Selecta Advanced Floor Gully Brochure

-

Upload

leonard-keane -

Category

Documents

-

view

223 -

download

0

Transcript of Selecta Advanced Floor Gully Brochure

-

8/2/2019 Selecta Advanced Floor Gully Brochure

1/36

UniclassL7315:P4131:P44

CI/SfB

(52.6) ACO Building Drainage

D r a i n a g e s y s t e m s

Product catalogue

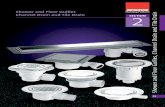

Selecta Advanced Floor Drainage Systems

-

8/2/2019 Selecta Advanced Floor Gully Brochure

2/36

Our built environment is becoming ever more

complex. Applications are becoming more

sophisticated and the increasing pressure of

regulations and standards make achieving design,

performance and financial goals ever tougher.

ACO Building Drainage is a new concept within the

ACO Group. Our mission: to eliminate design risk,

to reduce installed and life cost and to deliver

exceptional finish and performance in every

product application.

We achieve this through three factors:

High performance materials

Design experience and project support

Global manufacturing capacity

Our global resources and fabrication capacity make

it possible for us to deliver best value, both with our

standard products and with our bespoke designs.

Confidence is further assured with quality systems

that are in accordance with ISO 9001-2000.

ACO Building Drainages extensive portfolio

includes:

Stainless steel Modular Channel system

Stainless steel EuroGully gully system

Stainless steel and polymer composite

access covers

Biological Grease Management system

Gravity Grease Separator system

Anti-flood protection valves Stainless steel socketed pipe system

Rainwater outlets for flat roofs

ACO Building Drainage is a division of ACO

Technologies plc and part of the worldwide

ACO Group. The Group has sales in excess of 400

million worldwide with production facilities in the

UK, Germany, France, Switzerland, Denmark,

Spain, Poland, Czech Republic, Australia and the

USA. In total more than 3000 people are employed

in 30 countries throughout the world.

Tel:

01462 816666Fax:

01462 851490e-mail Enquiries:

website:

www.acobuildingdrainage.com

ACO Building Drainage

-

8/2/2019 Selecta Advanced Floor Gully Brochure

3/36

3

ACO SelectaACO SELECTA ADVANCED FLOOR DRAINAGE SYSTEMS

Advanced Floor Drainage Systems

Advanced floor gully introduction & key technologies 4

The role of the gully in preventative fire protection 6

Declaration of fire resistance performance 7

Grating material choice 8

Conservation of fuel and power 9

Load class 9

Application Guide

The application guide 10

Features and Benefits

Selecta two-part gully 12

Direct-couple gullies and rodding eyes 13

Components

Gratings and solid covers 14

Gully body tops - 2 part system 16

Gully bodies - 2 part system 18

Accessory options - fire protection 18

Gullies - direct couple 19

Installation Overview

Vertical gully with wet room gully top in ground floor wetroom with tiles 22

Vertical gully with resin finish using two-part screed gully top in ground floor 23

Vertical gully with sheet vinyl using two-part flexible floor clamp in ground floor 24

Horizontal gully with resin finish using two-part screed gully top in ground floor 25with optional back inlet inflow

Vertical firestop gully in wetroom with tiles using two-part wetroom gully top 26in raised concrete floor

Vertical firestop gully with sheet vinyl using two-part flexible floor clamp 27in raised acoustic concrete floor

Horizontal gully with resin finish using two-part screed gully top in raised floor 28

Direct connection gully with sheet vinyl using direct-couple flexible floor gully top in ground floor 29

Direct connection rodding access with resin finish using direct-couple screed gully top 30in ground floor

Vertical gully with tiles in raised concrete floor 31

Operation and Maintenance

Cleaning methods 32

Standard Specification Clauses

Standard specification clauses 34

Contents

-

8/2/2019 Selecta Advanced Floor Gully Brochure

4/36

4

Advanced floor gully introduction & key technologies

ACO Selecta - Floor DrainageADVANCED FLOOR DRAINAGE SYSTEMS

Fire protection in a gully!

ACO Building Drainage introduces the Selecta

range of floor gullies. A range that has evolved as

have changes in the construction environment.Durability and functional performance combine

with modern aesthetics and sustainable materials.

Added to these features are patented systems

designed to augment other measures that reduce

risk and aid compliance with the Regulatory

Reform (Fire Safety) Order.

Fire resistance performance: EI 120-U/U

High performance stainless steel or copper alloy gratings

Selecta provides choice: from high performance stainless steel designs through traditional copper alloy to low

cost economy options. Our sophisticated manufacturing techniques enable off-the-shelf availability.

Drainage options without body

Accessories such as sealed rodding eyes can be

used in stand alone or with the gully as required.

Advanced waterproofing systems

Ideal for concrete, tile and natural stone,

Selecta also integrates with flexible sheet

flooring as well as the most recent tanking

materials for wetrooms.

-

8/2/2019 Selecta Advanced Floor Gully Brochure

5/36

Advanced floor gully introduction & key technologies

ACO Selecta - Floor DrainageADVANCED FLOOR DRAINAGE SYSTEMS

5

Fire protection and cost reduction

Time and cost of installation can be enhanced through use of

the ACO Fit-In sleeve system - ideal for slab penetrations, Fit-In

removes the need for mortar and reduces build time, as well

as providing extra fire protection.

Intumescent fire cartridge

Tested in accordance with BS EN 1366. The more

stringent replacement for BS476 ensures performanceeven in the most severe fire situations, reducing

substantially smoke transfer to other building floor

levels as well as reducing oxygen paths that feed fire.

Designed and manufactured

to BS EN 1253

Remarkably few systems available on the

market meet the requirements of this

standard; specify confidently as factorsranging from self cleaning ability though

adequate dpm flange membrane clamping

area are ensured.

-

8/2/2019 Selecta Advanced Floor Gully Brochure

6/36

6

ACO Selecta - Floor DrainageADVANCED FLOOR DRAINAGE SYSTEMS

The role of the gully in preventative fire protection

There is now a wealth of material to consider

regarding fire safety. The Regulatory Reform (Fire

Safety Order) 20051 aims to reduce both hazard

and risk, where risk is the likelihood and

consequence of fire.

Current Building Regulations2 incorporate design

guidance where, given certain building types,

compartmentation is used to reduce fire

propagation. The efficacy of such schemes is

dependent on both integrity and insulation.

In the case of fire, Integrity prevents the passage of

flame and hot gas from the exposed to unexposed

side, whereas insulation restricts temperature rise

below specified levels3. Preserving the integrity and

insulation performance of a separating element is

problematic if gullies are used for other than

ground floor drainage. In effect, they present an

'open ended' pipe penetration when the water trap

is depleted and connecting pipework has beendestroyed. This worst case scenario is assumed in

the test protocol followed by ACO.

Penetrating devices, such as gullies, are tested in

accordance with BS EN 13664, and classified in

accordance with BS EN 135015 (see references

on page 7).

With a drainage gully, the underside is considered

more critical as fire spread is more likely from lower

floors. Attention must therefore be paid to the

design of the gully body and its installation.

Whilst measurements are taken at the grating via

thermocouples, these upper parts of the system

do not determine system performance.

The gully body is cast iron and is sited within a

thermally insulating pre-formed concrete jacket to

provide effective fire containment and limit

thermal transmittance. Protection is augmented by

an intumescent cartridge that sits in the outlet

spigot. This material expands at approximately

150C, closing off the system completely.

Used in combination, water trap depletion is

dramatically reduced and integrity and insulation

maintained. An additional, though unmeasured

benefit, is the reduced passage of smoke.

-

8/2/2019 Selecta Advanced Floor Gully Brochure

7/36

7

ACO Selecta - Floor DrainageADVANCED FLOOR DRAINAGE SYSTEMS

Risk proportionate

measuresThe Publicly Available Specification - PAS 796

comments on 'risk-proportionate' fire precautions.

In this context unnecessary expenditure is

precluded, but where appropriate, further

protection can be included if necessary.

The ACO Selecta system is designed to offer

another tool for the specifier to incorporate intotheir design where appropriate. Its components are

designed in such a way as to minimise the 'extra

cost' of using them. The economical body is

designed for multi-purpose applications; the

intumescant cartridge is an insignificant cost in

relation to the gully as a whole; the Fit-In

installation sleeve is in itself designed to speed up

the installation process.

Part or system costs are available from ACO

on request.

Declaration of fireresistance performance

The ACO Selecta vertical outlet body in conjunction

with the optional intumescent fire cartridge is tested

in accordance with BS EN 1366-34 and classified in

accordance with BS EN 13501-25.

The performance can be classified as EI 120-U/U

indicating the gullies are uncapped both inside

and outside the furnace.

Selecta gully system during BS EN 1366

fire resistance testing

References

1. - Regulatory Reform (Fire Safety Order) 2005;

- Fire (Scotland) Act 2005;

- Fire Safety (Scotland) Regulations 2006;

- Fire and Rescue Services Order

(Northern Ireland) 2006;

- Fire Safety (Northern Ireland) Regulations

2. Building Regulations Approved Document B

Fire Safety, April 2007

3. BS EN 1363-1:1999 Fire resistance tests

- Part 1: General requirements

4. BS EN 1366-3:2004 Fire resistance tests for

service installations - Part 3: Penetration seals

5. BS EN 13501-2:2003 Fire classification of

construction products and building elements

- Part 2: Classification using data from fire

resistance tests, excluding ventilation services

6. PAS 79:2007 Fire risk assessment - Guidance

and a recommended methodology

-

8/2/2019 Selecta Advanced Floor Gully Brochure

8/36

8

ACO Selecta - Floor DrainageADVANCED FLOOR DRAINAGE SYSTEMS

Grating material choiceACO offer both stainless steel and copper alloy

gratings in a variety of patterns.

The raw material cost of each alloy differs

significantly: the major constituent of stainless steel is

iron at over 70%, whilst copper is present in excess

of 50% by weight in most of its alloy forms. A cost

ratio of 2:1 is realistic favouring stainless steel.

For the applications intended both alloys haveexcellent mechanical properties and corrosion

resistance, although the manifestation of

corrosion differs.

Copper alloys

Popularly referred to as nickel bronze, the exact

constituents can be varied according to the

properties desired. Due to the large number of

alloys available, users may have to refer to the

manufacturer for guidance on corrosion resistance

in specific applications, however prolonged

exposure to ammonia should be avoided.

For many, the attraction of copper alloy is its

golden hue, evident when new. The surface will

initially tarnish quickly depending on environment.

The 'patina' is a result of oxidisation that forms a

passive layer that changes colour with time.

An intermediate stage is evident on the grating

aperture walls below. The passive layer protects the

underlying metal from further corrosion. This can

be removed but will reform continually. As such its

effects are considered aesthetic only.

The alloy has properties favourable to low cost

manufacturing techniques such as casting.

Corrosion effects are exacerbated by rough casting

surfaces, particularly where this roughness is not

subsequently removed. ACO manufacture all

cooper alloy gratings with smooth side walls.

Stainless steel alloys

The stainless steel alloy family is dominated by

austenitic '304' and '316' grades. As such there is a

wealth of data on corrosion resistance to aid the

user in specification and reduce uncertainty. In the

case of most stainless steels chlorides may cause

corrosion if exposure is prolonged.

Passive grades, as used by ACO, benefit from a

naturally occurring chromium-rich oxide that

spontaneously regenerates if damaged in normal

use. This passive layer is invisible to the eye and

therefore little change in appearance is evident

over the product life.

-

8/2/2019 Selecta Advanced Floor Gully Brochure

9/36

9

ACO Selecta - Floor DrainageADVANCED FLOOR DRAINAGE SYSTEMS

Conservation of fueland power

Building Regulations Approved Document Part L

relates to the thermal performance of the building.

It is generally accepted that this performance is the

result of complex interactions between many

systems. Floor penetrating gullies can complicate

the design particularly with regard to insulation

detailing.

The two-piece Selecta system accommodates floor

and insulation thicknesses up to 295mm via a

standard extension piece supplied with the gully

top. The plastic extension section can be easily cut

on-site to suit specific applications.

Load class

All product combinations meet the requirements of

BS EN 1253: 2003 for Load Class K3. The K3

application area is described as area without

vehicular traffic, such as bathrooms in dwellings,

care homes, hotels, schools, swimming baths,

public wash and shower facilities, balconies,

loggias, terraces and roofs with greenery.

-

8/2/2019 Selecta Advanced Floor Gully Brochure

10/36

10

GRATINGS

APPLICATION

GULLY BODIES

GULLY TOPS

VerticalFoul Air Trap

VerticalGully Body

Economy 100Two-Part

Economy 150Two-Part

Tile 150Two-Part

ScreedTwo-Part

Wet RoomTwo-Part

Vinyl Seal

Two-Part

FOULAIR TRAP

ACCESSORY

OPTIONS

Corrosion

resistance

High

ACO Selecta - Floor DrainageThe application guide

Below you will find a general application guide. In short there are two main product choices:Two-Part systems or Direct-Couple. The Two-Part system uses the cast iron body and in vertical

mode can incorporate fire protection features.

Economy stainless steel- non-locked

Standard stainless steel- locked

Stainless

Fire Protection Cartridge Fit-In Installation Core

-

8/2/2019 Selecta Advanced Floor Gully Brochure

11/36

11

High

Economy

Tiles

Resin

Screed

Flexible/Vinyl

Wet Room

Rodding Eye Double Seal

DIRECT COUPLEGULLY BODIES

Flexible FloorClamp Two-Part

ACCESSORYOPTIONS

HorizontalFoul Air Trap

Cost

Flexible FloorDirect-Couple

ACO Vinyl Seal

Direct-CoupleScreed

Direct-CoupleTile

Direct-Couple

Direct-Couple systems provide either a one-piece simple gully or rodding eye for connection to 110mmpipework, or allow use of the Slab Penetration unit. Choice of grating or solid covers for each system is

detailed in the componets section of the catalogue.

designer patterns and rodding eyes

Copper alloy designer patterns and rodding eyes

Stainless steelslip resistant

range

HorizontalGully Body

Slab Penetration Unit Foul Air Trap

-

8/2/2019 Selecta Advanced Floor Gully Brochure

12/36

12

ACO Selecta - Floor DrainageFEATURES AND BENEFITS

Selecta Two-Part gully

Choice of 8 'designer' premium electro-polished

locked stainless steel gratings. Bezel overall

dimensions: 150 x 150 mm.

Alternative 'designer' locked grating range in

brushed copper alloy.

Optional slip resistant finish on circular stainless

steel grating.

Cost effective ABS gully tops with choice of 100 x100mm or 150 x 150mm bezel unlocked slotted

steel grating.

Standard telescopic polyethylene gully top with

stainless steel 150 x 150mm bezel allows 240mm

vertical adjustment and full 360 bezel rotation.

Rubber drainage ring fitted to all gully tops ensures

any water seeping onto the membrane can freely

enter the gully.

Wet room gully top. Flexible polypropylene fleece

hermetically bonded to telescopic gully top provides

convenient integration to brush/roller applied wetroom tanking systems. Unique 150 x 150mm

stainless steel bezel feature permits full 35mm

horizontal and 360 adjustment to match tile

patterns alleviating the need for pinpoint positioning

accuracy of the gully body during installation.

Circular stainless steel gully top for flexible sheet

flooring with flooring clamp avoids disturbance of

the flooring integrity when accessing the gully.

ACO Vinyl Seal gully top for professional welded

flexible sheet flooring applications.

Circular 168mm stainless steel bezel for resin andcementitious floor screed applications.

Cast iron gully body with 110 mm horizontal or vertical

spigot outlet complete with removable foul air trap for

easy servicing, flow rate 1.4 l/s. Dpm membrane clamp

as standard. Horizontal bodies have universal back inlet

connector for all 40mm (11/2'') solvent weld and push-

fit waste pipes to BS 5254 and BS 5255.

Optional ACO patented intumescent fire cartridge

conforming to BS EN 1366 for vertical bodies only.

Optional fire protection dry installation kit for

installing vertical outlet gully body in concrete

decks. Eliminates the need for time-consuming

wet mortar sealing on installation.

1

2

3

4

5

6

7

8

9

10

11

12

13

21 3

7

8

9

10

11

12

13

4

6

4

5

-

8/2/2019 Selecta Advanced Floor Gully Brochure

13/36

13

ACO Selecta - Floor DrainageFEATURES AND BENEFITS

Direct-Couple gullies and rodding eyes

Choice of 8 'designer' premium electro-polished

locked stainless steel square gratings. Bezel overall

dimensions: 150 x 150mm.

Alternative 'designer' locked square grating range in

brushed copper alloy.

Solid circular and square access covers complete

with double EPDM seal manufactured from 304

stainless steel and copper alloy.Circular perforated 304 stainless steel grating for

flexible sheet flooring applications. Available in electro-

polished or slip resistant options.

Universal optional foul air trap. Water seal depth:

50mm to BS EN 1253, flow 1.2 l/s.

Circular 304 grade stainless steel bezel for flexible

sheet flooring applications, with independent rigid

nylon membrane clamp. Vertical spigot outlet:

110mm OD.

Square 304 stainless steel bezel fitted with ACO

Vinyl Seal

for welded flexible sheet flooringapplications. Frame outside dimensions:

171 x 171mm, vertical outlet: 110mm OD.

Square 304 grade stainless steel bezel for ceramic

tile, resin and cementitious applications. Frame

outside dimensions: 150 x 150mm, vertical outlet:

110mm OD.

Circular 304 grade stainless steel bezel for resin and

cementitious floor applications. Frame outside

dimensions: 168mm OD, vertical spigot outlet:

110mm OD.

Optional through-slab penetration sleeve 325mmlong. Fully welded 304 stainless steel construction,

complete with 110mm OD spigot outlet and

independent rigid nylon membrane clamp.

May be used in conjunction with all direct

couple bezels above.

1

2

3

4

5

6

7

8

9

10

1 2 3 4

10

6

7

8

9

5

-

8/2/2019 Selecta Advanced Floor Gully Brochure

14/36

14

ACO Selecta - Floor DrainageCOMPONENTS

Square gratings

Classic K3 150mm 104078 105066 0.6

Weight

Kg

Part No

Copper

Alloy

Part No

Stainless

Steel

Load Class

to BS EN

1253

Overall Module

Including

Bezels

Grating

Style

Stainless Steel

(electro-polished)

Copper Alloy

(brushed)

Arco K3 150mm 104079 105067 0.6

Linea K3 150mm 104076 105064 0.6

Mondo K3 150mm 104074 105063 0.6

Pop K3 150mm 104080 105068 0.6

Quadrato K3 150mm 104075 105061 0.7

Wave K3 150mm 104081 105062 0.6

Wellness K3 150mm 104077 105065 0.6

K3 150mm 105056 105055 0.6

K3 150mm 105075 n/a 0.5

TraditionalSlotted

StandardSlotted

n/a K3 150mm 105073 n/a 1.1Economy

Non-locking(inc bezel)

n/a K3 100mm 105072 n/a 0.9Economy

Non-locking(inc bezel)

n/a

-

8/2/2019 Selecta Advanced Floor Gully Brochure

15/36

15

ACO Selecta - Floor DrainageCOMPONENTS

For flexible sheet flooring applications

Circular gratings for screed and resin systems

n/a K3 157mm 401185 n/a 0.25

Weight

Kg

Part No

Copper

Alloy

Part No

Stainless

Steel

Load Class

to BS EN

1253

Overall Module

Including

Bezels

Grating

Style

304 Stainless

Steel

Copper Alloy

(brushed)

n/a K3 157mm 104048 n/a 0.25

K3 157mm 105058 105057 0.5

StandardPerforated

(electro-polished)

Slip ResistantPerforated

StandardSlotted

(brushed)

K3 168mm 105051 105050 0.8Slotted

Solid cover - for Direct Couple gullies only

K3 150mm 105054 105053 0.6Solid Cover

K3 168mm 105049 105048 0.9Solid Cover

Notes:

1. All Gratings supplied complete with lockings unless otherwise stated.

2. Grating slot width typically 8mm.

3. Solid covers supplied complete with EPDM double seal and lockings.

4. When copper alloy gratings are assembled onto a bezel a mixed metal appearance will be visible against

a 3mm stainless steel edge.

-

8/2/2019 Selecta Advanced Floor Gully Brochure

16/36

16

ACO Selecta - Floor DrainageCOMPONENTS

Gully body tops - Two-Part system

Tiles, resin and cementitious flooring applications

Economy 100 Two-Part 105072 K3 0.9

Weight KgBS EN 1253 Load ClassModel Reference Part No

- Supplied complete with stainless

steel grating

- Not lockable

Economy 150 Two-Part 105073 K3 1.1

Weight KgBS EN 1253 Load ClassModel Reference Part No

- Supplied complete with stainless

steel grating

- Not lockable

Tile 150 Two-Part 105074 K3 1.1

Weight KgBS EN 1253 Load ClassModel Reference Part No

- Stainless steel frame

- Match to all 150mm gratings

- Supplied with locking

7

100 x 100

30-80

150 x 150

30-96

15

150 x 150

55-295

-

8/2/2019 Selecta Advanced Floor Gully Brochure

17/36

17

ACO Selecta - Floor DrainageCOMPONENTS

Gully body tops - Two-Part system

Resin and cementitious flooring applications

Screed Two-Part 105052 K3 1.7

Weight KgBS EN 1253 Load ClassModel Reference Part No

- Stainless steel frame

- Match to 105048 to 105051 inclusive

- Supplied with locking

ACO Vinyl Seal Two-Part 105071 K3 2.2

Weight KgBS EN 1253 Load ClassModel Reference Part No

Wetroom Spacer 104062 3mm 0.1

104063 9mm 0.1

Weight KghModel Reference Part No

Wetroom flexible flooring applications

Wetroom Two-Part 105078 K3 1.4

Weight KgBS EN 1253 Load ClassModel Reference Part No

- For tiles up to 10mm thick

- Tiles greater than 10mm usespacer below

- Match to all 150mm gratings

- 18mm horizontal and 360o rotationalbezel adjustment

- Supplied with locking

- Stainless steel frame

- Match to all 150mm gratings- For installation details see page 24

- Supplied with locking

Flexible Floor Clamp Two-Part 105069 K3 1.5

Weight KgBS EN 1253 Load ClassModel Reference Part No

- Match to all 157mm gratings

- 304 stainless steel

- Mechanical clamp

- Accepts flooring up to 4mm thick

- Supplied with locking

61-300

8-11

168

55-295

20

152

h

171x171

225x225

44-295

225

55-295

-

8/2/2019 Selecta Advanced Floor Gully Brochure

18/36

18

ACO Selecta - Floor DrainageCOMPONENTS

Gully bodies - Two-Part system

Accessory options - fire protection

Vertical Spigot Gully Body 105046 Grey iron to BS EN 1561 EN-GJL-200 1.4 8.5

Weight KgFlow Rate l/sMaterialModel Reference Part No

Horizontal Spigot Gully Body 105079 Grey iron to BS EN 1561 EN-GJL-200 1.4 8.5

Weight KgFlow Rate l/sMaterialModel Reference Part No

Fire Stop Cartridge 104056 0.1

Weight KgModel Reference Part No

Fit-In Vertical Installation 104057 215 150 225 2.0Kit 2 Hour Fire Rating

BS EN 1366

Weight KgExternal Diameter mm Height mm Core Bore Diameter mmModel Reference Part No

Core Former 104058 225 250 225 0.5

Weight KgExternal Diameter mm Height mm Core Bore Diameter mmModel Reference Part No

294

110

7

294

134

33

40

80

110

6

215

150

215

251

-

8/2/2019 Selecta Advanced Floor Gully Brochure

19/36

19

ACO Selecta - Floor DrainageCOMPONENTS

Gullies - Direct-Couple

Tiles, resin and cementitious flooring applications

Tile Direct-Couple 104010 K3 2.0 1.2

Weight KgBS EN 1253 Load ClassModel Reference Part No Flow Rate

- Match to all 150mm gratings

- 304 stainless steel

- Brushed frame

- Supplied with locking

135

150x150

110

Resin and cementitious flooring applications

Screed Direct-Couple 104004 K3 2.0 1.3

Weight KgBS EN 1253 Load ClassModel Reference Part No Flow Rate

- Match to 105048 to 105051 inclusive

- 304 stainless steel

- Supplied with locking

135

168

110

Flexible sheet flooring applications

ACO Vinyl Seal - Direct-Couple 105070 K3 2.0 1.7

Weight KgBS EN 1253 Load ClassModel Reference Part No Flow Rate

- Match to all 150mm gratings

- 304 stainless steel

- Brushed frame

- ACO Vinyl Seal

- Supplied with locking

171 x 171

225 x 225

135

Flexible Floor - Direct-Couple 97231 K3 2.0 1.7

Weight KgBS EN 1253 Load ClassModel Reference Part No Flow Rate

- Match to all 157mm gratings

- 304 stainless steel

- Mechanical clamp

- Accepts flooring up to 4mm thick

- Supplied with locking

225

110

115

-

8/2/2019 Selecta Advanced Floor Gully Brochure

20/36

20

ACO Selecta - Floor DrainageCOMPONENTS

Gullies - Direct-Couple

Accessory options - Direct-Couple gullies

- 304 stainless steel

- 1.2 l/s flow rate

- 50mm water seal

- BS EN1253 compliant

50

Foul Air Trap 401221 0.4

Weight KgModel Reference Part No

- 304 stainless steel

- Used in conjunction with

Direct-Couple gullies

225

320

110

18

Slab Penetration Unit 104028 1.2

Weight KgModel Reference Part No

-

8/2/2019 Selecta Advanced Floor Gully Brochure

21/36

21

ACO Selecta - Floor DrainageINSTALLATION OVERVIEW

IntroductionThe installation details shown in the following

pages set out to provide the designer with

integrated solutions to floor drainage identifying

preparation, installation and construction processes

required to install waterproof floor gullies in a

variety of environments including specific details

for wet rooms and where acoustic treatment

is required.

Whilst these details do not cover every possible

situation, they do provide a practical reference to

most design applications.

ACO Building Drainage acknowledge with

thanks the advice provided in the following

specialist fields:

Building Adhesives Ltd

WP1 and Fastflex wet room floor tanking systems.

Tel: 01782 591100

www.bal-adhesives.co.uk

Hodgson & Hodgson Group Ltd

REDUC acoustic overlay flooring systems.

Tel: 01664 821810

www.acoustic.co.uk

Schluter Systems Ltd

Schluter DITRA & Schluter KERDI wet room floor

uncoupled tanking systems.

Tel: 01530 813396

www.schluter.co.uk

Saint-Gobain Weber Ltd

Weber.sys protec wet room floor tanking system.

Tel: 08703 330070

www.weberbuildingsolutions.co.uk

-

8/2/2019 Selecta Advanced Floor Gully Brochure

22/36

22

ACO Selecta - Floor DrainageINSTALLATION

Vertical gully with wet room gully top in ground floor

wetroom with tiles

1. Prepare hardcore base A with sand blinding B

and connect vertical gully body C to drain pipe

and set to the required DPM level. Test

pipework for leaks. Fit polystyrene debris

protection cap during building work.

2. Box out and backfill concrete D around gully

body/pipe.

3. Remove shuttering, cast concrete floor slab E

and lay DPM F over flange G of gully body. If

very thin sealing membranes are used a

proprietary construction sealant should be used

on the flange area to ensure proper function.

Fit clamp ring H. Remove debris protection cap

and locate trap into the gully body.

4. Cut the telescopic height-adjustable tube I to the

required length. Push the rubber drainage ringJ

onto the telescopic tube and set the assembly

into the gully body. The socket should extendbelow the drainage ring by 5mm minimum.

5. Lay insulation K and fit around the gully body

and telescopic tube.

6. Locate the wet room gully top L in the

telescopic tube to the required finished floor

level. (Fit additional plastic bezel spacers if

ceramic tiles thicker than 10mm). Lift and tape-

up the integral polypropylene fleece M to

protect during the screeding process.

7. Lay the screed N to a 1:80 fall working the mixunder and flush with, the flange of the gully top.

8. Apply a proprietary tanking membrane O to the

whole floor in accordance with manufacturer's

instructions, un-tape and embed the flexible

polypropylene fleece whilst wet. Apply second

application of tanking membrane and fully

envelope fleece.

9. Adjust sliding bezel P to suit desired tile

orientation and fix to the gully top with screws

provided.

10. Lay tiles working away from bezel leaving a5mm gap Qto allow for flexible sealant

between tile edge and bezel.

11.Prime trap and fit grating.

A

B

D

G

Q

MOP

N

KH

I

L

J

E

F

C

-

8/2/2019 Selecta Advanced Floor Gully Brochure

23/36

23

ACO Selecta - Floor DrainageINSTALLATION

Vertical gully with resin finish using Two-Part screed gully

top in ground floor

1. Prepare hardcore base A with sand blinding B

and connect vertical gully body C to drain pipe.

Set to the required DPM level and test

pipework for leaks. Fit polystyrene debris

protection cap during building work.

2. Box out and backfill concrete D around gully

body/pipe.

3. Remove shuttering, cast concrete floor slab E

and lay DPM F over flange G of gully body. If

very thin sealing membranes are used a

proprietary construction sealant should be used

on the flange area to ensure proper function.

Fit clamp ring H. Remove debris protection cap

and locate trap into the gully body.

4. Cut the telescopic height-adjustable tube I to the

required length. Push the rubber drainage ringJ

onto the telescopic tube and set the assembly

into the gully body. The socket should extend

below the drainage ring by 5mm minimum.

5. Lay insulation K and fit around the gully body

and telescopic tube.

6. Locate the circular gully top L in the telescopic

tube to the required finished floor level. Bend

down tangs M to key with screed.

7. Lay the screed N to a 1:80 fall working the mix

under the flange of the gully top. When dry, lay

resin finish O to required thickness leaving a

5mm gap P at the bezel edge for a gun applied

flexible sealant.

8. Prime trap and fit grating.

A

B

D

G

P

MO N

KH

I

L

J

E

F

C

-

8/2/2019 Selecta Advanced Floor Gully Brochure

24/36

24

ACO Selecta - Floor DrainageINSTALLATION

Vertical gully with sheet vinyl using flexible floor clamp or

welded Vinyl Seal in ground floor

1. Prepare hardcore base A with sand blinding B

and connect vertical gully body C to drain pipe,

set to the required DPM level. Test pipework for

leaks. Fit polystyrene debris protection cap

during building work.

2. Box out and backfill concrete D around gully

body/pipe.

3. Remove shuttering, cast concrete floor slab E

and lay DPM F over flange G of gully body. If

very thin sealing membranes are used a

proprietary construction sealant should be used

on the flange area to ensure proper function.

Fit clamp ring H. Remove debris protection cap

and locate trap into the gully body.

4. Cut the telescopic height-adjustable tube I to the

required length. Push the rubber drainage ringJ

onto the telescopic tube and set the assembly

into the gully body. The socket should extendbelow the drainage ring by 5mm minimum.

5. Lay insulation K and fit around the gully body

and telescopic tube.

6. Locate the circular gully top L OR the square

gully top M in the telescopic tube to required

finished floor level and bend down tangs N to

key with screed.

7. Lay the screed O to a 1:80 fall working the

mix under and flush with, the flange of the

gully top.

8. Lay vinyl sheet flooring P in adhesive bed over

a) compression flange Qand secure with

clamping ring OR b) the ACO Vinyl Edge flange

R and hot air weld to the ACO Vinyl Seal strip.

9. Prime trap and fit grating to suit.

A

B

D

G

R

O

Q

P

KH

I

L MN

J

E

F

C

-

8/2/2019 Selecta Advanced Floor Gully Brochure

25/36

25

ACO Selecta - Floor DrainageINSTALLATION

Horizontal gully with resin finish using Two-Part screed

gully top in ground floor with optional back inlet inflow

1. Prepare hardcore base A with sand blinding B

and connect horizontal gully body C to drain

pipe and set to the required DPM level. If back

inlet required, remove stopper and connect

40mm pipe to fall of 2 degrees. Test pipework

for leaks. Fit polystyrene debris protection cap

during building work.2. Box out and backfill concrete D around gully

body/pipe.

3. Remove shuttering, cast concrete floor slab E

and lay DPM F over flange G of gully body. If

very thin sealing membranes are used a

proprietary construction sealant should be used

on the flange area to ensure proper function.

Fit clamp ring H. Remove debris protection cap

and locate trap into the gully body.

4. Cut the telescopic height-adjustable tube I to the

required length. Push the rubber drainage ringJ

onto the telescopic tube and set the assembly

into the gully body. The socket should extend

below the drainage ring by 5mm minimum.

5. Lay insulation K and fit around the gully body

and telescopic tube.

6. Locate the circular gully top L in the telescopic

tube to the required finished floor level. Bend

down tangs M to key with screed.

7. Lay the screed N to a 1:80 fall working the mix

under the flange of the gully top. When dry,

lay resin finish O to required thickness leaving a

5mm gap P at the bezel edge for a gun applied

flexible sealant.

8. Prime trap and fit grating.

A

B

D

G

P

MO N

KH

I

L

J

E

F

C

-

8/2/2019 Selecta Advanced Floor Gully Brochure

26/36

26

ACO Selecta - Floor DrainageINSTALLATION

Vertical firestop gully in wetroom with tiles using Two-Part

wetroom gully top in raised concrete floor

A

BD

P

L

F

N

E

OM

JG

K

I

H

C

1. Core drill hole A in concrete floor, fill any

breached voids and position ACO Fit-In

fireproof linerB at structural deck level.

2. Locate gully body into the liner and connect to

pipework using proprietary coupling. Test

pipework for leaks.

3. Gap seal all voids C between gully body and

structural deck with a proprietary intumescent

sealant. Push fit ACO Selecta Fire Stop

Cartridge D into gully body and locate foul air

trap into the gully body. Fit polystyrene debris

protection cap during building work.

4. Apply a reinforced polyester mesh tanking

membrane E over the whole floor slab and

dress over compression flange F of gully body.

5. Fit clamp ring G and cut the telescopic height

adjustable tube H to the required length. Push

the rubber drainage ring I onto the telescopic

tube and set the assembly into the gully body.

The socket should extend below the drainage

ring by 5mm minimum.

6. Lay insulationJ and fit around the gully body

and telescopic tube.

7. Locate the wet room gully top K in the

telescopic tube to the required finished floor

level. (Fit additional plastic bezel spacers if

ceramic tiles thicker than 10mm). Lift and

tape-up the integral polypropylene fleece L to

protect during the screeding process.

8. Lay the screed M to a 1:80 fall working the mix

under and flush with, the flange of the gully top.

9. Apply a proprietary tanking membrane N to thewhole floor in accordance with manufacturers

instructions, un-tape and embed the flexible

polypropylene fleece whilst wet. Apply a second

application of tanking membrane and fully

envelope fleece.

10. Adjust sliding bezel O to suit desired tile

orientation and fix to the gully top with screws

provided. Lay tiles working away from bezel

leaving a 5mm gap P to allow for flexible

sealant between tile edge and bezel.

11. Prime trap and fit grating.

-

8/2/2019 Selecta Advanced Floor Gully Brochure

27/36

27

ACO Selecta - Floor DrainageINSTALLATION

Vertical firestop gully with sheet vinyl using Two-Part

flexible floor clamp in raised acoustic concrete floor

1. Core drill hole A in concrete floor, fill any

breached voids and position ACO Fit-In

fireproof linerB at structural deck level.

2. Locate gully body into the liner and connect

to pipework using proprietary coupling.

Pipe support brackets should be rubber lined.

Test pipework for leaks.

3. Gap seal all voids C between gully body and

structural deck with intumescent sealant. Push

fit ACO Selecta Fire Stop Cartridge D into gully

body and locate foul air trap into the gully

body. Fit polystyrene debris protection cap

during building work.

4. Apply a reinforced polyester mesh tanking

membrane E over the whole floor slab and

dress over compression flange F of gully body.

5. Fit clamp ring G and cut the telescopic height-

adjustable tube H to the required length. Push

the rubber drainage ring I onto the telescopic

tube and set the assembly into the gully body.

The socket should extend below the drainagering by 5mm minimum.

6. Lay screed to 1:80 fall up to edge of rubber

drainage ring I.

7. To fit grating frame, form double rebated

rectangular hole in an acoustic floor panelJ and

centre over the height adjustable tube H

following manufacturers guidelines.

8. Locate the square ACO Vinyl Edge gully top K

into the telescopic tube H to finished floor

level. Bond and fix gully top using non ferrousNo. 8 x 12mm countersunk screws to

preserve acoustic isolation fixings must not

penetrate through acoustic top board.

9. Lay and bond flexible sheet flooring onto ACO

Vinyl Edge profile K and hot air weld sheet

flooring to ACO Vinyl Seal L.

10. Prime trap and fit grating.

A

B D

L J

GE

H

F

K

I

C

-

8/2/2019 Selecta Advanced Floor Gully Brochure

28/36

28

ACO Selecta - Floor DrainageINSTALLATION

Detail 05

Horizontal gully with resin finish using Two-Part screed

gully top in raised floor

1. Position horizontal gully body A to the required

DPM level and connect to soil pipe system B

using proprietary coupling. If back inlet

required, remove stopperC and connect 40mm

pipe to fall of 2 degrees. Test pipework for

leaks. Fit polystyrene debris protection cap

during building work.2. Cast suspended concrete floor slab around

gully body.

3. Apply a reinforced polyester mesh tanking

membrane D over the whole floor slab and

dress over compression flange E of gully body.

Fit clamp ring F. Remove debris protection cap

and locate trap into the gully body.

4. Cut the telescopic height-adjustable tube G to

the required length. Push the rubber drainage

ring H onto the telescopic tube and set the

assembly into the gully body. The socket should

extend below the drainage ring by 5mm

minimum.

5. Lay insulation I and fit around the gully bodyand telescopic tube.

6. Locate the circular gully topJ in the telescopic

tube to the required finished floor level. Bend

down tangs K to key with screed.

7. Lay the screed L to a 1:80 fall working the mix

under the flange of the gully top. When dry, lay

a resin finish M to required thickness leaving a

5mm gap N at the bezel edge for a gun

applied flexible sealant.

8. Prime trap and fit grating.

EF

N

KM

H

A

B

C

D

I

L

G

J

-

8/2/2019 Selecta Advanced Floor Gully Brochure

29/36

Direct connection gully with sheet vinyl using Direct-Couple

flexible floor gully top in ground floor

29

ACO Selecta - Floor DrainageINSTALLATION

1. Install drain pipe A and prepare hardcore base

B with sand blinding C. Apply debris protection

to pipe end, box out and backfill concrete D

around pipe.

2. Remove shuttering and pour concrete floor

slab E.

3. Lay DPM F and lay insulation G around

drain pipe.

4. Remove debris protection and connect circular

gully top H or the square gully top I to pipe

end and set to required floor level.

5. Bend down tangsJ to key with screed and fit

foul air trap K. Reapply debris protection.

6. Lay the screed L to a 1:80 fall working the

mix under and flush with either flange of the

gully top.

7. Lay vinyl sheet flooring M in adhesive bed

over a) compression flange N and secure with

clamping ring OR b) the ACO Vinyl Edge flange

O and hot air weld to the ACO Vinyl Seal

strip P.

8. Prime trap and fit grating to suit.

H I

J

O

K

L M

PN

A

B

C

D E

F

G

-

8/2/2019 Selecta Advanced Floor Gully Brochure

30/36

Direct connection rodding access with resin finish using

Direct-Couple screed gully top in ground floor

30

INSTALLATION

1. Install access pipe A and prepare hardcore base

B with sand blinding C. Cover pipe end, box

out and backfill concrete D around pipe.

2. Remove shuttering and pour concrete floor

slab E.

3. Lay DPM F and lay insulation G around

access pipe.

4. Connect square or circular rodding access top

H to drain pipe and set to finished floor level.

Bend down tangs I to key with screed.

5. Lay the screedJ to a 1:80 fall working the mix

under the flange of the gully top. When dry, lay

a resin finish K to required thickness leaving a

5mm gap L at the bezel edge for a gun applied

flexible sealant.

6. Fit double seal M and solid cover to suit.

ACO Selecta - Floor Drainage

M I

H

J K

L

A

A

A

B

C

DE

F

G

-

8/2/2019 Selecta Advanced Floor Gully Brochure

31/36

31

ACO Selecta - Floor DrainageINSTALLATION

Vertical gully with tiles in raised concrete floor

F

HK

A

E

J

GL

B

D

C

I

1. Core drill and rebate hole A in suspended

concrete slab B to receive Slab Penetration

Unit C.

2. Insert the Slab Penetration Unit and screw fix to

slab. Connect to 110mm pipework D and

test for leaks.

3. Apply a reinforced polyester mesh tanking

membrane E over floor slab and dress over

compression flange F of Slab Penetration Unit.

Fix clamping ring to compression flange

ensuring that membrane is fully bonded

between both components.

4. Insert the square or circular gully top G into the

Slab Penetration Unit and set to required floor

level. Bend down the tangs H to key with

screed, insert foul air trap I and provide debris

protection prior to screeding.

5. Lay the screedJ to a 1:80 fall working the mix

under the flange of the gully top.

6. Lay ceramic tiles K working away from bezel

leaving a 5mm gap L to allow for flexible

sealant between tile edge and bezel.

7. Prime trap and fit grating to suit.

-

8/2/2019 Selecta Advanced Floor Gully Brochure

32/36

32

ACO Selecta - Floor DrainageOPERATION AND MAINTENANCE

Cleaning methods

Selecta gully components are easy to clean.

Washing with soap or a mild detergent and warm

water followed by a clear water rinse is usually

quite adequate for most applications. An enhanced

aesthetic appearance will be achieved if the

cleaned surface is finally wiped dry.

Precautions

Acid cleaners should only be used for cleaning

only when other methods have been proved

unsatisfactory.

Problem Cleaning Agent Comment

Routine cleaning, all finishes Soap or mild detergent and water Sponge, rinse with clean water,and materials. (such as washing up liquid). wipe dry if necessary.

Fingerprints, all finishes. Soap or warm water or organic Rinse with clean water,solvent (e.g. acetone or alcohol). wipe dry if necessary.

Stubborn stains and Mild cleaning solutions, (e.g. Cif, Rinse with clean water,discolouration. Goddard Stainless Steel Care). wipe dry.

Oil and grease marks, Organic solvent Clean after with soap and water,all finishes. (e.g. acetone or alcohol). rinse with clean water and dry.

Rust and other corrosion Most mild corrosion and staining Rinse well with copiouseffects. effects can be removed by amounts of clean water

application of commercially (precautions for acid cleanersavailable metal polishes. should be observed).Check manufacturers detailsbefore use.

Scratches on brushed Household synthetic fibre scouring Never use ordinary steel woolfinishes. pads (e.g. Scotch Brite fibre pad). as iron particles can become

Apply in direction of brushed embedded in the surface beingfinish. Clean with soap or cleaned and cause corrosiondetergent as per routine cleaning. problems.

ALWAYS READ INSTRUCTIONS ON PROPRIETRY CLEANING AGENTS.

-

8/2/2019 Selecta Advanced Floor Gully Brochure

33/36

33

ACO Selecta - Floor DrainageOPERATION AND MAINTENANCE

Cleaning the foul air trap & gully body

1. It is highly recommended that before

beginning to clean the foul air trap and gully

body, suitable hand protection is used, such as

latex gloves to prevent possible infection.

2. Release the grating locking screws and lift out

the grating.

3. Reach down into the gully body and turn

the red foul air trap locking lever 90 ANTI-

CLOCKWISE and ease the trap away from

the body and lift it clear of the body.

4. Thoroughly clean the gully body and foul

air trap with soapy water and rinse with

clean water.

5. Lubricate the trap seal with proprietory silocone

lubricant and re-insert into the body, making

sure the lower ledge of the trap engages with

the recess in the gully body. Ease the trap

towards the outlet to engage the seal and turnthe red locking lever 90 CLOCKWISE to lock

the trap in place.

6. Prime the trap with clean water to prevent

odours and replace grating and lockings.

-

8/2/2019 Selecta Advanced Floor Gully Brochure

34/36

34

ACO Selecta - Floor DrainageSTANDARD SPECIFICATION CLAUSES

ACO Building Drainage - Selecta Floor Gullies

A range of two-part floor drains consisting of cast iron bodies complete with odour trap and one piece

rodding access points with a range of gully tops, gratings and accessories.

Suitable for point drainage in changing rooms, showers, wet rooms, kitchens, retail, hospitals, abattoirs,

chemical plants, swimming pools, food and drink processing plants and washdown areas.

Manufacturer: ACO Building Drainage,

ACO Business Park, Hitchin Road, Shefford, Bedfordshire UK. SG17 5TE

Tel: 01462 816666, Fax: 01462 851490.

Email: [email protected]

Material: Grey cast iron bodies to BS EN 1561 EN-GJL-200.

Polypropylene.

Stainless steel grade 304 pickle passivated.

Copper alloy.

Product: ACO Selecta Trapped Floor Gully, flow rate 1.4 l/s.

ACO Direct Couple double sealed access points and gullies.

Literature: Consult ACO Building Drainage technical literature for details.

Link to web: http://www.acobuildingdrainage.com/selecta.php

Design: ACO Building Drainage Technical Services provide design and specification.

Selecta Rodding Points & Gullies

Description: Double sealed rodding point with

solid cover or direct connection floor gully Class

K3 to BS EN 1253.

Function: Light duty rodding point or point drainage

in healthcare, commercial, changing rooms, showers,

wet rooms, kitchens, retail, hospitals, abattoirs,chemical plants, swimming pools, food and drink

processing plants and washdown areas.

Type of Floor: Solid ground floor and suspended

concrete floor.

Material: Stainless steel grade 304 pickle passivated.

Copper alloy.

EPDM double seal.

Type of Body:Vertical 110mm spigot outlet,

optional foul air trap.

Type of Grate: Range of designs in 304 stainless

steel or copper alloy.

Selecta Trapped Floor Drain

Description: Floor Gully Load Class K3 to BS EN 1253.

Function: Light duty point drainage in healthcare,

commercial, changing rooms, showers, wet rooms,

kitchens, retail, hospitals, abattoirs, chemical plants,

swimming pools, food and drink processing plants

and washdown areas.

Type of Floor: Solid ground floor and suspended

concrete floor.

Material: Grey cast iron bodies to BS EN

1561 EN-GJL-200.

Polypropylene.

Stainless steel grade 304 pickle passivated.

Copper alloy.

Type of Body: Trapped 110mm spigot outlet,

horizontal or vertical orientation.

Type of Grate: Range of designs in 304 stainless

steel or copper alloy.

-

8/2/2019 Selecta Advanced Floor Gully Brochure

35/36

35

ACO SelectaNOTES

-

8/2/2019 Selecta Advanced Floor Gully Brochure

36/36

ACO Technologies plc

ACO Building DrainageACO Business Park,Hitchin Road,Shefford,BedfordshireSG17 5TE

Tel: 01462 816666Fax: 01462 851490

e-mail: [email protected]

website: www.acobuildingdrainage.co.uk