Sheerness of Extended Circular INGKnitted Fabrics

-

Upload

anonymous-zd5hpb5 -

Category

Documents

-

view

221 -

download

0

Transcript of Sheerness of Extended Circular INGKnitted Fabrics

-

8/13/2019 Sheerness of Extended Circular INGKnitted Fabrics

1/7

http://trj.sagepub.com

Textile Research Journal

DOI: 10.1177/0040517500070009032000; 70; 763Textile Research Journal

Yoshiaki Azuma, Yo-Ichi Matsumoto, Hideki Saito, Kazuo Shinohara, Kiyoto Wakashima and Hideo MorookaSheerness of Extended Circular Plain Knitted Fabrics

http://trj.sagepub.com/cgi/content/abstract/70/9/763The online version of this article can be found at:

Published by:

http://www.sagepublications.com

can be found at:Textile Research JournalAdditional services and information for

http://trj.sagepub.com/cgi/alertsEmail Alerts:

http://trj.sagepub.com/subscriptionsSubscriptions:

http://www.sagepub.com/journalsReprints.navReprints:

http://www.sagepub.co.uk/journalsPermissions.navPermissions:

by Ershad Khan on October 7, 2008http://trj.sagepub.comDownloaded from

http://trj.sagepub.com/cgi/alertshttp://trj.sagepub.com/cgi/alertshttp://trj.sagepub.com/subscriptionshttp://trj.sagepub.com/subscriptionshttp://www.sagepub.com/journalsReprints.navhttp://www.sagepub.com/journalsReprints.navhttp://www.sagepub.co.uk/journalsPermissions.navhttp://www.sagepub.co.uk/journalsPermissions.navhttp://trj.sagepub.com/http://trj.sagepub.com/http://trj.sagepub.com/http://www.sagepub.co.uk/journalsPermissions.navhttp://www.sagepub.com/journalsReprints.navhttp://trj.sagepub.com/subscriptionshttp://trj.sagepub.com/cgi/alerts -

8/13/2019 Sheerness of Extended Circular INGKnitted Fabrics

2/7

763

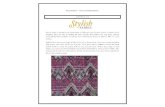

Sheerness of Extended Circular Plain Knitted Fabrics

YOSHIAKIAZUMA

Nara Prefectural Institute of Industrial Technology, Nara, Japan

YO-ICHI MATSUMOTO, HIDEKI SAITO,AND KAZUO SHINOHARA

Faculty of Textile Science and Technology, Shinshu University, Ueda, Japan

KIYOTO WAKASHIMA

Department of Living Science, Minatogawa Womens College, Sanda, Japan

HIDEO MOROOKA

Department of Textile andApparel Science, Nara Womens University, Nara, Japan

ABSTRACT

To improve the sheerness of pantyhose to enhance the beauty of womens legs, thedesign and development of a new yarn and product are proposed. The sheerness of circularplain knitted fabric made from single covered yarns is examined, and the relationshipsbetween color, covering level of single covered yarns, and degree of extension of knittedfabrics are discussed. The results show that the appearance and sheerness of pantyhose aregreatly influenced by yarn characteristics, degree of extension, and color. Furthermore,sheerness cannot be defined only by light transmittivity. It is necessary to evaluate thelightness difference L* of a uniform color space for a colorless sample and/or chroma-ticity differences, a* and b* of a uniform color space for a colored sample.

Pantyhose or stockings have become one of the most

necessary textile products in a womans life. These days,however, pantyhose purchases are down, and althoughthere are many types and kinds of pantyhose, their ap-pearance and sheerness have yet to be satisfactory forwomens needs. The aesthetic properties of pantyhosehave long been of great concern to women, and even

greater in recent years. In a survey of the sheerness of

pantyhose conducted among women and reported in our

previous paper [8], most Japanese women answered thatsheerness is one of the most important elements when

choosing pantyhose. Younger women are especially ea-

ger to have their legs appear more slender, and so theyselect pantyhose based on the color and count of the

yam.

Previous papers on handle, performance, and wearingcomfort have been published by Fujimoto et al. [ 1, 2],Harada et al. [3, 4], Inamura et al. [6], and Sugai et al.[ 10]. In other studies, Maekawa et al. [7] studied thechroma of the human skin color

observed througha

thinfabric and Suzuki [ 11-13] investigated the color of wom-ens nylon stockings. However, studies of pantyhose

sheerness are rare. Sheerness is greatly affected by lighttransmittivity. The evenness of sheerness over the entire

leg is influenced by the degree of pantyhose extension oneach leg part, and sheerness and sheerness evennessaffect appearance. In our previous paper [9], we exam-ined the relationship between the light transmittivity ofan extended knitted fabric and the covering level of

single covered yams. Pantyhose sheerness increased withincreased light transmittivity and the degree of fabricextension, but light transmittivity cannot be defined onlyby the count of single covered yarns. The experimentalresults of light transmittivity of colored pantyhose cur-

rently on the market are not in agreement with handevaluations of sheerness in our survey of women.

In this paper, we measure the background color

through extended knitted fabrics and consider a methodof evaluating sheerness by finding the relationship be-tween light transmittivity, the degree of fabric extension,and the chromaticity of pantyhose. We describe the

sheerness of extended knitted fabrics in order to developa new product that can enhance the beauty of wornenslegs.

by Ershad Khan on October 7, 2008http://trj.sagepub.comDownloaded from

http://trj.sagepub.com/http://trj.sagepub.com/http://trj.sagepub.com/http://trj.sagepub.com/ -

8/13/2019 Sheerness of Extended Circular INGKnitted Fabrics

3/7

764

Materials and Methods

COLORLESS SAMPLES

Single covered yam is produced from a combinationof polyurethane yarn (20 denier/3 filaments) as the corestrand and nylon yam (10 denier/5 filaments or 12 de-

nier/7 filaments) as the covering strand.Table I lists the characteristics of four experimental

yams and knitted fabrics. The length of the single cov-

ered yam is determined under a tension of 10 gf. The

sample yam count is calculated from the mean mass,determined when the test length is 1 m, and the test is

repeated ten times. The covering level is determined ten

times for each sample yam using a twist tester with a

gauge length of 10 cm. The circular plain knitted fabric

used as a testing sample is produced by an automatic

hosiery machine (model B, no. 3 needle, 13.8/cm gauge);the yam tension is 15 gf and there are two supplyingyams. The fabric sample is 3.5 x 15 cm in a flat shapewithout a load. The initial thickness of the knitted fabric

is also determined twenty times for each sample by usinga thickness tester at 50 gf/CM2 pressure, listed in Table I.

Despite the constant count of the single covered yamand the constant knitting condition, the knitted fabric

samples have different thicknesses and cover factors.

This phenomenon may have been caused by differencesin the bending stiffness of the yam at the cross point ofthe loop in the knitted fabric and by the knitted loopslanting in the covering direction of the yam against thefabric plane due to the snarling tendency of more highly

twisted yam.As the yam length in the knitted fabricbecomes longer, the cover factor increases.

COLOR SAMPLES .

Table II lists the characteristics of six pantyhose cur-

rentlyon the market.

Theyare three colors and can be

classified into two types: pure (&dquo;zokki&dquo;) and combined

(&dquo;kouhen&dquo;) knitted fabrics.Although the single covered

yam of the combined type has a greater count than the

pure type, the initial thickness of the combined type is

less than the pure type because of the combination with

15 denier nylon yam. _Because each part of the pantyhose leg is a different

original size and is extended by the dimensions of wom-ens legs, the degree of fabric extension varies with the

type and color of pantyhose. The ratio of extension andeach

partof the

legof the

pantyhoseare used as the

x-axis in the figures. When the ratio of extension R isdefined by R = Ep/E~, where Ep is the extension ofknitted fabric in each section of the leg and EK is that inthe knee section, R = 1 indicates the knee section. R

thus becomes smaller toward the ankle and larger towardthe thigh.

TRANSMITTIVITY PROCEDURE

Figure 1 is a schematic illustration of the experi-mental apparatus. The light source is a white light bulb

( 100 W), and the vertical distance from the lightsource to the surface of the sample is established at 70

TABLE I. Characteristics of experimental yams and knitted fabrics.

FABLE II. Characteristics of pantyhose currently on market.

* Pure = zokki type, all single covered yam.~Combined = kouhen type, a combination of single covered yam and nylon yam ( 15 denier).

by Ershad Khan on October 7, 2008http://trj.sagepub.comDownloaded from

http://trj.sagepub.com/http://trj.sagepub.com/http://trj.sagepub.com/http://trj.sagepub.com/ -

8/13/2019 Sheerness of Extended Circular INGKnitted Fabrics

4/7

765

cm. The measuring part is composed of a pipe made of

vinyl chloride and an illuminance meter (Tokyo Pho-toelectric Co., modelANA-FL 1, diameter of light re-

ceiving part = 25 mm). The pipe is opened up to

provide a 40 mm hole at a location corresponding tothe light receiving part. On the test, the surface of the

pipe body and the open hole are wrapped and coveredwith the circular plain knitted fabric and/or the panty-hose. The illuminance meter is fitted into the pipe, andthe space from the hole to the light receiving part isfilled with a small, short, vinyl chloride pipe. Theillumination of the knitted fabric sample is measured

twenty times for each sample using the experimentalapparatus, and the mean value is calculated. If theillumination with the sample is IE (Ix) and the illumi-nation without the sample is 10 (lx), the light trans-

mittivity IT (%) is given by IT = (IJIO) x 100.

FIGURE 1. Schematic illustration of experimental apparatusfor light transmittivity.

Table III is a comparison of the apparatus pipe size tothe leg dimension data. Human body dimension data for

ergonomic design have been published by the NationalInstitute of Bioscience and Human Technology in Japan[5].

CHROMATICITY PROCEDURE .

The color of the background through the extendedknitted fabric is measured by the L*a*b* of the uniform

TABLE III. Comparison of apparatus pipe size to kg dimension data.

a From report of National Institute of Bioscience and Human Tech-

nology.

color space using a color reader (Minolta Co., modelCR-310, diameter of measuring part = 50 mm). In auniform color space, lightness is indicated by L* and

chromaticity is indicated by a * and b * . The color of the

background is either a black fabricon

the surface of thepipe or the skin color of a Japanese womans leg. Theblack color is useful for developing a general evaluationmethod. The sample fabric covers the surfaces of the

pipe body and the leg at the same degree of extension. Inorder to estimate the effects of the sample fabric, it is

necessary to neglect the effect of the background color. Ifthe background color measured with the sample is LE*,aE*, and bE* and the background color measured with-out the sample is Lo*, ao*, and bo*, the lightnessdifference 3L*, the chromaticity difference 3a* and

3b*, and the color difference 3Eab* for the samplefabric are defined by

In order to preclude the effects of external light, alltesting occurs in a darkroom.

Results and Discussion,

Figures 2 and 3 show the relationship between thecolor difference ~Eab* of the skin and the degree offabric extension. Figure 2 shows that the color differenceof skin through the experimental colorless samples de-creases with the increased fabric extension and coveringlevel of the single covered yam. On various sections of awomans leg, the color difference decreases graduallyfrom thigh to ankle. Therefore, due to differences insheerness between the thigh and ankle, pantyhose areless attractive farther down on the leg. Moreover, as

shown in Figure 3, the color difference of skin throughthe pantyhose decreases slightly with an increased ratioof extension. The combined type shows less color dif-

by Ershad Khan on October 7, 2008http://trj.sagepub.comDownloaded from

http://trj.sagepub.com/http://trj.sagepub.com/http://trj.sagepub.com/http://trj.sagepub.com/ -

8/13/2019 Sheerness of Extended Circular INGKnitted Fabrics

5/7

766

ference than the pure type. In comparing the colors of

pantyhose, the color difference decreases in order ofblack, beige, and white. The color difference between

beige and white is very slight as opposed to black, that is,it will be difficult to distinguish the color difference ofskin through a colored sample since the color is greatly

affected by the background color. Therefore, an evalua-tion of sheerness using the color difference is useful forthe colorless sample but not for the colored sample.

FIGURE 2. Color difference of skin through extended colorless knittedfabric (Sample code of Table 1: 0 I, 0 II, . III, 0 IV).

FIGURE 3. Color difference of skin through extended colored panty-hose. Color/type: A white/pure,A white/combined. 0 black/pure, black/combined, 0 beige/pure, 0 beige/combined.

Equation 3 shows that evaluations with the color differ-ence might be suitable for some fabrics that have greatervalues of 3L* and smaller values ofAa* and 3b*.

Figure 4 shows the relationship between the lighttransmittivity of the extended fabric and the lightness ofthe background color through the extended fabric. On all

the samples, the lightness LE* of the background colorthrough the sample draws nearer to the lightness Lo* ofthe background color without the sample because the

light transmittivity or the degree of extension increases.The color through the sample is greatly affected by the

background color, so we believe that the sheerness of acolorless sample can be evaluated using only lightness.

Figures 5a and b show the relationship between lighttransmittivity and the chromaticity of the backgroundcolor through the extended knit. On all the samples, thechromaticities

aE*and

bE* throughthe knitted fabric

draw nearer to the chromaticities ao* and bo* of the

background color as the light transmittivity or the degreeof extension increases. The chromaticity variation be-tween the colorless samples is very slight, whereas thevariation between the colored samples is great. There-

fore, we believe the sheerness of colored pantyhose maybe evaluated using chromaticity. However, the resultsfrom pantyhose have yet to agree with the visual evalu-ation conducted among women.

Figure 6 shows the chromaticity differences 3a* and

Ab* on pantyhose of different colors.As the ratio ofextension increases, the chromaticity difference 3a* inthe direction of the red component tends to decrease and

the chromaticity differenceAb* in the direction of the

yellow component tends to increase. The chromaticitydifference of Ab* varies more than that of 3a * , and both

differences Da* and 3b * decrease in the order of black,

white, and beige. This phenomenon can be explained bythe chromaticity differences in a Japanese womans legthrough the beige pantyhose, which become smaller be-cause beige has greater red and

yellowcomponents than

black and white ones. Moreover, in comparing the panty-hose, the chromaticity difference through a combined(kouhen) type is less than that of the pure (zokki) type.

As for the color and type of pantyhose, these results

agree with the following results. First, in a survey on the

transparency of pantyhose, Japanese women answeredthat they were not satisfied with the sheerness of whiteand black colored pantyhose as reported in our previouspaper [8]. Second, in visual evaluatings of wearingpantyhose conducted among twenty female students, the

combined beige pantyhose was the best one. Therefore,we believe that the sheerness of colored pantyhose canbe evaluated by chromaticity differences 3a * and 3b*.

by Ershad Khan on October 7, 2008http://trj.sagepub.comDownloaded from

http://trj.sagepub.com/http://trj.sagepub.com/http://trj.sagepub.com/http://trj.sagepub.com/ -

8/13/2019 Sheerness of Extended Circular INGKnitted Fabrics

6/7

767

Ftcutt6 4. Relationship be-tween lightness of background

color through extended knit fab-ric and light transmittivity. Color:e colorless, 0 white, t black. 0

beige, background color: @ skin.L1 black fabric.

.

o

Conclusions

We have found that the color of womens legs throughpantyhose is greatly influenced by the characteristics of

theyam

and knitted fabric, i.e., the draw ratio-6f the core

yarn, the count of the covering yarn, the covering leveland stiffness of the single covered yam, and the thick-

ness, cover factor, color, and degree of fabric extension.

FIGURE 5. (a, top) Relation-

ship between chromaticity ofbackground color through ex-tended colorless knitted fabric

and light transmittivity. Sam-ple . code of Table I: O I,08 II,AA III, VV IV; back-

ground color: 0 skin, 0 blackfabric. (b, bottom) Extended

colored pantyhose and lighttransmittivity. Color: AAwhite, ON black, 08 beige;background color: 0 skin, 0black fabric.

by Ershad Khan on October 7, 2008http://trj.sagepub.comDownloaded from

http://trj.sagepub.com/http://trj.sagepub.com/http://trj.sagepub.com/http://trj.sagepub.com/ -

8/13/2019 Sheerness of Extended Circular INGKnitted Fabrics

7/7

768

FIGURE 6. Chromaticitydifference of skin throughextended colored panty-hose. Color/type: A

white/pure,A white/com-bined, 0 black/pure, 0black/combined, 0 beige/pure, 0 beige/combined.

We clearly recognize that sheerness cannot be defined

only by light transmittivity, and it is necessary to eval-uate the lightness difference 4L* of a uniform color

space for colorless samples and/or the chromaticity dif-ferencesAa* andAb* of a uniform color space for

colored samples. It will be necessary to vary the produc-tion conditions of single covered yams and knitted fab-rics depending on the color, the degree of extension, andthe dimension of the leg section of the pantyhose to be

produced and to develop amore

accurate definition ordescription of pantyhose sheerness. Only then will panty-hose more closely approach the desire of women to maketheir legs appear more slender and beautiful.

ACKNOWLEDGMENTS

This work was supported by a Grant-in-Aid for COEResearch (10CE2003) by the Ministry of Education,Science, Sports and Culture of Japan. We wish to thankMinolta Co., Okamoto Co., and Ms. Mariko Itoh for their

cooperation.

Literature Cited

1. Fujimoto, T., The Evaluation of Performance of WomensPantyhose, Part I: Characteristic of Deformations in theWearing Test and the Size Effects, Jpn. Res.Assoc. TextileEnd-uses 30, 80 (1989).

2. Fujimoto, T., The Evaluation of Performance of Womens

Pantyhose, Part II: Effects of the Tensile Properties on theSubjective Impressions, Jpn. Res.Assoc. Textile End-uses30, 118 (1989).

3. Harada, T., Comfort of Clothing and Sense Measurement,

Jpn. Res.Assoc. Textile End-uses 36, 24 (1995).

4. Harada, T., and Fusaka, K., Wear Feeling of Pantyhose,Jpn. Res.Assoc. Textile End-uses 23, 135 (1982).

5. Human body dimensions data for ergonomic design, Re-

port of National Institute of Bioscience and Human Tech-

nology, vol. 2, p. 96, 1994.6. Inamura,A., Nakanishi, M., and Niwa, M., Relationship

between Wearing Comfort and Physical Properties of Gir-dles, Jpn. Res.Assoc. Textile End-uses 36, 109 (1995).

7. Maekawa, I., Gunji, T., and Tsuboi, T., How the HumanSkin Color is Perceived Through a Thin Fabric, Jpn. Res.

Assoc. Textile End-uses 24, 156 (1983).8. Matsumoto, Y., and Morooka, H.,A Questionnaire Survey

on the Transparency of Pantyhose and the Transmittivity of

Light on Knitted Fabric, Jpn. Res.Assoc. Textile End-uses38,711 (1997).

9. Matsumoto, Y., Shinohara, K., Takatera, M.,Azuma, Y.,and Morooka, H., Light Transmittivity of an ExtendedCircular Plain Knitted Fabric, Textile Res. J.69,641-647( 1999).

10. Sugai, K., and Chinzei, T., The Effects of Clothing Mate-rial on Skin Temperature and Wearing Sensation underChangingAmbient Vapor Pressures, Jpn. Res.Assoc. Tex-

tile End-uses 36, 95 (1995).11. Suzuki, N., Studies on the Color of Womens Nylon Stock-

ings, Part 1: The Color on the Flat Face of the Body, Sci.Rep. Shiga Prefect. Jun. Coll. 14, 78 (1973).

12. Suzuki, N., Studies on the Color of Womens Nylon Stock-

ings, Part 2: The Color Comparison Between Non-wearingState and Wearing State, Sci. Rep. Shiga Prefect. Jun. Coll.18, 69 (1977).

13. Suzuki, N., Studies on the Color of Womens Nylon Stock-ings, Part 3: The Effects of the Value of Skin Color onWearing State, Sci. Rep. Shiga Prefect. Jun. Coll. 19, 67(1978).

Manuscript received June 28, /999; accepted September 17, 1999.

by Ershad Khan on October 7, 2008http://trj.sagepub.comDownloaded from

http://trj.sagepub.com/http://trj.sagepub.com/http://trj.sagepub.com/http://trj.sagepub.com/