Shear resistance degradation of lime –cement stabilized soil...

Transcript of Shear resistance degradation of lime –cement stabilized soil...

-

Shear resistance degradation of lime –cement

stabilized soil during cyclic loading

Alex Gezahegn Gebretsadik

Master of Science Thesis 14/01

Division of Soil- and Rock Mechanics

Department of Civil, Architectural and the Built Environment

Stockholm 2014

-

© Alex Gezahegn Gebretsadik

Master of Science Thesis 14/01

Division of Soil and Rock Mechanics

Royal Institute of Technology

ISSN 1652-599X

-

i

-

ii

ABSTRACT: This thesis presents the results of a series of undrained cyclic triaxial tests carried

out on four lime-cement stabilized specimens and clay specimen. The shear resistance

degradation rate of lime-cement column subjected to cyclic loading simulated from heavy truck

was investigated based on stress-controlled test. The influence of lime and cement on the

degradation rate was investigated by comparing the behavior of stabilized kaolin and

unstabilized kaolin with similar initial condition. The results indicate an increase in degree of

degradation as the number of loading cycles and cyclic strain increase. It is observed that the

degradation index has approximately a parabolic relationship with the number of cycles.

Generally adding lime and cement to the clay will increase the degradation index which means

lower degree of degradation. The degradation parameter, t has a hyperbolic relationship with

shear strain, but it loses its hyperbolic shape as the soil getting stronger. On the other hand, for

unstabilized clay an approximate linear relationship between degradation index and number of

cycles was observed and the degradation parameter has a hyperbolic shape with the increase

number of cycles. It was also observed that the stronger the material was, the lesser pore pressure

developed in the lime-cement stabilized clay.

Keywords: undrained cyclic triaxial test ;lime-cement stabilized column; shear resistance; shear

strain; degradation index; degradation parameter; pore pressure

-

iii

SAMMANFATTNING : I detta examensarbete presenteras resultat från en serie odränerade

cykliska triaxialtest som utfördes på fyra kalk- och cementstabiliserade prov och ett ostabiliserat

lerprov. Nedbrytningen av skjuvmotståndet hos kalkcementpelare vid cyklisk belastning

undersöktes med hjälp av spänningskontrollerade triaxialförsök. Inverkan av inblandning med

kalk och cement på nedbrytningen av skjuvmotståndet undersöktes genom att jämföra beteendet

hos stabiliserad och ostabiliserat kaolin med liknande initiala förhållanden. Resultaten visar på

en ökad grad av nedbrytningen allteftersom lastcykler och cyklisk töjning ökar. Det framgår att

nedbrytningsindex har ungefär ett paraboliskt förhållade till antalet cykler. Att tillsätta kalk och

cement till leran ökar i allmänhet nedbrytningsindex vilket innebär en lägre grad av nedbrytning.

Nedbrytningsparametern t har ett hyperbolisk förhållande med skjuvtöjningen, men den förlorar

sin hyperboliska form när jorden blir starkare. Å andra sidan observerades för ostabiliserad lera

ett ungefärligt linjärt samband mellan nedbrytningsindex och antalet belastningscykler och

nedbrytningsparametern har en hyperbolisk form med ökande antalet cykler. Det framgår också

att ju starkare material, desto mindre utvecklades porvattentrycket i kalk- och cementstabiliserad

lera.

Nyckelord: odränerade cykliska triaxialtest, kalkcementpelare, skjuvmotstånd,

spänningskontrollerade triaxialförsök, skjuvtöjning, nedbrytningsindex, nedbrytningsparameter,

porvattentryck

-

iv

Acknowledgement

I would like to express the deepest appreciation to Almir Draganovic for tremendous support and

help throughout the process of this master thesis. Without his guidance and persistent help this

dissertation would not have been possible. I would like to express my gratitude to my supervisor

Stefan Larsson for introducing me to the topic as well for the useful comments and remarks on

the process of this master thesis. Furthermore I would also like to thank Stefan Lagerquist from

IMCD Group and Håkan Wernersson, plant manager of Nordkalk Corporation for their support

in delivering necessary materials for the laboratory test. I would like to thank my friends, family

and colleagues who have supported me throughout entire process.

Alex G.Gebretsadik

Stockholm, February 2014

-

v

In memory of my dad, Rest In Peace

-

vi

TABLE OF CONTENTS

1 INTRODUCTION ................................................................................................................... 1

1.1 Aim and objective ............................................................................................................ 2

1.2 Limitations ....................................................................................................................... 3

2 LITERATURE REVIEW ........................................................................................................ 4

2.1 General ............................................................................................................................. 4

2.2 Post-cyclic response of soils ............................................................................................ 4

2.3 Factors affecting the degradation of soils ........................................................................ 8

2.4 Soil stabilization ............................................................................................................. 10

2.4.1 Mass Stabilization ................................................................................................... 10

2.4.2 Deep soil mixing (DSM) ......................................................................................... 10

2.5 Stabilization effect on degradation of soils .................................................................... 11

2.6 Cyclic triaxial shear test ................................................................................................. 14

2.7 Summary ........................................................................................................................ 14

3 METHOD AND MATERIALS............................................................................................. 16

3.1 Degradation model ......................................................................................................... 16

3.2 Column stress, σcol and confining pressure, σ3 ............................................................... 17

3.3 Experimental Procedure ................................................................................................. 19

3.4 Unconfined Compression (UC) test ............................................................................... 22

3.5 Cyclic triaxial tests - test set-up and test procedure ....................................................... 23

4 TEST RESULTS AND ANALYSIS ..................................................................................... 28

4.1 Uniaxial compression test result .................................................................................... 28

4.2 Cyclic Triaxial test results and discussion ..................................................................... 29

-

vii

5 CONCLUSIONS AND COMMENTS .................................................................................. 36

6 REFERENCES ...................................................................................................................... 37

-

viii

List of figures

Figure 1: A plot of degradation index versus number if cycles in log-log scale (Basack and

Purkayastha, 2009) ........................................................................................................... 6

Figure 2: Variation of degradation parameter with cyclic shear strain amplitude for different

marine clays (Basack and Purkayastha, 2009) ................................................................. 6

Figure 3: The effect of frequency, f on cyclic degradation ( Mortezaie, A. and Vucetic, M. ,2013)

.......................................................................................................................................... 9

Figure 4: Shear strength of different soils mixed with two quantities of lime and cement at three

curing times (Hartlen and Holm, 1995) .......................................................................... 11

Figure 5: Variation of degradation index with N/Nf, (a) uncemented sample, (b) 1.5 %

cemented sample and (c) 3 % cemented sample (Haeri et al., 2002) ............................. 13

Figure 6: Layout of lime-cement column under the embankment ................................................ 18

Figure 7: Position of point A of in lime-cement column under moving vehicle load .................. 18

Figure 8: Stress distribution at point A due to a track passing the road ....................................... 19

Figure 9: GDS triaxial testing system ........................................................................................... 20

Figure 10: The four components used to prepare the specimens; (a) cement (b) lime (c) clay (d)

water ............................................................................................................................. 21

Figure 11: Unconfined uniaxial compression test ........................................................................ 22

Figure 12: Sample is covered with a rubber membrane and sealed before putting the chamber. 24

Figure 13: Typical example of test plan during testing a sample ................................................. 26

Figure 14 : Stress-strain during uniaxial compression test. .......................................................... 28

Figure 15: Variation of axial strain with number of cycles (a) for samples cured for 7 days and

(b) for samples cured for 28 days ................................................................................. 31

Figure 16: Variation of shear strain with number of cycles; (a) for samples cured for 7 days and

(b) for samples cured for 28 days ................................................................................. 31

Figure 17: Degradation index plotted against number of cycles in log-log scale; (a) for samples

cured for 7 days and (b) for samples cured for 28 days ............................................... 32

-

ix

Figure 18: Degradation parameter plotted against cyclic shear strain; (a) for samples cured for 7

days and (b) for samples cured for 28 days .................................................................. 32

Figure 19: Pore pressure variation with number of cycles; (a) for samples cured for 7 days and

(b) for samples cured for 28 days ................................................................................. 33

Figure 20: Plot results for a clay soil sample for 28 days curing time ......................................... 34

Figure 21: (a) Degradation index plotted against number of cycles and (b) degradation parameter

plotted against cyclic shear strain for unstabilized clay sample for 28 days ................ 35

-

x

List of tables

Table

1. Stabilizer combination scheme for stabilized soils ......................................................................... 20

2. General input data summary for each specimen ............................................................................. 24

3. Test conditions ............................................................................................................................. 25

-

xi

List of symbols and abbreviations

δ Degradation index

G Shear modulus

Gmax maximum shear modulus

��� Secant shear modulus at cycle N

��� Secant shear modulus at 1st cycle

��� Cyclic shear stress at cycle N

��� Cyclic shear stress at 1st cycle

� Cyclic shear strain

Degradation parameter

�� Cyclic axial strain

Parameter used to determine degradation parameter, t

� Number of cycles

Nf Number of cycles at failure

�� Plastic index

ESAL Equivalent single axle load

GDS Global Digital Systems

�� Major vertical stress

�� Confining pressure

��� Effective major stress

��� Effective confining pressure

-

xii

���� Column stress

A Point of investigation in the lime-cement column

r Horizontal distance of the moving vehicle from the point

above the column point, A

R Radius of the vehicle from point, A

Z Depth of column point A

Q Vertical point load

�� Specific gravity

f frequency

OCR Overconsolidation ratio

NGI Norwegian Geotechnical institute

���� Effective consolidation stress

DSM Deep soil mixing

CD Consolidated- Drained

CU Consolidated-Undrained

UU Unconsolidated-Undrained

-

1

1 INTRODUCTION

Improvement of soft ground using lime-cement columns has widely been used as a construction

technique since 1970´s for railway and highway embankments over organic and soft soils. Many

studies are performed on stability and settlement of lime-cement column under the embankment

due to static loading but very limited attention has been given to understanding their shear

resistance behavior under cyclic loading of moving vehicles (Thach et al., 2013). Studying the

shear resistance degradation is important to know how the structure is endangered in the long-

term serviceability after large number of cycles. In this study, how the cyclic shear resistance

behaves in lime-cement columns under repetitive heavy vehicles are investigated through

laboratory tests.

Different researchers have different ideas concerning post cyclic strength of soils. Seed et al.

(1971) concluded that the response to cyclic loading can be either complete loss of strength in

sands to an increase or decrease of strength in clays. The decrease in stiffness and strength with

the number of load cycles is called degradation. Cyclic degradation can be investigated based on

the results of either strain-controlled or stress-controlled cyclic tests. During cyclic stress-

controlled test, the cyclic stress amplitude is set to constant, where as in the cyclic strain-

controlled test; the cyclic strain amplitude is kept constant. Cyclic degradation changes with, N

number of cycles and it is the most important factors influencing the degradation. Ishihara (1996)

stated the fundamental aspects of the cyclic degradation of clays in cyclic strain-controlled tests,

and also the cyclic stress-controlled tests.

Cyclic laboratory studies performed using the cyclic strain-controlled undrained direct simple

shear tests have shown that the loading parameters which govern the cyclic response of saturated

soils are those that govern the deformation of soil skeleton (Vucetic, 1992). The main reason for

such distortion is relative displacement between soil particles, which can be expressed in terms

of the shear strain, γc. Such displacements are directly responsible for the breakage of particle

-

2

bonds, slippage at the particle contacts, corresponding change of microstructural repulsion forces

and the tendency towards volume change which causes pore pressure variation. The most

important cyclic loading parameters are therefore the shear amplitude γc, (measures the relative

magnitude of displacements between soil particles in a single loading cycle), and the number of

cycles N (related to the cumulative distortion of the soil skeleton).

Poulos, H.G. (1980) pointed out main reasons behind the degradation in a single pile due to

cyclic load. Partial to zero dissipation of excess pore water pressure which is generated during

cyclic loading process, destruction of inter-particle bond with particle realignment &

rearrangement and gradual accumulation of irreversible plastic strains are the reason behind the

degradation.

1.1 Aim and objective

The primary purpose of this investigation is to increase the knowledge about the extent of the

cyclic shear resistance reduction in lime-cement column in soft clay when subjected to different

degrees of disturbance. This will help to be able to monitor the lime-cement column that would

be subjected to cyclic loading in the long term and to get a better idea of how they react to the

real repeated load.

From the laboratory test program the following were analyzed:

• How the degree of shear resistance degradation of the stabilized soil behaves with a number

of load cycles

• The effect of the stabilizing agent and curing time on the degree of degradation of a soil

• Pore pressure behavior with a number of load cycles

-

3

The test results are presented in different plots to reveal the behavior of the shear strain, axial and

radial strain, degradation index, degradation parameter and pore pressure due to a cyclic load

applied on the specimen.

1.2 Limitations

The main limitation is the number of test performed. Some of the other limitations in this

laboratory study include:

• The soil type

• Binder content

• Type of binder

• Water content

-

4

2 LITERATURE REVIEW

2.1 General

There are different situations in which soils are subjected to cyclic loading such as sea wave

loading, cyclic loads on permanent way support systems (roads, airfields, railways) subject to

moving load, blasting, piling, sheet piling, installation of lime-cement columns, heavy transports,

etc.

Infrastructure renewal projects often require placement of roadway embankments on soft,

compressible ground. One of the options available for controlling stability and mitigating

settlement problems is to provide columnar support (deep soil mixing) through the soft ground.

And these columns are repeatedly exposed to cyclic loads from heavy vehicles running on the

embankment.

2.2 Post-cyclic response of soils

Many studies have been performed on the investigation of post-cyclic behavior different types of

soils. These studies include the loss of static undrained shear strength and strain softening of

soils under cyclic loads. However, different researchers have different opinions regarding; for

example the strength of clay soils after cyclic load. While researchers like Thiers and Seed and

Yasuhara et al. (1992) claim there is a considerable reduction in the undrained strength of clay

after cyclic loading whereas Moses et al. (2003) observed an increase of undrained strength after

cyclic loading for cemented marine clay under higher effective confining pressure. Pillai et al.

(2013) also observed a higher undrained strength during post-cyclic monotonic test compared to

samples that was not subjected to prior cyclic loading.

-

5

According to Carter et al. (1982), when a soil which is saturated is exposed to cyclic loading

under undrained condition an accumulated pore pressure which is not released completely during

unloading phase is observed. And this residual pore pressure resultants in decrease in the mean

effective stress that governs the behavior of the soil mass in an undrained condition, causing the

yield stress to decrease.

The behavior of soils under cyclic loading is different from soils under monotonic loading.

Under cyclic loading there is excessive settlement and the progressive generation of pore

pressure causes the reduction in the effective normal stress which is the reason behind in

reduction in strength (Koutsoftas, 1978).

Soltani-Jigheh and Soroush (2006) investigated on the post-cyclic behavior of compacted clay-

sand mixtures using monotonic and post-cyclic triaxial tests. It is observed that the undrained

cyclic loading reduces the effective stresses by generating excess pore pressures and induces

apparent overconsolidation in the specimens. The results of the test show that cyclic loading

degrades undrained shear strength and secant deformation modulus of the mixed specimens.

Different constitutive models have been developed to understand the behavior of soft clays.

Idriss et al. (1978) have introduced the index δ and parameter t in the context of the evaluation of

the cyclic degradation of marine clay deposits underlying offshore structures for oil explorations.

According to the findings of Idriss et al. (1978) for many types of clay the relationship δ versus

N, in a log-log format is approximately a straight line. For overconsolidated clays, δ versus N in

a log-log format is also approximately a straight line (Vucetic and Dobry, 1988), while for sands

it is typically curved (Dobry et al., 1982 and Mortezaie, 2012). Bahr (1991) and Matsui et al.

(1999) found that the parameter t depended on plasticity index of the soil. Lower values of δ

mean the higher degrees of degradation.

Basack and Purkayastha (2009) carried out an investigation on cyclic characteristics of the

marine clay from the eastern coast of India. A series of cyclic tests were performed in

-

6

unconsolidated and undrained state under strain controlled mode and put the results in the

following diagrams.

Figure 1: A plot of degradation index versus number if cycles in log-log scale

(Basack and Purkayastha, 2009)

Figure 2: Variation of degradation parameter with cyclic shear strain amplitude for

different marine clays (Basack and Purkayastha, 2009)

-

7

.

Bahr (1991) has also suggested an equation to predict the degradation parameter t for clay as

follows:

= (�� )�.� Equation 3.1

= 0,52 − 0,0170�� − − − −(�� < 23) Equation 3.2

= 0.16 − 0.0014�� − − − − − (�� > 23) Equation 3.3

Where εc is the cyclic axial strain and a the parameter which depends upon the degree of clay

plasticity. Tan and Vucetic (1989) and Bahr (1991) have observed that clays become less

susceptible to the degradation in the course of cyclic load application because of high plasticity.

Yasuhara et al. (1997) used a similar approach to that of Idriss et al. (1978) to find out the shape

of the graph for plastic silt, but a more linear relationship is obtained when δd is plotted against N

on a semi-log scale, and proposed the following relationship:

δ* = 1 − dlgN Equation 3.4

Where δ* is degradation index and d is degradation parameter.

Diaz-Rodríguez (1989) described a series of cyclic triaxial tests on undisturbed soil samples of

Mexico City soil. Based on tests results, a procedure to determine a stress threshold is proposed

from the reduction of post-cyclic strength after 100 cycles of loading. Below the stress threshold,

repeated loading has a negligible effect on the post-cyclic undrained shear strength. Over this, a

remarkable reduction of shear strength is observed.

-

8

Depending upon the cyclic stress level the soil either fails during cyclic loading itself or reaches

a non-failure, stable state (Seed and Chan, 1966, Castro and Christian, 1976, Vucetic and Dobry,

1988 and Yasuhara and Hyde, 1997).

2.3 Factors affecting the degradation of soils

Strain rate and load cycles effect on undrained shear strength is investigated on sensitive

Canadian clay by Lefebvre and LeBoeuf (1987) using monotonic and cyclic triaxial tests. The

test results show that the cause of the reduction in undrained shear strength with lower strain rate

appears to be different for structured (naturally overconsolidated) and destructured (normally

consolidated) clays. Decreasing the rate of loading reduces effective stresses and, as a result of

this the undrained shear strength is reduced. Reducing the strain rate or cycling the load results in

weakening the resistance of the clay skeleton due to a fatigue phenomenon.

Type of consolidation method (anisotropic or isotropic) is found to affect the degradation rate of

soft clay under the same cyclic loading according to test done by (Li and Huang, 2010) on

offshore soft clay. The experimental results show that the strength and stiffness degradation of

anisotropically consolidated soft clay is lower than that of isotropically consolidated soft clay.

This means anisotropic consolidation decelerates the degradation of stiffness of the clay soil. It is

also observed that under the same consolidated condition there is a decrease of undrained

strength and stiffness of soft clay with the increase of the cyclic stress ratio and number of

cycles.

The effect of overconsolidation ratio (OCR) on the cyclic shear modulus degradation of clay is

presented by Vucetic and Dobry (1986). The research is based on a series of strain-controlled test

on offshore Venezuelan clay by consolidating to ORC= 1, 2 and 4. The results show that the rate

of cyclic modulus degradation decreases with increased OCR and increases with cyclic strain, ��.

-

9

The effects of frequency, f of cyclic shearing on cyclic degradation were investigated by

Mortezaie and Vucetic using NGI (Norwegian Geotechnical Institute) simple test device. The

test was performed on normally-consolidated kaolinite clay (PI =28) with the help of the cyclic

strain-controlled simple shear test. The testing program made up of three cyclic strains, γc=0.1,

0.25, and 0.5%, two vertical effective consolidation stresses, σ’ vc =220 and 680 kPa, and three

frequencies, f =0:001, 0.01, and 0.1 Hz. According to the findings the cyclic degradation

parameter, t increases with f and decreases with σ’ vc. It is also shown in figure 3 that the

degradation will increase with increasing of cyclic strain, γc.

Figure 3: The effect of frequency, f on cyclic degradation ( Mortezaie, A. and Vucetic, M. ,2013)

An investigation was done by Soltani-jigheh, H. and Soroush, A. using cyclic triaxial test on the

degradation effect when a granular material is mixed with clay. According to the result obtained,

the inclusion of sand and gravel material into clay leads to increasing of degradation and pore

water pressure build up during cyclic loading. And the degradation index decreases as the

number of loading cycles and cyclic strain increase.

-

10

2.4 Soil stabilization

Stabilization is the process of mixing stabilizing agents with a soil to improve geotechnical

properties of the soil material such as compressibility, strength, durability and permeability. It

includes the blending of soils to get a desired gradation or the mixing of additives that may alter

the gradation, texture or plasticity of the soil.

Stabilization of soft soils with binders is the most popular method of ground improvement

technique in Sweden, and is increasingly being used internationally. The most common binders

used today are cement and lime. Lime modification has been traditionally utilized as a

construction expedience for highway project with clayey sub-grade. These highways are likely

exposed to heavy vehicles loads which induce cyclic load effect in a soil mass.

2.4.1 Mass Stabilization

Stabilization is done by mixing an appropriate amount of dry or wet binder throughout the

volume of the treated soil layer. The binder can be a single substance or a mixture of various

substances like cement, lime, fly ash or furnace slag. This system is used to stabilize soils to a

maximum of 5m depth.

2.4.2 Deep soil mixing (DSM)

This method is used to improve soil strength and stabilities for foundations, deep excavations,

highways and other engineering projects in soft soils to a max depth of 40m. During DSM

installation, either cement slurry (wet mixing) or cement powder (dry mixing) is injected into the

soil ground under pressure. This method is expensive but very fast and effective deep down the

soft soil.

-

11

Most of current studies of DSM are focused on the soil strength improvement and soil treatment

effectiveness. Cement treatment leads to significant increase in unconfined compressive strength

and modulus of elasticity of the soils.

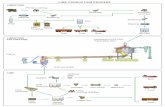

Laboratory unconfined shear strength test results on different soil types treated with 25% lime

and 75% cement is reported by Hartlen and Holm (1995). The results are shown on Figure 11.

2.5 Stabilization effect on degradation of soils

Many researches have been done concerning the benefit of stabilizing a soil with lime and

cement with respect to increase strength and resistance to permanent deformation but limited

experimental data and constitutive models are, however, available on the resistance of cyclic

strength for cement-lime improved soft clays.

Figure 4: Shear strength of different soils mixed with two quantities of lime and

cement at three curing times (Hartlen and Holm, 1995)

-

12

Marshll et al. (2007) have tried to improve the durability of cement stabilized expansive

subgrade by pretreatment with lime. It is found that lime treatment increases resistance to

degradation of strength upon saturation and cyclical wet/dry strength testing and maintaining

plasticity reduction after a year of exposure to in place conditions.

Sharma and Fahey (2003) studied cemented sand under cyclic load and found that the deviator

stress and deviatoric strain at yield reduced with increasing number of cycles. This is due to the

continuous degradation of bond, which results in a very significant decrease in stiffness.

Haeri et al. (2002) conducted an experiment on mechanical behavior of cemented gravely sand

under cyclic load. The samples range from uncemented to 3% cemented. The degradation index

is plotted against normalized number of cycle, N/Nf, Nf is the number of cycles associated with

the failure. Here, the degradation index is the normalized shear modulus or G/Gmax, Gmax is the

maximum shear modulus.

,

,

-

13

Figure 5: Variation of degradation index with N/Nf, (a) uncemented sample, (b) 1.5 %

cemented sample and (c) 3 % cemented sample (Haeri et al., 2002)

Yasuhara et al. (1997) suggested a linear relationship between degradation index and the number

of cycles in logarithmic scale. However, the test results in this study show that almost a nonlinear

relation for all samples.

(b)

(c)

-

14

2.6 Cyclic triaxial shear test

A cyclic loading can be defined as a periodic action that when applied to a material body tends to

change its stress and strain state. In Peralta (2010) a definition of cyclic loading is given as a load

frequency between 0 and 1 Hz. Inertia forces can be neglected due to the low frequency, and the

accumulated strain is mainly plastic (Shajarati et al., 2012).This test is similar to conventional

triaxial shear strength test except the load is applied in a cyclic way with certain limited

frequency range.

The triaxial shear test is one of the most reliable methods available for determining shear

strength parameters. It is mostly used for research and conventional testing.

Generally there are three standard types of triaxial tests:-

1. Consolidated-drained test or drained test (CD test)

2. Consolidated-undrained test (CU test)

3. Unconsolidated-undrained test or undrained test (UU test)

Consolidated-undrained (CU) test method is preferred for this project. In this test, drainage from

the soil specimen is not permitted during the application of chamber pressure. The test specimen

is sheared for couple of hours by the application of deviator stress.

2.7 Summary

Different results were obtained on cyclic response of soils under cyclic loading. The results

mainly depend on the type of soil investigated, method of testing, test condition, etc. However,

the majority of the investigations show the reduction of strength on post-cyclic response. The

introduction of index δ and parameter t by Idriss et al. (1978) has helped to evaluate the cyclic

degradation of soils by many researchers. And similar results were obtained with Idriss et.al

(1978) on investigation of many types of clays.

-

15

The post-cyclic degradation of soils is dependent on different factors such as strain rate, vertical

effective stress, consolidation method, frequency of loading and soil type. It can also be observed

that adding stabilizing agents such as lime and cement will increase the resistance to the

degradation of a soil. Both linear and non-linear relationship is observed on degradation index

relationship with the number of cycles on log-log scale depending on the type of soil being

investigated.

-

16

3 METHOD AND MATERIALS

In this study, a series of cyclic undrained triaxial tests were conducted on both stabilized and

unstabilized soil specimens, by using a triaxial testing apparatus, type Geotechnical Digital

System (GDS). The rate of cyclic shear resistance degradation is calculated from the laboratory

test data results obtained using a degradation model according to Idriss et al. (1978) as described

below. Stress- controlled cyclic tests were performed under different curing time and additive

amount. Different combinations of cement and lime were used for stabilization of the clay soils.

3.1 Degradation model

According to Idris et al. (1978) the cyclic degradation in the cyclic stress-controlled mode is

expressed with a degradation index, δ which describes the reduction of the secant shear modulus,

�� with number of cycles, N as follows:

δ =

���

���=

��/0��

��/01�

=���

���

Equation 3.1

And the degradation parameter, t

= −

log δ

log � 34 5 = �67

Equation 3.2

Here, cyclic shear stress, �� is constant while the cyclic shear strain amplitude,γ9:, varies with

N. ��� is the shear strain registered at first cycle and γ9: is the final shear strain at which the test

is stopped. The index δ decreases with N because γ9: increases with N. Lower values of δ mean

the higher degrees of degradation.

-

17

Idriss et al. (1978) found that for many types of clay soils the relationship δ versus N, in

a log-log graph is approximately a straight line. The slope obtained from this line is the

degradation parameter, t which for a given γc describes the rate of cyclic degradation with N.

3.2 Column stress, σcol and confining pressure, σ3

In this experiment, it is assumed that the stress on a column comes from a heavy truck on a

stabilized soil column underneath the embankment. The column stress level at a point A, 2

meters below the embankment surface, is calculated from a truck axle load. The concept of

equivalent single axle load (ESAL) which is equivalent to 80 kN is used as a unit to measure the

effect of the truck load on the column. The embankment has 8 meter width and 1 meter height

.The type of the stabilization is assumed to be deep mixing stabilization with cement and lime

forming a column type.

The type of vehicle considered which causes cyclic load is heavy vehicles such as heavy truck

with six axle loads ignoring light traffic e.g. cars. For this specific scenario an average of 40 ton

of traffic load (maximum of 60 ton of truck load is permitted in Sweden and Finland) is

considered. And its equivalent ESAL will be approximately 2 (Truck Size and Weight, North

Dakota department of transportation).

-

18

Assuming the load from the truck is applied approximately as a point load Q on the pavement

from the single axle load of 2 ESALs, equivalent to 2*80 kN=160 kN. The stress level from

the heavy truck at a desired depth Z can be calculated using Boussinesq (1883) formula for a

point load, Q and presented on Figure 7.

Moving vehicle

Desired column Point, A

Figure 6: Layout of lime-cement column under the embankment

A Soft Clay

Z

r, horizontal distance

Figure 7: Position of point A of in lime-cement column under

moving vehicle load

-

19

0

5

10

15

20

25

0 5 10 15 20

vert

ical

Str

ess,

kP

a

Horizontal distance from point A ,m

Stress induced at A as a function of horizonatal distance, r

Figure 8: Stress distribution at point A due to a track passing the road

A vertical stress 20 kN is considered as a vertical sinusoidal load at a point A on the column at a

depth 2 m depth from surface. At the same point A, the confining pressure �� = 20 ;� and

water pressure of 5 kPa is approximately assumed for the entire tests performed.

3.3 Experimental Procedure

The soil used to be stabilized is kaolin type ASP 400 with a specific gravity Gs =2580

kg/m3.The type of binders used are Portland cement and burnt lime (quick lime).

The cyclic tests were conducted using GDS Triaxial Automated System. The equipment unit

consists of a triaxial cell, a load frame, three computer controlled flow pumps for delivering the

cell, back pressure and load, electro actuator for applying loading, data acquisition unit and a PC

for controlling the resulting data. 3 transducers are mounted in the system for confining pressure,

back pressure and load chamber. Water is used as a chamber medium.

-

20

Table 3-1: Stabilizer combination scheme for stabilized soils

Sample mixture proportion

Sample no. Binder dosage Water cont. lime:cement ratio Curing time

(Kg/m3) (%) (%) (days)

1 150 50 70:30 7

2 150 50 70:30 7

3 150 50 70:30 28

4 200 50 70:30 28

5 - 35 - 28

Four kinds of materials; tap water, dry kaolin, quicklime and cement were used to prepare the

specimen. A total of 5 samples were prepared for the tests, 4 samples with binder and one sample

without binder. All the samples had 2 to 2.5 heights to diameter ration. A cylindrical tube of

diameter 50 mm was used for all tests performed. Most specimens had approximately 2:1 height

to diameter ratio.

Figure 9: GDS triaxial testing system

-

21

It is assumed that the typical lime-cement stabilized column has a density of 1.5 t/m3.Binder

contents of 150kg/m3 and 200 kg/m3 was used during sample preparation. The binder

percentage 30% cement to 70% lime was used for all samples prepared. A water content of 50%

was used for all specimens except for the clay sample where the water content was 35%. Two

samples, only clay with no binders was prepared and tested to observe the effect of adding the

binders.

The specimen mix was prepared using hand mix. The dry clay powder and lime was first blended

thoroughly for 5 min. Then cement was added and mixed. Water was added step by step and

mixing was continued until a uniform mix was obtained. To compact the sample in the cylinder a

wooden block weighing 260 gm was used. 10 blows of wooden block were applied for every 2

cm thickness during the compaction process.

(a) (b) (c) (d)

Figure 10: The four components used to prepare the specimens; (a) cement

(b) lime (c) clay (d) water

-

22

Curing period and temperature

The curing time of the samples was 7 and 21 days. To keep the humidity 100%, the specimens

were sealed with plastic bags and submerged in a water bath and placed at room temperature.

3.4 Unconfined Compression (UC) test

The primary purpose of this test was to determine the unconfined compressive strength of the

specimen. 60 percent of the maximum strength value was then taken as the initial vertical

principal stress on the specimens as an input in the later cyclic triaxial tests. The specimen had a

diameter of 50 mm and height of 80 mm.

A cylindrical specimen was subjected to a steadily increasing axial load until failure occurs. The

sample is loaded at strain rate of 0.3% per min during the test.

Figure 11: Unconfined uniaxial compression test

-

23

3.5 Cyclic triaxial tests - test set-up and test procedure

The purpose of this test was to determine the behavior of axial strain, radial strain and shear

strain and also to investigate the behavior of cyclic shear degradation after some repetitive loads.

There are two kinds of cyclic triaxial test namely stress-controlled and strain-controlled cyclic

traixial test. Stress-controlled test was performed in this study. An important requirement of the

cyclic axial load testing was to achieve load-controlled repeated load tests which consist of

applying predetermined controlled load intensity to the specimen in a specific wave shape at a

specific frequency.

Consolidated undrained (CU) triaxial tests with pore pressure measurement were performed in

this project because it is required to deal with long term stability problems in the embankment

requiring effective stress analysis. The tests were performed according to the following

procedure:

• The test specimen was extruded from the tube carefully, measured and cut as required. Then

the sample weight was recorded. Disturbance to the specimen was kept to minimum during

the preparation.

• Following placement of the specimen in the apparatus, the triaxial cell components and

system were assembled.

• Then the cell was filled with water. Cell pressure and back pressure controllers and

transducers readings set as required before creating the test stages.

-

24

Table 3-2: General input data summary for each specimen

Test

sample

no.

Height,

mm

Diameter,

mm

Binder,

kg/m3

Curing

days

Vertical

cyclic load

(kPa)

Effective

vertical stress

,σ1 ( kPa)

Average

verical load

(kN)

1 103 50 200 7 20 57 67

2 92 50 150 7 20 57 67

3 110 50 150 28 20 57 67

4 117 50 200 28 20 57 67

5 100 50 - 28 20 57 67

Figure 12: Sample is covered with a rubber membrane and sealed before putting the chamber.

Probable failure plane

-

25

The following four basic stages were performed for each sample in the test plan:-

a. Saturation: This process is designed to ensure all voids within the test specimen are filled

with water, and that the pore pressure transducer and drainage lines are properly de-aired. In

this case due to the cement in the specimen it is difficult to get the desired saturation stage

unlike unstabilized clay soil. The back pressure is increased to ensure a good saturation and

so the cell pressure by the same amount to maintain the same effective consolidation stress.

b. B-check: To check the degree of specimen saturation is sufficiently high before moving to the

consolidation stage, a short test was performed to determine Skepton’s B-value called B-

check. It is recommended to obtain B-check ≥0.95 but it was obtained 0.8 in average in most

of this test trials.

c. Consolidation: This stage is used to bring the specimen to the effective stress state required

for shearing. It is typically conducted by increasing the cell pressure whilst maintaining a

constant back pressure. An isotropic consolidation type was performed in this stage.

d. Shearing or cycling stage: This is the last stage which lasts for longer period of time.

Necessary input date such as time for one cycle and datum for pressure and amplitude was

set. Confining pressure was set constant and variable repeated deviator stress was applied by

the axial loading device in the vertical direction in the form of sign wave. The frequency of

cyclic loading was set to 1 cycle per minute.

Table 3-3: Test conditions

sample Additives

(kg/m3)

curing time

(days)

cyclic loading

frequency, f (Hz)

loading cycles,

(N)

1 200 7 0.02 1200

2 150 7 0.02 1200

3 150 28 0.02 1373

4 200 28 0.02 1309

5 NA 28 0.02 457

-

26

Various testing and material factors that may affect cyclic shear resistance results are:

• Membrane stiffness which restrains the specimen. The stiffness of the membrane can

resist freedom of the specimens to displace horizontally. The specimen become stiff and

this affect the results on axial and radial strain.

• Contact between the specimen end and porous stone. If the porous stone is not placed

correctly on the ends of the samples the loads will not be transferred fully to the sample.

• Lateral motion or tilting of the specimen during cyclic loading process. If the sample is

tilting the vertical load will not be transferred to the sample vertically and this will give

different result

• Presence of foreign matters or impurities. Foreign matters in the soil will alter the

behaviour of the soil and beside it will affect the hydration of cement in the stabilized soil.

Figure 13: Typical example of test plan during testing a sample

-

27

• Water to cement - lime ratio. An optimum amount of water to cement-lime ratio is used to

obtain sufficient compaction which is desirable for the test. The amount of water ratio has

also an effect on the hydration of cement in the stabilized soil.

-

28

4 TEST RESULTS AND ANALYSIS

This section presents the test results obtained in the laboratory. One uniaxial compression test

and four triaxial tests were performed on the stabilized soils in the laboratory. One specimen

which was unstabilized clay was tested for comparison with the properties of the treated samples.

The results are shown in a number of different plots.

4.1 Uniaxial compression test result

In this type of test failure is defined as the peak stress, which typically occurred at 2 to 8 percent

strain (Jacobson and George, 2002).The specimen had 150 kg/m3 of binders and was cured for

21 days. During the test the specimen was unable to take anymore load after 4% of strain level.

The failure of specimen was observed at 95 kPa and elastic strain is about 2.5% as shown on

Figure 13.

Figure 14 : Stress-strain during uniaxial compression test.

0

20

40

60

80

100

0 1 2 3 4 5

Unc

onf

ined

Co

mp

ress

ive

Str

engt

h (k

Pa)

Axial strain, ε (% )

-

29

4.2 Cyclic Triaxial test results and discussion

During the laboratory test process the Skepton’s B-Value was obtained as 0.8 which shows that the

sample was not saturated fully. The binders used might have an effect on the degree of saturation and

it is also difficult to get full saturation in soils in reality.

The test results revealed that there is a sudden increase of axial and shear strain in the first 100

cycles then continues with almost constant value. The amount of the binders had a significant

effect on the strain magnitude with time as shown in Figure 15-16. It means that curing time has

a major effect on the magnitude of the plastic strain in the column. As shown in Figure 16(a), the

amount of binder is insignificant on the shear strain for the first 7 days. From the Figure 15-16, it

can be observed that the axial strain and shear strain values were similar in every cyclic test

performed in the case of treated soils.

For the stabilized kaolin the degradation index, 5 had a half parabolic relationship with number

of cycles on log-log scale graph as shown in Figure 17(a). In figure 17(b), it can be observed that

when the specimen getting stronger after 28 days, the relationship becomes approximately

straight line. The figures also show that most of the degradation has taken place during the first

100 cycles. As shown in Figure 17(b), the amount of binder is almost insignificant on the value

of degradation index at 28 days. Generally, the degradation index decreases as the amount binder

increases and the specimen getting stronger. The decrease in degradation index is probably due

to granular effect of lime and cement on kaolin. Adding lime and cement to kaolin will change

the mechanical behavior and the mixture turns into composite kaolin with a granular texture.

The degradation parameter, t versus cyclic shear strain, �� plot maintains its hyperbolic

relationship for the 7 days old stabilized soil which is in a good agreement with the results

presented by Idriss et al. (1980) for clays. However, in the case of treated soil which is cured for

28 days as shown in Figure 18(b), the degradation parameter t is non-hyperbolic. The parameter,

t is highly affected by the shear strain which is the main parameter responsible for the breakage

-

30

of interparticle bonds. Generally the parameter, t increases with increased amount of binder in

the first 7 days of curing time. However, for the 28 days old sample the parameter, t is not

affecting by the binder content. Comparing the evaluated t of stabilized soil with unstabilized

clays, in the case of stabilized soil the parameter starts to decrease after reaching some maximum

value because of the small strain value. But for the unstabilized clay it increases with even higher

rates which lead to breakage after certain value of strain.

As shown in Figure 18, the strain threshold where material degradation starts to occur is different

from one sample to another. The samples cured for 7 days have higher values of strain threshold

at the beginning of cyclic loading because they already had higher strain values before they were

sheared during cyclic stage as shown in Figure 18(a). By increasing the binder content from 150

kg/m3 to 200 kg/m3 at 28 days the strain threshold decreased from 0.323% to 0.065% as shown

in Figure 18(b).

Generally, the test results show that adding the binder had an effect on decreasing the

degradation of a soil. However, increasing the amount of binder was not as significant as thought

in decreasing degradation for higher curing time, 28 days. Therefore it is economical to use 150

kg/m3 of binder content for 28 days instead of 200 kg/m3. The test results were based on

frequency value of 0.02 Hz; however, increasing and decreasing the frequency could affect the

degradation. The pore water pressure was not built throughout the test as expected on both

stabilized and unstabilized soils. This might be due to the low frequency value used during the

test process. Using low frequency would allow the specimen to have enough time to relief the

pore pressure instead of building up during the cyclic process.

-

31

0,4

0,6

0,8

1

1,2

1,4

1,6

0 500 1000

Axi

al s

trai

n, ε

(%)

Number of cycles, N

150 kg/m3

200 kg/m3

0

0,2

0,4

0,6

0,8

0 500 1000

Axi

al s

trai

n, ε(

%)

Number of cycles, N

150 kg/m3

200 kg/m3

0,4

0,6

0,8

1

1,2

1,4

1,6

0 500 1000

She

ar s

trai

n, γ (%

)

Number of cycles, N

150 kg/m3

200 kg/m3

0

0,2

0,4

0,6

0,8

0 500 1000

She

ar s

trai

n, γ(%

)

Number of cycles, N

150 kg/m3

200 kg/m3

(a) (b)

(a) (b)

Figure 15: Variation of axial strain with number of cycles (a) for samples cured for 7 days and (b) for samples cured for 28 days

Figure 16: Variation of shear strain with number of cycles; (a) for samples cured

for 7 days and (b) for samples cured for 28 days

-

32

0,1

1

1 10 100 1000

Deg

rad

atio

n in

dex

, lo

g δ

Number of cycles, logN

200 kg/m3

150 kg/m3

0

0,1

0,2

0,3

0,4

0 0,2 0,4 0,6 0,8

deg

rad

atio

n p

aram

eter

, t

Cyclic shear strain, γc (%)

150 kg/m3

200 kg/m3

0

0,1

0,2

0,3

0,4 0,9 1,4

Deg

rad

atio

n p

aram

eter

, t

cyclic shear strain, γc(%)

150 kg/m3

200 kg/m3

0,1

1

1 10 100 1000

Deg

rad

atio

n in

dex

, lo

g δ

Number of cycles, log N

150 kg/m3

200 kg/m3

(a) (b)

(a) (b)

Referring to Figure 19(a) and 13(b), the pore pressure increases significantly at the beginning of

the test at the first load cycles. Then it decreases slowly before it continues as a constant

Figure 18: Degradation parameter plotted against cyclic shear strain; (a) for samples

cured for 7 days and (b) for samples cured for 28 days

Figure 17: Degradation index plotted against number of cycles in log-log scale; (a) for

samples cured for 7 days and (b) for samples cured for 28 days

-

33

8

9

10

11

12

13

14

0 500 1000

po

re p

ress

ure

, kP

a

Number of cycles, N

200 kg/m3

150 kg/m30

5

10

15

20

25

0 500 1000

Po

re p

ress

ure,

kP

a

Number of cycles, N

150 kg/m3

200 kg/m3

magnitude after about 1200 cycles. The stronger the material, the lower pore pressure at the

beginning of the test. Eventually the two stabilized soil samples with different binder contents

tend to have a closer constant magnitude of pore pressure.

For samples treated with 150 kg/m3, the pore pressure is built up in the first few cycles then it

decreases. However, for the sample with a binder content of 200 kg/m3, the pore pressure is built

up through the entire test as shown in Figure 19(a). From the laboratory results, failure was not

observed in any of the stabilized soil samples. Looking on the results in Figure 19(a) and 19(b),

it can be deduced that the stronger the material the less pore pressure developed in the sample.

(a) (b)

Below are the results from the unstabilized clay sample. The clay sample was loaded by a limited

number of cycles compared to the stabilized soil samples due to its soft behavior. From the test

result, a horizontal crack and a small diameter increase at the middle of the sample was observed.

This phenomenon occurred at around 300 cycles which can be observed from the discontinuity

of the graphs in the following Figures.

Figure 19: Pore pressure variation with number of cycles; (a) for samples cured for

7 days and (b) for samples cured for 28 days

-

34

0

2

4

6

8

10

0 200 400 600

Axi

al s

trai

n, ε(

%)

Number of cycles, N

Clay

0

1

2

3

4

5

6

0 200 400 600

Rad

ial s

trai

n (%

)

Cyclic Number, N

clay

0

2

4

6

8

10

12

0 100 200 300 400 500

She

ar s

trai

n,γ,

(%)

Number of cycles, N

Clay

0

5

10

15

20

25

0 200 400 600

po

re p

ress

ure

,kP

a

Number of cycle, N

Clay

The result shown in figure 20(d) shows that the pore pressure decreased as the number of cycles

increased. This could be because the sample has enough time to relieve pore water pressure due

to small frequency used during test as a result it didn’t develop pore pressure. It can be

concluded that the small crack observed during the test was due to the gradual development of

shear strain rather that gradual development of pore pressure.

(a) (b)

(c) (d)

For the clay sample which is shown in Figure 21(a), the degradation index decreases linearly

with the number of loading in a log-log scale and matches reasonably well with the previous

Figure 20: Plot results for a clay soil sample for 28 days curing time

-

35

0

0,2

0,4

0,6

0,8

1

1,2

1 10 100 1000

Deg

rada

tion

ind

ex,lo

g δ

Number of cycles, N

0

0,1

0,2

0,3

0,4

0,5

0,6

0 5 10de

grad

atio

n pa

ram

eter

, t

cyclic shea r strain, γ c(%)

studies. The degradation parameter, t versus shear strain plot maintains its hyperbolic

relationship for the clay soil which has a good agreement with the result presented by Idriss et al.

(1980).

(b) (b)

Figure 21: (a) Degradation index plotted against number of cycles and (b) degradation parameter

plotted against cyclic shear strain for unstabilized clay sample for 28 days

-

36

5 CONCLUSIONS AND COMMENTS

In order to analyze the cyclic shear resistance degradation of stabilized kaolin, cyclic tiaxial tests

were performed on specimens prepared in the laboratory. The following conclusions can be

drawn from the test results:

1. For the stabilized specimen, the shear strain and axial strain increased rapidly during initial

cycles then it continued with a constant but small rate of deformation.

2. The influence of the binder content on the magnitude of the shear strain was insignificant for

the first 7 days of curing time.

3. The stronger the material, the quicker the strain rate stops within few numbers of cycles.

4. The degradation index of stabilized kaolin has a parabolic relationship with the number of

cycles on log-log scale graph.

5. Degradation index decreased as the number of loading cycles and cyclic strain increased. The

major parts of degradations have taken place during the first 100 cycles. Increasing amount

of binder decreased the degradation index.

6. This study shows that above certain cyclic shear strain amplitudes, the cyclic degradation rate

change practically do not take place for stabilized soils.

7. There was an accumulation of pore pressure during the test for the samples with binder

content of 200 kg/m3 .However, for the samples with binder content of 150 kg/m3, the pore

pressure decreased.

8. Unlike many studies, the results on the clay didn’t show gradual development of excessive

pore pressure which is mostly governing the failure in sand and clay.

9. Regarding the clay test result, at 300 cycles there was a sudden change in the shear strain vs

number of cycles graph shape due to failure in the specimen. The plane of failure was not

diagonal but horizontal due to soft material property of the clay sample.

-

37

6 REFERENCES

Addison, M. and Polma, F. (2007). Extending Durability of Lime Modified Clay Subgrades with

Cement Stabilization. Soil Improvement, 1-10

Alzubaidi,R. (2013). Effect of Strain Rate on the Strength Characteristics of Soil–Lime Mixture.

Journal of Geotechnical and Geological Engineering, 31(4), 1317-1327

Bahr, M.A. (1991). Mechanical behavior and modelling of saturated clays subjected to cyclic

loading, Ph.D. Thesis, Osaka University

Basack, S. and Purkayastha, R. D. (2009). Engineering properties of marine clays from the

eastern coast of India. Engineering and Technology Research. 1(6), 109-114

Carter, J.P., Booker, J.R., Wroth, C.P. (1982). A Critical State Soil Model for Cyclic Loading.

Soil Mechanics – Transient and Cyclic Loads, John Wiley and Sons Ltd, 219-252

Chew, S., Kamruzzaman, A., and Lee, F. (2004). Physicochemical and Engineering Behavior of

Cement Treated Clays. Geotechnical and Geoenvironmental Engineering,130(7), 696–706

Díaz-Rodríguez, J.A. and López-Molina, J.A. (2008).Strain thresholds in soil dynamics. The 14th

World Conference on Earthquake Engineering, October 12-17, Beijing, pp.1-8

Dobry, R., Ladd, R.S., Yokel, F.Y., Chung, R.M., and Powell, D. (1982). Prediction of pore

water pressure buildup and liquefaction of sands during earthquakes by the cyclic strain method.

National Bureau of Standards, Washington, DC

-

38

Erken,A. and Ulker,B.M. (2007).Effect of cyclic loading on monotonic shear strength of fine-

grained soils. Engineering Geology, 3(4), 243-257

Esrig, M. and MacKenna, P. (2001). Lime Cement Column Ground Stabilization for I-15 in Salt

Lake City. Pract. Period. Struct. Des. Constr., 6(3), 104–115

Gharib,M., Saba,H. and Barazesh, A. (2012). The Effect of Additives on Clay Soil Properties

Using Cement and Lime. International Journal of Basic Sciences & Applied Research, 1(3), 66-

78

Haeri, S. M., Shahcheraghi, S.A., Shakeri, R. and Seiphoori, A. (2009). Mechanical behavior of

a cemented gravely sand under monotonic and cyclic loading-case study of Tehran alluvium. 8th

International Congress on Civil Engineering. Shiraz University, Iran, pp. 1-7

Hartlen, J. and Holm, G. (1995). Deep Stabilization of Soft Soils With Lime-Cement Columns.

Proceedings of Bellgt B. Broms Symposium on Geotechnical Engineering, Singapore, Japan, pp.

173-179

Idriss, I.M., Dobry, R., and Singh, R.D. (1978). Nonlinear behavior of soft clays during cyclic

loading. Journal of Geotechnical Engineering, 104(GT12), 1427–1447

Jacobson, J. and George, M. F. (2002). Factors affecting strength gain in lime-cement columns

and development of a laboratory testing procedure. Blacksburg, Virginia Teck, 1-83

Joint Departments of the Army and Air Force. (1994). Soil Stabilization for Pavements. TM 5-

822-14/AFMAN 32-8010.USA

-

39

Koutsoftas, D.C. (1978). Effect of cyclic loads on undrained strength of two marine clays.

Journal of the Soil Mechanics and Foundation Division, 104 (5), 609-620

Lefebvre, G. and LeBoeuf, D. (1987). Rate Effects and Cyclic Loading of Sensitive Clays.

Journal of Geotechnical Engineering, 113(5), 476–489

Li, S. and Huang, M. (2010). Undrained Long-Term Cyclic Degradation Characteristics of

Offshore Soft Clay. Soil Dynamics and Earthquake Engineering, 375)32, 263-271

Lucian,C. (2012). Stress-Strain Behaviours Of Two Stage Lime-Cement Treated Expansive

Soils. International Journal of Modern Engineering Research (IJMER), 2(3), 4405-4409

Matasović, N. and Vucetic, M. (1995).Generalized Cyclic-Degradation-Pore-Pressure

Generation Model for Clays. Journal of Geotechnical engineering, 121(1), 33–42

Matsui, T., Nabeshima,Y. and El Mesmary, M.A. (1999). Degradation in Cyclic Shear Behavior

and Soil Properties of Saturated Clays. The International Society of Offshore and Polar

Engineering, 536-541

Mortezaie, A. and Vucetic, M. (2013). Effect of Frequency and Vertical Stress on Cyclic

Degradation and Pore Water Pressure in Clay in the NGI Simple Shear Device. Geotechnical and

Geoenvironmental Engineering, 139(10), 1727–1737

Mortezaie, A. R. (2012). Cyclic threshold strains in clays versus sands and the change of secant

shear modulus and pore water pressure at small cyclic strains. Ph.D. thesis, Department of Civil

and Environmental Engineering, University of California, Los Angeles

-

40

Moses, G. G., and Rao, N. S. (2003). Degradation in Cemented Marine Clay Subjected to Cyclic

Compressive Loading. Marine Georesources and Geotechnology. 21(1), 37-62

Murthy, V.N.S. (2003). Geotechnical Engineering: Principles and Practices of Soil Mechanics

and. New York: CRC Press, 173-205

North Dakota Department of Transportation. Truck Size and Weight.Available:

http://www.ndenergy.org/usrfiles/news/Truck Size and Weight Presentation.pptx.Last accessed

20th Jan 2014

Pillai, R., Nazeeh, K. and Robinson, R. (2013). Post-Cyclic Behaviour of Clayey Soil. Indian

Geotechnical Journal, 2(8), 1-10

Poulos, H.G. (1981). Cyclic axial response of single pile. Journal of Geotechnical Engineering,

1(107), 41-58

Prisco, C. and Zambelli, C. (2003). Cyclic and dynamic mechanical behavior of granular soils:

experimental evidence and constitutive modeling. Milan University of Technology (Politecnico

di Milano) Department of Structural Engineering. Milan, Italy. pp.881-910

Shajarati, A., Sørensen, K., Nielsen, S. and Ibsen, L. (2012). Behaviour of Cohesionless Soils

During Cyclic Loading. DCE Technical Memorandum No. 14, Aalborg University, Department

of Civil Engineering. Aalborg.Denmark, pp. 1-7

Sharma, S. and Fahey, M. (2003). Degradation of Stiffness of Cemented Calcareous Soil in

Cyclic Triaxial Tests. Geotechnical and Geoenvironmental Engineering, 129(7), 619–629

-

41

Sharma, S. and Fahey, M. (2003). Evaluation of Cyclic Shear Strength of Two Cemented

Calcareous Soils. Journal of Geotechnical and Geoenvironmental Engineering, 129(7), 608–618

Shen, S., Han, J., and Du, Y. (2008). Deep Mixing Induced Property Changes in Surrounding

Sensitive Marine Clays. Journal of Geotechnical and Geoenvironmental Engineering, 134(6),

845–854

Soltani-Jigheh, H. and Soroush, A. (2006). Post-cyclic behavior of compacted clay-sand

mixtures. International Journal of Civil Engineering, 4(3), 226-243

Soltani-Jigheh, H. and Soroush, A. (2010). Cyclic Behavior of Mixed Clayey Soils. International

Journal of Civil Engineering, 8(2), 99-106

Sridhanya, K.V. , Rajagopal K., and Lakshmana Rao, C. (2008). Modelling of Degradation of

Clayey Soils under Repeated Loading. Indian Geotechnical Journal, 39(2), 139

Tan, K. and Vucetic, M. (1989). Behaviour of medium and low plasticity clays under cyclic

simple shear consitions. Proc.4th international conference on soil dynamics and earthquake

engineering. Mexico city, Mexico, 131-142

Thach, P., Liua, H. and Kong, G. (2013). Vibration analysis of pile-supported embankments under high-speed train passage. Soil Dynamics and Earthquake Engineering, 55, 92–99

Thiers, G.R. and Seed, H.B. (1969). Strength and stress-strain characteristics of clays subjected

to seismic loading conditions, Vibration effects of earthquakes on soils and foudnations. ASTM

STP 450, American society for testing and materials

-

42

Upper Great Plains Transportation Institute. (2007). North Dakota Strategic Freight Analysis

Truck Size and Weight Issues in North Dakota. North Dakota State University

Fargo, North Dakota. pp 1-47

Vucetic, M., (1992). Soil properties and seismic response. Earthquake Engineering, Tenth World

Conference. Rotterdam . University of California.California, USA . pp.1199-1204

Vucetic, M. and Dobry, R. (1988). Degradation of Marine Clays under Cyclic Loading. Journal

of Geotechnical Engineering, 114(2), 133–149

Yasuhara K., Hirao K. and Hyde A.F.L. (1992). Effects of cyclic loading on undrained strength

and compressibility of clay. Soils and Foundations, 32 (1), 100-116

Åhnberg, H. and Larsson, R. (2012). Strength degradation of clay due to cyclic loadings and

enforced deformation.Report 75. Linköping. Sweden. pp.1-142