified: 11/29/2011 11:48:48 AM Using Ver 4.182 (OSN# 6198192) Date Printed: 4/2/2012 1:52:45 PM

2425 South Yukon Ave - Tulsa, Oklahoma 74107-2728 - Ph. (918) 583-2266 Fax (918) 583-6094AAONEcat32 Ver. 4.182 (SN: 6198192-7E1PR2FF)

1A

1B

1C

1D

2

3

4

5A

5B

5C 6A

6B

6C

7

8

9

10

11

12

13

14A

14B

15

16

17

18

19

20

21

22

23

R N- 018-3- 0-EB 0A -349 :VEDE- E0 B- DQG- AGC-CD CA HN3- 00 -000 00 00AB Tag: Music VAV AHU-11 Job Name: Westlake High VCMX For: Job Number: Osborn VCMX Date: November 29, 2011

Hardware Included For VCMX Controller

Part # Included Parts Assigned ChannelV07150 VCMX Controller with EBUSP94320 Space Temp Sensor - Field Installed MainController\AI1R82890 Supply Air Temp Sensor - Field Installed MainController\AI2R82890 Return Air Temp Sensor MainController\AI3R81550 Outside Air Temp Sensor MainController\AI4R69190 VCMX Large Expansion ModuleR37030 Building Static Pressure Sensor LargeExpansionModule\AI4P62520 Proof of Flow Sensor LargeExpansionModule\BI3P62520 Dirty Filter Sensor LargeExpansionModule\BI2R34690 Space Humidity Sensor - Field Installed LargeExpansionModule\AI2R74870 VCMX Full Digital ModuleR28390 Suction Pressure Transducer

1 2 3 4 5 6 7

VCMXControllerwith EBUS

Analog In X X X XAnalog Out X XBinary InRelay Out X X X X XDigital Sensor(s)

1 2 3 4 5 6 7 8VCMXLarge

ExpansionModule

Analog In X XAnalog OutBinary In X X XRelay Out

VCMX Components

Date Created/Modified: 11/29/2011 11:48:48 AM Using Ver 4.182 (OSN# 6198192) Date Printed: 4/2/2012 1:52:46 PM

Date Created/Modified: 11/29/2011 11:48:48 AM Using Ver 4.182 (OSN# 6198192) Date Printed: 4/2/2012 1:52:46 PM