Ships' Fastenings- From Sewn Boat to Steamship

-

Upload

ramseybush -

Category

Documents

-

view

409 -

download

55

Transcript of Ships' Fastenings- From Sewn Boat to Steamship

-

Ships Fastenings

00-A3433-FM 6/8/05 12:01 PM Page i

-

00-A3433-FM 6/8/05 12:01 PM Page ii

-

Ships FasteningsFrom Sewn Boat to Steamship

Michael McCarthy

Texas A&M University Presscollege station

00-A3433-FM 6/8/05 12:01 PM Page iii

-

Copyright 2005 Michael McCarthy

Manufactured in the United States of America

All rights reserved

First edition

The paper used in this book meets the minimum requirements

of the American National Standard

for Permanence of Paper for Printed Library Materials,

z39.48-1984.

Binding materials have been chosen for durability.

Library of Congress Cataloging-in-Publication Data

McCarthy, Mike, 1947

Ships fastenings : fr0m sewn boat to steamship /

Michael McCarthy.1st ed.

p. cm. (Ed Rachal Foundation nautical archaeology series)

Includes bibliographical references and index.

isbn 1-58544-451-0 (cloth : alk. paper)

1. FastenersHistory. 2. ShipbuildingHistory.

3. Hulls (Naval architecture)History. 4. Underwater archaeology.

I. Title. II. Series

vm15.m39 2005

623.862dc22

2005002898

00-A3433-FM 6/8/05 12:01 PM Page iv

-

To Debbie,Kim, Katie, Ellen

and Phillip:the anchor and

fastenings on my ship

00-A3433-FM 6/8/05 12:01 PM Page v

-

00-A3433-FM 6/8/05 12:01 PM Page vi

-

Contents

preface ix

introduction 3

1 Fastened without Nails: The Sewn Boat 11

2 The Advent of Metals 30

3 Metal Fastenings on the Sewn-Plank Boat 38

4 Fastened with Metal and Wood 44

5 Clinker Shipbuilding 52

6 Carvel Building in Northern Europe 63

7 The Manufacture of Fastenings 86

8 Sheathing: The Key to Copper and Copper-Alloy Fastenings 101

9 The Advent of Muntz Metal through to the Composite Ship 115

10 Registers, Treatises, and Contemporary Accounts 122

11 The Archaeological Evidence 130

12 Iron and Steel Ships 143

13 Modern Terminology 159

Conclusion 165

Appendix: Explanatory Notes on Metallic Fastenings 169

Notes 188

References 197

Index 217

00-A3433-FM 6/8/05 12:01 PM Page vii

-

00-A3433-FM 6/8/05 12:01 PM Page viii

-

Preface

ixFastenings have fascinated me for well over thirty years now, since myrst glimpse of them when I spent a few seasons helping the MaritimeArchaeology Association of Western Australia excavate an Americanwhale ship on behalf of the Western Australian Maritime MuseumsDepartment of Maritime Archaeology. Then in 1978 I joined the de-partment and assisted Jeremy Green in the excavation of a number ofseventeenth-century British and Dutch East India ships. Another col-league, Graeme Henderson, was also excavating and analyzing a seriesof colonial-period shipwrecks: a British naval frigate sent in pursuit ofthe Bounty mutineers; an early-nineteenth-century American Chinatrader; a British whaler; a British French-built colonial trader once anotorious slave ship; a mid-nineteenth-century Quebec-built tradingbarque; and a colonial whaler.1 Many other people joined in these proj-ects as support staff, including Myra Stanbury, the departments Arte-fact Manager, whose comprehensive analyses and catalogues becamethe mainstay of the museums collection management system.

Another early inuence was the work of my predecessor, the mu-seums rst Wreck Inspector, Scott Sledge, whose job it was to in-spect, and if possible to identify, the many wrecks then being reportedto the museum. This was effected utilizing a combination of the physi-cal remains (of which fastenings were an important element) and con-temporary accounts.2 I joined Sledge in inspecting the wrecks of thesecolonial-period vessels, all from a time frame that neatly dovetailedinto the advent and rise of the rst of the worlds underwriters, Lloydsof London, after 1760. After he departed in 1981, my own wreck in-spection teams came to inspect vessels ranging from wooden-hullediron, copper, and copper-alloy fastened ships, through to riveted iron-hulled sailing ships and steamers traveling from many distant cornersof the globeBrazil, England, France, Holland, India, Italy, Croatia,Mauritius, North America, Portugal, Scotland, Wales, and so forth.

Given the myriad of fastenings encountered as a result of these ac-tivities, it became evident that a typology for the use of collection man-agers, conservators, and archaeologists like me, who had little practicalgrounding in shipbuilding methods, was needed. This was tentativelypublished in the Bulletin of the Australian Institute for Maritime Archae-ology in 1983, edited by Myra Stanbury and Jeremy Green, and then byrequest of Valerie Fenwick (who was then its editor), in the pages of the

00-A3433-FM 6/8/05 12:01 PM Page ix

-

International Journal of Nautical Archaeology (IJNA) in 1996.3 Mythanks to them all.

The focus of these two studies was a narrow two centuries of Euro-pean-tradition shipbuilding from 1760, however, and the roots of mydesire to expand on that earlier work can be traced to the many workscontained in our departmental library. On those shelves appear nameslike Bass, Bill, Boudriot, Cederlund, Crumlin-Pederson, Deqing,Greenhill, Hourani, Litwin, Maarleveld, Marsden, McGrail, Pomey,Prins, Reinders, Sexton, Steffy, Throckmorton, and many more re-searchers whose names also appear throughout this work. To them Iam indirectly indebted, for this work of necessity has relied on theirproducts and those of many others. My expanded interest can also betraced to the work of colleagues like Green who, after rst focusing onthe East India types, traveled throughout Asia and elsewhere recordingThai, Chinese, and Korean ship structures at sea and on land. Anothercolleague, Tom Vosmer, was active in Sri Lanka and Oman, observingshipbuilding there, and both he and Nick Burningham had a long-standing interest in the examination of Arab, Asian, and Indonesianshipbuilding methods.

Their research also left them all in a position to provide useful in-sights when the time came to construct an authentic impression of therst-known European vessel to visit the shores of Australia in 1606, theDutch East India Company Jacht Duyfken, which was built just outsidethe museum. Although the builder, Scottish Australian Bill Leonard,shipwright to the Endeavour replica, and his multinational team of fel-low shipwrights attempted to use ancient techniques where possible,the Duyfken has proved useful in examining the fastenings and theterms used in modern times. They welcomed me into their yard and, asthe vessel grew on the stocks, I came on board. They answered a myr-iad of questions, explaining terms and techniques with patience andenthusiasm. Finally, on these shores I was inuenced by the work ofanthropologists at the Western Australian Museum, such as Ian Craw-ford, who lived with Aboriginal groups on land and with Indonesianseafarers at sea. He and Moya Smith provided me with numerous in-sights into Aboriginal culture and relayed to me examples of their craftand instances of indigenous Australian borrowings from the visitorsto northwest Australian shores.

In order to progress on from these roots, I ventured into early boatand shipbuilding treatises, and have mentioned many in the text in def-erence to each authors expertise. From there I progressed into metal-lurgywith R. F. Tylecotes work a major inuenceand then intomodern corrosion science with Ian MacLeod, Vicki Richards, and L. E.Samuels prominent in their contribution.

Apart from those colleagues mentioned here and the many special-ists and their works featured in the text, many individual researchersalso provided assistance. Not appearing mentioned in this work or incredits for photographs and illustrations in this text are Tom and Irene

xPreface

00-A3433-FM 6/8/05 12:01 PM Page x

-

Gollop, Rosemary Harper, K. de Heer, Ross Chadwick, Nigel Erskine,Dena Garratt, Mike Pollard, Paul Mardikian, A. Pierce Middleton, Rus-sell Miners, Robert Parthesius, Neil Shand, Ross Shardlow, C. G. Sco-eld, and Marit van Huystee. In more recent times, Randall Sasaki rep-resenting Director Kenzo Hayashida and the Kyusu Okinawa Societyfor Underwater Archaeology has also assisted in respect to Chinese hullremains in Japan.

At Texas A&M University I thank George Bass, Cheryl Ward, andthen Donny Hamilton for considering this work worthy of publicationin their series. Thanks are also due to the Texas A&M University Pressteam of Shelley Wachsmann, Kevin Crisman, Linda Lou Salitros, JamesSadkovich, Mary Lenn Dixon, Stephanie Attia, Diana Vance, their edi-torial and art staff, and all their colleagues.

Finally, I acknowledge those who provided illustrations, the manyartists and photographers whose work appears throughout here, andthose on whose works the nal depictions are based. All their namesappear in the captions alongside the art or photographs. Thanks also toMuseum Librarian Margaret Trift, who obtained many texts from ex-ternal holdings, Departmental Secretary Sue Cox for her invaluable as-sistance in the ofce, the referees J. Barto Arnold and James P. Delgado,and the many readers who assisted by reading part or all of the text.These are Nick Burningham, Carl-Olof Cederlund, Jeremy Green,Michael Gregg, Bill Leonard, Thijs Maarleveld, Jennifer Rodrigues, BobSexton, Bob Sheppard, Corioli Souter, Ray Sutcliffe, Nick Truelove,Vicki Richards, Michael Rowe, Peter Worsley, and Tom Vosmer. Tothem all I am much in debt.

xiPreface

00-A3433-FM 6/8/05 12:01 PM Page xi

-

00-A3433-FM 6/8/05 12:01 PM Page xii

-

Ships Fastenings

00A-A3433-INT 6/8/05 12:01 PM Page 1

-

00A-A3433-INT 6/8/05 12:01 PM Page 2

-

Introduction

3The object of this book is a mundane, sometimes hidden element ofboat and shipbuilding, the way in which hulls are fastened. It is a cen-tral element, nonetheless, for without effective and durable fastenings,the boat or the ship once one of the largest structures produced byhuman handscould not have existed. Efcient fastenings also help avessel resist the often violent temporary distortions that occur as a shipworks among the waves and swells, and they allow it to resist the ef-fects of gravity over time. Hogging, sagging, working, and wracking areterms coined by those who served on ships to describe these effects.These forces serve to draw the fastenings from the timbers in thehull, or cause them to shear or break apart. Thus, fastenings can bepresented or studied as a central element in the worlds boat and ship-building traditions over place and time.

Many works and many authors appear named in the text, not asmere references or footnotes as is traditionally the case in a truly aca-demic work, which is a product of a number of factors. One is as a con-stant reminder that this work has relied heavily on the products, under-standings, and expertise of others. Another factor is that this work is anecessarily compressed overview of one small, but nonetheless essen-tial, element in boat and shipbuilding, and as a result it is one that can-not exist in isolation from the boat and shipbuilding treatises men-tioned throughout. A third factor is that this book gives the reader aglimpse of what is available should they wish to pursue a particularsubject or type of vessel further. Lastly, the strategy might also prove auseful tool for the student of boat and shipbuilding, for the researchersand builders to whom I naturally defer inevitably disagree on terminol-ogy. Many readers might wish to study their works more closely and tofollow their line of reasoning as a result.

It is also evident that across the many countries, language, and cul-tural groups with a maritime tradition, thousands of descriptive termswould have been used to describe the building methods and the fasten-ings used. Most terms have also evolved over time, some more slowlythan others and by virtue of their isolation some are quite unique, wererarely copied, and many are now forgotten. To illustrate this point, andfor other reasons that will soon become apparent, two examples, onefrom Kashmiri and the other from Australian Aboriginal tradition arechosen.

00A-A3433-INT 6/8/05 12:01 PM Page 3

-

In the rst instance recourse is made to the words of a Europeancleric, C. E. Tyndale Biscoe. Writing of the situation at Srinagar in theearly twentieth century soon after it was linked to the outside worldby road, he stated that, The Kashmiris have their own way of buildingboats, and very clever they are at their art. I have always been interestedin boats and boat-building, but I have never come across boats built asin Kashmir. 1

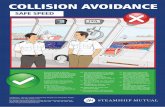

Half a century after Tyndale Biscoe wrote thesewords, one of my colleagues, Paul Hundley, visitedSrinagar, a place acknowledged as the KashmiriVenice of the East, where he viewed a boat-buildingyard on the Jhelum River. In a short article attestingto the persistence of ancient techniques and to therange of craft being built on those inland waters,Hundley advised that the Kashmiris were using kul(nails), wangen (large staples), and muhuge (an ele-gant twisted fastening) on a type of large boat calledthe doongaa multipurpose vessel which, while it canbe found up to about twenty-six meters in length, wasstill being built in the traditional method. The fasten-ings he collected on that visit are shown here.2

In other places ancient shipbuilding methods appear to have re-mained static for years, as in Kashmir, only to enter into a state of al-most constant evolution as a result of trade and from contact with oth-ers and their technology. Sometimes entire vessels were copied andthen modied over time. Often the terms used to describe introducedwatercraft, fastenings, and building methods were not indigenous andwere derived from the visitors themselves.

One example appears in the form of the dugout canoes that werenot originally part of the ancient northwestern Australian Aboriginaltradition. These are generally accepted to have been either gifted orstolen from the Macassan trepangers who rst came to the Kimberleyregion from what is now the Indonesian Archipelago in the eighteenthcentury.3 The anthropologist Ian Crawford advises that one Aboriginaltribe called these introduced canoes namandi or barrawang, and thatthese are possibly loan words obtained from the visitors.4 These sameterms inevitably suffered greatly in the phonetic transfer from the par-ent, or visiting, culture into indigenous languages and later still intomodern equivalents, no matter how careful each observer may havebeen with the transition.

Often, an introduced type was modied to suit local activities(such as dugong hunting) and the sides of the Macassan canoes can befound raised with splash boards or wash strakes that are fastenedwith a rope or cord produced from a variety of natural bers. Some be-lieve these additions were introduced by European missionaries, othersby Aboriginal contact with island visitors.5 As but two examples, cords

4Introduction

Figure 1.Range of Kashmiri fastenings

from a boatyard at Srinagar.Photograph by Pat Baker.

00A-A3433-INT 6/8/05 12:01 PM Page 4

-

made of the outer bark of the aerial roots of the g tree called albayi,and sometimes largarda, the roots of the boab tree, were used to securethese hull extensions.6

Modication of indigenous watercraft is clearly an ongoing process.In a work subtitled Aborigines and Outsiders on the North-West Coast ofthe Kimberley, for example, Crawford also notes that with the advent ofAllied airbases in the northwest Kimberley in World War II, one Ab-original group began copying the North American Indian canoes theyhad seen in the lms being shown to the troops at the Truscott AirBase.7 Often old and new existed side-by-side. Introduced canoes aug-mented, but did not entirely replace, the original log rafts of the Kim-berley region.

Often there were many variations on a basic design, each with itsown name. The early-nineteenth-century European explorer PhillipParker Kings record of one Kimberley log raft, for example, shows it asa single-layered lashed craft, fastened with rope or cord within an ex-ternal framework of wood.8 He was not aware that there were many hy-brids along the Kimberley coast and across the twenty tribal boundariesthere, however. Nor did he report on an entirely different form, onefound in King Sound on the same coastthe double-layered raft ofthe Badi tribe of William Dampier fame. Later described as a local in-novation, in many ways it is similar to those of the neighboringWorora and Djau tribes with whom they had regular social contact(and from whom they are believed to have copied the form).9

Reproduced in an illustration from 1917, below, is a peggeddouble-layered form made of logs of Tjulbul, a light species of man-grove tree.10 These are joined to each other with roughly hewn, oftenobliquely driven, wooden fastenings that English-speaking authors havevariously described as pins, pegs, or dowels of harder timber driven atvarious angles to one another. This oblique dowelling is a fasteningvariation that will surface in a number of other boat- and shipbuildingtraditions across the globe.

A similar method is found on central Java rafts, and Crawford believes that the method of fastening the raft was copied from theMacassans.11 Although some might consider this an indicator of an in-ferior fastening method, the reader is referred to the early-twentieth-century American shipbuilder Charles Desmond, who states that,Tests of the holding power of fastenings driven parallel to each otherand fastenings driven at various angles [to one another] show that various angle fastenings have a holding power 60 percent greater thanparallel fastenings. 12

In these two diverse examples, the sheer impossibility of account-ing for the many thousands of types of craft used across the globe over time, or their variants and hybrids, becomes evident. Thus, while numerous types, ranging from the sewn boat through to thesteamship, are chosen in order to illustrate a particular technique or

5Introduction

00A-A3433-INT 6/8/05 12:01 PM Page 5

-

fastener, many other important craft or traditions do not appear in this work.

Although they also serve to illustrate that there is a vast range of craftand terms, the Kashmiri and Australian Aboriginal instances are cho-sen for other reasons, not the least in that they require that I start thiswork with an apology.

Rather than make a futile and unsatisfying attempt to reproduce thetens of thousands of indigenous and local names and terms for the fas-tenings that exist throughout the world today, or even to enter upon asearch for those used over time, I will use English-language terminol-ogy from this point on. It is hoped that the reader will now excuse andunderstand the reasons for doing so. In mitigation, reference is made to D. H. Robertss English translation of Jean Boudriots French studyLe vaisseau de 74 canons. A modern work, it contains over twenty pagesdescribing the fastenings for this one type of ship from that one country

6Introduction

Figure 2.An Aboriginal raft from theKunmunya area in northwest-ern Australia (the man, knownto the Europeans as Sampson,is acting as a sail). Photo-graph by W. J. Jackson.

00A-A3433-INT 6/8/05 12:01 PM Page 6

-

alone, and Roberts was led to comment in providing English-languageequivalents for the French names that in many cases such terms areimpossible to translate, each country having its own peculiarities. 13

Further complicating the matter, language is constantly evolving.My study of fastening nomenclature in the well-documented 200-yearperiod after the advent of the underwriters, Lloyds of London around1760, revealed nearly 100 English-language terms alone. It also showedthat not only were there regional differences in the meaning of thesesame terms across the English-speaking world, but some were alsofound to be slowly evolving even in that very short 200-year span.Clearly, new terms were being coined and old ones falling out of use,and some terms even came to have a different meaning over this rela-tively short amount of time.14 Another example appears in Peter Mars-dens reproduction of a series of contemporary accounts relating to thebuilding of late-fourteenth-century boats in London. Among a range offastenings whose form is still recognizable today, there appears an entryfor 300 wrong-nails, leaving the reader wondering at the meaning.15

This evolutionary process is another consideration in necessarily limit-ing this work to one language.

In many ways, that earlier study was the beginning of a restricted typology designed for those with little grounding in the subject. In aim-ing toward that same audience, what follows might fail to satisfy thosepossessing existing knowledge or an expertise in boat and shipbuilding,for they may come to disagree with my emphasis, having understand-ing, knowledge, and a terminology based on their culture, experience,and reading. Those seeking a chronological account, or details of anyone vessel, or type, or a detailed analysis of a particular shipbuildingtradition may be similarly disappointed, and those requiring such in-formation are referred to the works and authors mentioned in text andto the list of references, where many other specialist works appear.

For those seeking alternatives in their parent tongue, or in the par-ent language of those who built and operated the vessel they are study-ing, there are numerous anthropological texts and rst-hand accountsproduced by scholars who lived with indigenous boat and shipbuildersfrom countries across the globe and learned their languages and terms.Nick Burningham in Indonesia, Ian Crawford in northwest Australia,Tom Vosmer in Oman, Peter Worsley in Papua New Guinea are fourwho spring to mind, from just my own circle. Clearly one challenge inthis workand one partly unanswered in the Kashmiri instance men-tionedhas been to provide English-language equivalents for fasten-ing terms that would prove satisfactory to both the indigenous buildersand to their foreign visitors.

Another problem is encountered when attempting to produce En-glish-language equivalents from ancient treatises in another tongue. Anexample appears in Jerzy Litwins account of the building of a vessel be-lieved to be the rst Polish galleon. In translating the terms used todescribe fastenings delivered in 1570 by the blacksmith, he describes

7Introduction

00A-A3433-INT 6/8/05 12:01 PM Page 7

-

large pins priced at from 1.5 to 5 grozy apiece (some had extrattings) . . . 3780 nails at 1 szelag each . . . 800 small bolts . . . 5300 largebolts . . . 296 bolts with rings and wedges . . . various bolts, including4917 at 4 grosze apiece [and in an entry that clearly perplexed Litwinhimself ] . . . 7500 beautiful nails at 1 szelag each. 16 This example alsoserves to provide an early indication of the numbers of fastenings ofany one type that can be involved in building a large ship.

Major European works such as J. H. Rdings Allgemeines Wrter-buch de Marine produced in 1793, and Captain H. Paaschs IllustratedMarine Encyclopaedia of 1890 provide equivalent European-languagenames for many common fastenings. So too does Ren de Kerchove,who covers the early to mid-twentieth century up to the printing of thesecond edition of the International Maritime Dictionary in 1961. Thereare also many modern bilingual reprints of earlier works such as Fer-nando Oliveiras Liuro da fabrica das naos from 1580. Other useful ex-amples can be found in works such as C. Ozakis Japanese-English Dic-tionary of Sea Terms from 1942, and in the Chinese Institute ofNavigations Ships of China that was produced in 1988. Hundreds ofother works have also been translated into English, many appearing inthis text.

Reference is also made to numerous archaeological reports. Some ofthese are also bilingual, for example, the French-English literature ofNorth America, the Dutch-English literature of the Netherlands, and awork with Danish, German, and English equivalents recently producedby Ole Crumlin-Pedersen.17 There are many others, some of which willbe mentioned here. Broadening the net further and bringing us all intothe virtual world, in consulting thirty-ve sources dating from 1570 to1928, Lars Bruzelius has included in his Web site works in Spanish,Swedish, Dutch, German, English, and Danish.18

Finally, the ancient Aboriginal and Kashmiri instances are also cho-sen in respect of the passing of time. While reference is made through-out this book to methods, rafts, boats, and ships produced by once-isolated peoples, and from many of the worlds great maritime culturesand ancient seafaring traditionsall with their own chronologies anddeities, the term b.c., an indicator of the time between the events de-scribed and the birth of Christappears, as is now common practiceacross the globe. All other dates indicate the years that have passedsince that time, with c.e. (Common Era) used where necessary.

Dening the WorkThe often-represented twenty-ve-meter-long ship from Queen Hat-shepsuts reign that is reputed to have gone to sea around 1500 b.c. is auseful example with which to enter into the process of dening thiswork.19 In order to prevent hogging and to hold up the ends, it re-quired a strong multistrand cable that ran down the center of theship.20 The cable was tightened by means of a pole thrust through twoor more of its strands and turned so as to twist and thereby shorten it.

8Introduction

00A-A3433-INT 6/8/05 12:01 PM Page 8

-

Also called a Spanish windlass, the same system, albeit on a muchsmaller scale, is also found on farms, sheep or cattle stations (ranches),and the like for the tensioning of box-strainers on paddock fences,such as those on my small farm. The analogy is presented here partly tomake the point that the fasteners and tensioning systems used at seahave a common rootsimilar applications on land. It is only wherecontinuous immersion, storms, and the constant movement of the searequired an adaptation of the methods used on land that the fastenersevolved into a form that is easily recognized as a nautical type, the boator ships fastening.

This example also serves to give notice at this early stage that manyof the fastenings being used in modern times differ little from those ofthe ancients, and this will be one of the common threads foundthroughout this book. As but one example, the Egyptian methodreects a system that has survived in water transport for thousands ofyears appearing with the hog-beam, hogging-chains, or hogging trusson long American sternwheelers in the nineteenth century.21 The hog-ging truss is as much a tensioner as a fastening, however, and its ap-pearance here, while of use in illustrating the survival of ancient prac-tices, provides an example of the sort of mechanical devices that, whilethey also serve to secure a hull, will be mentioned only in passing in thecourse of this book.

Further, as this book will focus on those fastenings that appear in, oron, a hull serving to secure it in service, the myriad fastenings used insecuring upper-works, bulwarks, cabins, light deck structures, and suchare also not dealt with in any detail. While similar to hull fastenings,these fall within the domain of what the early-twentieth-century Amer-ican shipwright Charles Desmond has called ship joinery, statingfrom his perspective that the fastenings used in that context do notadd to structural strength and therefore can be removed without af-fecting strength. 22 While outside the scope of this work, these typesare briey dealt with, and appear also in a section on nails, mainly be-cause they are often encountered in the literature and on the vessel assmaller forms of those used in and on the hull. They also often appearon the archaeological (shipwreck) site, one of the many primarysources used in this work, and are also referred to in order to help re-searchers differentiate between the various forms. More difcult to dis-cern are the fastenings carried as cargo, or as carpenters spares. Thesecan be for land or sea use and often can have a similar form, makingtheir identication difcult, especially when found out of context on awreck site.

Caulkings and lutings, which keep a hull watertight, also do not ap-pear in this work, except where they are specically designed to serve toswell and tighten a joint, as in the Bronze Age Dover boat. 23 Nor dofastenings, cordage, and lashings appearing on masts, yards, or otherspars appear. Devices such as the deadeyes and the bottle screwsthat serve to tighten or loosen the shrouds of the large sailing vessels

9Introduction

00A-A3433-INT 6/8/05 12:01 PM Page 9

-

that frequented the seas in the last few centuries are also omitted. Chainbolts, ring bolts, hook bolts, and the likewhose primary purpose isto secure rigging and ropesare briey mentioned, however, for theyoften serve to fasten timbers, albeit in a secondary capacity. The nu-merous temporary fasteners used in building a vessel are also men-tioned only in passing. While the rst categories are obvious omissions,the last is quite an important distinction, for while most builders fas-tenings such as wrain bolts or wring bolts are removed after servingtheir purpose, some can appear on a hull in service.24 One example, theprospective purchaser of the late-eighteenth-century ship Lord Dart-mouth, was led to specify to his shipwright that all reaming irons, iron wedges, spikes, ribband nails and other irons not driven into theship after building was complete to be taken care of and removed. 25

Here, in this quotation is evidence that some builders fastenings can be driven into the ship, partly as additional fasteners, or more likely,purely for convenience to save the time and effort needed in their removal.

Further, as another useful example reecting the need to be con-stantly aware of anomalous types of boats and ships and of strange fas-tenings and building methods, reference is made to what is claimed tohave been the rst concrete-built ocean steamer, SS Faith. It was a5,000-ton ship launched in 1918 for the run from San Francisco to Van-couver.26 Although this book is titled Ships Fastenings: From Sewn Boatto Steamship, the fastenings used in this particular steamer are omitted,for it was clearly anomalous. In contrast, the steam-driven Liberty Shipsof World War II became commonplace almost overnight, and they willprovide the cut-off point for this book. In post-dating them and theirfastening systems, the glues, breglasses, and resins that eventually be-came common on boats and small ships will receive little attention inthese pages.

10Introduction

00A-A3433-INT 6/8/05 12:01 PM Page 10

-

Fastened without NailsThe Sewn Boat

1

11An ancient Egyptian hieroglyphic appearing in George Basss A Historyof Seafaring Based on Underwater Archaeology is not unlike a papyrus-bundle boat that was seen thirty years ago south along the Nile in theSudan.1 Reed boats or rafts of a similar design have also been usedfrom pre-Columbian times along the coast of Chile and Peru and arepresently used on Lake Titicaca in the Andes.2 All are fastened entirelywith cordage, and it is anticipated that the methods used today differlittle from those Napoleons savants saw at the Pyramids of Memphisand vividly reproduced in La description de LEgypte.3 The form wascommon in ancient Egypt and a similar scene appears alongside otherboats under construction at the Fifth Dynasty tomb of Ty (or Ti).4

Many types of bundle boats have de-veloped over time and place.5 They appearconstructed of reeds (for example, Egypt;north, central, and southern America;southwest Asia; Corfu; Ireland; Hungary;Oceania; Sardinia; New Zealand), ofpolesbranches and saplings (for ex-ample, Africa and India), and of bark (forexample, Tasmania in southeastern Aus-tralia). The last example was described andillustrated by French explorers in 1802, andwhile rolls of sedge or bark tied together to form long tapered cylindersprovided buoyancy, the binding fastening them together was a twoply grass-twine lattice in the form of a net.6

In the bundle raft tradition, the logs forming the raft are oftenfound secured with coir in India, with bark strips in Australia, withwithies (young shoots or thin branches) in Sweden, and with rattan(a form of climbing palm) in New Ireland, for example. From the per-spective of our focus on fastenings, sufce it to note that, though therewere many regional variations, all are considered to be lashed to-gether. 7 While acting as a patrol ofcer in the 1960s Territory of Papuaand New Guinea, for example, my colleague Peter Worsley saw bundlerafts of bamboo or other light timber being secured with bamboolashing made in the same way as that used as string for hunting bowsand in constructing houses. In that instance, he described a long lengthof bamboo split into suitable widthsabout 8 12 mm was used for

Figure 3.Ancient Egyptian reed boatunder construction. Sketchfrom part of an engraving atthe tomb of Ti. By Jennifer Rodrigues.

01-A3433 6/8/05 12:01 PM Page 11

-

bowstringsand then the outer skin was peeled off to form therope. When green it remains exible, with little stretch, was strongand resistant to abrasion, and could be tied in knots.8 Another form ofbundle raft found in South America used transverse timbers that arefound lashed to the longitudinal members using vines. The knot needsno elucidation for all have seen or tied one, though in order to view themyriad of possibilities, readers are referred to works such as The AshleyBook of Knots (where 3,800 appear). Lash, however, as dened by theOxford English Dictionary (OED), means to fasten or make fast with acord, rope, thong, piece of twine etc.

Others used roughly cylindrical wooden fastenings to secure thelogs. In the seventeenth century these were often referred to as pins. 9

In the case of the Aboriginal raft described and illustrated earlier, thesecan be found driven at various angles, while in Peru they were foundfastened vertically, and in one Swedish case they appeared fastened lon-gitudinally.10 Rafts from places like Oceania, South America, and Aus-tralia also exhibited a method of through pinning logs by a series ofhardwood timbers, though these are driven horizontally through themfrom one side of the raft to the other.11

The variations are legion, as one would expect. In Panama in 1684,William Dampier described the people of Colon being much addictedto shing, which they pursued in a short form of sailing raft com-posed of logs of light wood about eight feet long, joined to each otheron the sides with wooden pegs and withes. In stating that the barklogs (rafts) in the region were constructed in different manners, ac-cording to the use they are intended for, or the custom of the peoplethat make them, he also describes another form, a three-decked typewith a large rudder and mast intended for carrying merchandize. Ca-pable of carrying large amounts of cargo, it was about ten meters longcomprising upward of thirty tree trunks, upon which they fasten, withwooden pins, another shorter row of logs cross-ways. 12

Sometimes there were variations across surprisingly small distances.In describing a method of tying timbers of log rafts, Shinji Nishimararecognized differences on opposite banks of the same river, the Yalu,for example. On the Manchurian side the end of each log comprisingthe raft was cut with a central hole, and the logs were fastened togetherby means of a thin pole passed through the holes. On the Korean sidethe holes were similarly aligned, but the logs were fastened togetherwith climbers or twigs softened by crushing, by running them throughthe holes. Nishimara believed that this was a Japanese inuence.13

In dealing with the many thousands of types found above andwithin other classes, such as the bundle rafts, bundle boats, basketboats, log boats, bark boats, hide boats, plank boats etc.,identied by Sen McGrail in his work subtitled The Archaeology of Wa-ter Transport, it needs be reiterated that our focus is on fastenings andthus the techniques used in constructing them, the variations, the many

12Chapter One

01-A3433 6/8/05 12:01 PM Page 12

-

typologies, and other equally important details are given little attentionin this book.14

Log boats (or dugouts) range from simplest of forms such as thoseunearthed in prehistoric England and Wales (as but two examples) tomore complex types such as the Shniaka, an ancient Russian White Seaform that carried up to three masts (See gure 23). The typealsoused by the Laps in shing expeditions into Arctic regionshad sidesthat were further extended by sewing on one or two washstrakes withOsier twine.15 Another form is that seen in the early 1960s by Worsleywhile he was operating on mainland New Guinea not far from thewestern end of New Britain. There he encountered a twenty-two-meter-long sailing canoe carved from a single log with an outrigger andwith sides he describes as being built up two planks high and thensewn to the hull with a sennit made from coconut ber or coir. Ac-cording to Worsley, the coir was rst rolled on the thigh to makestring, then a number of the strings were plaited to make sennit . . . asdistinct from cord, rope, cable, etc. which are twisted. It was woventwo or three times through two adjacent holes, then taken diagonallyacross to the next pair of holes and again woven through two or threetimes. Finally, the holes were stopped (made watertight) with resinor gum.16 In a chapter appearing in Archaeology of the Boat, BasilGreenhill describes other more complex variations, including a highlydeveloped form, the Yamato-gata type from Japan built on a dugoutbase, and an 1860s development, the log Bugeye of the Maryland oys-ter shery in America. He also describes another modern type, theBalam, a large ocean-going type from the Bay of Bengal, with deckbeams lashed with split bamboo and up to ve strakes sewn on eachside. Of relevance to ensuing chapters of this book, Greenhill advisesthat strakes of the Balam can be found in one form joined ush toeach other and in another fastened clinker-style. 17

Here in understanding the wide range of terms used by such a vari-ety of authors and commentators, the reader is rst referred to them asresident experts, and then to works such as the Oxford English Dictio-nary (OED) that copiously provide meanings, alternative spellings, andoften the origin of words. In the OED, for example, the term ligatureappears as anything used in binding, or tying and it is that context inwhich it is used here.18

Ligatures can appear in many forms, for example, as sennit orsinnet, which is dened as at braided cordage formed by pleating[plaiting] together several strands of rope-yarn, coarse hemp, grass, orother brous material. Another ligature, cord, is dened in the OEDas string composed of several strands twisted or woven together. As aterm it rst appeared in the context of shipping in 1483. Yet anotherform of ligature, twine is a thread or string composed of two or moreyarns or strands twisted together. Rope is dened as a length ofstrong and stout line or cordage, usually made of twisted strands of

13Fastened without Nails

01-A3433 6/8/05 12:01 PM Page 13

-

hemp, ax or other brous material, but also of strips of hide, plant,twigs . . . etc., with cable originally a stout rope of any thickness, butnow, like the hawser, restricted to very thick applications, such as moor-ing lines and the like. In that context, the last two are not ligatures.19

To take the case of the xing of hull coverings at the bow or stern ofindigenous craft in the bark boat category, Peggy Leshikar advises thatthe seams of American Indian bark canoes were usually sewn togetherwith the roots of the black spruce. 20 This is a system not far removedfrom the use of organic bers to secure the bow and stern of the Ab-original bark canoes of southeastern Australia.21 In this and in anothercategory, the hide boat, which had exible coverings stretched over aninternal framework of wicker or wood, our focus is not on the frame-work or the outer covering, but on the fastenings that are used to se-cure the frame or hull, for example, the roots of black spruce, boab andmangrove, white cedar, larch, jack pine, juniper, and then the animalsinews, hides, the reeds, even baleen.

In venturing further aeld, the Arab Quffah, such as those of theRiver Tigris, used a form of what the Coracle Society has described ascoiled basketry . . . producing a multitude of curved ribs of treebranches sewn with coir cord to the basketry walls. 22 Now oftenfound covered in bitumenas are plaited bamboo vessels presentlyoperating in North Vietnamthe Quffah were originally encased inhides. So too were the Arctic Umiak, the Kayak, and the British Coraclesand the Curraghs of Ireland that are described at length and in great de-tail in James Hornells work.23 In Ireland, as in Tibet, South America,

14Chapter One

Figure 4.Fastening raised strakes on

a New Guinea canoe. By Peter Worsley.

01-A3433 6/8/05 12:01 PM Page 14

-

and India, a waterproong envelope of hide is prepared by sewing together a number of skins stretched or molded, most often over a pre-erected framework. This can be woven of twilled wooden bas-ketry or a framework of wood that is either lashed, pegged or nailedto shape.24 These hide boats have stood the test of time, and photo-graphs of a number of modern examples appear in Douglas Phillips-Birts work The Building of Boats. The interior of one described as aPlains Indian hide boat appears below.

As Peter Marsden advises in his study of the ships of the Romanperiod in Britain, it is evident that as boats were seen for therst time, the best or most useful elements were adopted byobservant others, by trading partners, and by conqueror andconquered alike.25 Here is another recurrent theme in thiswork. Hornell advises that in nding himself in need ofboats for use against his rival Pompey in Spain, Julius Caesarhad his men build copies of the skin covered craft he re-membered seeing ve years earlier in Wales.26

The Sewn Plank BoatIn progressing on to the last category, the plank boat, it is evidentthat a work edited by Sen McGrail and Eric Kentley, titled Sewn PlankBoats, introduced many, who were unaware of it, to the sewn boat,stitched boat, or stitched-plank boat traditions. It appeared in 1985,and in the following year A. H. J. Prins added further to the under-standing of the type in his work titled A Handbook of Sewn Boats. Therehe reinforced the perception that the method was once nearly univer-sal, dating back nearly 5,000 years.27 Noting that the tradition also ap-pears in Arabia, Burma, East Africa, Malaysia, North and South Amer-ica, Oceania, Thailand, Vietnam, and Yugoslavia, McGrail widened thenet when he commented that, Sewn plank boats are, or have been,used worldwide: from Finland, Denmark and Britain in the North toChile in the South; and from California in the West to India, China andthe South Pacic in the East. They range in time from atleast 2600 b.c. to the present day. 28

An examination of these and other sources shows thatwithin the sewn-plank tradition the strakes of the hull weresecured to each other with ligatures of thread, cord, rope, orsinnet produced from substances as varied as strips of ani-mal hides, sinews, roots, withies, or withes of wood, andplant bers. In Ships of China, edited by Peng Deqing, thereis reference to one type of ancient sewed plank boat thatwas fastened with ropes made of materials like rattan,bamboo strips or coconut bre. 29

There are many ancient references to the type. Virgilmentions a cymba sutilis, or sewn-boat, and later, when chroniclingHomers exploits in a passage from the Iliad, Pliny uses the term sutilesnaves, which translates to a eet of sewn boats.30 As but one manifesta-

15Fastened without Nails

Figure 5.Interior of Plains Indian hideboat, showing a lashedframe. Sketch by Chris Buha-giar, after Phillips-Birt 1979,251.

Figure 6.Sewing plank in 1539. Sketchby Chris Buhagiar after OlausMagnuss Carta Marina. Fors-sell 1985, 196.

01-A3433 6/8/05 12:01 PM Page 15

-

tion of methods used in the early phases of this tradition, McGrail de-scribes a circa 1600 b.c. fragment of oak planking from a stitched boatthat was found in the River Severn in Wales. It was fastened by with-iesin this case of the yew treethat had been twisted upon them-selves to separate the bers and thus make them sufciently pliable toform a rope with three or more strands, or a twine with two.31 Indescribing a number of sewn-boat nds in Finland, Henry Forssell pro-vides an indication of the methods used when he advises of cases wherethe sewing material was juniper switches about the thickness of apencil . . . pre-processed by soaking them in hot water and then peelingoff the bark and smoothing them with a knife.32

This vast range of ligatures was generally drawn through holes boredat intervals in each adjacent plank. These holes were produced in vari-ous congurations, with a wide variety of simple hand tools; for thesewn-plank technique occurred within most major boat-buildingtraditions across the globe, and it is also one that has persisted intomodern times, as will be seen.33 While gouges, chisels, and awls (sharp-ened metal spikes, sometimes applied red-hot) were commonly used toproduce the fastening holes, one of the simplest early machines was thebow drill. These appeared in many parts of the world and the drillingend or bit could be of a variety of forms depending on the materialsand the technology available. An ancient Egyptian form of bow drillwith a bronze arrow-shaped bit appears in John Horsleys Tools of theMaritime Trades. As but one example of the longevity of this type oftool, in his work Ancient Carpenters Tools, Henry Mercer describes avery efcient Chinese, three-man shipbuilders thong drill. An ad-vanced form of bow drill, it is described as being held down by oneoperator, while the other two worked the thong back and forth on thespindle of the boring tool, causing the bit to spin.34 While this particu-lar example was seen in action by Mercer in modern times, a similartype is described in Book IX of Homers Odyssey.35 Finally, one of thebest-known and durable drilling tools used in early boat and shipbuild-ing was the hand augerlarger cousin to the gimlet.

In his Dictionary of Woodworking Tools, R. A. Salaman describes theauger as having a bit (the cutting part) on a shank which ends in aneye or tang and the gimlet as a miniature auger with a spiral twist orshell body and a screw point; the handle usually . . . [of wood] forms aT with the shank. While his illustrations show augers and gimletswith shanks and handles that were in use from 1700 into modern times,they are little different from those found among caches of Roman andViking boat-building tools. The main differences over time and placeappear at the cutting end, with the early types appearing as a plainshell body with a nose shaped like a gouge. 36 Clearly the form andcomposition of the ironwork involved was partly a reection of the rel-ative sophistication of the blacksmiths art at the time.

Returning to the fastenings themselves, in examining a wide varietyof types of sewn plank boats across the globe and over time, McGrail

16Chapter One

Figure 7.John Horsleys depiction of an-cient Egyptian bow drill and a

hand auger. Reproduced bypermission of the Horsley

family. Horsley 1978, 3335.

01-A3433 6/8/05 12:01 PM Page 16

-

has observed that the method used to secure the strakes to each othercan be seen in a continuous or non-continuous form, appearing aseither continuous sewing or individual lashings. 37 As an exampleof the latter, McGrail observes that Middle Bronze Age Ferriby boatsfrom the Humber area had a non-continuous stitch of yew lash-ings that were passed two and a half times through opposing orpaired ligature holes. He refers to the method as a form of lashedplanking. 38

Continuous sewing, or lacing, as it is sometimes called in thecontext of a lace as a string or cord serving to draw together oppositeedges [often through holes], 39 appears in a variety of patterns. In thecase of a small Bronze Age river ferry from circa 800 b.c. that wasfound at Lincolnshire, England, McGrail describes ve planks buttededge to edge, and fastened together by a continuous zig-zag stitchingwith a two-strand rope of split willow. 40 Such a conguration servesan important purpose, and Jeremy Green has observed that lashings(bindings between holes directly opposite each other in the seam) serveto hold the planks together, but have little effect in preventing longitu-dinal movement. To counteract this, lashings also run diagonally be-tween adjacent lashing holes, thus helping reduce longitudinal shear. 41

Both individual lashings or continuous sewing can appear on theone boat. As with clothing and other manifestations of the seamstresssor tailors art in the sewing of clothes, the many lacing patterns foundacross place and time depend on cultural and technical preferences andon phenomena such as the alignment of what Richard Steffy calls theligature holes. The ensuing pattern can depend on many variables,for example, whether the boat-builder is progressing from inside thehull to out, from mid-ships to aft, or whether the stitching is limited tothe inner surface of the planks. Thus, apart from vertical, horizontal, ordiagonal lashings, authors have also described a multitude of continu-ous stitching patterns, and terms like zigzag line, single web,double web, criss-cross web, single vertical bars, and so on, ap-pear in the literature.42 As an example, the following illustration isbased on a pattern appearing in G. F. Houranis Arab Seafaring in theIndian Ocean in Ancient and Early Medieval Times.

17Fastened without Nails

Figure 8.A stitching pattern across theseams of an Arab boat.Hourani 1951, 92. By JenniferRodrigues after Hourani.

01-A3433 6/8/05 12:01 PM Page 17

-

There are many terms used to describe the methods used, withsewing, stitching, lacing, tying, binding, and lashing common. For sim-plicity, a stitched boat could be considered as one exhibiting indi-vidual lashings throughout, while a sewn boat as one that has con-tinuous sewing, or is sewn with a continuous thread. The holes canalso be described as being paired or diagonally disposed. 43

The archaeological record can also pro-vide important examples, such as MikeFleckers description and illustration ofwadding on a ninth-century wreck inIndonesian waters. There he also describesbutt stitching, that is, a method of fas-tening a butt joint, where planks compris-ing a strake (a continuous line of plankingstretching from stem to stern) meet to obtain the required length: The hullplanks . . . are stitched edge-to-edge withcord passing through holes at 5 to 6 cmspacing. The main stitch is straight acrossthe seam, with secondary cross-stitchingbetween each main stitch. Wadding mate-rial is placed under the stitching both in-

board and outboard. The same system fastens the garboard strake tothe keel and stempost. Hull planks are butted. . . . The butt stitching isthe same as for the seams. However, there are two additional stitchesset back from the butt to fasten it. 44

Those ligature holes that become submerged after the boat islaunched are sometimes stopped (made watertight) with smallwooden plugs or ligature pegs of various shapes and forms.45 Thoseabove water are often similarly treated, but not just to make the holewatertight, for driving the plug in over the ligature with force can alsoserve to wedge or tighten the cord passing through the ligature hole.This is an important feature and in his engineering analysis J. F. Coatesfound that without the tightening and securing effect of ligature pegs,symmetrical zig-zag, or helical stitching could not resist shearingforces between planks.46

Ligature pegs can be left in position, or are all removed bar the lastin the sequence. Further, while all the stitching or lashing can be left inplace after the ligature holes are pegged, it can also be found cut offoutboard for aesthetic reasons, or for hydrodynamic efciency, butonly where the builder has sufcient condence in the holding powerof the ligature pegs that are driven into the holes and left in place. Inthis circumstance, McGrail has observed that each becomes the equiva-lent of the staple found in a later section about metallic fastenings.47

This process leaves only the inboard line of stitching or lashing in place.Sometimes, where it is to be left in placebut the builder is still con-cerned about the cordage projecting proud of the strakes, for aesthetic,

18Chapter One

Figure 9.Mike Fleckers record of the

stitching patterns on a ninth-century Arab or Indian wreck.

01-A3433 6/8/05 12:01 PM Page 18

-

hydrodynamic, security, or other considerationsthe outboard stitch-ing or lashing can be found recessed in grooves as in some Maori boats.While often the groove is prepared beforehand it can also be formed bytightening, working in the seams, or by hammering the cordage overthe face of soft timber. Also, as indicated, stitching sometimes does notpass completely through the planks and can be completely internal, forexample in parts of Southeast Asia. Thus, in the sewn-boat tradition,the external manifestations of the fastenings can remain invisible or to-tally different from those inboard, thereby posing problems for the ca-sual or incautious observer.

McGrail has observed that individual stitches and continualstitches have to be tightened by some form of lever before they are(temporarily) wedged. 48 Kentleys description of a four strake Masulatype of sewn boat he saw in operation at Tamil Nadu on the Indian eastcoast adds another dimension to this method, and it also refers to theuse of a bow drill of the type mentioned earlier: Two planks are bound together tightly with some form of wadding under the rope. Asthis wadding gets wet, it expands, pushing against the rope and forcingthe planks even closer together . . . holes about a centimetre in diame-ter are drilled in the lower strake with a bow drill about three ngers-width apart. The plank to be sewn is matched up and marked so that aline of holes can be drilled on it vertically above those on the lowerstrake. Once these have been made, the plank is roughly lashed in twoor three places to hold it in situ. The actual sewing, with adoubled coir rope and a large blunt needle, is a two-manoperation . . . the pattern produced is a series of uncon-nected vertical bars outboard and . . . inboard there is . . . across stitch web with vertical bars.49

The expanding wadding that serves to tighten thestitches in this instance reects a technique used in theMiddle Bronze Age (ca. 1300 b.c.) Dover boat. Finally, NickBurningham illustrates another system he saw in SoutheastAsia using bamboo wedges to tighten the stitches.

It is worth noting here that though a useful and self-explanatory term, the term sewn-boat can be a misleadingdescriptor in more ways than one. First, there exists the di-chotomy with the individual lashings or continuoussewing techniques mentioned previously; second, manyprefer to use different descriptive terms, such as lacing,tying, or binding; and third, the vessels were often more than mereboats.50 As but one example, in his work We the Navigators, DavidLewis presents an illustration from 1939 of a Baurua, a type of sewnproa, or Micronesian voyaging canoe, that was described as being100 feet long (about thirty meters).51 Further, David Goddard de-scribes examples between twenty and thirty meters long and in 1985,when he produced his work on the subject, the type was still being builtin a tradition that apparently spanned thousands of years using only

19Fastened without Nails

Figure 10.Using bamboo wedges fortightening stitches. By NickBurningham.

01-A3433 6/8/05 12:01 PM Page 19

-

those materials available on a typical coral atoll. This included coconutber to make the sennit (braided as opposed to laid rope as men-tioned previously) that was used to sew the whole boat together. 52

As in the New Guinea instance, the sennits are prepared from thehusks of mature coconuts. After the ber has been soaked, pounded,and carefully picked again it was rolled on the thigh into a double-stranded string that can be plaited into heavier four- or six-strand sen-nit (braid). It has been estimated that for a twenty to thirty meter Bau-rua, thirty kilometers of multistrand sennit was required, as well as 180kilometers of single-strand cord.53

This observation leads us to the shell-built Sohar, a twenty-six-meter sewn dhow (boom), again using many kilometers of coir. It wasproduced in Oman in 1980 as a representative of Arab merchant shipsthat had voyaged along the route from Muscat to Canton and otherports in the Far East from the eighth century. Like the Duyfken, whosereconstruction will also be mentioned, there were necessary compro-misesfor there were no sewn boats being made in the Sultanate and the skills had been lost. As a result, a team of Islanders from theLaccadiveswhere communities were still familiar with seagoing sewn boat techniquestraveled across to do the fastenings. Theybrought thousands of bundles of coir in standard hanks of twenty-four to thirty-two feet long (7.3 to 9.7 meters) from the hills behindCochin.54

According to Tom Vosmer, who was the construction supervisor forthe Sohar project, these eventually made over 100 miles (about 150kilometers) of cord. In his report on the building process and the sub-sequent ocean voyage, Tim Severin observed that much of it was usedfor four-ply 14 inch (8 mm) coir cord threaded through the 40,000ligature holes required to fasten the vessel.55 Eleven stitchers wereemployed, sewing the strakes of the hull, a feat they achieved in twenty-one weeks working six days a week for eleven hours a day. The topsideframes took another three weeks to stitch in place, with another six weeks needed to complete the fastenings of the stringers, shelves,deck beams, and mast steps, and such, which Vosmer advises weretreenailed in. This phenomenon will be discussed later. He also ad-

Figure 11.External stitching on a

Micronesian sailing canoe. ByJ. Rodrigues after Prins,

Hadden and Hornell. Prins1986, 151; Hadden and

Hornell 1975.

01-A3433 6/8/05 12:01 PM Page 20

-

vises that the hood ends were sewn together rst, after which the exter-nal stem and sternpost were sewn to the hood ends.56

Although much of the coir was required for fastening the hull, inthe two instances quoted here much of it was for rigging. This observa-tion provides us with a useful opportunity to note that coconut ber isno inferior substance. As one exampleand admittedly digressingsomewhat in order to make the pointthe late-eighteenth-centuryBritish merchant ship Sydney Cove that was built in Bengal or Burma,had all its rigging made of coir. Not as durable as other natural berssuch as sisal, manila, and hempthat were apparently rated three tosix times strongercoir was noted for its exibility and lightness.57

Further, it was resistant to stretch, was nearly one-third the price of imported European cordage, and was reputed to be stronger when wet. As a result, it was widely used for light rigging in the famouscountry-built shipbuilding tradition of the eighteenth and nine-teenth centuries.58

Leaving vessels fastened entirely with cordage we turn to A. H. J.Prinss translation of the explorer Marco Polos description of ocean-going ships he saw in the Persian Gulf in the late thirteenth century:Their ships are . . . not fastened with nails but stitched together withthread made of coconut husks. They soak the husk until it assumes thetexture of horse hair, then they make it into threads and stitch theirships. They have no iron for nails, so they employ wooden pegs andstitch with thread. 59

The great explorers comment on the use of wooden pegs, pro-vides a useful opportunity to lead us into the next section of this work,those sewn plank boats where dowels or tenons are also present.

Edge Fasteners of WoodIt is also evident that the terms stitched-planking, sewn-plank, or lashed-plank, as used in the previous section, can be somewhatdecient if used as a sole descriptor in that they do not mention or im-ply the presence of the timber fastenings that often appear along withligatures.

One early example is the Dover boat mentioned earlier. Here theside planking was described by Peter Clark of the Canterbury Archaeo-logical Trust as being stitched to the bottom planks of the vessel withyew withies, and these in turn were joined across the seam withtransverse timbers (that have been called wedges, though they ap-parently do not perform that function) up to 60 cm long. They weredriven across the central seam to lodge rmly in slots (or mortises) inrails and cleats raised above the planking. These are joined by whatClark describes as more robust timbers over a metre in length, whichpassed through the central rails as well as holes cut into opposing pairsof cleats left upstanding on the bottom planks (see below). He also be-lieves it is possible that the primary role of the wedges was to se-cure the thin timber lath between the central rails that compressed

21Fastened without Nails

01-A3433 6/8/05 12:01 PM Page 21

-

pads of moss luted over the central seam to help make it watertight.In turn, the lath and the underlying luting of compressed moss servedto tighten the stitches, thereby also becoming an aid to securing the fas-tenings. The transverse timbers on the other hand, helped stop thebottom planks shifting in a vertical dimension relative to each other. 60

As well, the term sewn boat does not provide adequate recogni-tion of the internal edge-to-edge plank joiners such as those that ap-peared on Sohar. These can be both fasteners and aligners and arefound across the globe in a variety of forms. Examples include the thin,rectangular, sometimes tapering, tongues or tenons of hardwoodin the Mediterranean tradition, or the cylindrical (or nearly cylindrical)pin or dowel that is found in the Asian and Indian Ocean context.

While Marco Bonino refers to sewing with tenons to describe theformer instance,61 in the latter context Jeremy Green refers to vesselsbeing edge-joined with dowels. Adrian Horridge refers to the processof edge pinning with internal dowels and to boats that are sewnand edge-dowelled. Finally, in discussing a situation with sewn-plankboats where edge-fastenings (such as tongues or tenons) serve to-gether with ligatures (for example, rope, cord, lashings, or stitching) tosecure the hull, Patrice Pomey has argued for the use of the termmixed construction. 62

In the process of edge fastening, each tongue, key, tenon, or dowelwas tted into a hole or mortise, drilled, carved, shaped, or cut into thetimbers being joined. Sometimes, it was as a plank locatorlooselytted as an aid to alignmentand in other times as a stiffener, or sec-

Figure 12.Internal fastenings on the

Dover boat. Photograph cour-tesy Canterbury Archaeologi-

cal Trust Ltd.

01-A3433 6/8/05 12:01 PM Page 22

-

ondary fastening, driven tightly in the opposing holes or mortises, be-fore a primary fastening (such as ligatures) was applied. McGrail callsthose tenons used in this context draw tongues, while Steffy uses theterm free tenon or loose tenon to describe tenons not xed into atleast one of the timbers being joined. Thus, one encounters the methodvariously described as a mortise-and-tenon, or a draw-tongue jointtechnique when referring to vessels that are tenon-built. 63 A. J.Parker uses an alternative spelling and denes the mortice-and-tenonjoint as one where mortices (slots) were cut into the edge of planks toreceive tenons (tongue shaped pieces of wood), which positioned thetwo joining timbers. 64

There is an underlying reason why these practitioners use such a va-riety of terms, for in shipbuilding the mortise-and-tenon joint appearsin many other applications. In some European traditions, it appears atthe junction of the stern post and keel, where the tenon is a xedwooden projection cut at the lower end of the stern post to t snuglyinto a mortise cut on the keel. Steffy describes the latter as a xedtenon and single mortise system, and the former as a free-tenon andtwo-mortise system.65

One of the best known examples of edge-fastening is the circa 3,500-year-old, about forty-two-meter-long carvel-built boat from theCheops (Khufu) boat pit that lies beside the Great Pyramid of Giza.66

Here the planks (the largest over twenty meters) have lashings of halfagrass as the primary fasteners and mortise-and-tenons between eachstrake as plank aligners. Further, in examining the Cheops instance, it

23Fastened without Nails

Figure 13.Tom Vosmers depiction of anOmani sewn hull with dowelfastening. Vosmer 1997, 220;234.

01-A3433 6/8/05 12:01 PM Page 23

-

needs be recognized that the hulls of vessels built purely for pleasure, oras symbols of stature, often had recognizable differences when com-pared with their mundane counterparts. Here, it is useful to considerCheryl Haldanes analyses of timbers dated to circa 2000 b.c. found at apyramid near Lisht, south of Cairo. These were from workingboat(s), or freighters and here the mortises were described as beingso deep they often pass over halfway through each timber, while thetenons were very tightly ttedthat is, they were hull stiffenersrather than aligners. 67

Haldanes account of the circa 2000 b.c. Dashur boats, which werealso buried near a pyramid, is again of importance for these and otherreasons. She notes that these boats were of mixed construction, withboth sewing and mortise-and-tenon fastenings used along plankedges. In this instance the hull mortises measure 7.5 cm wide and 1.8 2.0 cm thick, a seemingly random gureuntil it is recognized that (asHaldane notes), these measurements coincide with standard Egyptianmeasurements of one palm and one digit or nger, respectively. 68 Inthis ancient example appears an irrefutable reason for the continuedneedalmost an obligationto report on ship length, timber scant-lings, fastening sizes, and so forth, not only in internationally recog-nized units for the sake of comparison but also in the units used in theplace and at the time that a vessel was built. It is only then that, if oneexists, a recognizable or meaningful pattern becomes evident. In re-spect to Haldanes recording of the depth of the mortises as betweenten and 13 cm deep, Nick Burningham observed that while length andbreadth of the mortises are critical for a good t, when chiseling amortise or drilling a hole for an edge dowel or tenon the only consid-eration is that it must not be too shallow. If it is the planks cannot bedriven together and as a result the mortices in the upper plank (the onebeing added to the plank shell) will tend to be randomly deeper thannecessary.69

In these vessels, wooden, dovetail-shaped pieces are often foundsunk into the surfaces of adjoining planks across a seam. Mercer callsthem dovetail keys in the sense that in shipbuilding a key is denedas a slightly tapered piece of wood to be driven into scarfs, to wedge

24Chapter One

Figure 14.A hypothetical run of plank-

ing, showing dovetails, tenonsand ligatures. By J. Rodrigues,

after Abell 1948, 10.

01-A3433 6/8/05 12:01 PM Page 24

-

deck planks, or to join any pieces of wood tightly together in order toprevent warping across the seam.70 McGrail calls them double dove-tail clamps, while others refer to them as just dovetails. 71

In the absence of proof that the Egyptian ships of this early periodwent to sea, the fteen- to sixteen-meter-long circa fourteenth-centuryb.c. wreck at Uluburun on the southern coast of Turkey constitutes theearliest known seagoing ship with edge-fastened strakes. Here, oaktenons were used, and here each tenon was found locked into the twostrakes being joined with tapered wooden pegs. These were driventhrough pre-drilled peg holes and are called tenon pegs. 72 Tenonpegs could be square, round, or multisided in cross section and withdiffering tapers.

Thus we have unpegged tenons and pegged tenons, or as Mc-Grail calls the latter form, locked draw tongues. In being locked, theyare far more than mere plank locators or stiffeners and representan advance on those used primarily in aligning or stiffening the jointbetween the strakes. Here, they be-come fastenings in the true sense ofthe word.73 Finally, in what he de-scribes as a free tenon with three ormore mortise arrangement, Steffyprovides a situation where the tenonpasses entirely through one (middle)strake to join those on either side.74

Mensun Bound describes a sea-going sewn-plank ship dated tocirca 600 b.c. that was found nearthe island of Giglio in the TuscanArchipelago. It had a hull as-sembled with monocot cord whichthreaded through diagonal holesacross the seam . . . jammed andsealed with wooden ligature pegs.75

Its contemporary the Bon-Portwreck, found near St. Tropez, France,was similar, with lashings of veg-etable bre locked in place by pegs.In describing the Bon-Port wreck,Patrice Pomey introduces yet anotherdimension, the fastening of strakesand frames with treenails. 76 Con-sidered almost certainly Etruscan,Steffy has advised that this vesselrepresents an alternate form of con-struction with treenails and lashingscoexisting with mortise-and-tenonjoined planks. 77 Moreover, Bonino

25Fastened without Nails

Figure 15.Pegged mortise-and-tenonsystems. By Chris Buhagiarand Ross Shardlow, afterSteffy 1994, 276; 297.

01-A3433 6/8/05 12:01 PM Page 25

-

has indicated that the twenty-three-meter-long rst-century b.c. Com-machio wreck found in Italian waters was a seagoing form built inidentiable phases, with a lower hull fastened solely with ligatures andan upper hull joined by pegged tenons in mortises. It also had oortimbers and futtocks both treenailed and lashed to the planking.78

A need arises at this juncture to clearly differentiate between themany rounded wooden fastenings found in boat and shipbuildingacross time and place. First, there are the small often-cylindrical (butsometimes multifaceted) ligature pegs that serve to stop or make wa-tertight, and to wedge, or secure and tighten cord, lashings, and lac-ings in their ligature holes. Then there are the small pegs that served tolock tenons in their mortises (tenon pegs). These too can be circular, ormultifaceted (multisided). Larger wooden pins, rods, or dowels, are ev-ident between the seams in edge dowelling of planks and sometimesbetween other timbers. These types of fastenings vary, not necessarilyin size or form, but certainly in purpose, from yet another category ofcylindrical wooden fastening, the newly arrived treenail. All of thesefastenings can also be found within the sewn-plank or lashed-planktradition.

Notwithstanding Vosmers use of the term in the Sohar case, one ofthe simplest denitions of the word treenail, trennal, or trunnal,is found in William Falconers 1815 New Universal Dictionary of the Marine. There he states that treenails are long cylindrical [wooden]pins . . . used for fastening the inside and outside of the plank of a shipto the upright timbers. 79 The upright timbers referred to here are theribs or frames of a vessel. In order to differentiate between those vari-ous forms of cylindrical wooden fastenings used in the boat and ship-building mentioned earlier, in this particular section of this book thosecylindrical wooden pins, rods, or dowels found fastening planks toframes and other structural members are called treenails. Later, for rea-sons that will become apparent, we will adopt a more expansive deni-tion accepting that treenails also appear in many other applications.

Returning to the ubiquitous nature of the sewn-plank tradition andits persistence over time and across regional boundaries, Carl-OlofCederlund has stated that it might even be misleading to stress thesewing technique as a separate entityrather it must be seen as oneelement in one or more building traditions. 80 This is an important ob-servation, for the sewn-plank boat discussed in carvel (edge-to-edgeplanking) form has also been seen in the clinker form in the northernEuropean tradition.81 Here the upper strakes of a hull are found over-lapping those below and fastening is performed across the lap. Moreof this tradition and its variants later, but one example of the applica-tion of the lashing or sewing technique to clinker or lapstrake construc-tion is the circa 350 b.c. sixteen-meter-long Hjortspring boat on the is-land of Als in Denmark with continuous stitched planking across thelap. The planks were fastened with lime bast [from the cambium]cord and the hull was also reinforced with ribs of hazel branches

26Chapter One

01-A3433 6/8/05 12:01 PM Page 26

-

lashed to cleats carved from the planking stock, and here woodendouble dovetails were also found.82

In the comprehensive British Museum Encyclopedia of Underwaterand Maritime Archaeology, there appear many references to the sewn-boat tradition. In one entry for example, the chief editor James P. Del-gado provides a prcis of Zdenko Brusic and Milenko Domjans earlierreport of rst-century carvel planked boats discovered off the Adriaticport of Zaton in Croatia. Both were apparently sewn together withrope made from ax and Spanish Broom. As this was an area once in-habited by Liburnians, the name Liburnian sewn boats was applied tothem. One was around six meters long and the other eight meters longwith a keel and twenty-seven frames. The rst boat had planks thatwere attached to the frames with treenails and the second showed evi-dence of a row of inner boards, or ceiling.83

In another tradition, the planks were worked with an adze, leavingprojecting cleats or lugs on the inner surfaces that were de-signed to facilitate the lashing of the planks to the frames.An example of this form appears with the approximatelyfteen-meter-long, edge-dowelled, fourth- to tenth-centuryButuan boats of the southern Philippines recorded by WillieRonquillo. He states that a distinctive feature of thewooden planks is a succession of at rectangular protru-sions or lugs which are carved out of the planks on the sidewhich is inside the boats. Placed exactly opposite one an-other on each plank, these lugs . . . have holes along theiredges through which cords and lashings can be passed. 84

Horridge provides numerous examples of the tradition,showing that it was common throughout the Philippines,Sulawesi, the Moluccas, and in the Indian Ocean region,and he calls it a lashed-lug design. 85 He also describes and illustratesa system where edge-fastened planks are compressed tightly onto eachother by lashings between transverse timbers that are locked into placeagainst lugs on the planking.86

The lashed-lug system does not occur in isolation, how-ever, and Green has observed that the lashed-lug construc-tion features strongly in Archipelago Southeast Asia . . . butthe whole issue of lashed-lug, edge-joined with dowels andthe sewn construction seem to be intermixed. 87

Burningham also depicts a system of edge dowelling in Indonesian craft where some of the elements of the hull have a fastening function. Here, thwarts are showndowelled and recessed into the rail timbers to prevent the two sides of the hull pulling apart, thereby acting asboth thwarts and as fastenings.88 Similar systems, for ex-ample where the deck beams are dovetailed into deckclamps to prevent a hull spreading, are found in moderncraft.

27Fastened without Nails

Figure 16.A lashed lug construction byNick Burningham, alongside amultiple beam system withedge-joining. By MatthewGainsford, after Horridge1985, 52.

Figure 17.Nick Burninghams depictionof edge dowelling and of theuse of thwarts as a fasteningmechanism.

01-A3433 6/8/05 12:01 PM Page 27

-

In Asia and elsewhere, sewn-plank craft could be substantial, andsome are quite modern. Pierre-Yves Manguin, for example, hasnoted that European travelers in the seventeenth and eighteenth cen-turies saw Vietnamese seagoing (coastal) sewn-plank craft that werebuilt of ve long planks, edged-fastened with wooden dowels, andjoined with rattan stitches. Between fteen and twenty-ve meters longthey were capable of carrying 100 to 150 tons of cargo.89 While at thehood ends the planks are generally found fastened with ligatures, dow-els were also used.

In his work The Prahu: Traditional Sailing Boat of Indonesia, Hor-ridge regales the senses with a vast range of illustrations and descrip-tions of colorful watercraft such as the Lambo, the Madurese Janggolan,and the modern Bugis Pinisi. Like so many others in the moderntime, their builders part-copied the best elements of visiting Europeancraft, from sails through to fastenings and in some cases center-line(axial) rudders; and in turn they themselves were copied.90 Horridgealso provides many examples of the fastenings used at the stem andstern of some of these vessels. While initially organic many later cameto be of a metallic form.

Finally, as a type, the Mtepe and dau la Mtepe of Africa providesome of the best examples with which to contemplate the myriad offastening variations possible in sewn craft. They are also both an an-cient and modern ocean-going vessel and were described while an-chored off Mozambique in 1498 by Vasco da Gama as being fastenedentirely with coir from coconut ber. Normally around fteen metersin length and of ten to twenty tons, they were built well into the twenti-eth century, and the last was apparently wrecked off the coast of Kenyaaround 1935.91