Services and upgrades for your GE® 1.5 MW WTG. · PDF filewith two inductive proximity...

Transcript of Services and upgrades for your GE® 1.5 MW WTG. · PDF filewith two inductive proximity...

Transparently solved.

GE®

W E L I S T E N .

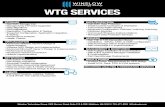

Services and upgrades for your GE® 1.5 MW WTG.

Contents Page

Axis cabinet ventilation 04

Diagnosis of base frame/generator support 04

BGV A3 inspection 07

Gearbox position monitoring 07

IceFree sensors 08

LED beacon light 08

Bypass filtration 09

Grid coupling contactor 09

Permanent lubrication systems 10

Access monitoring 11

'GE' is a registered trademark of GENERAL ELECTRIC COMPANY, US.

"Turbines by GE® can be found everywhere. Even in the heads of our engineers."

The USA is well-known for being the land of unlimited opportunities. In the wind turbine generator (WTG) sector, the word 'unlimited' is meant literally. For thousands of WTGs by the American manufacturer GE® – particularly the GE® 1.5 MW – are turning, not just between LA and New York, around the world, across all borders.

What's nice about this is the more turbines of one type are turning, the more experiences there are to collect. And benefits, for example, for developing new optimisations. That's why our engi-neers and I have been grappling with turbine technology even more intensively.

We have come across interesting challenges at our competence centre in Hamburg. You can find out about the interesting solutions we have found to these challenges over the following pages. Incidentally, if your American wind turbine generators should actually be located on American soil, that's not a problem. We have been represented in the USA since 2009. We now even have two locations.

My colleague Michael Richter knows a thing or two about GE® wind turbine generators. As the manager of global sales, he is used to listening to customers. But he also ensures that their requests are successfully transformed into actions. Details of how to contact him can be found on the back of this brochure.

Kind regards,

Olaf Kleesch(Director Global Technical Support and Engineering)

03

Problem:The weather does not just have an influence on the immediate surroundings of a WTG. If it turns warmer or colder on the outside, the temperatures inside the nacelle also change accordingly. This is not necessarily an ideal environment for sensitive components such as the accumulators, that often react to major temperature fluctuations with a reduced service life.

Solution:Two challenges were at the heart of the search for a solution: preventing cold-related failures and avoiding heat loss in the control cabinet. The climate concept developed for this from battery heating and insulation permanently ensures the optimum and continuous environmental temperature of a pitching battery within the control cabinet.

Overview of benefits and features of diagnosis of base frame/generator support:

• Maintains WTG’s operational reliability

• Checking generator support for cracks (magnetic powder test)

• Ultrasound inspection if necessary

• Welding and sanding preventative measures with the removal of tension peaks

• Abolition of cracks using MAG, E and WIG welding procedures

• Prevention and/or delay of recurrent crack formation in steel components under dynamic loads

• For GE® 1.5 MW turbines

Axis cabinet ventilation.

Problem:A good wind location brings with it many challenges for materials and technology. Base frames and generator supports are subject to enormous traction and bending torque. The result can be cracks and unstable weld seam connections and can lead to particularly costly and time-consuming repairs.

Solution:Together with WPT-Nord, the experts in non-destructive material testing, Availon has many years of experience and the expertise to secure the quality of base frames and generator supports. All this whilst upholding nationally and internationally recognised certifications.

Diagnosis of base frame /generator support.

Overview of benefits and features of axis cabinet ventilation:

• Increase of pitching battery service life

• Optimum and continuous environmental temperature thanks to battery heating and insulation

• Avoidance of heat loss and temperature fluctuations in the axis cabinet

• Pitching batteries require less frequent changes

• For GE® 1.5 MW turbines

04

0505

06

1

2

3 4 5 6 7 8 9

10 11 12

geprüft nach BGV A3Nächster Prüftermin

12 13 14 15 16 17

BGV A3 check.*

Problem:The consistent checking of the complex electronics of a WTG has not yet been established, even though it has been a legal requirement for several years now. And rightly so, as electrical accidents lead to serious burns and, in the worst case, death.

Solution:Together with ABO Wind, Availon has developed the first BGV A3 testing especially for WTGs. Taking into account the various WTG types, every use follows its own, turbine-specific plan. Over 150 measurement points and kilometres of cables are responsibly tested, taking into account all legal requirements.

Overview of benefits and features of BGV A3 testing:

• Upholds the safety of the electrical equipment in WTGs

• According to the requirements of BGV A3, DIN VDE 0105-100 and VDS clause 3602

• Avoids accidents with serious consequences due to electrical faults

• Reduces the liability risk for operators

• First BGV A3 testing process especially for WTGs

• Seamless documentation including detailed description and, if necessary, photos

• Implementation recommended every four years, for mobile devices: annually

Problem:In the event of an undetected main bearing washer breakage, even the gearbox moves backwards by up to 9mm and is axially only limited by the pedestal bearing. The pressure of the power train is transferred to the planet carrier bearing. The consequence: damage to the entire planet carrier bearing and therefore the entire gearbox.

Solution:The position of the gearbox can be consistently monitored with the solution by Availon. Two inductive proximity switches register every change of position and immediately pass these on as a notification to remote monitoring.

Gearbox position monitoring.

Overview of benefits and features of gearbox position monitoring:

• Permanent monitoring of the gearbox position with two inductive proximity switches

• Avoidance of massive gearbox damage

• Seamless connection of turbine control and remote monitoring

• Automatic stop of the turbine upon a fault notification

• For GE® 1.5 MW turbines

* Performance exclusively applies to Germany and is based on German legal principles and guidelines.

07

Problem:Below-zero temperatures barely have an effect on gearbox oil. But this is somewhat different on the outside of the nacelle. Even at temperatures around freezing there are cracks in the anemometer and the weather vane. In this case, the only option is the use of a service team. Or better weather. Both scenarios require a lot of time. By which point the sensors are measuring a wind speed of 0.0 m/s. Meaning the turbine is stopped due to the fault notification and does not produce any yields in spite of the wind. Losses of up to €5,000 per turbine and winter period are not uncommon.

Solution:Redress creates IceFree sensors that are able to withstand even extreme minus temperatures with their tested heating concept. The solution is not only very robust and set up for a temperature range of -40°C to +60°C. The magnetically damped wind vane also ensures a high level of precision of measurements.

Overview of benefits and features of IceFree sensors:

• Weather sensors with high-performance 230V heating

• Prevents icing over of anemometer and wind vane

• Guarantees normal operation of the WTG even under extreme temperatures

• Temperature range of between –40 °C and +60°C

• High mechanical stability due to double-screened stainless steel ball bearings (anemometer)

• Maximum accuracy due to magnetically dampened wind vane

• Worldwide tried and tested system

IceFree sensors.

Problem:Wind turbine generators are getting taller and taller. But they are also intruding on an area critical for air traffic. WTGs must therefore be identified from a total height of 100 m. The beacon light plays an important role in this, but is exposed to adverse weather conditions.

Solution:Availon has a tested LED beacon light system for WTGs on offer. LEDs are unbeatable when it comes to efficiency and reliability. This low maintenance and wear system ensures a higher level of safety and makes the costly replacement of conventional bulbs and other components redundant.

Overview of benefits and features of LED navigation lighting:

• Plug & play: works as soon as the power supply is provided

• Highly efficient LED system

• Minimal maintenance and wear

• Hard-wearing, even in adverse weather conditions

• Increases the safety of the WTG

• For GE® 1.5 MW turbines

LED beacon light.

08

Problem:Oil is a decisive factor for the duration of a gearbox. However, the technology of many turbines only allows the filtration of particles and oil ageing products from a size of 10 µm. Smaller particles remain in the oil and lead to permanent damage of the gearbox.

Solution:The engineers at Availon have developed an additional system that filters out all particles and oil ageing products from a size of 3 μm in the bypass flow.

Overview of benefits and features of bypass filtration:

• Filtration of particles and oil ageing products from a size of 3 µm (standard from 10 µm)

• Potentially longer oil life due to efficient cleaning of gearbox oil

• The change interval of the gearbox oil can be increased to 60 months or more

• Additives remain dissolved in gearbox oil

• For GE® 1.5 MW turbines

Bypass filtration.

Problem:In the event of under and overvoltage, for example, due to a storm, every WTG must switch itself off and later reconnect. This task is undertaken by the circuit breaker with 2,500 to 3,000 cycles every year. As the precision mechanism is heavily stressed by this, the maintenance costs become that much higher. A faulty circuit breaker can also lead to major damage to the converter and generator.

Solution:The grid coupling contactor developed by Availon reduces the cycles of the circuit breakers to a maximum of 20 to 30 per year. This significantly increases the service life of the circuit breaker.

Overview of benefits and features of the grid coupling contactor:

• Increase of turbine safety

• Takes on the majority of regular cycles (up to 250,000)

• Significant increase of service life of the circuit breaker by reducing cycles to a max. of 20-30 per year

• Prevents increased wear, thermal overloading, malfunctioning

• Avoids consequent damage to the converter and generator

• Reduces maintenance costs

• Increases turbine availability

• Installation and configuration for each WTG in no more than 2 days

• For GE® 1.5 MW systems

Grid coupling contactor.

09

Problem:Be it open gear teeth, planetary stages or roller bearings, the moving, mechanical components in wind turbine generators perform a task that is as difficult as it is greasy. After all, the right lubrication contributes towards less wear and better corrosive protection. However, a perfectly even lubrication film is required to avoid excess grease. And this is hard to achieve even for experienced engineers.

Solution:The permanent lubrication systems by Availon automatically and optimally supply every moving component with lubrication. Be it for yaw gears, main bearings, generator bearings or pitch gears. Every permanent lubrication system guarantees a perfectly even lubrication film and thereby ensures better corrosive protection and less wear. The grease container has to be replaced once per year. The maintenance work required is reduced to a minimum.

Permanent lubrication systems.

Overview of benefits and features of permanent lubrication systems:

• More safety thanks to a permanently continuous lubrication supply

• Permanently even lubrication film

• Avoidance of excessive and insufficient lubrication

• Better corrosive and wear protection

• Reduction of maintenance and repair works

• The grease cartridge has to be replaced just once per year

• For GE® 1.5 MW turbines

A breakdown of the special benefits and features of permanent lubrication systems:

The main bearing permanent lubrication system:

• Continuous lubrication and supply

• Independent system for each separate bearing

• Prevents duplicate lubrication during maintenance

• Increases the service life of the main bearings

The permanent lubrication system for generator bearing

• Continuous lubrication/supply of fast running generator bearing

• Independent turbine for each separate bearing

• Prevents duplicate lubrication during maintenance

• Increases the service life of the generator bearings

The permanent lubrication system of pitch gear rings:

• Permanent, even lubrication film on gears

• Hard foam pinion supplies the gear of the drive with a thin, even lubricating film

• Relieves the gear rings of the rotor blades

• Only ¼ of the gear ring is loaded during operation

• No corrosion – no wear

• Improves WTG performance

• Prevents costly distortion of blade bearing

The permanent lubrication system of yaw gears:

• Continuous lubrication yaw pinions/gears

• Prevents corrosion

• Additionally installed weather protection directly catches any dripping lubricant

• Prevents further soiling of tower and contamination of the environment

• Improves provision of cooling air to the drive train through additional ventilation hole in nacelle floor

10

Problem:If thieves tamper with WTGs, they often do so with little expertise, but great criminal energy. Possible consequences: major damage due to stolen copper cables and destroyed WTG installations.

Solution:Possible defence: Availon access monitoring. As those who ignore the warning sign on the WTG, set off more than they might think: along with the acoustic alarm directly in the WTG, a message is immediately sent to the remote monitoring. They are able to listen via an acoustic sensor on the inside of the WTG. If nothing can be heard and there is no longer anybody in the entry area, the warning alarm switches off. Otherwise, the police are immediately informed.

Access monitoring.

Overview of benefits and features of access monitoring:

• Solution independent of WTG control

• Movement sensor and remote monitoring are directly connected via GSM modem

• Immediate alarm and reaction to break in attempts

• Acoustic alarm directly in the turbine

• Acoustic sensor on the inside (optional: monitoring camera)

• Prevents damage, downtimes and yield cuts

• Can also be used for transformer or transfer stations

11

Availon GmbH | Jacksonring 2 | 48429 Rheine | Germany | www.availon.eu

When it comes to wind turbine generators by GE®, I welcome every challenge with joy. Above all, because I am certain that, thanks to our experience, we can master each and every one of them to your complete satisfaction. No challenge is too small to contact me with. Just give me a call. I look forward to speaking with you.

All the best,

Michael Richter

09/201

4

Michael Richter

Manager Global Sales

Phone +49 (0) 40 181313-532

Mobile +49 (0) 173 8780908

Hallo and hello there!